Page 1

Sense it! Connect it! Bus it! Solve it!

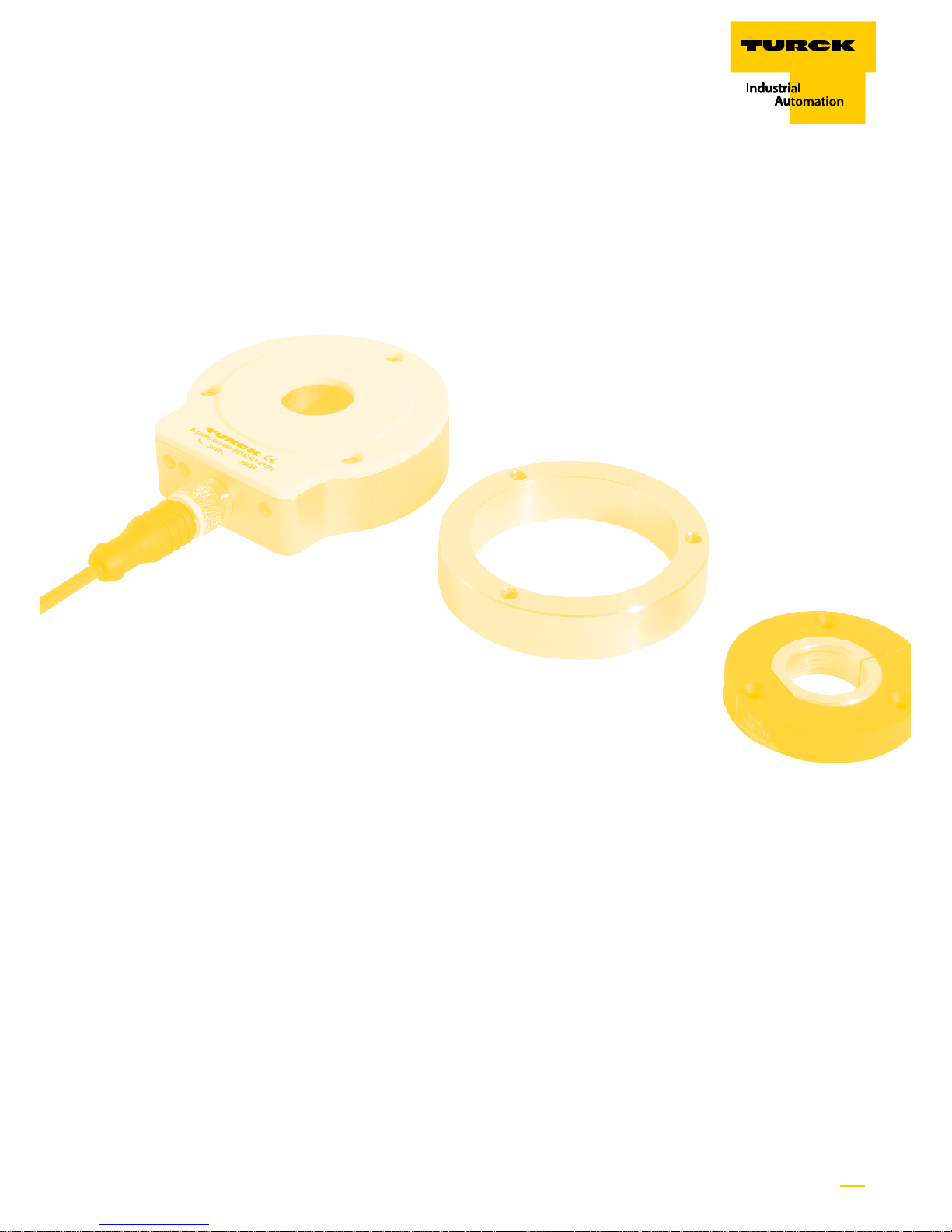

CONTACTLESS

ENCODERS

WITH SSI

INTERFACE

USER

INFORMATION

Page 2

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

2

Contactless encoders with SSI interface –

General information

1 General information

Please read this section carefully. Safety as-

pects cannot be left to chance when dealing

with electrical equipment.

