TURFCO TriWave 85851 Operator, Maintenance And Parts Manual

™

™

™

™

™

60” Inch Seeder

®

OPERATOR’S MANUAL

MAINTENANCE MANUAL

PARTS LIST

®

TURFCO

60” Inch Seeder

Product Number 85851

Starting Serial Number P00801

PATENT PENDING

Manual Number 665365 Rev B

DANGER -

THOSE WHO USE AND MAINTAIN THIS MACHINE SHOULD BE TRAINED IN ITS

PROPER USE, WARNED OF ITS DANGERS, AND SHOULD READ THE ENTIRE MANUAL

BEFORE ATTEMPTING TO SET-UP, OPERATE OR SERVICE THE MACHINE.

IF INCORRECTLY USED THIS MACHINE CAN CAUSE SEVERE INJURY.

TURFCO MFG. INC.

1655 101st. Avenue NE • Minneapolis, MN 55449-4420 USA

Phone (763) 785-1000

FAX (763) 785-0556 • www.turfco.com

•

2011 Turfco Mfg., Inc.

™

™

TURFCO

SS85851-01REVA

TURFCO MFG., INC

1655 101ST Avenue NE

Minneapolis, Minnesota

USA 55449-4420 www.turfco.com

(763) 785-1000 FAX (763) 785-0556

PRODUCT SERIAL

TABLE OF CONTENTS

All specifications, information, illustrations or photos in this manual are

based on the latest information at the time of printing. The right is reserved to make changes without notice.

Product Records ......................................................................................................................2

Specifications ...........................................................................................................................3

Registered Trademarks and Patents ........................................................................................3

How To Obtain Parts And Service ............................................................................................3

Recognizing Safety Warnings And General Safety Practices .................................................4

Setup And Installation ...............................................................................................................6

Description .............................................................................................................................10

Operation

Pre-Operation Check List and Work Site Preparation .......................................................13

Raising Storage Wheels ....................................................................................................13

Ground Operating Speed and Maximum Angle Of Operation ...........................................13

Loading Seed Hopper ........................................................................................................14

Setting Seed Gate Dial ......................................................................................................14

Operating Seed Gate Control Handle ................................................................................14

Setting Blade Depth Adjustment ........................................................................................15

Setting Down Pressure Adjusters ......................................................................................15

Operation ...........................................................................................................................16

In Operation Quality Checks ..............................................................................................16

Decals ....................................................................................................................................17

Operator Daily Inspection .......................................................................................................18

Storage ...................................................................................................................................18

Trouble Shooting Table ...........................................................................................................19

Service

Seed Distribution Box Height Adjustment .......................................................................... 20

Lubrication .........................................................................................................................22

Chain Adjustment ..............................................................................................................23

Cutting Head Removal And Blade Replacement ............................................................... 24

Jackshaft Bearings and Collar Adjustment ........................................................................27

Part Lists ................................................................................................................................28

Table of Contents

Product Records

IMPORTANT: Record the information from the serial number plate of your TriWave 60” Seeder. It will be

necessary to furnish your Model Designation, Product Number, and Serial Number when ordering parts.

Model Designation TriWave 60” Seeder

Product Number 85851 Serial Number ________________________

Date Purchased __________________________________________________________________

Purchased From __________________________________________________________________

2

85851 Rev B

™

™

SPECIFICATIONS

Specifications

Intended Use: The TriWave Seeder is intended to be USED ONLY to overseed grass seed on existing

turf at sports turf fields and on golf courses. The TriWave is not intended to be a primary seeder and is

not intended to be used to seed areas without existing turf. The TriWave Seeder is intended only to be used

with grass seed. The TriWave Seeder is NOT intended to be used for any purpose other than to apply grass

seed to the turf. The TriWave Seeder is not intended to be used for the application of fertilizers or lawn foods.

The TriWave Seeder is not intended to be used as a sod cutter, aerator, rototiller, compaction roller, or any

other type of soil preparation or turf maintenance tool. Use of the TriWave Seeder is intended at a properly

prepared worksite where deficiencies have been corrected to avoid injury and/or damage to the machine. The

TriWave Seeder is not designed for or intended to accept riders.

TriWave Seeder Dimensions:

Width ...................................................................1.88 Meter (74” Inches)

Height (On Ground In Operating Position) ..........1.3 Meter (51” Inches)

Length (Without PTO Shaft) ................................1.02 Meter (40” Inches)

Seed Hopper Capacity ............................................0.135 Cubic Meter (8251 Cubic In. Or 4.77 Cubic Ft.)

Approximately 45.35 Kg. (100 Pounds) of Grass Seed

Seed Application Pattern ........................................30 Rows Spaced 38.1 mm (1-1/2” inches) apart

Seed Application Width ..........................................1.52 Meter (60” Inches)

Seed Gate .................................................................Manually Operated, Variable Opening

Ground Operating Speed .......................................Up To 8.85 km/h (5.5 MPH)

Productivity .............................................................8,094 Square Meters At 5.63 km/h

(2 Acres - 9680 Square Yards at 3.5 MPH)

Cutting Heads ..........................................................3 Heads, Independently Floating

Blade Assembly .......................................................3 Blade Sets, Total 30 Blades

Blade Assembly Operating Depth Range .............0 to 34.9 mm (0 to 1-3/8” Inch)

Tractor/Horsepower Requirements .......................26.1 Kw Minimum to 44.7 Kw Maximum

(35 HP to 60 HP)

Drive .........................................................................540 PTO (Tractor)

Hitch Type ................................................................Category 1 or Category 2 Three-Point Hitch

Weight (Hopper Empty) ..........................................521.6 Kg (1150 Pounds)

Maximum Weight With Seed Hopper Full .............Approximately 567 Kg (1250 Pounds)

Registered Trademarks and Patents

Patent Pending

TriWave™ is a Trademark of Turfco Manufacturing. TURFCO® is a registered Trademark of Turfco Mfg., Inc.

Gandy® is a registered trademark of the Gandy Company.

Seed Gate Patents are Property of the Gandy Company.

How To Obtain Parts and Service

To order parts, or to arrange repair service, contact

the nearest authorized TURFCO dealer. For a list of

a u t h o r i z e d TURFCO dealers in your area, or for

a d d i t i o n a l information regarding the TriWave

Seeder, direct inquiries to:

TURFCO Mfg. Inc.

1655 101st. Avenue North East

Minneapolis, MN. 55449-4420 USA

Telephone (763) 785-1000

FAX (763) 785-0556

E-mail - service@turfco.com

Internet - www.turfco.com

85851 Rev B

To ensure safety and proper operation, always purchase

genuine TURFCO replacement parts from

an authorized TURFCO dealer. Re pl a ce me n t

parts from other sources may damage the TriWave

Seeder and/or create a safety hazard. Always refer

repairs to properly trained service personnel.

DO NOT ALTER the TriWave Seeder in any manner.

Unauthorized alterations may affect its operation,

performance, and may result in injury or death to the

operator as well as other individuals in the work area.

3

™

™

Recognizing Safety Warnings Used In Manual

LOOK FOR THE SAFETY HAZARD WARNING SYMBOL

The symbol is used to alert the operator of safety hazards.

It is used in conjunction with the words DANGER, WARNING, and CAUTION.

“DANGER” identifies immediate hazards which will result in serious injury or death.

“WARNING” identifies potential hazards which could result in serious injury or death.

“CAUTION” identifies hazardous situations which may result in minor injury and/or could result in

damage or destruction of equipment.

WARNING CAUTION

DANGER

SAFETY

General Safety Practices

Safety on the job should always be a top priority.

Training and experience are important factors in the safe

operation of equipment. Please consider the following

information and realize that safe operation is a matter

of using common sense as it relates to the machine, its

maintenance, the operator, the training, and the operating

conditions. These are general safety instructions that

apply to most turf maintenance equipment.

This list includes many, but not all, general

safety instructions as they relate to turf

equipment. Common sense must always be

used to determine the safest way to operate a

machine under specific conditions.

TRAINING:

Always read the manual before operating a machine for

the first time.

Always read the warning decals before operating a

machine for the first time.

Always check the location and use of each control before

operating a machine for the first time.

