turck TN915-Q120L130-H1147, TN920-Q120L130-H1147, TN921-Q120L130-H1147, TN865-Q175L200-H1147, TN902-Q175L200-H1147 Operating Instructions Manual

...Page 1

Your Global Automation Partner

Operating Instructions

TN…-Q…L…-H1147

UHF Read/Write Heads

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Contents

Page 3

3

V01.00 | 2018/06

1 About These Instructions 5

1.1 Target groups 5

1.2 Explanation of symbols 5

1.3 Other documents 5

1.4 Naming convention 6

1.5 Feedback about these instructions 6

2 Notes on the Product 7

2.1 Product identication 7

2.2 Scope of delivery 7

2.3 Legal requirements 8

2.4 Manufacturer and service 8

3 For Your Safety 9

3.1 Intended use 9

3.2 Obvious misuse 9

3.3 General safety notes 10

4 Product Description 11

4.1 Device overview 11

4.1.1 Indication elements 11

4.2 Properties and features 11

4.3 Operating principle 12

4.4 Functions and operating modes 12

4.4.1 Operating frequency 13

4.4.2 Combination of UHF read/write heads and tags 13

4.5 Technical accessories 14

5 Mounting 15

5.1 Screw fastening on a mounting plate 16

5.2 Mounting with an application-specic adapter 17

5.3 Mast/tube mounting 18

5.4 Mounting with the RH-Q240L280/Q280L640 arm bracket 19

6 Connection 20

6.1 Wiring diagrams 20

7 Commissioning 21

8 Operation 21

8.1 LEDs 21

9 Setting and Parameterization 22

9.1 Connecting read/write heads with the PC 22

9.1.1 Connecting the read/write heads with a PC via the RFID interface 22

9.1.2 Connecting read/write heads with a PC via the interface converter 23

9.1.3 Creating a project in PACTware 24

9.2 Testing the read/write heads 27

9.2.1 Starting the RFID test 27

Contents

Page 4

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

9.2.2 Start window – Overview 28

9.2.3 “RFID Test” – Main menu 29

9.2.4 “RFID Test” – “Basic Test” window 30

9.2.5 “RFID Test” – “Tag Actions” window 31

9.2.6 “RFID Test” – “Logger” window 34

9.2.7 “HF diagnosis” window 35

9.3 Setting read/write heads parameters via the DTM 36

9.3.1 Starting the extended read/write head parameter setting 36

9.3.2 Main menu – Overview 37

9.3.3 Choosing the access level 38

9.3.4 “Basic setup” 39

9.3.5 “Antenna” 39

9.3.6 “Communication” 39

9.3.7 “EPC Class1 Gen2” 39

9.3.8 “Error Handling” – Selectable parameters 39

9.3.9 “Event Handling” – Selectable parameters 39

9.3.10 “Post Read Filter” – Selectable parameters 39

9.3.11 “Signaling” – Selectable parameters 39

9.4 Device information via the DTM 40

10 Troubleshooting 42

11 Maintenance 42

12 Repair 42

12.1 Returning devices 42

13 Disposal 42

14 Technical Data 43

14.1 Technical data – TN865… 43

14.2 Technical data – TN902… 44

14.3 Technical data – TN840/920… 45

14.4 Technical data – TN917… 46

14.5 Technical data – TN866… 47

14.6 Technical data – TN902/915… 48

14.7 Technical data – TN920… 49

14.8 Technical data – TN921… 50

15 Appendix: Conformity Declarations and Approvals 51

15.1 EU conformity declaration 51

15.2 FCC/IC Digital Device Limitations – TN902-Q120L130-H1147 51

15.3 FCC/IC Digital Device Limitations – TN902-Q175L200-H1147 52

Page 5

5

V01.00 | 2018/06

1 About These Instructions

This manual describes the setup, the functions and use of the product and helps you to operate

the product for its intended use. Read the instructions carefully prior to using the product. This

will prevent the risk of personal injury and damage to property. Keep these instructions safe

during the service life of the product. If the product is passed on, pass on these instructions as

well.

1.1 Target groups

These instructions are written for suitably qualified and trained personnel and must be read by

anyone entrusted with the mounting, commissioning, operation, maintenance, disassembly or

disposal of the device.

1.2 Explanation of symbols

The following symbols are used in these instructions:

DANGER

DANGER indicates an immediate hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a possible hazardous situation with the risk of death or serious

injury if it is not prevented.

NOTICE

NOTICE indicates a situation that may cause possible damage to property if it is not

prevented.

NOTE

NOTE indicates tips, recommendations and important information. The notes contain

information, particular operating steps that facilitate work and possibly help to avoid

additional work resulting from incorrect procedures.

MANDATORY ACTION

This symbol denotes actions that the user must carry out.

RESULT OF ACTION

This symbol denotes the relevant results of actions and procedures.

1.3 Other documents

Besides this document the following material can be found on the Internet at www.turck.com:

■

Data sheet

■

Quick start guide

■

RFID engineering manual

■

Startup manuals

Page 6

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

About These Instructions

1.4 Naming convention

Common synonyms for “tags” are “data carriers”, “transponders” and “mobile data memory”.

Read/write heads are also called “transceivers” or “readers”.

1.5 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If you have any suggestions for improving the design or if some information is missing in

the document, please send your suggestions to techdoc@turck.com.

Page 7

7

V01.00 | 2018/06

2 Notes on the Product

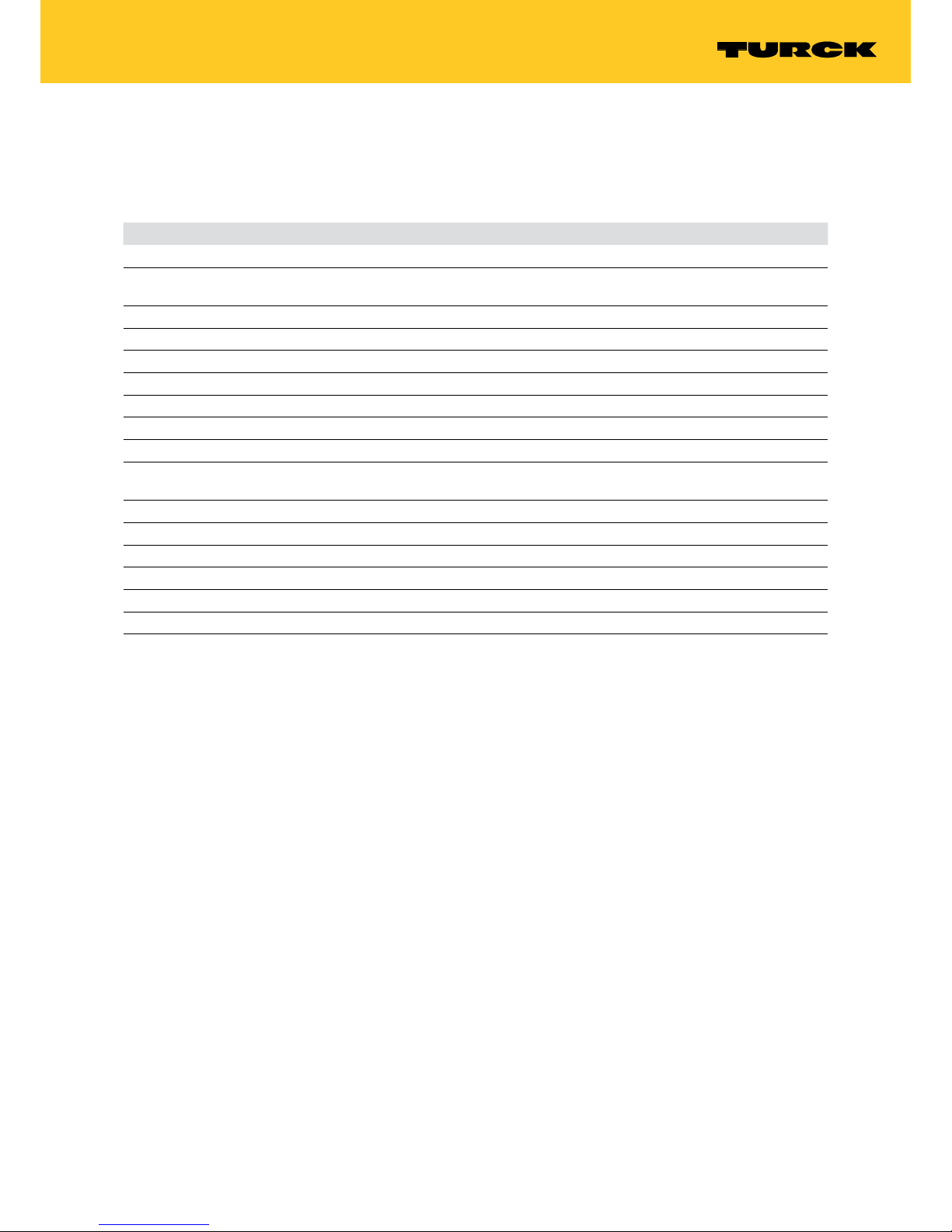

2.1 Product identication

These instructions apply to the following UHF read/write heads:

Type code Operating frequency Region

TN865-Q120L130-H1147 865…868 MHz Europe

TN902-Q120L130-H1147 902…928 MHz North America (USA,

Canada, Mexico)

TN840/920-Q120L130- H1147 920.5…924.5MHz China

TN917-Q120L130-H1147 917…920.8 MHz Korea

TN866-Q120L130-H1147 866…868 MHz Russia

TN902/915-Q120L130-H1147 915…928MHz Brazil

TN920-Q120L130-H1147 920…926 MHz Australia, New Zealand

TN921-Q120L130-H1147 920…925 MHz Singapore

TN865-Q175L200-H1147 865…868 MHz Europe

TN902-Q175L200-H1147 902…928 MHz North America (USA,

Canada, Mexico)

TN840/920-Q175L200- H1147 920.5…924.5MHz China

TN917-Q175L200-H1147 917…920.8 MHz Korea

TN866-Q175L200-H1147 866…868 MHz Russia

TN902/915-Q175L200-H1147 915…928MHz Brazil

TN920-Q175L200-H1147 920…926 MHz Australia, New Zealand

TN921-Q175L200-H1147 920…925 MHz Singapore

2.2 Scope of delivery

The following are included in the scope of delivery:

■

Read/write head

■

Quick start guide

■

Mounting aid incl. fixing clamp and 2 M6 ×8 screws

■

Grounding set

■

4 screw covers

■

Turck RFID-DVD

■

1 screw cap M12

Page 8

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Notes on the Product

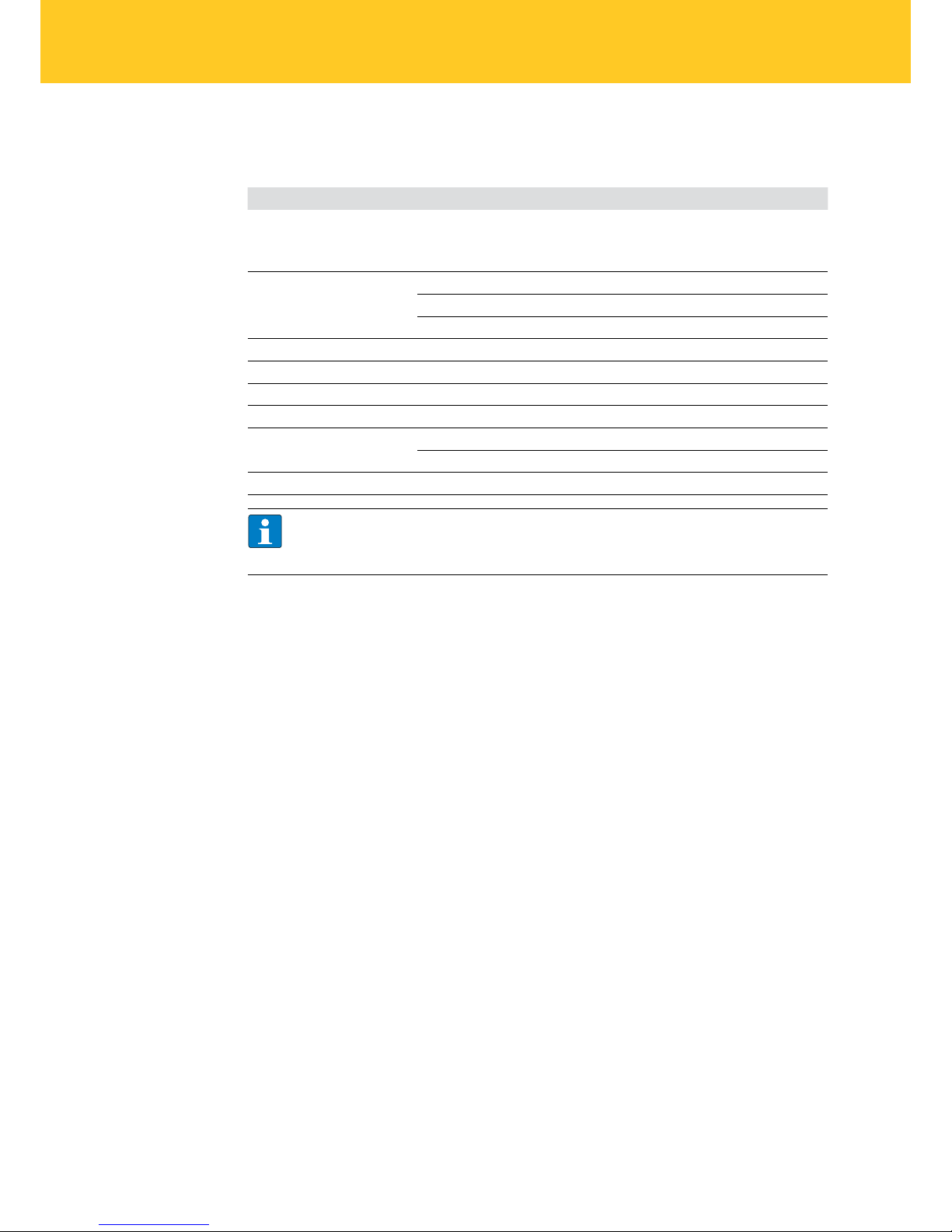

2.3 Legal requirements

The devices comply with the following regulations:

Device Region of use Regulations

TN865-Q…L…-H1147 e.g. Europe – 2014/30/EU (electromagnetic compatibility)

– 2014/35/EU (low voltage)

– 2014/53/EC (RED Directive)

– 2011/65/EU (RoHS)

TN902-Q…L…-H1147 USA FCC Rules Part 15

Canada Industry Canada RSS-210

Mexico IFETEL, Dictamen (electrical safety)

TN840/920-Q120L130- H1147 China SRRC

TN917-Q120L130-H1147 Korea KCC

TN866-Q120L130-H1147 Russia Import license for wireless devices

TN902/915-Q120L130-H1147 Brazil ANATEL

TN920-Q120L130-H1147 Australia ACMA

New Zealand RSM

TN921-Q…L…-H1147 Singapore IDMA

NOTE

Additional certification may be required, depending on the region of use. Tests for

other national approvals can be carried out and implemented if necessary.

2.4 Manufacturer and service

Turck supports you in your projects – from the initial analysis right through to the commissioning of your application. The Turck product database offers you several software tools for programming, configuring or commissioning, as well as data sheets and CAD files in many export

formats. You can access the Product Database directly via the following address:

www.turck.de/products

For further inquiries in Germany contact the Sales and Service Team on:

Sales: +49 208 4952-380

Technical: +49 208 4952-390

For overseas inquiries contact your national Turck representative.

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Mülheim an der Ruhr

Germany

Page 9

9

V01.00 | 2018/06

3 For Your Safety

The product is designed according to state of the art technology. Residual hazards, however,

still exist. Observe the following warnings and safety regulations in order to prevent danger to

persons and property. Turck accepts no liability for damage caused by failure to observe these

warnings and safety instructions.

3.1 Intended use

The devices are designed only for use in industrial areas.

The BL ident® read/write heads are used for contactless data exchange with the BL ident® tags

in the BL ident® UHF RFID system. The following table shows the operating frequency of the

devices.

Type code Operating frequency

TN865-… 865…868 MHz

TN902-… 902…928 MHz

TN840/920-… 840.5…844.5MHz and 920.5…924.5MHz

TN917-… 917…920.8 MHz

TN866-… 866…868 MHz

TN902/915-… 902…907.5MHz and 915…928MHz

These devices may only be started up under the following conditions:

■

The particular frequency range is permissible for the use of UHF-RFID.

■

The operating frequency range of the devices is compliant with the permissible UHF RFID

range of the region.

■

A valid certification and/or approval is available for the region of use.

The device must only be used as described in these instructions. Any other use is not in accordance with the intended use. Turck accepts no liability for any resulting damage.

