Page 1

TBEN-LF

EtherNet/IP

TM

Configuration

Guide

0719A

Page 2

2

— This page intentionally left blank —

Page 3

3

1 General Information 4

1.1 About these instructions 4

1.2 Explanation of symbols used 4

1.2.1 Warnings 4

1.3 Contents 5

1.4 Feedback about these instructions 5

1.5 Technical support 5

2 Getting Started 6

2.1 About this document 6

2.2 Factory default IP address 6

2.3 Address switches 6

2.3.1 Static rotary mode 7

2.3.2 BOOTP mode (300) and DHCP mode (400) 7

2.3.3 PGM mode (500) 7

2.3.4 PGM-DHCP mode (600) 7

2.3.5 Factory Reset mode (900) 7

2.3.6 Restore IP Address (000) 8

2.4 TURCK Service Tool (TST) 8

2.4.1 Search (F5) 9

2.4.2 DHCP Server (F6) 9

3 TBEN-LF Quick View 12

3.1 Installation instruction and pinout 12

3.1.1 Dimensions and connector assignment 12

3.1.2 Ethernet P1 and P2 connectors pin assignment 12

3.1.3 Discrete IO connector pin assignment 13

3.1.4 Power connector pin assignment and distribution 14

3.1.5 LEDs 15

3.2 IO data maps 17

3.3 Generic device configuration 19

3.3.1 TBEN-LF-16DIP 20

3.3.2 TBEN-LF-16DOP 20

3.3.3 TBEN-LF-16DXP 21

3.3.4 TBEN-LF-8DIP-8DOP 21

4 EtherNet/IP Class Objects 22

4.1 EtherNet/IP Standard Objects 23

4.2 EtherNet/IP Vendor Specific Objects 27

Page 4

4

1 General Information

1.1 About these instructions

The following configuration guide describes the setup, functions, and use of the TBEN-LF stations. It helps you

to plan, design, and implement the system for its intended purpose.

Note*: Please read this manual carefully before using the system. This will prevent the risk of personal injury

or damage to property or equipment. Keep this manual safe during the service life of the system. If the system

is passed on, be sure to transfer this manual to the new owner as well.

1.2 Explanation of symbols used

1.2.1 Warnings

Action-related warnings are placed next to potentially dangerous work steps and are marked by graphic

symbols. Each warning is initiated by a warning sign and a signal word that expresses the gravity of the

danger. The warnings have absolutely to be observed:

DANGER!

DANGER indicates an immediately dangerous situation, with high risk, the death or severe injury, if

not avoided.

WARNING!

WARNING indicates a potentially dangerous situation with medium risk, the death or severe injury, if

not avoided.

ATTENTION!

ATTENTION indicates a situation that may lead to property damage, if it is not avoid-ed.

NOTE

In NOTES you find tips, recommendations and important information. The notes facilitate work,

provide more information on specific actions and help to avoid overtime by not following the correct

procedure.

➢ CALL TO ACTION

This symbol identifies steps that the user has to perform.

➔ RESULTS OF ACTION

This symbol identifies relevant results of steps

Italic Text in Italic is associated with the function of the third party software or application

(E.g. Controller Organizer)

Page 5

5

1.3 Contents

The TBEN-LF EtherNet/IP configuration guide provides information about configuration of the following

modules:

◼ TBEN-LF-16DIP

◼ TBEN-LF-16DOP

◼ TBEN-LF-8DIP-8DOP

◼ TBEN-LF-16DXP

The “TBEN-LF”, assigned to the product family, is used throughout the guidet to describe the common

features of the devices.

The complementary documentation and files:

◼ TBEN-LF data sheets

◼ EDS files revision 2.7

The Rockwell PLC demo:

◼ 1756-L72 controller v30

◼ 1756-EN2TR Ethernet Bridge

◼ Studio5000 Logic Designer V30

1.4 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If you have

any suggestions for improving the design or if some information is missing in the document, please send your

suggestions to techdoc@turck.com.

1.5 Technical support

For additional support, email inquiries to appsupport@turck.com, or call Application Support at 763-553-7300,

Monday-Friday 8AM-5PM CST.

Page 6

6

2 Getting Started

2.1 About this document

The configuration guide provides information about configuration of the TBEN-LF including:

◼ Address switches

◼ IP address assignment

◼ Configuration options with Rockwell and Omron PLCs

NOTE

The device data sheet and technical information is available for download at

www.turck.us

2.2 Factory default IP address

The TBEN-LF default rotary switches are set at 000 with default IP address of:

◼ IP address: 136.129.1.1

◼ Netmask: 255.255.0.0

NOTE

Position 000 is used to “Restore” or recover the default IP address if lost or forgotten.

