Page 1

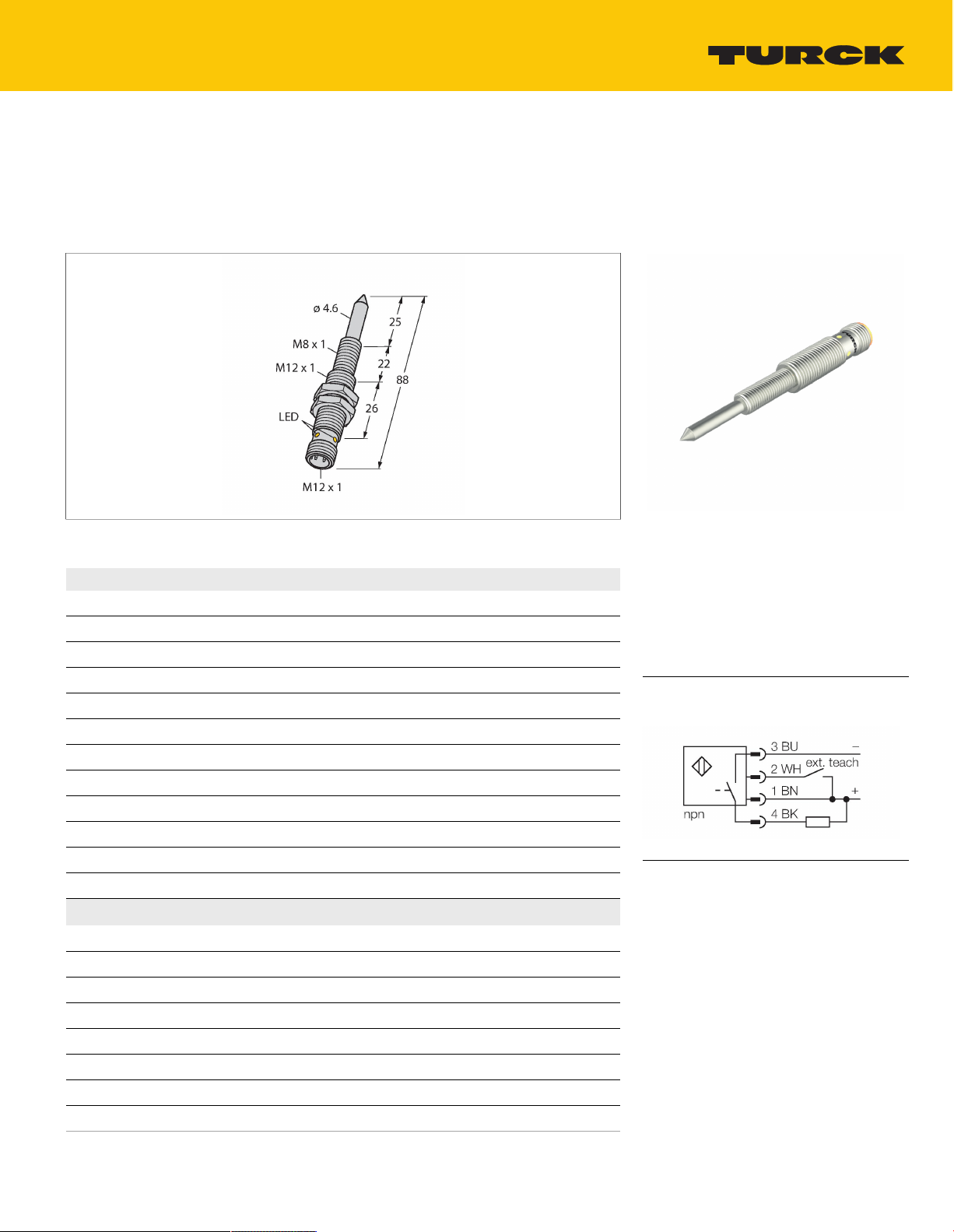

NIMFE-M12/4.6L88-UN6X-H1141

Magnetic Field Sensor

For Detection of Ferromagnetic Parts

Technical data

Type

Ident. no. 1600610

Ambient temperature -25…+70°C

Operating voltage 10…30VDC

Residual ripple ≤10% U

DC rated operational current ≤200mA

No-load current ≤15mA

Residual current ≤0.1mA

Isolation test voltage ≤0.5kV

Short-circuit protection yes / Cyclic

Voltage drop at I

Wire breakage/Reverse polarity protection yes / Complete

Output function 3-wire, Connection programmable, NPN

e

Design

Dimensions 88mm

Housing material Metal, CuZn, Chrome-plated

Active area material Metal, CuZn, chrome-plated

Max. tightening torque of housing nut 10Nm

Electrical connection Connector,M12 × 1

Vibration resistance 55Hz (1 mm)

Shock resistance 30g (11 ms)

