Page 1

Your Global Automation Partner

TBEN-L…-8IOL

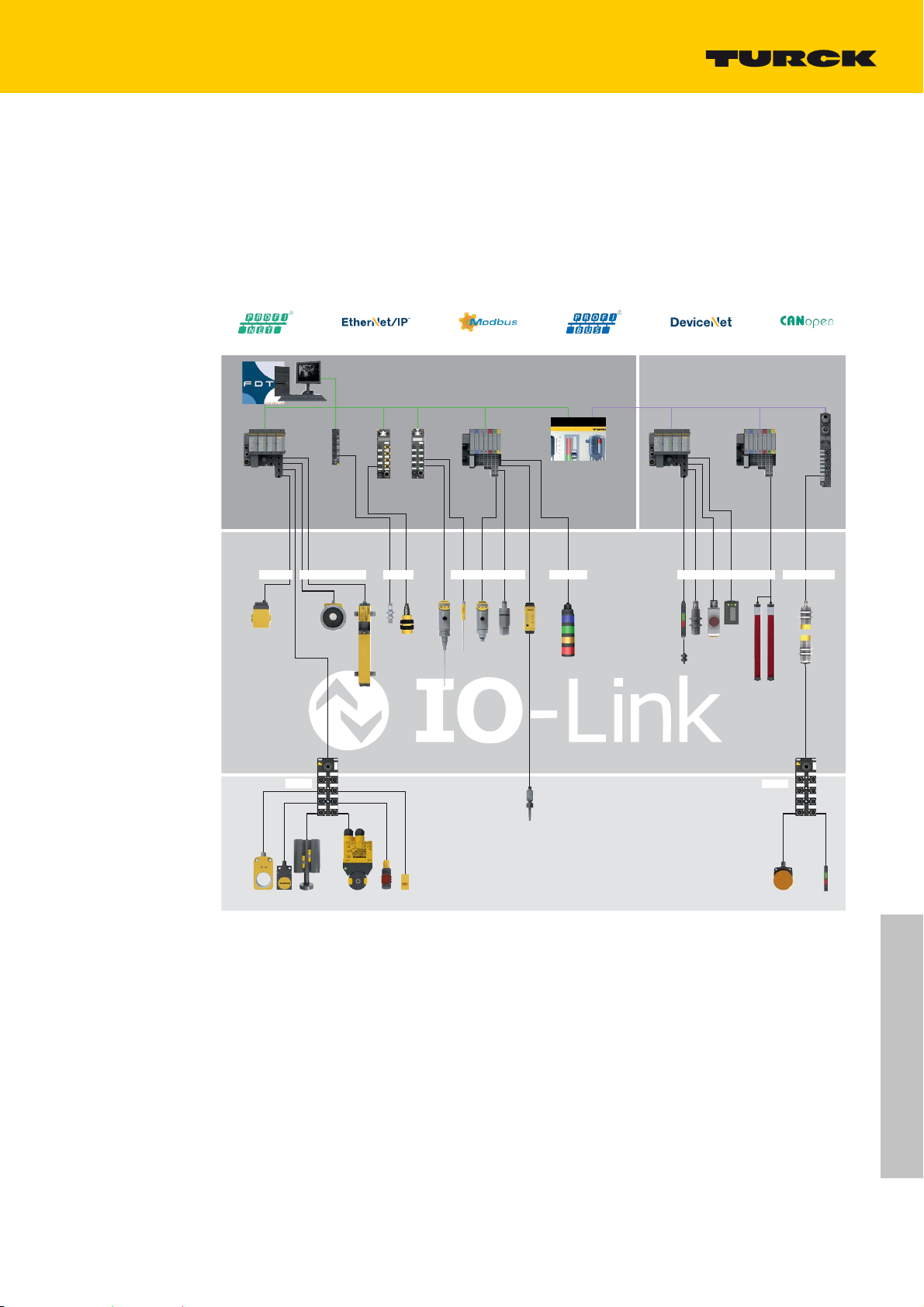

IO-Link Master Module

Operating instructions

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 3

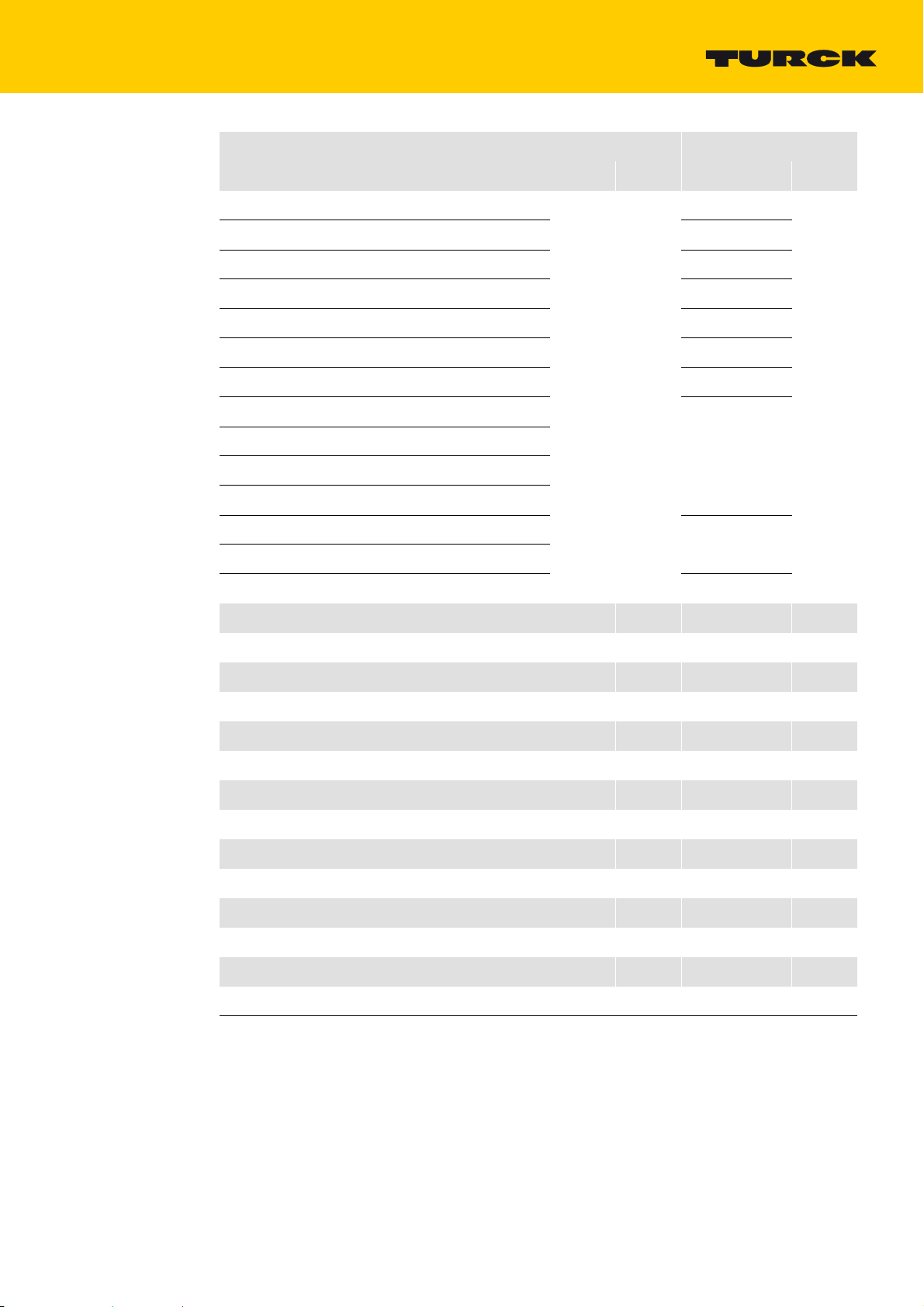

1About this manual 5

1.1 Documentation concept 5

1.2 Explanation of symbols used 6

1.2.1 Warnings 6

1.3 General notes 7

1.3.1 Prescribed use 7

1.3.2 Notes concerning planning/installation of this product 7

2 Further documentation 9

2.1 Product family TBEN-L 9

3IO-Link – Basics 11

3.1 IO-Link- interface – the fieldbus independent communication interface 11

3.1.1 Communication 11

3.1.2 Data transmission 11

3.1.3 Transmission media 12

3.1.4 Fieldbus/Ethernet integration 13

4 TBEN-Lx-8IOL 15

4.1 Product identification 15

4.2 Block diagram 16

4.3 Technical data 17

4.4 Wiring diagrams 18

4.4.1 Ethernet/voltage supply 18

4.4.2 IO-Link ports 18

4.5 Process data 19

4.5.1 Process input data 19

4.5.2 Process output data 21

4.6 Parameters 22

4.6.1 Adaptation of the process data mapping 28

4.7 Device status 29

4.7.1 LED behavior 29

4.7.2 Diagnostic data 31

4.7.3 Diagnostic telegram 31

4.7.4 Status and control word 35

V01.00 | 2016/12

4.8 IO-Link data storage 36

4.8.1 General 36

4.8.2 Parameter "data storage mode" = activated 37

4.8.3 Parameter "data storage mode" = read in 39

1

Page 4

4.8.4 Parameter "data storage mode" = overwrite 39

4.8.5 Parameter "data storage mode" = deactivated, clear 39

4.9 IO-Link - functions for acyclic communication 40

4.9.1 Port functions for port 0 (IO-Link master) 40

4.10 IO-Link and Turck device DTMs 45

4.10.1 Topology-Scan 45

4.10.2 Special DTM parameters 46

5 TBEN-Lx-8IOL with Modbus TCP 47

5.1 General 47

5.1.1 Implemented Modbus functions 47

5.1.2 Modbus registers 47

5.2 Data width of the TBEN-Lx-8IOL in the Modbus-register area 52

5.3 Register mapping TBEN-Lx-8IOL 52

5.4 Error behavior (watchdog) 53

5.4.1 Behavior of outputs 53

5.4.2 Behavior of the BUS LED 54

5.5 Parameters and diagnostic messages of the I/O channels 54

6 TBEN-Lx-8IOL with EtherNet/IP™ 55

6.1 EDS-file 55

6.2 QC - QuickConnect 55

6.3 Diagnostic messages via the process data 55

6.4 EtherNet/IP™-standard classes 56

6.4.1 Identity Object (0x01) 56

6.4.2 Assembly Object (0x04) 57

6.4.3 Connection Manager Object (0x06) 61

6.4.4 TCP/IP Interface Object (0xF5) 62

6.4.5 Ethernet Link Object (0xF6) 65

6.5 VSC-Vendor Specific Classes 67

6.5.1 Class Instance der VSCs 67

6.5.2 Gateway Class (VSC 100) 68

6.5.3 Miscellaneous Parameters Class (VSC 126) 71

6.5.4 IO-Link Port Class 137 (89h) 72

6.5.5 IO-Link Events Class 138 (90h) 75

6.5.6 VAUX Control Class 161 (A1h) 76

6.5.7 Basic Class 153 (99h) 78

7 TBEN-Lx-8IOL with PROFINET 81

7.1 GSDML-file 81

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 5

7.2 Configuration, TBEN-Lx-8IOL 81

7.3 FSU - Fast Start-Up 82

7.4 PROFINET-diagnostics - TBEN-Lx-8IOL 82

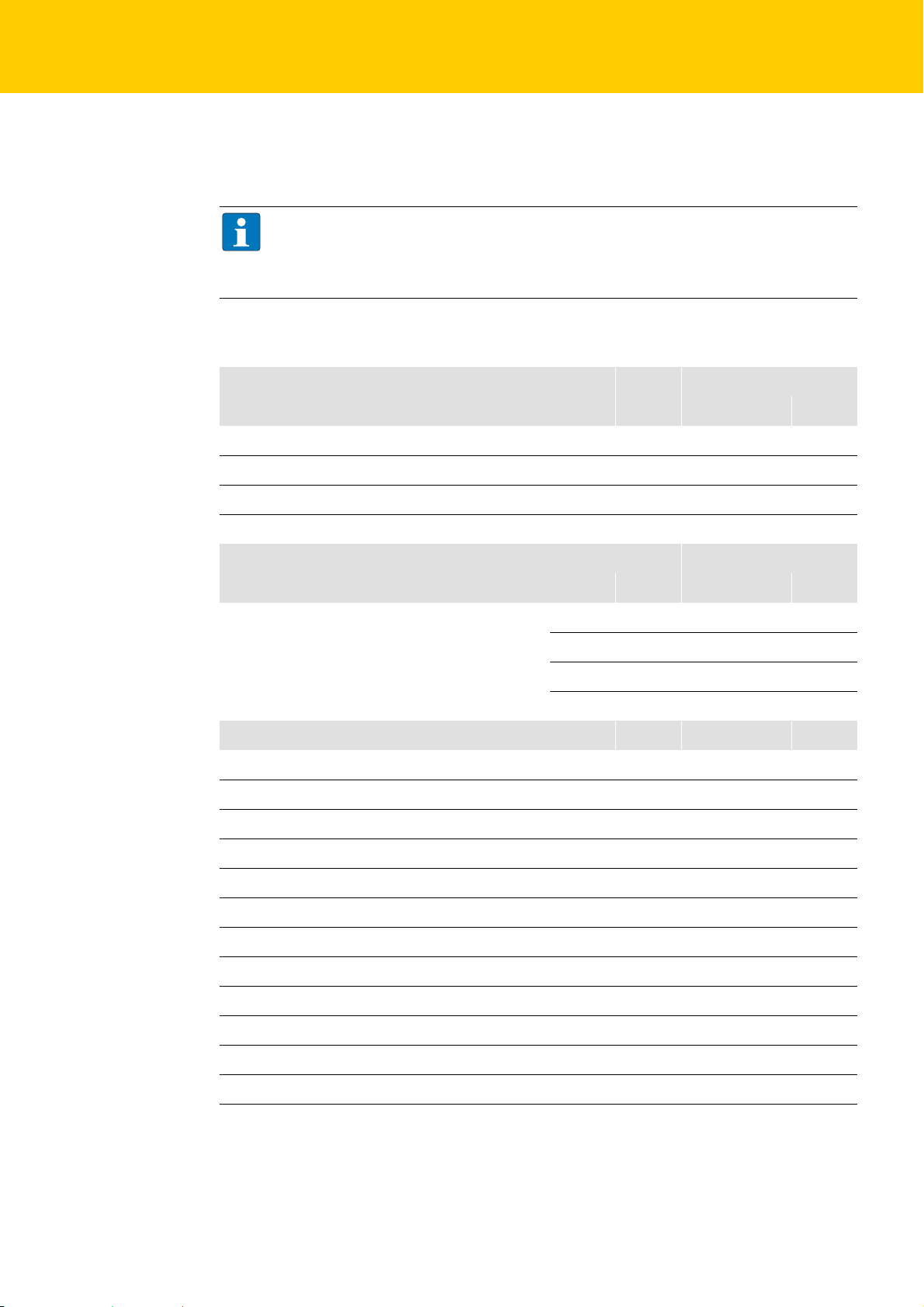

7.5 Parameters 84

7.5.1 General module parameters 84

7.5.2 Parameters for I/O channels 84

7.6 Description of user data for acyclic services 85

7.6.1 Description of the acyclic device user data 85

7.6.2 Description of the acyclic I/O-channel user data 86

7.6.3 IM99 (IOL_M) 87

8 The IO-Link function block IOL_CALL 89

8.1 General 89

8.2 IOL_CALL in accordance with IO-Link specification 89

8.2.1 Input variables 90

8.2.2 Output variables 91

8.2.3 STATUS - communication error status 92

8.2.4 IOL_STATUS 93

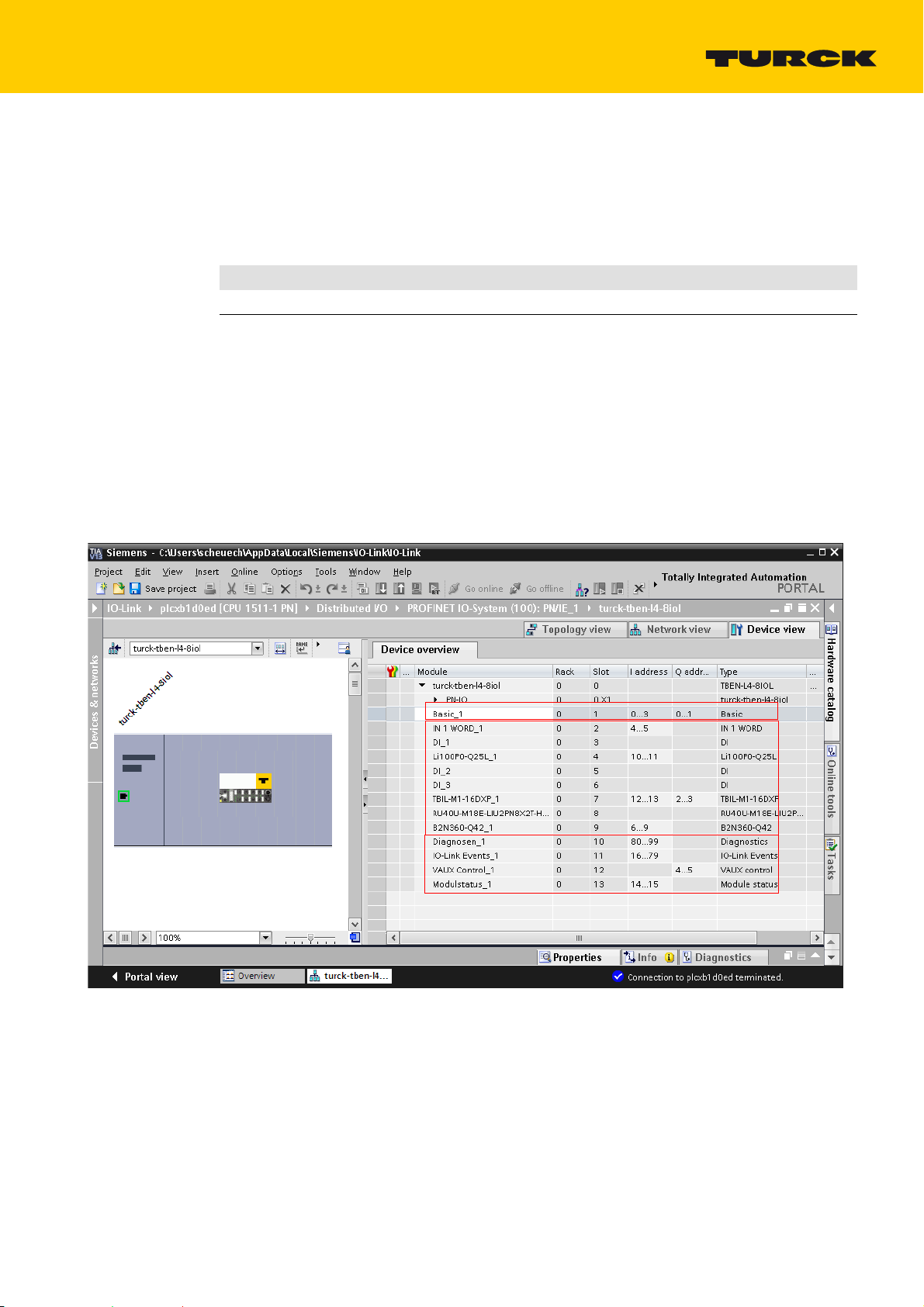

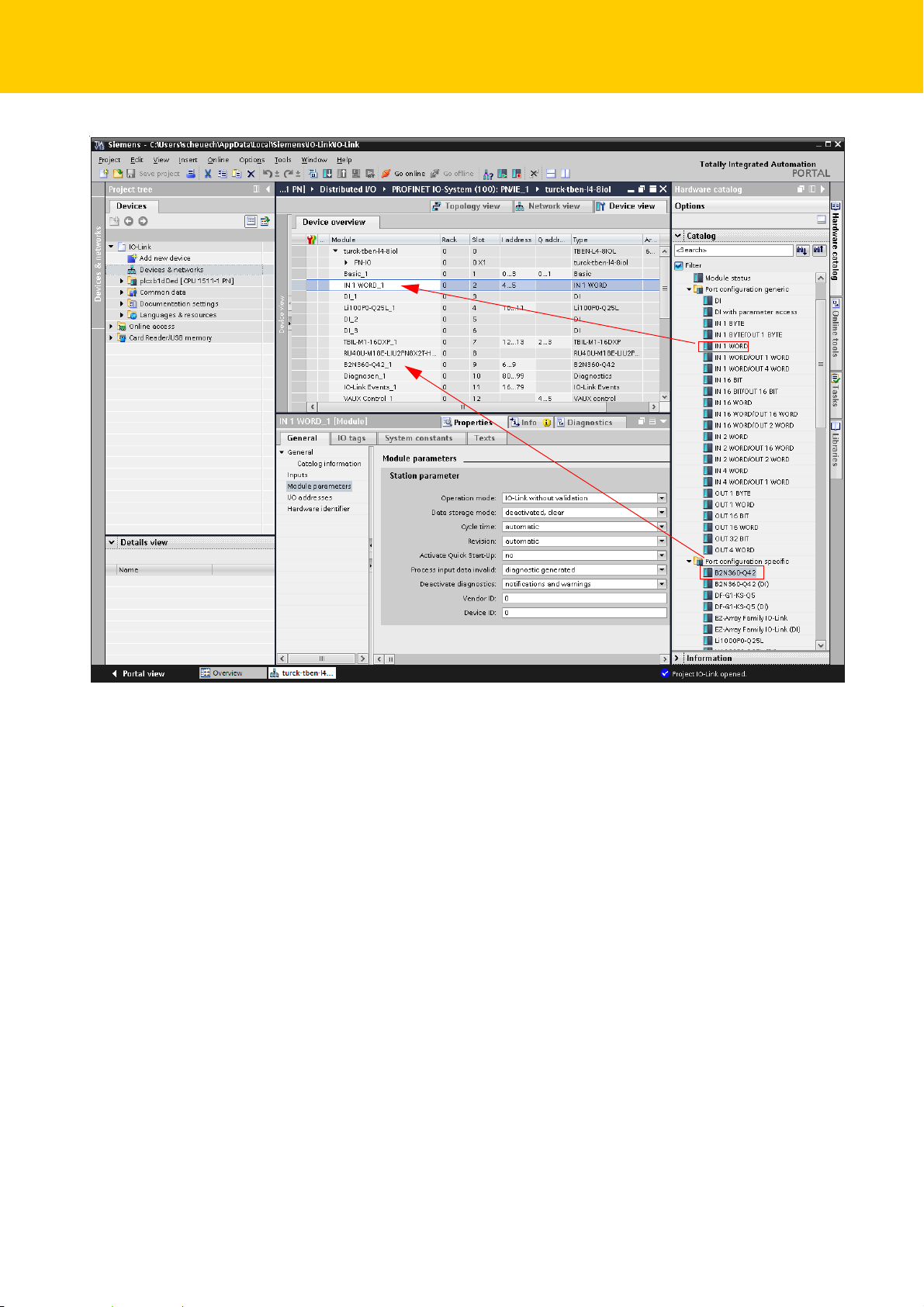

9 Integration of the IO-Link master in TIA Portal 95

9.1 Example project 95

9.1.1 Used hardware 95

9.1.2 Used software 95

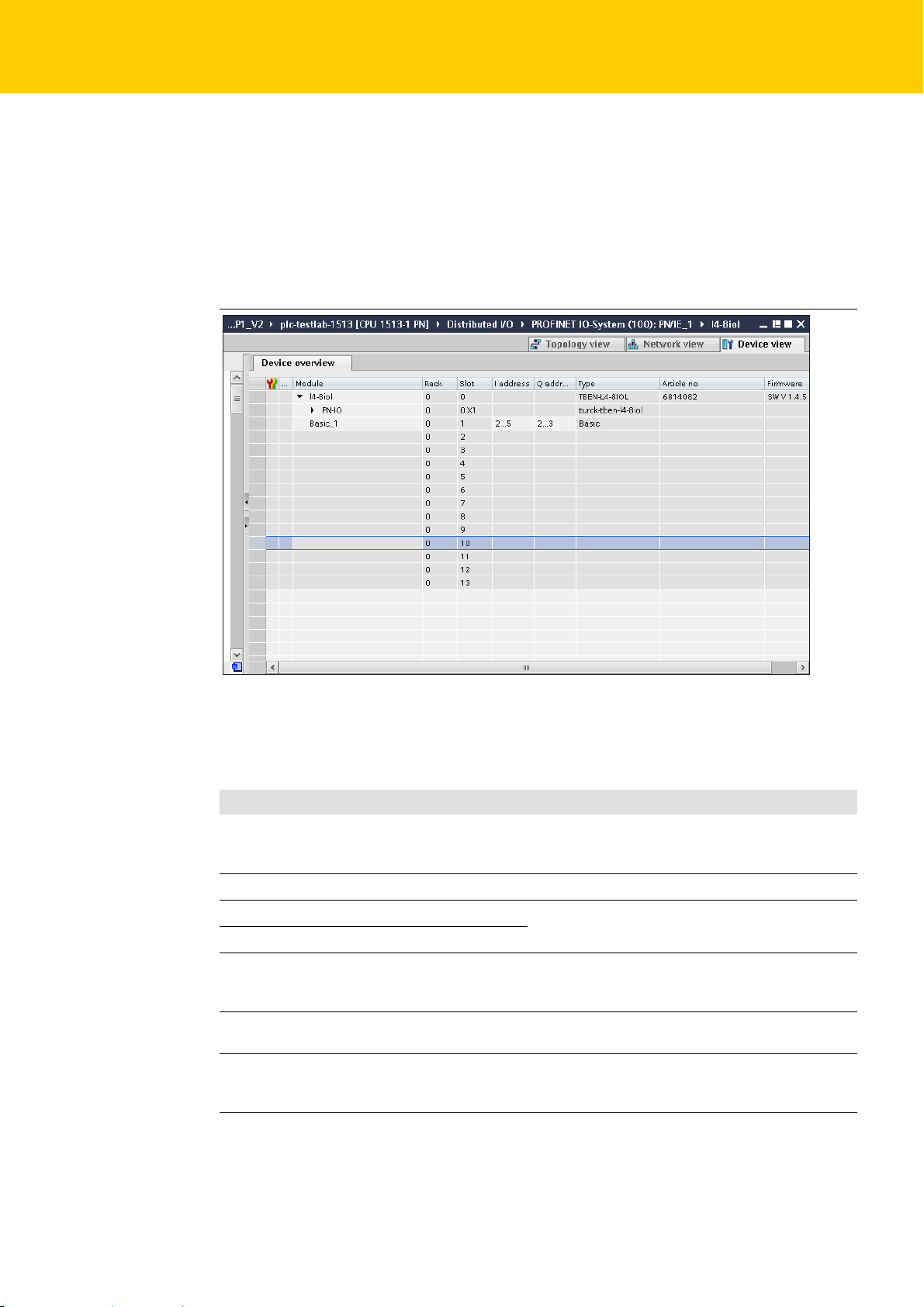

9.2 Hardware configuration 96

9.2.1 Configuration of the IO-Link master 96

9.2.2 Configuration of the IO-Link ports 99

9.3 Using the "IOL_LINK_DEVICE" function block in TIA Portal 100

9.3.1 Example accesses with IO_LINK_DEVICE 101

10 Appendix 109

10.1 Start-up: IO-Link-Device with IO-Link V1.0 109

10.2 Start-up: IO-Link-Device with IO-Link V1.1 110

10.3 Start-up problems - frequent failure causes 111

10.3.1 IO-Link 111

10.3.2 DXP-channels 111

V01.00 | 2016/12

3

Page 6

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 7

1 About this manual

1.1 Documentation concept

This document contains all information about the Turck IO-Link master module TBEN-Lx-8IOL of the

TBEN-L product series with 4 IO-Link ports Class A at connectors C0 to C3 and 4 IO-Link ports Class B.

The following chapters contain:

A general device description and its process data image in the different Ethernet protocols,

A short description of the communication interface IO-Link,

A description of the IO-Link master functionality,

A general description of the function block (FB) IOL_Call according to the IO-Link specification and

its in- and output variables,

An example for the IO-Link-Master's integration in TIA Portal V13 including a description of the Sie-

mens function block IOL_DEVICE in PROFINET,

Helpful information for the operation of IO-Link devices and a list of possible

failure causes

V01.0 | 2016/12

5

Page 8

About this manual

1.2 Explanation of symbols used

1.2.1 Warnings

Action-related warnings are placed next to potentially dangerous work steps and are marked by

graphic symbols. Each warning is initiated by a warning sign and a signal word that expresses the

gravity of the danger. The warnings have absolutely to be observed:

DANGER!

DANGER indicates an immediately

injury, if not avoided.

WARNING!

WARNING indicates a potentially dangerous situation with medium

severe injury, if not avoided.

ATTENTION!

ATTENTION indicates a situation that may lead to property damage, if it is not avoided.

dangerous situation, with high risk, the death or severe

risk, the death or

NOTE

In NOTES you find tips, recommendations and important information. The notes facilitate

work, provide more information on specific actions and help to avoid overtime by not following the correct procedure.

CALL TO ACTION

This symbol identifies steps that the user has to perform.

RESULTS OF ACTION

This symbol identifies relevant results of steps

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 9

1.3 General notes

This manual includes all information necessary for the prescribed use of the modules of type TBENLx-8IOL. It has been specially conceived for personnel with the necessary qualifications.

1.3.1 Prescribed use

The devices described in this manual must be used only in applications prescribed in this manual or

in the respective technical descriptions, and only with certified components and devices from third

party manufacturers.

