Page 1

TURCK

Innovative Solutions for Automation

Selection Guide - Section M

Introduction to Sensor Products

Introduction ..............................................M2

Glossary of Terms .........................................M3-M4

General Specifications

Operating Principles ........................................M5-M6

Operating Distances ........................................M7-M8

Wiring Instructions - DC (Green)

DC Outputs, Short-Circuit and Overload Protection, TTL Compatible ..................M11

Sinking and Sourcing .........................................M11

"AD" 2-Wire DC Output ........................................M11

"AN4" and "AP4", "AN6(7)" and "AP6(7)" 3-Wire DC Outputs .......................M12

"VN4" and "VP4", "VN6" and "VP6" 4-Wire DC Outputs..........................M13

"LIU" 4-Wire Linear Analog DC Output .................................M15

Series / Parallel Connection ...................................M15 - M16

Wiring Instructions - AC (Red)

Short-Circuit and Overload Protection .................................M17

AC and AC/DC Outputs ........................................M18

Series Connection, Mechanical Switches in Series............................M19

Parallel Connection, Mechanical Switches in Parallel ..........................M20

Wiring Instructions - NAMUR (Blue)

NAMUR (Y0 and Y1) Outputs, Typical Output Curves ..........................M21

Typical Intrinsically Safe Installation, Interface Circuits .........................M22

eurofast

Innovative Sensor Solutions ...................................M25 - M26

®

Pinout Diagrams and Mating Cordset .........................M23 - M24

General Specifications

................................................M27 - M32

Compliances and Hazardous Locations

Third Party Compliances .....................................LL33M33

Hazardous Location Approvals .................................M33 - M34

Enclosure Ratings and Material Properties

Enclosure Ratings ...........................................M35

Material Descriptions - Plastic and Metal ................................M36

Matrix of TURCK Sensor Materials ................................M37 - M38

Chemical Compatibility ........................................M38

M1 B1008 TURCK Inc. Minneapolis, MN 55441

Page 2

Industrial

Automation

Important Safety Warning!

TURCK sensors and peripheral devices DO NOT include the self-checking redundant circuitry required to

permit their use in personnel safety applications. A device failure or malfunction can result in either an

energized or a de-energized output condition.

Never use these products as sensing devices for personnel protection. Their use as safety devices may create

unsafe conditions that could lead to serious bodily injury or death.

Selection Guide - Section M

How does Proximity Sensing compare to conventional methods?

TURCK proximity sensors are entirely solid state electronic controls that contain no moving parts to wear out as do mechanical

switches. They require no physical contact for actuation, no cams or linkages, have no contacts to bounce or arc and are completely

encapsulated, making them impervious to most liquids, chemicals and corrosive agents. In addition, TURCK has a line of sensors that

can be used in hazardous explosive environments without any special enclosures.

See Hazardous Area Locations in Section A.

If any of the following conditions exists, a Proximity Sensor should be used:

• The object being detected is too small, too lightweight, or too soft to operate a mechanical switch.

• Rapid response and high switching rates are required, as in counting or ejection control applications.

• Object has to be sensed through non-metallic barriers such as glass, plastic, or paper carton.

• Hostile environments demand improved sealing properties, preventing proper operation of mechanical switches.

• Long life and reliable service are required.

• Fast electronic control system requires bounce-free input signal.

Proximity Sensors are being used today in all industries:

Mining and Metallurgy Sheet Metal Fabrication

Foundries Automotive and Appliance Plants

Automatic Assembly and Robotics Electroplating Installations

Conveyor Systems in Airports and Factories Can Plants, Food Processing and Breweries

Chemical Plants and Oil Refineries Shipyards, Docks, and Off-shore Drilling Rigs

Semiconductor Equipment PC-board Handling Machinery

Typical applications:

Parts Detection Void or Jam Control Valve Position Indication

Parts Counting Feed Control Missing Parts Control

Positioning Indexing Parts Diverting

Motion and Speed Control Inter-lock Control Coin Counting and Sorting

Bottle Cap or Can Lid Detection Liquid Level Control Edge Guide Control

Punch Press Feed and Ejection Control Leak Detection Robotics and Conveyors

Broken or Damaged Tool Detection Machine Programming

TURCK Inc. Minneapolis, MN 55441 B1008 M2

Specifications

Page 3

TURCK

Innovative Solutions for Automation

Axial Approach

The approach of the target with its center maintained on

the sensor reference axis.

Axially Polarized Ring Magnet

A ring magnet whose poles are the two flat sides of the disk.

Mounted on pistons for permaprox

sensing through nonmagnetic cylinder walls.

Capacitive Proximity Sensor

A proximity sensor producing an electrostatic field that

senses conductive targets and nonconductive materials

having a dielectric constant of >1 within its sensing zone.

Complementary Output

Two outputs, one N.O. and one N.C., that can be used

simultaneously. The sum of both load currents cannot

exceed the sensor’s rated Continuous Load Current.

Continuous Load Current

The maximum current allowed to continuously flow

through the sensor output in the ON state.

Correction Factors

Percentage of the rated operating distance (Sn) that

represents the operating distance for targets constructed

from materials other than mild steel (mild steel’s correction

factor is 1.0).

Differential Travel (Hysteresis)

The difference between the operating point as the target

approaches the sensor face, and the release point as the

target moves away. Given as a percentage of the operating

distance (Sn).

Dynamic Output

A sensor output that stays energized for a set duration

of time, independent of the time the target is present

(one-shot).

Embeddable (Shielded) Proximity Sensor

A sensor that can be flush-mounted in any material without

that material influencing the sensing characteristics.

Free Zone

The space around a proximity sensor that must be

kept free of any material capable of affecting the

sensing characteristics.

Inductive Proximity Sensor

A proximity sensor producing an electromagnetic field

that senses only metal targets within its sensing zone.

Inductive Magnet Operated Sensor (permaprox ®)

A solid-state sensor consisting of a sensing element

susceptible to magnetic field strengths of 20-350 Gauss, and

switching circuitry similar to that of an inductive proximity

sensor.

®

cylinder position

Inrush Current

The maximum short-term load current that the output

of a sensor can tolerate.

IP Rating

Ingress Protection rating per IEC 529.

Lateral Approach

The approach of a target perpendicular to the sensor

reference axis.

Load

A device or circuit that is operated by the energy output

of another device such as a proximity sensor.

M Threading

ISO 68 Metric straight threading, designated as

“Nominal Size” X “Pitch”, in mm. (Ex. M5X0.5)

Minimum Load Current

The minimum amount of current that is required by

the sensor for reliable operation.

NAMUR

The acronym for a European standards organization.

NAMUR Sensor

A 2-wire variable-resistance DC sensor whose operating

characteristics conform to DIN 19 234. Requires a

remote amplifier for operation. Typically used for

intrinsically safe applications.

NEMA Rating

An enclosure rating per NEMA Standard 250.

No-Load Current

The current drawn by a DC proximity sensor from the power

supply when the outputs are not connected to a load.

Nonembeddable (Nonshielded) Proximity Sensor

A sensor is nonembeddable when a specified free zone

must be maintained around its sensing face in order

not to influence the sensing characteristics.

Normally Closed (N.C.)

The output is OFF when the target is detected by

the sensor.

Normally Open (N.O.)

The output is ON when the target is detected by

the sensor.

NPN Output (Current Sinking)

A transistor output that switches the common or negative

voltage to the load. Load is between sensor and positive

supply voltage.

NPSM Threading

American National Standard Straight Pipe Thread for

Free-Fitting Mechanical Parts.

M3 B1008 TURCK Inc. Minneapolis, MN 55441

Page 4

Industrial

Automation

NPT Threading

American National Standard Taper Pipe Thread.

Off-State (Leakage) Current

The current that flows through the load circuit when

the sensor is in the OFF-state. Also known as leakage

or residual current.

Operating Distance

A distance at which the target approaching the sensing face

along the reference axis causes the output signal to change.

Overload Protection

The ability of a sensor to withstand load currents between

continuous load rating and short-circuit condition with

no damage.

PG Threading

Steel conduit threading per German standard DIN 40 430.

PNP Output (Current Sourcing)

Transistor output that switches the positive voltage to

the load. Load is between sensor and common.

Programmable Output

Sensor output whose N.O. or N.C. function can be selected

by means of a jumper or specific terminal connection.

Radially Polarized Ring Magnet

A ring magnet whose poles are the inner and outer

diameter rings.

Rated Operating Distance (Sn)

A conventional quantity used to designate the operating

distance. It does not take into account either

manufacturing tolerances or variations due to external

conditions such as voltage and temperature.

Reference Axis

An axis perpendicular to the sensing face and passing

through its center.

Repeatability

The difference between actual operating distances

measured at a constant temperature and voltage over

an 8-hour period. It is expressed as a percentage (%) of

rated operating distance (Sn).

Response frequency

The maximum rate that the output can change in response

to the input and still maintain linearity.

Response Time

The time required for the device switching element to

respond after the target enters or exits the sensing zone.

Reverse Polarity Protection

Internal components that keep the sensor from being

damaged by incorrect polarity connection to the

power supply.

Ripple

The alternating component remaining on a DC signal after

rectifying, expressed in percentage of rated voltage.

Sensing Face

The surface of the proximity sensor through which the

electromagnetic (or electrostatic) field emerges.

Short-Circuit Protection

The ability of a sensor to withstand a shorted condition (no

current-limiting load connected) without damage.

Slew Rate

The rate of change of the output voltage with respect to a

step change in input. A change in output of 0 to 10 volts at

a slew rate of 1.25 V/ms would take 8 ms to slew to the new

value.

Solid State

Pertains to devices using semiconductors instead of

mechanical parts.

Static Output

A sensor output that stays energized as long as the target

is present.

Switching Frequency

The maximum number of times per second that the sensor

can change state (ON and OFF) under ideal conditions,

usually expressed in Hertz (Hz).

Time-Delay Before Availability

The length of time after power is applied to the sensor

before it is ready to operate correctly, expressed in

milliseconds (ms).

Uprox Sensor ®

An inductive proximity sensor that detects all metals at the

same range. Uprox sensors are inherently weld-field

immune, operate over a wider temperature range and have

a higher switching frequency than standard inductive

sensors.

Uprox+ Sensor ®

Same basic characteristics as the Uprox Sensor, but with a

redesigned multi coil system which provides increased

sensing capabilities. Uprox+ also carries an IP68

environmental rating

Weld-Field Immunity (WFI)

The ability of a sensor not to false-trigger in the presence

of strong magnetic fields typically produced by resistance

welders.

Wire-Break Protection

Results in the output being OFF on a DC sensor if either

supply wire is broken.