Protection class IP67

NIMFE-M12/4.6L88-UN6X-H1141

ss

≤1V

Threaded barrel,M12 × 1

Features

Threaded barrel, M12/M8

■

Chrome-plated brass

■

DC 3- wire, 10…30 VDC

■

Programmable (NC/NO) with teach adapter

■

VB2‐SP1

M12 x 1 connector

■

Wiring diagram

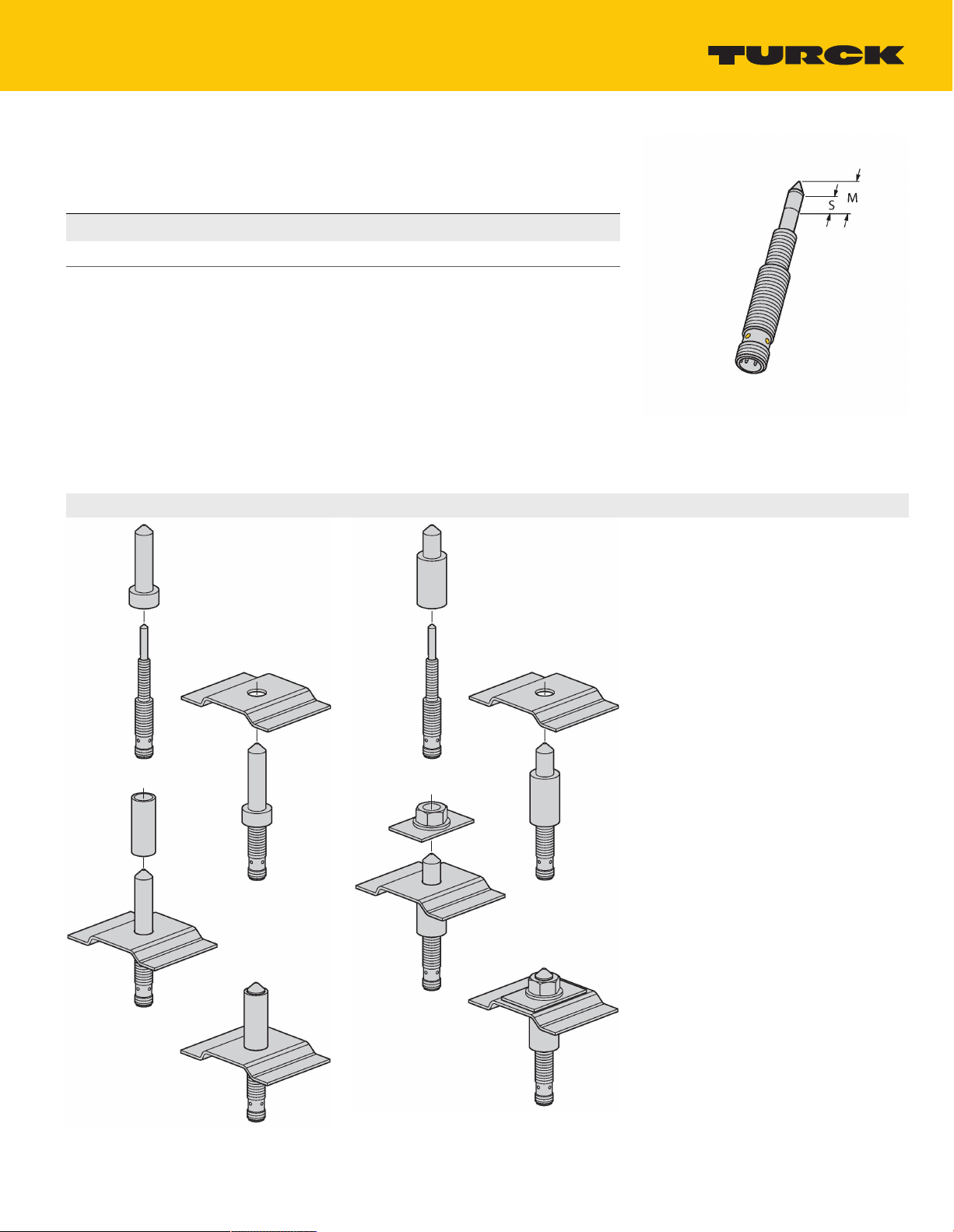

Functional principle

The weld sensors are available in different

versions, with different signal intensities

and diameters. Ferromagnetic parts which

differ strongly in their material properties and

diameters can thus be detected. A target part

has to be located within the so called sensitive

area in order to be detected. The internal

sensor signal reaches the maximum intensity if

the sensitive area is completely covered by the

target. Partial coverage is also possible.

Sensitive area S = 9 mm

Within this area the sensor signal changes

when components are connected.

Maximum range M = 13 mm

In case of complete coverage of the sensitive

area the maximum signal intensity is achieved.

NIMFE-M12/4.6L88-UN6X-H1141 | 12/03/2020 06-37 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

1|3

Page 2

Technical data

MTTF 874years acc. to SN 29500 (Ed. 99) 40

°C

Power-on indication

LED,Green

Switching state LED,Yellow

Mounting instructions

Mounting instructions/Description

The magnetic field sensor is especially suited

for the detection of welding nuts as well as

spacer or reinforcing sleeves. The parts to be

detected must always consist of ferromagnetic