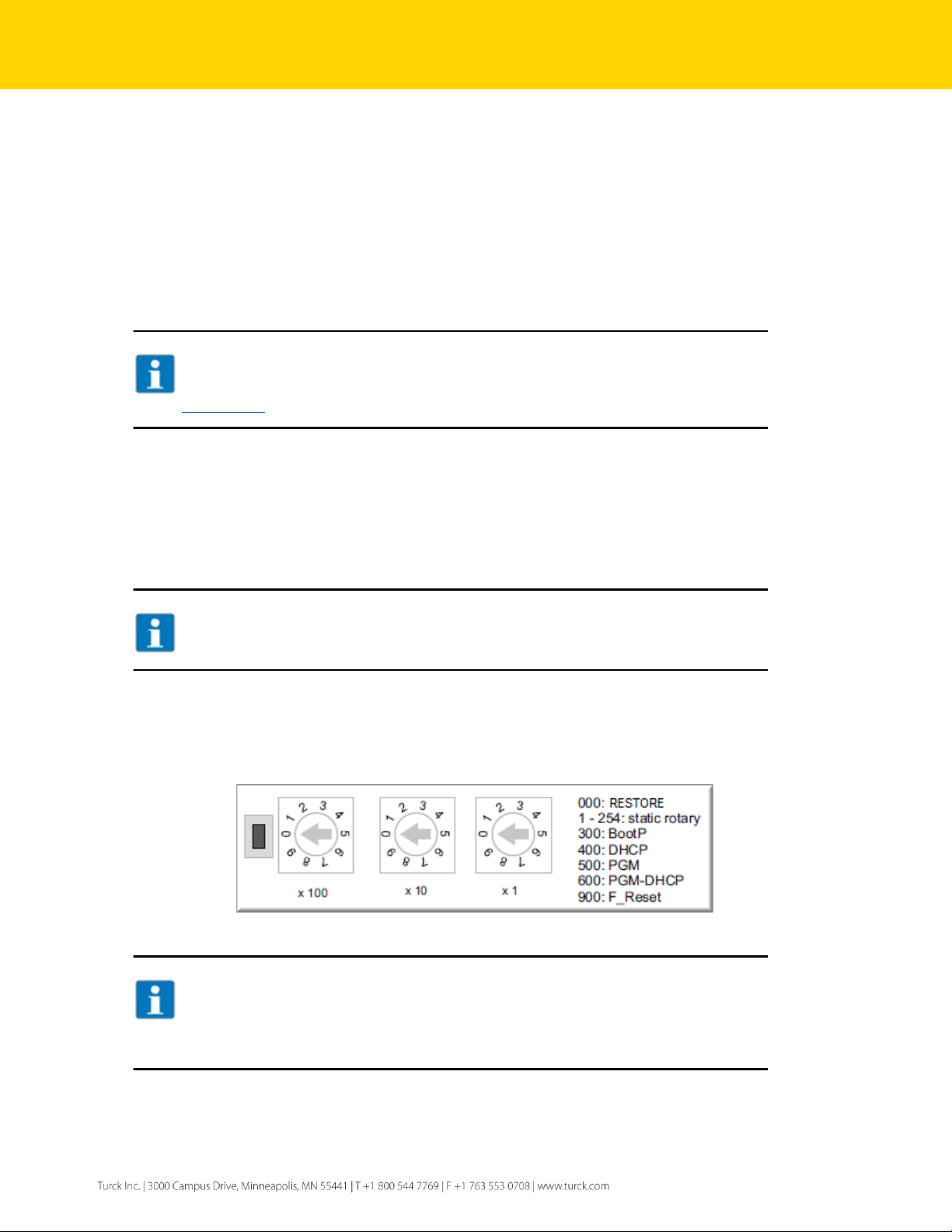

2.3 Address switches

The device has 3 rotary address switches (see Figure 2.2 below). The position of the them determines the

mode of operation.

Figure 2.1 – Rotary switches

NOTE

Protective cover opened - Protection class IP65/IP67/IP69K not warranted

➢ Screw the protective cover over the rotary coding-switches firmly

➢ Check if seal of the protective cover is correctly placed

Page 7

7

Table 2.1 below provides a description of the device action when switches are set to a specific position and

the device is powered up.

Switch position

Mode

Description

000

Restore

IP address is restored to 136.129.1.1

001,…,254

Static rotary

mode

Sets the last octet of IP address in range [1…254].

300

BOOTP

BOOTP client is active and requesting an IP address

400

DHCP

DHCP client is active and requesting an IP address

500

PGM

Device comes up with the last IP address saved in

EEPROM. IP address is programmable.

600

PGM-DHCP

DHCP client is active and requesting an IP address.

When IP address is acquired, the device transitions to

PGM mode.

900

Factory Reset

Device is reset to the factory default setup.

Table 2.2: Address Modes

2.3.1 Static rotary mode

Set the last octet of the IP address using the rotary switches in the range [xxx = 1,…, 254],

e.g. 136.129.1.120 or 10.10.10.120.