3.2 Obvious misuse

■

The devices are not suitable for the protection of persons or property and must not be used

in safety-related applications.

■

The devices must not be used under water.

Page 10

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

For Your Safety

3.3 General safety notes

■

The device must only be fitted, installed, set, operated and maintained by trained and qualified personnel.

■

The devices only meet the EMC requirements for industrial areas and are not suitable for use

in residential areas.

■

Only use the devices in compliance with the applicable national and international regulations, standards and laws.

■

Any extended stay within the area of radiation of the UHF read/write heads may be harmful

to health. Observe minimum distances from the actively radiating surface of the UHF read/

write head:

Region max. permissible total radiant

output power

Safety distance

Europe, Russia, China 2 W ERP (according to ETSI) > 0.24 m

USA, Canada, Brazil, Korea,

Australia, New Zealand

4 W EIRP > 0.30 m

Singapore 0.5 W ERP > 0.24 m

■

The radiation of the UHF read/write heads may have an adverse effect on the operation of

electrically controlled medical equipment. Keep an additional distance from active radiation

sources up to the maximum transmission distance.

Page 11

11

V01.00 | 2018/06

4 Product Description

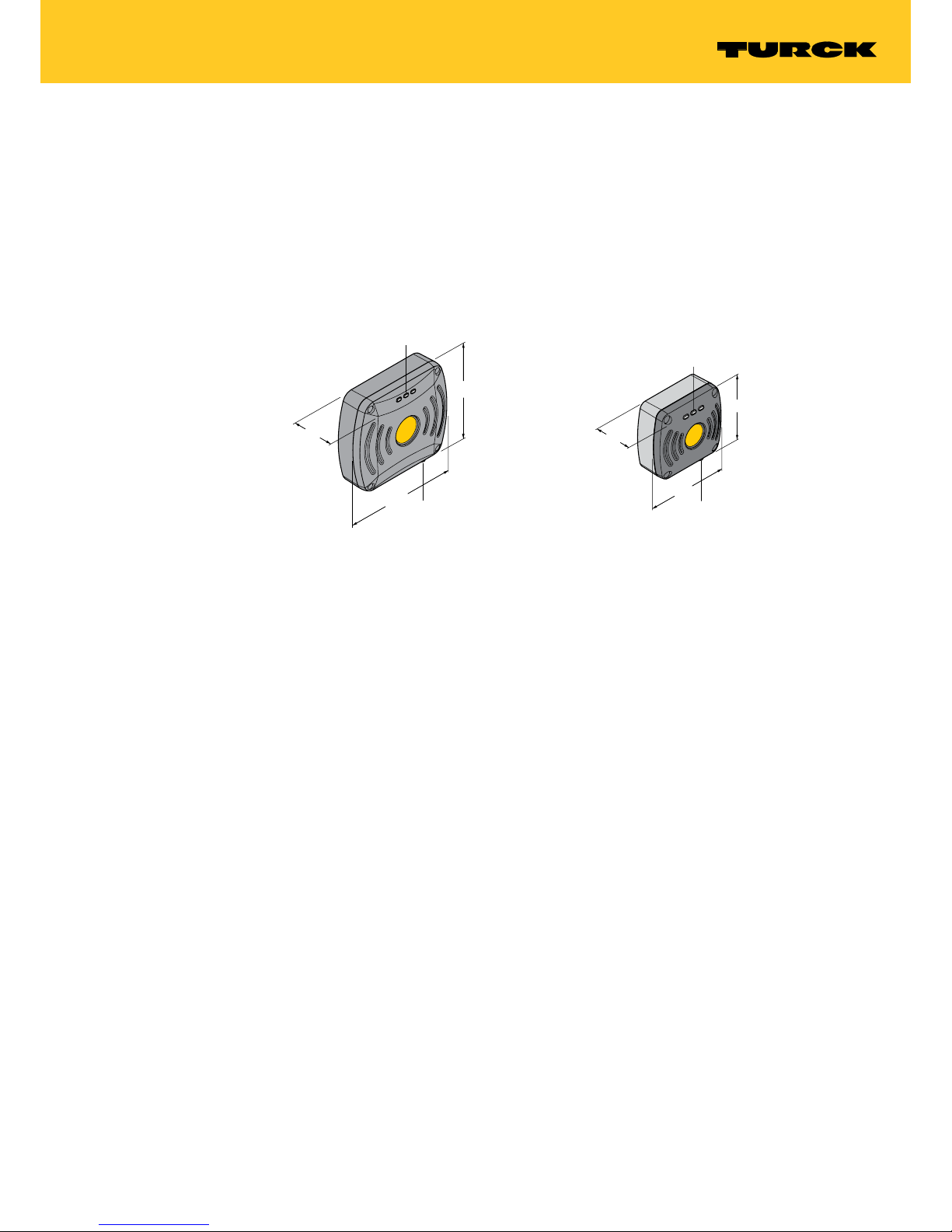

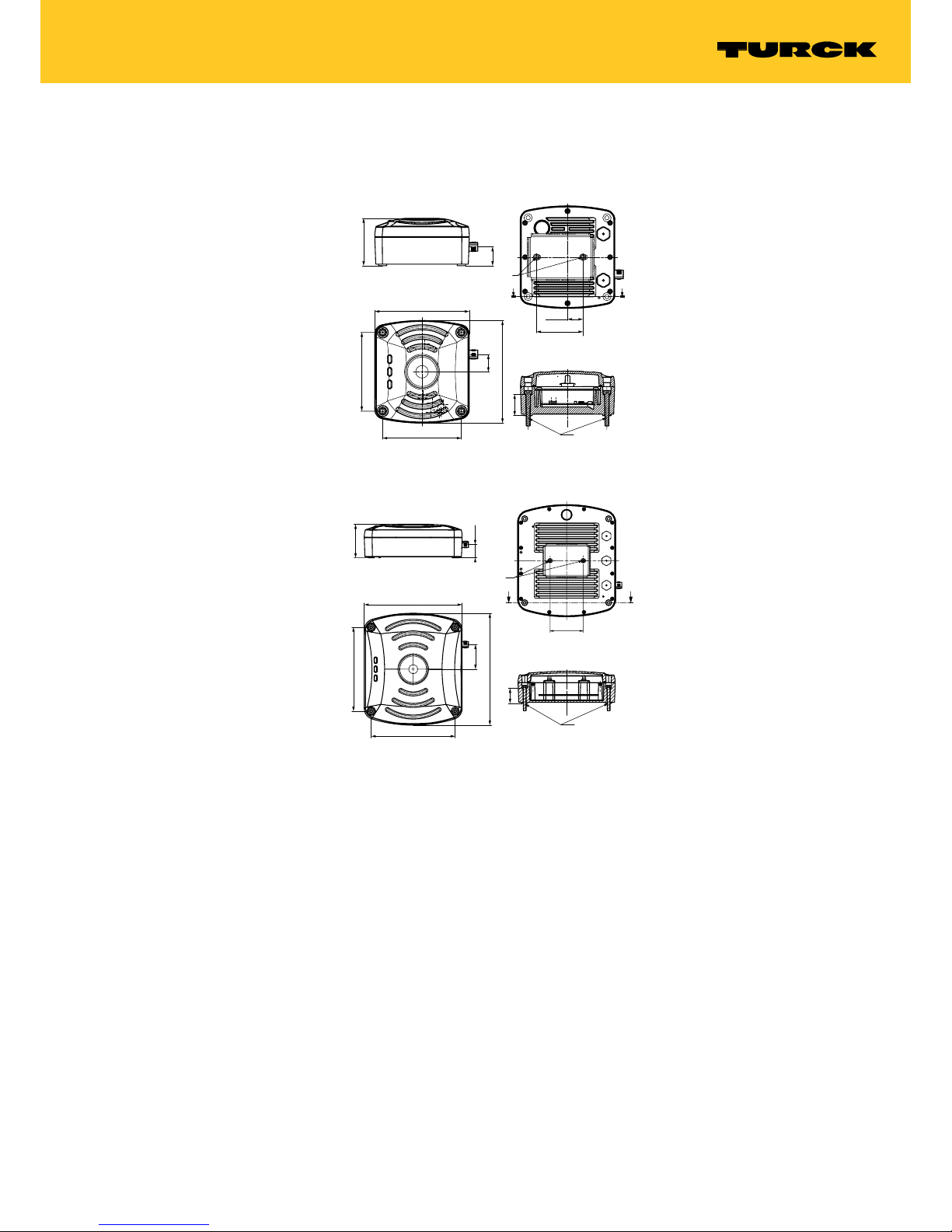

The UHF read/write heads have a rectangular design (120 × 130 mm or 175 × 200 mm). The

devices are rated to degree of protection IP67 and are contained in an aluminum housing with

a plastic front. The power supply to the device and data exchange with the controller are implemented via a BL ident® RFID interface. A 4-pin M12 x 1 connector is provided for connecting to

the RFID interface.