Practice operating the machine in a safe area with no

obstructions until becoming familiar with the controls.

If you have questions, ask your supervisor or call the

factory.

CLOTHING:

Cloths should be snug fit. Loose fitting clothing is

hazardous because it may get caught in the mechanism

during service or operation.

Remove jewelry before operation. Again, jewelry may

get caught in the mechanism.

Wear shoes that will protect your feet. In most cases,

sneakers do not protect and do not provide the protection

of leather shoes or boots. Steel toed safety shoes should

be considered for many situations.

Hard Hat: The use of a hard hat should be considered

4

when using equipment on a golf course. The danger of

being hit by a golf ball should be a major concern as well

as protection while operating under trees .

Eye Protection: Safety glasses and/or face shields should

be considered when operating, as well as working in

close proximity to high speed rotary equipment. Watch

for rotary mowers, edgers, brush and string trimmers.

Rotary mowers can throw debris at speed up to 200

MPH.

Hearing: If the noise level of the equipment is too loud,

consider the use of ear protection.

Do not use stereo headsets during operation. This is a

distraction that may lead to an accident. Headsets also

make it difficult to hear other people and equipment

while operating in the work area.

Respirators: When operating in dusty, windy conditions,

wear a respirator. This is also an important consideration

if operating equipment while spraying chemicals and

fertilizers.

Gloves: Use gloves when handling sharp or hazardous

objects.

THE OPERATOR:

The operator should never use a machine while under

the influence of alcohol or drugs. The operator should

be aware of the hazards of working in the sun and

should take proper precautions to avoid heat stress and

dehydration. Use sun screen products when necessary.

The operator should never attempt to ride a machine

that is not designed for that propose. Do not allow others

to ride a machine that is not designed for passengers.

Care should always be taken when mounting and

dismounting a riding machine. Prevent injuries and falls

by making sure the operator does not slip. Unless it is

an emergency, do not jump off a machine. Injury may

result when an operator’s foot slips trying to jump from

a machine.

Do not operate any equipment at unsafe speeds.

Speeds should be reduced when turning or operating

85851 Rev B

™

™

SAFE-13

SAFETY

SAFE-14

on slopes. The operator must use common sense to

determine a safe speed based on the equipment, the

load, the slope, the surface, and other conditions that

may affect safe operation.

The operator must be aware of the conditions around

the area. Be careful to observe other people and

machines.

Beware of slippery conditions. Wet turf can be

encountered on slopes, when turning or stopping, or

at higher speeds.

Keep hands and feet away from cutting devices and

drive components. Shut off the engine and remove the

key or ignition wire when servicing cutting devices or

drive components.

If required to lift, an operator should ask for help if the

object is too heavy. The operator should lift with his or

her legs instead of the back. Care should be taken to

avoid twisting the back while lifting a heavy load.

Never allow children to operate the machine.

THE MACHINE:

Do not modify the machine in any manner. Always

check the machine to make sure it is in good working

order.

Do not place hands or feet near moving or rotating

parts. Inspect to insure that all guards are in place. Do

not operate a machine without all guards in place.

Check to assure that all controls are in good operating

condition. Make sure the brakes are operating

properly.

Do not overload machinery. The components

are designed for certain weights and capacities.

Overloading machine will cause unsafe conditions.

Shut off the engine before servicing the machine.

Check machines on a level area. Machines on a slope

may roll when the engine is off.

Refer unfamiliar repairs and adjustments to mechanics

that have been trained to do them properly.

Replace decals that have become damaged or

illegible.

EQUIPMENT WITH ENGINES:

Prevent accidental starting by removing the spark

plug wire when servicing the engine or the equipment.

Disconnect the negative wire from the battery terminal

if the engine is equipped with an electric starting

system.

Do not strike the flywheel with a hammer or any hard

object. This may cause the flywheel to shatter in

operation. Use the correct tools to service the machine.

Pull the starter cord slowly until resistance is felt. Then

pull the cord rapidly to avoid kickback and to prevent

hand or arm injury.

Do not run the engine in an enclosed area. The exhaust

gases contain carbon monoxide, an odorless and deadly

poison. Engine Exhaust Contains Chemicals Known

to the State of California to Cause Cancer, Birth

Defects or Other Reproductive Harm

Do not store, spill, or use gasoline near an open flame,

nor near an appliance like a stove, furnace, or water

heater that uses a pilot light or can create a spark.

Do not refuel indoors or in an unventilated area. Check

the fuel level. Do not over fill. Do not add fuel while the

machine is hot because spilled fuel may cause a fire.

Use fresh gasoline. Stale fuel can gum the carburetor

and can cause leakage. Check the fuel lines and fittings

frequently for cracks and leaks. Replace if necessary.

Do not remove the fuel tank cap or fill fuel tank while the

engine is hot or running. Allow the engine to cool before

refueling.

Do not operate the engine if gasoline is spilled or when the

smell of gasoline is present or other explosive conditions

exist. Move the equipment away from the spill and avoid

any ignition until the gasoline has evaporated.

Do not transport the engine with fuel in the tank.

Do not start the engine with the air cleaner and/or the air

cleaner cover removed.

Do not choke the carburetor to stop the engine.

Whenever possible, gradually reduce the engine speed

before stopping.

Do not tamper with the governor springs, links or other

parts to increase the engine speed. Run the engine at

the speed set by the equipment manufacture.

Do not check for a spark with the spark plug removed.

Use an approved tester. Do not crank the engine with

the spark plug removed. If the engine is flooded, place

the throttle in fast and crank until the engine starts.

Keep the cylinder fins and the governor parts free of dirt,

grass, and other debris which can affect engine speed.

Do not operate the machine without a muffler. Inspect

the muffler periodically and replace it if it is leaking or

worn. If necessary, replace it with correct muffler. Do

not touch a hot muffler, cylinder, or fin. It may cause

burns. Do not operate the engine with an accumulation

of grass, leaves, or other combustible material in the

muffler area.

Do not use the engine on any forest covered, brush

covered, or grass covered unimproved land unless

a spark arrester is installed in the muffler. The spark

arrester must be maintained in working order by the

operator. In the State of California, the above is required

by law (Section 4442 of the California Public Resources

Code). Other state may have similar laws. Federal laws

apply on federal lands.