These directions of use contain the informa-

tion necessary for use of the inductive en-

coders Ri-QR24 from TURCK and is intended

for personnel with the necessary qualifica-

tions.

Prescribed use

Attention

The devices described hereafter must only

be used in the prescribed way and only

with certified components and devices from

third party manufacturers.

Appropriate transport, storage, deployment

and mounting as well as careful operating

and thorough maintenance guarantee the

troublefree and safe operation of these de-

vices.

Notes concerning planning /

installation of this product

Attention

All respective safety measures and accident

protection guidelines must be considered

carefully and without exception.

Safety note

WARNING

Due to improper fastening, the positioning element may loosen from mounting

position

Possible danger to life caused by loose

parts!

ӹ Follow the mounting instructions

carefully

ӹ Check tightness, tightening torque:

M = 0.6…0.8 Nm

Page 3

3

more@turck.com • www.turck.com • 2014/11

Contactless encoders with SSI interface –

Contents

Contactless encoders Ri-QR24 – with SSI Interface

1 General information ...................................................................... 2

2 Type code ................................................................................ 4

3 SSI interface description ...................................................... 5

4 Commissioning ..................................................................... 6

5 Mounting ............................................................................... 7

6 SSI process data .................................................................... 8

7 Parametrization via teach function .................................. 8

8 Parametrization via PACTware™ and IODD ..................... 9

9 Mounting accessories and positioning elements .......... 11

10 Technical data ........................................................................ 13

Page 4

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

4

Contactless encoders with SSI interface –