4.1 Device overview

200

175

60

M12

LED

130

120

60

M12

LED

Fig. 1: Dimensions

– TN…-Q175L200-H1147

Fig. 2: Dimensions

– TN…-Q120L130-H1147

4.1.1 Indication elements

Each device is provided with three adjustable LEDs. An audible alarm can also be set using

software tools.

4.2 Properties and features

■

Robust read/write heads in industrial design

■

Writing and reading of passive UHF tags in single and multitag mode

■

Read/write distances up to several meters (depending on ambient conditions, the parameter

setting of the read/write head and the selected tag)

■

Compact design for mounting in restricted spaces

Page 12

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

4.3 Operating principle

The read/write heads are used for contactless data exchange with tags. For this the controller

sends commands and data via the interface to the read/write head and receives the corresponding response data from the read/write head. The reading of the IDs of all RFID tags in the

read area or the writing of an RFID tag with a specific production date are examples of typical

commands. To communicate with the tag, the data of the read/write head is coded and transferred via an electromagnetic field, which at the same time supplies the tags with power.

A read/write head contains a transmitter and a receiver, an interface to the interface and a

coupling element (coil and dipole antenna) for communicating with the tag. Electromagnetic

wave propagation is used for the transmission between read/write head and tag on devices for

the UHF range.

Fig. 3: Operating principle of UHF-RFID

The antenna of the read/write head generates electromagnetic waves. This produces a transmission window as a so-called air interface in which the data exchange with the tag takes place.

The size of the transmission window depends on the combination of read/write heads and tags,

as well as on the relevant environmental conditions.

Each read/write head can communicate with a number of tags. This requires the read/write

head and the tag to operate in the same frequency range. Depending on the power and

frequency used, the device ranges vary from a few millimeters up to several meters. The specified maximum read/write distances only represent typical values under laboratory conditions

without allowing for the effect of materials. The achievable distances may vary due to component tolerances, the mounting situation in the application, ambient conditions and the effect of

materials (particularly metal and liquids).

4.4 Functions and operating modes

The devices enable passive UHF tags to be read or written in single and multi-tag operation.

For this the devices form a transmission zone that varies in size and range according to the tags

used and the operating conditions of the application. Refer to the data sheets for the applicable

maximum read/write distances. The devices can be fully tested, configured and parameterized

from a PC using the specified software tools.

IC

Read/write head

Data carrier

UHF: electromagnetic wave

Page 13

13

V01.00 | 2018/06

4.4.1 Operating frequency

The Turck BL ident® UHF system uses nationally specified transmission frequencies for the communication between the tags and read/write heads. These national operating frequencies for

UHF are the frequency ranges that are individually specified by the national regulation bodies.

The operating frequency of the devices in the UHF band is for example 865…868 MHz for Europe and 902…928 MHz for the USA. The BL ident® read/write heads in the UHF band can therefore only be used in the countries they are intended for and must not be put into operation

outside of these regions. As the BL ident® UHF tags are passive, and therefore do not radiate

their own radio waves, these are suitable for use worldwide.

Turck offers different tag variants that are specially designed and optimized for national

frequency bands in order to achieve as large a communication range as possible. Wide-band

multi-range tags for international use are also available as an alternative.

The various Turck read/write heads support the following operating frequencies:

■

865...868 MHz (e.g. for Europe)

■

866…868 MHz (e.g. for Russia)

■

902...928 MHz (e.g. for USA and Canada)

■

920…925 MHz (e.g. for China and Singapore)

■

902...907.5 MHz and 915...928 MHz (e.g. Brazil)

■

917...920.8 MHz (e.g. for Korea)

The relevant national specifications for UHF such as frequency range, output and the status of

any national regulations can be obtained from the Internet at:

http://www.gs1.org/docs/epcglobal/UHF_Regulations.pdf

For more detailed information please contact the regulation authorities of the country where

you wish to use the UHF RFID system.

HF RFID systems can be run parallel to UHF RFID systems in an installation.

4.4.2 Combination of UHF read/write heads and tags

The UHF read/write heads form a transmission zone for which the size depends on the combination of read/write head and tag. The listed maximum read/write distances only represent

typical values under laboratory conditions without the effect of materials.

The achievable distances may be different due to component tolerances, mounting location in

the application, ambient conditions and the effect of materials (particularly metal).

For this reason, the application must be tested in all cases under real conditions (particularly

with read and write operations in motion).

Page 14

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

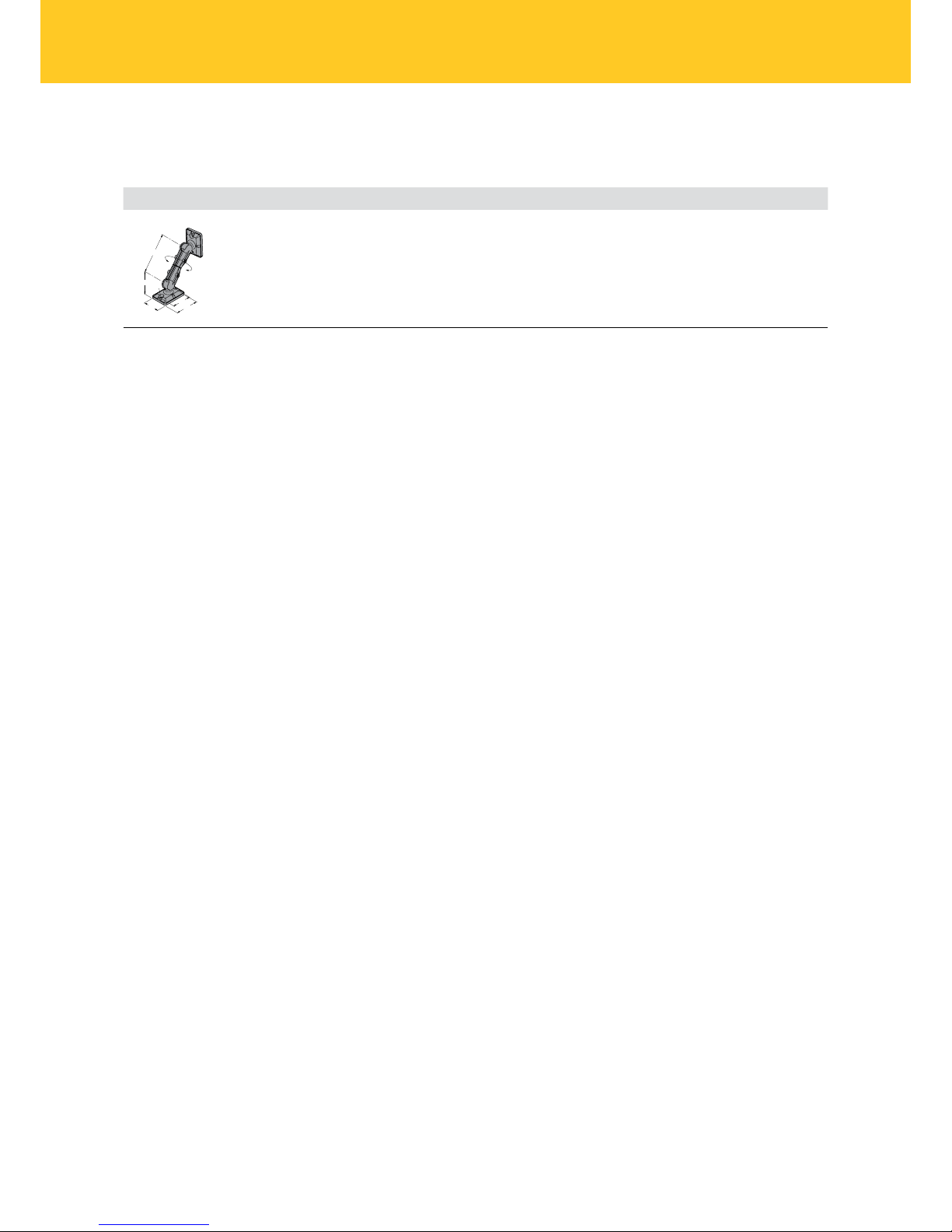

4.5 Technical accessories

The following accessories are not supplied with the device:

Dimension drawing Type Ident no. Description

RH-Q240L280/Q280L640 7030296 Arm bracket for UHF read/write heads

Page 15

15

V01.00 | 2018/06

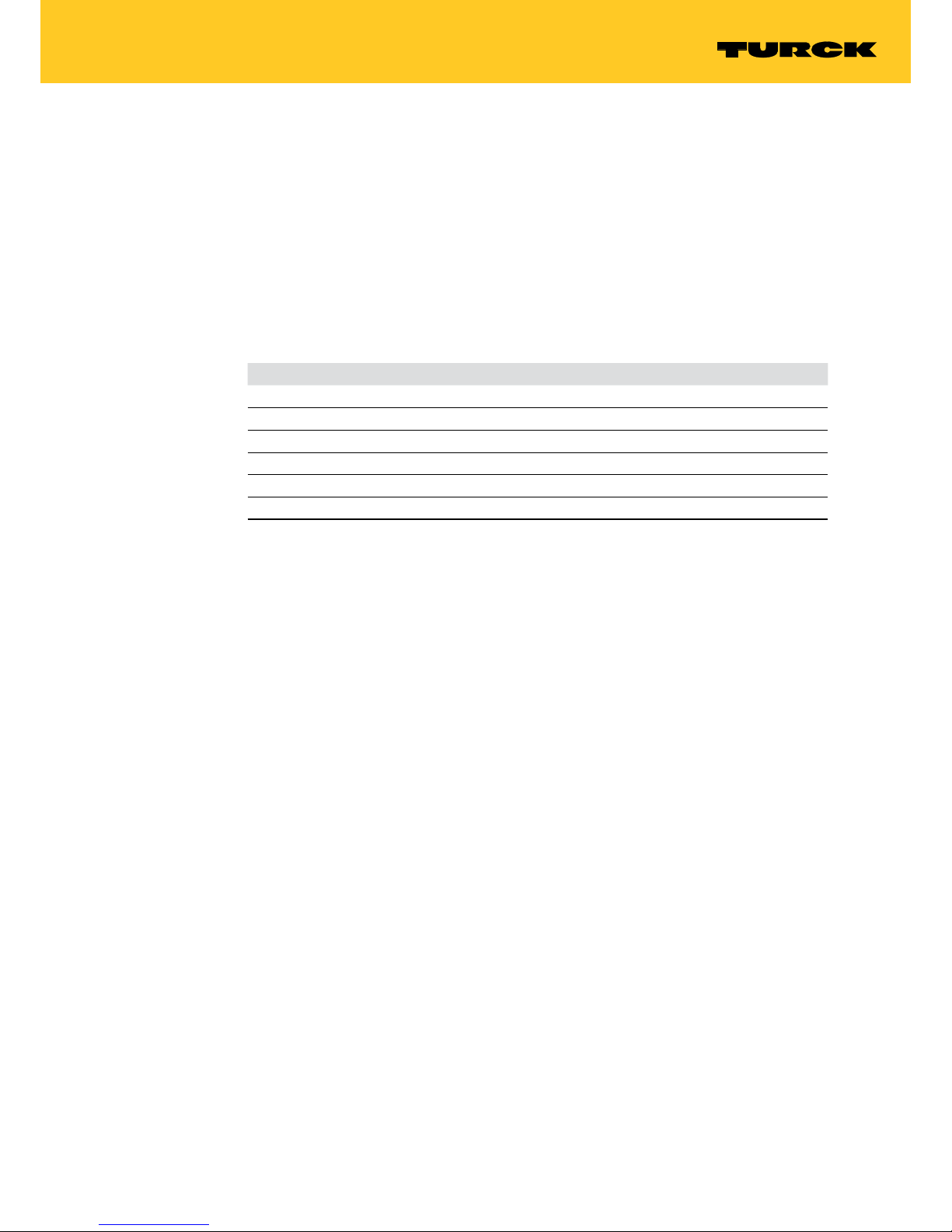

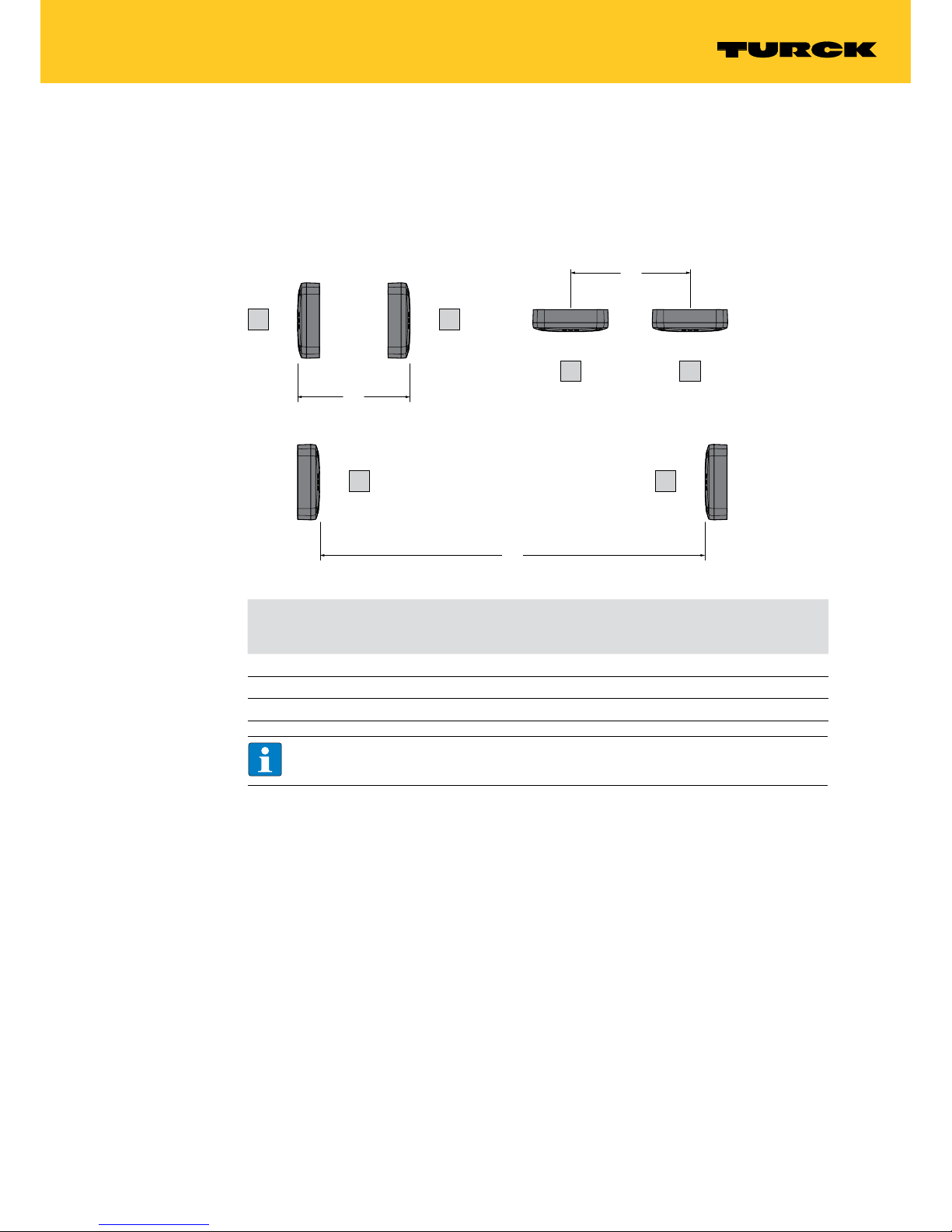

5 Mounting

The devices can be mounted in any position.

Mount the device with the appropriate fixing accessories.

The minimum distance between two read/write heads using the same frequency depends on

the maximum radiant power and the alignment of the antenna.

Fig. 4: Antenna alignment

Antenna alignment Minimum distance D for TN…-

-Q175L200-H1147 with ERP = 1 W

Minimum distance D for TN…-

-Q120L130-H1147 with ERP = 0.5

W

Back to back 0.5m 0.25m

Side by side 1m 0.5m

Front to front 2.5m 1.25m

NOTE

The stated values do not take into account the effect of the tags.