Appropriate transport, storage, deployment and mounting as well as careful operating and thorough maintenance guarantee the trouble-free and safe operation of these devices.

1.3.2 Notes concerning planning/installation of this product

All respective safety measures and accident protection guidelines must be considered carefully and

without exception.

V01.0 | 2016/12

7

Page 10

About this manual

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 11

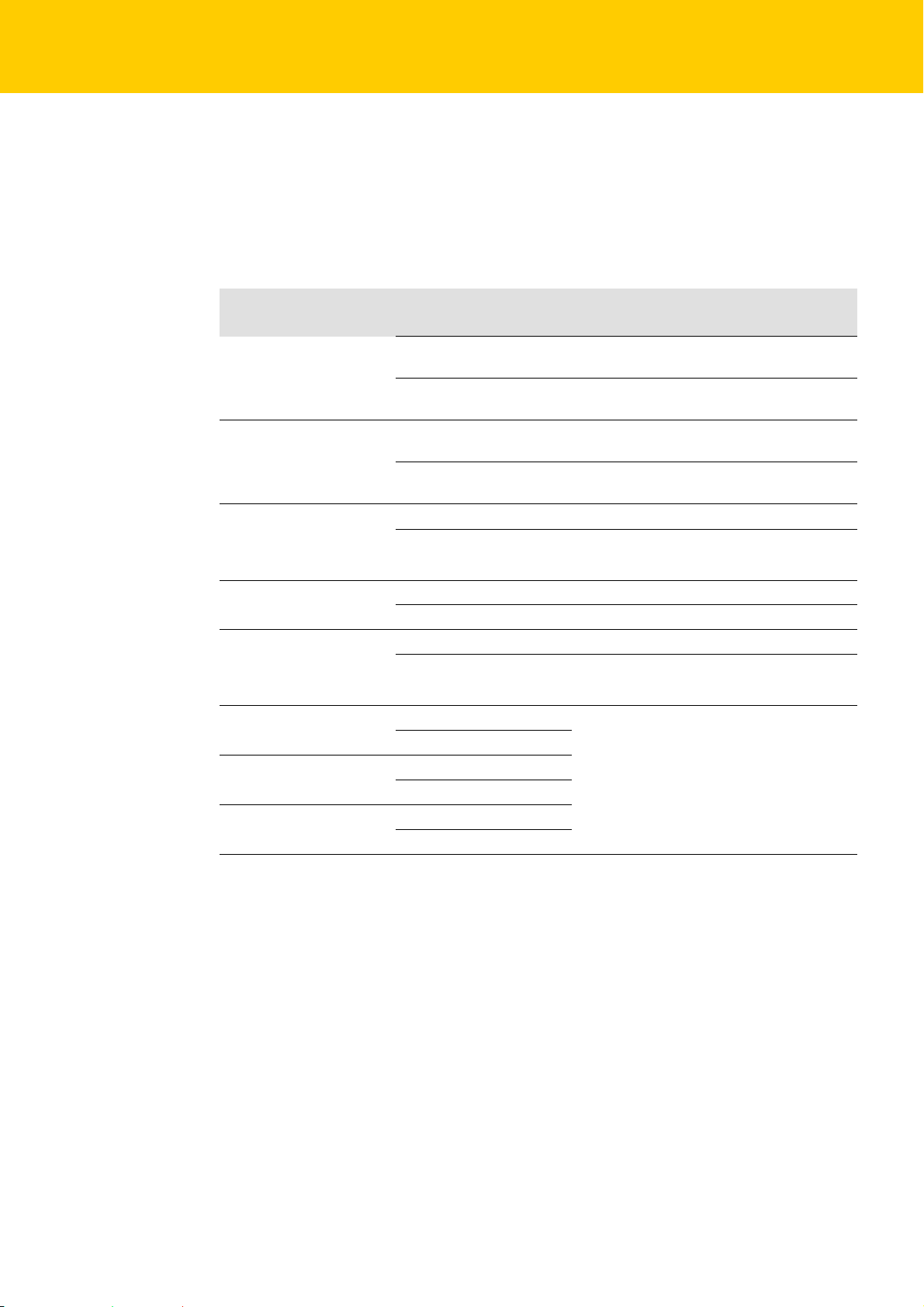

2 Further documentation

2.1 Product family TBEN-L

User manual, D301324 -

„TBEN-L/TBDP-L Compact I/O modules for Ethernet/PROFIBUS-DP“

The user manual for the TBEN-L product family contains comprehensive topics like for example:

–

General technical properties

– Mounting the TBEN-L-modules

– Connection options at module

– General information about Ethernet, the multiprotocol functionality and about the single pro-

tocols

– A description of the web server

– Information about the electrical installation

V01.0| 2016/04

D301368 - 0815 TBEN-S2-4IOL

9

Page 12

Further documentation

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 13

3 IO-Link – Basics

3.1 IO-Link- interface – the fieldbus independent communication interface

IO-Link is a fieldbus-independent communication interface for sensors and actuators.

It is based on the IO-Link specification "IO-Link Interface and System Specification" version 1.1.2,

November 2012, and on the IEC 61131-9 (2013-09), ed. 1.0, „Programmable controllers - part 9: Single-drop digital communication interface for small sensors and actuators (SDCI)“.

IO-Link is a point-to-point connection between an IO-Link device (e.g. sensor, I/O hub, valve terminal) and the IO-Link master. Up to now, the binary connection was only designed for transferring

switching information, but IO-Link now allows 2 bytes to be transferred normally in a 2.3 ms cycle

via a combined switching status and data channel.

Other information can be exchanged in addition to the process values, such as parameters or diagnostic messages.

This enables communication with sensors and actuators down to the "last meter" to be established

for universal communication.

Further information: : www.io-link.com

3.1.1 Communication

Standard I/O-connection technologies in point-to-point connection, unshielded, 20 m wire

length

Cyclic process data transfer in typ. 2.3 ms

Parallel service data exchange without any impact on the process data

Communication via 24 V-pulse modulation, standard UART protocol

Communication between master and device in 3 different transmission speeds

–

4.800 Baud (COM 1)

– 38.400 Baud (COM 2)

– 230.400 Baud (COM 3)

3.1.2 Data transmission

Basically 4 different types of data exist, which are transmitted either cyclically or acyclically.

Process data cyclic data exchange

Value status cyclic data exchange

Device data acyclic data exchange

Events acyclic data exchange

V01.0| 2016/04

Process data:

The devices' process data are transmitted cyclically, whereas the process data size is defined

through the device. The device process data can contain from 0 to 32 Byte (for both in- and output).

11

D301368 - 0815 TBEN-S2-4IOL

Page 14

IO-Link – Basics

Value status:

The value status displays if process data are valid or not. It is transmitted cyclically with the process

data.

Device data:

Device data are parameters, identification data and diagnostic information. The transmission is

done acyclically and only on demand of the IO-Link master.

Events:

Events are error messages or warnings/maintenance data. Error messages are transmitted from the

device to the PLC or similar via the IO-Link master. The IO-Link master itself can also transmit events

and status information. Those events can be for example an open circuit, communication loss or an

overload.

3.1.3 Transmission media

IO-Link does not require any special wiring. The sensors and actuators can continue to be connected

using the proven, attractively priced and unshielded industrial cables.

The operating modes available for selection are the standard switch mode and the communication

mode.

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 15

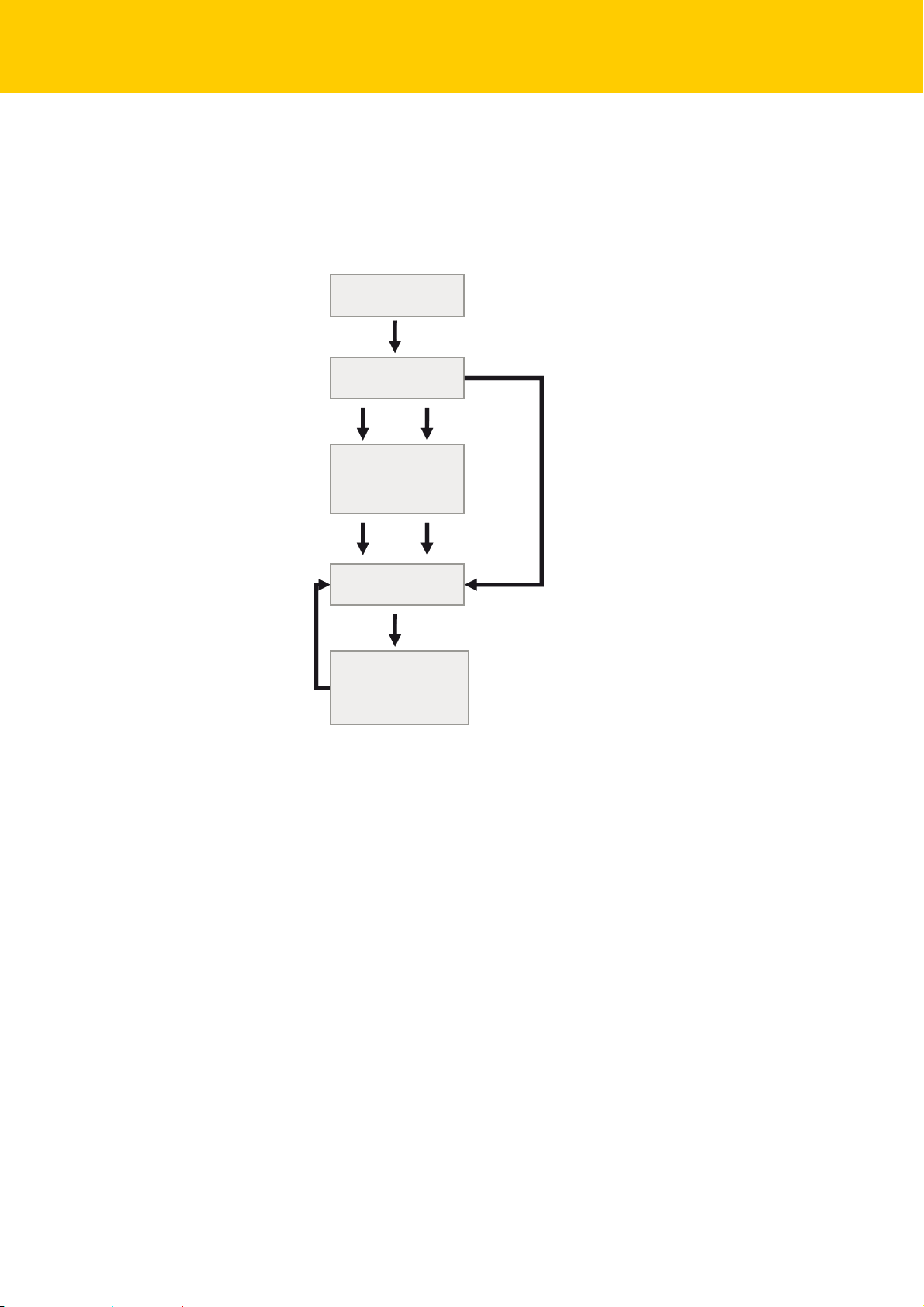

3.1.4 Fieldbus/Ethernet integration

FIELDBUSETHERNET

CONVERNTIONAL I/O

I/O-Hub

I/O-Hub

Inclination Encoder, Linear Position Inductive CouplersProximity Temperature, Pressure, Flow LED Indicator Ultrasonic and Photoelectric Sensors

Usage of the standard-transport mechanisms of established fieldbusses/sensor/actuator busses

(DPV0, DPV1, Ethernet …)

Simple integration in engineering systems by means of configuration files (GSD, GSDML, …)

Comfortable usage of even complex product features by means of tool based engineering (FDT/

DTM, …)

Fig. 1: IO-Link overview

D301368 - 0815 TBEN-S2-4IOL

V01.0| 2016/04

13

Page 16

IO-Link – Basics

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 17

4 TBEN-Lx-8IOL

4.1 Product identification

The TBEN-Lx-8IOL is the 8-channel IO-Link-master module of the product family TBEN-L.

Like all modules of the TBEN-L-product family, the TBEN-Lx-8IOL is a device with Turck multiprotocol functionality, which means, it can be used in the three Ethernet protocols PROFINET, EtherNet/

IP™ and Modbus TCP. An integrated Ethernet-switch allows the building up of a line topology.

Besides the eight IO-Link channels (4 with IO-Link Class A and 4 with IO-Link Class B), the TBEN-Lx8IOL provides four universal digital DXP-channels (PNP).

The eight IO-Link channels can be parameterized independently and can optionally be operated in

IO-Link mode (IOL) or in standard I/O mode (DI mode).

Thanks to the "Simple IO-Link Device Integration (SIDI)“, Turck IO-Link devices can directly be

selected from the device GSDML in PROFINET.

The four universal digital channels are designed as DXP-channels and can therefore be parameterized as in- or output.

Properties:

8-channel IO-Link master according to IO-Link specification V1.1

–

four IO-Link Class A-channels (C0 to C3)

– four IO-Link Class B-channels (C4 to C7)

4 universal digital channels, PNP, channel diagnostics, 0.5 A at the connectors C0 to C3

Connector for voltage supply:

–

TBEN-L4-8IOL: 7/8“ (4-pole)

– TBEN-L5-8IOL: 7/8“ (5-pole)

V01.0| 2016/12

15

Page 18

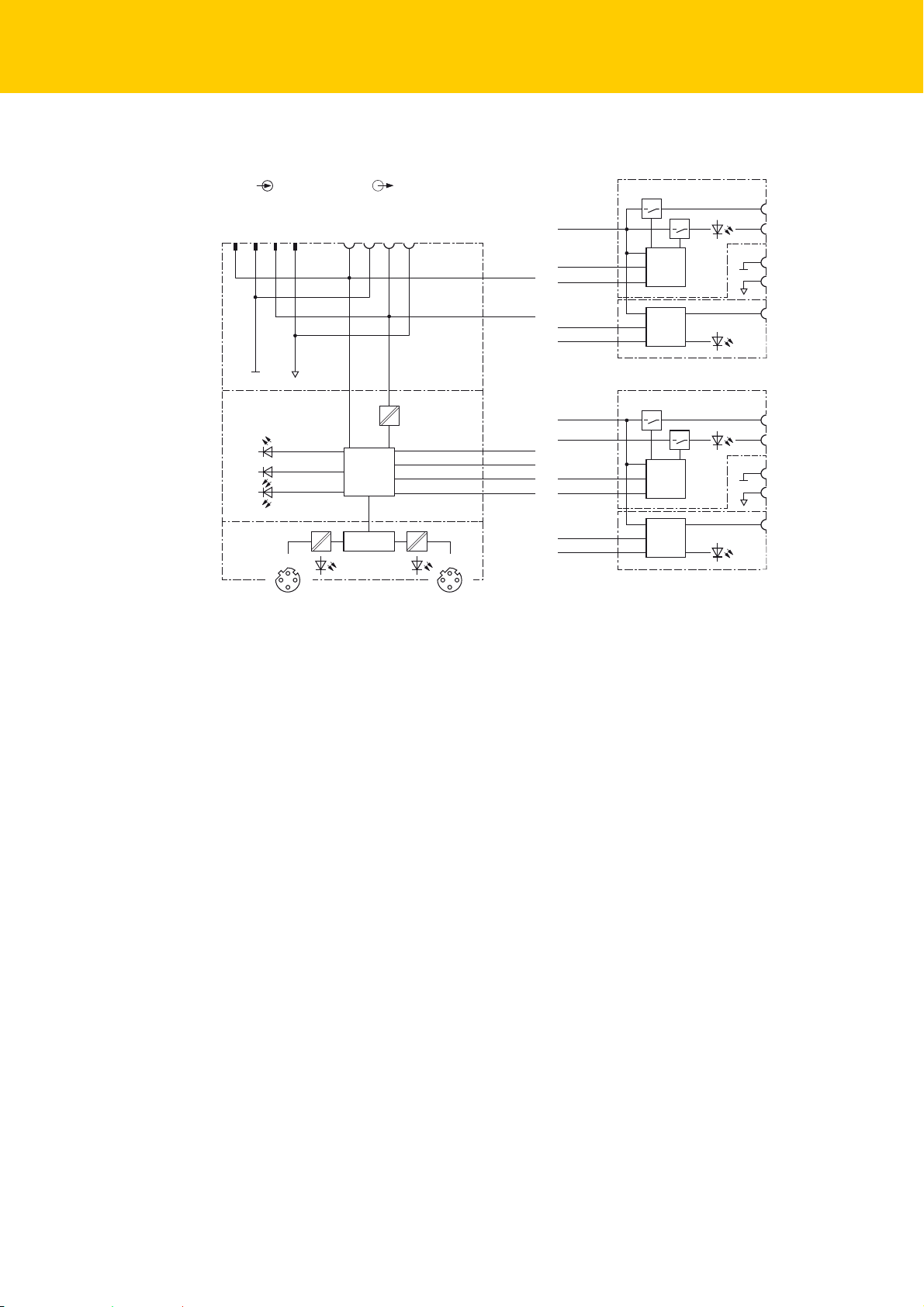

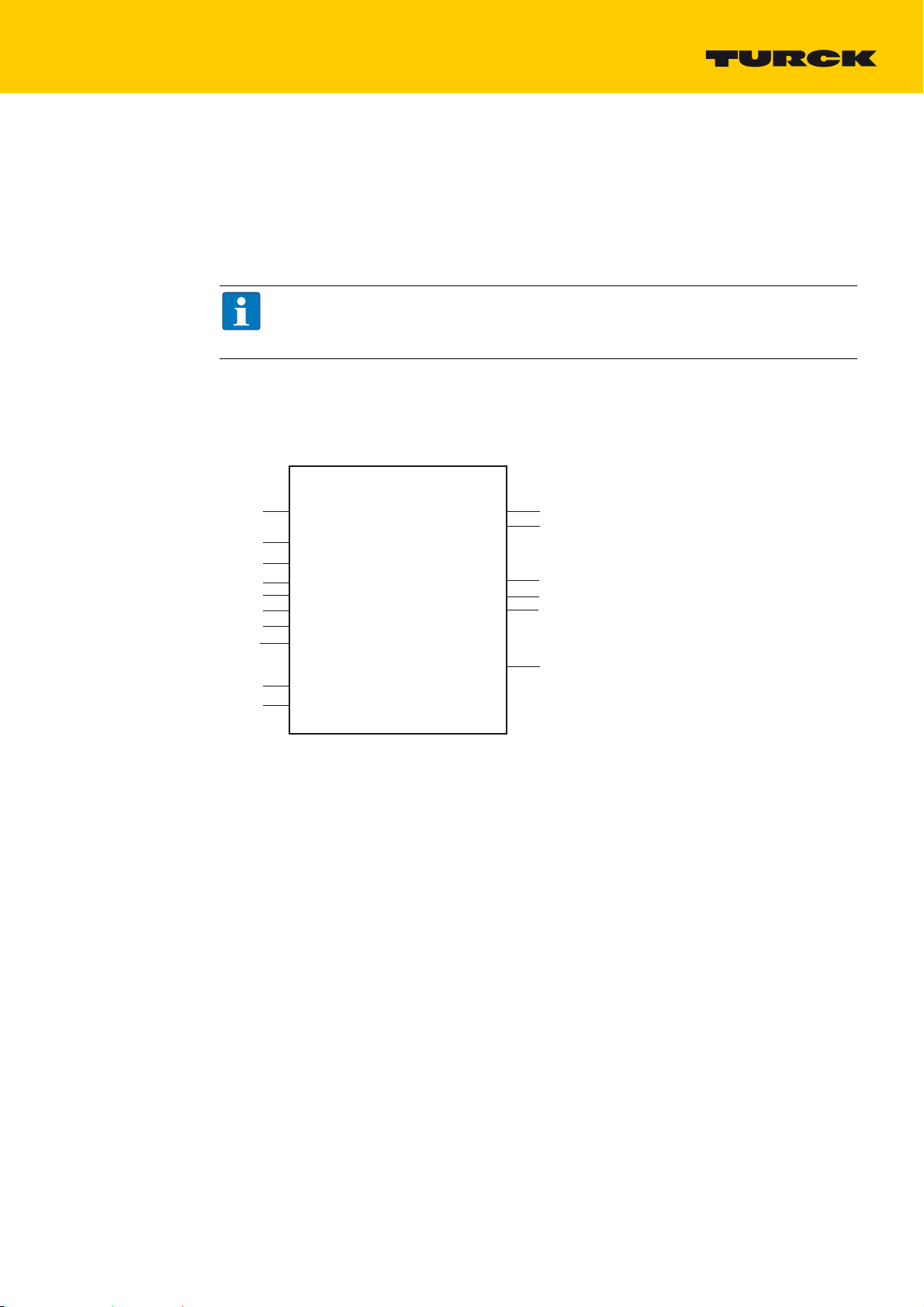

TBEN-Lx-8IOL

ERR

BUS

PWR

µC

Supply

µC

+2–3+1–

4

V1 V2

+2–3+1–

4

V1 V2

X1 X2

IN Diag

OUT Diag

IO-Link Data

V1 Diag V2 Diag

IO-Link Diag

Ethernet

V1 +

IN Diag

IO-Link Diag

IO-Link Data

1 V

AUX1

(V1)

2 IN/OUT

(V1)

4 C/Q(V1)

OUT Diag

3 GND (V1)

In/OutputClass A

I/O

IO-Link

µC

5 n.c.

