Page 1

Your Global Automation Partner

Operating Instructions

TW-R…-M-B146

RFID Tags with a Password

Function

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Contents

Page 3

3

2018/04

1 About These Instructions 5

1.1 Target groups 5

1.2 Explanation of symbols 5

1.3 Other documents 5

1.4 Naming convention 5

1.5 Feedback about these instructions 6

2 Notes on the Product 6

2.1 Product identication 6

2.2 Scope of delivery 6

2.3 Legal requirements 6

2.4 Manufacturer and service 6

3 For Your Safety 7

3.1 Intended use 7

3.2 Obvious misuse 7

3.3 General safety notes 7

4 Product Description 8

4.1 Device overview 8

4.2 Properties and features 8

4.3 Operating principle 9

4.4 Functions and operating modes 9

4.5 Technical accessories 9

5 Mounting 10

5.1 Aligning tags to the read/write head 10

5.2 Fastening tags to the object 11

6 Operation 12

7 Setting – Protecting Tags with a Password 12

7.1 Component and rmware version 12

7.2 BLxx-2RFID-A module – Overview of commands 14

7.2.1 Set Transceiver PWD command 14

7.2.2 Set Tag PWD command 16

7.2.3 Set Tag Protection command 18

7.2.4 Get Tag Protection Status command 20

7.2.5 Resetting the password in the read/write head 21

7.3 BLxx-2RFID-S module – Overview of commands 22

7.3.1 BLxx-2RFID-S module – Process output data 22

7.3.2 Set Transceiver PWD command 23

7.3.3 Set Tag PWD command 25

7.3.4 Set Tag Protection command 27

7.3.5 Get Tag Protection Status command 29

7.3.6 Resetting the password in the read/write head 31

7.4 Setting password protection for tags 32

7.4.1 Multiple tags with the same password in an application (example) 32

7.4.2 Multiple tags with dierent passwords in an application (example) 33

Contents

Page 4

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

7.4.3 Setting password protection via FDT/DTM 35

7.5 Addressing password protected areas of a tag 39

8 Troubleshooting 40

9 Maintenance 40

10 Repair 40

10.1 Returning devices 40

11 Disposal 40

12 Technical Data 41

13 Appendix: EU conformity declaration 42

Page 5

5

2018/04

1 About These Instructions

These instructions describe the setup, the functions and use of the product and help you to operate the product for its intended use. Read the instructions carefully prior to using the product.

This will prevent the risk of personal injury and damage to property. Keep these instructions

safe during the service life of the product. If the product is passed on, pass on these instructions

as well.

1.1 Target groups

These instructions are written for suitably qualified and trained personnel and must be read by

anyone entrusted with the mounting, commissioning, operation, maintenance, disassembly or

disposal of the device.

1.2 Explanation of symbols

The following symbols are used in these instructions:

DANGER

DANGER indicates an immediate hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a possible hazardous situation with the risk of death or serious

injury if it is not prevented.

NOTICE

NOTICE indicates a situation that may cause possible damage to property if it is not

prevented.

NOTE

NOTE indicates tips, recommendations and important information. The notes contain

information, particular operating steps that facilitate work and possibly help to avoid

additional work resulting from incorrect procedures.

MANDATORY ACTION

This symbol denotes actions that the user must carry out.

RESULT OF ACTION

This symbol denotes the relevant results of actions and procedures.

1.3 Other documents

Besides this document the following material can be found on the Internet at www.turck.com:

■

Data sheet

■

Device approvals

■

RFID engineering manual

■

Startup manuals

1.4 Naming convention

Common synonyms for “tags” are “data carriers”, “transponders” and “mobile data memory”.

Page 6

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Notes on the Product

1.5 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If you have any suggestions for improving the design or if some information is missing in

the document, please send your suggestions to techdoc@turck.com.

2 Notes on the Product

2.1 Product identication

These instructions apply to the following tags:

■

TW-R10-M-B146

■

TW-R12-M-B146

2.2 Scope of delivery

The delivery consists of the tag.

2.3 Legal requirements

The device is subject to the following EU directive:

■

2014/35/EU (R&TTE Directive)

This directive stipulates the following requirements related to health and safety as well as electromagnetic compatibility:

■

Health and safety: Compliance with the objectives of safety requirements from directive

2014/35/EU (Low Voltage Directive), however, without the application of the voltage limits

■

Electromagnetic compatibility: Compliance with the special requirements of directive

2014/30/EU (EMC Directive)

2.4 Manufacturer and service

Turck supports you in your projects – from the initial analysis right through to the commissioning of your application. The Turck product database offers you several software tools for programming, configuring or commissioning, as well as data sheets and CAD files in many export

formats. You can access the Product Database directly via the following address: www.turck.de/

produkte

For further inquiries in Germany contact the Sales and Service Team on:

Sales: +49 208 4952-380

Technical: +49 (0) 208 4952-390

For overseas inquiries contact your national Turck representative.

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Mülheim an der Ruhr

Germany

Page 7

7

2018/04

3 For Your Safety

The product is designed according to state of the art technology. Residual hazards, however,

still exist. Observe the following warnings and safety regulations in order to prevent danger to

persons and property. Turck accepts no liability for damage caused by failure to observe these

warnings and safety instructions.

3.1 Intended use

The devices are designed only for use in industrial areas.

The passive BL ident® tags are designed for contactless write and read operations from several

BL ident® HF read/write heads with an operating frequency of 13.56 MHz. The tags are suitable

for mounting in metal. The achievable read/write distances may vary according to factors such

as component tolerances, mounting locations, ambient conditions and the effect of materials.

For this reason, the application must be tested in all cases under real conditions (particularly

with read and write operations in motion).

The device must only be used as described in these instructions. Any other use is not in accordance with the intended use; Turck accepts no liability for any resulting damage.

3.2 Obvious misuse

The devices are not safety components and must not be used for the protection of persons and

property.

3.3 General safety notes

■

The device must only be fitted, installed, set, operated and maintained by trained personnel.

■

Only use the device in compliance with the applicable national and international regulations,

standards and laws.

■

The device only fulfills the EMC requirements for industrial applications and is not suitable for

use in residential areas.