Type code

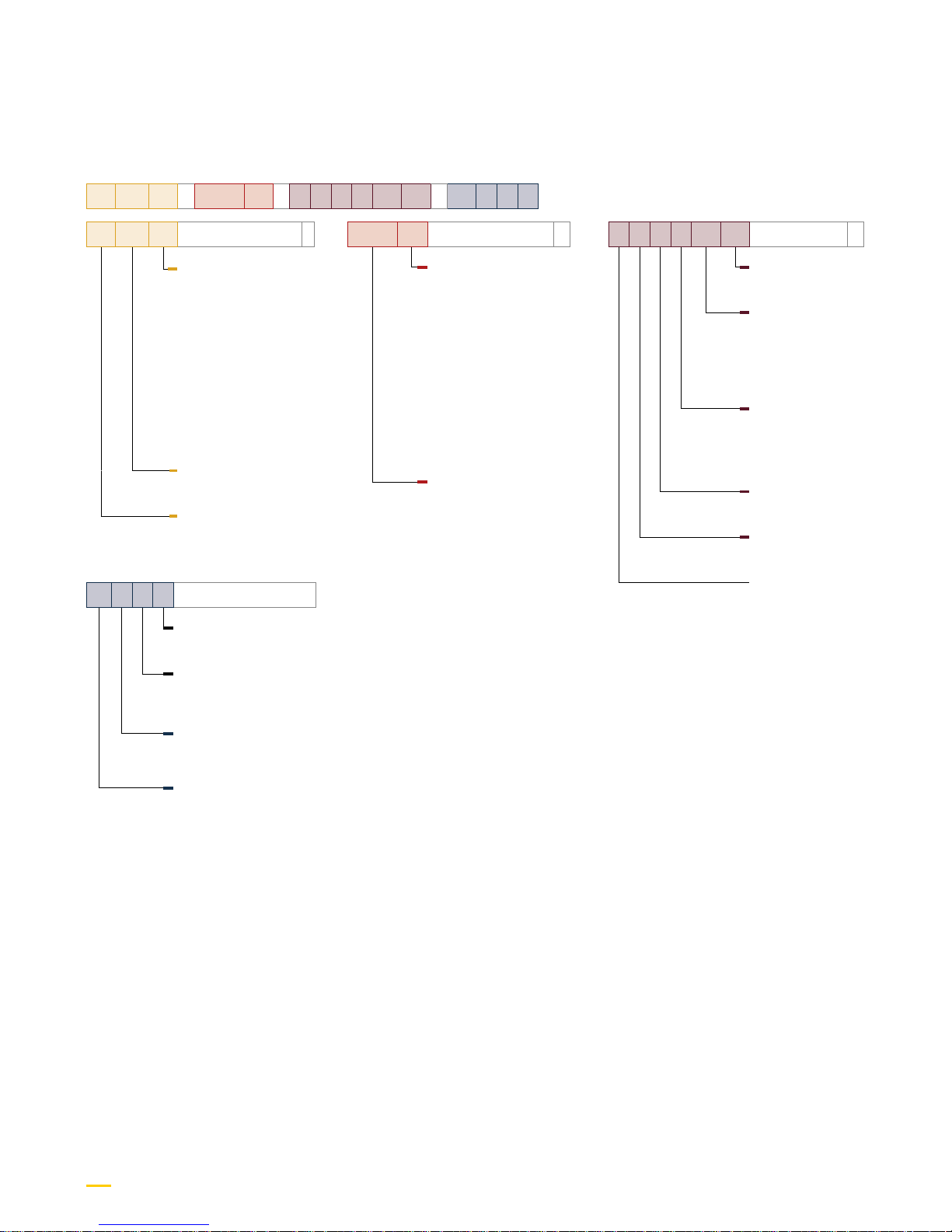

2 Type code

Note

The sensor, mounting accessories and posi-

tioning elements are individually available

or as a kit.

Ri 360 P1 – QR24 M1 – H E S G 25 X3 – H1 1 8 1

Ri 360 P1

Operating principle

–

Positioning element/

shaft diameter

P0 without positioning

element

P1 P1-Ri-QR24/20 mm*

P2 P2-Ri-QR24/14 mm*

P3 P3-Ri-QR24/12 mm*

P4 P4-Ri-QR24/10 mm*

P5 P5-Ri-QR24/6 mm*

P6 P6-Ri-QR24 / /"*

P7 P7-Ri-QR24 / /"*

P8 P8-Ri-QR24 / -

Measuring range

360 360°

Operating principle

Ri Rotatory inductive

QR24 M1

Housing style

–

Alu protective unit

M0 without alu

protective unit

M1 with alu

protective unit

M2 Set M2-QR24

(M1-QR24 +

SP1-QR24)

M3 Set M3-QR24

(M1-QR24 +

SP2-QR24)

M4 Set M4-QR24

(M1-QR24 +

SP3-QR24)

Housing style

QR24

H1 1 8 1

Electrical connection

Assignment (digit 5)

1 Standard assignment

Number of contacts

(digit 4)

8 8-pin M12 x 1

Connector type (digit 3)

1 straight

Connector type

(digit 1 and 2)

H1 Male connector

M12 x 1

H E S G 25 X3

Electrical version

–

Number of LEDs

X3 3 x LEDs

Number of bits

25 Number of bits

(default setting,

other values can

be set by the

customer)

Code

G Gray (default

setting, binary

can be set by the

customer)

SSI interface

S SSI interface

Resolution

E Higher resolution

Scan rate

H Higher scan rate

* Positioning elements with hollow shaft

Page 5

5

more@turck.com • www.turck.com • 2014/11

3 SSI interface

The encoders provide an absolute signal of

a guided or free positioning element. The

sensor is contactlessly coupled with the po-

sitioning element via a stable inductive RLC

circuit.

In addition to the indication of process val-

ues via current and voltage outputs, the SSI

interface (Synchronous Serial Interface) has

become an established alternative in the

field of industrial automation. The process

value is transmitted either directly to the

higher-level controller (with SSI-card) or

to an appropriate fieldbus participant that

connects to all standard fieldbuses, such as

piconet®, BL67, BL20 or BLcompact.