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M4

Page 5

TURCK

Innovative Solutions for Automation

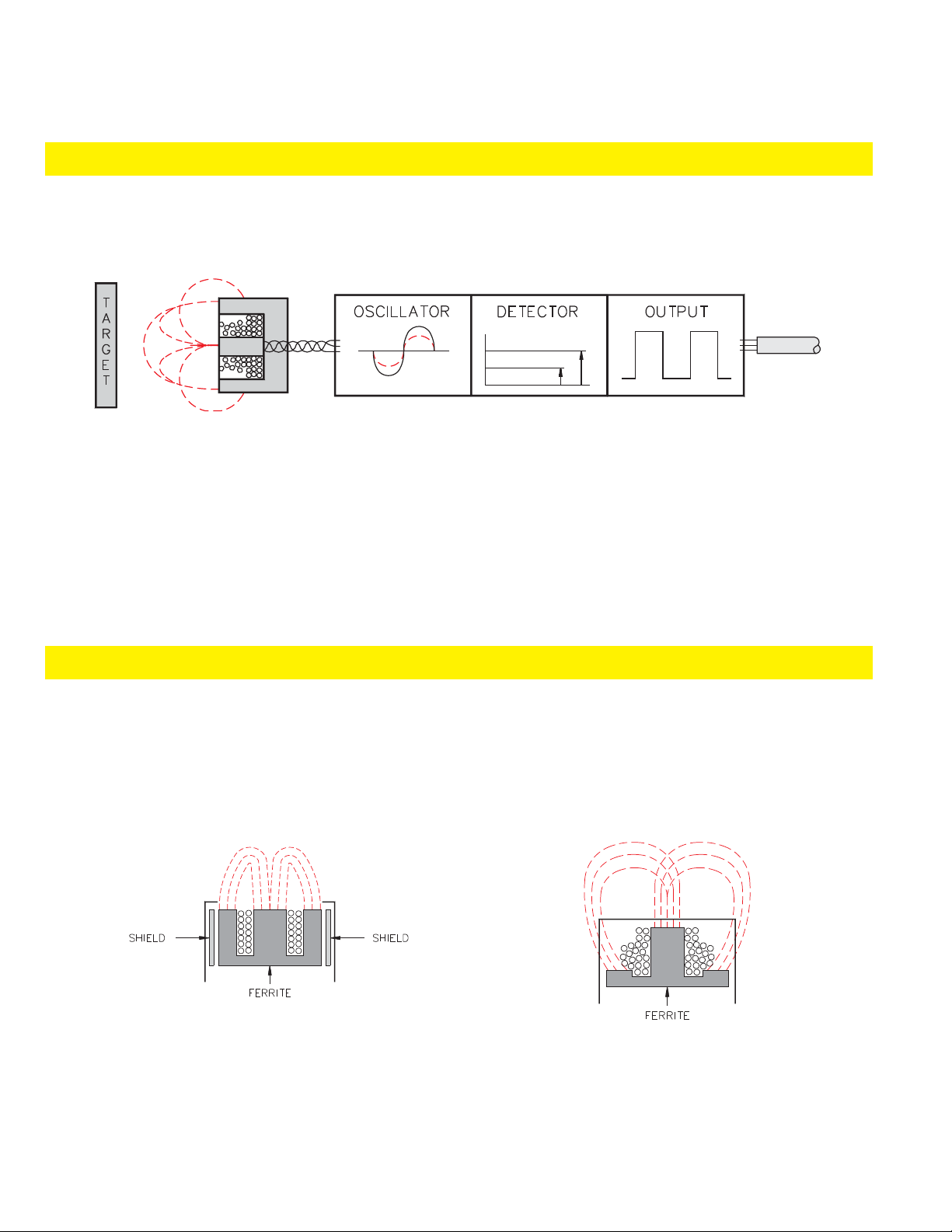

Operating Principle Ferrite Core

Figure 1

An inductive proximity sensor consists of a coil and ferrite core arrangement, an oscillator and detector circuit, and a solid-state

output (Figure 1). The oscillator creates a high frequency field radiating from the coil in front of the sensor, centered around the axis

of the coil. The ferrite core bundles and directs the electro-magnetic field to the front.

When a metal object enters the high-frequency field, eddy currents are induced on the surface of the target. This results in a loss of

energy in the oscillator circuit and, consequently, a smaller amplitude of oscillation. The detector circuit recognizes a specific change

in amplitude and generates a signal which will turn the solid-state output “ON” or “OFF”. When the metal object leaves the sensing

area, the oscillator regenerates, allowing the sensor to return to its normal state.

Embeddable (Shielded) vs. Nonembeddable (Nonshielded)

See mounting characteristics at the front of each section.

Figure 2

Embeddable construction includes a metal band

that surrounds the ferrite core and coil

arrangement. This helps to “bundle” or direct the

electro- magnetic field to the front of the sensor.

Figure 3

Nonembeddable (Nonshielded Sensor)Embeddable (Shielded Sensor)

Nonembeddable sensors do not have this

metal band; therefore, they have a longer

operating distance and are side sensitive.

M5 B1008 TURCK Inc. Minneapolis, MN 55441

Page 6

Industrial

15

Automation

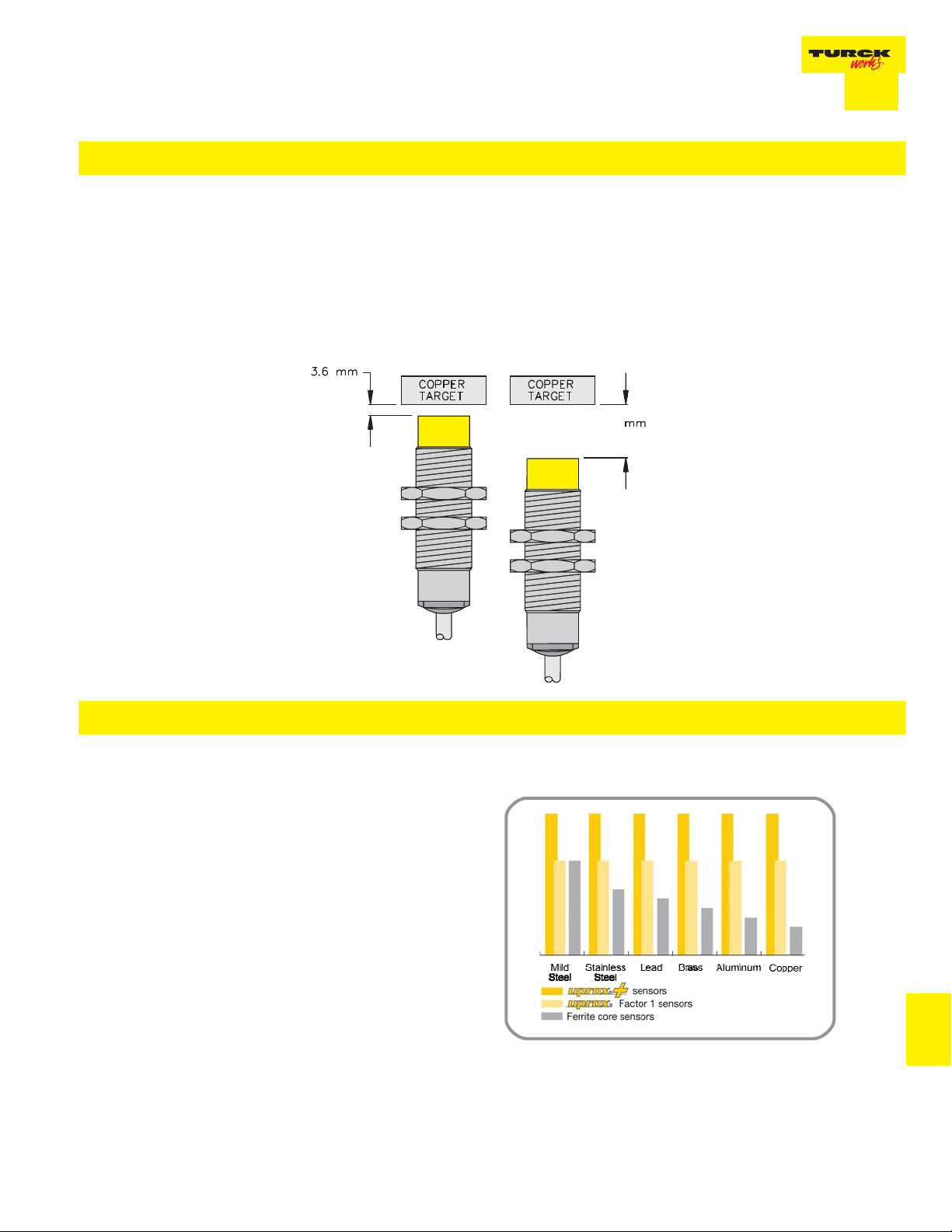

Uprox ® and Uprox+ ® Characteristics

No Correction Factor - Same rated operating distance for all metals.

•

Extended Operating Distance - Up to 400% greater than standard inductive sensors when using non-ferrous targets (Figure 4).

•

Weld Field Immunity - Uprox is unaffected by strong electromagnetic AC or DC fields because of its unique patented design.

•

High Switching Frequencies - Up to 10 times faster than standard inductive sensors.

•

Extended Temperature Range - Uprox can withstand temperatures up to 85°C (+185°F) with a ±15% temperature drift.

•

Figure 4

Standard

Ni 8-M18-..

TURCK Uprox is a patented next generation

development of inductive sensors that uses a

multi-coil system. Active coil(s) induces eddy

currents on the metal target and passive coil(s) are

affected by these eddy currents. Ferrous and

nonferrous metals have the same effect on the two

coils. Therefore, all metals, including galvanized

metals, have the same rated operating distance.

TURCK standard inductive sensors use a single coil

randomly wound around a ferrite core. The single

coil both induces eddy currents on the metal target

and is affected by these eddy currents. Ferrous and

nonferrous metals affect the sensor differently,

making it impossible to detect both types of metals

at the same rated operating distance.

Uprox

Ni15U-M18-..

Operating Principle Uprox ® and Uprox+ ®

Figure 5

Specifications

Operating distances comparison of Uprox

sensors and standard inductive sensors.

TURCK Inc. Minneapolis, MN 55441 B1008 M6

Page 7

TURCK

Innovative Solutions for Automation

Operating Distance (Sensing Range) Considerations

The operating distance (S) of the different models is basically a function of the diameter of the sensing coil. Maximum operating

distance is achieved with the use of a standard or larger target. Rated operating distance (Sn) for each model is given in the manual.

When using a proximity sensor the target should be within the assured range (Sa).

Standard Target

A square piece of mild steel having a thickness of 1 mm (0.04 in) is used as a standard target to determine the following operating

tolerances. The length and width of the square is equal to either the diameter of the circle inscribed on the active surface of the

sensing face or three times the rated operating distance Sn, whichever is greater.

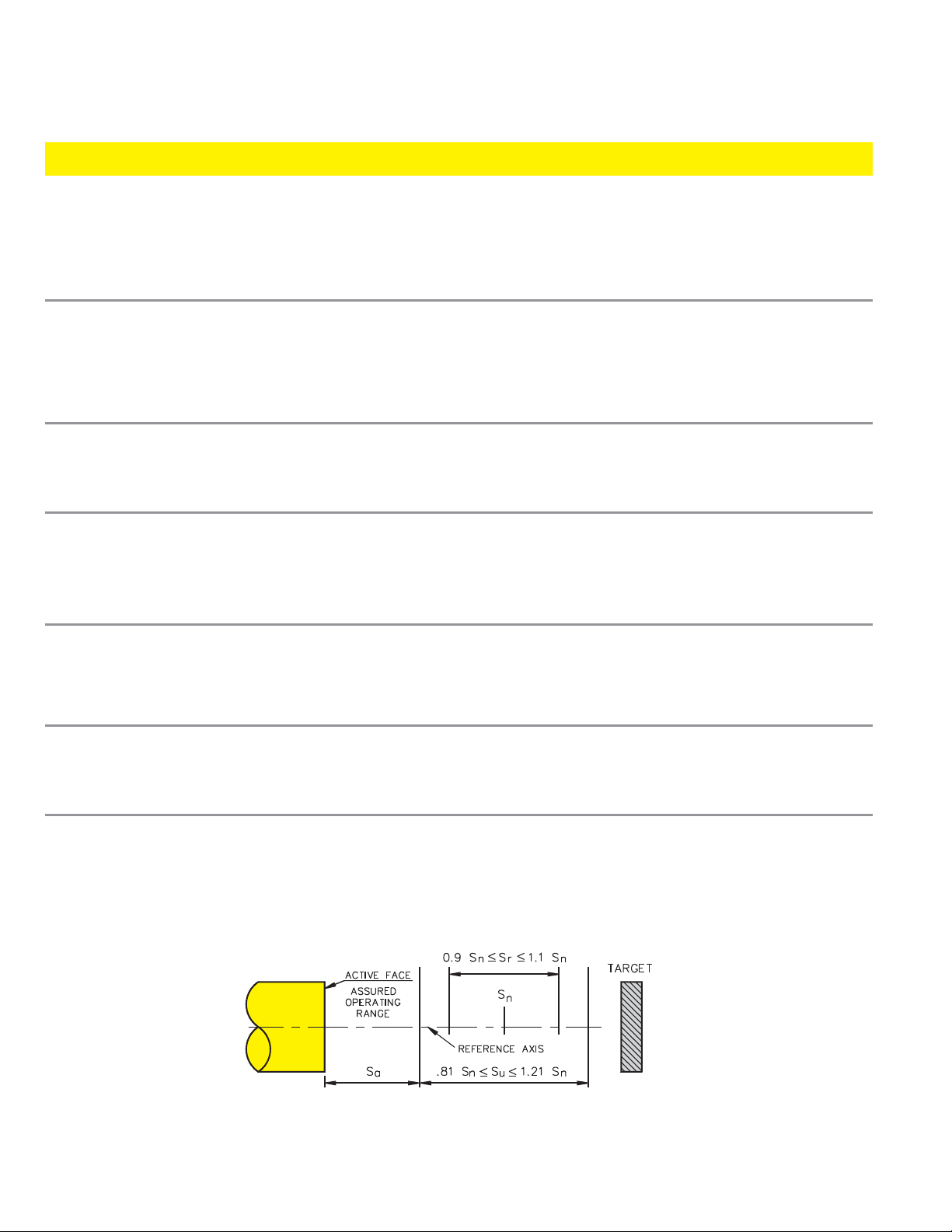

Operating Distance = S

The operating distance is the distance at which the target approaching the sensing face along the reference axis causes the output

signal to change.