V1 +

V2 +

IO-Link

IN Diag

IO-Link Diag

IO-Link Data

1 V

AUX1

(V1)

(V2)

4 C/Q(V1)

OUT Diag

3 GND (V1)

5 GND (V2)

In/OutputClass B

I/O

IO-Link

µC

V2 +

V1 +

IO-Link

P2P1

4

1

3

2

4

1

3

2

ETH2ETH1

Ethernet

2 V

AUX2

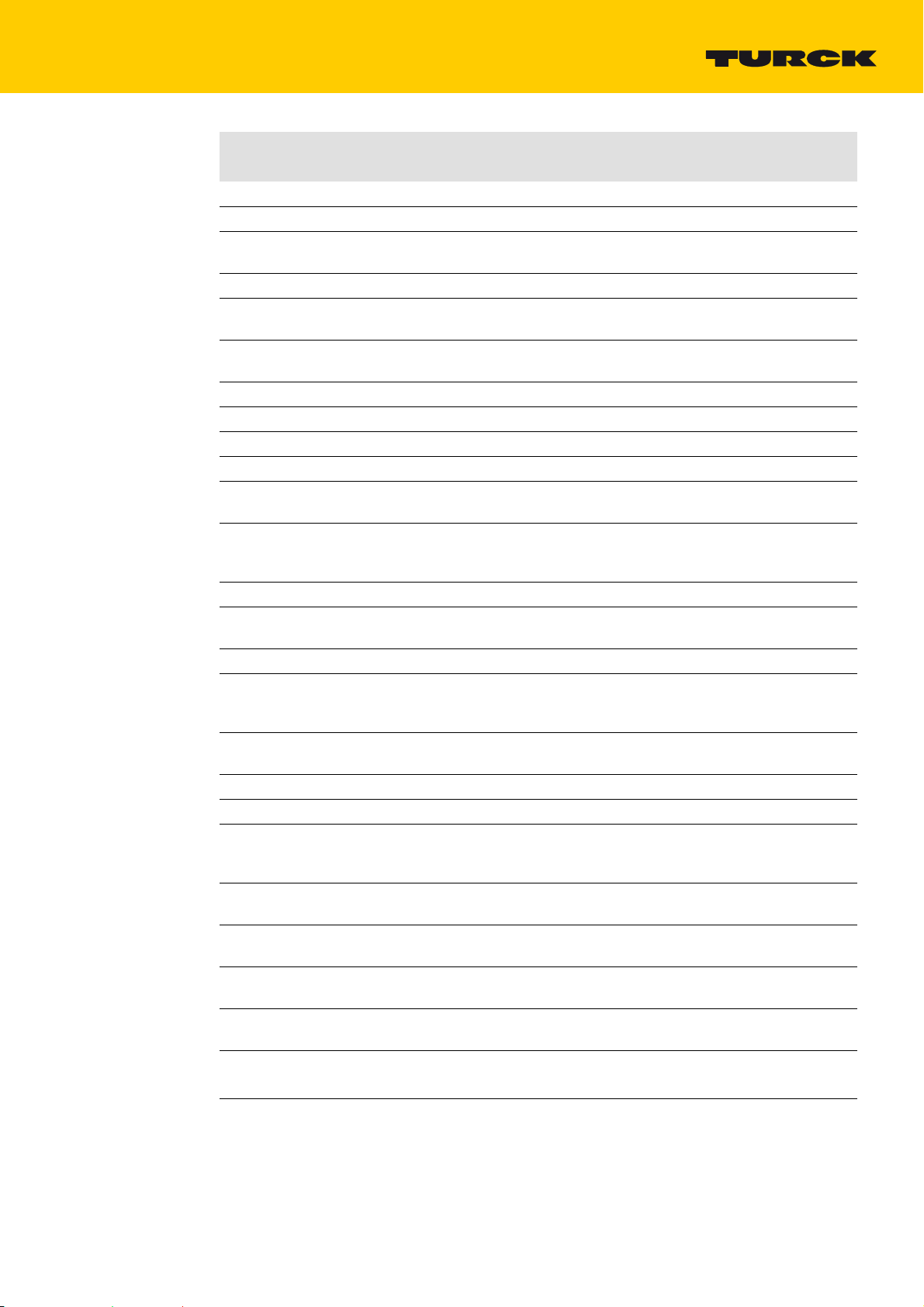

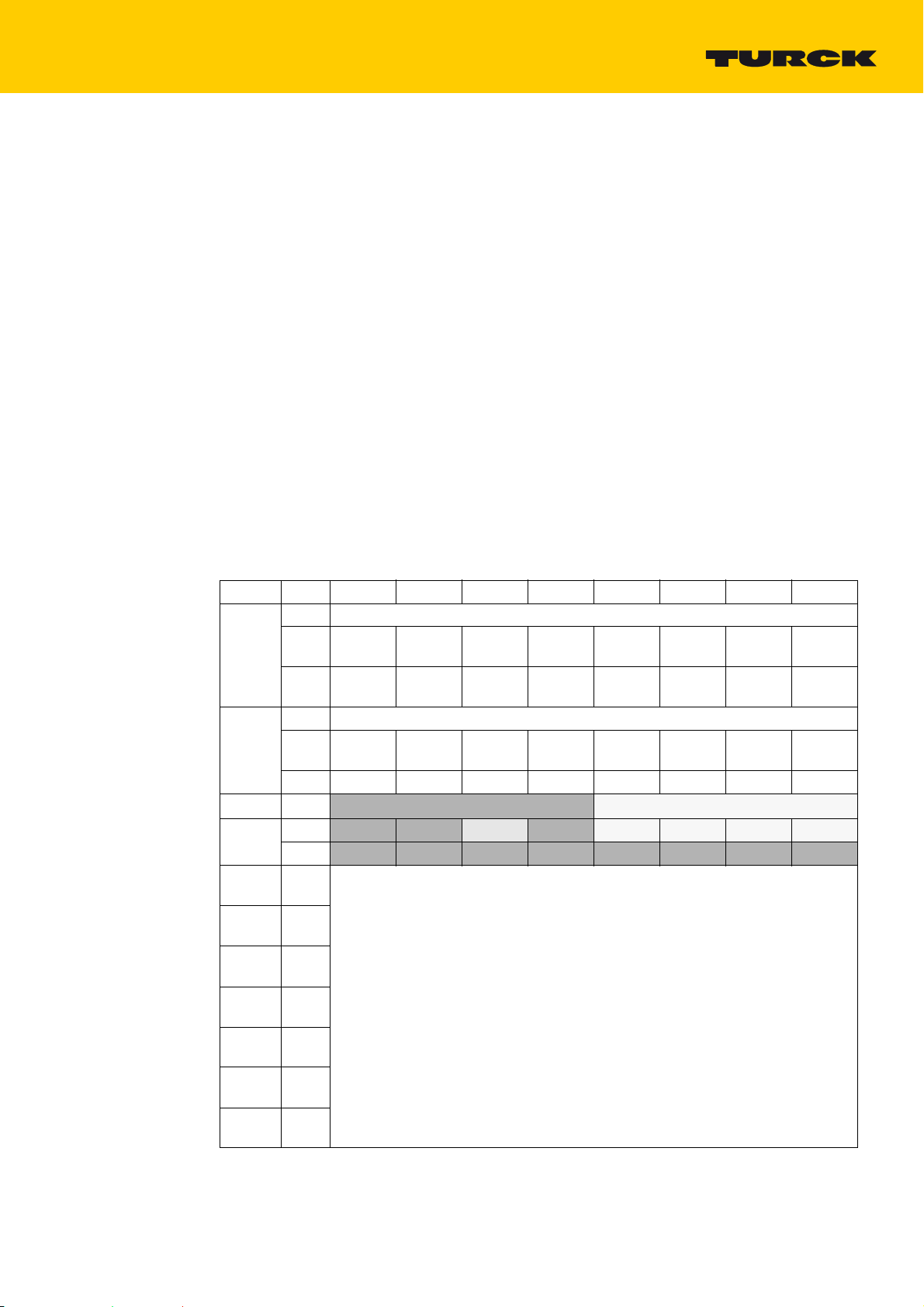

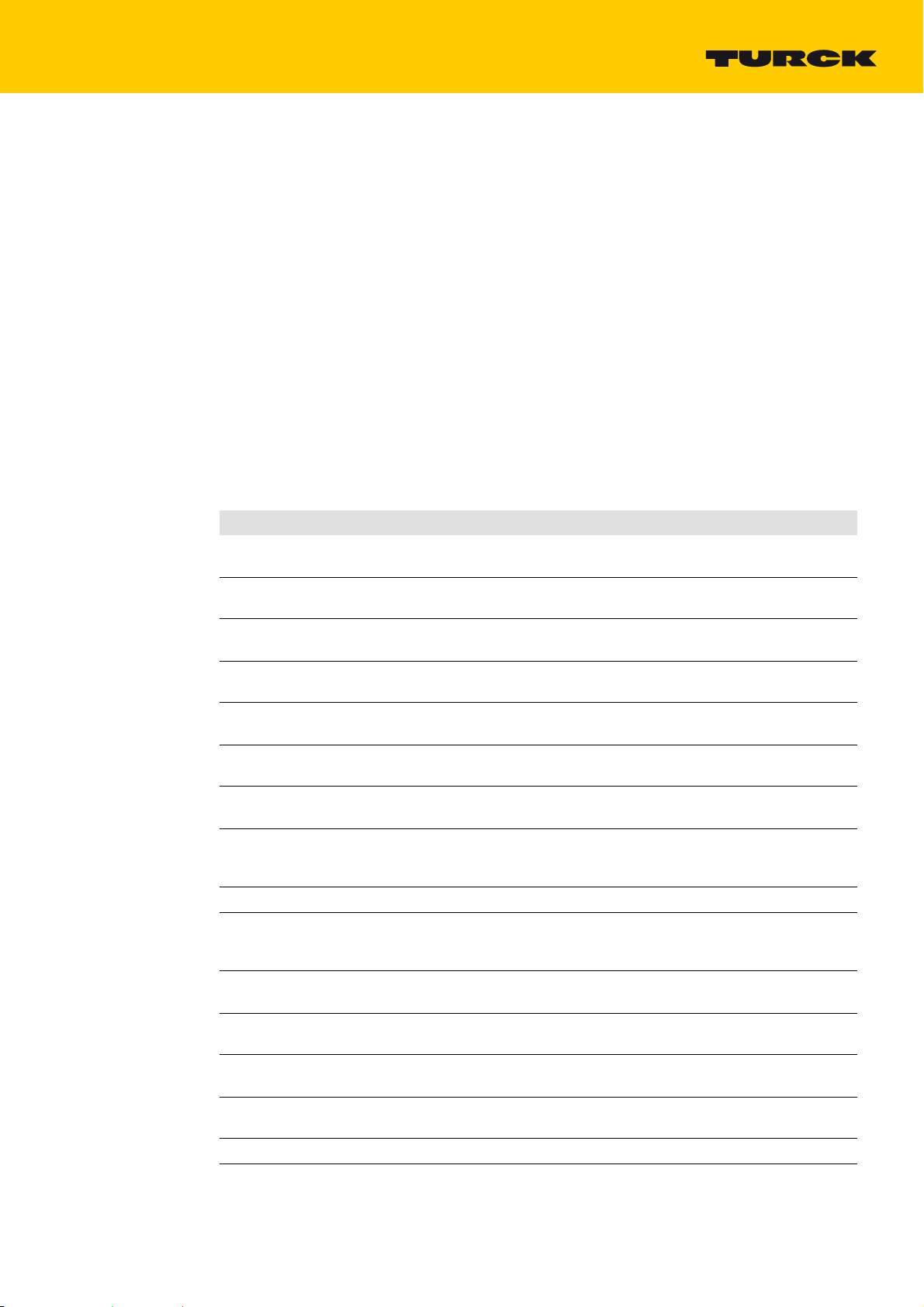

4.2 Block diagram

Fig. 2: Block diagram TBEN-Lx-8IOL

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 19

4.3 Technical data

Power supply

Supply voltages 24 V DC from operating voltage

Permissible range 18 … 30 V DC

Operating current < 120 mA

Sensor/actuator supply V

Sensor/actuator supply V

Potential isolation 500 V (V2 to Ethernet and V1)

IO-Link

Number of ports 8

IO-Link specification V1.0, V1.1 according to IEC 61 61131-9

IO-Link port type Class A at C0 to C3

Frame type Supports all specified frame types

Process data for IO-Link devices

– Input data max. 32 Byte per channel

– Output data max. 32 Byte per channel

Transmission rate 4,8 kbps (COM 1)

Transmission cable Length: max. 20 m

AUX1

AUX2

IO-Link:

20,4 … 28,8 V DC (acc. to IO-Link standard)

Total current max. 9 A per module

Supply from V1

short-circuit proof, max. 4 A for C0 & C4,

short-circuit proof, 2 A per group C1 - C4, C5 - C8

Class B-supply from V2

short-circuit proof, 2 A per connector C0-C7

Class B at C3 to C7

38,4 kbps (COM 2)

230,4 kbps (COM 3)

standard cables,

3- or 4-wire (depending on the application),

unshielded

V01.0| 2016/12

NOTE

General data for the products of the TBEN-L-series can be found in D301324 - „TBEN-L/

TBDP-L Compact I/O modules for Ethernet/PROFIBUS-DP“.

17

Page 20

TBEN-Lx-8IOL

4

1

3

2

5

v

1 = V

aux

1 (V1)

2 = DXP (V1)

3 = GND (V1)

4 = C/Q (V1)

5 = n.c.

C0...C3

4

1

3

2

5

v

1 = V

aux

1 (V1)

2 = V

aux

2 (V2)

3 = GND (V1)

4 = C/Q (V1)

5 = GND (V2)

C4...C7

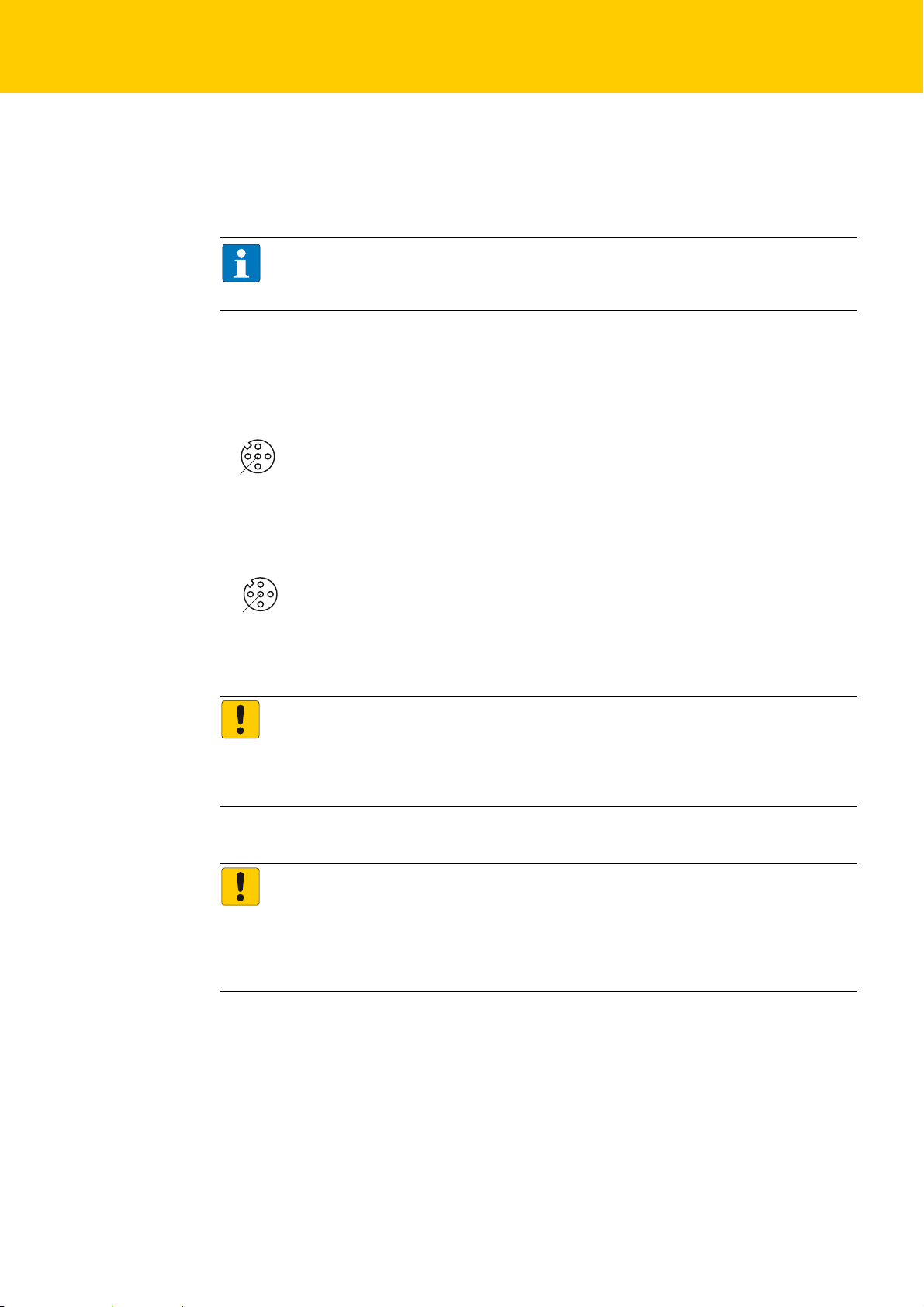

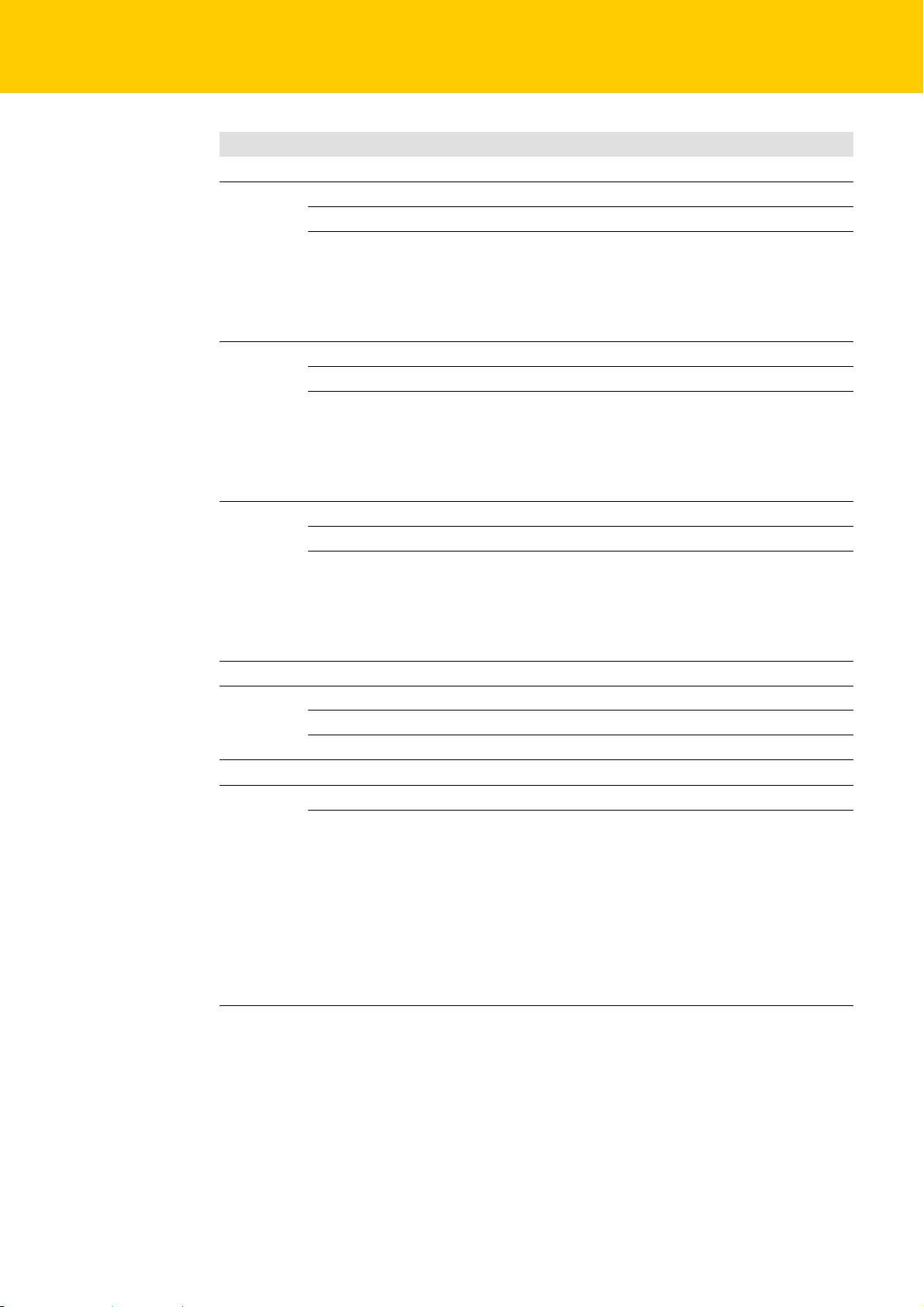

4.4 Wiring diagrams

4.4.1 Ethernet/voltage supply

NOTE

Information about network connection and voltage supply can be found in the user manual D301324: „TBEN-L/TBDP-L Compact I/O modules for Ethernet/PROFIBUS-DP“

4.4.2 IO-Link ports

Pin 1: VAUX1 switchable via process data

Pin 4: IO-Link or digital input

C0…C3: IO-Link Master Class A

Pin 2: digital in- or output (DXP)

C4…C7: IO-Link Master Class B

Pin2: switchable Class B supply (VAUX2)

Fig. 3: Pin assignment of M12 x 1-connectors, 5-pole

ATTENTION!