The advantage of the SSI-interface is that

signals are directly and digitally transmitted

via the SSI telegram and are therefore more

precise and immune to interferences. Not

only process data is transmitted via SSI tel-

egram but also diagnostic bits.

Contactless encoders with SSI interface –

SSI interface Description

The fieldbus device is the master com-

manding a clock signal to which the sen-

sor responds synchronously via the SSI

telegram. The clock rate and the data

frame length are specified by the master.

Depending on the length of the connection

cable different clock rates are recommend-

ed (see section "Commissioning" on page

6). In order to adapt the clock rate to the

cable length, it is adjustable on the master

side. The data frame length and the process

value displayed as Gray or binary code must

be the same on the master and sensor side.

The encoder position can be captured in the

SSI synchronous as well as in asynchronous

mode. You can toggle between both modes

with a DIP switch (see section "Parametriza-

tion via teach function ", page 8). The asyn-

chronous mode is factory set. This makes

the SSI encoder compatible with virtually all

major SSI masters.

Page 6

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

6

Contactless encoders with SSI interface –

Commissioning

Status displayed via LED

■ green steady on:

Sensor is supplied properly, asynchronous

mode

■ green flashes:

Sensor is supplied properly, synchronous

mode

■ green flashes rapidly:

Sensor is supplied properly but is not

receiving CLK pulses from the SSI master

■ yellow steady on:

Positioning element has reached the end

of the measuring range. This is indicated

by a weaker signal, see status bit 23.

■ yellow flashing:

Positioning element is outside the measur-

ing range, see status bit 24.

Multiturn error

■ red steady on:

Position was changed during power loss,

see status bit 22

4 Commissioning

Sensor and SSI-master are linked with a con-

nection cable. In order to ensure proper data

traffic, it is recommended that you always

use shielded twisted-pair lines.

Make sure that the SSI-master and the sen-

sor have the same settings. The sensor's

type code contains the factory-set data

frame length of 25 bits as well as the Gray

code. The encoder adjusts itself automati-

cally to the specified master clock frequency

(62.5 kHz to 1 MHz).

In dependence on the transmission frequen-

cies, the following line lengths are recom-

mended:

Cable length Clock frequency

< 25 m < 1000 kHz

< 50 m < 500 kHz

< 100 m < 400 kHz

< 200 m < 200 kHz

< 400 m < 100 kHz

If the selected SSI-master doesn't provide

the request packets on time, operate the

sensor in the factory-set asynchronous

mode. This mode also works with an accu-

rately functioning master.

In time-critical applications, such as in the

control technology or motor commutation,

it is necessary that the encoder provides

extremely short and, in particular, constant

(synchronous) signal propagation times.

Here, the sensor must be operated in syn-

chronous mode together with a suitable

master. The sensor's sampling rate depends

on the master's SSI-cycle time, allowing syn-

chronous operation with SSI-cycle times of

700 Hz to 5 kHz. In synchronous mode, the

signal propagation delay is 200 µs, regard-

less of the cycle time. On selecting the SSI

master, note that a jitter of < 5 µs is required

in synchronous mode.

The nominal distance between positioning

element and sensor is 1.5 mm. Use the in-

cluded mounting aid MT-QR24 to adjust the

distance.

If positioning element and encoder are

mounted too far away from each other, the

signal will be weak. This status is indicated

by a steady yellow LED. If the distance be-

tween positioning element and encoder is

too large, i.e. RLC coupling is not given. This

status is indicated by a flashing yellow LED.

In addition, status bits within the SSI-process

data deliver diagnostic messages for proper

RLC coupling. If the encoder is moved dur-

ing a power cut, this is – after reconnecting

power – indicated by a red LED and a status

bit.

The encoder is factory set to a data frame

length of 25 bit. In this case, the singleturn

process data are found in bits 0 to 15 and

the multiturn process data in bits 16 to 21.