Rated Operating Distance = Sn

The rated operating distance is a conventional quantity used to designate the nominal operating distance. It does not take into

account either manufacturing tolerances or variations due to external conditions such as voltage and temperature.

Effective Operating Distance = Sr 0.9 Sn≤Sr≤1.1Sn

The effective operating distance is the operating distance of an individual proximity sensor at a constant rated voltage and 23°C

(73°F). It allows for manufacturing tolerances.

Usable Operating Distance = Su 0.81 Sn≤Su≤1.21Sn

The usable operating distance is the operating distance of an individual proximity sensor measured over the operating temperature

range at 85% to 110% of its rated voltage. It allows for external conditions and for manufacturing tolerances.

Assured Operating Range = Sa 0 ≤ Sa ≤ 0.81Sn

The assured actuating range is between 0 and 81% of the rated operating distance. It is the range within which the correct operation

of the proximity sensor under specified voltage and temperature ranges is assured.

Figure 6

M7 B1008 TURCK Inc. Minneapolis, MN 55441

Page 8

Industrial

Automation

Operating Distance (Sensing Range) Considerations

These correction factors apply to standard inductive sensors when a nonferrous target is being detected.

The correction factors are nominal values. Deviations may be due to variations in oscillator frequency, alloy composition, purity

and target geometry.

Aluminum foil 1.00

Stainless steel 0.60 to 1.00

Mercury 0.65 to 0.85

Lead 0.50 to 0.75

Brass 0.35 to 0.50

Aluminum (massive) 0.35 to 0.50

Copper 0.25 to 0.45

Correction factors do not apply to TURCK Uprox®sensors. These sensors see all metals at the same range.

•

TURCK also manufactures “nonferrous only” sensors. These sensors will selectively detect nonferrous targets at the rated

•

operating distance. They will not detect ferrous targets; however, ferrous targets positioned between them and a

nonferrous target may mask the nonferrous target. The rated operating distance of these sensors is not subject to the

correction factors that apply to standard inductive sensors.

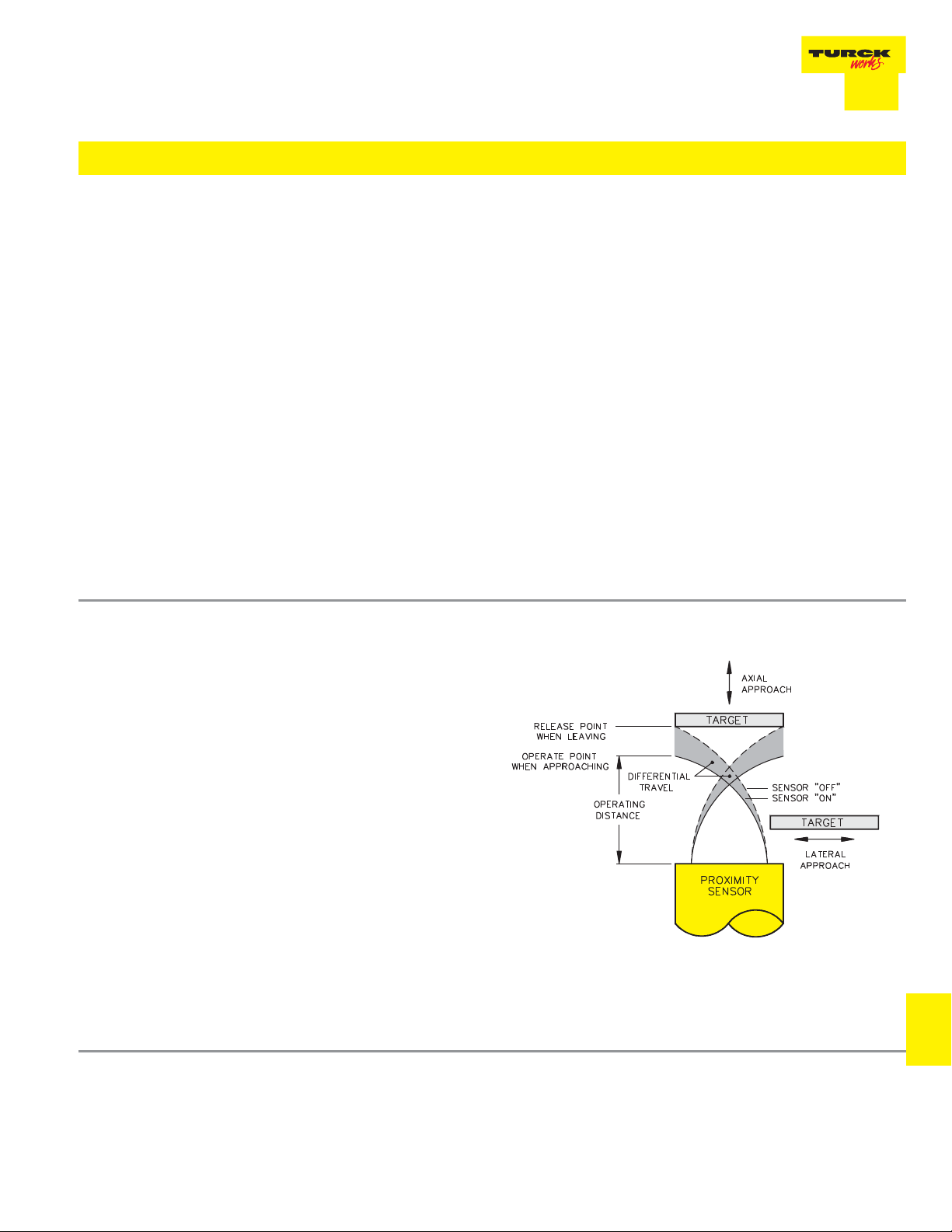

Differential Travel (Hysteresis)

The difference between the “operate” and “release”

points is called differential travel (See shaded area in

Figure 7).It is factory set at less than 15% of the effective

operating distance.

Differential travel is needed to keep proximity sensors from

“chattering” when subjected to shock and vibration, slow

moving targets, or minor disturbances such as electrical noise

and temperature drift.

Figure 7

Specifications

Actuation Mode

Inductive sensors can be actuated in an axial or lateral approach (See Figure 7). It is important to maintain an air gap between the

target and the sensing face to prevent physically damaging the sensors.

TURCK Inc. Minneapolis, MN 55441 B1008 M8

Page 9

TURCK

Innovative Solutions for Automation

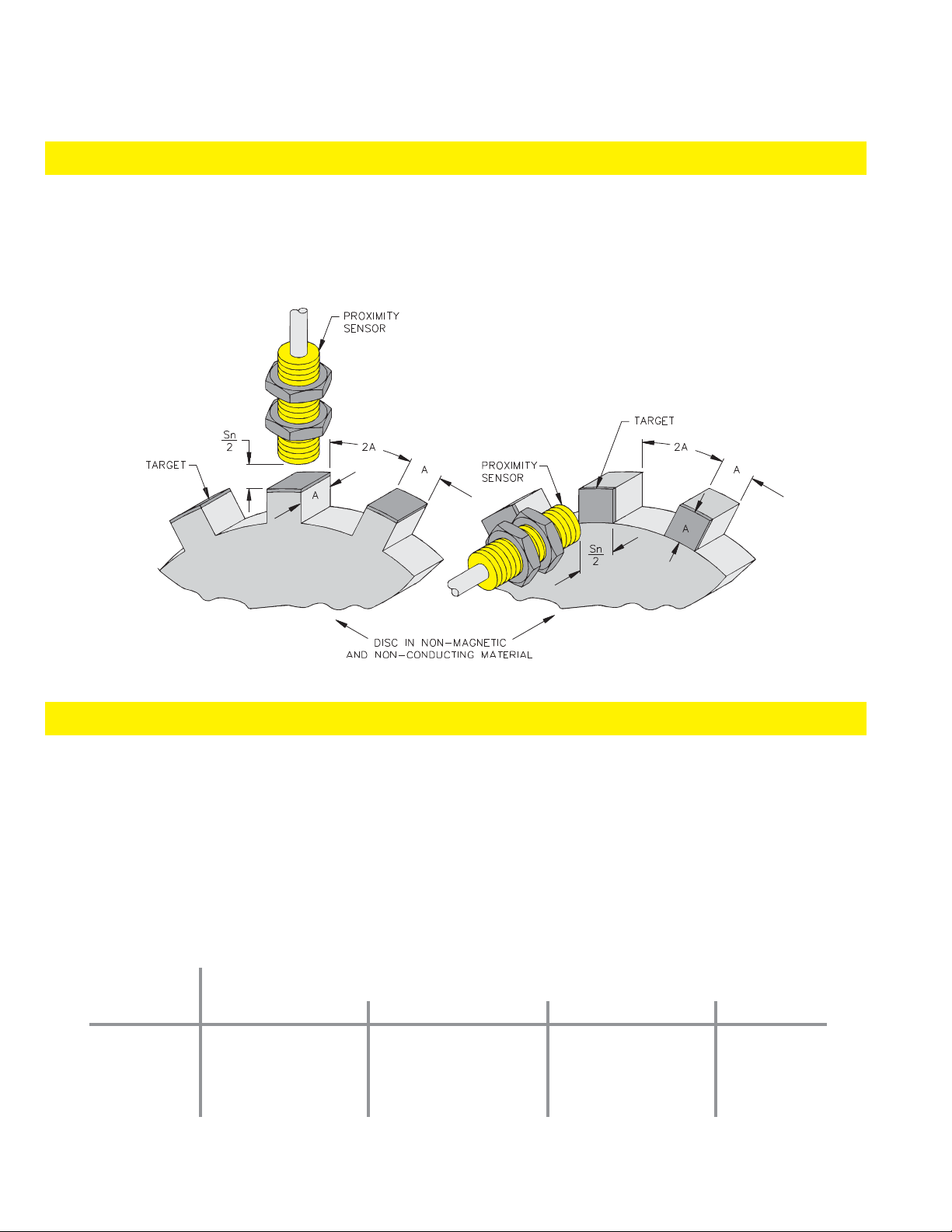

Maximum Switching Frequency

Minimum parameters for measuring at maximum switching frequency are shown in Figure 8. Using a smaller target or space may

result in a reduction of a specific sensor’s maximum switching frequency and decrease sensor to target air gap tolerance. See page

M7 for determining dimension “A” of standard target.

Weld Field Immunity

Many critical applications for proximity sensors involve their use in weld field environments. AC and DC resistance welders used in

assembly equipment and other construction machines often require in excess of 20 kA to perform their weld function. Magnetic

fields generated by these currents can cause false outputs in standard sensors.

