turck MC96-12EX0-R/24VDC, Ri360P1-DSU35TC-ELi-Exi Quick Start Manual

Signal processor

MC96 for flow sensors

MC96-12EX0-R/24VDC

Type MC96-12EX0-R/24VDC

Ident-No. 9078511

Ambient temperature -20…40 °C

Operating voltage 19.2…28.8 VDC

No-load current I

Output function Relay output, changover contact

Device designation

Protection type [Ex ia] IIC

Ex approval acc. to conformity certificate TÜV 97 ATEX 1183X

Protection class IP20

Protection class (terminals/housing) IP20 / IP40

0

ð 80 mA

É II (1) G [EEx ia] IIC

■

ATEX category II (1) G, Ex Zone 0

■

Single-channel intrinsically safe signal

processor

■

type MC96 „multicart“

■

Adjustment via potentiometer

■

Intrinsically safe control circuit, [EExia]

IIC

■

2 relay outputs: 1 changerover switch

each for flow and temperature monitoring

■

Flow status indication via 6 LEDs

■

Wire-break monitoring

■

Temperature monitoring, adjustable

range -20…+100°C

■

Programmable switch-on/off delay, adjustable range of 0…25 s

Wiring diagram

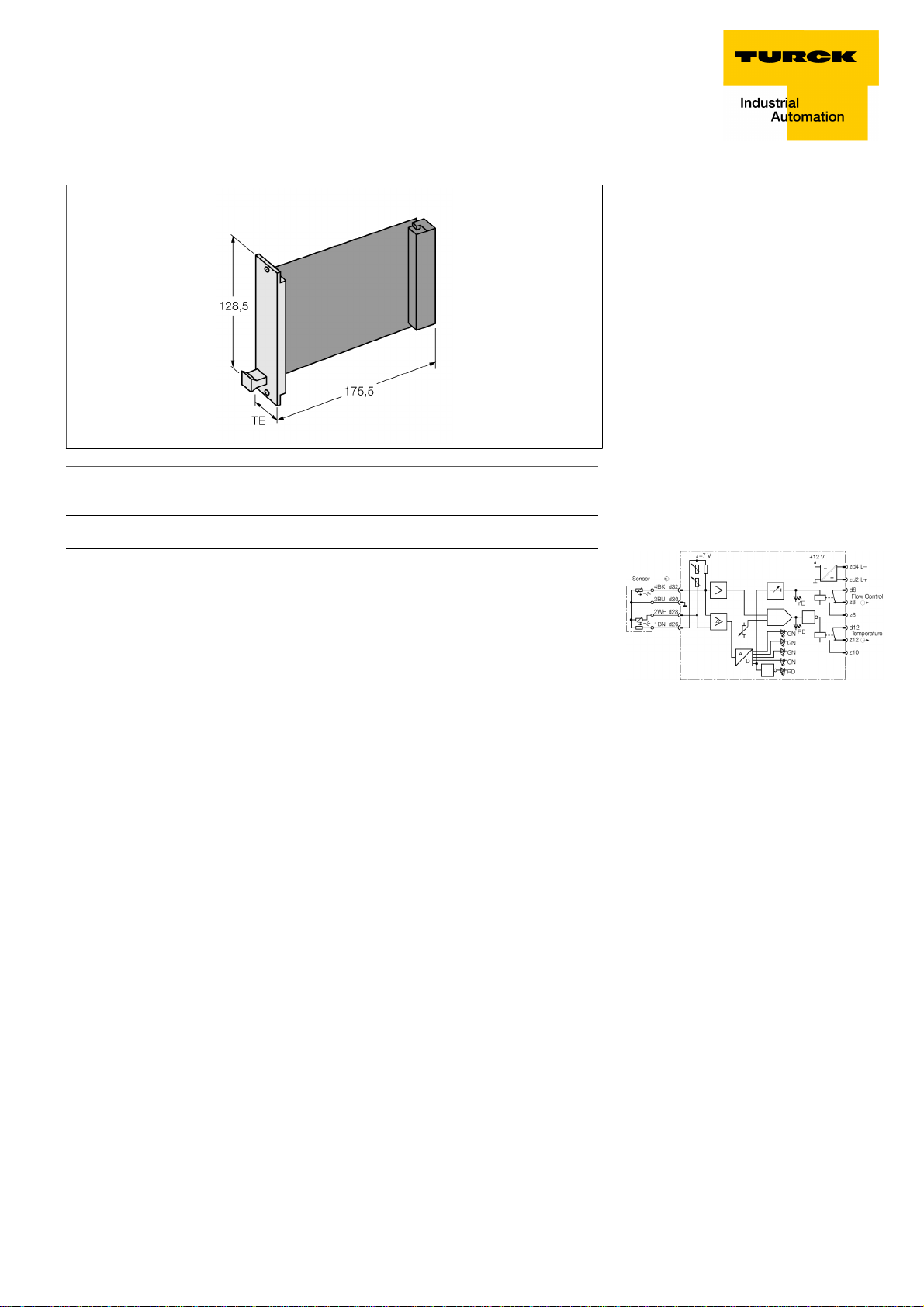

Design Eurocard

Dimensions 175.5 x 20.3 x 128.5 mm

Housing material Metal/plastic

Connection connector

Indication: Drop below setpoint LED red

Indication: Setpoint reached LED yellow

Indication: Setpoint exceeded 4 x LEDs green

Functional principle

Signal processors not only supply insertion

and inline sensors with voltage, they also process and display the measured signals. Devices with MK96…, MS96… and MC96…

housing styles are available. The individual

housing styles are designed for different operating voltages and feature various output and

supplementary functions. For intrinsically safe

flow sensors it is required to use signal processors with intrinsically safe control circuits

of the series MS96…Ex… and MC96…Ex… .

Edition • 2011-09-17T06:58:24+02:00

1 / 2 Hans Turck GmbH & Co.KG ñ D-45472 Mülheim an der Ruhr ñ Witzlebenstraße 7 ñ Tel. 0208 4952-0 ñ Fax 0208 4952-264 ñ more@turck.com ñ www.turck.com

Signal processor

MC96 for flow sensors

MC96-12EX0-R/24VDC

Operating manual

Intended use

This device fulfills the directive 94/9/EC and is suited for use in explosion hazardous areas according to EN50014 and EN50020.