Tag Tag

TagTag

Tag Ta g

D

D

D

Page 16

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

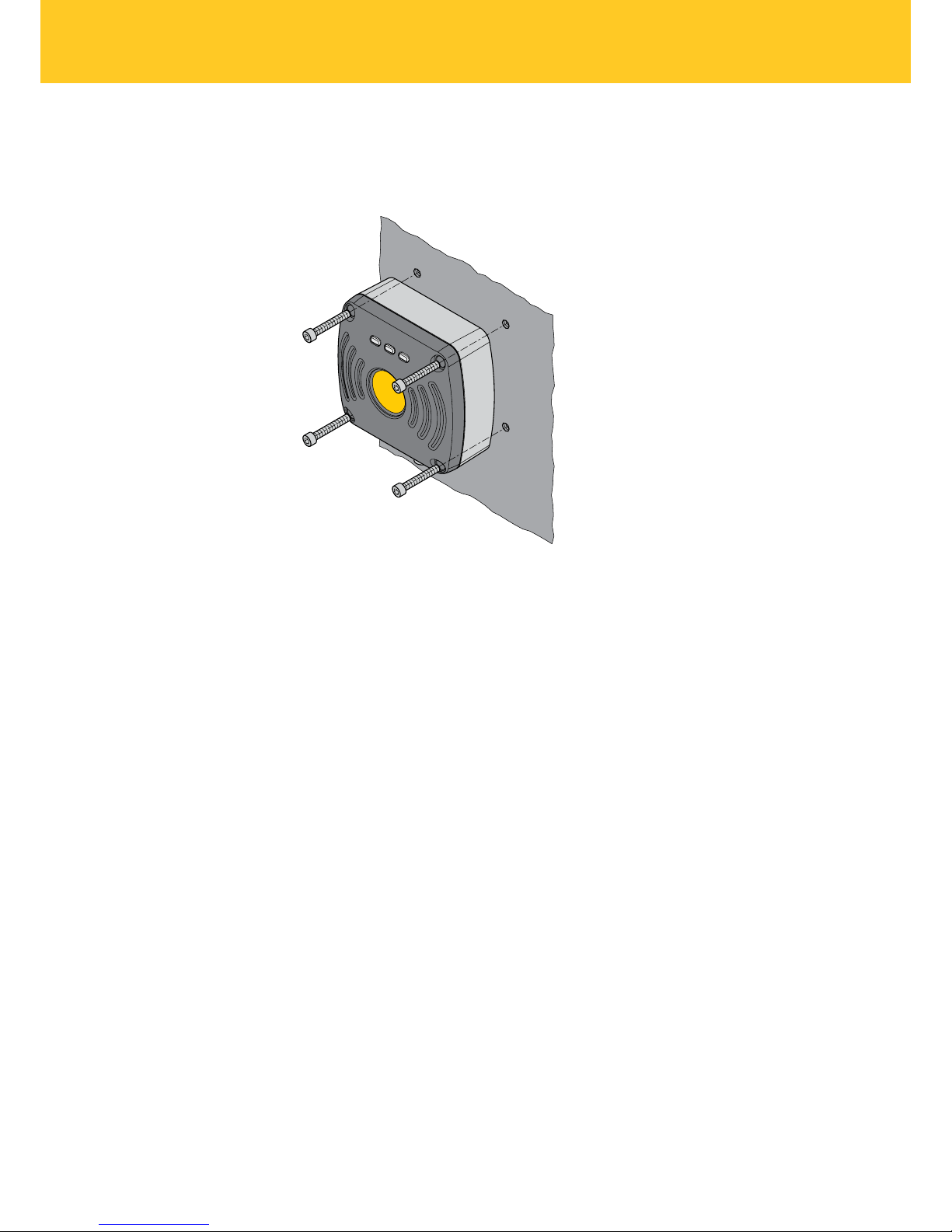

5.1 Screw fastening on a mounting plate

Fasten the device with four M5 × 35 cylinder screws on a pre-drilled mounting plate.

Fig. 5: Screwing the read/write head onto the mounting plate

Page 17

17

V01.00 | 2018/06

5.2 Mounting with an application-specic adapter

Make the adapter according to the following dimension drawings.

Fig. 6: Dimension drawing for TN…-Q120…

Fig. 7: Dimension drawing for TN…-Q175…

Fit the device at the intended mounting location

60

24

M6 x 8 (2x)

19.5

59

A

A

A - A

M5 x 35 (4x)

27

130

22

100

120

100

24

60

175

150

44

200

59

A - A

M5 x 35 (4x)

M6 x 10 (2x)

150

27

AA

Page 18

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

5.3 Mast/tube mounting

Fit the device with the intended mounting aid as shown in the following figure.

M6 x 8

Fig. 8: Mast/tube mounting

Page 19

19

V01.00 | 2018/06

5.4 Mounting with the RH-Q240L280/Q280L640 arm bracket

The RH-Q240L280/Q280L640 arm bracket (Ident no. 7030296) is not supplied with the device

and must be ordered separately.

Fasten the device with two M6 × 12 screws through the fixing holes of the read/write head

and arm bracket.

Fig. 9: Mounting read/write heads with an arm bracket

M6 x 12

Page 20

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Connection

6 Connection

DANGER

Effect on electrically controlled medical devices such as pacemakers

Danger to life due to malfunction or failure of medical equipment

Determine and ensure the recommended distances between medical equipment

and radiation sources.

Connect the power supply via the M12 plug connector to the interface as shown in wiring

diagrams below.

6.1 Wiring diagrams

Pin layout Wiring diagram

Fig. 10: Connection cables …/S2500

Pin layout Wiring diagram

Fig. 11: Connection cables …/S2501

Pin layout Wiring diagram

1 BN

3 BU

4 WH

2 BK

+

–

Data

Data

Fig. 12: Connection cables …/S2503

Page 21

21

V01.00 | 2018/06

7 Commissioning

The device is operational automatically once the cables are connected and the power supply is

switched on.

The planning and preparation of an RFID system require different measures, depending on the

application. Further information on this is provided in the RFID engineering manual.

8 Operation

8.1 LEDs

The devices are provided with three LEDs for displaying the status of the device. The indication

functions can be adjusted for the specific application via the DTM. The LEDs are factory set with

the following indication functions after a voltage reset:

LED Color State Meaning

1 (operating state) Green Off No operating voltage present

Lit Operating voltage connected

Off 0.2 s Tag detected

2 (state of the wireless field) Yellow Off Wireless field deactivated

Lit Wireless field activated

3 (errors) Red Off No internal error

Lit Internal error detected

Page 22

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9 Setting and Parameterization

The read/write heads can be assigned additional parameters via the DTM in the PACTware™ 5.0

FDT frame application. FDT and DTM can be downloaded free of charge from www.turck.com.

9.1 Connecting read/write heads with the PC

In order to carry out extended parameter setting with the DTM, the read/write head must be

connected with a PC. The read/write heads can be connected with a PC via a TBEN-RFID interface (e.g. TBEN-S2-2RFID-4DXP) or via the STW-RS485-USB interface converter.

9.1.1 Connecting the read/write heads with a PC via the RFID interface

Connect the read/write head to the RFID interface converter using an appropriate connection

cable (e.g. RK4.5T-2RS45/S2500).

Connect the RFID interface via a suitable Ethernet cable to the PC.

Connect the RFID interface to a power supply.

Fig. 13: Connecting the read/write head with a PC via the TBEN-S2-2RFID-4DXP

UHF RFID read/write head

e.g. TNxxx-Q175L200-H1147

RFID interface

TBEN-S2-2RFID-4DXP

RFID cable

e.g. RK4.5T-…-RS4.5T/S2500

Ethernet cable

e.g. RSSD-RJ45…

PC / Notebook

with Ethernet interface

Page 23

23

V01.00 | 2018/06

9.1.2 Connecting read/write heads with a PC via the interface converter

The following accessories are required to connect read/write heads to a PC:

■

STW-RS485-USB interface converter (Ident no. 7030354)

■

STW-RS485-USB-PS power supply unit (Ident no. 7030355),

Accessories are not supplied with the device and must be ordered separately.

Connect the read/write head to the interface converter using a suitable connection cable (e.g.

RK4.5T-2/S2500) according to the following color coding:

STW-RS485-USB Connectors …/S2500 Male connector …/

S2501

Male connector …/

S2503

VCC Brown (BN) Brown (BN) Red (RD)

GND Blue (BU) Blue (BU) Black (BK)

RS485-A White (WH) Black (BK) White (WH)

RS485-B Black (BK) White (WH) Blue (BU)

Connect a USB cable to the interface converter (USB1.1 type B).

Connect the open end of the USB cable to a free USB port on the PC (USB1.1 type A).