TURCK has pioneered the design and development of inductive proximity sensors that not only survive such environments, but

remain fully operative in them.

The limit of the weld field immunity depends on the kind of field (AC or DC), the housing size of the sensor and its location in the

field. For example, in an AC or DC weld field, the “/S34" inductive sensors can be positioned one inch from a 20 kA current carrying

bus. See Section H for a list of weld field immune sensors.

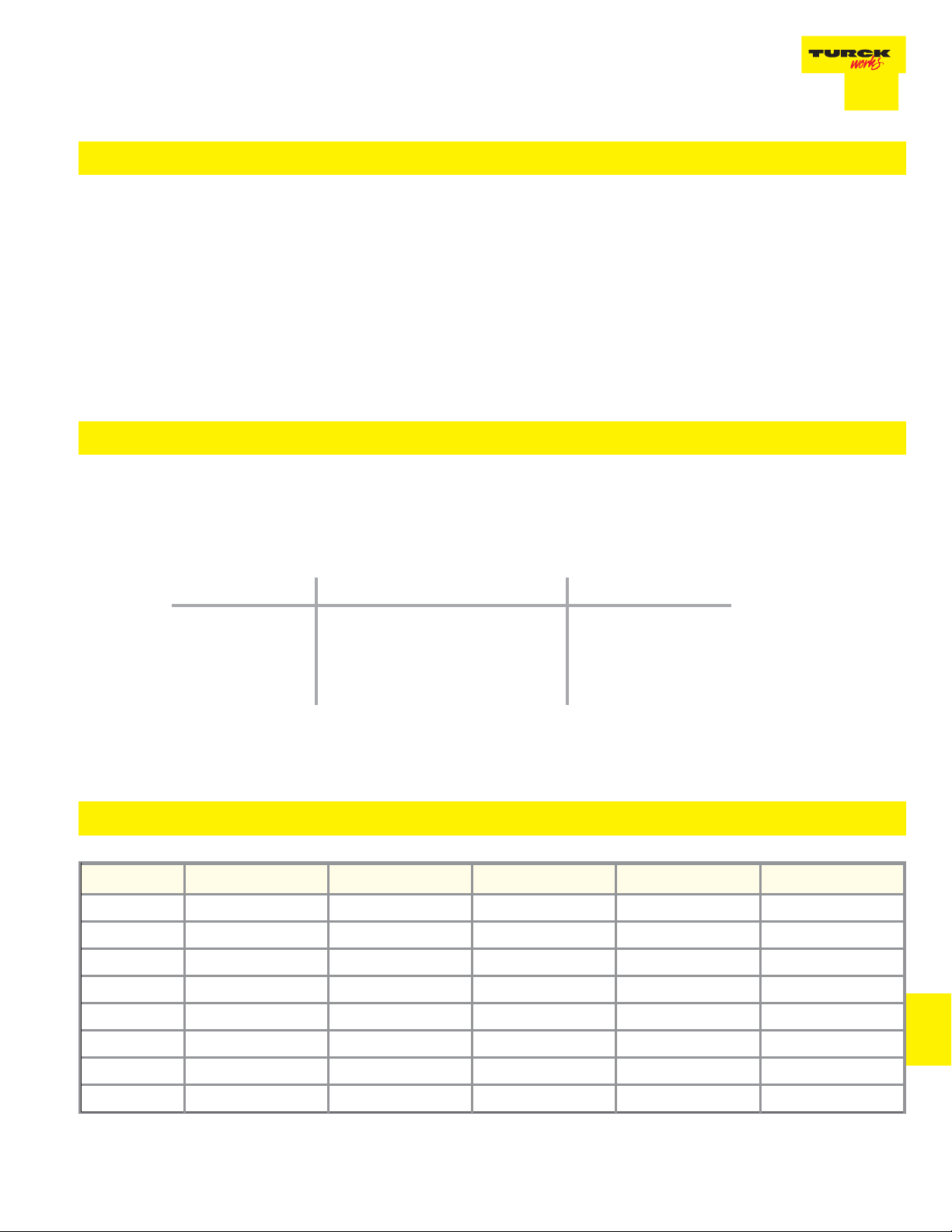

Reference values for magnetic induction:

Distance [mm]

I [kA]

5

10

20

50

100

Gauss = 10 x mT

12.5

80 mT

160 mT

320 mT

800 mT

1600 mT

25

40 mT

80 mT

160 mT

400 mT

800 mT

50

20 mT

40 mT

80 mT

200 mT

400 mT

100

10 mT

20 mT

40 mT

100 mT

200 mT

M9 B1008 TURCK Inc. Minneapolis, MN 55441

Page 10

Industrial

Automation

TURCK inductive proximity sensors are manufactured with a shielded coil, designated by “Bi” in the part number, and a

nonshielded coil, designated by “Ni” in the part number. Embeddable (shielded) units may be safely flush-mounted in

metal. Nonembeddable (nonshielded) units require a metal free area around the sensing face. Because of possible

interference of the electromagnetic fields generated by the oscillators, minimum spacing is required between adjacent

or opposing sensors.

It is good engineering practice to mount sensors horizontally or with the sensing face looking down. Avoid sensors that

look up wherever possible, especially if metal filings and chips are present.

Maximum Locknut Torque Specifications

The locknut torque should be considered for all threaded sensors to prevent the housing from being over stressed.

The values below pertain to the locknut provided with each sensor. Liquid thread sealants of an anaerobic base, such as

Loctite, are recommended if strong vibrations are likely.

Caution: Sensor barrels are typically brass. Consider break torque when selecting grade of thread sealant.

Mounting

Barrel Size Metal Barrel Plastic Barrel

5 mm 5 Nm (3.7 ft-lb) ---8 mm 10 Nm (7.4 ft-lb) ---12 mm 10 Nm (11 ft-lb) 1 Nm (0.7 ft-lb)

18 mm 25 Nm (18 ft-lb) 2 Nm (1.4 ft-lb)

30 mm 90 Nm (66 ft-lb) 5 Nm (3.7 ft-lb)

47 mm 90 Nm (66 ft-lb) ----

Drill Hole Sizes for Metric Threads

Thread Size Pitch Thru Hole (mm) Tap Hole Dia. (mm) Thru Hole (in) Tap Hole Dia. (in)

M5 x 0.5 0.5 5.0 4.5 13/64 5/32

M8 x 1 1.0 8.0 7 21/64 1/4

M12 x 1 1.0 12.0 11 31/64 13/32

M18 x 1 1.0 18.0 17 23/32 41/64

M30 x 1.5 1.5 30.0 28 1-3/16 1-5/64

Specifications

PG 9 1.41 15.2 14 5/8 1/2

PG 13.5 1.41 20.4 19 13/16 23/32

PG 36 1.59 47.0 45.5 1-7/8 1-47/64

TURCK Inc. Minneapolis, MN 55441 B1008 M10

Page 11

TURCK

Innovative Solutions for Automation

DC Outputs

Two-, three-, or four-wire proximity sensors contain a transistor oscillator and a snap-action amplifier. This provides exceedingly high

accuracy to a set switching point, even with very slowly approaching targets. Switching characteristics are unaffected by supply

voltage fluctuations within the specified limits.

The sensors can drive electromechanical relays, counters, solenoids, or electronic modules, and interface directly with logic systems

or programmable controllers without additional interface circuitry. They are available with either NPN output transistors (current

sinking) or PNP output transistors (current sourcing).

Load current ratings vary from 100 mA to 200 mA depending on physical size. Standard voltage range is 10-30 VDC with certain

types available for 10-65 VDC. All models incorporate wire-break, transient and reverse polarity protection.

Power-On false pulse suppression is also standard.

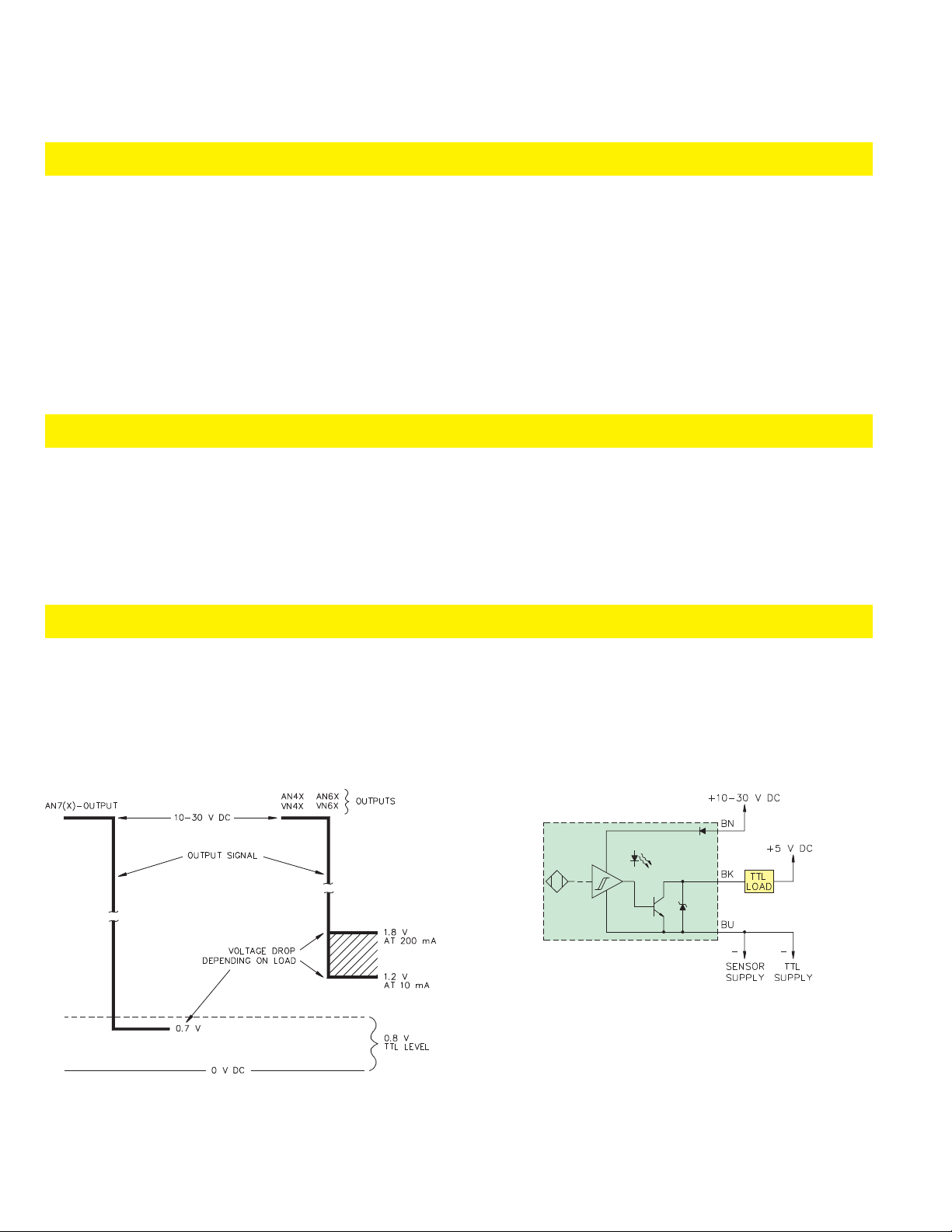

Short-Circuit and Overload Protection

TURCK DC sensors with a Voltage Range designation of "4", "6" or "8" in the part number are short-circuit and overload protected

(automatic reset). These sensors incorporate a specially designed circuit which continuously monitors the ON state output current

for a short-circuit or overload condition. If either of these fault conditions occurs, the output is turned OFF and pulse tested until the

fault is removed. This added protection causes a ≤1.8 V drop across the output in the normal ON state. This may be a problem when

interfacing with some logic low inputs (see TTL compatibility).

TTL Compatibility

Some solid-state loads requiring NPN (sinking) input signals need a ≤0.8 V signal to reliably turn ON. The output of these sensors will

have a voltage drop of ≤0.7 V (0.3 V typical), which will ensure reliable operation. Do not use voltage ranges "4" and '6" when TTL

compatibility is required. Contact the factory for a list of part numbers with this specification.

