Page 1

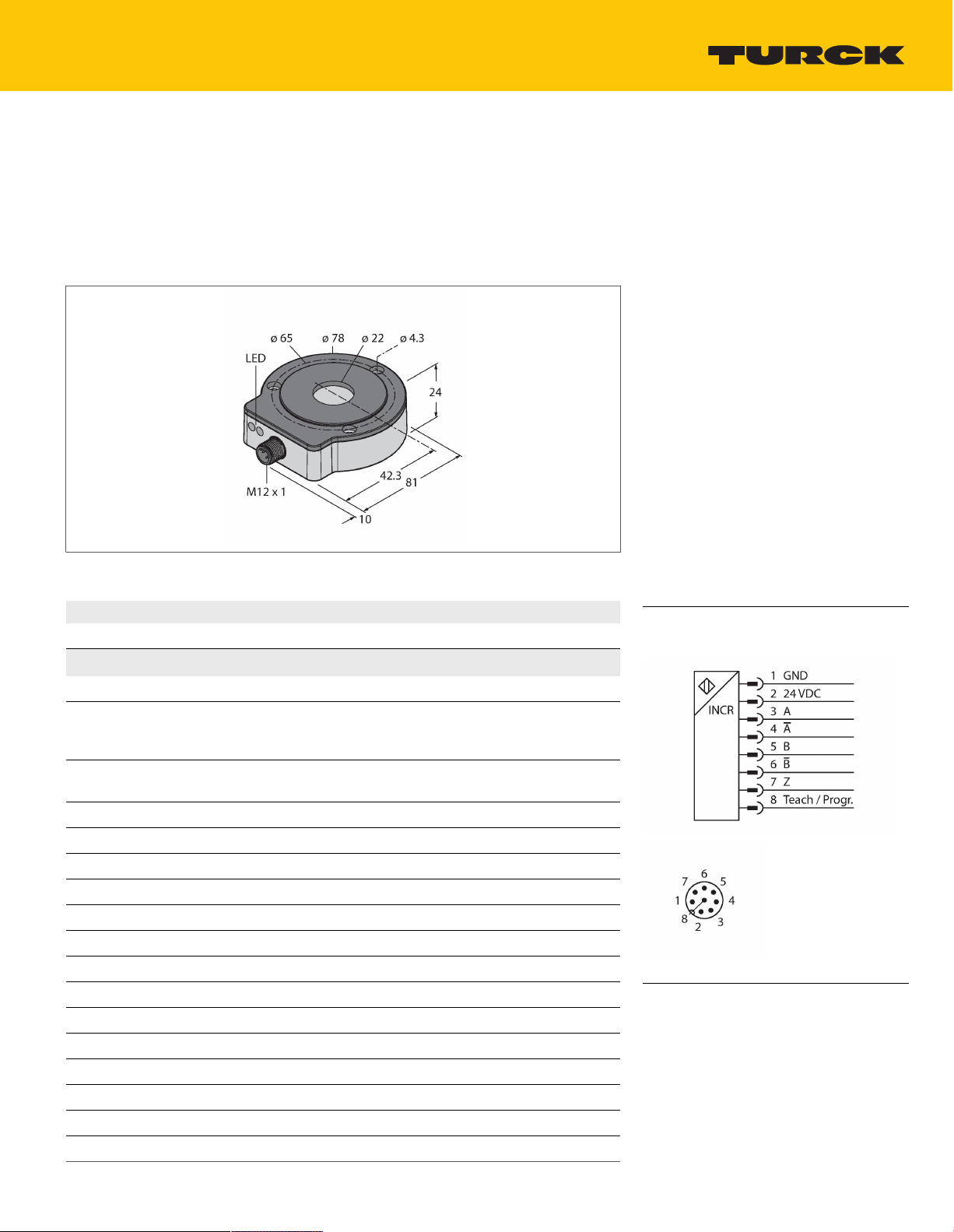

RI360P0-EQR24M0-INCRX2-H1181

Contactless Encoder with Stainless Steel Housing –

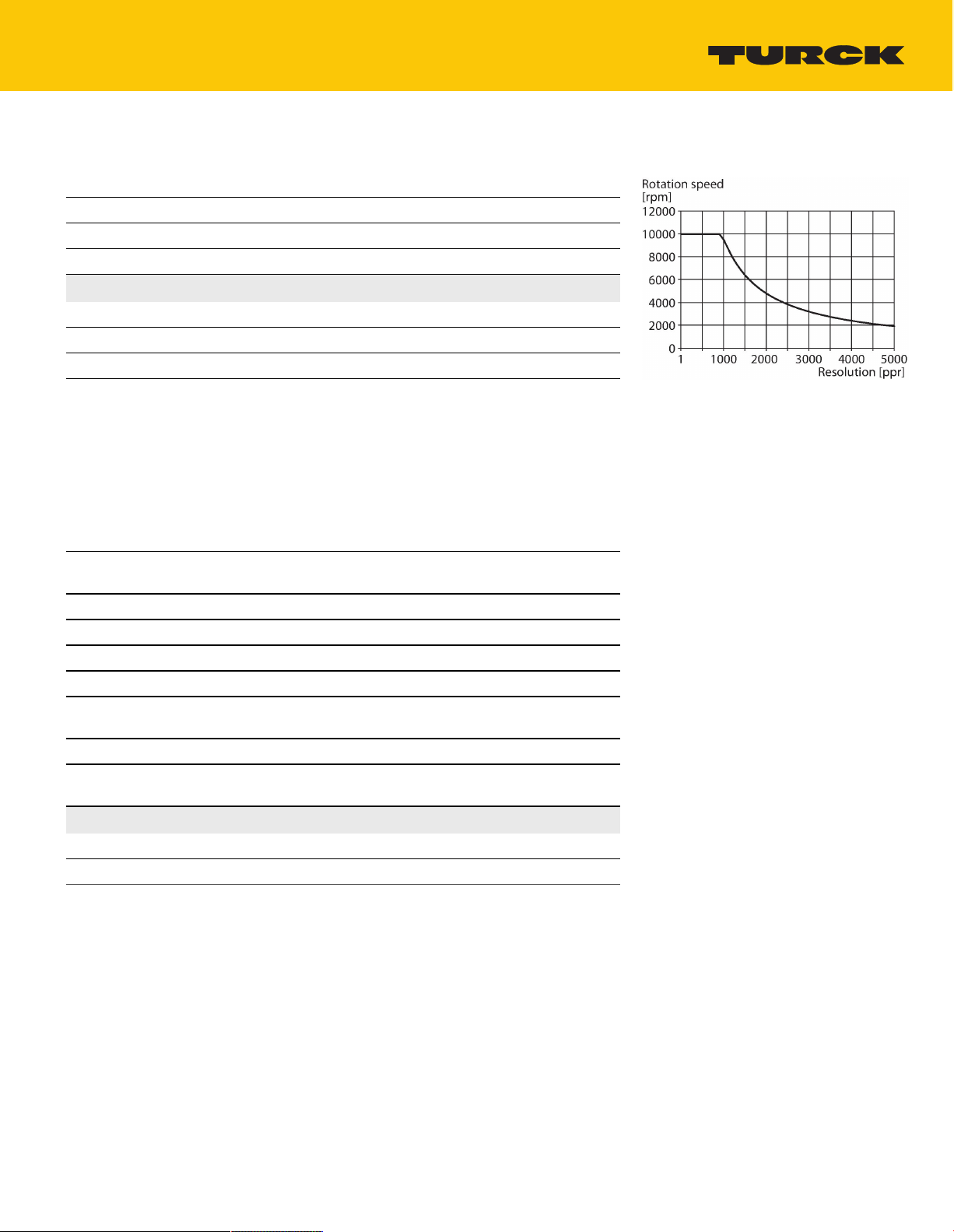

Incremental: 1 … 5000 ppr

Premium Line

Features

Compact, rugged housing

■

Active face, plastic PA12-GF30

■

Housing, stainless steel V4A (1.4404)

■

Status displayed via LED

■

Immune to electromagnetic interference

■

1024 pulses per revolution (default)