Wrong supply of IO-Link devices

Damage to the electronics

The IO-Link devices must only be supplied with the voltage provided at the supply ter-

minals of the TBEN.

s

ATTENTION!

Connection of Class A devices to Class B ports

Loss of the galvanic isolation

Only use Class A devices with signals on pin 1, pin 3 and pin 4 at Class B ports.

The connection of Class A devices with signals on pin 2 and pin 5 leads to the loss of the

galvanic isolation.

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 21

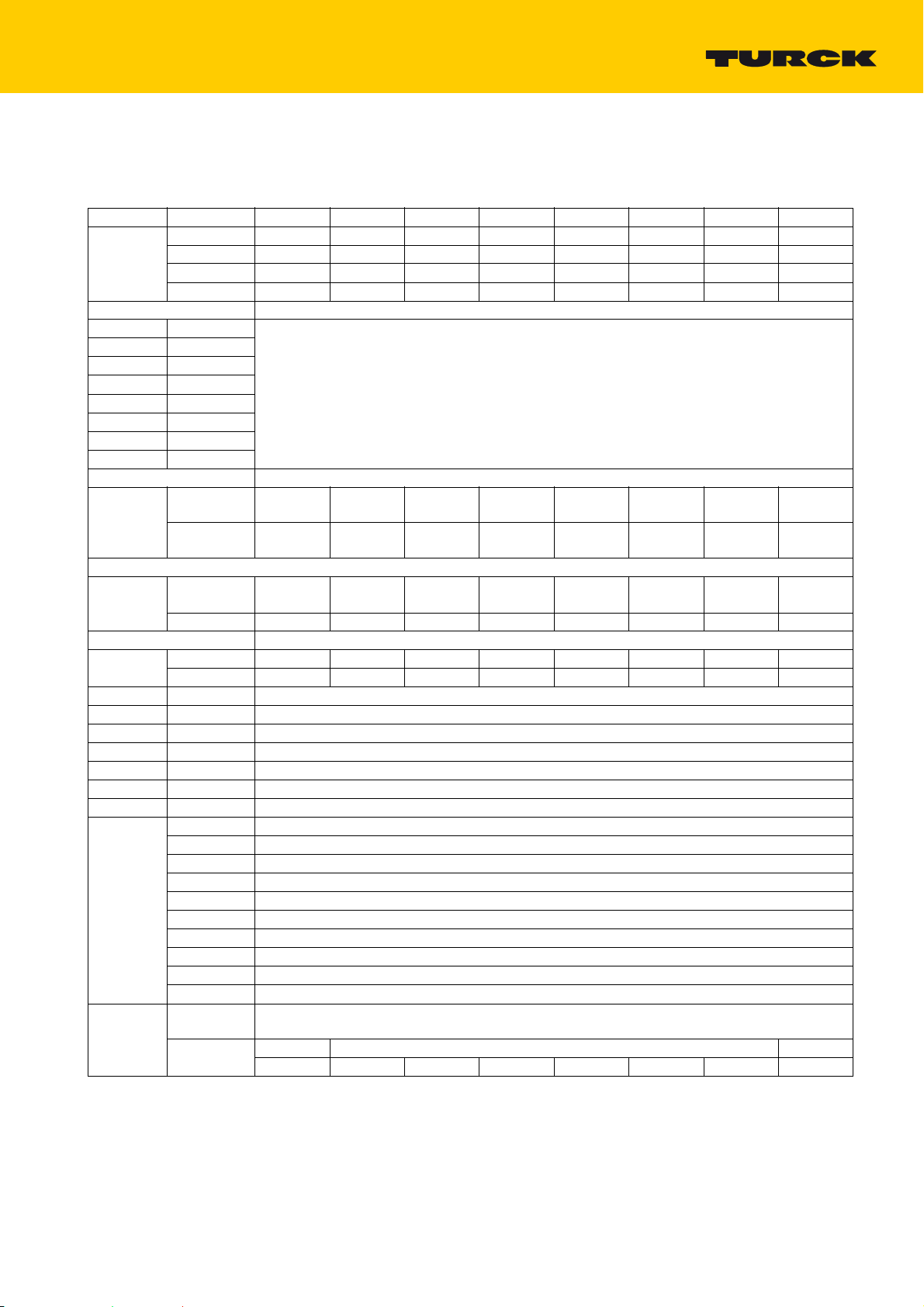

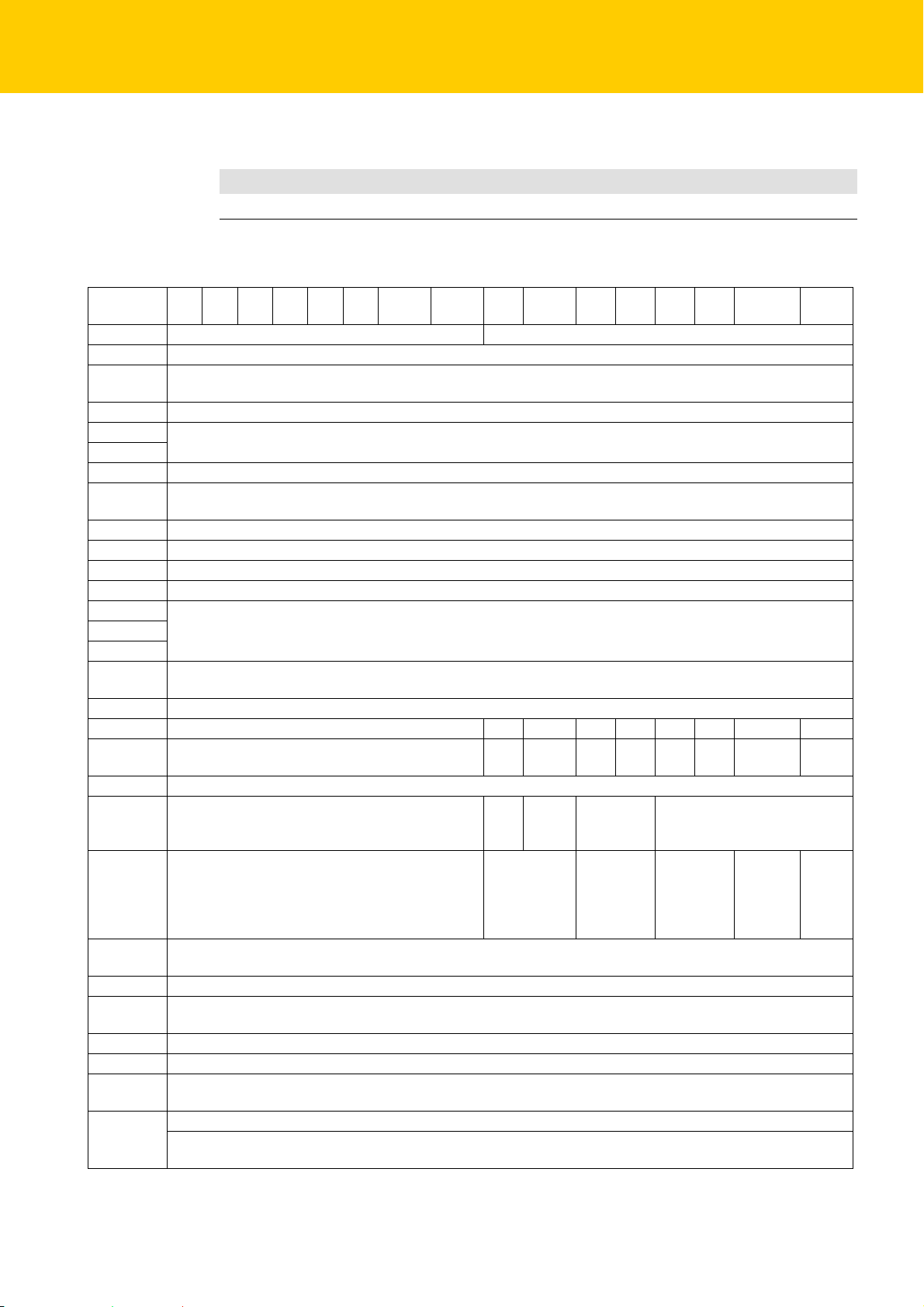

4.5 Process data

4.5.1 Process input data

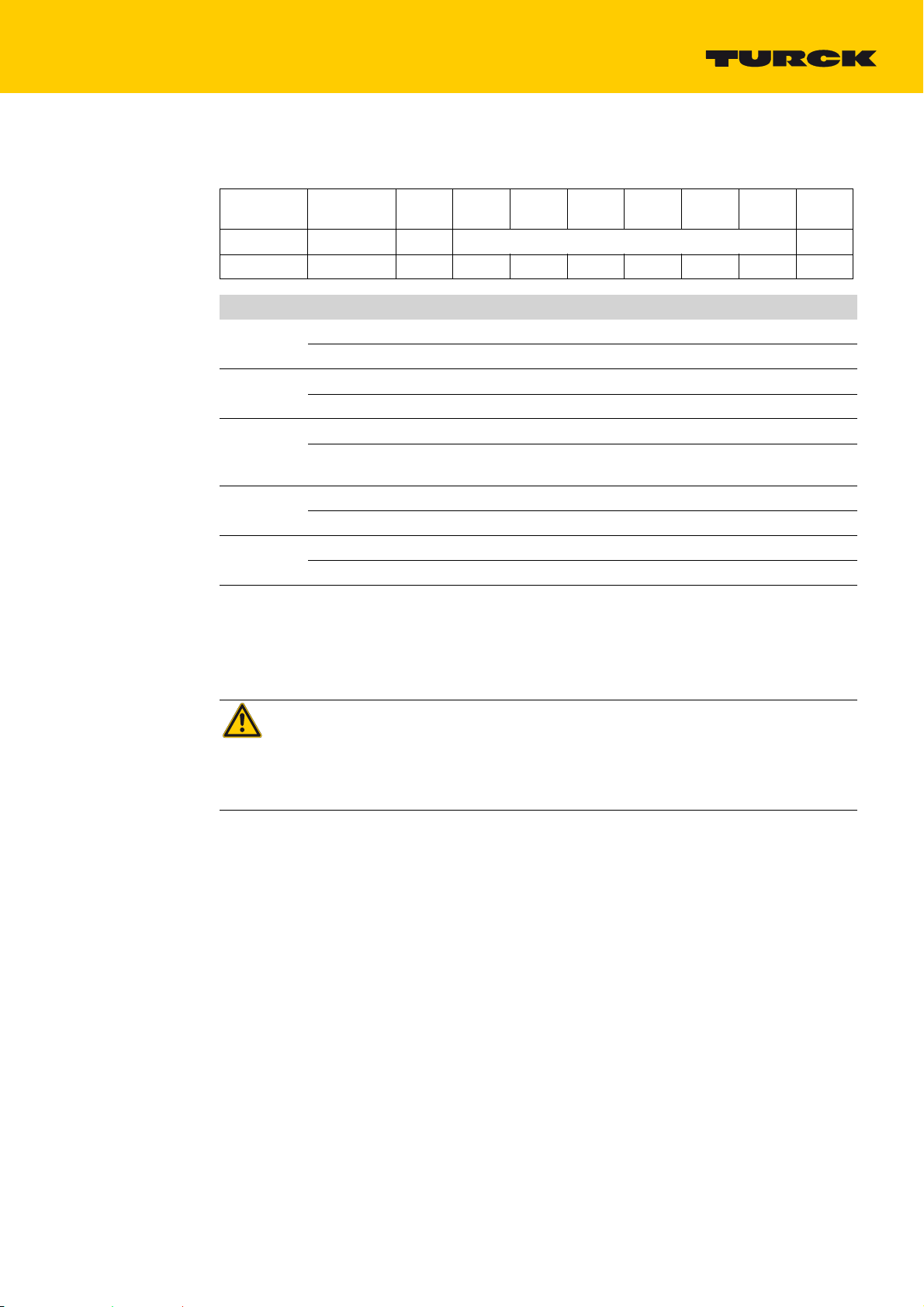

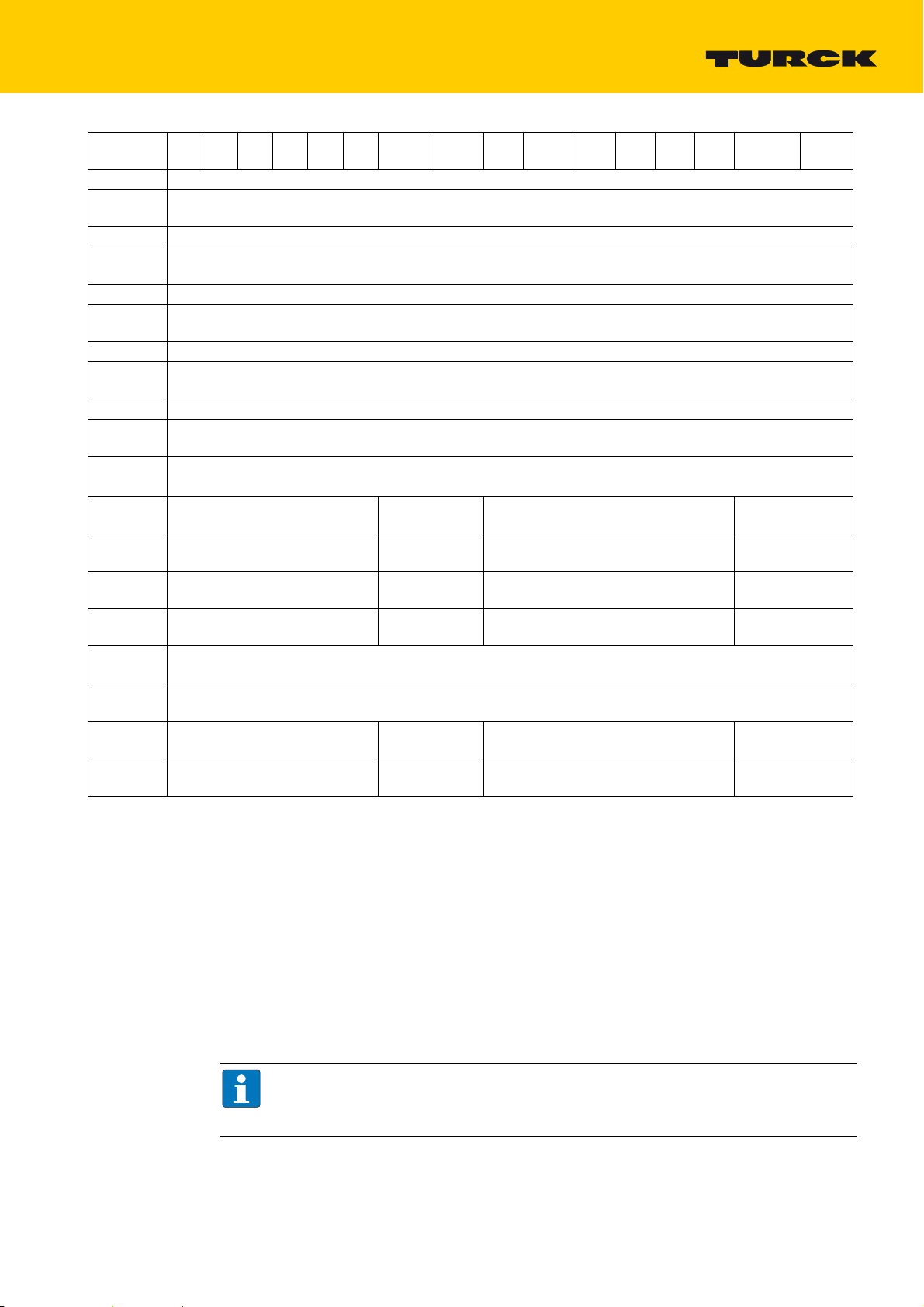

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Basic

IO-Link ports IO-Link process input data

Port 1 4 - 35

Port 2 36 - 67

Port 3 68 - 99

Port 4 100 - 131

Port 5 132 - 163

Port 6 164 - 195

Port 7 196 - 227

Port8 228 - 259

VAUX1/VAUX2 Diagnostics (see Diagnostic data, page 31)

DXP-channels

IO-Link ports (see Diagnostic data, page 31)

Port 1 264 EVT1 EVT2 PDINV HWER DSER CFGER PPE -

Port 2 266 + 267 assignment similar to port 1

Port 3 268 + 269 assignment similar to port 1

Port 4 270 + 271 assignment similar to port 1

Port 5 272 + 273 assignment similar to port 1

Port 6 274 + 275 assignment similar to port 1

Port 7 276 + 277 assignment similar to port 1

Port 8 278 + 279 assignment similar to port 1

Module Module status (status word)

0 DXP7 DI6 (SIO) DXP5 DI4 (SIO) DXP3 DI2 (SIO) DXP1 DI0 (SIO)

1 - DI14 (SIO) - DI12 (SIO) - DI10 (SIO) - DI8 (SIO)

2 - DVS6 - DVS4 - DVS2 - DVS0

3 - DVS14 - DVS12 - DVS10 - DVS8

structure depends on the channel parameterization

(0 - 32 byte per channel)

260

261

262

263--------

265 GENER OVL VHIGH VLOW ULVE LLVU OTMP PRMER

280 Qualifier (1st Event)

281 Port (1st Event)

282 Event Code high byte (1st Event)

283 Event Code low byte (1st Event)

... ...

340 Qualifier (16th Event)

341 Port 16th Event)

342 Event Code high byte (16th Event)

343 Event Code low byte (16th Event)

344 + 345

VErrV1

C7K14

VErrV2

C7K15

ERR

DXP7

V2 - Diag

-FCE----V1-

VErrV1

C6K12

VErrV2

C6K13

-

VErrV1

C5K10

VErrV2

C5K11

ERR

DXP 5

(see Status and control word, page 35)

VErrV1

C4K8

VErrV2

C4K9

-

IO-Link Events

VErrV1C3

K6K7

----

ERR

DXP 3

VErrV1C2

K4K5

-

VErrV1C1

K2K3

ERR

DXP 1

VErrV1C0

K0K1

-

V01.0| 2016/12

19

Page 22

TBEN-Lx-8IOL

Name Value Meaning

DIx Digital input

0 No signal at DI (pin 4, SIO)

1 Input signal at DI (pin 4, SIO)

DXPx DXP input

0 No input signal at DXP-channel (pin 2)

1 Input signal at DXP-channel (pin 2)

DVSx Input value valid (Data Valid Signal)

0 The IO-Link data are valid.

Possible causes:

– Sensor supply is below the admissible range,

– IO-Link port is parameterized as simple digital input,

– No device connected to the masters,

– No input data received from the connected device (only valid for devices with an

input data length > 0),

– No reaction from the connected device to the sending of output data (only valid

for devices with an output data length > 0),

– The connected device sends an error "process input data invalid.

1 The IO-Link data are valid.

IO-Link process input data

Process input data of the connected device

The order of the IO-Link process input data can be changed via the parameter "Process input data mapping"

(

page 22).

Diagnostics

(see Diagnostic data, page 31)

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 23

4.5.2 Process output data

Byte

Basic 0 DXP7 - DXP5 - DXP3 - DXP1 -

IO-Link ports IO-Link process output data

Port 1

Port 2 34 - 65

Port 3 66 - 97

Port 4 98 - 129

Port 5 130 - 161

Port 6 162 - 193

Port 7 194 - 225

Port 8 226 - 257

VAUX1

VAUX2

2 - 33

258

259

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 reserved

structure depends on the channel parameterization

(0 - 32 byte per channel)

VAUX1 Pin1

C7 (Ch14)

VAUX2 Pin2

C7 (Ch15)

Name Value Meaning

DXPx DXP output

IO-Link process output data

Process output data of the connected device

The order of the IO-Link process output data can be changed via the parameter "Process output data mapping" (page 22).

VAUX1 pin 1 Cx (Chy/

Chz)

VAUX2 Pin 2 Cx (Chy) 0 The Class B supply at Pin2 of the connector is switched off.

VAUX1 Pin1

C6 (Ch12)

VAUX2 Pin2

C6 (Ch13)

0 Output inactive

1 Output active, max. output current 2 A

0 The 24 VDC sensor/actuator supply at Pin1 of the connector is

1 The 24 VDC sensor/actuator supply at Pin1 of the connector is

1 The Class B supply at Pin2 of the connector is switched on.

VAUX1 Pin1

C5 (Ch10)

VAUX2 Pin2

C5 (Ch11)

switched off.

switched on.

VAUX1 Pin1

C4 (Ch8)

VAUX2 Pin2

C4 (Ch9)

VAUX1 Pin1

C3 (Ch6/7)

VAUX1 Pin1

C2 (Ch4/5)

VAUX1 Pin1

C1 (Ch2/3)

VAUX1 Pin1

C0 (Ch0/1)

V01.0| 2016/12

21

Page 24

TBEN-Lx-8IOL

4.6 Parameters

The module provides 4 byte of module parameters and 16 byte of IO-Link port-parameters for each

IO-Link port.

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Basic

Port 1 4

Port 2 20 - 35

Port 3 36 - 51

Port 4 52 - 67

Port 5 68 - 83

Port 6 94 - 99

Port 7 100 - 115

Port 8 116 - 131

VAUX1-

monitoring

VAUX2-

monitoring

0 SRO7 - SRO5 - SRO3 - SRO1 -

1-

2 EN DO7 - EN DO5 - EN DO3 - EN DO1 -

3-

5 Cycle time

6 Process output data

7 - 11 reserved

12 Vendor ID (LSB)

13 Vendor ID (MSB)

14 Device ID (LSB)

15 Device ID

16 Device ID

17 Device ID (MSB)

18 reserved

19 reserved

132 VAUX1 Pin1 C0 (Ch0/1)

133 VAUX1 Pin1 C1 (Ch2/3)

134 VAUX1 Pin1 C2 (Ch4/5)

135 VAUX1 Pin1 C3 (Ch6/7)

136 VAUX1 Pin1 C4 (Ch8)

137 VAUX1 Pin1 C5 (Ch10)

138 VAUX1 Pin1 C6 (Ch12)

139 VAUX1 Pin1 C7 (Ch14)

140 - 143 reserved

144 VAUX2 Pin2 C4 (Ch9)

145 VAUX2 Pin2 C5 (Ch11)

146 VAUX2 Pin2 C6 (Ch13)

147 VAUX2 Pin2 C7 (Ch15)

GSD

Start-Up

mapping

Quick

data storage mode Mode

Process input data map-

ping

Assignment similar to port 1 (byte 4 - 19 )

Diagnostics

deactivate web server

Process input

data invalid

Revision

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 25

Name Meaning

Value A = default

SRO Manual output reset after overcurrent

00 = no A The output switches on automatically after an overload.

1 1 = yes The output is manually switched-off after an overload until a new

set-command is given (rise and fall).

EN DO Activate output

00 = no A The output at pin 2 is deactivated.

1 1 = yes The output at pin 2 is activated.

Mode

0000 IO-Link without

validation A

Pin 4 is operated in IO-Link mode.

The master does not check if the connected device matches the

configured one.

0001 IO-Link with family

compatible device

4 is operated in IO-Link mode.

The master checks if the Vendor ID and the MSB of the Device ID

(this byte defines the product family) of the connected device

match those of the configured one.

If the master detects a mismatch, the IO-Link communication is

established, but there is no process data exchange. The device

remains in the safe state (Pre-Operate). Parameters and diagnostic information can be read and respectively written.

0010 IO-Link with compati-

ble device

4 is operated in IO-Link mode.

The master checks if the Vendor ID and the Device ID of the connected device match those of the configured one.

If the Vendor ID matches, but the Device ID not, then the master

tries to write the Device ID to the device.

If the writing is successful, then the device is a compatible one,

process data exchange is possible.

If writing the Device ID is not successful, then process data

exchange is not possible. The device remains in the safe state (PreOperate). Parameters and diagnostic information can be read and

respectively written.