85851 Rev B

5

™

™

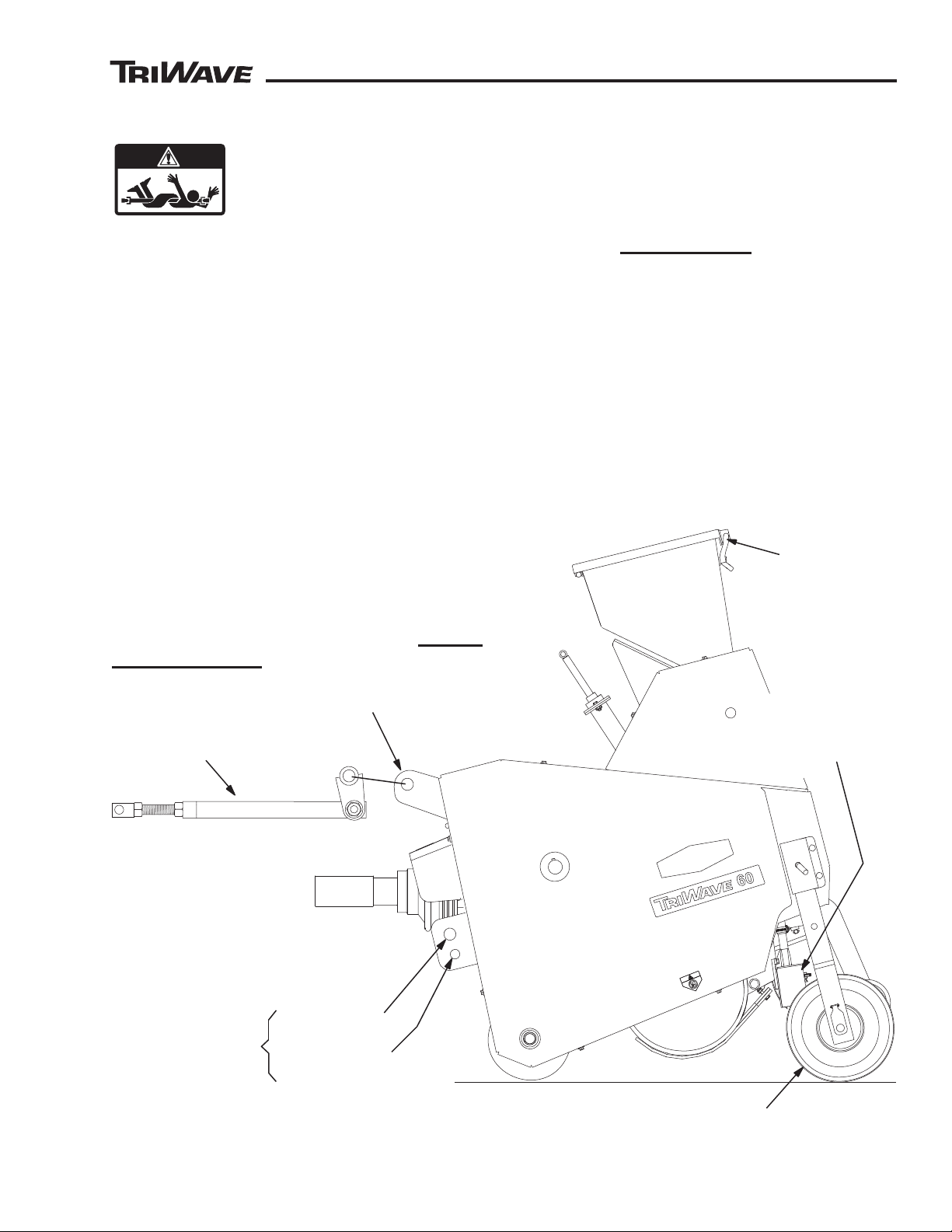

SETUP AND INSTALLATION

WARNING

SAFE-06

WARNING

TURFCO

AS85851-06REVA

THREE-POINT

HITCH

STORAGE WHEELS

INSPECT

INSIDE OF

SEED BOX

WARNING

Setup and Installation

TO AVOID SERIOUS INJURY,

Read and Understand the Entire

Operator Manual For the T

and the TriWave Seeder Before

Operating.

TRACTOR REQUIREMENTS

The TriWave Seeder is designed to be attached

to and powered by a tractor. The tractor must

meet the following specifications:

● Minimum 26.1 Kw (35 horsepower) to Maximum

44.7 Kw (60 horsepower) rating.

540 PTO

●

● Gearing to provide engine speed (RPM) to

produce PTO power and RPM while not

exceeding 8.85 Km/h (5.5 MPH).

Category 1 or Category 2 Three Point Hitch

●

equipped to lift and tow 567 Kg. (1,250

Pounds).

Adequate Brakes to control and stop a hitched

●

load of 567 Kg. (1,250 Pounds).

ractor

to the hitch and drive system on the TriWave

Seeder. Safe movement can only be done with

proper equipment.

tractor must have an appropriate three point

The

hitch to attach to the TriWave Seeder. The TriWave

Seeder

is equipped to accept either a Category 1

or Category 2 three point hitch. Heavy-duty hitch

components are strongly recommended for your

tractor.

The Tractor Must Be Equipped With an

Adequate Category 1 or Category 2 Three

Point Hitch, Rated for Proper Lifting and

Carrying Capacity

, and Have Adequate

Functional Brakes.

When Properly Loaded, the T

riWave Seeder

can Weigh 567 Kg (1,250 Pounds).

Attach Only To a Properly Rated Tractor. Always

use the proper size tractor to move the TriWave

Seeder

, even if moving only short distances. Using

improper hitching methods may cause damage

6

85851 Rev B

™

™

AS85851-03REVA

FIGURE 1

CATEGORY 1

CATEGORY 2

UPPER LINK

STORAGE WHEELS (SHOWN IN LOWERED “STORAGE” POSITION)

SEED

DISTRIBUTION

BOXES

SEED

BOX

UPPER MOUNT

LOWER MOUNT

SETUP AND INSTALLATION

SAFE-14

HITCHING TO THE TRACTOR

SAFETY FIRST!!

To Avoid Serious Injury,

Wear the Appropriate Personal

Safety Gear.

Use Caution When W

orking Near Moving

Parts and Rotating Parts.

ork Safely and Follow All Safety Warnings

W

In TriWave Seeder Operators Manual and the

ractor Operators Manual.

T

Do Not Modify The T

riWave Seeder Or The

PTO Shaft To Hitch To The Tractor.

Verify that the tractor meets the requirements

to safely attach and power the TriWave Seeder.

Refer to the section “Tractor Requirements”.

STEP 1. Inspect the inside of the seed box.

Remove anything remaining from shipping,

manufacturing, or previous use.

STEP 3. (See Figure 1) Align the tractor to the

TriWave Seeder’s three-point hitch mounts.

● Shut off the tractor engine and set the

brakes.

Tractors PTO must be disengaged

●

● Tractors draft control off.

● The tractors rear lower sway stabilizers should

be set to keep the seeder centered and in line

with the tractor.

STEP 4. (See Figure 1) Use hitch pins to attach

tractor’s lower arms to the TriWave’s lower

the

mounts. Refer

to Figure 1 for proper location of

Category 1 or Category 2 lower mounts.

STEP

Seeder rear storage wheels. DURING HITCHING,

the rear storage wheels should be in the lowered

“storage” position.