Page 8

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

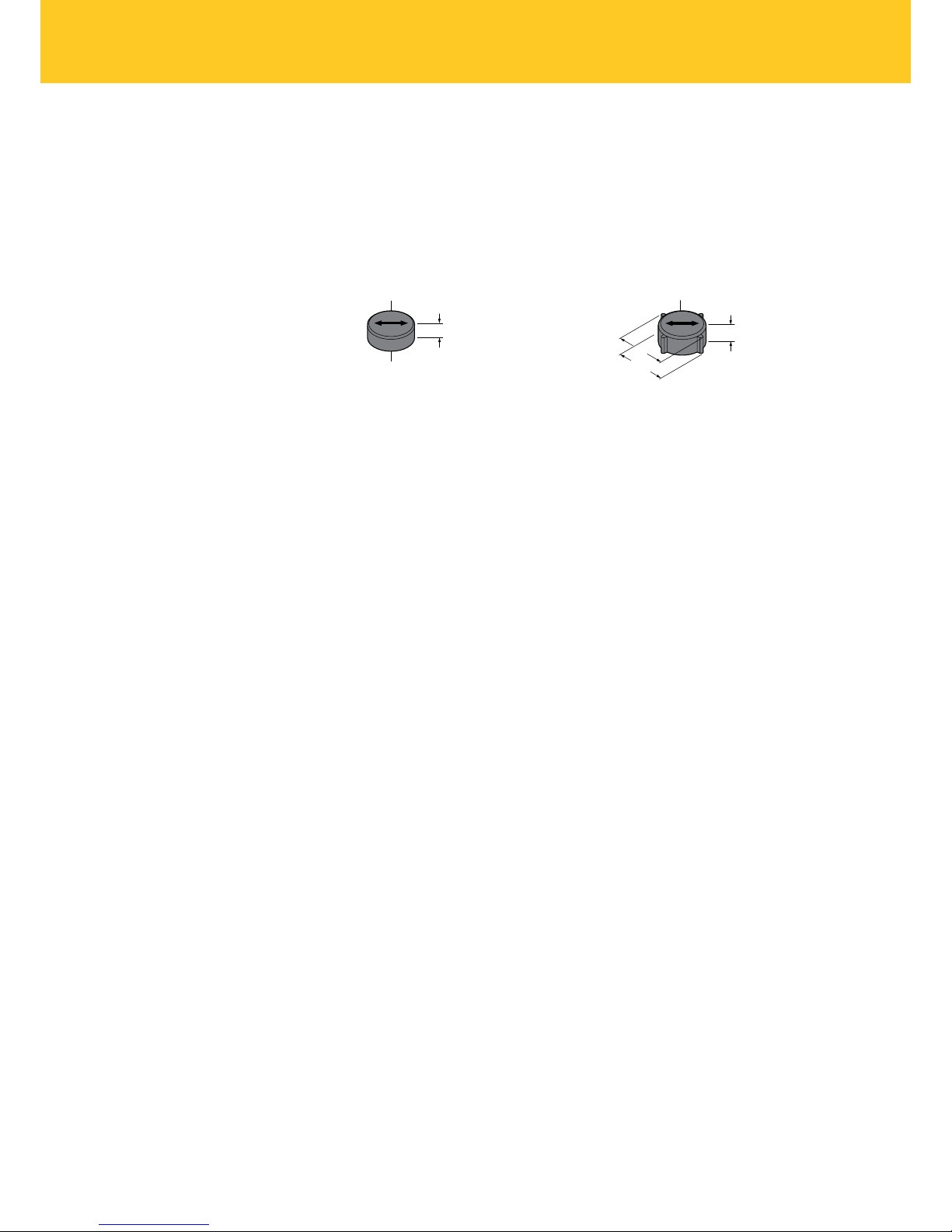

4 Product Description

The TW-R…-M-B146 tags have 146 bytes of EEPROM memory and can be read or written with

BL ident read/write heads as well as Turck handhelds. The tags are available with a diameter of

10 mm or 12 mm.