Figure 2Figure 1

Voltage drop is measured from output wire black (BK) to ground wire blue (BU).

M11 B1008 TURCK Inc. Minneapolis, MN 55441

Page 12

Industrial

Automation

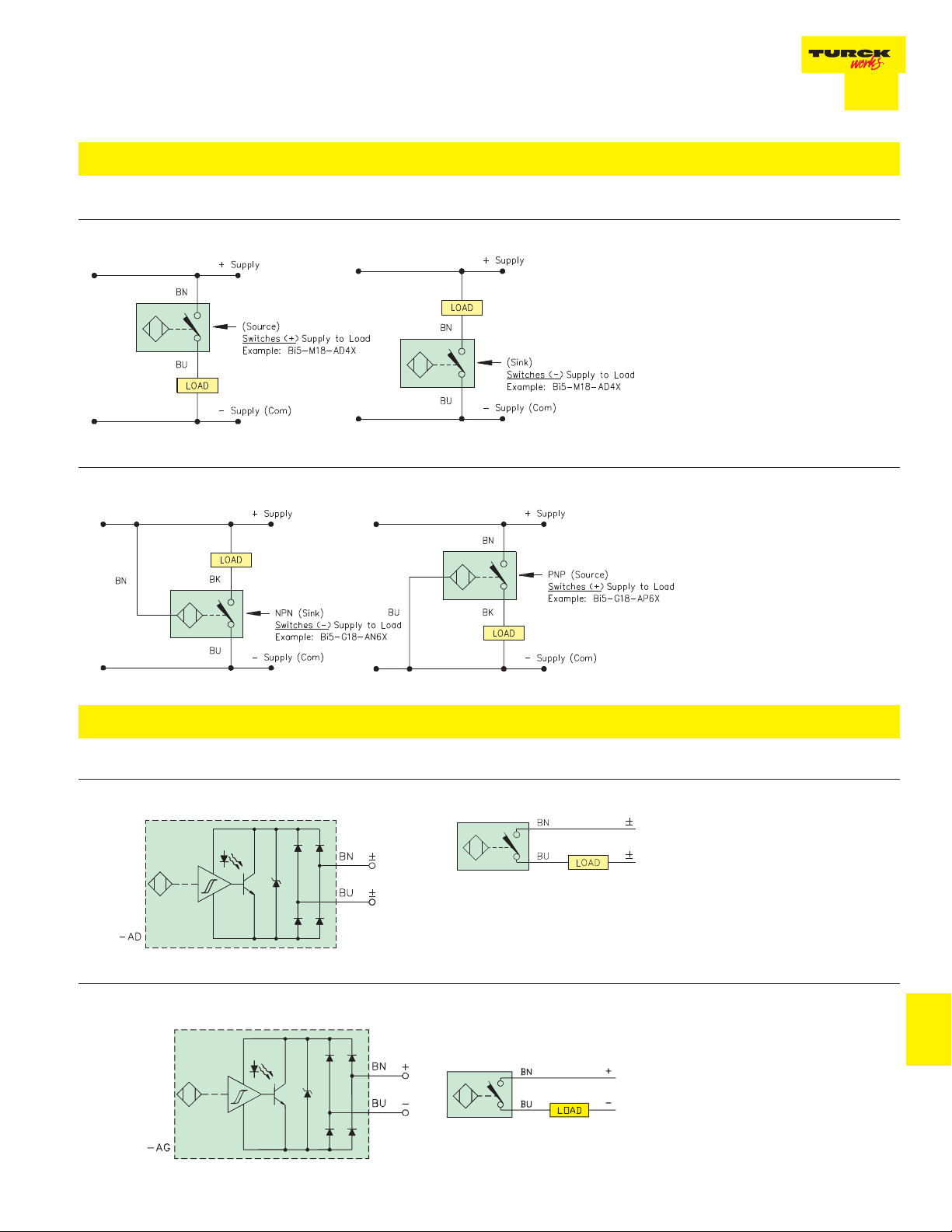

DC Sourcing and Sinking

2-Wire DC

Figure 3 Source (PNP)

Figure 6 Sink (NPN)

Figure 4 Sink (NPN)

Note: TURCK 2-wire DC

sensors with an "AD"

designation are not

polarity sensitive and can

be used to sink or source

a load.

3-Wire DC

Figure 5 Source (PNP)

Figure 7

Figure 9

Figure 8

DC Outputs

“AD” 2-Wire DC Output

“AG” 2-Wire DC Output

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M12

Page 13

TURCK

Innovative Solutions for Automation

DC Outputs

“AN4" and ”AP4" 3-Wire DC Outputs

Figure 11 Wiring DiagramFigure 10 Electronic Output Circuit

NPN transistor

(i.e. current sinking

negative switching)

N.O. output

PNP transistor

(i.e. current sourcing

positive switching)

N.O. output

“AN6(7)" and ”AP6" 3-Wire DC Outputs

Figure 13 Wiring DiagramFigure 12 Electronic Output Circuit

TURCK TIP

NPN transistor

(i.e. current sinking

negative switching)

N.O. output

PNP transistor

(i.e. current sourcing

positive switching)

N.O. output

•

Order current sinking (NPN) sensors with

the voltage range “7" only when low

voltage drop for TTL gates is required. In all

other cases, order sensors with voltage

ranges ”4" or “6".

M13 B1008 TURCK Inc. Minneapolis, MN 55441

Page 14

Industrial

Automation

DC Outputs

“VN4" and ”VP4" 4-Wire DC Outputs

Figure 15 Wiring DiagramFigure 14 Electronic Output Circuit

NPN transistor

(i.e. current sinking

negative switching)

complementary

output (SPDT)

PNP transistor

(i.e. current sourcing

positive switching)

complementary

output (SPDT)

“VN6" and ”VP6" 4-Wire DC Outputs

Figure 17 Wiring DiagramFigure 16 Electronic Output Circuit

NPN transistor

(i.e. current sinking

negative switching)

complementary

output (SPDT)

PNP transistor

(i.e. current sourcing

positive switching)

complementary

output (SPDT)

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M14

Page 15

TURCK

Innovative Solutions for Automation

DC Outputs

“LIU" 4-Wire Linear Analog DC Output

Figure 18 Electronic Output Circuit

Figure 20 Wiring Diagram

Figure 19 Typical Response Curve

Linear Analog Output; Current and Voltage

Series/Parallel Connection

Logic functions with DC proximity sensors:

Self-contained proximity sensors can be wired in series or parallel to perform such logic functions as AND, OR, NAND, NOR. The

wiring diagrams show the hook-up of four sensors with NPN and PNP outputs.

Take into account the accumulated no-load current and voltage drop per sensor added in the series string.

Series-connection:

N.O. sensors: AND Function

(target present, all sensors: load “on”)

N.C. sensors: NOR Function

(target present, any sensor: load “off”)

Parallel-connection:

N.O. sensors: OR Function

(target present, any sensor: load “on”)

N.C. sensors: NAND Function

(target present, all sensors: load “off”)

TURCK TIP

•

To prevent the load from seeing the cumulative voltage drop of multiple 3-wire sensors in series, alternating polarity sensors can

be used provided that the desired polarity is at the load.

•

Wiring 3-wire sensors in series delays the load by the accumulated “time delay before availability" of all sensors in the string.

M15 B1008 TURCK Inc. Minneapolis, MN 55441

Page 16

Industrial

Automation

Figure 21 NPN Connection

Series/Parallel Connection

Figure 22 PNP Connection

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M16

Page 17

TURCK

Innovative Solutions for Automation

Short-Circuit and Overload Protection

TURCK AC sensors with the Voltage Range designation “30", “32" or ”40" are short-circuit and overload protected

(manual reset). These sensors incorporate a specially designed circuit which continuously monitors the ON state

output current for a short-circuit or overload condition. If either of these fault conditions occurs, the output is latched

OFF until the power has been cycled OFF and ON again.

Always select short-circuit and overload protected sensors whenever possible.

CAUTION!

DO NOT…

operate an incandescent light bulb as a load.

The extremely high cold current will cause an overload condition.

DO NOT…

operate a proximity sensor from a wall outlet without a load.

This is considered a “dead” short and can cause catastrophic

damage to nonshort-circuit protected sensors.

DO NOT…

directly operate a motor with a proximity sensor.

The inrush current can cause an overload condition.

Always use a motor starter, relay or other appropriate device.

DO NOT…

forget to ground. AC and AC/DC sensors must be grounded or there exists

a potential of electrical shock.

M17 B1008 TURCK Inc. Minneapolis, MN 55441

Page 18

Industrial

Automation

AC and AC/DC Outputs

Figure 1 AC/DC Outputs - "3", "31", "33", non-SCP

SCP = Short-circuit Protected

These sensors are used as pilot devices for AC-operated loads such as relays, contactors, solenoids, etc. The solid-state output

permits use of the sensors directly on the line in series with an appropriate load. They, therefore, replace mechanical limit switches

without alteration of circuitry, where operating speed or environmental conditions require the application of solid-state sensors.

These sensors are typically available in a voltage range of 20-250 VAC. All models are available with either normally open (N.O.),

normally closed (N.C.) or programmable outputs (from N.O. to N.C.). Careful consideration must be given to the voltage drop across

AC/DC sensors when used at 24 VDC.

Figure 2 AC/DC Outputs - "30", "32", "40" SCP

Figure 3 Electro-Mechanical Equivalents

Since the sensors are connected in series with the

load by means of only two leads, an off-state

current flows through the load in the magnitude of

approximately 1.7 mA.

This, however, does not affect the proper and

reliable performance of most AC loads. Another

characteristic of solid state sensors isa5to7volt

drop developed across the sensor in the ON state.

All models contain a snubber network to protect

against transients from inductive loads, which can

cause false triggering.

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M18

Page 19

TURCK

Innovative Solutions for Automation

Series Connection

Figure 4

Series-connection: (Figure 4)

N.O. sensors: AND Function

(target present, all sensors: load “on”)

N.C. sensors: NOR Function

(target present, any sensor: load “off”)

The maximum number of sensors to be operated in series depends on the stability of the line voltage and the operating

characteristics of the load in question. The supply voltage minus the accumulative on state voltage drop across the series connection

(approximately 7 Vrms per sensor) must be ≥ the minimum required load voltage.

Mechanical Switches in Series

Problem:

Mechanical switches in series with proximity sensors should always

be avoided because they can create an open circuit, leaving the

proximity sensor without power. In order to operate properly, a

proximity sensor should be powered continuously. A typical

problem encountered when the mechanical contact closes while

the target is present is a short time delay that is experienced before

the load energizes (time delay before availability).

Solution:

A33kΩ, 1W by-pass resistor can be added across the mechanical

contact to eliminate the time delay before availability. This will

allow enough leakage current to keep the sensor ready for

instantaneous operation.

Figure 5

Figure 6

M19 B1008 TURCK Inc. Minneapolis, MN 55441

Page 20

Industrial

Automation

Parallel Connection

Figure 7

Parallel Connection: (Figure 7)

N.O. sensors: OR Function

(target present, any sensor: load “on”)

N.C. sensors: NAND Function

(target present, all sensors: load “off”)

Wiring AC proximity sensors in parallel can result in inconsistent operation and should generally be avoided.

On-state voltage drop: With any sensor ON, the voltage across all other sensors is typically 7 Vrms. Since the minimum rated

voltage for AC sensors is 20 Vrms, no other sensor with a target present can turn ON until the first sensor turns OFF. This transition is

not instantaneous due to the time delay before availability, during which the load may drop out.

Leakage current through the load: This is equal to the total leakage of all sensors wired in parallel. Too much leakage into a solid

state load can cause the input to turn ON and not turn OFF. Small relays may not drop out if the leakage current exceeds the relay’s

holding current.