Bits 22 to 24 contain the diagnostic data.

You can apply further settings with the

software tool PACTware™, the TURCK pro-

gramming box USB-2-IOL-0002 (ident no.

6825482) and the associated adapter cable

RKC8.302T-1.5-RSC4T/TX320 (ident no.

6625003) as well as the IODD-file "IODD_

IOL_Ri-QR24.zip". (PACTware™ and IODD-file

can be downloaded from www.turck.com).

You can change the data frame length (24,

25 or 26 bit), the coding (Gray/binary) or the

distribution of the process data for example.

You can also disable the diagnostic data and

use the vacant bits for multiturn or single-

turn resolution instead. Only the singleturn

bits have to be set – the remaining bits in the

data packet are filled with the multiturn and

status bits accordingly (if these are enabled).

Page 7

7

more@turck.com • www.turck.com • 2014/11

5 Mounting

Extensive range of mounting accesso-

ries (see section "Mounting accessories"

on page 11) for easy adaptation to many

different shaft diameters. Based on the

functional principle of oscillation circuit

coupling, the sensor operates absolutely

wear-free and is immune to magnetized

metal splinters and other interference

fields. Wrong installation is hardly possible.

.

Contactless encoders with SSI interface –

Mounting

Warning

Due to improper fastening, the positioning element may loosen from mounting

position

Possible danger to life caused by loose

parts!

ӹ Follow the mounting instructions

carefully

ӹ Check tightness, tightening torque:

M = 0.6…0.8 Nm

6

2

1

5

4

3

2.5

A

0.6...0.8 Nm

SP2-QR24

6

2

1

5

4

3

2.5

A

C

0.6...0.8 Nm

SP2-QR24

4

3

1

2

2.5

0.6...0.8 Nm

0.6...0.8 Nm

SP3-QR24

2

3

5

6

4

2.5

1

B

1.4...1.5 Nm

0.6...0.8 Nm

SP1-QR24

ø 42

M4 x 0.5 x 7.5

In order to increase the allowed distance

between the positioning element and the

sensor you can optionally use the shields

SP1-QR24, SP2-QR24 or SP3-QR24.

The figures A, B, and C below show three

different ways of mounting the sensor and

the positioning element.

1 Use shielding plate SP2-QR24 optionally

2 Use mounting aid for optimal alignment

of positioning element

3 Place positioning element on the shaft

and make sure that the active face is

correctly aligned (see side label of posi-

tioning element)

4 Tighten the monting bracket with

Allen key

5 Remove mounting aid

6 Place encoder and protective ALcover

on the rotating part. Screw tight with

the three screws until you get a stable

and protected unit

1 Push the encoder from the rear on the

shaft and fasten it

2 Use mounting aid for optimal alignment

of positioning element

3 Interconnect positioning element and

rotatable shaft. Make sure that the ac-

tive face is correctly aligned (see side la

bel of positioning element)

4 Tighten the clamping bracket with

Allen key

5 Remove mounting aid

6 The protective Al cover and the shield-

ing plate SP1-QR24 can be used option-

ally

If positioning element is to be screwed on a

rotating machine part:

1 Use the RA8-QR24 plug which is includ-

ed in the delivery

2 Tighten the clamping bracket with

Allen key

3 Use shielding plate SP3-QR24 optionally

4 Fixate positioning element with three

M3 countersunk head screws

Mount encoder as required

Page 8

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

8

Contactless encoders with SSI interface –

SSI process data/Parametrization

6 SSI-Prozess data

7 Parametrization via easy teach function

6.1 Process data mapping, diagnostic data active

Position Singleturn Bit 0 ... Bit [ singleturn bit length – 1] LSB

Multiturn counter (SSI bit length 25 bit) Bit [singleturn bit length]…Bit [SSI word length – 3] …

Multiturn counter (SSI bit length 26 bit) Bit [singleturn bit length]…Bit [SSI word length – 4] …

1 Multiturn error Bit 22 (see note below) …

2 Amplitude weak Bit 23 (see note below) …

3 Amplitude error Bit 24 (see note below) MSB

Note

If the SSI word length is less than 25 bits, the diagnostic data 1 to 3 automatically become inactive.