2. (See

Figure 1) Check the TriWave

85851 Rev B

7

™

™

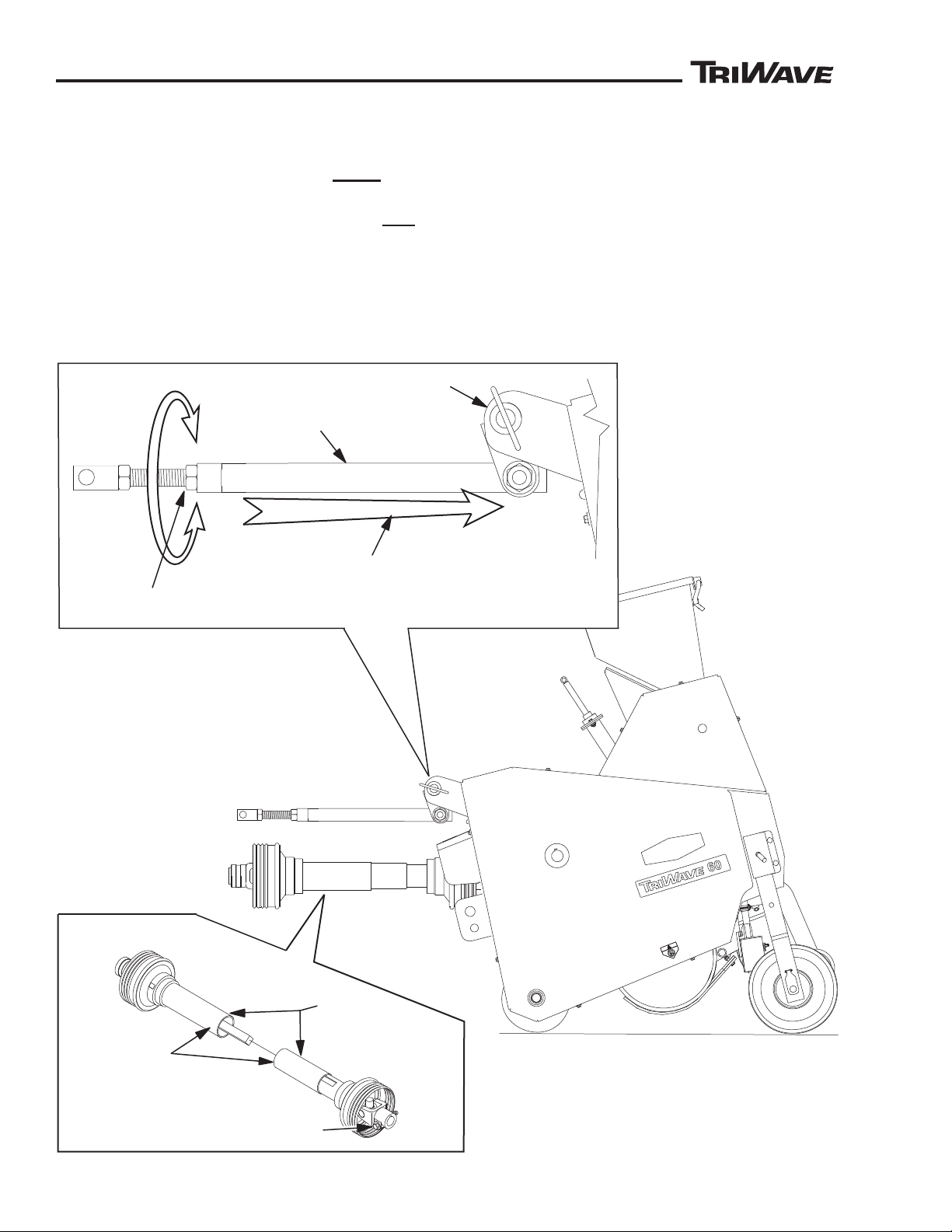

SETUP AND INSTALLATION

AS85851-02REVA

FIGURE 2

B: THREAD LINK IN OR OUT TO REACH TRACTOR

A: PUSH UPPER LINK BACK TO SEEDER

UPPER LINK

TRIWAVE TOP MOUNT

CHECK LOCKING

HARDWARE ON SEEDER END

CHECK

GUARDS

ASSEMBLE

PTO SHAFT

TRACTOR

END

SEEDER

END

STEP 5. (See Figure 2) Install the upper link to

the TriWave.

● The link should be located below

the

TriWave top mount.

● Use a hitch pin to attach the link to the first

(outside) hole on the

TriWave’s top mount.

STEP 6. (See Figure 2) Attach upper link to

tractor.

● Push the upper link back against the

TriWave.

● Thread end out (or in) until the upper link

reaches the tractor.

● Choose a tractor hitch hole that will set the

TriWave’s upper link as level with the ground as

possible. Avoid

interference with any tractor

guards or components

● Use a hitch pin to attach to the tractor

.

8

85851 Rev B

™

™

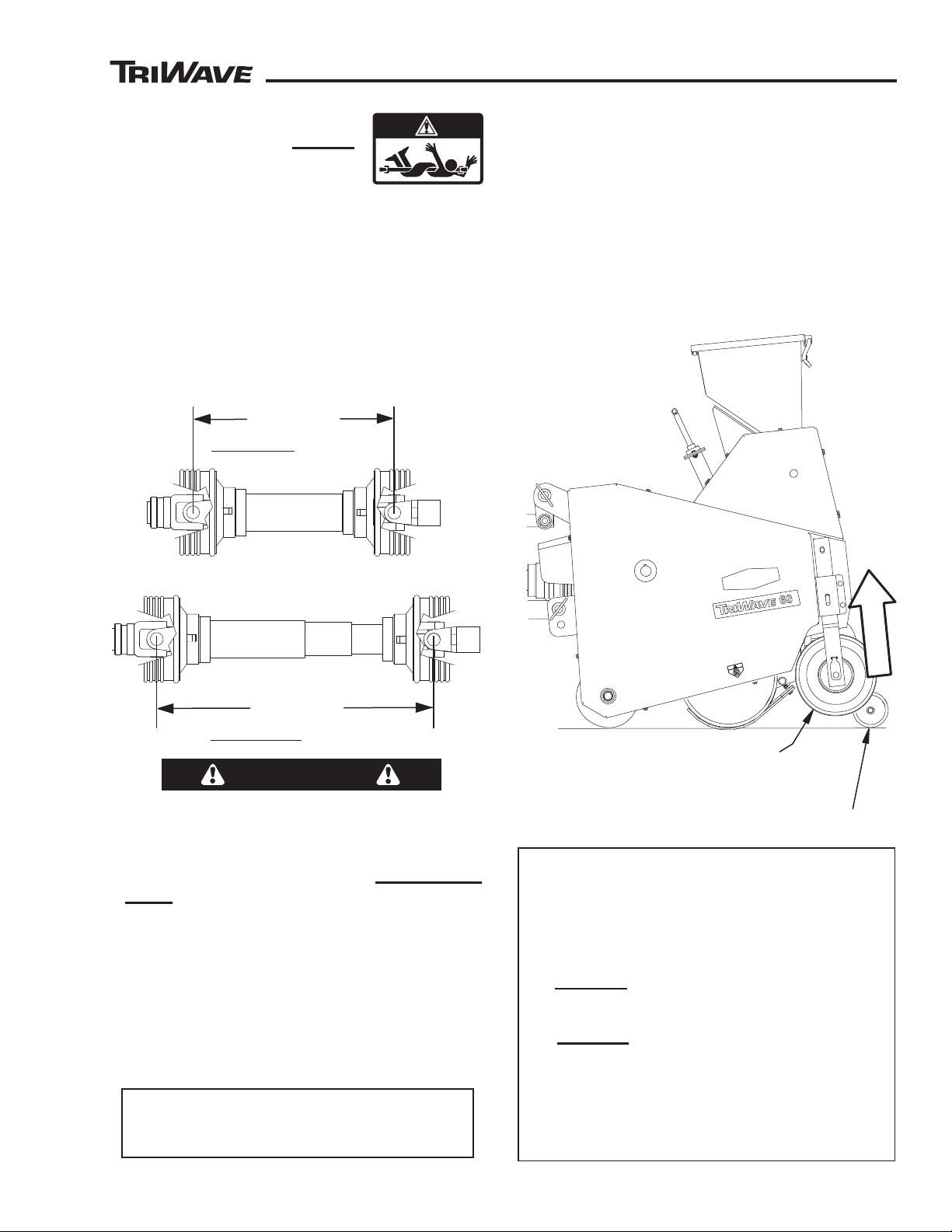

AS85851-04REVA

23-5/8” INCHES

(600 mm)

MAXIMUM LENGTH

FIGURE 3

16-1/2” INCHES

(419 mm)

MINIMUM LENGTH

AS85851-05REVA

FIGURE 4

STORAGE WHEELS IN

RAISED “OPERATING POSITION”

PACKER WHEELS

SETUP AND INSTALLATION

SAFE-14

DANGER

STEP 7. (See Figure 3) Attach

PTO shaft to tractor. Do Not

remove

any guards from the

PTO shaft or the TriWave to

install.

Assemble PTO shaft halves together. Check

●

PTO shaft guards for free movement.

● Install PTO shaft with TriWave lowered.

● Ensure that PTO locks to tractor. Check lock

on TriWave end.

● Check the minimum and maximum operating

dimensions for the PTO shaft.

STEP 8. (See Figure 4) Raise rear storage

wheels.

Start tractor, lift seeder and move to a turf

●

covered area.

Move the TriWave rear storage wheels into

●

the raised “operating” position.

NOTE: To protect the blades, the rear storage wheels

must be returned to the lowered “storage” position when

the seeder is unhitched or lowered over a hard surface.

STOP!!

IF THE PTO SHAFT CANNOT BE INSTALLED

WITHIN THE MINIMUM/MAXIMUM

DIMENSIONS, THE PT

USED WITH THE TRACTOR AND SEEDER.

ANOTHER PT

LENGTH AND GUARDING MUST BE USED

BEFORE OPERATING THE SEEDER.

If the PTO shaft can not be installed because it

will not fit between the TriWave and the tractor,

(space is less than 16-1/2”) extensions for the

TriWave lower mounts are available to reposition

the TriWave further away from the tractor.

CONTACT TURFCO FOR INFORMATION

ON AVAILABLE LOWER THREE POINT

85851 Rev B

O SHAFT WITH SUITABLE

MOUNT EXTENSIONS.

O SHAFT CANNOT BE

FINAL ADJUSTMENT

STEP 9. Adjust Upper Link. Move the tractor

and seeder over a turf covered area

● SLOWL

the cutting head to settle into the turf.

● SLOWL

cutting head seed distribution boxes.

If the seed distribution boxes touch and dig

●

into the turf during raising, shorten the length

of the upper link.