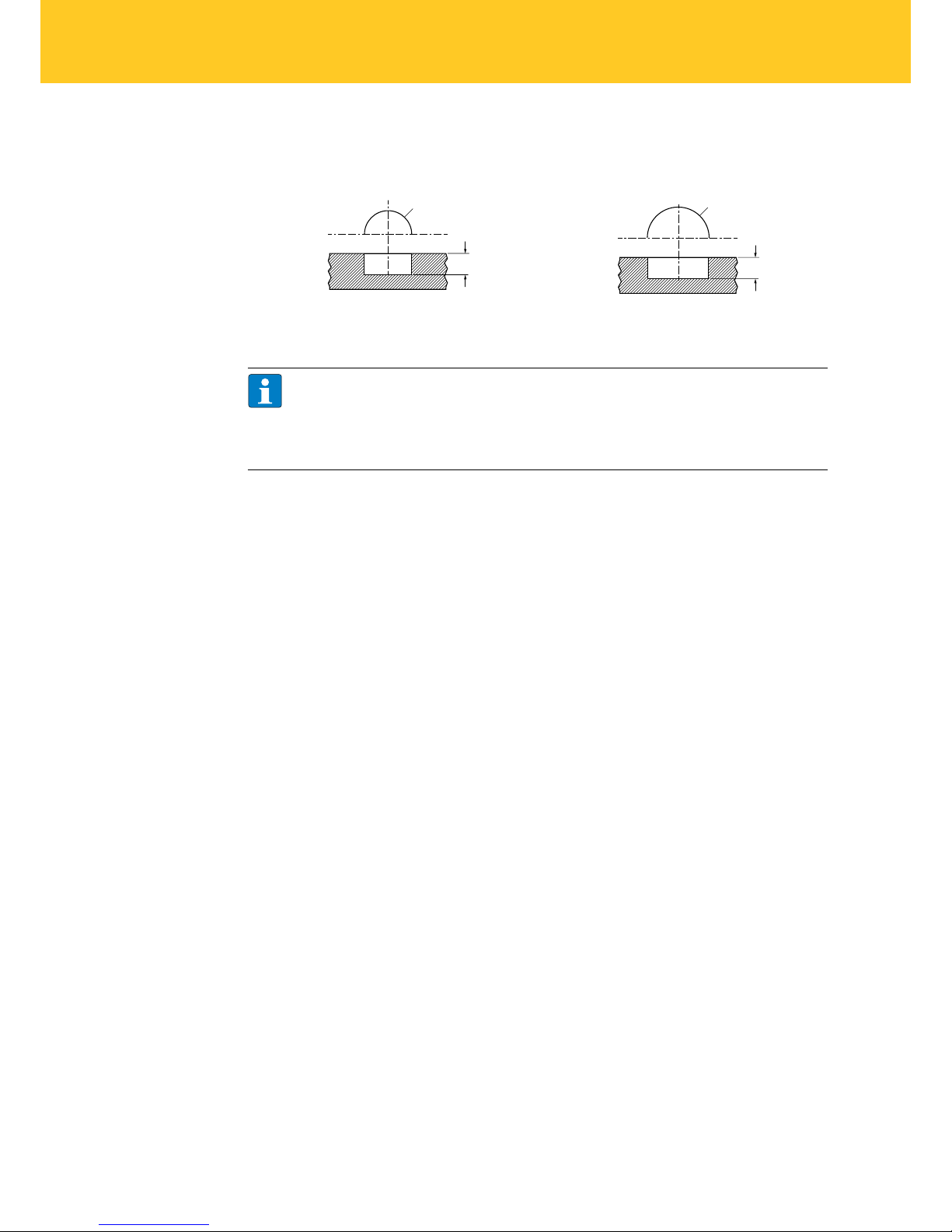

4.1 Device overview

4.5

ø 10

ø 9.9

ø 10

4.5

12

11.8

Fig. 1: Dimensions – TW-R10-M-B146 Fig. 2: Dimensions – TW-R12-M-B146

4.2 Properties and features

■

Tags for direct mounting on and in metal

■

EEPROM memory

■

128 bytes of user data memory

4.3 Operating principle

BL ident tags are passive, i.e. they operate without the use of a battery and are powered by

the magnetic or electromagnetic field generated by the read/write head. If the tag enters the

transmission field of the read/write head, it is activated for writing and reading the data. The

tag does not generate its own field for this, but the field of the read/write head simply changes

through load modulation. For this, a load resistor is switched on and off in the cycle of the transferred data and the mutual inductance of the HF tag is consequently changed. These changes

are detected by the read/write head and evaluated.

4.4 Functions and operating modes

The passive BL ident HF tags can be written and read by HF read/write heads at an operating

frequency of 13.56 MHz. The tags have a 146 byte EEPROM memory. Refer to the data sheets for

the maximum achievable read/write distances. The memory areas of the tag can be password

protected from write and read access.

4.5 Technical accessories

The tags can only be written or read with the appropriate read/write heads and handhelds.

Information about compatible devices is provided in the relevant product data sheet.

An overview of other RFID system components is provided in the RFID engineering manual.

Page 9

9

2018/04

5 Mounting

The tags can be fitted flush to the mounting environment. An undermount installation (1 mm

in metal) will reduce the read/write distance by approx. 30 %.

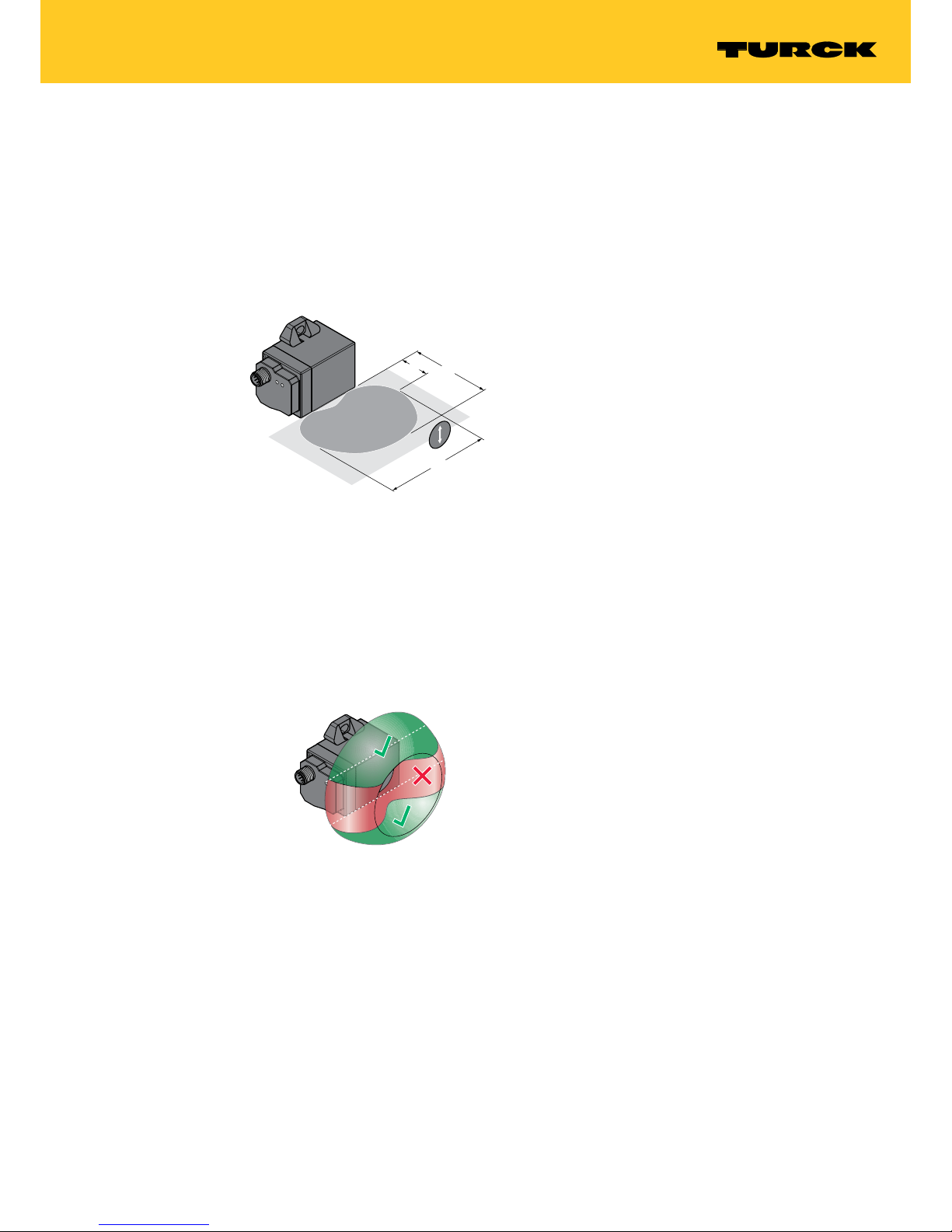

5.1 Aligning tags to the read/write head

Align tags to the read/write head as shown in Fig. 3.