2.3.2 BOOTP mode (300) and DHCP mode (400)

When rotary switches are set to either 300 or 400, the device BOOTP or DHCP client is active, requesting an

IP address assignment. The setup procedure - from any switch position:

➢ Turn OFF device power and set switches to 300 or 400

➢ Turn ON device power

➢ Start BOOTP / DHCP server and assign IP address

➢ Wait for the acknowledgement from the server

➢ Set rotary switches to either the last octet of the IP address or to 500 (PGM)

➢ Cycle the power.

2.3.3 PGM mode (500)

When rotary switches are set to 500 while device is powered, the current IP address, Netmask and Gateway

addresses are saved into the EEPROM. The IP address is programmable and may be changes using TURCK

Service Tool. The setup procedure – from any switch position set switches to 500 and then cycle the power.

2.3.4 PGM-DHCP mode (600)

When out-of-box TBEN-LF is powered for the first time, while the rotary switches are set to 600, the device

DHCP client is enabled and running. Use any DHCP server to assign the IP address. When IP address is

acquired, the DHCP client is disabled and device transitions to the PGM mode.

2.3.5 Factory Reset mode (900)

When rotary switches are set to 900 and the power is cycled, the device resets itself to the factory default

mode (out-of-box). The QC setup is deleted; the ETH1 and ETH2 ports are set to Autonegotiation and AutoMDIX.

Page 8

8

From any switch position:

➢ Set address switches to 900

➢ Cycle the power of the device and wait 10sec

➢ Set switches to either static address 1…254 or specific mode of operation 300/400/500/600

➢ Cycle the power.

2.3.6 Restore IP Address (000)

When rotary switches are set to 000 and the power is cycled, the IP address is set to 136.129.1.1. The device

preserves custom data /setup while restoring IP address.

From any switch position:

➢ Set the address switches to 000

➢ Cycle the power of the device and wait 10sec

➢ Set switches to either static position or 300/400/500/600 mode

➢ Cycle the power.

2.4 TURCK Service Tool (TST)

The TURCK Service Tool can be downloaded from the TURCK Web site:

➢ Enter “TURCK Service Tool” in the search field

➢ Follow the link

➢ Download and install the tool

➢ The tool is used for the management of the TURCK devices only

Figure 2.3 – TURCK Web page

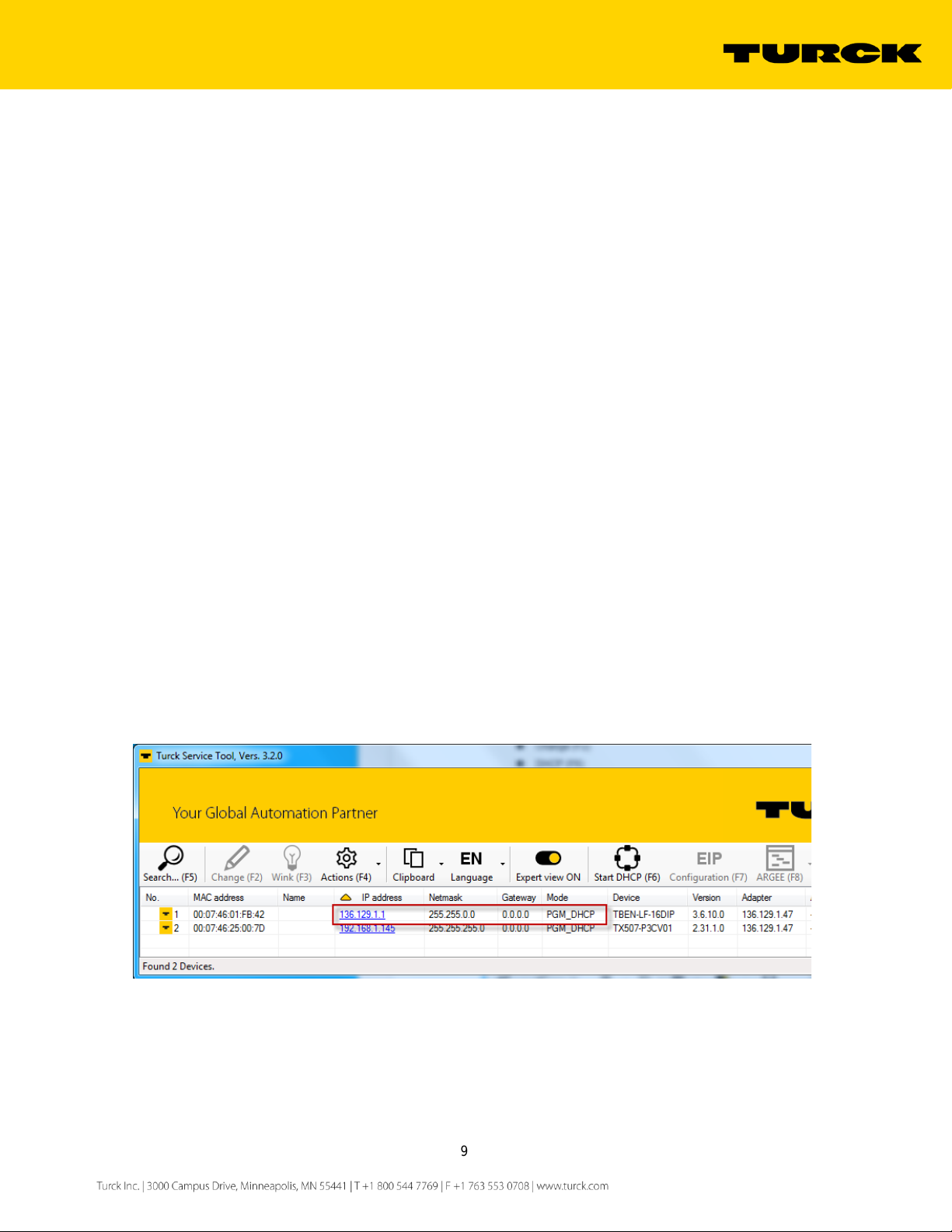

The tool has a set of action buttons in the tool bar:

Figure 2.4 – Service Tool

Page 9

9

The tool features are:

◼ It scans for existing devices (F5). All devices are found by using DCP (PROFINET Standard) and

IBTP (TURCK Service Protocol) protocols. The IBTP protocol provides extended information such

as FW version and operating mode improved scanning are read out of TURCK devices and

displayed.

◼ It set an IP address (F2)

◼ It locates device using Wink function (F3)

◼ Actions menu that resets the device to the factory default or reset network (F4)

◼ It assigns the PROFINET name to the device

◼ It supports Clipboard menu

◼ Expert view, when enabled, provides additional functions like DHCP Server, ARGEE and BEEP

features by TURCK multiprotocol device

◼ DHCP server

◼ ARGEE status

◼ BEEP status

Frequently used action buttons / functions are:

◼ Search (F5)

◼ Change (F2)

◼ DHCP (F6)

◼ Action (F4)

2.4.1 Search (F5)

The Search is used to identify TURCK multiprotocol device on the continuous physical network segment,

including devices connected to the layer 2 switches. The IP address 136.129.1.1 appears when the device is

in the PGM-DHCP mode and DHCP client is active. The IP address transitions to 0.0.0.0 when DCHP server

is started.