0011 IO-Link with

identical device

4 is operated in IO-Link mode.

The master checks if the device type (Vendor ID and Device ID)

and the serial number of the connected device match the data of

the configured one.

If the master detects a mismatch, the IO-Link communication is

established, but there is no process data exchange. The device

remains in the safe state (Pre-Operate). Parameters and diagnostic information can be read and respectively written.

0100 DI (with parameter

access)

Pin 4 is generally operated as simple digital input.

However, an acyclic parameter access from the PLC or the DTM is

possible.

The IO-Link master starts the port in IO-link mode, parameterizes

the device and sets the port back into DI-mode. The port remains

in DI mode until a new IO-Link request is sent from the higherlevel control.

Data storage is not supported.

Connected devices have to support the SIO-mode (DI-mode).

00

10

DI Pin 4 is operated as simple digital input.

Data storage is not supported.

V01.0| 2016/12

23

Page 26

TBEN-Lx-8IOL

Name Meaning

Value A = default

NOTE

Parameter Mode", "DI (with parameter access)“:

In case of a parameter access, the IO-Link communication at the port is started.

Switching signals are interrupted.

Data storage mode

Synchronization of parameter data of IO-Link devices (storing the parameter

master).

If the synchronization is not possible, a diagnostic message is displayed (DS

31

). In this case select option "11 = deactivated, clear" in order to clear the data buffer of the device.

Information about data storage, see

00 activated Synchronization of parameter data activated. The actual data

01 overwrite Synchronization of parameter data activated, the data in the mas-

10 read in Synchronization of parameter data activated. The data in the con-

11 deactivated, clear A Synchronization of parameter data deactivated. The data set in

IO-Link data storage, page 36

(master or device) serve as the reference data.

ter serve as reference data.

nected IO-Link device serve as reference data.

the master is deleted.

of the connected device in the

, see Diagnostic data, page

ER

NOTE

IO-Link devices in accordance with IO-Link specification V1.0 do not support data storage. In this

case the data storage has to be deactivated (data storage mode: 11 = deactivated, clear).

Activate Quick Start-Up

For fast applications (e.g. tool changing applications) th

The start-up time defined in the IO-Link specification (TSD = Device Detection Time) is reduced.

00 no A The start-up time is within the specified range (0.5 s). All IO-Link

devices in accordance with the specification can be operated.

01 yes The start-up time is reduced to approx. 100 ms. It is not supported

by every IO-Link device.

It can thus be necessary to check if the used IO-Link device starts

in this mode.

e start-up time of IO-Link devices can be shortened.

24

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 27

Name Meaning

Value A = default

Device parameterization via GSD

0 inactive A The port is generic or is not parameterized.

1 active In PROFINET the port is parameterized with a specific device type

from the GSDML-file.

Cycle time

00 automatic A The Master reads the minimum cycle time from the connected

device.

0×01 -

0×BF

0.8 to 132.8 ms Settable in steps of 0.8 or 1.6 ms.

(see page 27)

Revision

00 automatic A The Master defines the IO-Link-revision automatically.

01 V1.0 IO-Link-Revision V 1.0 is used.

Process input data invalid

00 diagnostics generated

Diagnosis A

01 no diagnostics gener-

If the process data are invalid, a respective diagnostic message is

generated.

Invalid process data do not cause a diagnostic message.

ated

Diagnosis

Deactivate diagnostics

Influences the sending of IO-Link-Events from the master to the fieldbus. Depending on the parameterization, the master transmits Events based on their priority to the fieldbus or not.

00 no The master transmits all IO-Link Events to the fieldbus.

01 notifications The master transmits all IO-Link Events to the fieldbus except for

IO-Link notifications.

10 Notifications and warn-

ings A

The master transmits all IO-Link Events to the fieldbus except for

IO-Link notifications and warnings.

11 yes The master doesn't transmit any IO-Link Event to the fieldbus.

Process input data mapping

Optimization of the process data mapping for the used fieldbus:

The I/O-Link-data can be swapped depending on the used fieldbus in order to achieve an optimized data

mapping on the fieldbus side.

00 direct A The process data are not swapped.

(0×0123 4567 89AB CDEF)

01 swap 16 bit The bytes are swapped per word.

(0×2301 6745 AB89 EFCD)

10 swap 32 bit The bytes are swapped per double word.

(0× 6745 2301 EFCD AB89)

11 swap all All bytes are swapped.

(0×EFCD AB89 6745 2301)

Process output data mapping

see: Process input data mapping

V01.0| 2016/12

25

Page 28

TBEN-Lx-8IOL

Name Meaning

Value A = default

Vendor ID

0x0000 - 0xFFFF Enter the IDs for the port configuration check.

Device ID

0x0000 - 0xFFFF

VAUX1 Pin 1 Cx (Chy/Chz)

00 24 VDC A The 24 VDC sensor/actuator supply at Pin1 of the connector is

switched on.

01 switchable The 24 VDC sensor/actuator supply at Pin1 of the respective con-

nector is switchable via the process data, see also

put data, page 21

10 Out The 24 VDC sensor/actuator supply at Pin1 of the connector is

switched off.

VAUX2 Pin 2 Cx (Chy)

00 24 VDC A The Class B supply at Pin2 of the respective connector is switched

on.

01 switchable The Class B supply at Pin2 of the respective connector is switch-

able via the process data, see also

21

.

10 Out The Class B supply at Pin2 of the respective connector is switched

off.

.

Process output data, page

Process out-

26

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 29

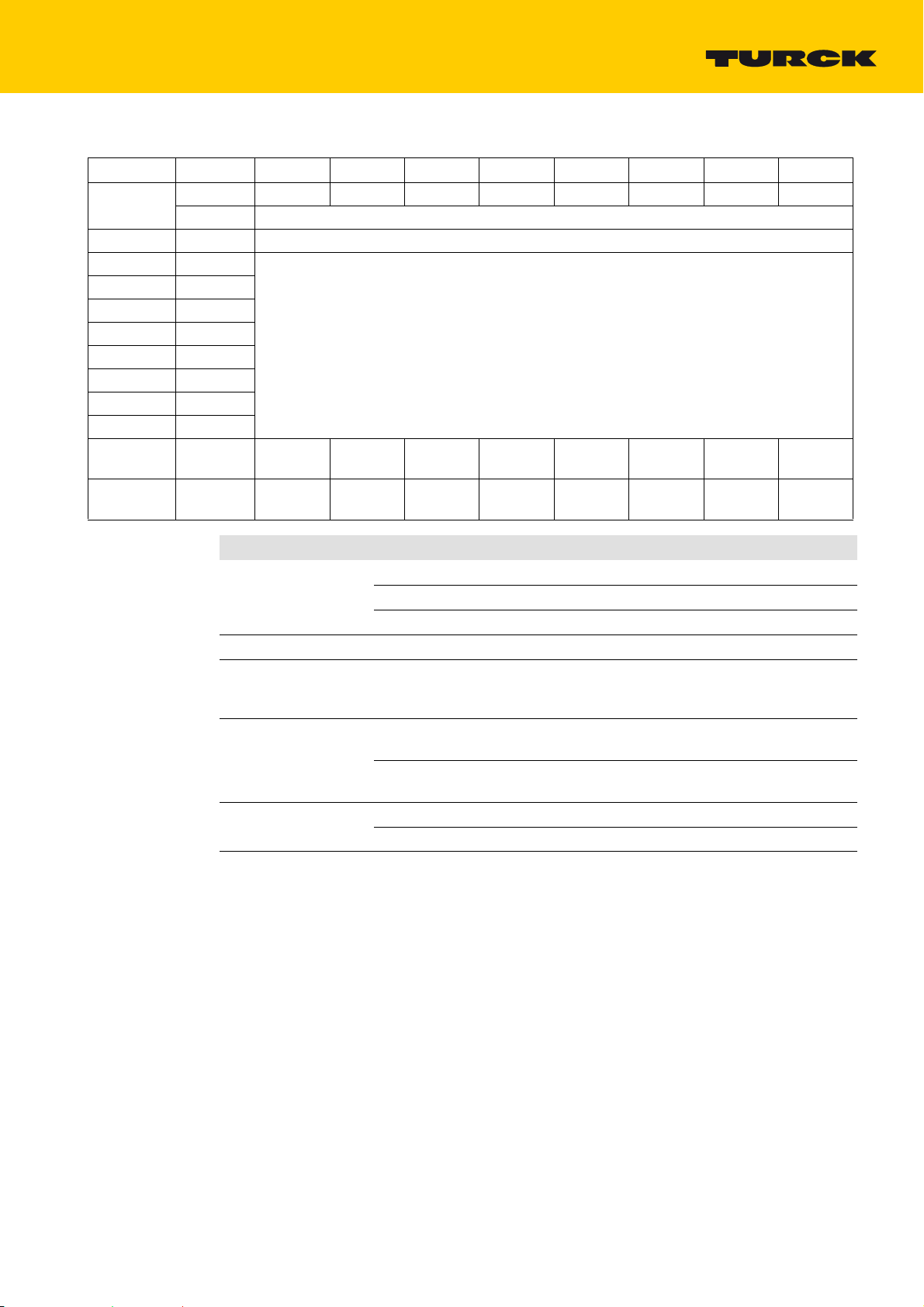

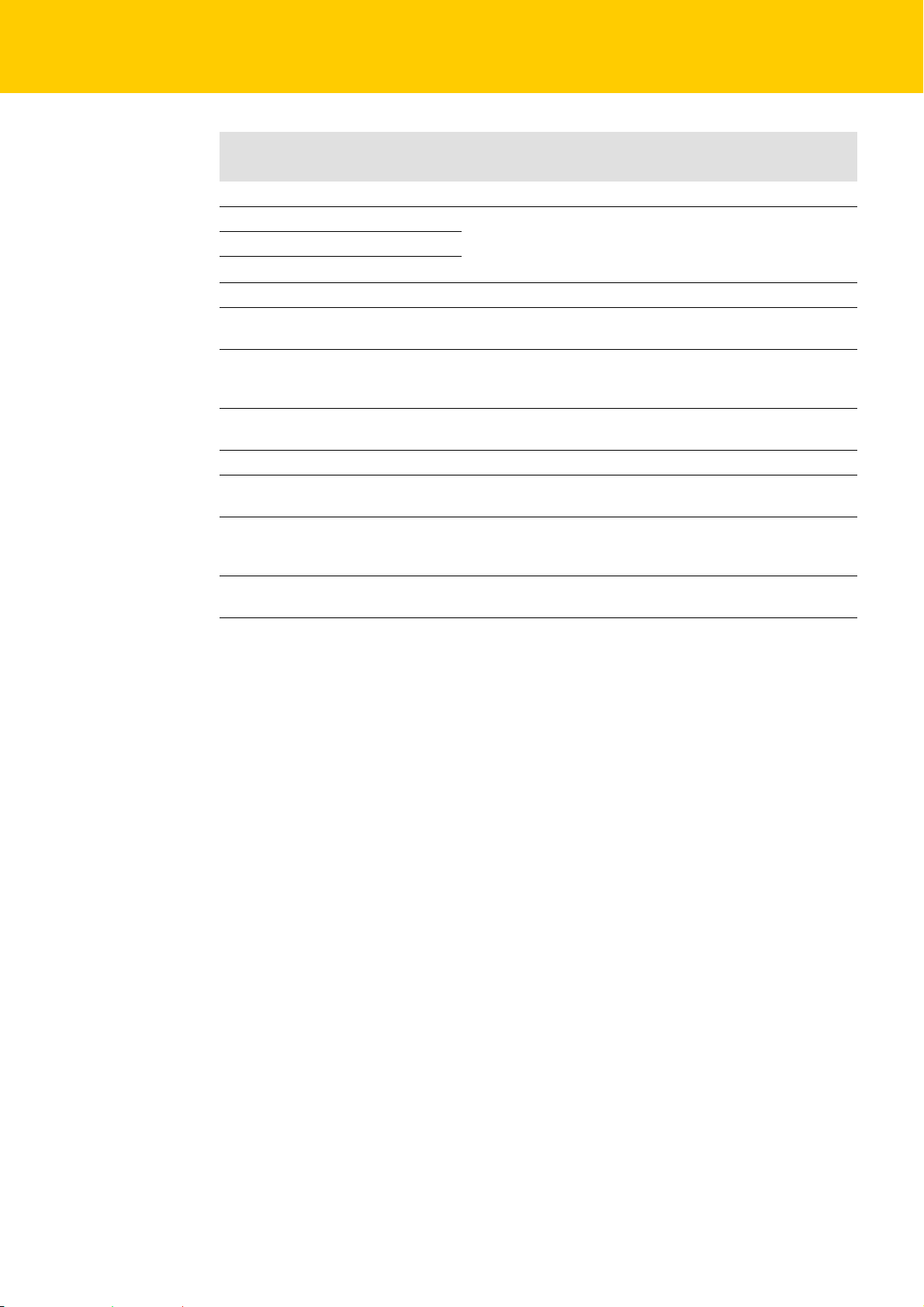

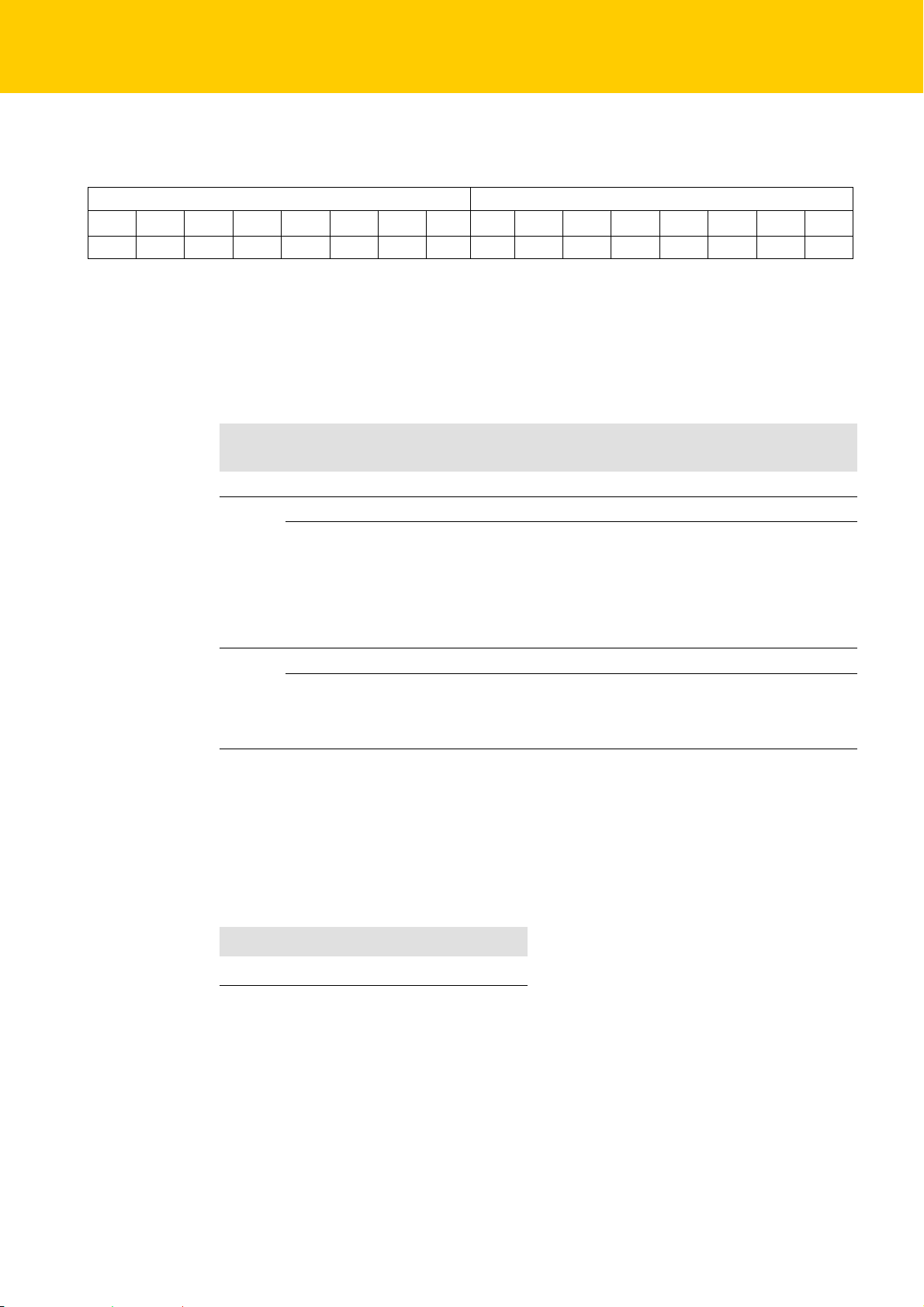

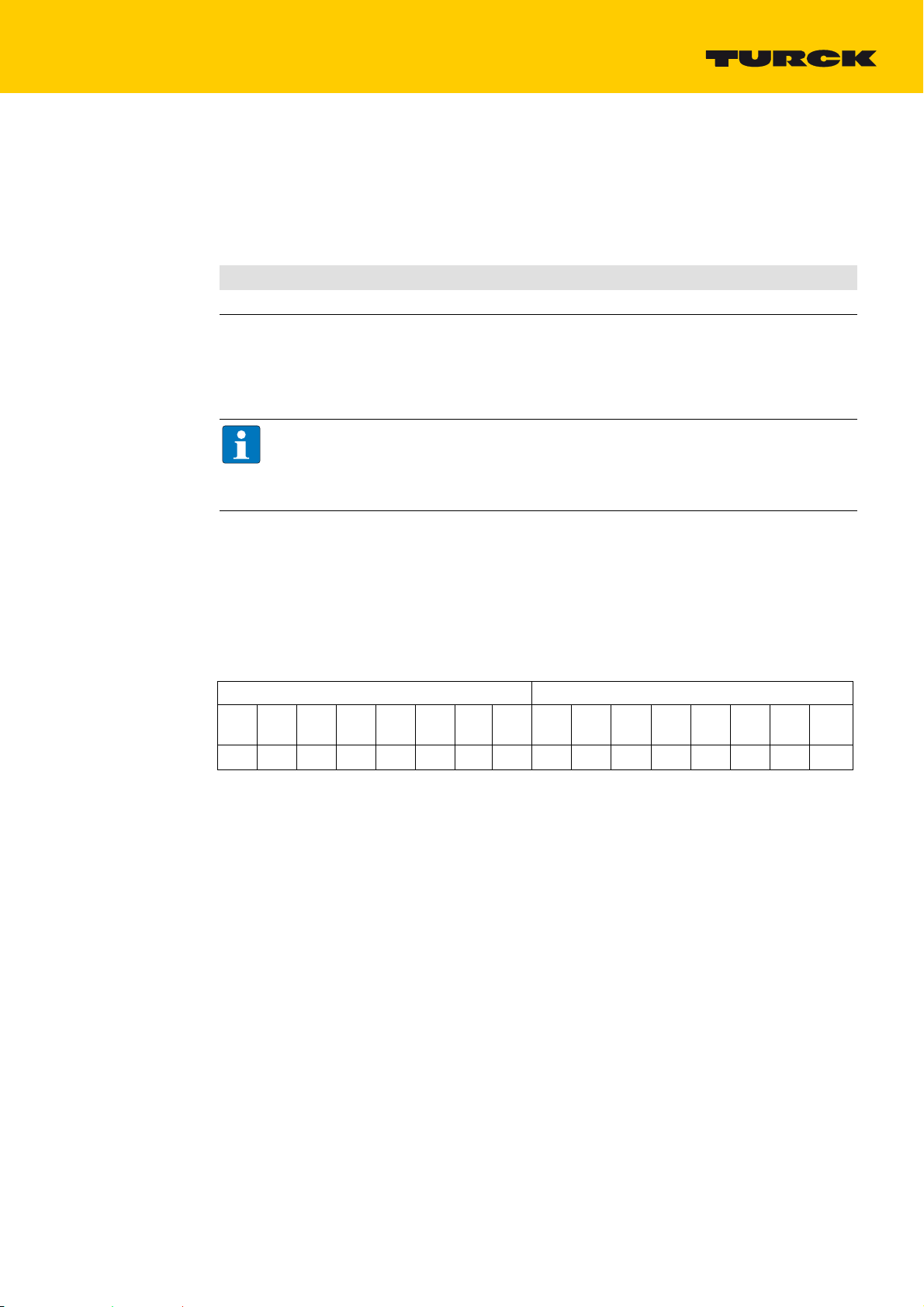

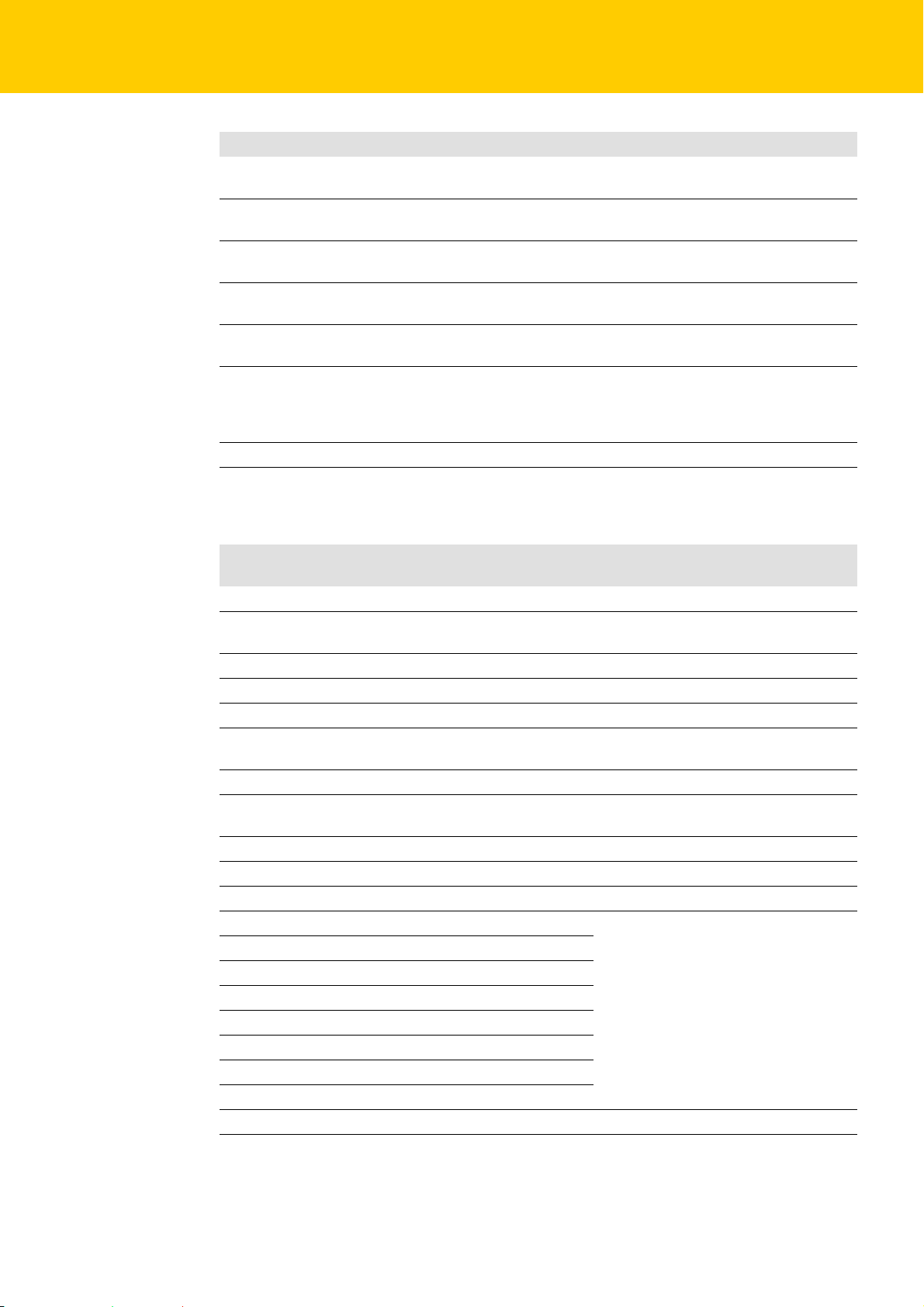

Values for the parameter "cycle time" [ms]:

Time Value Time Value Time Value Time Value Time Value Time Value

auto A 0×00 15.2 0×56 30.4 0×7C 59.2 0×91 89.6 0×A4 120 0×B7

0.8 0×08 16 0×58 31.2 0×7E 60.8 0×92 91.2 0×A5 121.6 0×B8

1.6 0×10 16.8 0×5A 32 0×80 62.4 0×93 92.8 0×A6 132.2 0×B9

2.4 0×18 17.6 0×5C 33.6 0×81 64 0×94 94.4 0×A7 124.8 0×BA

3.2 0×20 18.4 0×5E 35.2 0×82 65.6 0×95 96 0×A8 126.4 0×BB

4 0×28 19.2 0×60 36.8 0×83 67.2 0×96 97.6 0×A9 128 0×BC

4.8 0×30 20 0×62 38.4 0×84 68.8 0×97 99.2 0×AA 129.6 0×BD

5.6 0×38 20.8 0×64 40 0×85 70.4 0×98 100.8 0×AB 131.2 0×BE

6.4 0×40 21.6 0×66 41.6 0×86 72 0×99 102.4 0×AC 132.8 0×BF

7.2 0×42 22.4 0×68 43.2 0×87 73.6 0×9A 104 0×AD - -

8 0×44 23.2 0×6A 44.8 0×88 75.2 0×9B 105.6 0×AE - -

8.8 0×46 24.0 0×6C 46.4 0×89 76.8 0×9C 107.2 0×AF - -

9.6 0×48 24.8 0×6E 48 0×8A 78.4 0×9D 108.8 0×B0 - -

10.4 0×4A 25.6 0×70 49.6 0×8B 80 0×9E 110.4 0×B1 - -

11.2 0×4C 26.4 0×72 51.2 0×8C 81.6 0×9F 112 0×B2 - -

12.0 0×4E 27.2 0×74 52.8 0×8D 83.2 0×A0 113.6 0×B3 - -

12.8 0×50 28 0×76 54.4 0×8E 84.8 0×A1 115.2 0×B4 - -

13.6 0×52 28.8 0×78 56 0×8F 86.4 0×A2 116.8 0×B5 - -

14.4 0×54 29.6 0×7A 57.6 0×90 88 0×A3 118.4 0×B6 - -

automatic: The lowest cycle time supported by the device is taken from the table.