Fig. 3: Aligning tags to the read/write head (example: TNSLR-Q42TWD-H1147)

Take read/write distances into account. Refer to the product data sheet for the values for

recommended distance (A), maximum distance (B) and the length of the transmission zone

(C) at the recommended distance.

Position the tag so that it moves past the edges of the read/write head housing during a read

or write operation (see Fig. 4, green areas).

Fig. 4: Highlighting of usable transmission zone (example: TNSLR-Q42TWD-H1147)

A

B

C

Page 10

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

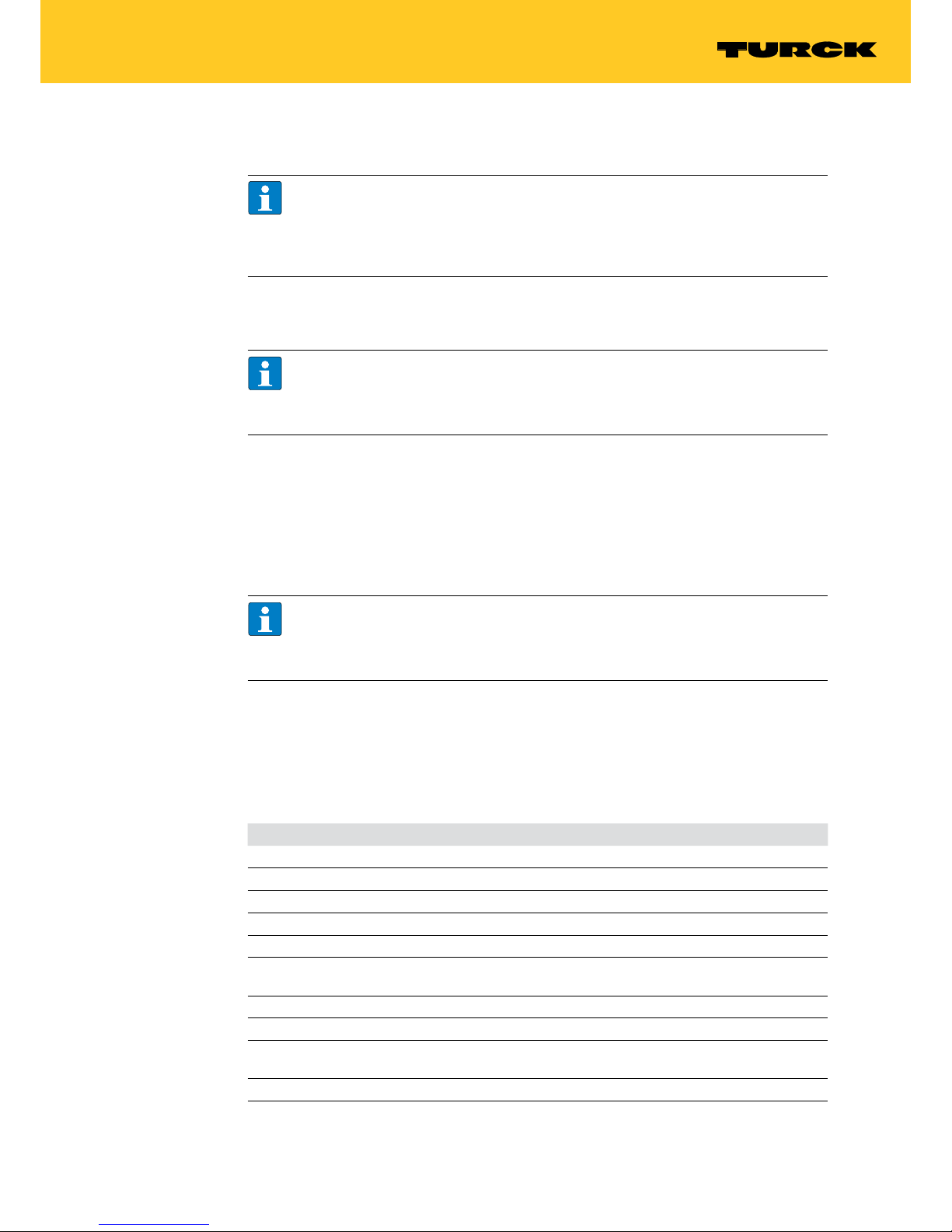

5.2 Fastening tags to the object

Cut hole as shown in Fig. 5.

4,5

ø 10

4,5

ø 12

Fig. 5: Hole dimensions for inserting the tag in metal (left: TW-R10…, right: TW-R12…)

Fill the hole with an adequate quantity of adhesive material or potting material.

NOTE

Turck can provide on request a recommendation for adhesives that meet FDA and EU

requirements for accidental contact with food. This recommendation does not release

the user from an examination regarding the suitability of a particular adhesive for the

relevant application.

Push the tag correctly aligned in the hole. The tags cannot be correctly aligned in the hole at

a later time.

Let the adhesive cure in order prevent the tags from turning.

Optional: Fill any recess or cavity with adhesive.

Optional: Spread the adhesive to produce a flush surface.

Page 11

11

2018/04

6 Operation

NOTE

The achievable read/write distances may vary according to factors such as component

tolerances, mounting locations, ambient conditions and the effect of materials. For this

reason, the application must be tested in all cases under real conditions (particularly

with read and write operations in motion).

7 Setting – Protecting Tags with a Password

NOTE

The following describes the password function with the BL…-2RFID-A and BL…2RFIDS RFID electronic modules. The use of the password function with the TBEN… compact

RFID interfaces is described in the operating instructions of the relevant interfaces.

The password function enables the memory areas of the tags to be protected from write and

read access.

The password function consists of different commands that are executed via a Get command.

The password must consist of 4 bytes. Information on the individual commands are provided in

this chapter.

The assignment of a password is only possible in Standard access mode.

NOTE

The password function only offers basic access protection. The function contains no

encryption and does not meet the requirements of increased access protection. The

password function is not suitable for safety-related applications.