Note that the SSI word length can be modied via PACTware™ (see parameter" SSI bit length", page 10)!

6.2 Process data mapping, diagnostic data inactive

Position Singleturn Bit 0 ... Bit [ singleturn bit length – 1]

Multiturn counter Bit [singleturn bit length]…Bit [SSI word length – 1]

Denitions

Bit 0: LSB (least signicant bit)

Singleturn bit length = parametrized resolution for a full revolution (10…18 bit)

SSI word length = parametized SSI bit length (24…26 bit)

The encoder can be adjusted via "easy

teach function". Pin 8 is used as teach in-

put (see wiring diagram on page 13).

The parameters are adjusted by bridging

Pin 8 and Pin 1 (GND) or Pin 8 and Pin 2 (U

B

).

For simple teaching with DIP switch use the

optionally available teach adapter TX2-

Q20L60 with the ident no. 6967117.

Parameters Teach input LED display Description

Zero point bridge Pin 1 (GND) and

Pin 8 for 2 s

status LED ashes, after 2 s steady the encoder's position is set as zero point

Switching between

sync/async mode

bridge Pin 2 (U

B

) and Pin

8 for 2 s

status LED ashes, after 2 s steady

power LED steady green: async mode,

power LED ashes green: sync mode

async mode default set;

encoder switches between async/sync

mode by means of a teach pulse

Direction mode bridge Pin 2 (U

B

) and Pin

8 for 10 s

after 10 s status LED ashes for 2 s encoder rotates in CW direction (factory

setting)

bridge Pin 1 (GND) and

Pin 8 for 10 s

after 10 s status LED ashes for 2 s encoder rotates in CCW direction

Multiturn error ag bridge Pin 1 (GND) and

Pin 8 for 15 s

after 15 s, power and status LED ash

alternately

multiturn error ag is deleted

Switching between

singleturn/multiturn

mode

bridge Pin 2 (U

B

) and Pin 8

for 20 s

after 10 s, the red LED ashes Validity depends on revision status

Easy teach reset bridge Pin 2 (U

B

) and Pin 8

for 15 s

after 15 s, power and status LED ash

alternately

the following parameter are restored:

CW rotation, zero point, multiturn error

(delete), multiturn counter (zero)

Page 9

9

more@turck.com • www.turck.com • 2014/11

8 Parametrization via PACTware™ and IODD

Contactless encoders with SSI interface –

Parametrization

8.1 Software download and install

You can download PACTware™, the IODD-

interpreter and the encoder IODD-file from

www.turck.com. Once you have installed

PACTware™, activate the "IODD_IOL_Ri-

QR24..zip" file with the IODD-interpreter and

update the device catalog in PACTware™.

8.2 Set Parameters

The following encoder parameters can be

set in PACTware™:

Page 10

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

10

Contactless encoders with SSI interface –

Parametrization

1

) This parameter is not adjustable via "Easy teach function".

MSB

…

LSB

Error Multiturn Singleturn

Bit 24…Bit 22 Bit 21…Bit 16 Bit 15…Bit 0

8.4 Factory setting SSI-Process data

8.3 Detailed list of adjustable parameters

Parameters Description

Multiturn reset In multiturn mode multiturn process data is stored in the encoder even after power loss. This means

that the device continues to count with the stored multiturn value after power recovery.

If the positioning element was relocated during a power loss, this is indicated by a status bit (multiturn error ag) and a red LED.

This incident and the multiturn data are reset with this command.

SSI bit length 23, 24, 25, or 26 bit are parametrizable (factory setting "25 Bit")

SSI singleturn bit length

1

) 10 to 18 bit are parametrizable.