Figure 8

Figure 9

Formula:

minimum operating voltage of proximity sensor

R=

load current at operating voltage

Mechanical Switches in Parallel

Problem:

As previously discussed, proximity sensors should be

powered continuously to avoid the time delay before

availability during power-up.

With mechanical switches in parallel, the sensor is

shorted out every time the contact is closed, leaving it

without power. If the target is present when the

mechanical contact is opened, a small delay will be

experienced during which the load may drop out.

Solution:

This delay can be avoided by adding a resistor in series with the mechanical

contact. The voltage drop developed across the resistor with the contact closed

will be enough to keep the sensor active. Use the formula below to determine the

value and wattage.

Example:

20 V

R=

180 mA

R = 110 W

Minimum resistor wattage rating: E x I

Example: 20 V x 180 mA = 3.6 W

recommended

≈ 5 watts

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M20

Page 21

TURCK

Innovative Solutions for Automation

NAMUR (Y0 and Y1) Output

NAMUR sensors are 2-wire sensing devices used with switching amplifiers. Because of the small amount of energy needed to operate

NAMUR sensors, they can be used in intrinsically safe applications.

The operation of this sensor is similar to that of a variable resistor with a change in impedance as a target approaches the sensor.

When no metal is being sensed, the inductive sensor is in a low impedance state and draws a current of more than 2.2 mA. When a

metal target enters the high-frequency field radiated from the sensor head, the impedance increases as the target approaches. When

fully damped, the sensor draws less than 1.0 mA. Note: For capacitive and inductive magnet operated sensors, the current change

characteristics are opposite.

The current differential from the undamped to the damped (metal present) state is used to trigger an amplifier at a defined switching

point. These sensors contain a relatively small number of components, which allows the construction of small devices and also

assures a high degree of reliability.

In the undamped and damped state, the devices have fairly low impedance and are therefore, unaffected by most transients. NAMUR

sensor circuits operate on direct current. Therefore, cable runs of several sensors may be run parallel to one another without mutual

interference.

The NAMUR (Y0 and Y1) sensor behaves like

a variable resistor when a target

approaches.

The impedence increases or decreases

between 1 kΩ and8kΩ.

Typical Output Curves

Figure 2

Note:

The typical curve of

current versus sensing

distance with 8.2 V DC

supply and 1 kΩ source

impedence. All NAMUR (Y0

and Y1) sensors are

calibrated to pass through

1.55 mA at nominal

sensing range±10%.

Figure 1

Figure 3

M21 B1008 TURCK Inc. Minneapolis, MN 55441

Page 22

Industrial

Automation

Typical Intrinsically Safe Installation

Figure 4

For guidance on installation of TURCK intrinsically safe systems, refer to the Instrument Society of America publication

ISA-RP12.6-1995, “Wiring Practices for Hazardous (Classified) Locations Instrumentation".

The complete line of Intrinsically Safe and Associated Apparatus is featured in the TURCK “Isolated Barriers and Amplifiers” catalog.

Custom Interface Circuits

Figure 5

NAMUR sensors can operate outside the nominal operating values when the sensor is used in a nonhazardous area.

The supply voltage limits are: V

= 5 VDC; V

min

Within this voltage range the load resistance R

=30VDC

max

must be adjusted for the supply voltage.

i

The following table gives typical values:

V

(DC) Ri(k )I

supply

5 0.39 ≈0.7 ≈0.1

12 1.8 ≈2.3 ≈0.3

15 2.2 ≈2.9 ≈0.4

24 3.9 ≈3.8 ≈0.5

Figure 6

(mA) I (mA)

sn

Specifications

If these values are used, the current Isncorresponds to the rated operating distance (Sn) of the sensor.

NAMUR sensors are short-circuit protected up to 15 VDC and reverse polarity protected up to 10 VDC.

TURCK Inc. Minneapolis, MN 55441 B1008 M22

Page 23

TURCK

Innovative Solutions for Automation

eurofast ® Pinout Diagrams and Mating Cordset

AD4X-H1141

Mating Cordset: RK 4.2T-*

AD4X-H1144

Mating Cordset: RK 4.2T-*/S674

RD4X-H1141

Mating Cordset: RK 4.21T-* (Y0)

RD4X-H1143

Mating Cordset: RK 4.2T-*

AG41X-H1341

Mating Cordset: RK 4.23T-*/S748

AP6X-H1141/H1341

Mating Cordset: RK 4T-*

AN6X-H1141/H1341

Mating Cordset: RK 4T-*

M23 B1008 TURCK Inc. Minneapolis, MN 55441

Page 24

Industrial

Automation

eurofast ® Pinout Diagrams and Mating Cordset

RN6X-H1141

Mating Cordset: RK 4.4T-*

RN6X-H1143/H1343

Mating Cordset: RK 4.42T-*

RP6X-H1141

Mating Cordset: RK 4.4T-*

RP6X-H1143/H1343

Mating Cordset: RK 4T-*

AG41X-H3141

Mating Cordset: RK 4.23T-*/S748

VP4X2-H1141/H1341

Mating Cordset: RK 4.4T-*

VN4X2-H1141/H1341

Mating Cordset: RK 4.4T-*

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M24

Page 25

TURCK

Innovative Solutions for Automation

Innovative Sensor and Connector Solutions

TURCK is the market leader in providing innovative sensor and connectivity solutions for industrial automation. Combine

TURCK's high quality, high performance sensors with our ability to quickly mold multiple styles of cordsets give our customers

an infinite selection of unique connectorized sensing solutions.

All TURCK sensors with potted-in cable are available with customized cable length and connector options. The broadest

selection of connector options provides custom sensing solutions for the most diverse industrial applications.

Because it is TURCK, you can expect the same fast, flexible support. Even with custom configurations, YOUR

be made within several days. Best of all, minimum quantity for YOUR

Part numbers are developed through your TURCK representative or application support.

In general, the formula below illustrates how to configure a custom, connectorized TURCK sensor.

sensor; ONE!

sensor can often

Bi 8U-MT18-AN6X + 0.5 Meters + RS 4T

New Part Number = Bi 4-M12-AN6X-0.5-RS 4T

Sensors with Connector Examples:

+ Length in Meters +

Bi 5-MT18-AN6X - 0.2M - RS 4T

Cable Sensor

M25 B1008 TURCK Inc. Minneapolis, MN 55441

Cable

Length

(meters)

eurofast®

Male

Connector

Bi 2-EG08K-AP6X - 0.5M - RS 4T

Cable Sensor

Cable

Length

(meters)

eurofast

Male

Connector

Page 26

Industrial

Automation

Innovative Sensor and Connector Solutions

Sensors with Connector Examples:

Bi 2-Q5.5-AP6X - 0.3M - PSG 3

Cable Sensor

Cable

Length

(meters)

picofast®

Male

Connector

Bi10U-EM30-AP6X - 0.2M - RS 4T

Cable Sensor

Cable

Length

(meters)

eurofast

Male

Connector

Bi 8-M18-AN6X - 0.1M - RSM 40

Cable Sensor

Cable

Length

(meters)

minifast®

Male

Connector

Ni 5U-Q10S-AN6X - 0.4M - RS 4T

Cable Sensor

Cable

Length

(meters)

eurofast

Male

Connector

Bi 8U-Q10-APX2 - 0.1M - PSG 3M

Cable Sensor

TURCK Inc. Minneapolis, MN 55441 B1008 M26

Cable

Length

(meters)

picofast®

Male

Connector

Specifications

Page 27

TURCK

Innovative Solutions for Automation

2-Wire DC NAMUR - (Y0 and Y1)

Differential Travel (Hysteresis)..........................1-10% (5% typical)

Nominal Voltage ..................................8.2VDC(EN60947-5-6)

Resistance Change from

Nonactivated to Activated Condition .....................Typical <1.0 to >8.0 kΩ

Resulting Current Change ............................≥2.2 mA to ≤1.0 mA

Recommended Switching Point for

Remote Amplifier..................................>1.2 to <2.1 mA, typ. 1.55 mA ON/1.75 mA OFF

Power-On Effect...................................Realized in Amplifier

Reverse Polarity Protection ...........................Incorporated

Wire-Break Protection ...............................Realized in Amplifier

Transient Protection ................................Realized in Amplifier

Shock .........................................30g,11ms

Vibration .......................................55Hz,1mmAmplitude in all 3 Planes

Repeatability.....................................≤2% of Rated Operating Distance

2-Wire DC - (AD4, RD4, AG41 and RG41)

Ripple .........................................≤10%

Differential Travel (Hysteresis)..........................3-15% (5% typical)

Voltage Drop Across Conducting Sensor ...................Non-polarized (AD) <5.0 V

.............................................Polarized (AG) <4.0 V

Trigger Current for Overload Protection ...................≥120 mA

Minimum Load Current ..............................≥3.0 mA

Off-State (Leakage) Current ...........................≤0.8 mA

Power-On Effect...................................PerIEC947-5-2

Transient Protection ................................PerEN60947-5-2

Shock .........................................30g,11ms

Vibration .......................................55Hz,1mmAmplitude in all 3 Planes

Repeatability.....................................≤2% of Rated Operating Distance

REED (AC) and (DC) - (AR7X)

Ripple .........................................≤10%

Differential Travel (Hysteresis)..........................≤1 mm (Depends on magnet)

Maximum Switching Capacity..........................10W

No-Load Current ..................................0mA

Maximum Approach Velocity ..........................≤10 m/s

Power-On Effect...................................PerIEC947-5-2

Transient Protection ................................PerEN60947-5-2

Shock .........................................30g,11ms

Vibration .......................................55Hz,1 mm Amplitude in all 3 Planes

Repeatability.....................................≥ ±0.1 mm

.............................................(constant temperature & voltage)

Temperature Drift .................................≤0.1 mm

Voltage Drop.....................................≤0.5 Volts

M27 B1008 TURCK Inc. Minneapolis, MN 55441

Page 28

Industrial

Automation

3-Wire DC - (AN, RN, AP, RP)

Ripple..........................................≤10%

Differential Travel (Hysteresis) ..........................3-15% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤1.8 V

..............................................- Si...K08/K10(AP71, AN7). . . ≤0.7 V

..............................................- Bi/Ni../S34 ...........≤1.8 V

..............................................- Bi 2-Q8SE-AP/AN.. ......≤2.5 V

Trigger Current for Overload Protection ....................≥220 mA on 200 mA Load Current

..............................................≥170 mA on 150 mA Load Current

..............................................≥120 mA on 100 mA Load Current

Off-State (Leakage) Current ............................<100 μA

No-Load Current ...................................<10mA(Uprox ≤15 mA)

Time Delay Before Availability ..........................≤8ms

Power-On Effect ...................................PerIEC947-5-2

Reverse Polarity Protection ............................Incorporated

Wire-Break Protection ...............................Incorporated

Transient Protection ................................PerEN60947-5-2

Shock ..........................................30g,11ms

Vibration ........................................55Hz,1mmAmplitude in all 3 Planes

Repeatability .....................................≤2% of Rated Operating Distance

..............................................Bi 2-Q8SE-AP/AN.. ≤5% of Rated Operating Distance

4-Wire DC (VN, VP)

Ripple..........................................≤10%

Differential Travel (Hysteresis) ..........................3-15% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤1.8 V at 200 mA

Trigger Current for Overload Protection ....................≥220 mA on 200 mA Load Current

..............................................≥170 mA on 150 mA Load Current

..............................................≥120 mA on 100 mA Load Current

Off-State (Leakage) Current ............................<100 μA

No-Load Current ...................................<10mA(Uprox ≤15

Power-On Effect ...................................PerIEC947-5-2

Reverse Polarity Protection ............................Incorporated

Wire-Break Protection ...............................Incorporated

Transient Protection ................................PerEN60947-5-2

Shock ..........................................30g,11ms

Vibration ........................................55Hz,1mmAmplitude in all 3 Planes

Repeatability .....................................≤2% of Rated Operating Distance

mA)

Solid State Relay (AM6 and VM6)