7.1 Component and rmware version

In order to use the password function, the RFID components used must have at least the following firmware versions:

Read/write heads – Firmware version

Read/write head Ident-No. FW version

TB-M18-H1147 7030001 1v85

TN-M18-H1147 7030002 1v85

TB-M30-H1147 7030003 1v85

TN-M30-H1147 7030004 1v85

TN-CK40-H1147 7030006 1v85

TN-Q80-H1147 7030007 1v85

7v85_TN_TNLR-Q80

TN-S32XL-H1147 7030008 1v85

TN-Q14-0.15-RS4.47T 7030235 1v85

TNLR-Q80-H1147 7030230 3v85

7v85_TN_TNLR-Q80

TB-EM18WD-H1147 7030224 1v85

Page 12

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Read/write head Ident-No. FW version

TN-EM18WD-H1147 7030223 1v85

TB-EM30WD-H1147 7030221 1v85

TN-EM30WD-H1147 7030222 1v85

TB-Q08-0.15-RS4.47T 7030553 1v85

TNLR-Q350-H1147 7030220 5v85

TNLR-Q80L400-H1147 7030204 5v85

7v85_SLR-Q350_Q80L

TNLR-Q80L400-H1147L 7030234 5v85

7v85_SLR-Q350_Q80L

TNLR-Q80L800-H1147 7030522 7v85_SLR-Q350_Q80L

TNSLR-Q80WD-H1147 7030418 7v85_SLR-Q42_Q80

TNSLR-Q42TWD-H1147 7030424 7v85_SLR-Q42_Q80

TNSLR-Q350-H1147 7030454 7v85_SLR-Q350_Q80L

HT-IDENT-H1147 7030236 1v85

TN-Q80-H1147-EX 7030302 1v85

TNLR-Q80-H1147-EX 7030303 3v85

TB-EM18WD-H1147-EX 7030381 1v85

TN-EM18WD-H1147-EX 7030382 1v85

TB-EM30WD-H1147-EX 7030385 1v85

TN-EM30WD-H1147-EX 7030386 1v85

RFID electronic modules – Firmware version

Read/write head Ident-No. FW version

BL20-2RFID-A 6827233 SR49

BL67-2RFID-A 6827225 SR49

BL20-2RFID-S 6827306 SR49

BL67-2RFID-S 6827305 SR49

Page 13

13

2018/04

7.2 BLxx-2RFID-A module – Overview of commands

The commands required for the password function are sent to the BLxx-2RFID-A module via a

Get command.

For this the following entries must be made with all commands:

■

CMDREF[x].CMD = 0x62

■

Refer to the descriptions of the individual commands for the values for CMDREF[x].length.

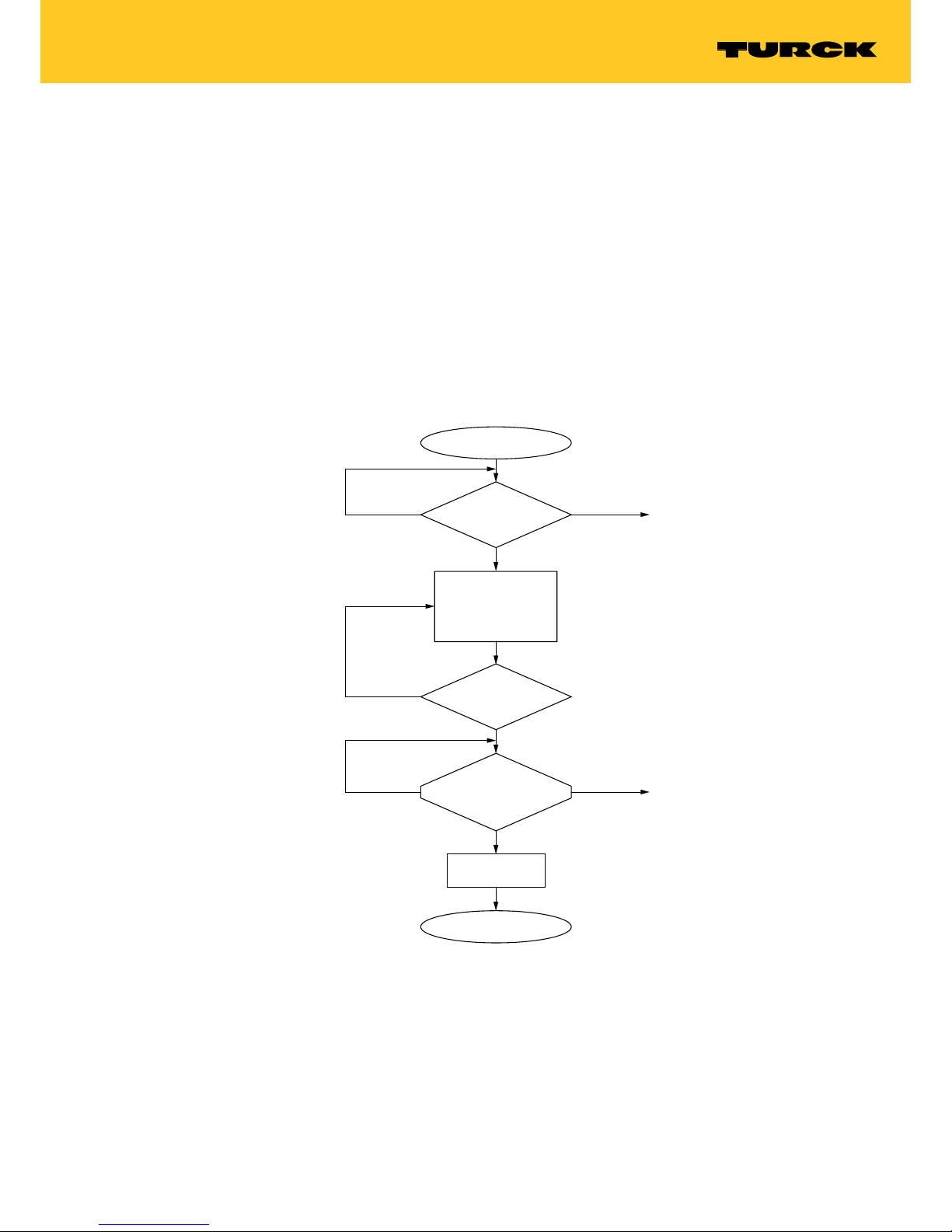

7.2.1 Set Transceiver PWD command

The Set Transceiver PWD command sets a password in the read/write head via a Get command.

The password is stored temporarily in the memory of the read/write head. After the power supply of the read/write head is reset, the password must be set again in the read/write head.

If an incorrect password is sent, this causes a timeout (unknown error, error code E1FE8100).