Set the switches on the side of the interface converter for the termination to “ON”.

Connect the interface converter via the STW power supply unit to a power supply.

Fig. 14: Connecting the read/write head via the interface converter with a PC

UHF RFID read/write head

e.g. TNxxx-Q175L200-H1147

Interface converter

STW-RS485-USB

Power supply

STW-RS485-USB-PS

RFID cable

e.g. RK4.5T/S2500

PC / Notebook

with USB-interface

Page 24

24

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9.1.3 Creating a project in PACTware

Launch PACTware™.

Right-click Host PC in the project tree.

Click “Add device”.

Fig. 15: Adding a device in PACTware™

NOTE

The example shows the connection via an interface converter. When using a TBENRFID interface, choose the “BL Service Ethernet” option.

Example: Select “RS485 RFID” to connect the read/write head to the PC via the RS485

interface.

Fig. 16: Example: Selecting “RS485 RFID”

Page 25

25

V01.00 | 2018/06

Double-click “RS485 RFID” in the project tree.

Select the COM port. The COM port to which the device is connected is shown in the device

manager in the control panel of the PC (COM & LPT).

Set the baud rate.

Fig. 17: Setting up the RS485 interface

Confirm the changes by clicking “Accept”.

Right-click “RS485 RFID” in the project tree.

Click “Add device”.

Fig. 18: Adding the device to the RS485 interface

Page 26

26

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

Select the connected device (example: TN865-Q175L200-H1147).

Confirm the selection with OK or double-click the device.

Fig. 19: Select the connected device (example: TN865-Q175L200-H1147)

Right-click the device in the project tree.

Establish a connection.

Fig. 20: Establishing a connection

The “RFID Test” and "Parameterization” functions can be started from the project tree at “Ad-

ditional functions”.

Page 27

27

V01.00 | 2018/06

9.2 Testing the read/write heads

The following functions can be executed via the RFID Test in the DTM:

■

Displaying read data

■

Displaying the protocol of the communication between host or PC and read/write head

■

Logging of the interface communication between host or PC and read/write head

■

Sending of user-specific deBus commands

■

Writing of tags with a user-defined number

■

Sending tag-specific commands

Requirements for the RFID test:

■

PACTware™ must be installed.

■

The DTM for UHF read/write heads must be installed.

■

The connection between the read/write head and the PC must be established.

■

A project must have been created in PACTwareTM.

9.2.1 Starting the RFID test

Right-click the device in the project tree.

In the context menu choose “Additional functions” “RFID Test”.

Fig. 21: Starting the RFID test

Page 28

28

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9.2.2 Start window – Overview

The “RFID Test” window consists of the following elements:

■

Main menu

■

Basic test

■

Tag actions

■

Logger

Fig. 22: “RFID Test” – Start window

Page 29

29

V01.00 | 2018/06

9.2.3 “RFID Test” – Main menu

Fig. 23: “RFID Test” – Main menu

The main menu provides the following functions:

Icon Function Description

Start trigger/ON Starts the trigger for command execution

Stop trigger/OFF Closes the trigger for command execution

Switch on antenna Switches on the read/write head antenna

Switch off antenna Switches off the read/write head antenna. Trigger commands are

ignored.

Configure message content Displays the content to be transferred with a read operation. The

following can be selected:

– Phase

– RSSI

– Socket

– Time

Switch mode (report/polling) Switches between Report mode (automatic read/write) and polling

mode (read/write started through an explicit polling command)

Read read/write head Calls the following information from the read/write head and pro-

vides the information in the “Logger” window:

– Read/write head status

Read read/write head version Calls the following information from the read/write head and pro-

vides the information in the “Logger” window:

– Hardware revision

– Firmware status

– Serial number

Reset read/write head Offers three ways of resetting the read/write head:

– Voltage reset

– Factory reset: Reset to factory settings

– Reset read/write head status

When reset to factory settings, any modified baud rate or RS485

address is not changed because the read/write head could not

otherwise be addressed any longer.

HF diagnosis Opens the window to the HF diagnostics

Page 30

30

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9.2.4 “RFID Test” – “Basic Test” window

Fig. 24: “RFID Test” – “Basic Test” window

The following functions are available in the “Basic test” window.

Icon Function Description

Polling Shows the first tag in the polling memory of the device in the tag

list. The function is only available in polling mode.

Poll all Shows all tags in the polling memory of the device in the tag list.

The function is only available in polling mode.

Delete polled tags of the read/write head Clears the polling memory of the read/write head

CSV export of the current data Saves the tag list in CSV format

Delete tag list Deletes the list of displayed tags

The queried data is displayed in the tag list. The content of the message can be set via the “Configure message content” function.

Page 31

31

V01.00 | 2018/06

9.2.5 “RFID Test” – “Tag Actions” window

The functions in the “Tag actions” window are available if a tag is marked in the tag list of the

“Basic Test” window.

Fig. 25: “RFID Test” – “Tag Actions” window

The following functions are available in the “Tag actions” window:

Icon Function Description

Read tag Starts the read operation

The chip type is automatically displayed. One word is always read

with the first read operation. The following parameters can be set

for other read operations:

– Memory bank (TID, EPC/UID, PC, access password or kill

password)

– Start word

– Number of words

The read data is displayed in the “Data” area.

Write tag Starts the write operation

The chip type is automatically displayed. The following parameters

can be set for the write operations:

– Memory bank (TID, EPC/UID, PC, access password or kill

password)

– Start word

– Number of words

Data to be written is displayed in the “Data” area.

Switch access password on/off Switches the password for write or read access on or off.

Page 32

32

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

Example: Execute tag actions

Position tag in detection range of the read/write head.

Activate the trigger for the read/write head in the main menu.

Fig. 26: Main menu – Activating trigger

“Basic Test” window: Execute polling command in order to display tag in the tag list.

“Basic Test” window: Select tag from the tag list.

Fig. 27: Select the tag

Page 33

33

V01.00 | 2018/06

“Tag actions” window: Enter required values and confirm entry with ENTER.

Fig. 28: Entering the data

Execute the required function by clicking the appropriate button (here: “Read”).

Fig. 29: Execute tag action (example: “Read”)

Page 34

34

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

Successful access is displayed via the status message at the bottom of the window.

Fig. 30: Example: Successful read operation

9.2.6 “RFID Test” – “Logger” window

The “Logger” window displays read/write information and error messages.

The list can be cleared via the “Delete” button.

Fig. 31: Messages in the “Logger” window

Page 35

35

V01.00 | 2018/06

9.2.7 “HF diagnosis” window

The current power level of the read/write head is displayed for each channel in the “HF diagnosis” window.

Fig. 32: “HF diagnosis” window

The following functions can be executed in the “HF diagnosis” window:

Icon Function Description

Start/stop HF diagnostic Starts or closes the HF diagnostics

Delete values Deletes the displayed values

Page 36

36

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9.3 Setting read/write heads parameters via the DTM

The functions of the read/write heads can be assigned additional parameters via the parameterization function of the DTM.

NOTE

The parameterization function is only available in English. All parameters are written in

the DTM.

The individual read/write heads are available in different variants. When a connection is made

to a connected read/write head, the DTM automatically detects the relevant device and deactivates menu items that are not supported. The connection cannot be established if a different

variant than set in the project tree is connected.

Requirements for extended parameter setting

■

PACTware™ must be installed.

■

The DTM for UHF read/write heads must be installed.

■

The connection between the read/write head and the PC must be established.

■

A project must have been created in PACTwareTM.

9.3.1 Starting the extended read/write head parameter setting

Right-click the device in the project tree.

Choose “Parameter” “Parameterization” or “Online parameterization” in the context menu.

Fig. 33: Example: Starting online parameter setting via the context menu

Page 37

37

V01.00 | 2018/06

9.3.2 Main menu – Overview

Fig. 34: Parameterization – Main menu

The main menu provides the following functions:

Icon Function Description

Help on the DTM Starts the DTM help

Help on the device Opens the data sheet of the connected read/write head

Activating/deactivating Expert mode Opens the drop-down menu to select the access level. The follow-

ing access levels are available:

– Basic (default setting)

– Advanced

– Administrator

Channel-wise display Toggles the view between standard display and channel-wise

display

Load parameters from the database Loads previously stored parameters from the database (e.g. an

existing project)

Transfers parameters to the database Transfers the current read/write head parameters to the database

of the project

Read parameters from the device Calls up the parameters saved on the connected read/write head

Transfer parameters to the device Transfers the parameter set in the DTM to the device

Compare values with database Compares the values displayed in the DTM with the values saved in

the database

CSV export Exports the current values from the DTM to a CSV file

Page 38

38

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

The following setup windows can be opened in tabs via the main menu:

■

Basic setup

■

Antenna

■

Communication

■

EPC Class1 Gen2

■

Error handling

■

Event handling

■

Post read filter

■

Signaling

9.3.3 Choosing the access level

Three access levels are available for setting the device parameters. Different parameters can be

set depending on the access level.