A

V01.0| 2016/12

27

Page 30

TBEN-Lx-8IOL

4.6.1 Adaptation of the process data mapping

The mapping of process data can be adapted application-specifically via the IO-Link-master's

parameterization.

Depending on the used fieldbus, it can be necessary to swap process data word-wise, double wordwise or completely in order to align them to the data structure in the PLC.

The process data mapping is determined channel by channel through the parameters "process

input data mapping" and "process output data mapping"" (see Parameters, page 22).

Example mapping for field buses with Little Endian-format:

Maping from master

fieldbus PLC

Byte (A) Byte (A)

Status Byte 0

Byte 1 Control

PORT1

Byte 2 temperature Low byte 2 byte process

Byte 3 High byte Low byte

PORT2

Byte 4 position Low byte 2 byte process

Byte 5 High byte Low byte

PORT3

Byte 6 Digital signal 0... 7 2 byte process

Byte 7 Digital signal 8 ...15 Digital signal 8 ...15

PORT4

Byte 8 Diagnosis 4 byte process

Byte 9 Counter/

Byte 10 High byte Low byte

Byte 11 MSByte Diagnosis

position value

Low byte High byte

Devices at channel Parametrization

of the channel

data

swap 16 bit)

(

data

swap 16 bit)

(

data

direct)

(

swap all)

data (

Process output data mapping

IO-Link device

temperature High byte

position High byte

Digital signal 0... 7

Counter/

position value

MSByte

A Low byte, the lowest byte Low-Byte

High byte High-Byte

MSByte: Most Significant Byte

28

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 31

4.7 Device status

4.7.1 LED behavior

The following table describes the protocol-independent behavior of the device LEDs.

The protocol specific LED behavior in PROFINET, EtherNet/IP™ and Modbus TCP is described in the

respective chapters.

LED Color Status Meaning Remedy

PWR

ETHx greenon Link established,100 Mbps

ERR greenon No diagnostic message available

greenoff V1 missing or < 18 V DC Check V1

on V1 and V2 OK -

blinking V2 missing or < 18 V DC Check V2

Red on V2 missing or < 18 V DC Check V2

the behavior of the PWR-LED at undervoltage of V2 can be set via parameter "LED behavior (PWR)

at V2 undervoltage.

blinking Ethernet Traffic, 100 Mbps

yellow

- off No Ethernet link. Check the Ethernet connection.

on Link established,10 Mbps

blinking Ethernet Traffic, 10 Mbps

red on Diagnostic message pending

BUS greenon Active connection to a master -

blinking Device is ready for operation -

Red on IP address conflict or restore mode

or timeout

blinking Blink-/wink-command active see also description of LED "right

red/

gree

n

on Autonegotiation and/or waiting

for DHCP-/BootP-address assignment.

control IP addresses in the network

waiting for the device to be ready

for operation

to ERR"

V01.0| 2016/12

29

Page 32

TBEN-Lx-8IOL

LED Color Status Meaning Remedy

IOLx Channel in IO-Link-mode

greenoff No IO-Link communication, diag-

nostics deactivated

flashing IO-Link communication active,

valid process data

Red on No IO-Link communication and/or

module error,

invalid process data

– connect an IO-Link device

– Parameterize the channel as DI if

necessary.

-

Possible causes:

– Sensor supply is below the admis-

sible range,

– IO-Link port is parameterized as

simple digital input,

– No device connected to the mas-

ters,

Red flashing IO-Link communication active and

module error, invalid process data

– No input data received from the

connected device (only valid for

devices with an

input data length > 0),

– the connected device does not

respond on sending

output data (only valid for

devices with an output data

length of > 0).

– connected device sends an error:

"process data invalid".

see also:

Start-up problems - frequent

failure causes, page 111

Channel in DI-mode –

greenoff -

greenon Input signal active –

DXPx greenoff -

greenon In-/ output signal active

Red on Short circuit at output of the

right

to

ERR

white flashing Support for localizing a module if

respective channel

the blink-/wink-command is activated

30

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 33

4.7.2 Diagnostic data

For the diagnostic messages we distinguish between V1/V2 overcurrent diagnostics, DXP-diagnostics, IO-Link-master and IO-Link-device diagnostics.

The „PDINV" diagnostic (process data invalid) can be sent from both devices, IO-Link master or IOLink device.

V1/V2 overcurrent diagnostics

Overcurrent diagnostics for the sensor-/ actuator supply VAUX1 and the Class B supply VAUX2

DXP-diagnostics

Diagnostic messages of the digital channels of the module (DXP 1, 3, 5, 7).

IO-Link master diagnostics

The IO-Link-master reports problems within the IO-Link communication.

IO-Link device diagnostics

The device diagnostics map the IO-Link Event Codes (according to the IO-Link specification) sent

from the IO-Link devices to the diagnostic telegram of the master.

Event Codes can be read from the connected devices by using appropriate device tools (e.g.

IODD-Interpreter).

Further information concerning the IO-Link Event Codes and their meaning can be found in the

IO-Link specification or in the documentation of the connected devices.

4.7.3 Diagnostic telegram

channel Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

V1/V2 V1/V2 overcurrent diagnostics

0

1 VErrV2

DXP DXP-diagnostics

0ERR

1 --------

IO-Link

IO-Link

port 1

IO-Link

port 2

IO-Link

port 3

IO-Link

port 4

IO-Link

port 5

IO-Link

port 6

IO-Link

port 7

IO-Link

port 8

0 EVT1 EVT2 PDINV HWER DSER CFGER PPE -

1

2 + 3

4 + 5

6 + 7

8 + 9

10 +

11

12 +

13

14 +

15

VErrV1

C7K14

C7K15

DXP7

GENER OLV VHIGH VLOW ULVE LLVU OTMP PRMER

VErrV1

C6K12

VErrV2

C6K13

-

VErrV1

C5K10

VErrV2

C5K11

ERR

DXP 5

VErrV1

C4K8

VErrV2

C4K9

-

VErrV1C3

K6K7

ERR

DXP 3

VErrV1C2

K4K5

----

-

VErrV1C1

K2K3

ERR

DXP 1

Device diagnostics Master diagnostics

assignment similar to port 1

VErrV1C0

K0K1

-

V01.0| 2016/12

31

Page 34

TBEN-Lx-8IOL

Bit Meaning Remedy

V1/V2 overcurrent diagnostics

VErrV1

CxChyChz

Overcurrent VAUX1 (pin 1) at Cx for channel y/channel z

0 No overcurrent

1 Overcurrent at the sensor supply at pin 1 of the respective

port:

– C0: Channel 0 and 1

– C1: Channel 2 and 3

– C2: Channel 4 and 5

– C3: Channel 6 and 7

VErrV1

CxChy

Overcurrent VAUX1 (pin 1) at Cx, channel y

0 No overcurrent

1 Overcurrent at the sensor supply at pin 1 of the respective

port:

– C4: Channel 8

– C5: Channel 10

– C6: Channel 12

– C7: Channel 14

VErrV2

CxChy

Overcurrent VAUX2 (pin 2) at Cx, channel y

0 No overcurrent

1 Overcurrent at the Class B supply at pin 2 of the respective

port:

– C4: Channel 9

– C5: Channel 11

– C6: Channel 13

– C7: Channel 15

DXP-diagnostics

ERR DXP x Overcurrent output

0 No overcurrent

1 Overcurrent at the output (if the DXP channel is used as output)

IO-Link master diagnostics

PPE Port parameterization

The port parameters are inconsistent.

The device parameterization via GSD is active, but not working.

Possible causes:

The IO-Link-master did not receive GSDML-parameters for a connected device. The connected device was not parameterized by a PROFINET PLC via GSDML.

The port is in operation mode "IO-Link without validation" or "DI". These modes do not allow

parameterization via GSD.

The data storage mode is active, which means, the parameter is not set to "deactivated,

clear". A device parameterization via GSDML is not possible with activated data storage.

Vendor or Device ID are "0". The connected device can not be identified and is thus not

parameterizable.

32

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 35

Bit Meaning Remedy

CFGER Wrong or missing device

The connected device does not match the

channel configuration or there is no device

connected to the channel.

This diagnostic message depends on the

parameterization of the channel (see parame-

page 23).

ters,

Change the parameterization of the IOLink port at the master.

Correct the vendor-ID, device-ID, etc.

The parameterization can be done by

teaching the master via IOL_CALL using

the port function Subindex 67: Teach

Mode

tion.

DSER data storage error

Possible causes:

– Data storage mismatch IO-Link device in accordance with IO-Link

V1.0 connected.

Deactivate the data storage.

To do so, set parameter

Data storage mode" to "deactivated,

"

clear", see

The data storage buffer contains data of

another device.

Clear the data storage buffer of the master.

To do so, set the parameter "Data stor-

age mode

page 24, and re-activate the data storage

if necessary.

– Overflow of the data storage buffer Clear the data storage buffer of the master.

To do so, set the parameter "Data stor-

age mode

page 24, and re-activate the data storage

if necessary.

– Parameter access for data storage not possi-

ble

Master/device diagnostics

PDINV Process input data invalid

The IO-Link master or the IO-Link device

report invalid process input data.

The connected device may be locked for

parameter changes or for data storage.

Check the status of the IO-Link index

"Device Access Locks" (index 0×C) of the

connected device and unlock the device.

The connected device is not in status

"operate", which means, it is not ready for

operation.

Possible sources:

The connected device does not match the

configured one, additional diagnostic

message

Certain IO-Link devices send a "process

input data invalid"-diagnosis if the process

value cannot be measured.

Deactivate the sending of the "process

input data invalid"-diagnosis for the

respective port. To do so, change the

parameter "

invalid

see page 25.

or via a manual port parameteriza-

page 24.

" to "deactivated, clear", see

" to "deactivated, clear", see

Wrong or missing device.

Process input data

" to "no diagnostics generated",

V01.0| 2016/12

33

Page 36

TBEN-Lx-8IOL

Bit Meaning Remedy

Device diagnostics

For the exact specification of the device diagnostics, please read the device documentation of the device

manufacturer.

HWER Hardware error

General hardware error or device malfunction.

EVT2 Out-of-specification events

An Out-of-Specification Event in accordance with the IO-Link specification occurred.

EVT1 Maintenance events

A Maintenance Event in accordance with the IO-Link specification occurred, maintenance

necessary.

PRMERR Parameterization error

The connected device reports a parameterization error (loss of parameters, no parameter

initialization, etc.)..

OTMP Overtemperature

Temperature diagnostic message at the connected device.

LLVU Lower limit value underrun

The process value lies under the parameterized measurement range or the chosen measurement range has been chosen too high.

ULVE Upper limit value exceeded

The process value exceeds the parameterized measurement range or the chosen measurement range has been chosen too low.

VLOW Undervoltage

One of the voltages at the connected device is below the defined range.

VHIGH Overvoltage

One of the voltages at the connected device is below the defined range.

OLV Overload

The connected device detected an overload.

GENER Common error

The device sends an error (device status 4, in accordance with IO-Link specification), which

is not clearly specified.

Read out the device Event Codes in order to be able to specify the error more precisely.

34

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 37

4.7.4 Status and control word

Status word

EtherNet/IP™

Modbus

Byte 0 Byte 1

Byte 1 Byte 0

Name Value Description

COM 0 -

DIAG 0 -

FCE 0 -

V1 0 -

V2 0 -

PROFINET Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

V2 - DIAG

-FCE- - -COMV1 -

1 Internal error, the device-internal communication is disturbed.

1 Diagnostics available at the device.

1 The Force Mode is activated, which means, the actual output values may no

match the ones defined and sent by the field bus.

1 System power supply too low (< 18 V DC).

1 V2 too low (< 18 V DC).

The status word is mapped into the module's process data.

EtherNet/IP™

In EtherNet/IP™, the mapping can be disabled (seeGateway Class (VSC 100), GW Status Word,

page 69 and GW Control word, page 69).

Modbus TCP

see Register 0x100C: Module status, page 50

PROFINET

see PROFINET-diagnostics - TBEN-Lx-8IOL, page 82

Control word

The control is not in use.

ATTENTION!

Activate/deactivate the Status and Control Word in EtherNet/IP™

Changes in the process data mapping

Observe that activating/deactivating the Status and Control Word causes changes in

the process data mapping.

V01.0| 2016/12

35

Page 38

TBEN-Lx-8IOL

IO-Link-Master

(IOLM)

IO-Link-Device

(IOLD)

DS_UPLOAD_FLAG

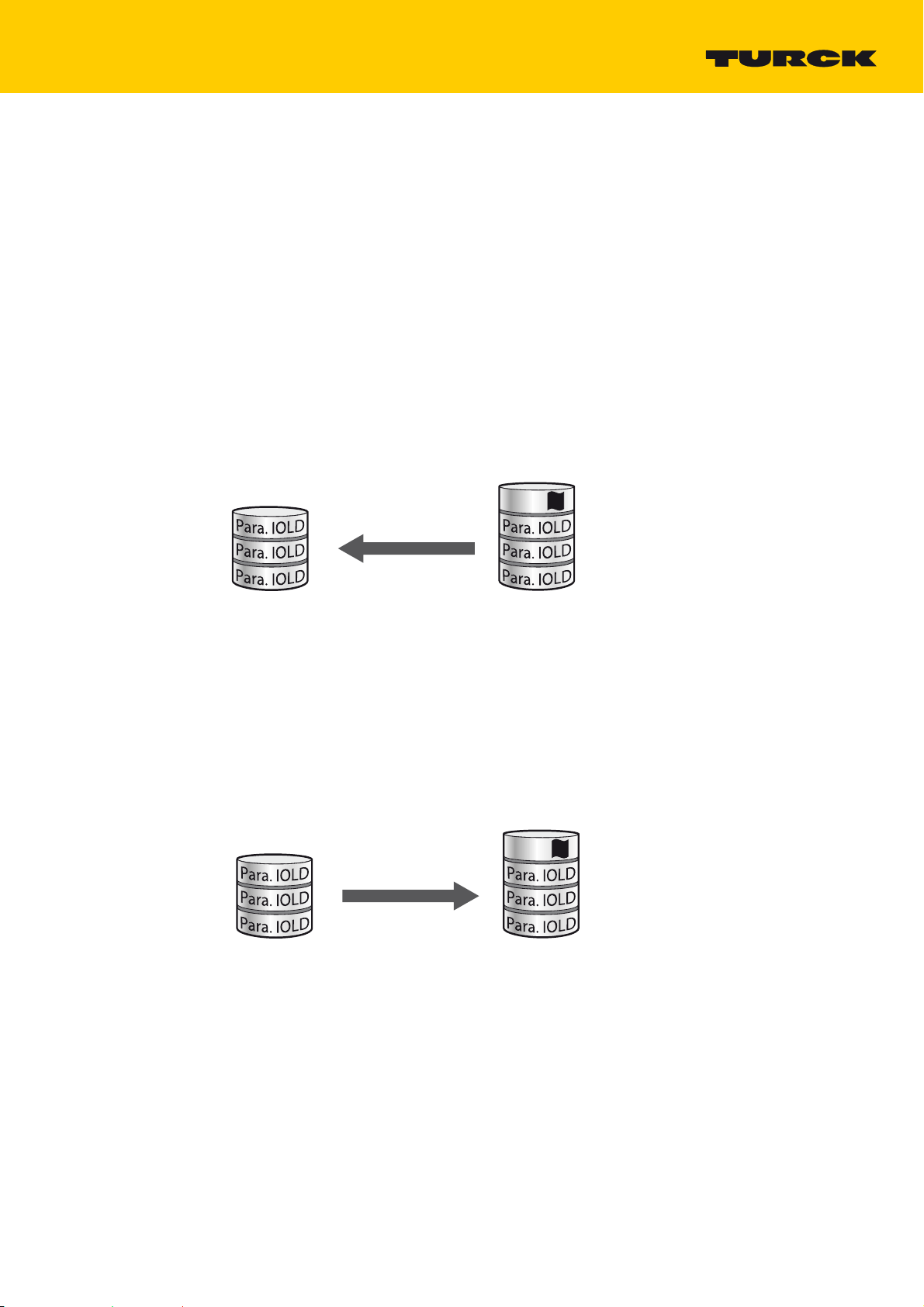

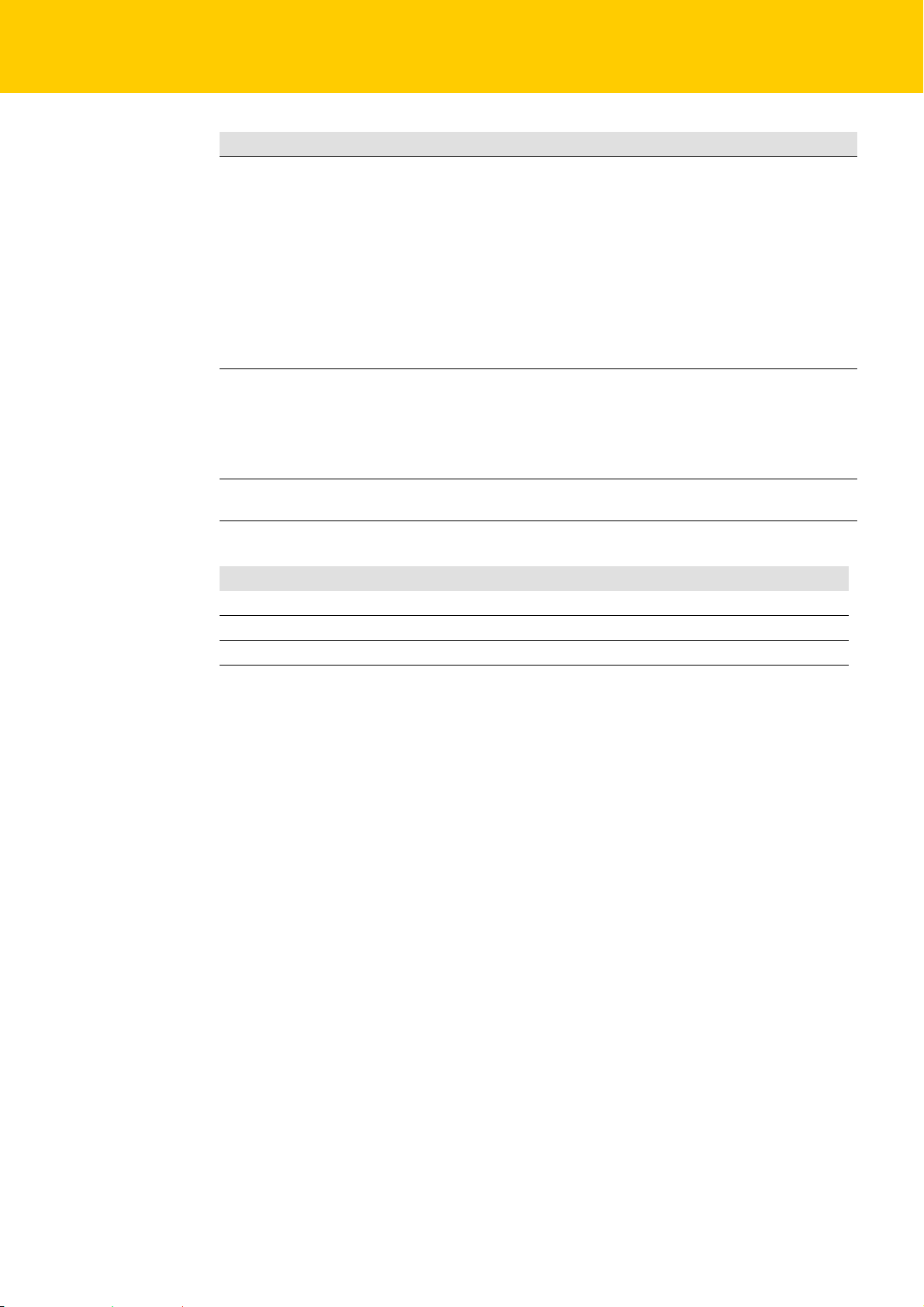

4.8 IO-Link data storage

4.8.1 General

Data storage allows to change an IO-Link device when maintenance is required without any configuration or parameterization.

The IO-Link master, as well as the IO-link device, store the device parameters. The data storage

mechanism serves for synchronizing these different data storage buffers.

In case of a device change, the master writes the stored device parameters to the new device. The

application can be re-started without any further intervention using a configuration tool or similar.