Y lower TriWave to the turf. Allow

Y raise TriWave while observing

9

™

™

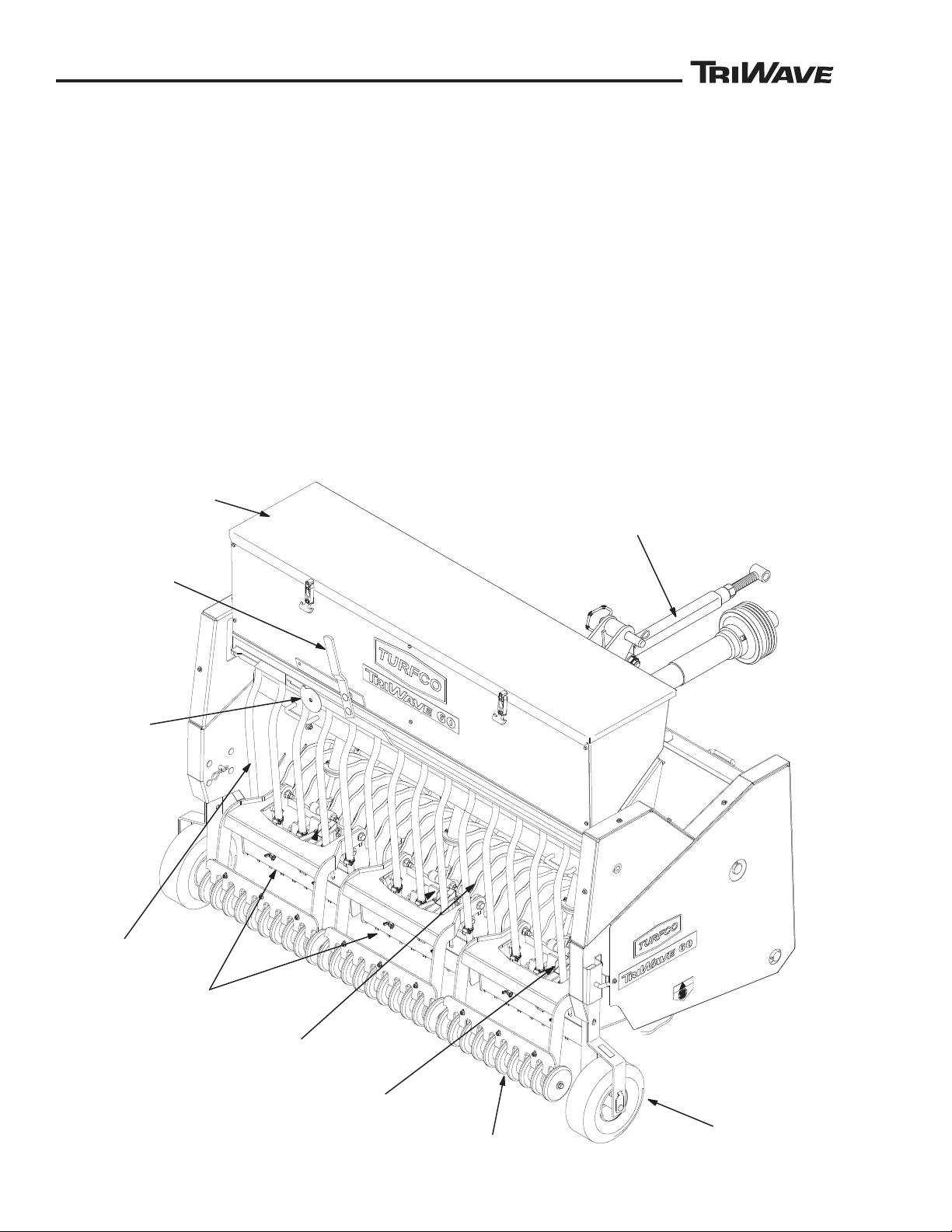

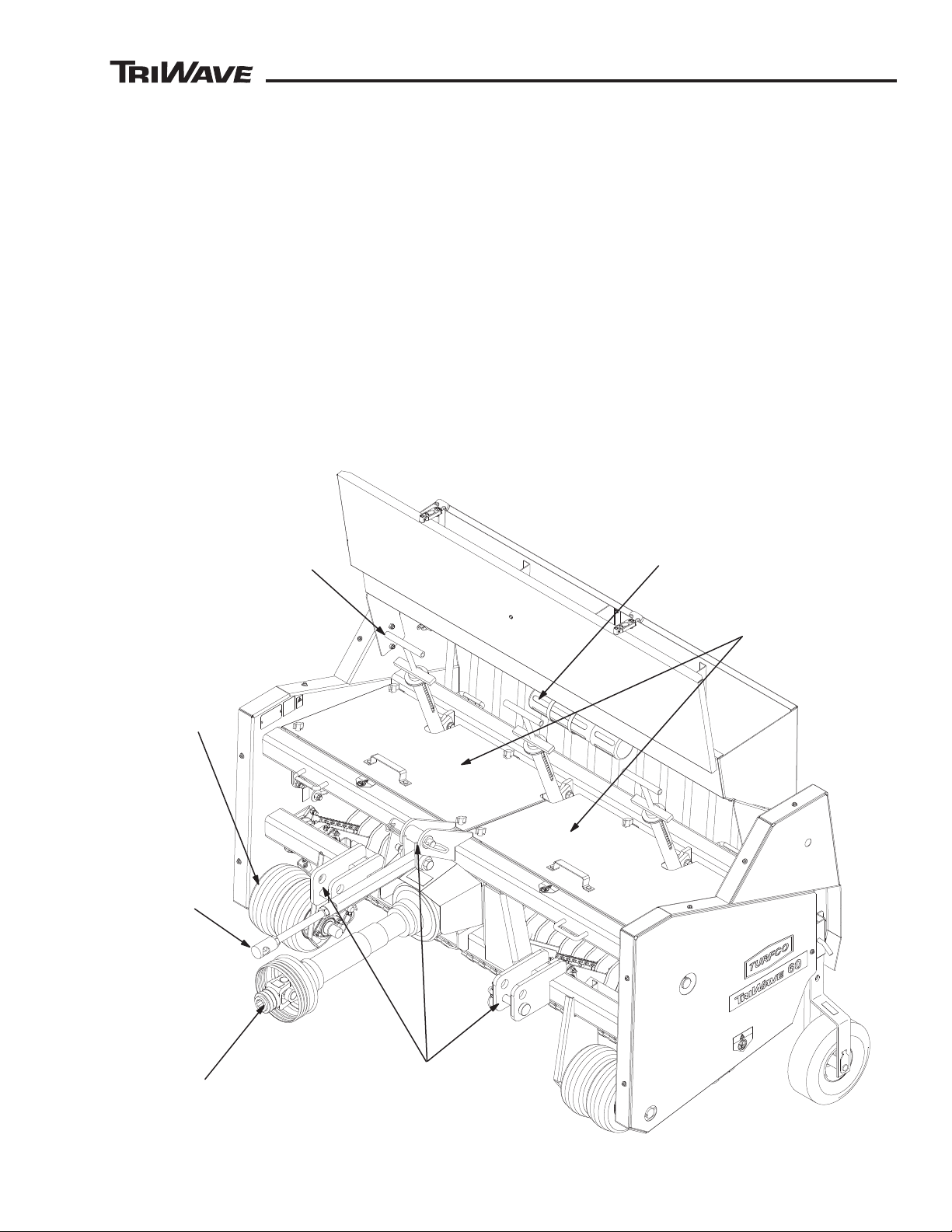

SEED

GATE

DIAL

SEED GATE

HANDLE

CUTTING HEAD

ASSEMBLIES

AND BLADES

STORAGE

WHEELS

SEED

TUBES

PACKER WHEELS

SEED HOPPER

FIGURE 5

DS85851-01REVA

BLADE

DEPTH

ADJUSTERS

SEED

DISRIBUTION

BOXES

UPPER

LINK

TURFCO

TURFCO

DESCRIPTION

Description

INTENDED USE AND FUNCTION

The TriWave Seeder is intended to be USED ONLY to

overseed grass seed on existing turf at sports turf fields

and on golf courses. The TriWave is not intended to

be a primary seeder and is not intended to be used to

seed areas without existing turf. The TriWave Seeder is

intended only to be used with grass seed. The TriWave

Seeder is NOT intended to be used for any purpose

other than to apply grass seed to the turf. The TriWave

Seeder is not intended to be used for the application

of fertilizers or lawn foods. The TriWave Seeder is not

intended to be used as a sod cutter, aerator, rototiller,

compaction roller, or any other type of soil preparation

or turf maintenance tool. Use of the TriWave Seeder

is intended at a properly prepared worksite where

deficiencies have been corrected to avoid injury and/

or damage to the machine. The TriWave Seeder is not

designed for or intended to accept riders.