Figure 2.5 – Search function

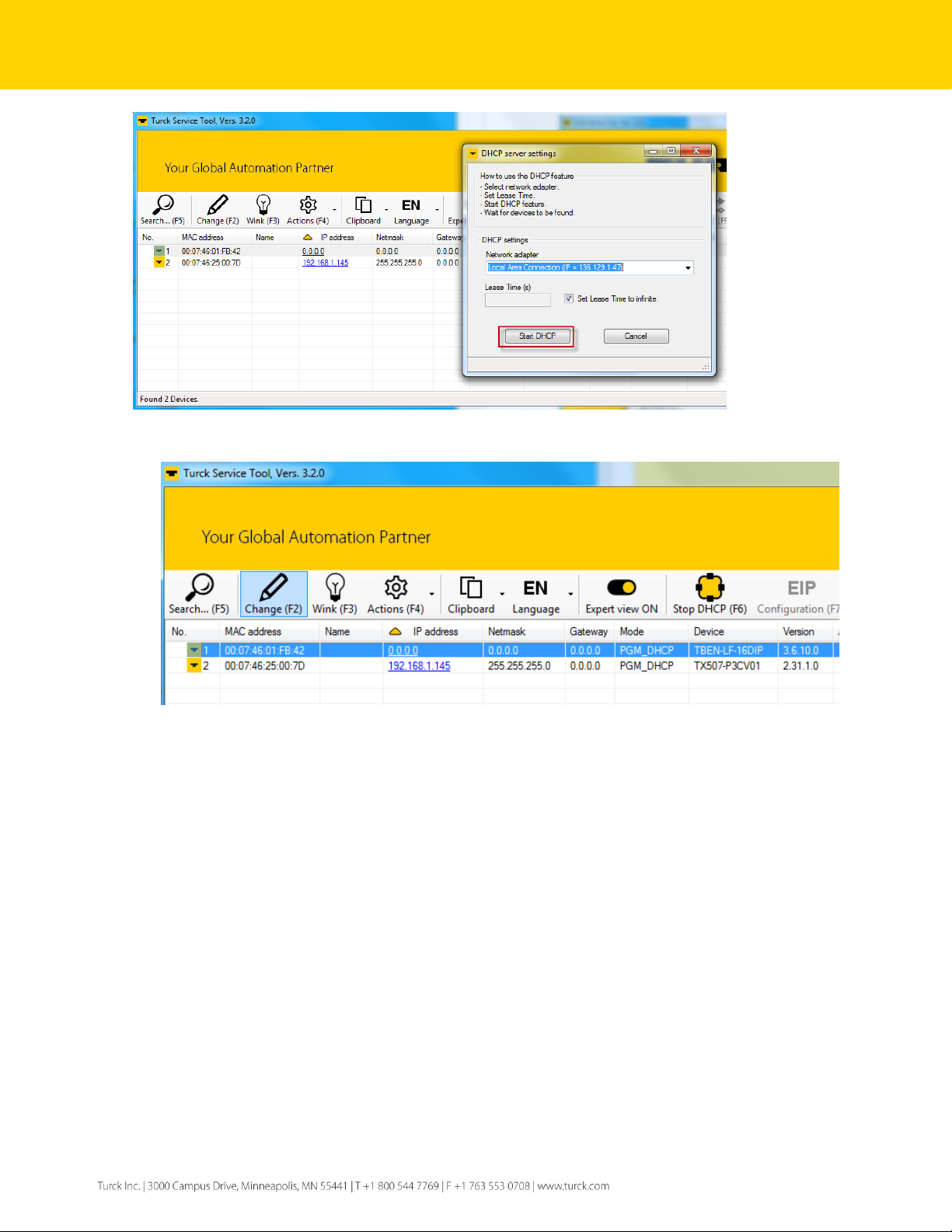

2.4.2 DHCP Server (F6)

The IP address may be assigned to the device using DHCP server (F6). Procedure:

➢ Search (F5) to discover device with address 136.129.1.1

➢ Start DHCP server (F6)

➢ Select network adapter in the DHCP server settings page and click Start DHCP

Page 10

10

Figure 2.6 – Initialize DHCP server

➢ Highlight the device with 0.0.0.0 IP address

Figure 2.7 – Device DHCP client active view

➢ Click Change (F2); A “Change device configuration” pop-up page appears

➢ Assign IP address and click at Set in device button

Page 11

11

Figure 2.8 – Set IP Configuration

➢ Click at Stop DHCP (F6) button

Figure 2.9 – Stop DHCP server

Page 12

12

3 TBEN-LF Quick View

3.1 Installation instruction and pinout

The summary of the device installation guidance, connector’s assignment, power distribution and grounding

requirements are as follows.

3.1.1 Dimensions and connector assignment

Figure 3.1 – Connector assignment

3.1.2 Ethernet P1 and P2 connectors pin assignment

Figure 3.2 – P1 and P2 connector pinout

Page 13

13

3.1.3 Discrete IO connector pin assignment

➢ Discrete inputs

Connect digital sensors to the device according to the pin assignment.

Figure 3.3 – Discrete input wiring diagram

➢ Discrete outputs

Connect digital actuators to the device according to the pin assignment.

Figure 3.4 – Discrete output wiring diagram

Page 14

14

➢ Discrete combined IO

Connect digital combined IO to the device according to the pin assignment

Figure 3.5 – Discrete combined IO wiring diagram

3.1.4 Power connector pin assignment and distribution

➢ Connect power to the device according to the pin assignment

Figure 3.6 – X1 and X2 connector pinout

Figure 3.7 – V1 and V2 power distribution

Page 15

15

3.1.5 LEDs

Figure 3.8 – LED assignment

LED

Color

Status

Meaning

Remedy

PWR

green

off

V1 missing or < 18 VDC

Check V1

on

V1 and V2 OK

blinking

V2 missing or < 18 VDC

Check V2

ETHx

green

on

Link established, 100Mbps

blinking

Ethernet traffic, 100Mbps

yellow

on

Link established, 10Mbps

blinking

Ethernet traffic, 10Mbps

none

off

No Ethernet link

Check Ethernet connection

ERR

green

on

No diagnostic message

red

on

Diagnostic message pending

BUS

green

on

Active connection to a master

blinking

Device is ready for operation

red

on

IP address conflict

Check duplicate IP address

Restore mode (900)

Check setup of rotary switches

Connection timeout

Check media

blinking

Blink / wink command active

red/green

on

Autonegotiation

BootP/DHCP client active

Waiting for IP address assignment

Figure 3.9 – Module LED behavior

Page 16

16

TBEN-LF-16DIP LED Status I/O

LED

Color

Status

Meaning

Remedy

LED 0…15

green

on

Input active

off

Input off

red blinking

Overcurrent at input

Check short condition

TBEN-LF-16DOP LED Status I/O

LED

Color

Status

Meaning

Remedy

LED 0…15

green

on

Output active

off

Output off

red blinking

Overcurrent at output

Check short condition

TBEN-LF-16DXP LED Status I/O

LED

Color

Status

Meaning

Remedy

LED 0…15

green

on

IO signal active

input or output

off

IO signal off

input or output

red

blinking

Overcurrent at input

Check input short condition

Solid

Overcurrent at output

Check output short condition

TBEN-LF-8DIP-8DOP LED Status I/O

LED

Color

Status

Meaning

Remedy

LED 0…7

green

on

Input active

off

Input off

red blinking

Overcurrent at input

Check short condition

LED 8…15

green

on

Output active

off

Output off red

Overcurrent at output

Check short condition

Figure 3.10 – IO LED behavior

Page 17

17

3.2 IO data maps

◼ TBEN-LF-16DIP

◼ TBEN-LF-16DOP

◼ TBEN-LF-8DIP-8DOP

◼ TBEN-LF-16DXP

Page 18

18

IO Map key:

Device status word

Meaning

DIAG

Module Diagnostics Available

V2

Undervoltage Field Supply V2 <18V

V1

Undervoltage Field Supply V1 <18V

COM

Modulebus Communication Lost

CFG

Modulebus Configuration Error

ETH1

Ethernet Port 1 Errors

ETH2

Ethernet Port 2 Errors

FCE

Force Mode Enabled

Device scheduled diagnostics

EM0

Internal slot 0

EC5

Diagnostics active

Error-Cx

Input short at connector Cx [x=0, 1, …, 7]

OSC-x

Output short at condition at output x [x=0, 1, …, 15]

Device IO channels

I-x

Input channel [x=0, 1, …, 15]

O-x

Output channel [x=0, 1, …, 15]

◼ TBEN-LG Configuration assembly data and size

Configuration Assembly Data

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

reserved

Byte 1

reserved

Byte 2

reserved

Byte 3

reserved

Byte 4

reserved

Byte 5

reserved

Byte 6

reserved

Byte 7

reserved

Byte 8

reserved

Byte 9

reserved

QC

Byte 10

reserved

Byte 11

reserved

Byte 12

reserved

Byte 13

reserved

Byte 14

reserved

Byte 15

reserved

QC = QC enable / disable bit

Page 19

19

3.3 Generic device configuration

The TBEN-LF is configured with the Rockwell PLCs using “ETHERNET MODULE – Generic Ethernet Module”

profile:

TBEN-LF configuration requirements:

◼ Catalog Number: Generic Ethernet Module

◼ Comm.Format: Data – INT

◼ Select “Connection Parameters” listed for specific device as follows:

Figure 11: TBEN-LF connection summary

Figure 12: New Module page

Page 20

20

3.3.1 TBEN-LF-16DIP

Figure 13: TBEN-LF-16DIP configuration page

3.3.2 TBEN-LF-16DOP

Figure 14: TBEN-LF-16DOP configuration page

Page 21

21

3.3.3 TBEN-LF-16DXP

Figure 15: TBEN-LF-16DXP configuration page

3.3.4 TBEN-LF-8DIP-8DOP

Figure 16: TBEN-LF-8DIP-8DOP general page

Page 22

22

4 EtherNet/IP Class Objects

The TBEN-LF supports following CIP1 objects:

CIP Object Classes

Class Code

Object type

01 (0x01)

Identity Object

04 (0x04)

Assembly Object

06 (0x06)

Connection Manager

71 (0x47)

DLR Object

72 (0x48)

QoS Object

245 (0xF5)

TCP/IP Interface Object

246 (0xF6)

Ethernet Link Object

Figure 4.1 – EtherNet/IP standard objects

The Vendor Specific objects are defined hereafter:

Following

VSC Object Classes

Class Code

Object type

100 (0x64)

Gateway Object

117 (0x75)

DXP Object

Figure 4.2 – Vendor Specific objects

Common service:

Common class and instance services

Service code

Service Name

01 (0x01)

Get_Attribute_All

05 (0x05)

Reset

14 (0x0E)

Get_Attribute_Single

16 (0x10)

Set_Attribute_Single

Figure 4.3 – Common services

1

The CIP Networks Library, Volume 1, Common Industrial, Protocol (CIP

TM

) by ODVA, Edition 3.24, April 2018

The CIP Networks Library, Volume 2, EtherNet/IP Adaptation of CIP, by ODVA, Edition 1.23, April 2018

Page 23

23

4.1 EtherNet/IP Standard Objects

Identity Object

Class code: 01 (0x01)

Instance 1 (0x01) Attributes

Attribute

Access

Name

Data type

Value

1 (01h)

Get

Vendor

UINT

48 (0x0030)

2 (02h)

Get

Product Type

UINT

12 (0x000C)

3 (03h)

Get

Product Code

UINT

Device specific code

4 (04h)

Get

Revision major

USINT

2

Revision minor

USINT

7

Revision Internal

35

5 (05h)

Get

Device Status

WORD

Status

6 (06h)

Get

Serial Number

UDINT

Device specific number

7 (07h)

Get

Product name

STRING[length]

TBEN-LF-xxxx

Supported services

Service code

Class

Instance

Service

01 (0x01)

yes

Get_Attribute_All

05 (0x05)

yes

Reset

14 (0x0E)

yes

Get_Attribute_Single

Figure 4.5 – Identity Object

Assembly Object

Class code: 04 (0x04)

Instance 103 (0x67) Attributes

Attribute

Access

Name

Data type

Value

3 (03h)