■

360, 512, 1000, 1024, 2048, 2500, 3600,

■

4096, parametr. via Easy-Teach

Free parametrization of the pulse number in

■

the range from 1 to 5000 via PACTware™

Position of z-track set via Easy-Teach

■

Burst function, absolute angular position

■

output incrementally per Easy-Teach pulse

10…30 VDC

■

Male M12 x 1, 8-pin

Technical data

■

Push-pull A, B, Z, A (inverse), B (inverse)

■

Type

Ident. no. 1590912

Measuring principle

Max. Rotational Speed 10000rpm

Starting torque shaft load (radial / axial) not applicable, because of contactless

Nominal distance 1.5mm

Repeat accuracy ≤0.01% of full scale

Linearity deviation ≤0.05%f.s.

Temperature drift ≤ ±0.003% / K

Ambient temperature -25…+85°C

Operating voltage 10…30VDC

Residual ripple ≤10% U

Isolation test voltage ≤0.5kV

Short-circuit protection yes / Cyclic

Wire breakage/Reverse polarity protection yes / yes (voltage supply)

Output type Incremental

Resolution, incremental 1024ppr

Pulse frequency max. 200kHz

Signal level high min. UB - 2 V

RI360P0-EQR24M0-INCRX2-H1181

Inductive

Determined with standardized

construction, with a steel shaft Ø 20 mm, L

= 50 mm and reducer Ø 20 mm

measuring principle

ss

Wiring diagram

Functional principle

The measuring principle of inductive angle

sensors is based on oscillation circuit coupling

between the positioning element and the

sensor, whereby an output signal is provided

proportional to the angle of the positioning

element. The rugged sensors are wear and

maintenance-free, thanks to the contactless

operating principle. They convince through

their excellent repeatability, resolution and

RI360P0-EQR24M0-INCRX2-H1181 | 12/03/2020 06-55 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

1|5

Page 2

Technical data

Signal level low max. 2.0V

Output function 8-pin, Push-Pull/HTL

Sample rate 1000Hz

Current consumption < 100 mA

Design

Dimensions 81x78x24mm

Flange type Flange without mounting element

Shaft Type Hollow shaft

Shaft diameter D [mm] 6

Housing material Stainless-steel/Plastic, 1.4404 (AISI 316L)/

Electrical connection Connector,M12 × 1

Vibration resistance 55Hz (1 mm)

Vibration resistance (EN 60068-2-6) 20 g; 10…3000 Hz; 50 cycles; 3 axes

Shock resistance (EN 60068-2-27) 100 g; 11 ms ½ sinus; 3 x each; 3 axes

Continuous shock resistance (EN

60068-2-29)

Protection class IP68 / IP69K

MTTF 138years acc. to SN 29500 (Ed. 99) 40

Power-on indication

Measuring range display LED, yellow, yellow flashing

Included in delivery Adapter sleeve MT-QR24

EQR24

6.35

9.525

10

12

12.7

14

15.875

19.05

20

PA12-GF30

40 g; 6 ms ½ sinus; each 4000 x; 3 axes

°C

LED,Green

linearity within a broad temperature range. The

innovative technology ensures a high immunity

to electromagnetic DC and AC fields.

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

RI360P0-EQR24M0-INCRX2-H1181 | 12/03/2020 06-55 | technical changes reserved

2|5

Page 3

Mounting instructions

Mounting instructions/Description

Extensive range of mounting accessories

for easy adaptation to many different shaft

diameters. Based on the functional principle of

RLC coupling, the sensor operates absolutely

wear-free and is immune to magnetized metal

splinters and other interference fields. Wrong

installation is hardly possible.

The adjacent figure shows the two separate

units, sensor and positioning element.

Mounting option A:

First, interconnect positioning element and

rotatable shaft. Then place the encoder above

the rotating part in such a way that you get a

tight and protected unit.

Mounting option B:

Push the encoder on the back site of the shaft

and fasten it to the machine. Then clamp

the positioning element to the shaft with the

bracket.

Mounting option C:

If the positioning element is to be screwed on a

rotating machine part and not on a shaft, install

first the dummy plug RA8-QR24. Then tie up

the bracket. Screw on the encoder via the three

bores.