Depending on the setting, the following assignments for singleturn process data are used:

bits 0 to 9 (10 bit), or bits 0 to 17 (18 bit). (factory setting "16 Bit“)

SSI Code (Gray/binary)

1

) Bit coding (Gray, binary) parametrizable (factory setting "Gray")

SSI mode

(async/auto-sync/sync)

Parametrization of the encoder for operation with sync (deterministic) SSI-master (jitter < 5 µs) or

async SSI-master.

In sync mode the signal propagation time is optimal.

(Factory setting "Async")

SSI ags enabled

1

) Bits 22, 23, 24 provide status information. These status bits can be disabled in this command. The va-

cated bits are used in this case for the multiturn process data. If 23 or 24 bit are parametrized under

SSI bit length, the SSI ags will automatically be disabled.

(Factory setting "SSI Flags On")

zero point Both singleturn as well as multiturn process data and the multiturn error ag will be reset.

Direction mode The direction can be parametrized from clockwise to counterclockwise as appropriate.

(Factory setting "CW Clockwise" in plan view on the positioning element)

factory setting

1

) All parameters are reset to factory setting.

Page 11

11

more@turck.com • www.turck.com • 2014/11

Dimension drawing Type Description

60

30

50

20

M12 x 1

M12 x 1

42.5

ø 15

ø 4.5

8

TX2-Q20L60 Teach adapter for easy program-

ming

USB-2-IOL-0002 IO-Link master with integrated

USB interface for parametrizing

the IO-Link-capable encoders

via a PC

without figure RKC8.302T-1,5-

RSC4T/TX320

Adapter cable for connection

of SSI sensor to USB-2-IOL-0002

parametrizing unit; female M12,

straight, 8-pin - male M12,

straight, 3-pin; cable length:

1.5 m; sheath material: PVC;

sheath color: black; cULus approved, RoHS conform, IP67

rated

ø 24

ø 28

2

9.9

ø 20

RA1-QR24

RA2-QR24

RA3-QR24

RA4-QR24

RA5-QR24

RA6-QR24

RA7-QR24

Reducing bushing, for Ø 20 mm

shafts

Reducing bushing, for Ø 14 mm

shafts

Reducing bushing, for Ø 12 mm

shafts

Reducing bushing, for Ø 10 mm

shafts

Reducing bushing, for Ø 6 mm

shafts

Reducing bushing, for Ø 3/8"

shafts

Reducing bushing, for Ø 1/4"

shafts

ø 24

ø 28

2

9.9

RA8-QR24 Blanking plug for positioning

element

1.5

MT-QR24 Mounting aid for optimal align-

ment of positioning element

9 Accessories

9.1 Mounting accessories

For accessories, see the table below.

Contactless encoders with SSI interface –

Mounting accessories

Set Description

M1-QR24 Protective ring, aluminium

ø 74

ø 4.5

ø 65

ø 57

120°

14.3

M2-QR24 M1-QR24 +

SP1-QR24

shielding plate

Ø 74 mm, aluminium

ø 74

ø 4.5

ø 65

120°

2

M3-QR24 M1-QR24 +

SP2-QR24

shielding plate

Ø 74 mm with bore with shaft

guidance, aluminium

ø 74

ø 4.5

ø 65

ø 22

120°

2

M4-QR24 M1-QR24 +

SP3-QR24

shielding plate

Ø 52 mm, aluminium

ø 52

ø 3.2

ø 42

120°

2

41

24

54

M12 x 1

16

USB-Mini

IN-DC

LED:

CH1 (C/Q)

CH2 (DI/DO)

Error

LED: PWR

9.2 Standard mounting accessories

For each device type a suitable mount-

ing kit is available (see Type Code, Design,

page 4. The mounting kits contain the

M1-QR24 aluminium ring for protection

and a shielding plate (either SP1-QR24 or

SP2-QR24 orSP3-QR24).