In the IO-Link master, the data storage mode can be set using the parameter "data storage mode"

(see Parameters, page 22).

data storage mode

00 = activated (page 37)

01 = overwrite (see page 39)

10 = read in (see page 39)

11 = deactivated, clear (see page 39)

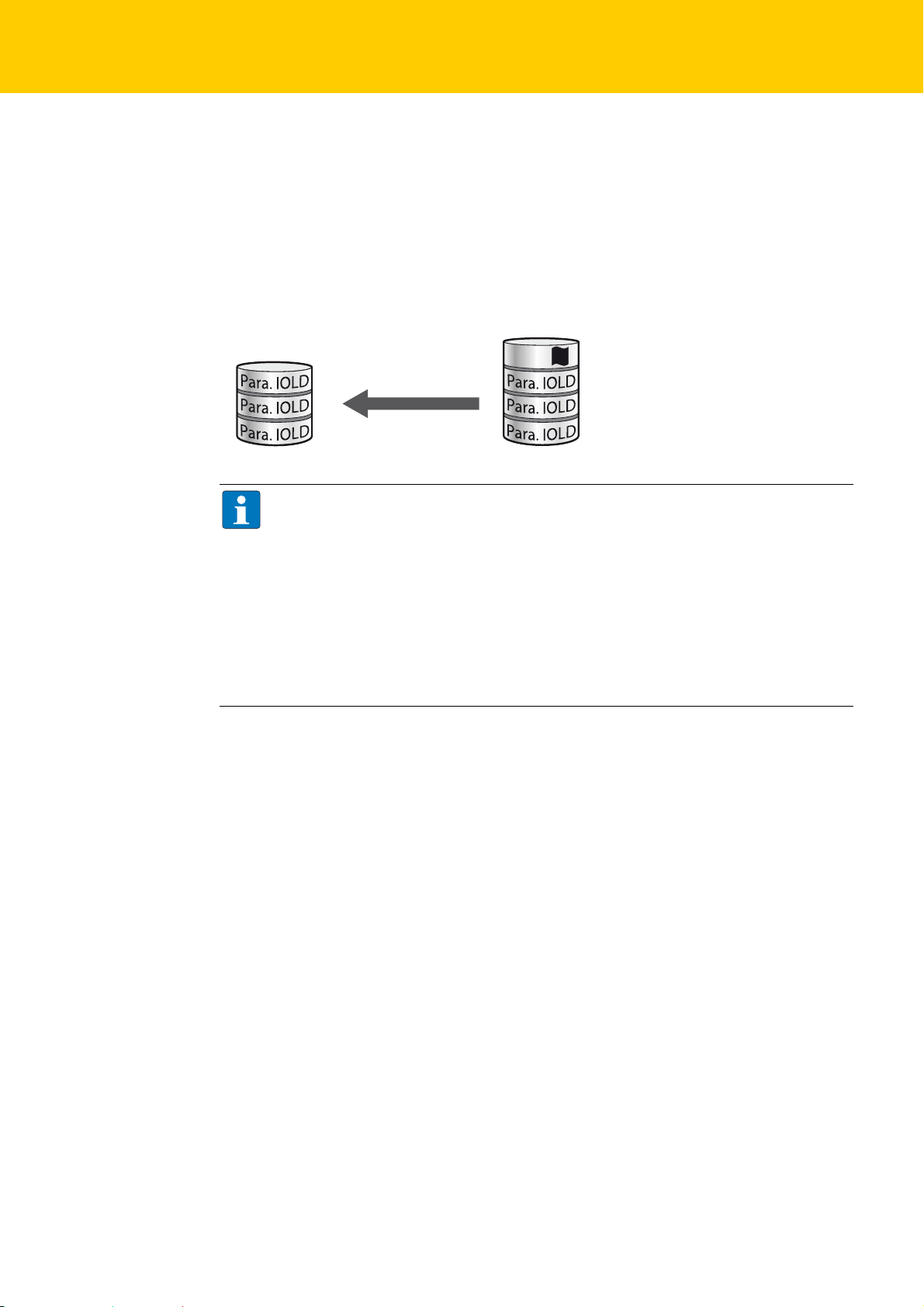

General principle of the data storage mechanism

Para. IOLD = parameter data of the IO-Link device

A change of parameters in the device is indicated by the status of the DS_UPLOAD_FLAG bit:

DS_UPLOAD_FLAG:

0 = no changes in the device's parameter set

1 = changes in the device's parameter set (e. g. via DTM, at the device, etc.)

36

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 39

4.8.2 Parameter "data storage mode" = activated

1

IO-Link-Master

IO-Link-Device

0

IO-Link-Master

IO-Link-Device

The synchronization of the parameter sets is bidirectional.

The actual data set (master or device) is valid:

The following applies:

–

The data set in the device is actual, if DS_UPLOAD_FLAG = 1

– The data set in the master is actual, if DS_UPLOAD_FLAG = 0

Parameterizing a device in the installation:

A device, which is already used in the installation, is for example parameterized via a DTM.

Prerequisites:

The IO-Link device is already connected to the master.

DS_UPLOAD_FLAG = 1

changes in the device's parameter see

Para. IOLD

device

Maintenance - exchange device in delivery status:

A defective device is replaced by a new device in delivery status.

Prerequisites:

The new IO-Link device has not been connected to the master before.

DS_UPLOAD_FLAG = 0

no changes in the device's parameter set

Para. IOLD

device

= parameter data of the IO-Link

= parameter data of the IO-Link

V01.0| 2016/12

37

Page 40

TBEN-Lx-8IOL

1

IO-Link-Master

IO-Link-Device

Maintenance - exchange device with eventually modified parameter set:

A defective device is replaced by a new device with a parameter set that was already changed before (for

example via DTM).

Prerequisites:

The new IO-Link device has not been connected to the master before.

DS_UPLOAD_FLAG = 1

changes in the device's parameter see

Para. IOLD

device

= parameter data of the IO-Link

NOTE

If a device change is necessary when data storage is activated, the following has to be

observed:

An IO-Link exchange device with unknown parameter data should be reset to factory

defaults before connecting it to the master.

This prevents unknown device parameter settings to be downloaded to the master when

establishing the connection.

Turck IO-Link devices can be reset to factory settings via a system command using a

generic IO-Link-DTM and the device-specific IODD.

For the reset of third party devices, please read the corresponding manufacturer documentation.

38

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 41

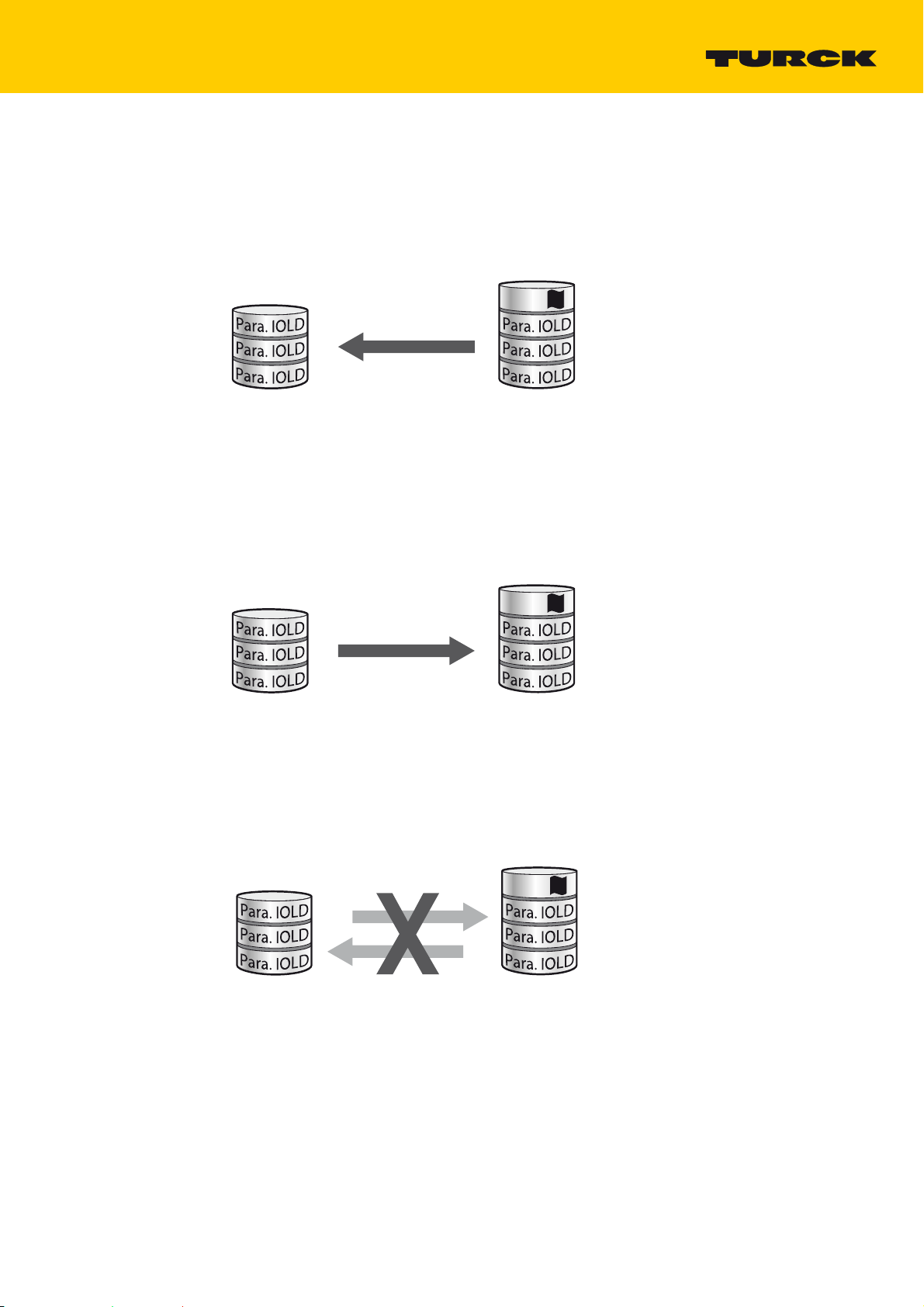

4.8.3 Parameter "data storage mode" = read in

1

IO-Link-Master

IO-Link-Device

1

IO-Link-Master

IO-Link-Device

IO-Link-Master

IO-Link-Device

The data set in the device is always the reference data set.

The synchronization of the parameter sets is unidirectional towards to the master.

The status of the DS_UPLOAD_FLAG is ignored.

4.8.4 Parameter "data storage mode" = overwrite

The data set in the master is always the reference data set.

The synchronization of the parameter sets is unidirectional towards to the device.

The status of the DS_UPLOAD_FLAG is ignored.

Para. IOLD = parameter data of the IO-Link

device

4.8.5 Parameter "data storage mode" = deactivated, clear

The data set in the master is deleted.

The synchronization of parameter sets is deactivated.

Para. IOLD = parameter data of the IO-Link

device

Para. IOLD = parameter data of the IO-Link

device

V01.0| 2016/12

39

Page 42

TBEN-Lx-8IOL

4.9 IO-Link - functions for acyclic communication

The acyclic access to the data of IO-Link devices is realized via IO-Link CALLs.

Therefore it is necessary to distinguish between data of an IO-Link master or of an IO-Link device.

The addressing of the IO-Link CALL is realized via the so called Entity_Port- It defines which device

is addressed via the CALL:

Entity_Port 0 = IO-Link master module (IOLM - TBEN-Lx-8IOL)

Entitiy_Port 1 = IO-Link device at 1st IO-Link-port

...

Entitiy_Port 8 = IO-Link device at 8th IO-Link-port

4.9.1 Port functions for port 0 (IO-Link master)

IO-Link-Index (Port function invocation)

The access to the IO-Link master functionalities (port 0) is done via index:

65535

Subindex 64: Master Port Validation Configuration

Entity_

Port

0 64 w max. 72 byte This object serves for writing a defined config-

IO-Link

subindex

Read

Write

Length Description

Subindex 66: Set Default Parameterization

Entity_

Port

0 66 w 4 byte Writing this object sets the IO-Link master

Structure of the reset command:

Byte 3 Byte 2 Byte 1 Byte 0

0xEF 0xBE 0xAD 0xDE

IO-Link

subindex

Read

Write

Length Description

uration of the IO-Link ports into the master.

back to factory settings. Any parameter setting and configuration is overwritten. The data

storage buffer is deleted as well.

40

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 43

Subindex 67: Teach Mode

Entity_

Port

0 67 w 1 byte The master reads all data (device-Id, ven-

IO-Link

subindex

Read

Write

Length Description

dor-ID, serial number, etc.) from the connected device and saves them. All all previously saved device data are overwritten.

Structure of the teach command:

Byte 0

0x00 Teaching all 4 ports

0x01 Teaching port 1

0x02 Teaching port 2

0x03 Teaching port 3

0x04 Teaching port 4

0x05 - 0xFF reserved

V01.0| 2016/12

41

Page 44

TBEN-Lx-8IOL

Subindex 68: Master Port Scan Configuration

Entity_

Port

0 68 r max. 120 byte This object serves for reading the

IO-Link

subindex

Read

Write

Length Description

configuration of the IO-Link devices connected to the IO-Link master.

28 byte are returned per IO-Link port

Structure of the answer telegram:

IO-Link

Port

Port 1 Vendor_ID 2 byte UINT16 Vendor ID of the connected device

Port 2 Structure similar to port 1

Port 3

Port 4

Content Length Format Description

Device_ID 4 byte UINT32 Device-ID of the connected device

Function_ID 2 byte UINT16 reserved

Serial_Number 16 byte String Serial number of the connected device

COM_Revision 1 byte UINT8 IO-Link version

Proc_In_Length 1 byte UINT8 Process input data length of the con-

nected device

Proc_Out_Length 1 byte UINT8 Process output data length of the con-

nected device

Cycle time UINT8 Cycle time of the connected device

42

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 45

Subindex 69: Extended Port Diagnostics

Entity_

Port

0 69 r max. 8 byte This object serves for reading the

IO-Link

subindex

Read

Write

Length Description

Extended Port Diagnostics.

Structure of the Extended Port Diagnostics:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0

Byte 1 - WD MD PDI_H - PDI_E NO_PD -

Byte 3

Byte 4

Diagnostic bit Meaning

NO_DS The parameterized port mode (see Parameters, page 22) does not support data

NO_SIO TCYC - - DS_F NO_DS - -

Device status according to IO-Link specification (see Device Status, page 44)

storage.

Remedy:

– Change the parameterization of the port.

DS_F Error in the data storage, synchronization not possible

Possible causes:

– Connected device does not support data storage.

– Overflow of the data storage buffer.

Remedy:

– Connect a device that supports data storage.

– Clear the data storage buffer.

– Deactivate the data storage.

TCYC The device does not support the cycle time parameterized in the master.

Remedy:

– Increase the cycle time set in the master.

NO_SIO The device does not support the standard DI mode (see parameter

22

).

Remedy:

Mode, page

– Select the IO-Link mode for this port.

NO_PD No process data available The connected device is not ready for operation.

Remedy:

– Checking the configuration

PDI_E The connected device reports invalid process data in accordance with IO-Link speci-

fication V1.0.

V01.0| 2016/12

43

Page 46

TBEN-Lx-8IOL

Device Status

Diagnostic bit Meaning

PDI_H The connected device reports invalid process data in accordance with IO-Link speci-

fication V1.1.

MD Missing device: No IO-Link device detected

Remedy:

– Check the IO-Link cable.

– Change the device.

WD Wrong device detected: one or more parameters of the connected device (Vendor ID,

Device ID, serial number) does not/do not match the data which are stored in the

master for this device.

Remedy:

– Change the device.

– Adapt the master parameterization (see parameter Mode, page 22)

Value Meaning

0 Device works correctly

1 Maintenance Event

2 Out-of-Specification Event

3 Functional check

4 error

5-255 reserved

44

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 47

4.10 IO-Link and Turck device DTMs

FDT enables a fieldbus and system independent engineering environment to be set up. Generic

DTMs allow any type of sensor and actuator to be integrated easily in the system.

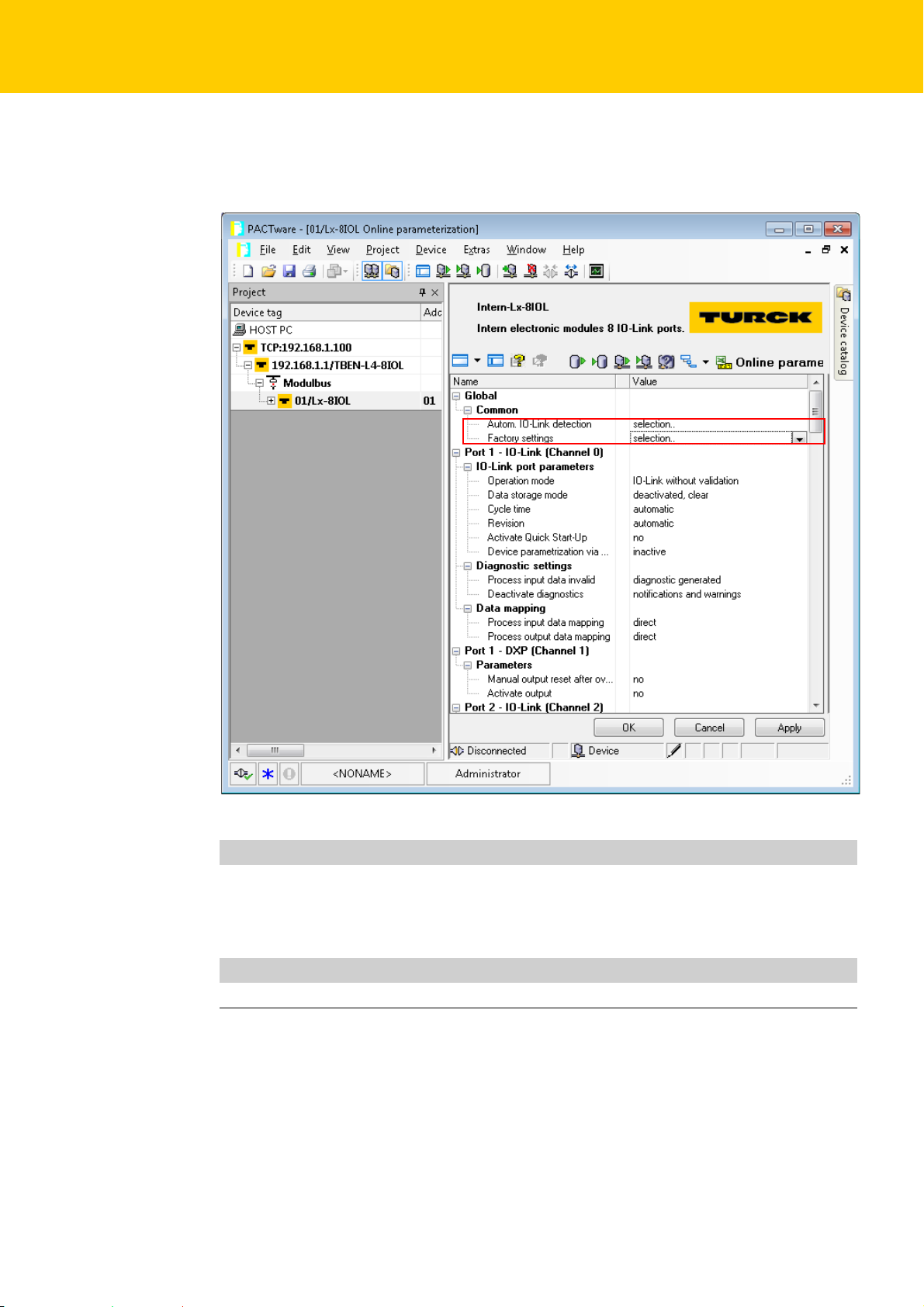

4.10.1 Topology-Scan

The Topology Scan in PACTware also allows the read-in of an IO-Link configuration down to the IOLink device.

IO-Link devices, known in PACTware, are added to the IO-Link ports of the master.

Therefore, either the respective sensor DTMs in PACTware or the sensor IODDs via IODD DTM Configurator have to be installed.

Fig. 4: Topology Scan in PACTware

V01.0| 2016/12

45

Page 48

TBEN-Lx-8IOL

4.10.2 Special DTM parameters

The Turck DTMs offer, besides the normal parameters of the IO-Link master modules, special function for configuring the master module.

46

Fig. 5: Special DTM-function within Online parameterization.

Automatic IO-Link detection

The data of the connected device/ the connected devices are read-in by the master.

This function affects, depending on the parameter group in which it is activated, all ports or only one special

port. In the "Common"-group it is valid for the whole module, in the "Port configuration" group it is only valid

for the respective port.

Factory settings

The master is set back to its factory settings.

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 49

5 TBEN-Lx-8IOL with Modbus TCP

5.1 General

5.1.1 Implemented Modbus functions

The modules TBEN-Lx-8IOLsupport the following Modbus TCP functions for accessing process data,

parameters, diagnostics and other services:

Function codes

No. Function

Description

1 Read Coils

Reading multiple output bits

2 Read Discrete Inputs

Reading multiple input bits

3

4 Read Input Registers

5 Write Single Coil

6

15 Write Multiple Coils

16 Write Multiple Registers

23

Read Holding Registers

Reading multiple output registers

Reading multiple input registers.

Writing a single output bit.

Write Single Register

Writing a single output register.

Writing multiple output bits.

Writing multiple output registers.

Read/Write Multiple Registers

Reading and writing of multiple registers

5.1.2 Modbus registers

V01.0| 2016/12

NOTE

For the register mapping of the different Modbus addressing methods see page 49.

47

Page 50

TBEN-Lx-8IOL with Modbus TCP

Register assignment

Address (hex.) Access

ro = read only

rw = read/write

0x0000 0x01FF ro Process data of inputs

0x0800 0x09FF rw Process data of outputs

0x1000 0x100B ro Module identifier

0x100C ro Module status

0x1010

0x1016

0x1017 ro Register mapping revision

0x1020 ro Watchdog, actual time [ms]

0x1120 rw Watchdog predefined time [ms] (default: 0)

0x1130 rw Modbus connection mode register, page 50

0x1131 rw Modbus connection timeout in sec. (default: 0 = never).