NOTE

Modifications made in the “Administrator” access level can result in serious changes in

operation. The “Administrator” access level is therefore only available for Turck service

technicians. All relevant settings for the successful parameter setting of an application

are available in the “Advanced” access level.

Access level Description Initial password

Basic Basis access for initial configuration and

commissioning

Not required

Advanced Extended access, e.g. for applications Not required

Administrator Administrator access for critical security or wire-

less settings

Required

The current access level is displayed in the top right screen area of the DTM.

Fig. 35: Display of the access level

Page 39

39

V01.00 | 2018/06

9.3.4 “Basic setup”

The “Basic Setup” tab is used to set the basic parameters for the read/write heads. All parameters and the settable values are written in the DTM.

9.3.5 “Antenna”

The “Antenna” tab is used to set the antenna parameters for the read/write heads. All param-

eters and the settable values are written in the DTM.

9.3.6 “Communication”

The “Communication” tab is used to set the parameters for the configuration of the deBus messages. All parameters and the settable values are written in the DTM.

9.3.7 “EPC Class1 Gen2”

The “EPC Class1 Gen2” tab is used to set the EPC Class1 Gen2 parameters for the air interface.

The parameters set are used if the read/write head performs an Inventory command. All parameters and the settable values are written in the DTM.

9.3.8 “Error Handling” – Selectable parameters

The behavior of the read/write head in response to different events (e.g. LED behavior) can be

set in the “Error Handling” tab. All parameters and the settable values are written in the DTM.

9.3.9 “Event Handling” – Selectable parameters

The behavior of the read/write head in response to errors (e.g. LED behavior) can be set in the

“Event Handling” tab. All parameters and the settable values are written in the DTM.

9.3.10 “Post Read Filter” – Selectable parameters

The parameters for filtering event messages can be set in the “Post Read Filter” tab.

The set filters do not reduce the data traffic on the air interface and are not suitable for multitag

applications with many tags or high passing speeds. All parameters and the settable values are

written in the DTM.

9.3.11 “Signaling” – Selectable parameters

The “Signaling” tab enables the default settings for the LEDs to be edited. All parameters and

the settable values are written in the DTM.

Page 40

40

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting and Parameterization

9.4 Device information via the DTM

The DTM provides access to hardware and software information as well as regulations on the

connected device.

Right-click the device in the project tree.

Choose “Additional functions” Select “Identify”.

Fig. 36: Calling up “Identify”

Page 41

41

V01.00 | 2018/06

The DTM shows the available information on the device according to the selected access

level.

Fig. 37: Example: Device information for TN865-Q175L200-H1147 in the “Advanced” access

level

Page 42

42

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Troubleshooting

10 Troubleshooting

If the device does not function as expected, first check whether ambient interference is present.

If there is no ambient interference present, check the connections of the device for faults.

If there are no faults, there is a device malfunction. In this case, decommission the device and

replace it with a new device of the same type.

11 Maintenance

Ensure regularly that the plug connections and cables are in good condition.

The devices are maintenance-free, clean dry if required.

12 Repair

The device must not be repaired by the user. The device must be decommissioned if it is faulty.

Observe our return acceptance conditions when returning the device to Turck.

12.1 Returning devices

If a device has to be returned, bear in mind that only devices with a decontamination declaration will be accepted. This is available at

https://www.turck.de/en/retoure-service-6079.php

and must be completely filled in, and affixed securely and weather-proof to the outside of the

packaging.

13 Disposal

The devices must be disposed of correctly and must not be included in normal household

garbage.

Page 43

43

V01.00 | 2018/06

14 Technical Data

14.1 Technical data – TN865…

Technical data TN865-Q120… TN865-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 865…868 MHz 865…868 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EN 302208

EPCglobal Gen 2

ISO 18000-6C

EN 302208

EPCglobal Gen 2

Channel distance 200/600 kHz 200/600 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 44

44

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

14.2 Technical data – TN902…

Technical data TN902-Q120… TN902-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 902…928 MHz 902…928 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 500 kHz 500 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 45

45

V01.00 | 2018/06

14.3 Technical data – TN840/920…

Technical data TN840/920-Q120… TN840/920-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 920…925 MHz 920…925 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 250 kHz 250 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 46

46

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

14.4 Technical data – TN917…

Technical data TN917-Q120… TN917-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 917…920.8 MHz 917…920.8 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 600 kHz 600 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 47

47

V01.00 | 2018/06

14.5 Technical data – TN866…

Technical data TN866-Q120… TN866-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 866…868 MHz 866…868 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 200 kHz 200 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 48

48

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

14.6 Technical data – TN902/915…

Technical data TN902/915-Q120… TN902/915-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 915…928 MHz 915…928 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 250 kHz 250 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 49

49

V01.00 | 2018/06

14.7 Technical data – TN920…

Technical data TN920-Q120… TN920-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 920…926 MHz 920…926 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 500 kHz 500 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), adjustable

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 50

50

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

14.8 Technical data – TN921…

Technical data TN920-Q120… TN920-Q175…

Mounting condition Non-flush Non-flush

Ambient temperature -25…+50 °C -25…+50 °C

Operating voltage 12…24 VDC 12…24 VDC

Data transmission Electromagnetic AC field Electromagnetic AC field

Operating frequency 920…925 MHz 920…925 MHz

Wireless communication and

protocol standards

ISO 18000-6C

EPCglobal Gen 2

ISO 18000-6C

EPCglobal Gen 2

Channel distance 500 kHz 500 kHz

Output power 0.5 W (ERP), adjustable 1 W (ERP), controllable, the max.

output power of the devices is

currently limited to 0.5W ERP

due to licensing.

Antenna polarization Clockwise Clockwise

Antenna half power beam width 110° 90°

Read/write distance max. 1500 mm 4000 mm

Output function 4-wire, read/write 4-wire, read/write

Design Rectangular Rectangular

Dimensions 130 × 120 × 60 mm 200 × 175 × 60 mm

Housing material Aluminum, AL, silver Aluminum, AL, silver

Material of active face Plastic, ABS, black Plastic, ABS, black

Electrical connection Male connector, M12 x 1 Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm) 55 Hz (1 mm)

Shock resistance 30 g (11 ms) 30 g (11 ms)

Degree of protection IP67 IP67

MTTF 51 years to SN 29500 (Ed. 99)

40 °C

51 years to SN 29500 (Ed. 99)

40 °C

Page 51

51

V01.00 | 2018/06

15 Appendix: Conformity Declarations and Approvals

15.1 EU conformity declaration

Hans Turck GmbH & Co. KG hereby declares that the wireless system type TN865-… complies

with directive 2014/53/EC. The complete text of the EU declaration of conformity can be obtained from the following Internet address: www.turck.com

15.2 FCC/IC Digital Device Limitations – TN902-Q120L130-H1147

FCC ID: YQ7TN902-Q120L131

IC ID: 8821A-T902Q12L14

This device complies with Part 15 of the FCC Rules and Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes :

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

This equipment complies with FCC/IC exposure limits set forth for an uncontrolled

environment.

This equipment should be installed and operated with minimum distance 30 cm between the

radiator & your body.

CAN ICES-3 (A)/NMB-3(A)

Use only with listed LPS or class 2 power supply!

Page 52

52

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject

to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes :

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

This equipment complies with FCC/IC exposure limits set forth for an uncontrolled

environment.

This equipment should be installed and operated with minimum distance 30 cm between the

radiator & your body.

CAN ICES-3 (A)/NMB-3(A)

Use only with listed LPS or class 2 power supply!

Appendix: Conformity Declarations and Approvals

15.3 FCC/IC Digital Device Limitations – TN902-Q175L200-H1147

FCC ID: YQ7TN902-Q175L201

IC: 8821A-T902Q17L21

This device complies with Part 15 of the FCC Rules and Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions:

Page 53

53

V01.00 | 2018/06

Page 54

100000797 | 2018/06

*100000797*

Over 30 subsidiaries and over

60 representations worldwide!

www.turck.com

Loading...

Loading...