Page 12

Hans Turck GmbH & Co. KG • Tel. +49 208 4952-0 • Fax +49 208 4952-264

12

Contactless encoders with SSI interface –

Accessories positioning elements

9.3 Positioning elements

Different positioning elements are available.

The positioning elements are connected

to the movable parts of the machine. They

"float" freely above the active face of the

sensor.

Dimension drawing Type Description

ø 3.2

ø 20

ø 52

ø 42

10

P1-Ri-QR24 Positioning element,

for Ø 20 mm shafts

ø 3.2

ø 52

ø 42

10

ø 14

P2-Ri-QR24 Positioning element,

for Ø 14 mm shafts

ø 3.2

ø 52

ø 42

10

ø 12

P3-Ri-QR24 Positioning element,

for Ø 12 mm shafts

ø 3.2

ø 52

ø 42

10

ø 10

P4-Ri-QR24 Positioning element,

for Ø 10 mm shafts

ø 3.2

ø 52

ø 42

10

ø 6

P5-Ri-QR24 Positioning element,

for Ø 6 mm shafts

ø 3.2

ø 52

ø 42

10

ø 3/8“

P6-Ri-QR24 Positioning element,

for Ø 3/8" shafts

ø 3.2

ø 52

ø 42

10

ø 1/4“

P7-Ri-QR24 Positioning element,

for Ø 1/4" shafts

ø 3.2

ø 52

ø 42

10

P8-Ri-QR24 Positioning element with blank-

ing plug

Page 13

13

more@turck.com • www.turck.com • 2014/11

ø 78 ø 22 ø 4.3 ø 65

24

81

10

42.3

LED

M12 x 1

Measuring range

Measuring range 0…360 °

single or multiturn mode

System

Resolution

Repeatability

Linearity tolerance

Temperature drift

Ambient temperature

16-bit

0.01 %

≤ 0.05 % full scale.

≤ ± 0.003 %/K

-25…+85 °C

Electrical data

Operating voltage

Ripple

Rated insulation voltage

Reverse polarity protection

Output function

Process data range

Diagnostic bits

Sampling rate

Current consumption

15…30 VDC

≤ 10 % U

ss

≤ 0.5 kV

yes (power supply)

8-wire, SSi, 25-bit, gray coded

parametrizable

Bit 22: Position changed during a power loss

Bit 23: Positioning element is in the measuring range, reduced signal quality (e.g. distance too large)

Bit 24: Positioning element is outside of measuring range

data telegram parametrizable as multiturn or singleturn process data or as error bits

5000 Hz/the sensor's sampling rate depends on the master's SSI cycle time. It is 1 to 5 kHz (signal

propagation delay 200 s) in sync mode

< 100 mA

Housing

Dimensions

Housing material

Connection

Vibration resistance

Shock resistance

Degree of protection

MTTF

81 × 78 × 24 mm

metal/plastic, ZnAlCu1/PBT-GF30-V0

male connector, M12 × 1

EN 60068-2-6, 55 Hz

EN 60068-2-27, 30 g

IP67/IP69K

138 years to SN 29500 (Ed. 99) 40 °C

LEDs

Operating voltage indication

Measuring range indication

Fault indication

LED green

LED, yellow, yellow flashing

LED red

Miscellaneous

Included in scope of supply mounting aid MT-QR24

Wiring diagram

1 GND

2 24 VDC

3 CLK +

4 CLK –

5 Data +

6 Data –

7 n.c.

8 Te ach / Progr.

SSI

Contactless encoders with SSI interface –

Technical data

10 Technical data

Page 14

D102003 2014/11

*D102003ßß1411*

Hans Turck GmbH & Co. KG

Witzlebenstr. 7

45472 Muelheim an der Ruhr

Germany

Tel. +49 208 4952-0

Fax +49 208 4952-264

E-Mail more@turck.com

Internet www.turck.com

WORLDWIDE HEADQUARTERS

Your Global

Automation Partner!

Loading...

Loading...