0x113C 0x113D rw Modbus parameter restore, page 51

0x113E 0x113F rw Modbus parameter save, page 51

0x1140 rw Deactivate protocol

0x1141 ro Active protocol

0x1150 rw LED behavior (PWR) at V2 undervoltage

0x2400 ro V1 [mV]: 0 at < 18 V

0x2401 ro V2 [mV]: 0 at < 18 V

0x8000 0x8400 ro Process data inputs, see

0x9000 0x9400 rw Process data outputs, see

0xA000 0xA400 ro Diagnostics, see Diagnostic data, page 31

0xB000 0xB400 rw Parameters

ro reserved

Description

see Register 0x100C: Module status, page 50

Register mapping revision (always 2, if not, mapping is incompatible with this description)

see Error behavior (watchdog), page 53

page 50

(reset of parameters to default values)

(permanent storing of parameters)

Deactivates explicitly the selected Ethernet-protocol:

Bit 0 =Deactivate EtherNet/IP™

Bit 1 =Deactivate Modbus TCP

Bit 2 =Deactivate PROFINET

Bit 15 = Deactivate web server

Bit 0 = 1: EtherNet/IP™ active

Bit 1 = 1: Modbus TCP active

Bit 2 = 1: PROFINET active

Bit 15 = 1: web server active

Bit 0:

0 = green

1 = red

Process input data, page 19

Process output data, page 21

48

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 51

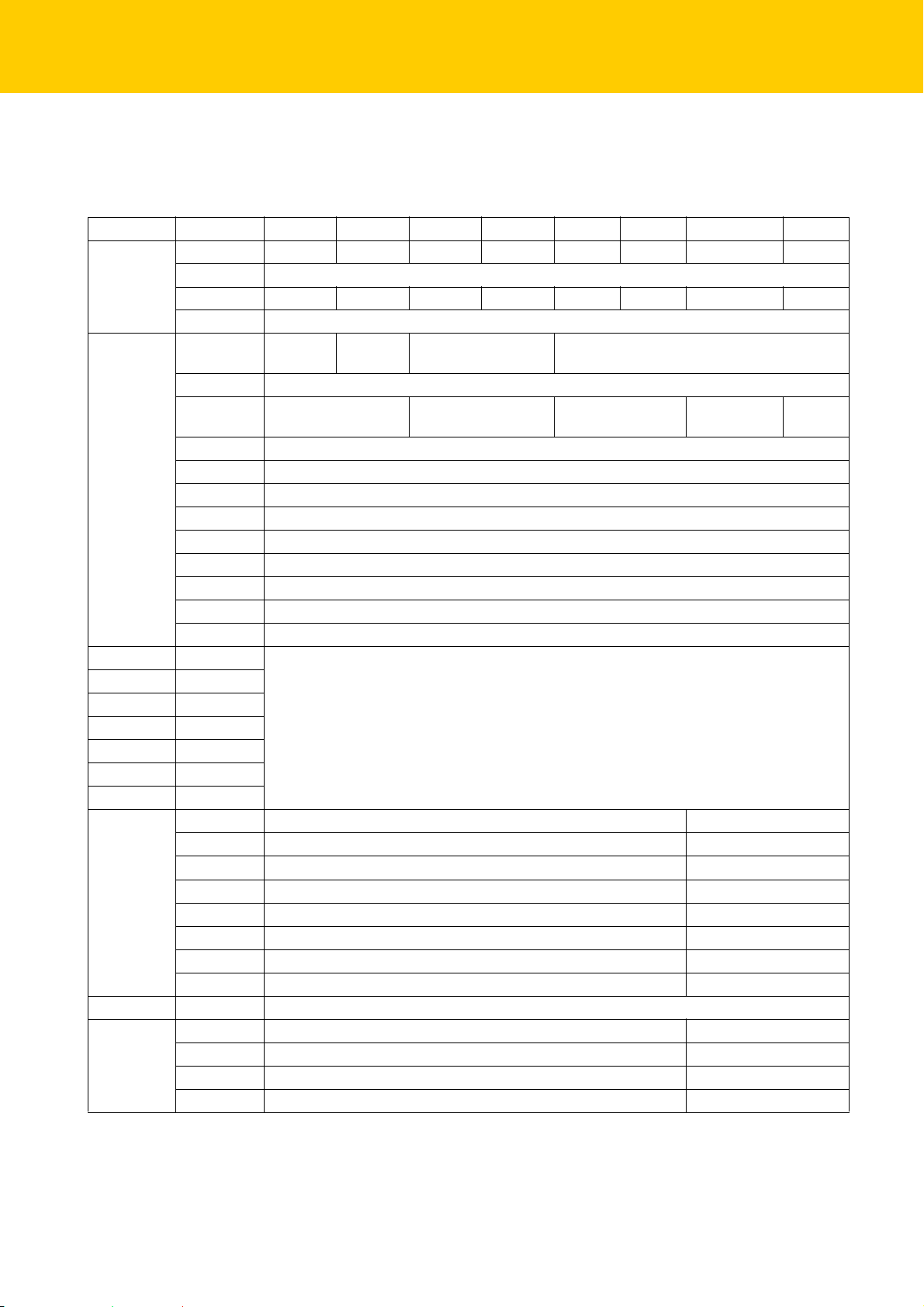

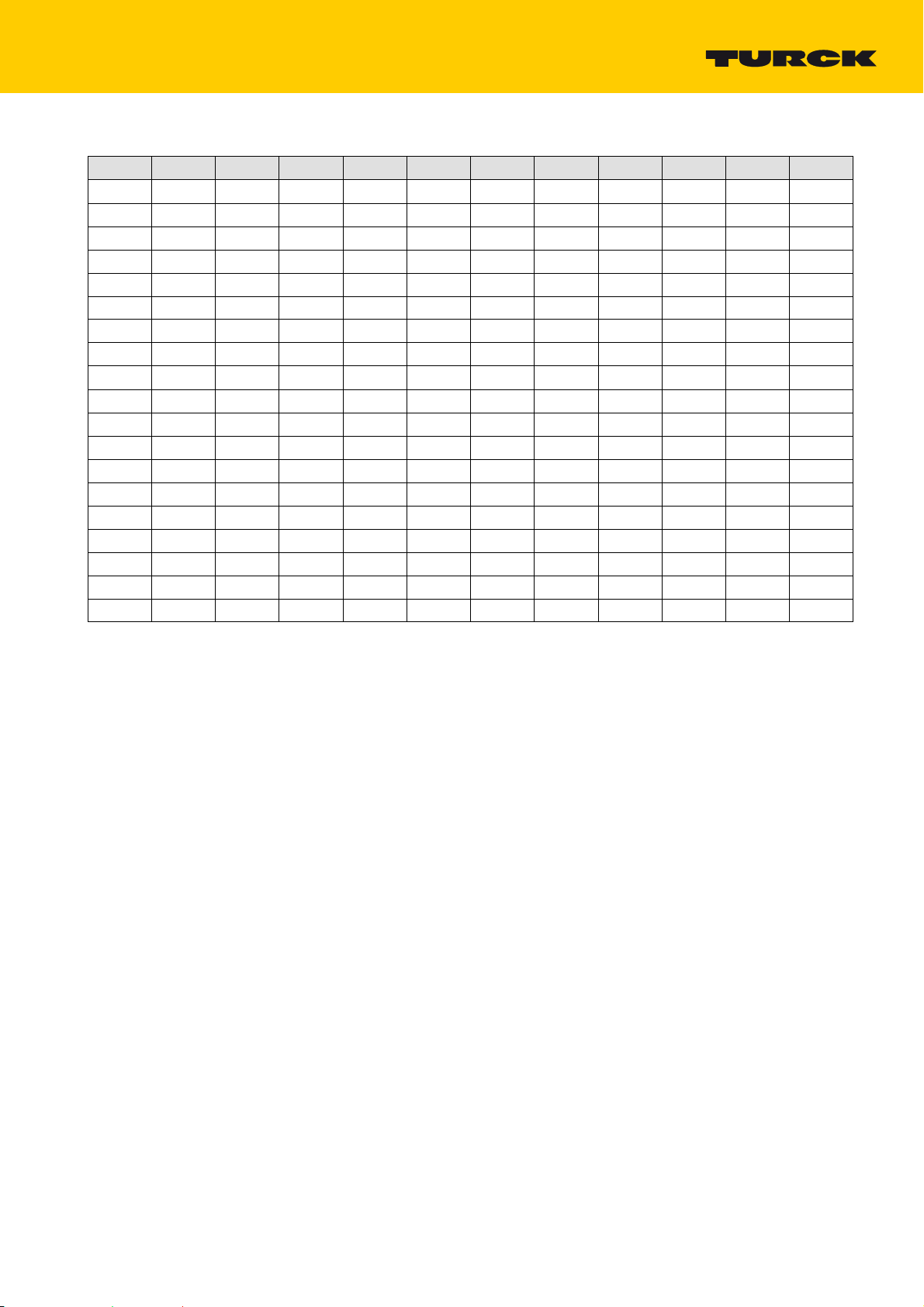

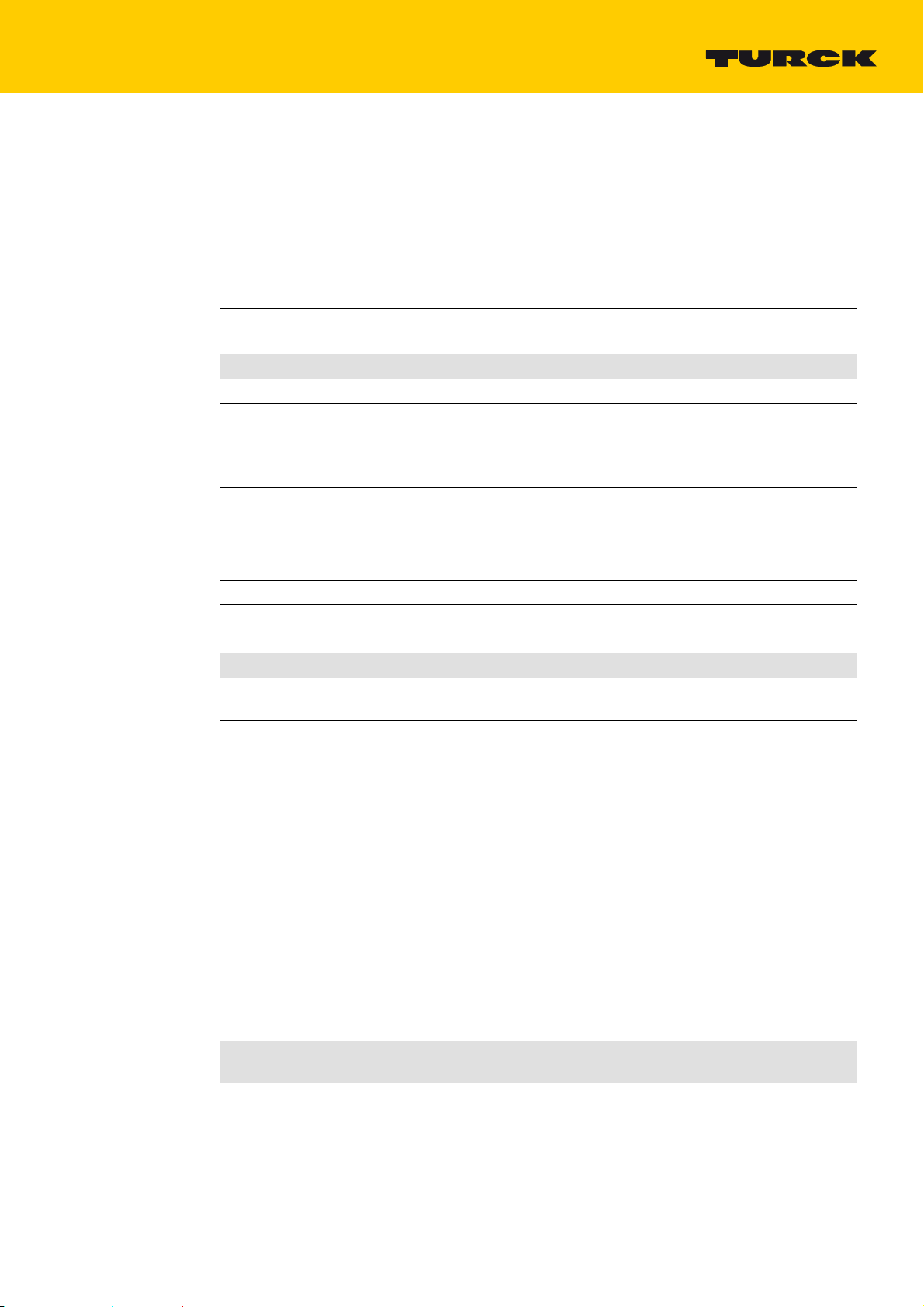

The following table shows the register mapping for the different Modbus addressing methods:

Description Hex Decimal 5-digit Modicon

Inputs 0x0000

0x01FF

Outputs 0x0800

0x09FF

Module identifier 0x1000

0x100B

Module status 0x100C 4108 44109 404109

Watchdog, actual time 0x1020 4128 44129 404129

Watchdog, predefined time 0x1120 4384 44385 404385

Modbus connection mode register 0x1130 4400 44401 404401

Modbus connection timeout in sec. 0x1131 4401 44402 404402

Modbus parameter restore, 0x113C

0x113D

Modbus parameter save, 0x113E

0x113F

Deactivate protocol 0x1140 4416 44417 404417

Active protocol 0x1141 4417 44418 404418

V1 [mV]: 0x2400 9216 49217 409217

V2 [mV]: 0x2401 9217 49218 409218

Process data inputs 0x8000,

0x8001

Process data outputs 0x9000,

0x9001

Diagnostics 0xA000,

00A001

Parameters 0xB000,

0xB001

0

511

2048

2549

4096

4107

4412

4413

4414

4415

32768

32769

36864,

36865

40960,

40961

45056,

45057

40001

40512

42049

42560

44097

44108

44413

44414

44415

44416

- 432769

- 436865,

- 440961,

- 445057,

400001

400512

402049

402560

404097

404108

404413

404414

404415

404416

432770

436866

440962

445058

V01.0| 2016/12

49

Page 52

TBEN-Lx-8IOL with Modbus TCP

Register 0x100C: Module status

This register contains the module's status word.

Byte 1 (MSB) Byte 0 (LSB)

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-FCE----V1-V2------DIAG

see also:

Chapter 4.7.4, Status and control word, page 35

Register 0x1130: Modbus connection mode

This register defines the behavior of the Modbus connections:

Bit Name

– Description

15 2 reserved

1

0 MB_OnlyOneWritePermission

MB_ImmediateWritePermission

– 0: With the first write access, a write authorization for the respective Modbus-connection is

requested. If this request fails, an exception response with exception-code 01h is generated. If

the request is accepted, the write access is executed and the write authorization remains active

until the connection is closed.

– 1: The write authorization for the respective Modbus-connection is already opened during the

connection establishment. The first Modbus-connection thus receives the write authorization,

all following connections don’t (only if bit 0 = 1).

– 0: all Modbus-connections receive the write authorization

– 1: Only one Modbus-connection can receive the write permission. A write permission is opened

until a Disconnect. After the Disconnect the next connection which requests a write access

receives the write authorization.

Register 0x1131: Modbus Connection Timeout

This register defines after which time of inactivity a Modbus-connection is closed through a Disconnect.

Behavior of the BUS LED

In case of a Connection Timeout the BUS LED's behavior is as follows:

Connection-Timeout BUS-LED

time-out green, blinking

50

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 53

Register 0x113C and 0x113D: Restore Modbus-Connection-Parameters

Registers 0x113C and 0x113D serve for resetting the parameter-register 0x1120 and 0x1130 to

0x113B to the default settings.

For this purpose, write 0x6C6F to register 0x113C. To activate the reset of the registers, write 0x6164

("load") within 30 seconds in register 0x113D.

Both registers can also be written with one single request using the function codes FC16 and FC23.

The service resets the parameters without saving them. This can be achieved by using a following

"save" service.

Register 0x113E and 0x113F: Save Modbus-Connection-Parameters

Registers 0x113E and 0x113F are used for the non-volatile saving of parameters in registers 0x1120

and 0x1130 to 0x113B.

For this purpose, write 0x7361 to register 0x113E. To activate the saving of the registers, write

0x7665 ("save") within 30 seconds in register 0x113F.

Both registers can also be written with one single request using the function codes FC16 and FC23.

V01.0| 2016/12

51

Page 54

TBEN-Lx-8IOL with Modbus TCP

5.2 Data width of the TBEN-Lx-8IOL in the Modbus-register area

Module Process input data Process output data Alignment

TBEN-Lx-8IOL 344 byte 260 byte word by word

5.3 Register mapping TBEN-Lx-8IOL

Register Bit15Bit14Bit 13Bit12Bit11Bit

MSB LSB

0x0000

0x00xx

0x00xx

+ 1 Reg.

0x0800

0x08xx

Diagnosis

0xA000 see Chapter 4, Diagnostic data, page 31

0xA001

0xA004

0xB000 - SRO7 - SRO5 - SRO3 - SRO1 0xB001

0xB002

0xB003

0xB004 …

0xB005

0xB006 Vendor ID

0xB007 +

0xB008

0xB009 -

0xB00A

… 0xB011

0xB012 …

0xB019

-

Cycle time GSD

-

Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

10

Input data

Process input data

see Chapter 4, Process input data, page 19

Module status

see Register 0x100C: Module status, page 50

Output data

process output data

see Chapter 4, Process input data, page 19

DXP-channel diagnostics

IO-Link channel diagnostics

see Chapter 4, Diagnostic data, page 31…

Parameters

see Chapter 4, Parameters, page 22

IO-Link-Basic

EN

DO7

IO-Link port 1

Quick

Start-

Process out-

put data map-

ping

process out-

put data

-

Device ID

IO-Link port 2

8 registers of parameter data,

assignment similar to port 1

IO-Link port 3

8 registers of parameter data,

assignment similar to port 1

-

Up

EN

DO5

data storage

Process out-

input data

-

mode

put data

mapping

process

EN

DO3

Deactivate

diagnostics

deactivate

web server

-

Mode

Process

inpu

EN

DO1

t data

valid

Revi-

sion

-

52

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 55

Register Bit15Bit14Bit 13Bit12Bit11Bit

10

0xB01A

… 0xB021

0xB022 …

0xB029

0xB02A

… 0xB031

0xB032 …

0xB039

0xB03A

… 0xB041

0xB042

0xB043

0xB044

0xB045

0xB046 …

0xB047

0xB048

0xB049

-

-

-

-

-

-

Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

IO-Link port 4

8 registers of parameter data,

assignment similar to port 1

IO-Link port 5

8 registers of parameter data,

assignment similar to port 1

IO-Link port 6

8 registers of parameter data,

assignment similar to port 1

IO-Link port 7

8 registers of parameter data,

assignment similar to port 1

IO-Link port 8

8 registers of parameter data,

assignment similar to port 1

VAUX1

monitoring

VAUX1 Pin1 C1

(Ch2/3)

VAUX1 Pin1 C3

(Ch6/7)

VAUX1 Pin1 C5

(Ch10)

VAUX1 Pin1 C7

(Ch14)

-

-

-

-

-

VAUX1 Pin1 C0

(Ch0/1)

VAUX1 Pin1 C2

(Ch4/5)

VAUX1 Pin1 C4

(Ch8)

VAUX1 Pin1 C6

(Ch12)

VAUX2

monitoring

VAUX2 Pin2 C5

(Ch11)

VAUX2 Pin2 C7

(Ch15)

-

-

VAUX2 Pin2 C4

(Ch9)

VAUX2 Pin2 C6

(Ch13)

5.4 Error behavior (watchdog)

5.4.1 Behavior of outputs

In case of a failure of the Modbus communication, the outputs’ behavior is as follows, depending on

the defined time for the Watchdog (register 0x1120,

Watchdog = 0 ms (default)

outputs hold the momentary value in case of an error

Watchdog > 0 ms

outputs switch to

NOTE

Setting the outputs to predefined substitute values is not possible in Modbus TCP. Eventually parameterized substitute values will not be used.

V01.0| 2016/12

page 48):

0 after the watchdog time has expired (setting in register 0x1120).

53

Page 56

TBEN-Lx-8IOL with Modbus TCP

5.4.2 Behavior of the BUS LED

If the Watchdog has tripped, the BUS LED behaves as follows:

Watchdog BUS-LED

tripped constantly red

5.5 Parameters and diagnostic messages of the I/O channels

NOTE

Please find explanations regarding parameters and diagnostic messages in the section

Register mapping TBEN-Lx-8IOL, page 52.

54

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 57

6 TBEN-Lx-8IOL with EtherNet/IP™

6.1 EDS-file

The actual EDS-files for TBEN-L can be downloaded from the Turck home page www.turck.com.

EDS-file ZIP-file

TBEN-Lx-8IOL_Rx.x.eds TBEN-L45_ETHERNETIP.zip

6.2 QC - QuickConnect

QuickConnect is not supported by TBEN-Lx-8IOL.

NOTE

Further information about QuickConnect and the configuration options can be found in

the user manual for the TBEN-S product family

„TBEN-L/TBDP-L Compact I/O modules for Ethernet/PROFIBUS-DP“

6.3 Diagnostic messages via the process data

The diagnostic messages of the IO-Link-channels are directly mapped into the process data (see

Parameter data mapping, TBEN-Lx-8IOL, page 61.)

Additionally, the device's status word contains the module diagnostics:

D301323 -

Status word

Bit 15Bit 14Bit 13Bit 12Bit 11Bit 10Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

see also

Chapter 4.7.4, Status and control word, page 35

or

Chapter 6.5.2, Gateway Class (VSC 100), page 68,

69

Byte 1 (MSB) Byte 0 (LSB)

-FCE----V1-V2------DIAG

Object Instance 2, gateway Instance, page

V01.0| 2016/12

55

Page 58

TBEN-Lx-8IOL with EtherNet/IP™

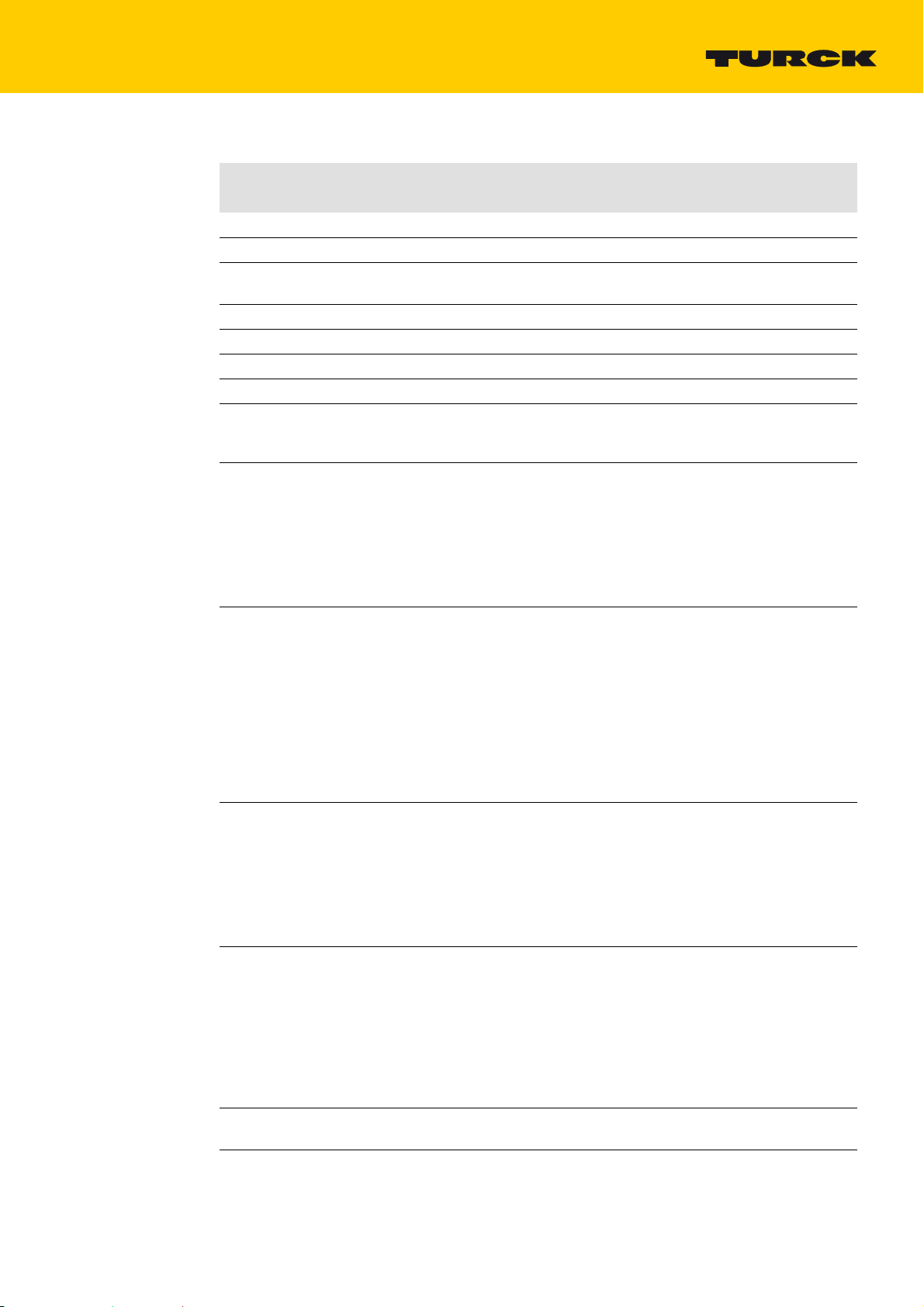

6.4 EtherNet/IP™-standard classes

The modules TBEN-L support the following EtherNet/IP™ Standard Classes in accordance with the

CIP specification.

Class Code Object name

01 (0x01) Identity Object (0x01)

04 (0x04) Assembly Object (0x04)

06 (0x06) Connection Manager Object (0x06)

245 (0xF5) TCP/IP Interface Object (0xF5)

246 (0xF6) Ethernet Link Object (0xF6)

6.4.1 Identity Object (0x01)

The following description of the Ethernet Link Object is taken from the CIP specification, Vol. 2, Rev.

2.1 by ODVA & ControlNet International Ltd. and adapted to TBEN-L.

Class attributes

Attr. No. Attribute name Get/

Set

1 (0x01) REVISION G UINT 1

2 (0x02) MAX OBJECT INSTANCE G UINT 1

6 (0x06) MAX CLASS ATTRIBUTE G UINT 7

7 (0x07) MAX INSTANCE ATTRIBUTE G UINT 7

Instance attributes

Attr. No. Attribute name Get

1 (0x01) VENDOR G UINT Contains the vendor ID.

2 (0x02) PRODUCT TYPE G UINT Shows the general product type.

3 (0x03) PRODUCT CODE G UINT Identifier for a specific product of a device

4 (0x04) REVISION

Major Minor

Type Description

/

Set

G STRUCT

OF:

USINT

USINT

TURCK = 48

Communications Adapter

= 0x0C

12

dec

type.

default: 27247

Revision of the item the Identity Object is representing.

0x01

0x06

dec =

Type Value

6A6F

56

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 59

5 (0x05) DEVICE STATUS G WORD See Device Status

6 (0x06) SERIAL NUMBER G UDINT Contains the ident-no. of the product (3 last

bytes of the MAC-ID).

7 (0x07) PRODUCT NAME

G STRUCT

OF:

e. g.:

TBEN-Lx-16DXP