In order to ensure correct operation to the intended purpose it is required to observe the national regulations and directives.

For use in explosion hazardous areas conform to classification

II 1 G (Group II, Category 1 G, electrical equipment for gaseous atmospheres).

Marking (see device or technical data sheet)

É II 1 G and EEx ia IIC T6 acc.to EN50020 and EN50284

Local admissible ambient temperature

-20…+60 °C

Installation / Commissioning

These devices may only be installed, connected and operated by trained and qualified staff. Qualified staff must have knowledge of protection

classes, directives and regulations concerning electrical equipment designed for use in explosion hazardous areas.

Please verify that the classification and the marking on the device comply with the actual application conditions.

This device is only suited for connection to approved EExi circuits acc. to EN500014 and EN50020. Please observe the maximum admissible

electrical values.

After connection to other circuits the sensor may no longer be used in EExi installations. When interconnected to (associated) electrical equipment, it is required to perform the "Proof of intrinsic safety" (EN60079-14).

Installation and mounting instructions

Avoid static charging of cables and plastic devices. Please only clean the device with a damp cloth. Do not install the device in a dust flow and

avoid build-up of dust deposits on the device.

If the devices and the cable could be subject to mechanical damage, they must be protected accordingly. They must also be shielded against

strong electro-magnetic fields.

The pin configuration and the electrical specifications can be taken from the device marking or the technical data sheet.

In order to avoid contamination of the device, please remove possible blanking plugs of the cable glands or connectors only shortly before inserting the cable or opening the cable socket.

service / maintenance

Repairs are not possible. The approval expires if the device is repaired or modified by a person other than the manufacturer. The most important

data from the approval are listed.

Edition • 2011-09-17T06:58:24+02:00

2 / 2 Hans Turck GmbH & Co.KG ñ D-45472 Mülheim an der Ruhr ñ Witzlebenstraße 7 ñ Tel. 0208 4952-0 ñ Fax 0208 4952-264 ñ more@turck.com ñ www.turck.com

Loading...

Loading...