Ripple ...................≤10%

Rated Operational Current......10-30 VDC

Differential................3-15% (5% typical)

Voltage Drop

(Across Conducting Sensor) at I

Continuous Load Current ......≤6 Amp

Off-State (leakage) Current .....≤0.1 mA

Inrush Current .............≤8.0 A (10.0 ms max)

No-Load Current ............≤25 mA

. . 400 m V

e

Time Delay before availability . . . ≤50 ms

Reverse Polarity Protection .....Incorporated

Wire-Break Protection ........Incorporated

Short Circuit Protected ........No

Transient Protection..........PerEN60947-5-2

Shock ...................30g,11ms

Vibration .................55Hz,1mmAmplitude,

.......................in all 3 planes

Repeatability ..............≤2%

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M28

Page 29

TURCK

Innovative Solutions for Automation

2-Wire AC w/o Short-Circuit Protection - (AZ, RZ, FZ)

Line Frequency ...................................40-60 Hz

Differential Travel (Hysteresis)..........................3-15% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤6.0 V at 400 mA

.............................................8 and 12 mm ≤6.0 V at 100 mA

Continuous Load Current.............................≤400 mA

.............................................8 and 12 mm ≤100 mA

Off-State (Leakage) Current ...........................≤1.7 mA

Minimum Load Current ..............................≥5.0 mA

Inrush Current ....................................≤8.0A(≤10 ms, 5% Duty Cycle)

Power-On Effect ..................................PerIEC947-5-2

Transient Protection ................................PerEN60947-5-2

Shock .........................................30g,11ms

Vibration .......................................55Hz,1mmAmplitude in all 3 Planes

Repeatability.....................................≤2% of Rated Operating Distance

2-Wire AC/DC w/Short-Circuit Protection - (ADZ, RDZ, FDZ, VDZ)

Line Frequency ...................................40-60 Hz

Differential Travel (Hysteresis)..........................3-15% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤6.0 V at 400 mA

.............................................8 and 12 mm ≤6.0 V at 100 mA

Trigger Current for Overload Protection ...................AC:≥440 mA; DC: ≥330 mA

.............................................8 and 12 mm AC: ≥120 mA; DC: ≥120 mA

Continuous Load Current.............................AC:≤400 mA; DC: ≤300 mA

.............................................8 and 12 mm AC: ≥100 mA; DC: ≥100 mA

Off-State (Leakage) Current ...........................≤1.7 mA (AC)

.............................................≤1.5 mA (DC)

Minimum Load Current ..............................≥3.0 mA

Inrush Current ....................................4.0A(≤20 ms, 10% Duty Cycle)

Power-On Effect...................................PerIEC947-5-2

Transient Protection ................................PerEN60947-5-2

Shock .........................................30g,11ms

Vibration .......................................55Hz,1mmAmplitude in all 3 Planes

Repeatability.....................................≤2% of Rated Operating Distance

M29 B1008 TURCK Inc. Minneapolis, MN 55441

Page 30

Industrial

Automation

3-Wire DC Capacitive - (AP, RP, AN, RN)

Ripple..........................................≤10%

Differential Travel (Hysteresis) ..........................2-20% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤1.8 V at 200 mA

Trigger Current for Overload Protection ....................≥220 mA

Off-State (Leakage) Current ............................<100 μA

No-Load Current ...................................≤15 mA

Power-On Effect ...................................PerIEC947-5-2

Reverse Polarity Protection ............................Yes

Wire-Break Protection ...............................Yes

Transient Protection ................................PerEN60947-5-2

Shock ..........................................30g,11ms

Vibration ........................................55Hz,1mmAmplitude in all 3 Planes

Repeatability .....................................≤2% of Rated Operating Distance

Temperature Drift ..................................<±20% of Rated Operating Distance

4-Wire DC Capacitive - (VP, VN)

Ripple..........................................≤10%

Differential Travel (Hysteresis) ..........................2-20 (5% typical)

Voltage Drop Across Conducting Sensor ...................≤1.8 V at 200 mA

Trigger Current for Overload Protection ....................≥220 mA

Leakage (Off-State) Current ............................<100 μA

No-Load Current ...................................≤15 mA

Power-On Effect ...................................PerIEC947-5-2

Reverse Polarity Protection ............................Incorporated

Wire-Break Protection ...............................Incorporated

Transient Protection ................................PerEN60947-5-2

Shock ..........................................30g,11ms

Vibration ........................................55Hz,1mmAmplitude in all 3 Planes

Repeatability .....................................≤2% of Rated Operating Distance

Temperature Drift ..................................<±20% of Rated Operating Distance

2-Wire AC Capacitive - (AZ, RZ)

Line Frequency ....................................50-60 Hz

Hysteresis (Differential Travel) ..........................2-20% (5% typical)

Voltage Drop Across Conducting Sensor ...................≤7.0 V at 500 mA

Off-State (Leakage) Current ............................≤1.7 mA

Minimum Load Current ..............................≥5.0 mA

Inrush Current ....................................≤8.0A(≤10 ms, 5% Duty Cycle)

Power-On Effect ...................................PerIEC947-5-2

Transient Protection ................................PerEN60947-5-2

Shock ..........................................30g,11ms

Vibration ........................................55Hz,1mmAmplitude in all 3 Planes

Repeatability .....................................≤2% of Rated Operating Distance

Temperature Drift ..................................<±20% of Rated Operating Distance

Specifications

TURCK Inc. Minneapolis, MN 55441 B1008 M30

Page 31

TURCK

Innovative Solutions for Automation

4-Wire DC Analog - (LIU)

Ripple ..................≤10%

No-Load Current ...........≤8.0 mA

Voltage Output ............0-10 V/R

Current Output ............0-20 mA/R

Linearity Tolerance ..........±3% of full scale

Temperature Tolerance .......±0.06% / °C

Reverse Polarity Protection.....Incorporated

≥4.7 kΩ

L

≤500 Ω

L

3-Wire DC Analog - (LI2)

Ripple ..................≤10%

No-Load Current ...........≤8.0 mA

Current Output ............4-20 mA/R

Linearity Tolerance ..........±3% of full scale

Temperature Drift ..........±0.06% / °C

Reverse Polarity Protection.....Incorporated

LI = indicates current output only.

2 = Indicates a variance to standard which is 0-20 mA.

≤500 Ω

L

3-Wire DC Analog - (LF10)

Ripple ..................≤10%

No-Load Current ...........≤8.0 mA

Frequency Output ..........1-10 kHz

Linearity Tolerance ..........±5% of full scale

Temperature Tolerance .......±0.06% / °C

Reverse Polarity Protection.....Incorporated

Wire-Break Protection ........Incorporated

Wire-Break Protection ........Incorporated

Transient Protection .........PerEN60947-5-2

Shock ..................30g,11ms

Vibration ................55Hz,1mmAmplitude,

......................in all 3 planes

Repeatability ..............≤1%

......................

Wire-Break Protection ........Incorporated

Transient Protection .........PerEN60947-5-2

Shock ..................30g,11ms

Vibration ................55Hz,1mmAmplitude,

......................in all 3 planes

Repeatability ..............≤1%

......................

Transient Protection .........PerEN60947-5-2

Shock ..................30g,11ms

Vibration ................55Hz,1mmAmplitude,

......................in all 3 planes

Repeatability ..............≤1%

......................

(0.5% after 30 min. warm up)

(0.5% after 30 min. warm up)

(0.5% after 30 min. warm up)

LF = Linear frequency (1-10 kHz) output.

4-Wire DC Analog - (LUAP6X)

Ripple ..................≤10%

No-Load Current ...........≤8.0 mA

Voltage Output ............0-10 V/R

Linearity Tolerance ..........±5% of full scale

Temperature Tolerance .......±0.06% / °C

Reverse Polarity Protection.....Incorporated

Wire-Break Protection ........Incorporated

Transient Protection .........PerEN60947-5-2

Shock ..................30g,11ms

Off-State (Leakage) Current ....<100 mA

M31 B1008 TURCK Inc. Minneapolis, MN 55441

≥4.7 kΩ

L

Voltage Drop Across Conducting Sensor..........≤1.8 V

Trigger Current for

Overload Protection .........≥220 mA on

......................200 mA load current

No-Load Current ...........<10mA

Vibration ................55Hz,1mmAmplitude,

......................in all 3 planes

Repeatability ..............≤1%

......................

(0.5% after 30 min. warm up)

Page 32

Industrial

Automation

3-Wire DC Analog - (LU)

4-Wire DC Analog - (LIU5)

Ripple ...................≤10%

No-Load Current ............≤8.0 mA

Voltage Output .............0-10 V/R

Current Output .............4-20 mA/R

Linearity Tolerance ..........±3% of full scale

Temperature Drift ...........±0.06% / °C

Reverse Polarity Protection .....Incorporated

Wire-Break Protection ........Incorporated

Transient Protection..........PerEN60947-5-2

Shock ...................30g,11ms

Vibration .................55Hz,1mmAmplitude,

.......................in all 3 planes

LIU = Linear voltage or current output.

5 = Indicates 4-20 mA and 0-10 V output.

Variations:

No Load Current

WIM 40-Q20L60 ............≤23.0 mA

WIM 70-Q20L100............≤23.0 mA

WIM 40-NTL/STL ............≤23.0 mA

Linearity Tolerance

WIM 40-Q20L60 ............≤2%

WIM 70-Q20L100............≤8%

WIM 40-NTL/STL ............≤2%

≥4.7 kΩ

L

≤500 Ω

L

Repeatability ..............≤1%

.......................

LIU = Linear voltage or current output.

5 = Indicates 4-20 mA and 0-10 V output.

Variations:

No Load Current

WIM 40-Q20L60 ............≤23.0 mA

WIM 70-Q20L100............≤23.0 mA

WIM 40-NTL/STL ............≤23.0 mA

Linearity Tolerance

WIM 40-Q20L60 ............≤2%

Relative Temp. Drift

WIM 40-Q20L60 ............≤±0.06% °C

WIM 70-Q20L100............≤±0.06% °C

WIM 40-NTL/STL ............≤±0.06% °C

(0.5% after 30 min. warm up)

Linearity Tolerance ..........≤5% of final value

Nominal Voltage ............8.2VDC(EN50227)

Current Output .............4-20 mA

Power-On Effect ............Realized in Amplifier

Reverse Polarity Protection .....Incorporated

Wire-Break Protection ........Realized in Amplifier

Transient Protection..........Realized in Amplifier

TURCK Inc. Minneapolis, MN 55441 B1008 M32

2-Wire DC Analog NAMUR - (LI-EXI)

Temperature Drift ...........≤±0.06% per °C

Shock ...................30g,11ms

Vibration .................55Hz,1mmAmplitude,

.......................in all 3 Planes

Repeatability ..............≤1%

.......................

(0.5% after 30 min. warm up)

Specifications

Page 33

TURCK

Innovative Solutions for Automation

Third Party Compliances

CSA - Canadian Standards Association

CSA certifies devices for use in Canadian and American hazardous and non-hazardous locations.

FM - Approvals

FM approves devices for use in explosive hazardous locations in the US. Intrinsically safe (IS)

devices are approved for Division 1 areas; nonincendive (NI) devices are approved for

Division 2 areas.

UL - Underwriter’s Laboratories

UL is a nationally recognized US test laboratory that tests equipment to meet US standards and

jurisdictional requirements. UL lists stand-alone devices, such as sensors, and recognizes system

components, such as relays.

Note: TURCK products comply with many International standards. Consult factory for more information.

Hazardous Location Approvals

The NAMUR sensors shown in this catalog are Intrinsically Safe per the following:

EUROPE: CENELEC Standards EN 50 014 and EN 50 020; EC Directive 94/9/EC (ATEX)

USA, CANADA: Class I, II, III Division 1 Groups A, B, C, D, E, F, G*

Any FM approved or CSA certified associated apparatus with the following Entity Concept parameters can be used with

these sensors:

V

or VT≤15 V Ca≥C

OC

or IT≤60 mA La≥L

I

SC

* Note: CSA does not allow the use of quick disconnects in Groups E and F

Many 3-wire DC sensors are Nonincendive for Class I, Division 2 hazardous areas. Only those 3-wire sensors identified with

the FM logo have this approval.