LOCATION AND DESCRIPTION OF THE TRIWAVE

Seeder MAJOR COMPONENTS

(See Figure 5 and Figure 6)

See

Figure 5 and 6 for the location of the major

components of the seeder. Do not modify the seeder in

any manner. Do not operate the seeder with damaged

or inoperable components.

Manual Tube: The manual tube is located on the front

panel of the seed box. The tube is used to store the

operators manual.

Storage Wheels: The storage wheels are designed to

protect the blades when the unit is lowered over a hard

surface or disconnected from the tractor for storage.

The storage wheels can be set in two positions, raised

and lowered. The positions are secured by pull pins.

10

85851 Rev B

™

™

CUTTING HEAD

GUARDS

SEED BOX

DRIVE

FRONT

ROLLER

UPPER AND LOWER

THREE-POINT

HITCH POINTS

DOWN

PRESSURE

ADJUSTERS

PTO SHAFT

DS85851-02REVA

FIGURE 6

MANUAL TUBE

UPPER

LINK

TURFCO

DESCRIPTION

The wheels are not designed for transport, DO NOT

tow the seeder on the storage wheels. Tires are

equipped with a sealant. Wear eye protection when

checking tires. Check only when the valve stem is at

the top of the wheel. Inflate the tires to the pressure as

shown on the tire sidewall.

Upper and Lower Three Point Hitch Mounts: The

lower hitch mounts are equipped to accept either

a Category 1 or Category 2. The lower hole is for

Category 1, the upper hole is for Category 2.

The upper hitch point is equipped with a upper link to

attach to the tractor. The upper link can be adjusted in

length to fit different tractors. The link can be adjusted

to provide level raising and lowering of the seeder and

to allow freedom of movement for operation on uneven

ground.

PTO Shaft: The shaft connects to the tractor 540 PTO

to provide power for the seeder cutting blades. The

shaft has an operating length range of 419 mm to 600

mm (16-1/2” to 23-5/8” inches).

Cutting Head Assemblies and Blades: The seeder

is equipped with three cutting heads designed to

operate individually. The seeder has 30 round blades,

ten on each cutting head assembly. Each blade cuts

a slit in the soil for the seed. Each cutting head floats

independently from the other heads to allow it to follow

the contours of the turf. The floating helps maintain

even seed depth and ground contact.

Blade Depth Adjusters: The adjusters set the blade

depth of cut. The range is 0” inches to 1-3/8” (0 to 34.9

mm) deep. Each cutting head has its own blade depth

adjuster. The numbers on the decal are for reference

only, they do not represent any actual measured

depth.

85851 Rev B

11

™

™

WARNING

DESCRIPTION

SAFE-14

Down Pressure Adjusters: The down pressure

adjusters provide downward force on the cutting

heads to keep the blades in the soil. The adjuster can

be adjusted to provide a light down pressure when

working in soft soil, or adjusted to provide a heavy force

to help the blades cut into hard soils. The alphabetical

letters on the decal are for reference only, they do not

represent any measured amounts of down pressure

force.

Packer Wheels: The packer wheels improve seed

contact with the soil and compress the silt cut by the

blades. There is one packer wheel for every blade.

The packer wheels are in line with the blades (slit) and

float with the cutting heads.

Seed Hopper: The hopper holds 0.135 Cubic Meter

(8251 Cubic In. Or 4.77 Cubic Ft.) or Approximately

45.35 Kg. (100 Pounds) of Grass Seed. At the bottom

of the box are rotors that evenly distribute the seed to

the seed gate.

Seed Box Front Drive Roller: The right front drive

roller provides power to the chain that drives the seed

box rotors. Power to the chain is only present when the

seeder is moving and the roller is turning. When the

seeder is raised, the front roller can be manually turned

by hand to observe (calibrate/measure) the amount

of seed being dispensed. Both the right and left front

roller are equipped with scrapers to control the buildup

of dirt and debris on the rollers. The scrapers can be

adjusted to correct for contact or wear.

Seed Gate Dial: The dial adjusts the amount of seed

flow by limiting the opening size of the seed gate. The

dial is numbered 0 thru 80, with 0 being the smallest

opening. The numbers are for reference only, they do

not indicate any seed volume or weight.

The height of the boxes is adjustable to accommodate

turf and soil conditions. If existing turf has a long length,

the boxes can be raise to avoid contact with the grass.

The grass will disrupt the even distribution of the seed

and any moisture present in the grass will transfer to

the openings in the boxes. On sites with short turf, a

lower seed box height will aid in the seed not being

blown out away from the slit by the wind before it

contacts the soil.

LOCATION AND DESCRIPTION OF THE TRIWAVE

SEEDER OPERATOR POSITION

Operator Position: The proper location for the

operator of the TriWave Seeder is seated in the tractor

seat. Always disengage the PTO drive, stop the

tractor engine and lock the brakes before leaving the

operator’s seat. Do not stand behind or allow anyone

to stand behind the seeder when it is operating. The

TriWave Blades Can Throw Objects.

TO AVOID SERIOUS INJURY,

Move To the Operator’s Position On The Tractor

Before Engaging the PTO Drive.

Always be at the operator’s position before engaging

the Tractor PTO drive.

Avoid Any Contact With the PTO Shaft. PTO Shaft

Guards Must Be Install and Operational.

Seed Gate Handle: The seed gate handle opens the

seed gate allowing flow of seed to the seed tubes

and the seed distribution boxes. When not in use, the

handle must be in the closed position to avoid seed

from emptying out of the seed hopper.

Seed Tubes: The seed tubes carry the seed from the

seed box to the seed distribution boxes. The tubes are

clear plastic to allow monitoring of the seed flow and to

monitor any buildup of moisture or debris which could

disrupt the seed flow.

Seed Distribution Boxes: The seed distribution

boxes divide the seed flow to place equal amounts

of seed in each slit. There are three boxes, one for

each cutting head. The boxes are covered with a clear

plastic window to allow monitoring of any buildup of

dirt, grass, or moisture that will slow, disrupt, or stop

the flow of seed.

12

DESCRIPTION OF THE TRACTOR OPERATOR

CONTROLS

Refer to the tractors operator manual for proper

identification and operation of the tractor controls. The

following controls are used to operate the TriWave

seeder -

Engine RPM and Gear Range Selector: Used to

control ground speed and PTO speed output.

Three Point Hitch Control: Used for raising and

lowering the TriWave seeder.

PTO Drive: Used to power the TriWave seeder.

85851 Rev B

™

™

Operation

WARNING

WARNING

STORAGE ONLY

DO NOT USE

FOR TOWING

SAFE-08

SAFE-06

TO AVOID SERIOUS INJURY,

Read and Understand the Entire Manual

For the Seeder. Be Trained and Familiar

With the Operators Controls For the

Tractor.

Keep Hands and Feet Away From the Blades.

Move To the Operator’s Position At The Tractor

Before Engaging The PTO Drive.

Always Slowly Lower the Seeder.

Follow All Safety Precautions And Wear The

Appropriate Safety Gear.

Be Aware Of Others In The Worksite. Keep

Observers Away From The TriWave During

Operation. The TriWave Blades Can Throw

Objects.

PRE-OPERATION CHECK LIST

● Read and understand the entire manual for the

TriWave seeder and the tractor.

● Follow all safety instructions, warnings, and decals.

● Safety First – Wear the appropriate safety gear. Safety

glasses, gloves and safety shoes are recommended

when operating the TriWave Seeder.