Fig. 6: Flow diagram for Set Transceiver PWD command

Execute command

TXBUF[1] = 5

TXBUF[2]

…

}

= password

TXBUF[5]

Error?

Error?

Ready?

(UIN0 = true)

DONE = true?

„GET“ active

(DONE = false)

(BUSY = true)

Waiting for

next command

Basic status

no

no

„GET“ successful

yes

yes

yes

ERROR = true

Ready and

successful?

(DONE = true)

(BUSY = false)

no ERROR = true

Page 14

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Get.request

TXBUF[1] 5

TXBUF[2] Password byte [0]

TXBUF[3] Password byte [1]

TXBUF[4] Password byte [2]

TXBUF[5] Password byte [3]

Get.response

RXBUF[1] 5

Page 15

15

2018/04

7.2.2 Set Tag PWD command

The Set Tag PWD command sets a password in the tag via a Get command. After the password

is sent, other commands (e.g. Set_Tag_Protection) can be sent to the tag.

Fig. 7: Flow diagram for Set Tag PWD command

yes

yes

yes

yes

Basic status

Waiting for next command

Ready?

(XIN0 = true)

DONE = true?

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

Execute command

TXBUF[1] = 4

TXBUF[2]

…

}

= password

TXBUF[5]

„GET“ successful

Tag present?

(TP = true)

no

Ready and

successful?

(DONE = true)

(BUSY = false)

Error?

no

ERROR = true

Error?

Page 16

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Get.request

TXBUF[1] 4

TXBUF[2] Password byte [0]

TXBUF[3] Password byte [1]

TXBUF[4] Password byte [2]

TXBUF[5] Password byte [3]

Get.response

RXBUF[1] 4

Page 17

17

2018/04

7.2.3 Set Tag Protection command

The Set Tag Protection command defines the password protection for the tag via a Get command. For this it has to be specified whether a write protection or a read protection should be

set and the area of the tag to which the password applies. Protection for all areas is defined

with one command.

Write protection is always also contained in a read protection.

The tags with the EM4233-SLIC chip have 8 pages. One page consists of 4 blocks of 4 bytes

each.

Page Block Byte

0 0…3 0…15

1 4…7 16…31

2 8…11 32…47

3 12…15 48…63

4 16…19 64…79

5 20…23 90…95

6 24…27 96…111

7 28…31 112…127

16 bytes can be write protected with a flag. A second flag must be set in order to set additional

read protection.

The flags for the password protection are described in the following table:

Page Write protection Read protection

0 Write, bit 0 Read, bit 0

1 Write, bit 1 Read, bit 1

2 Write, bit 2 Read, bit 2

3 Write, bit 3 Read, bit 3

4 Write, bit 4 Read, bit 4

5 Write, bit 5 Read, bit 5

6 Write, bit 6 Read, bit 6

7 Write, bit 7 Read, bit 7

Page 18

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Fig. 8: Flow diagram for Set Tag Protection command

Get.request

TXBUF[1] 7

TXBUF[2] Write, bit 0…7

TXBUF[3…5] 0

TXBUF[6] Read, bit 0…7

Get.response

RXBUF[1] 7

yes

yes

yes

yes

Basic status

Waiting for next command

Ready?

(UIN0 = true)

DONE = true?

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

Execute command

TXBUF[1] = 7

TXBUF[2] = write, bit 0…7

TXBUF[6] = read, bit 0…7

„GET“ successful

Tag present?

(TP = true)

no

Ready and

successful?

(DONE = true)

(BUSY = false)

Error?

no

ERROR = true

Error?

Page 19

19

2018/04

7.2.4 Get Tag Protection Status command

The Get Tag Protection Status command scans whether a specific area of the tag is password

protected.

Fig. 9: Flow diagram for Get Tag Protection Status command

Get.request

TXBUF[1] 8

Get.response

RXBUF[1] 8

RXBUF[2] Write, bit 0…7

RXBUF[3…5] 0

RXBUF[6] Read, bit 0…7

yes

yes

yes

yes

Basic status

Waiting for next command

Ready?

(UIN0 = true)

DONE = true?

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

Execute command

TXBUF[1] = 8

„GET“ successful

TXBUF[2] = write, bit 0…7

TXBUF[6] = read, bit 0…7

Tag present?

(TP = true)

no

Ready and

successful?

(DONE = true)

(BUSY = false)

Error?

no

ERROR = true

Error?

Page 20

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.2.5 Resetting the password in the read/write head

The Reset Password in the Read/Write Head command deletes the password in the read/write

head via a Get command.

Fig. 10: Flow diagram for resetting the password in the read/write head

Get.request

TXBUF[1] 6

Get.response

TXBUF[1] 6

yes

yes

yes

yes

Basic status

Waiting for next command

Ready?

(XIN0 = true)

DONE = true?

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

Execute command

TXBUF[6]

„GET“ successful

Tag present?

(TP = true)

no

Ready and

successful?

(DONE = true)

(BUSY = false)

Error?

no

ERROR = true

Error?

Page 21

21

2018/04

7.3 BLxx-2RFID-S module – Overview of commands

7.3.1 BLxx-2RFID-S module – Process output data

Byte no. Bit

7 6 5 4 3 2 1 0

0 XCVR NEXT TA G_ID READ WRITE TAG _INFO XCVR_INFO RESET

1 GET res. Domain_Count res. Byte_Count 2 Byte_Count 1 Byte_Count 0

2 MSB AddrHi LSB

3 MSB AddrLo LSB

4 8 bytes write data (WRITE_DATA)

5

6

7

8

9

10

11

Page 22

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.3.2 Set Transceiver PWD command

The Set Transceiver PWD command sets a password in the read/write head via a Get command.

The password is stored temporarily in the memory of the read/write head. After the power supply of the read/write head is reset, the password must be set again in the read/write head.

If an incorrect password is sent, this causes a timeout (unknown error, error code E1FE8100)

Fig. 11: Flow diagram for Set Transceiver PWD” command

The password set in the read/write head here must match the tag password. Refer to chapter

„Setting password protection for tags” for the procedure in the application.

yes

yes

Ready for

RFID-communication

Ready?

(XCVR_ON = true)

(DONE = true)

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

yes

GET command

(GET = true)

[false ➞ true ➞ false]

Preallocate values:

Address = 5

WRITE DATA [0]…[3]

= password

Tag present?