USA: Class I Division 2 Groups A, B, C, D

-AN6X, -AP6X

-RN6X, -RP6X

Factory P/N's ending in /S1751

Integrated cables and cordsets must have ITC-ER Rating.

cable

cable

+ 220 nF

+ 280 μH

Nonincendive

M33 B1008 TURCK Inc. Minneapolis, MN 55441

Page 34

Industrial

Automation

More on Hazardous Locations

Standards for Intrinsically Safe systems in hazardous locations are found in the following publications:

United States: National Electrical Code 1996 (ANSI/NFPA 70) Articles 504 and 505

Factory Mutual Approval Standard Class No. 3610

Underwriters Laboratory Standard UL 913

Canada: Canadian Electrical Code C22.1-94 Section 18 and Appendix F.

Europe: CENELEC Standards EN 50 020 and EN 50 014

Hazardous Location Definitions (U.S. and Canada)

Class I Locations in which flammable gases or vapors exist or may be present in the air in quantities sufficient to

produce explosive or ignitable mixtures.

Class II Locations that are hazardous because of the presence of combustible dust.

Class III Locations that are hazardous because of the presence of easily ignitable fibers or flyings, but in which

such fibers or flyings are not likely to be suspended in the air in quantities sufficient to produce

ignitable mixtures.

Division 1 Locations in which hazardous concentrations in the air exist continuously, intermittently, or periodically

under normal operating conditions.

Division 2 Locations in which hazardous materials are handled, processed or used, but in which they are normally

confined within closed containers or closed systems from which they can escape only in case of accidental

rupture or breakdown.

Group A Atmospheres containing acetylene.

Group B Atmospheres containing hydrogen, fuel and combustible process gases containing more than 30%

hydrogen by volume, or gases or vapors of equivalent hazard such as butadiene, ethylene oxide, propylene

oxide and acrolein.

Group C Atmospheres such as ethyl ether, ethylene, acetaldehyde, cyclopropane, or gases or vapors of

equivalent hazard.

Group D Atmospheres such as acetone, alcohol, ammonia, benzene, butane, cyclopropane, ethylene dichloride,

gasoline, hexane, lacquer solvent vapors, methane, natural gas, naphtha, propane, xylene, or gases or

vapors of equivalent hazard.

Group E Atmospheres containing combustible metal dusts, including aluminum, magnesium, and their commercial

alloys, and other combustible dusts with similarly hazardous characteristics.

Group F Atmospheres containing combustible carbonaceous dusts, including carbon black, charcoal and coal.

Group G Atmospheres containing other combustible dusts, such as chemical, agricultural or plastic dusts.

Exerpt from National Electrical Code:

Intrinsically safe apparatus and wiring shall be permitted in any hazardous (classified) location for which it is approved, and the

provisions of Articles 501 through 503 and 510 through 516 shall not be considered applicable to such installations except as

required by Article 504.

Wiring of intrinsically safe circuits shall be physically separated from wiring of all other circuits that are not intrinsically safe. Means

shall be provided to minimize the passage of gases and vapors. Installation of intrinsically safe apparatus and wiring shall be in

accordance with the requirements of Article 504.

TURCK Inc. Minneapolis, MN 55441 B1008 M34

Specifications

Page 35

TURCK

Innovative Solutions for Automation

Enclosure Ratings

NEMA 250-1991

NEMA 1 Enclosures are intended for indoor use primarily to provide a degree of protection against limited amounts of

falling dirt.

NEMA 3 Enclosures are intended for outdoor use primarily to provide a degree of protection against rain, sleet,

windblown dust, and damage from external ice formation.

NEMA 4 Enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against

windblown dust and rain, splashing water, hose-directed water, and damage from external ice formation.

NEMA 4X Enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against

corrosion, windblown dust and rain, splashing water, hose-directed water and damage from external ice

formation.

NEMA 6 Enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against

hose-directed water, the entry of water during occasional temporary submersion at a limited depth, and

damage from external ice formation.

IEC 529

IP 40 Protection against solid bodies larger than 1 mm. No protection against liquids.

IP 65 Dust tight. Protection against water spray from all directions at 14.2 PSI through a 12.5 mm nozzle.

IP 67 Dust tight. Protection against the effects of immersion in water for 30 minutes at 1 meter.

IP 68 Dust tight. Protection against the effects of indefinite immersion in water at a pressure specified by the

manufacturer. Ex. TURCK's IP 68 definitions is IP 67 plus.

•

24 hours at 70°C

•

24 hours at -25°C

•

7 days at 1 meter under water at a constant temperature

•

10 cycles +70°C and -25°C, minimum of 1 hour at each temperature

IP 69K

Hot steam jet cleaning per EN 60529 (IP enclosure ratings) and DIN 40050-9.

TURCK TIP

For oily environments - Use plastic sensors with quick disconnects and TURCK PUR “/S90" cordsets.

For washdown environments - Use TURCK's WashdownSensors and appropriate mating cordsets.

M35 B1008 TURCK Inc. Minneapolis, MN 55441

Page 36

Industrial

Automation

Plastics

Material Descriptions

ABS - Acrylonitrile-Butadiene-Styrene Impact resistant, rigid. Resistant to aqueous acids, alkalis, salts, alcohols, oils, concentrated

CPE, Thermoset (rubber cables) Excellent resistance to oils, acids, chemicals, ozone, extreme temperatures, cuts, abrasions;

PA - Polyamide (nylon) Good mechanical strength, temperature resistant

PA, Amorphous (Trogamid T) Similar properties to nylon, but transparent. Hard, rigid, good chemical resistance.

PA 12-GF30 Nylon 12, 30% glass filled

PA 66-GF25-V0 Nylon 66, 25% glass filled, self-extinguishing

PBT - Polybutylene Terephthalate

(when glass reinforced, Crastin

PBT-GF30-V0 PBT, 30% glass filled, self-extinguishing

PEI - Polyetherimide (Ultem®) Excellent resistance to most commercial automotive fluids, fully hydrogenated hydrocarbons,

POM - Polyoxymethylene / Polyacetal (Delrin®) High impact resistance; good mechanical strength; good resistance to oils, alcohols, alkalis,

PP - Polypropylene Excellent resistance against chemicals including acids, solvents and solutions.

PTFE - Polytetrafluoroethylene (Teflon®)* Optimum resistance against high temperature and chemicals; low dielectric constant (2.0)

TPU, Thermoplastic Polyurethane Elastic, resistant to abrasion, impact-resistant, oil- and grease-tolerant

PVC - Polyvinylchloride Good mechanical strength, viscosity to impact; resistant to acids, alkalis

PVC, irradiated

PVDF - Polyvinylideneflouride (Kynar®) Resistant to high and low temperatures, good resistance to chemicals

Silicon

IRPA12 - Irradiated Polyamide (nylon) Good mechanical strength, temp. resistant

EPTR - Elastomer, Polymer Thermal Plastic Good fluid resistance

TROG - Trogamid T Hard, rigid, good chemical resistance

®

)

hydrochloric acid; disintegrated by concentrated sulfuric or nitric acids, esters, ketones

flame retardant in welding applications

Good mechanical strength; resistant to abrasion; resistant to alcohols, oils, some acids,

trichloroethylene

alcohols, weak aqueous solutions. Withstands higher temperatures.

gasoline, xylene, toluene. Dielectric constant 3.7

High temperature resistance and good mechanical strength

Heat and chemical resistant, withstands short-term temperatures to 482° F

(similar to PTFE), high mechanical strength

For use at high or low ambient temperatures (-50...+180 °C), moderate mechanical strength,

average resistance against alkalis, acids, oils, and solvents

Metals

AG

SS - 306 Stainless Steel Excellent atmospheric resistance

CPB Chrome Plated Brass

CuZn - Brass Generally good resistance to industrial atmospheres

GD - AlSi12 - Aluminum, die-cast Low specific weight, long-life characteristics

GD - ZnAl4Cu1 (Z410) - Zinc, die-cast Long-life characteristics

TC Teflon Coated

WG

AL - Anodized Aluminum Long-life characteristics

SF - Stoneface® High abrasion resistance, excellent for MIG welding applications, high heat and

TS - Tool Steel Excellent durability

armorguard ®

weldguard ®

weld flow immunity

TURCK Inc. Minneapolis, MN 55441 B1008 M36

Specifications

Page 37

TURCK

Innovative Solutions for Automation

Matrix of TURCK Sensor Materials *

Housing Style ABS PA,

CA25, CA40

CK40

CP40

CP80, K90SR

DS20

EG

EM

G, M (potted-in cable)

G, M (connector)

G..SK

G47SR

INR, INT

K..SK, P..SK

K40SR, P30SR

KT34

M..T

PCS

P, S (potted-in cable)

P, S (connector)

P.../S139

PT30

QF5.5

Q06

Q6.5 (World Clamp)

Q6.5

Q5.5, Q9.5, ISI

Q08, Q8SE

Q10

Q10S

Q11S, Q12

Q14, Q20

Q14, Q20 Ring

Q18, Q25, Q30

Q26

Q34, Q80

S185

Cable Gland X

Wet Suit

Trog. T

XX X

XX

PA PBT POM

X** X

XXX

XX X

XX

PP

PUR PVC PVDF PEI 306SSAl Brass Zinc Thermoset

XX X X

XXX

XX

XXXX

XX

XXX X

XX

XX X

X

XXX

XXX X

XXX

X

XXX

X

X

XX

XX X

XX

XXX

XXXX

X

XXX

XX

XXX X

XX X X

XXX

XX X

XX

XXX

XXX

Plastic

M37 B1008 TURCK Inc. Minneapolis, MN 55441

Page 38

Industrial

Automation

Matrix of TURCK Sensor Materials *

Housing Style ABS PA,

Trog. T

A23

AKT

CRS

FST, NST, QST

IKE, IKM, IKT

KST

PSM

PST

PA PBT POM PUR PVC PVDF PEI 306 SS Al Brass Zinc Thermoset

XX XXX

XXXXX

XXX

XX XX

XX XXX

XXXXX

XXXXX

XXXX

The information in this chart is derived from reputable industry sources and is to be used only as

a guide in selecting materials suitable for your application. TURCK does not warrant in any

fashion that the information in this chart is accurate or complete, or that any material is suitable

for any purpose.

Most ratings listed here apply to a 48-hour exposure period.

Ratings: A - No effect

B - Minor effect

C - Moderate effect

D - Severe effect

ϕ - No specific data, but probable rating.

Plastic

Chemical Compatability

ABS Trog. T PA 12 PBT PEI POM PP PTFE PUR PVC PVDF 306 SS Al Brass Zinc

Ammonia, liquid B B A B D C/D A A C A A B A D A

Chlorine anhydrous liquid nd nd D D nd C D A C D A C D D nd

De-ionized water nd nd A nd A nd A A nd A A A A A nd

Formic acid D D D A nd C A A C A A A/B A D D

Gasoline D A A A A A C A A C A A A A nd

Hydrochloric acid <40% A A/B D A A C C A D B A D D D D

Hydrofluoric acid <50% C D D B A D A A C B A D D D nd

Methanol D D B A AAAA B A A A AA A

Phosphoric acid <40% B(C) D B A A D A A D

Potassium hydroxide <15% A A C B A B A A C A A B D D nd

Sodium hydroxide <55% A A C B A B A A B A D B D D D

Sodium hypochlorite ≤13%

Sulfuric acid <75% B A D A A D A A C A A D D D D

Toluene D A A A A A C A C D A A A A nd

Trichloroethylene D A C A nd B A D D B A/B D A A

Bnd B AndCAA B A A C DD A

TURCK Inc. Minneapolis, MN 55441 B1008 M38

ϕ

BB DCDD

Specifications

Loading...

Loading...