● Check – The seed hopper. The hopper should be

clean and dry. Check the operation of the seed gate.

The gate should operate smoothly without use of

excessive force on the control handle.

● Grease – The fittings in the PTO shaft (total 2) and

drive shafts bearings (total 4).

● Inspect – The blade assemblies for damage, dirt

buildup or foreign objects.

● Check – All guards are in place, especially the PTO

shaft guards.

● Check – Retighten any loose nuts and screws to

ensure safe operation.

● Inspect and prepare the work site.

● Check – The work site for above and below ground

obstructions and/or dangerous areas.

OPERATION

Locate and mark any shallow buried natural gas,

propane gas, or other gas or fuel line that may be

damaged by the seeding process.

Locate and mark all sprinkler and irrigation heads,

above and below ground irrigation control boxes,

water shutoffs, control valves, and any shallow

buried irrigation lines that may be damaged by the

seeding process.

Locate and mark any shallow buried roof drain pipes,

drain tiling, drain catch basins, or any other buried

drainage items that may be damaged in the seeding

process.

RAISING STORAGE WHEELS

The storage wheels are designed for storage only. The

wheels keep the blades elevated during storage to

avoid damage from contact with

a hard surface. The wheels are

not meant to be used for towing

of the seeder. After the seeder has been hitched and

lifted by the tractor, the wheels must be raised onto

the “Operating” position. Pull the pin and lift into the

next higher hole. The wheels do not touch the ground

during operation. After operation, the wheels should

be returned to the lowered “Storage” position before

the seeder is lowered over a hard surface.

GROUND OPERATING SPEED

Seed application rates are based on a operating speed

of 4.8 Km/h (3 mph). Maximum operating ground speed

is 8.8 Km/h (5.5 MPH). Do not exceed the maximum

speed as poor seeding quality and excessive stress on

the machine will occur.

Choose a gear in the tractor that will provide adequate

engine speed (RPM) and proper 540 PTO speed

while staying under the 5.5 MPH maximum. During

operation, always move at the same speed to ensure

even distribution of the seed. Operating at a constant

even speed will obtain the best results.

MAXIMUM ANGLE OF OPERATION

WORK SITE PREPARATION

Inspect the work site obstructions. Plan your path

and know the location of any above ground or below

ground objects.

Under certain conditions, the TriWave Seeder blades

can reach a depth of 50 mm (1-1/2” inches). Damage

will occur to any buried object that the blades may

come in contact with.

Locate and mark all shallow buried electrical cables,

including electric service, cable TV, telephone,

outdoor lighting, any other type of buried cable that

may be damaged by the seeding process.

85851 Rev B

Do not operate the TriWave Seeder on steep slopes.

Maximum angle of operation is 15° degrees. Serious

injury can occur if operated on steep slopes or when

operated in an unsafe manner. The tractor and TriWave

seeder can tip or roll over on to the operator.

TO AVOID SERIOUS INJURY, Do Not Operate

Seeder On Slopes Over 15° Degrees. Tractor

and TriWave Seeder Can Tip or Roll Over Onto

Operator If Operated On Steep Slopes.

13

™

™

OPERATION

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

Bentgrass

Kentucky

Bluegrass

Fescue

Ryegrass

Mixtures

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

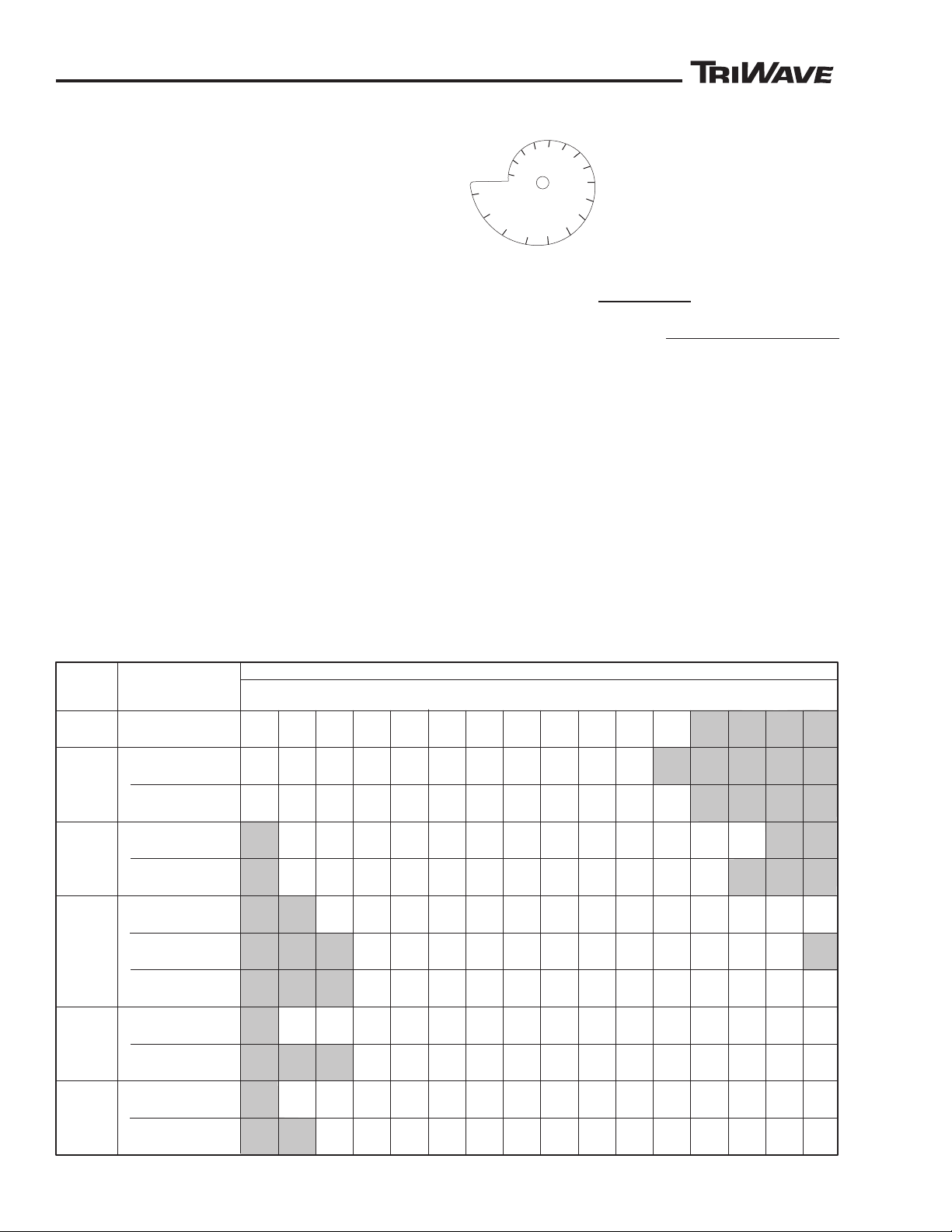

Approximate Pounds of Seed Per 1000 Square Feet at 3 MPH (Kilograms of Seed Per 92.9 Square Meters at 4.8 Km/h)

Cam Gauge Dial Setting

Penncross

0.40 0.55 1.0 1.4 2.1 2.8 3.7 4.7 5.9 7.5 8.8 9.8 11.2 11.3

0.15 0.25 0.35 0.45 0.65 0.85 1.2 1.7 2.2 2.6 3.2 3.8

Type

Of Seed

Variety

50% Bluegrass

50% Fescue

50% Bluegrass

50% Rye

Tall

Perennial

Hard

Creeping

Red

0.15 0.20 0.32 0.48 0.55 0.88 1.1 1.4 1.9 2.4 3.1 3.9 4.9 5.5 5.7

0.35 0.55 1.0 1.5 2.2 2.9 3.9 4.9 6.4 7.6 8.6 9.7 9.9

0.3 0.5 0.7 1.0 1.4 1.8 2.4 3.1 3.9 4.8 5.9 6.9 7.6 7.6

0.15 0.25 0.55 0.95 1.4 2.2 3.0 4.0 5.2 6.6 8.2 9.3 10.8 12.4 12.7

Annual

0.35 0.5 0.75 1.1 1.7 2.2 3.0 3.8 4.5 5.5 6.4 7.0 6.7

Bluegrass

Rough

0.45 0.9 1.5 2.3 3.4 4.5 6.1 7.3 8.8 10.9 13.0 15.0

0.15 0.35 0.55 1.1 1.7 2.4 3.1 3.8 5.2 6.2 7.4 8.4 9.7

Bermuda

0.15 0.45 1.1 1.8 3.2 4.2 5.9 7.9 9.7 12.1 14.7 18.4

Coated

Hulled

0.25 0.65 1.4 2.2 3.2 4.1 5.4 7.1 8.3 10.9 11.8 13.7

0.5 1.3 2.2 3.4 5.0 6.7 8.9 12.5 14.9 17.5 20.9

Pounds

(Kilograms)