Get

Input data

ARRAY of BYTE

4 (04h)

Get

Size

UINT

Number of bytes in Attr 3

Instance 104 (0x68) Attributes

Attribute

Access

Name

Data type

Value

3 (03h)

Get

Output data

ARRAY of BYTE

4 (04h)

Get

Size

UINT

Number of bytes in Attr 3

Supported services

Service code

Class

Instance

Service

14 (0x0E)

yes

Get_Attribute_Single

Figure 4.6 – Assembly Object

NOTE

Refer to the following reference for the omitted attribute values:

The CIP Networks Library, Volume 1, Common Industrial, Protocol by ODVA, Edition 3.24, April 2018

The CIP Networks Library, Volume 2, EtherNet/IP Adaptation of CIP, by ODVA, Edition 1.23, April 2018

Page 24

24

Connection Manager

Class code: 06 (0x06)

Attribute

Access

Name

Data type

Value

Supported services

Service code

Class

Instance

Service name

84 (0x54)

yes

FWD_OPEN_CMD

78 (0x4E)

yes

FWD_CLOSE_CMD

Figure 4.7 – Connection Manager Object

DLR Object

Class code: 71 (0x47)

Class attributes

Attribute

Access

Name

Data type

Value

1 (0x01)

Get

Revision

UINT

3

Instance 1 attributes

Attribute

Access

Name

Data type

Value

1 (0x01)

Get

Network topology

USINT

2 (0x02)

Get

Network status

USINT

10 (0x0A)

Get

Active supervisor address

STRUCT.

12 (0x0C)

Get

Capability flags

DWORD

Supported services

Service code

Class

Instance

Service

14 (0x0E)

yes

yes

Get_Attribute_Single

Figure 4.8 – DLR Object

QoS Object

Class code: 72 (0x48)

Instance 1 attributes

Attribute

Access

Name

Data type

Value

4 (0x04)

Set

DSCP Urgent

USINT

5 (0x05)

Set

DSCP Scheduled

USINT

6 (0x06)

Set

DSCP High

USINT

7 (0x07)

Set

DSCP Low

USINT

8 (0x08)

Set

DSCP Explicit

USINT

Supported services

Service code

Class

Instance

Service

14 (0x0E)

yes

Get_Attribute_Single

16 (0x10)

yes

Set_Attribute_Single

Figure 4.9 – QoS Object

Page 25

25

TCP/IP Object

Class code: 245 (0xF5)

Class attributes

Attribute

Access

Name

Data type

Value

1 (01h)

Get

Revision

UINT

3

2 (02h)

Get

Max instance

UINT

1

3 (03h)

Get

No. of instances

UINT

1

Instance 1 attributes

Attribute

Access

Name

Data type

Value

1 (0x01)

Get

Status

DWORD

2 (0x02)

Get

Configuration capability

DWORD

3 (0x03)

Get

Configuration control

DWORD

4 (0x04)

Get

Physical Link

Structure of:

Path Size

UINT

Path

Padded EPATH

5 (0x05)

Get

Interface Configuration

Structure of:

Get

IP address

UDINT

Get

Network mask

UDINT

Get

Gateway address

UDINT

Get

Name server

UDINT

Get

Name server 2

UDINT

Get

Domain name

UDINT

6 (0x06)

Get

Host name

String

10 (0x0A)

Set

ACD Enable

Bool 11 (0x0B)

Get/Set

Last Conflict detect

Structure of:

12 (0x0C)

Get/Set

QuickConnet

Bool

Supported services

Service code

Class

Instance

Service

01 (0x01)

yes

Get_Attribute_All

14 (0x0E)

yes

yes

Get_Attribute_Single

16 (0x10)

yes

Set_Attribute_Single

Figure 4.10 – TCP/IP Object

Page 26

26

Ethernet Link Object

Class code: 246 (0xF6)

Class attributes

Attribute

Access

Name

Data type

Value

1 (0x01)

Get

Revision

UINT

3

2 (0x02)

Get

Max instance

UINT

3

3 (0x03)

Get

No. of instances

UINT

3

Instance 1, 2, 3, attributes

Attribute

Access

Name

Data type

Value

1 (0x01)

Get

Interface speed

UDINT

2 (0x02)

Get

Interface flags

DWORD

3 (0x03)

Get

Physical address

Array of USINT

4 (0x04)

Get

Interface counters

Structure of UDINT:

5 (0x05)

Get

Media counters

Structure of UDINT:

6 (0x06)

Set

Interface control

Structure of:

Control bits

WORD

Forced intf. Speed

UINT

7 (0x07)

Get

Interface type

USINT

10 (0x0A)

Set

Interface label

SHORT_STRING

14 (0x0D)

Get

Ethernet errors

UDINT

15 (0x0F)