(TP = true)

no

yes

„GET“

successful?

(ERROR = false)

(DONE = true)

no yes

• Command recessed:

GET = false

• Ready for RFID communication:

DONE = true

BUSY = false

XCVR_CON = true

XCVR_ON = true

Error?

Error?

Page 23

23

2018/04

Get.request

StartAddress 5

WRITE_DATA[0] Password byte [0]

WRITE_DATA[1] Password byte [1]

WRITE_DATA[2] Password byte [2]

WRITE_DATA[3] Password byte [3]

WRITE_DATA[4…7] 0

Page 24

24

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.3.3 Set Tag PWD command

The Set Tag PWD command sets a password in the tag via a Get command. After the password

is sent, other commands (e.g. Set_Tag_Protection) can be sent to the tag.

Fig. 12: Flow diagram for “Set Tag PWD”

The password set in the read/write head here must match the tag password. Refer to chapter

„Setting password protection for tags” for the procedure in the application.

yes

yes

yes

Ready for RFIDcommunication

Ready?

(XCVR_ON = true)

(DONE = true)

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

yes

GET command

(GET = true)

[false ➞ true ➞ false]

Preallocate values:

Byte Count = 4

WRITE DATA [0]…[3]

= password

Tag present?

(TP = true)

no

„GET“

successful?

(ERROR = false)

(DONE = true)

(BUSY = false)

no yes

• Command recessed:

GET = false

• Data available in

receive buffer:

READ DATA (8 Byte)

• Ready for RFID communication:

DONE = true

BUSY = false

XCVR_CON = true

XCVR_ON = true

Error?

Error?

Page 25

25

2018/04

Get.request

StartAddress 4

WRITE_DATA[0] Password byte [0]

WRITE_DATA[1] Password byte [1]

WRITE_DATA[2] Password byte [2]

WRITE_DATA[3] Password byte [3]

WRITE_DATA[4…7] 0

Page 26

26

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.3.4 Set Tag Protection command

The Set Tag Protection command defines the password protection for the tag via a Get command. For this it has to be specified whether a write protection or a read protection should be

set and the area of the tag to which the password applies. Protection for all areas is defined

with one command.

Write protection is always also contained in a read protection.

The EM4233 tags have 8 pages. One page consists of 4 blocks of 4 bytes each.

Page Block Byte

0 0…3 0…15

1 4…7 16…31

2 8…11 32…47

3 12…15 48…63

4 16…19 64…79

5 20…23 90…95

6 24…27 96…111

7 28…31 112…127

16 bytes can be write protected with a flag. A second flag must be set in order to set additional

read protection.

The flags for the password protection are described in the following table:

Page Write protection Read protection

0 Write, bit 0 Read, bit 0

1 Write, bit 1 Read, bit 1

2 Write, bit 2 Read, bit 2

3 Write, bit 3 Read, bit 3

4 Write, bit 4 Read, bit 4

5 Write, bit 5 Read, bit 5

6 Write, bit 6 Read, bit 6

7 Write, bit 7 Read, bit 7

Page 27

27

2018/04

Fig. 13: Flow diagram for Set Tag Protection

Get.request

StartAddress 7

WRITE_DATA[0] Write, bit 0…7

WRITE_DATA[1…3] 0

WRITE_DATA[4] Read, bit 0…7

WRITE_DATA[5…7] 0

yes

yes

yes

Ready for RFIDcommunication

Ready?

(XCVR_ON = true)

(DONE = true)

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

yes

GET command

(GET = true)

[false ➞ true ➞ false]

Preallocate values:

Byte Count = 7

WRITE DATA [0] = write, bit 0…7

WRITE DATA [4] = read, bit 0…7

Tag present?

(TP = true)

no

„GET“

successful?

(ERROR = false)

(DONE = true)

(BUSY = false)

no yes

• Command recessed:

GET = false

• Data available in

receive buffer:

READ DATA (8 Byte)

• Ready for RFID communication:

DONE = true

BUSY = false

XCVR_CON = true

XCVR_ON = true

Error?

Error?

Page 28

28

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.3.5 Get Tag Protection Status command

The Get Tag Protection Status command scans whether a specific area of the tag is password

protected.

Fig. 14: Flow diagram for Get Tag Protection Status

yes

yes

yes

Ready for RFIDcommunication

Ready?

(XCVR_ON = true)

(DONE = true)

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

yes

GET command

(GET = true)

[false ➞ true ➞ false]

Preallocate values:

Byte Count = 8

Tag present?

(TP = true)

no

„GET“

successful?

(ERROR = false)

(DONE = true)

(BUSY = false)

no yes

• Command recessed:

GET = false

• Data available in

receive buffer:

READ DATA [0] = write, bit 0…7

READ DATA [4] = read, bit 0…7

• Ready for RFID communication:

DONE = true

BUSY = false

XCVR_CON = true

XCVR_ON = true

Error?

Error?

Page 29

29

2018/04

Get.request

StartAddress 8

WRITE_DATA[0…7] 0

Get.response

READ_DATA[0] Write, bit 0…7

READ_DATA[1…3] 0

READ_DATA[4] Read, bit 0…7

READ_DATA[5…7] 0

Page 30

30

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.3.6 Resetting the password in the read/write head

Fig. 15: Flow diagram for Reset read/write head

Get.request

StartAddress 6

WRITE_DATA[0…7] 0

Get.response

StartAddress 6

WRITE_DATA[0…7] 0

yes

yes

yes

Ready for RFIDcommunication

Ready?

(XCVR_ON = true)

(DONE = true)

„GET“ active?

(DONE = false)

(BUSY = true)

no

no

ERROR = true

yes

GET command

(GET = true)

[false ➞ true ➞ false]

Preallocate values:

Byte Count = 6

Tag present?

(TP = true)

no

„GET“

successful?

(ERROR = false)

(DONE = true)

(BUSY = false)

no yes

• Command recessed:

GET = false

• Data available in

receive buffer:

READ DATA (8 Byte)

• Ready for RFID communication:

DONE = true

BUSY = false

XCVR_CON = true

XCVR_ON = true

Error?

Error?

Page 31

31

2018/04

7.4 Setting password protection for tags

The following flow diagrams describe the programming of the tags.

7.4.1 Multiple tags with the same password in an application (example)

Fig. 16: Multiple tags with one password – Programming tags

Write desired data

to data carrier

Read-write-head

connected?