(0.11) (0.3) (0.64) (1.0) (1.45) (1.85) (2.45) (3.22) (3.75) (5.9) (5.35) (4.4)

(0.23) (0.59) (1.0) (1.54) (2.26) (3.04) (4.04) (5.67) (6.75) (7.94) (9.48)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

(0.07) (0.21) (0.5) (0.82) (1.45) (1.91) (2.68) (3.58) (4.4) (5.49) (6.67) (8.35)

(0.07) (0.16) (0.25) (0.5) (0.77) (1.09) (1.41) (1.72) (2.36) (2.81) (3.35) (3.81) (4.40)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

Pounds

(Kilograms)

(0.21) (0.41) (0.68) (1.05) (1.54) (2.04) (2.77) (3.31) (3.99) (4.95) (5.89) (6.80)

(0.14) (0.22) (0.31) (0.45) (0.64) (0.82) (1.09) (1.41) (1.77) (2.18) (2.67) (3.12) (3.45) (3.45)

(0.07) (0.11) (0.16) (0.21) (0.3) (0.38) (0.54) (0.77) (0.99) (1.18) (1.45) (1.72)

(0.16) (0.25) (0.45) (0.68) (1.0) (1.31) (1.77) (2.22) (2.90) (3.45) (3.90) (4.4) (4.49)

(0.18) (0.25) (0.45) (0.64) (0.95) (1.27) (1.67) (2.13) (2.67) (3.4) (4.0) (4.5) (5.08) (5.12)

(0.07) (0.11) (0.25) (0.43) (0.64) (1.0) (1.36) (1.81) (2.36) (2.99) (3.72) (4.21) (4.9) (5.62) (5.76)

(0.07) (0.09) (0.15) (0.22) (0.25) (0.40) (0.5) (0.63) (0.87) (1.09) (1.41) (1.77) (2.22) (2.5) (2.58)

(0.16) (0.22) (0.34) (0.5) (0.77) (1.0) (1.36) (1.72) (2.04) (2.50) (2.90) (3.17) (3.04)

OP85851-09REVA

SEED APPLICATION RATE CHART

LOADING SEED HOPPER

The seed hopper has a capacity of 45.35 Kg. (100

Pounds) of grass seed. The capacity is an approximate

measure due to the differences in seed size and shape.

The hopper is divided into four connecting cambers.

Fill each chamber with equal amounts of seed. Seed

from each chamber will mix to keep seed level equal

across the chambers.

Before filling the seed hopper:

► Inspect the operation of the seed gate. With the

seed dial set at “80”, the gate should operate smoothly.

The gate should move completely from open to close

without binding.

► Check for any foreign objects inside the hopper.

► Check for any buildup of seed chaff, dust and dirt.

► Check for any moisture in the seed hopper and the

seed tubes. Clean as needed. Moisture can cause the

seed to “clump” together and cause seed flow problems.

Remove any moisture before filling the hopper.

Close the seed gate and completely fill the hopper.

Seed must be clean and dry for proper flow thru the

seed gate. Hopper is meant to be used with seed only,

do not put any fertilizers or chemicals into the hopper.

Always keep the lid closed during operation to avoid

contamination of the seed.

SETTING SEED GATE DIAL

The seed gate dial is marked

“0” thru “80”. At “0” the gate is

fully closed. The gate opening

will continue getting larger as

the setting gets closer to “80”. At

“80” the gate is fully open. Refer

to the seed application rate chart

(located on the inside of the hopper cover) for a seed

dial settings of an approximate setting to control the

rate of seed application. Because of the differences in

seed size and shape, seed application rate can vary

from the chart. Turn the dial and lock into position at

the desired setting.

For a more accurate calibration of the seed dial setting,

the front roller can be turned by hand to observe

(calibrate/measure) the amount of seed actually being

dispensed. Raise the seeder to allow the front roller

to be turned by hand. Place a plastic sheet under the

seed distribution boxes to catch the seed and turn the

roller clockwise. 92 full revolutions of the front roller

equals 1000 square feet of coverage. Weight the

amount of seed dispensed and adjust the seed dial as

needed. Also compare the amounts of seed dispensed

from each seed distribution box, all three should be

equal.

14

85851 Rev B

™

™

OPERATING SEED GATE HANDLE

1

2

3

4

5

WARNING

25 x 25

25 x 50

50 x 50

50 x 75

75 x 75

75 x 100

100 x 100

100 x 150

150 x 150

Size of Area

To Be Seeded

In Feet

Total Area

in

Square Feet

625

1,250

2,500

3,750

5,625

7,500

10,000

15,000

22,500

8 x 8

8 x 15

15 x 15

15 x 23

23 x 23

23 x 30

30 x 30

30 x 45

45 x 45

64

120

225

345

529

690

900

1,350

2,025

Size of Area

To Be Seeded

In Meters

Total Area

in

Square Meters

Total Area

in

Square Yards

69

139

278

417

625

833

1,111

1,667

2,500

Area Conversion Chart

In Square Feet and Square Yards

Area Conversion Chart

In Square Meters

OP85851-04REVA

OPERATION

The seed gate handle, located on the rear of the

hopper, opens and closes the seed gate (located

on the bottom of the seed hopper). The handle has

only two positions, “Open” and “Close”. The range of

movement of the handle is limited by the adjustment

of the seed gate control dial. Because seed will begin

to flow as soon as the seed gate is opened, always

be prepared to move to the operators position on the

tractor and begin seeding as soon as possible. Always

close the seed gate after stopping.

The seed gate handle should move easily from open

to close, if excessive force is required to open or close

the gate, check for an obstruction in the seed gate

openings, or excess debris built up around the gate

opening and linkage.

SETTING BLADE DEPTH ADJUSTMENT

The blade depth adjustment controls the depth

of blade cut into the turf. Blade depth needs

to be adjustable to allow for the variations in

the thickness of existing turf, thatch buildup

and soil conditions. Always Stop the PTO

Drive Before Adjusting the Blade Depth

Adjustment.

TO AVOID SERIOUS INJURY,

Always Stop PTO Drive and Blades Before

Adjusting Blade Depth.

During operation, the cutting head assemblies ride

atop the existing turf on a depth plate. Only the part

of blade extending below the plate cuts the turf. The

depth of cut is controlled by how much of the blade

extends below the depth plate.

The blades must cut into the soil. The blade must cut

through any thatch to reach the soil.

Set the blade depth to cut into the soil at a planting

depth that is recommended for the seed variety being

planted. Cutting too deep can damage the existing

grass. Excessive blade depth will bury the seed

too deep. Seed buried too deep will not germinate.

Excessive blade depth will also cause undesired debris

in the slit cut by the blades.

Set the depth by loosening the adjuster locks and

moving the depth plate pointer along the scale. The

numbers on the scales are for reference only, they

do not represent any actual measured depth. A visual

measurement can be taken by measuring the distance

from the bottom edge of the blade to the bottom edge

of the depth plate finger (located between the blades)

Set all three cutting heads the same. Tighten the

locking handles firmly.

NOTE: As the blades wear the overall diameter of the

blade will become smaller. The blade depth setting will

have to be increased to compensate for blade wear

and to maintain the same depth of cut. If cutting heads

have a mix of new and used blades, the setting for

each head will vary to make up for the differences in

blade size.

85851 Rev B

15

Loading...

Loading...