Get

Link down counters

UDINT

Supported services

Service code

Class

Instance

Service

01 (0x01)

yes

Get_Attribute_All

14 (0x0E)

yes

yes

Get_Attribute_Single

16 (0x10)

yes

Set_Attribute_Single

76 (0x4C)

yes (attr. 4, 5)

Get_and_Clear

Figure 4.11 – Ethernet Link Object

Page 27

27

4.2 EtherNet/IP Vendor Specific Objects

Gateway Object

Class code: 100 (0x64)

Instance 2 attributes

Attribute

Access

Name

Data type

Value

109 (0x6D)

Get

GW Status Word

WORD

Structure of:

115 (0x73)

Get/Set

On Connection timeout

USINT

0: Switch IO Faulted

1: Switch IO OFF

2: Switch IO Hold

138 (0x8A)

Get/Set

Enable GW Status word

DWORD

0 = no; 1=yes

139 (0x8B)

Get/Set

Enable GW Control word

DWORD

0 = no; 1=yes

Supported services

Service ode

Class

Instance

Service

14 (0x0E)

yes

Get_Attribute_Single

16 (0x10)

yes

Set_Attribute_Single

Figure 4.20 – Gateway Object

DXP Object

Class code: 117 (0x75)

Instance 1 attributes

Attribute

Access

Name

Data type

Value

113 (71h)

Get

Digital In/Out – Input value

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

115 (73h)

Get

Digital In/Out – Output value

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

Page 28

28

119 (77h)

Get

Digital In/Out – Output

overcurrent

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

121 (79h)

Get

Digital In/Out – Input overcurrent

VAUX

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8-31 – reserved,

127 (7Fh)

Get / Set

Digital In/Out – Invert digital

input

UDINT

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

137 (89h)

Get / Set

Digital In/Out – Manual reset

output after overcurrent

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

139 (8Bh)

Get / Set

Digital In/Out – Activate output

DWORD

0 - "Channel 0",

1 - "Channel 1",

2 - "Channel 2",

3 - "Channel 3",

4 - "Channel 4",

5 - "Channel 5",

6 - "Channel 6",

7 - "Channel 7",

8 - "Channel 8",

9 - "Channel 9",

10 - "Channel 10",

Page 29

29

11 - "Channel 11",

12 - "Channel 12",

13 - "Channel 13",

14 - "Channel 14",

15 - "Channel 15",

16-31 – reserved,

149 (95h)

Get / Set

Digital In/Out 0 – Pulse stretch

USINT

0-255

150 (96h)

Get / Set

Digital In/Out 1 – Pulse stretch

USINT

0-255

151 (97h)

Get / Set

Digital In/Out 2 – Pulse stretch

USINT

0-255

152 (98h)

Get / Set

Digital In/Out 3 – Pulse stretch

USINT

0-255

153 (99h)

Get / Set

Digital In/Out 4 – Pulse stretch

USINT

0-255

154 (9Ah)

Get / Set

Digital In/Out 5 – Pulse stretch

USINT

0-255

155 (9Bh)

Get / Set

Digital In/Out 6 – Pulse stretch

USINT

0-255

156 (9Ch)

Get / Set

Digital In/Out 7 – Pulse stretch

USINT

0-255

157 (9Dh)

Get / Set

Digital In/Out 8 – Pulse stretch

USINT

0-255

158 (9Eh)

Get / Set

Digital In/Out 9 – Pulse stretch

USINT

0-255

159 (9Fh)

Get / Set

Digital In/Out 10 – Pulse stretch

USINT

0-255

160 (A0h)

Get / Set

Digital In/Out 11 – Pulse stretch

USINT

0-255

161 (A1h)

Get / Set

Digital In/Out 12 – Pulse stretch

USINT

0-255

162 (A2h)

Get / Set

Digital In/Out 13 – Pulse stretch

USINT

0-255

163 (A3h)

Get / Set

Digital In/Out 14 – Pulse stretch

USINT

0-255

164 (A4h)

Get / Set

Digital In/Out 15 – Pulse stretch

USINT

0-255

Supported services

Service code

Class

Instance

Service

14 (0x0E)

yes

Get_Attribute_Single

16 (0x10)

yes

Set_Attribute_Single

Figure 4.20 – DXP Object

Page 30

30

NOTE

Pulse stretch is a trigger to an internal TOF timer. The timer stretches an input discrete single

In 10msec increments. The time base is 10msec. Example:

0 = timer disabled (default value)

1 = 10 msec delay

10 = 100 msec delay

ATTENTION!

DXP object attributes cannot be SET while PLC – TBEN connection is running.

Page 31

31

TURCK sells its products through Authorized Distributors. These distributors provide our customers

with technical support, service and local stock. TURCK distributors are located nationwide –

Including all major metropolitan marketing areas

For Application Assistance or for the location of your nearest TURCK distributor, call:

1-800-544-7769

Specifications in this manual are subject to change without notice. TURCK also reserves the right to

make modifications and makes no guarantee of the accuracy of the information contained herein.

Loading...

Loading...