(XCVR_CON = true)

Start

Define password

Cpmmand:

Set_transceiver_password

(with default passwort of

data carrier = 0x00000000)

Command:

Set_transceiver_password

(with new password)

Command:

Set_tag_password

(with new password)

Error present?

(ERROR = True)

Command:

Set_tag_protection

(define password)

yes

no

yes

yes

no

Error present?

(ERROR = True)

End

Error message

ERROR CODE =

E1FE8100

Error message

ERROR CODE =

E1FE0200

Page 32

32

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Fig. 17: Multiple tags with one password – Access in the application

7.4.2 Multiple tags with dierent passwords in an application (example)

Fig. 18: Multiple tags with different passwords – Programming tags

Command:

Set_transceiver_password

(with default passwort of

data carrier = 0x0000)

Command:

Read …

Write …

Start

Read UID

Command:

Set_tag_password

Command:

Set_transceiver_password

(with new password)

Command:

Set_transceiver_password

(with default passwort of

data carrier = 0x0000)

1) Define password

2) Link password and protection

status (read and/or write

protection) with UID

3) Save data in control or database

Command:

Set_tag_protection

Page 33

33

2018/04

Fig. 19: Multiple tags with different passwords – Access in the application

Start

Read UID

Command:

Set_transceiver_password

(with the password stored in

the database)

Command:

Read …

Write …

new data carrier

Page 34

34

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.4.3 Setting password protection via FDT/DTM

The BLxx-2RFID-S module enables the password protection to be set by a PC via the FDT/DTM.

The example uses the following components:

■

FDT: PACTware™ with the DTM for BL67-2RFID-S

■

BL67-GW-EN

■

BL67-2RFID-S

■

TN-Q80-H1147 (channel 1)

Connect the RFID interface with a PC.

Launch PACTware™.

Define the required password.

Start the Simulation function (right-click the RFID-S module > Simulation) in PACTware™

Write the required user data to the tag (in the example: 8 bytes, data 1122334455667788).

Fig. 20: Writing user data to the tag

Page 35

35

2018/04

Set the password of the read/write head to 0 (default setting of the tag)

Fig. 21: Setting the password of the read/write head to 0

Set the defined password in the tag.

Fig. 22: Setting a new password in the tag (example: 11223344)

Page 36

36

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

Set the new password in the read/write head

Fig. 23: Setting a new password in the read/write head (example: 11223344)

Set write protection or read protection

Fig. 24: Setting read/write protection

Page 37

37

2018/04

Fig. 25: Setting read protection

Page 38

38

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting – Protecting Tags with a Password

7.5 Addressing password protected areas of a tag

The following table shows the possible access options to the tag when password protection is

set.

Action Response of the tag Remark

Access to read protected area

without password or with incorrect password

Tag responds with “0” The response of the tag with “0” can have two causes:

Either the memory area of the tag is written with 0 or is

read protected. Recommendation: In order to distinguish between a correct and an incorrect read operation, set a bit other than 0 in every page. This is read out

with every read operation.

Access to write protected area

without password or with incorrect password

Error message: E1FE0200 Error message E1FE0200 can have two causes: Either an

incorrect password was sent or the tag was too short in

the detection range.

Remedy: Execute the Get Tag Protection Status

command.

Inventory (scan UID) Tag sends UID The UID can always be read irrespective of password

protection.

Access (read or write) with a

password (in the read/write

head) to an area not protected

with a password

Access is carried out, and the DONE bit is set.

Access (read) with an incorrect

password or without a password

to a protected and unprotected

area

The data from the unprotected

area is displayed. The protected

area is displayed as “0”.

Access (write) to a protected and

an unprotected area

Error message E1FE0200, data

not written.

The protected area on the tag is in front of the unprotected area.

The unprotected area is written, followed by error message

E1FE0200.

The unprotected area on the tag is in front of the protected area.

Tag within the detection range The TP bit (Tag present) is set irrespective of password

protection.

Page 39

39

2018/04

8 Troubleshooting

If the device does not function as expected, first check whether ambient interference is present.

If there is no ambient interference present, check the connections of the device for faults.

If there are no faults, there is a device malfunction. In this case, decommission the device and

replace it with a new device of the same type.

9 Maintenance

The devices are maintenance-free, clean dry if required.

10 Repair

The device must not be repaired by the user. The device must be decommissioned if it is faulty.

Observe our return acceptance conditions when returning the device to Turck.

10.1 Returning devices

If a device has to be returned, bear in mind that only devices with a decontamination declaration will be accepted. This is available for download at

https://www.turck.de/en/retoure-service-6079.php

and must be completely filled in, and affixed securely and weather-proof to the outside of the

packaging.

11 Disposal

The devices must be disposed of correctly and must not be included in normal household

garbage.

Page 40

40

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

12 Technical Data

Technical Data TW-R10-M-B146 TW-R12-M-B146

Data transmission Inductive coupling Inductive coupling

Operating frequency 13.56 MHz 13.56 MHz

Memory type EEPROM EEPROM

Chip type EM4233SLIC EM4233SLIC

Memory size 146 byte 146 byte

Memory Read/write Read/write

Freely usable memory 128 bytes 128 bytes

Number of read operations unlimited unlimited

Number of write operations 10

5

10

5

Typical read time 2 ms/byte 2 ms/byte

Typical write time 3 ms/byte 3 ms/byte

Wireless communication and protocol

standards

ISO 15693 ISO 15693

Minimum distance to metal 0 mm 0 mm

Ambient temperature -40…+85 °C -40…+85 °C

Storage temperature -40…+85 °C -40…+85 °C

Diameter 10 mm ± 0.2 mm 12 mm ± 0.2 mm

Housing height 4.5 mm ± 0.3 mm 4.5 mm ± 0.3 mm

Housing material Plastic, open housing, encapsulated Plastic, open housing, encapsulated

Material of active face Plastic, black, PPS Plastic, black, PPS

Degree of protection IP68 IP68

Page 41

41

2018/04

13 Appendix: EU conformity declaration

Hans Turck GmbH & Co. KG hereby declares that wireless system types TW-R…M-B146 comply with directive 2014/53/EU. The complete text of the EU declaration of conformity can be

obtained from the following Internet address: www.turck.com

Page 42

D500054 | 2018/04

*D500054*

Over 30 subsidiaries and over

60 representations worldwide!

www.turck.com

Loading...

Loading...