The separately arranged sensor and positioning

element inhibit that compensating currents or

damaging mechanical loads are transmitted via

the shaft to the sensor. In addition, the encoder

remains tight and highly protected during its

entire lifespan.

The accessories enclosed in the delivery help

to mount encoder and positioning element at

an optimal distance from each other. LEDs

indicate the switching status. Optionally, you

can use the shields which are included in the

accessories to increase the allowed distance

between positioning element and sensor.

Status display via LED

green steady:

Sensor is operative

yellow steady:

Positioning element has reached the end of the

measuring range. This is indicated by a weaker

signal.

yellow flashing:

Positioning element is outside the measuring

range.

off:

Positioning element is in the measuring range

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

RI360P0-EQR24M0-INCRX2-H1181 | 12/03/2020 06-55 | technical changes reserved

3|5

Page 4

Individual Parameterization (Teaching with Positioning Element)

Jumper between teach

Gnd Pin 1 Ub Pin 2 LED

input Pin 8

2 s Z-track zero point

teaching

10 s CCW rotation

direction

One-time triggering of burst

function

Status LED flashes then

turns steady after 2 s

CW rotation direction After 10 s status LED

flashes fast for 2 s

15 s - Factory setting (z-track, CW) After 15 s power and

status LED alternate

To avoid unintended teaching, keep pin 8 potential-free.

Preset Programming Mode (Teaching without Positioning Element)

Jumper between teach

Gnd Pin 1 Ub Pin 2 LED

input Pin 8

2 s

Resolution setting

mode active for 10 s

2 s

Resolution setting

mode active for 10 s

Status LED steady, flashes after

2 s as long as selection mode is

active

360 pulses/360° Start value 1 x flashing

512 pulses/360° Press once 2 x flashing

1000 pulses/360° Press twice 3 x flashing

1024 pulses/360° Press three times 4 x flashing

2048 pulses/360° Press four times 5 x flashing

2500 pulses/360° Start value 1 x flashing

3600 pulses/360° Press once 2 x flashing

4096 pulses/360° Press twice 3 x flashing

5000 pulses/360° Press three times 4 x flashing

To avoid unintended teaching, keep pin 8 potential-free.

Accessories

PE1-EQR24 1590966

Positioning element with stainless

steel compression fitting, without

adapter sleeve

RA1-EQR24 1593019

Stainless steel adapter sleeve, for Ø

20 mm shafts

RA4-EQR24 1593023

Stainless steel adapter sleeve, for Ø

10 mm shafts

RA8-EQR24 100000289

Stainless steel plug for mounting

option C

M5-QR24 1590965

Plastic protecting ring for encoders

RI-EQR24

RA3-EQR24 1593020

Stainless steel adapter sleeve, for Ø

12 mm shafts

RA5-EQR24 100000375

Stainless steel adapter sleeve, for Ø 6

mm shafts

SP1-EQR24 1590979

Shield plate Ø 74 mm, stainless steel

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

RI360P0-EQR24M0-INCRX2-H1181 | 12/03/2020 06-55 | technical changes reserved

4|5

Page 5

SP5-QR24 100003689

Protective plate Ø 74 mm, plastic

Wiring accessories

Dimension drawing Type Ident. no.

RKCV8T-2/TFW 6934668 Connection cable, M12 coupling,

straight, 8-pin, stainless steel coupling

nut, cable length: 2 m, sheath

material: PP-EPDM, white; other cable

lengths and variants available, see

www.turck.com

RKC8T-2/TXL 6625142 Connection cable, female M12, straight,

RKC8.302T-1.5-RSC4T/TXL320 6625003 Adapter cable to connect sensor to

8-pin, cable length: 2 m, sheath

material: PUR, black; cULus approval;

other cable lengths and qualities

available, see www.turck.com

USB-2-IOL-0002 programming unit;

female M12, straight, 8-pin on male

M12, straight, 3-pin; cable length: 1.5

m; jacket material: PUR, jacket color:

black, cULus approved; RoHS conform;

protection class IP67

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

RI360P0-EQR24M0-INCRX2-H1181 | 12/03/2020 06-55 | technical changes reserved

5|5

Loading...

Loading...