material, so that a proper function can be

guaranteed. Most applications need center

bolts to tack the welding nuts and reinforcing

sleeves in place and thus provide mechanical

protection of the sensors. Theses bolts have

to be made of non-ferromagnetic material, like

stainless steel for example. Center bolts are

not available at Turck, as these have to be

individually produced for and adjusted to the

correspondent application.

The welding nut sensor detects ferritic targets

with diameters between 6mm and 12mm.

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

NIMFE-M12/4.6L88-UN6X-H1141 | 12/03/2020 06-37 | technical changes reserved

2|3

Page 3

examples

of use\\Graphics

\Pic1\00151691_0.EPS

Parameterisation

with the\\Graphics

\Pic3\00151685_0.EPS

teach

adapter:

examples

of use\\Graphics

\Pic1\00151691_0.EPS

Parameterisation

with the\\Graphics

\Pic3\00151685_0.EPS

teach

adapter:

\

\Graphics

\Pic0\00151682_0.EPS

\

\Graphics

\Pic6\00152122_0.EPS

\

\Graphics

\Pic0\00151682_0.EPS

\

\Graphics

\Pic6\00152122_0.EPS

\

\TextModule

\Text3\us1913.xml

\

\TextModule

\Text4\us1914.xml

\

\TextModule

\Text3\us1913.xml

\

\TextModule

\Text4\us1914.xml

examples

of use\\Graphics

\Pic1\00151691_0.EPS

Parameterisation

with the\\Graphics

\Pic3\00151685_0.EPS

teach

adapter:

examples

of use\\Graphics

\Pic1\00151691_0.EPS

Parameterisation

with the\\Graphics

\Pic3\00151685_0.EPS

teach

adapter:

\

\Graphics

\Pic0\00151682_0.EPS

\

\Graphics

\Pic6\00152122_0.EPS

\

\Graphics

\Pic0\00151682_0.EPS

\

\Graphics

\Pic6\00152122_0.EPS

\

\TextModule

\Text3\us1913.xml

\

\TextModule

\Text4\us1914.xml

\

\TextModule

\Text3\us1913.xml

\

\TextModule

\Text4\us1914.xml

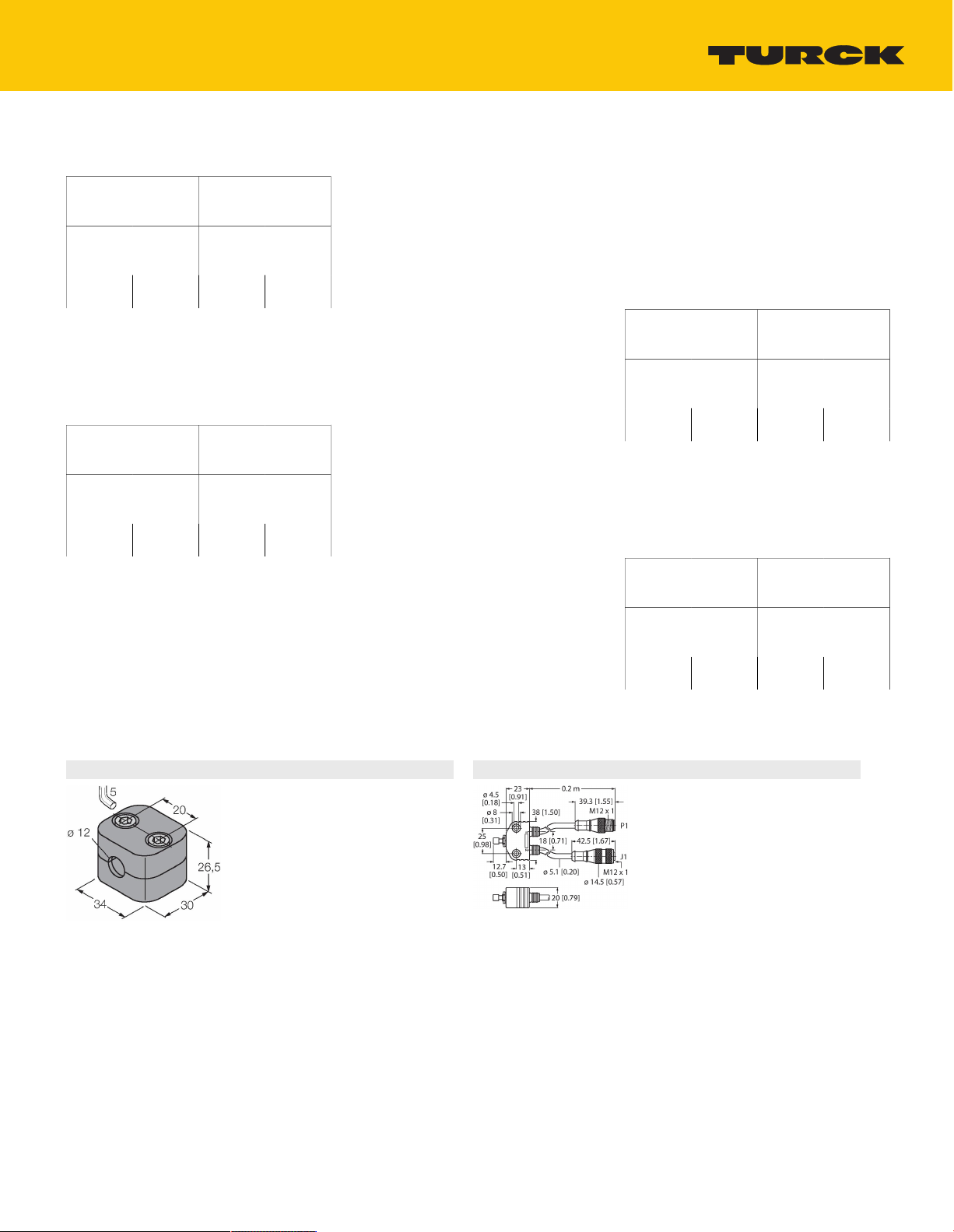

Accessories

BSS-12 6901321

Mounting clamp for smooth and

threaded barrel sensors; material:

Polypropylene

VB2-SP1 A3501-29

Teach adapter

NIMFE-M12/4.6L88-UN6X-H1141 | 12/03/2020 06-37 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

3|3

Loading...

Loading...