turck LTX Series, LTX-R10 Series, LTX-EF10 Series, LTX-ER10 Series, LTX-F10 Series Operating Instructions Manual

Page 1

Your Global Automation Partner

Operating instructions

LTX

Linear Position Sensors

with SSI Interface

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Contents

Page 3

3

2017/09

1 About these Instructions 5

1.1 Target Groups 5

1.2 Explanation of Symbols 5

1.3 Other Documents 5

1.4 Feedback on these Instructions 5

2 Notes on the Product 6

2.1 Product Identication 6

2.2 Scope of Delivery 6

2.3 Legal Requirements 7

2.4 Manufacturer and Service 7

3 For Your Safety 7

3.1 Intended Use 7

3.2 General Safety Instructions 7

4 Product Description 8

4.1 Device Overview 8

4.1.1 Display Elements 8

4.2 Properties and Characteristics 9

4.3 Functional Principle 9

4.4 Functions and Operating Modes 9

4.4.1 Automatic Signal Control 10

4.4.2 Update Mode 10

4.4.3 Measuring Functions 11

4.4.4 Preferred Type LTX…M-F10-SSI2-GAF1-X3-H1161 – Measuring Range 11

4.5 Technical Accessories 12

5 Mounting 14

5.1 Mounting the Device in a Hydraulic Cylinder 15

5.1.1 Mounting the Sensor 15

5.2 Fastening the Device Externally with Mounting Bracket 16

5.2.1 Mounting Additional Mounting Elements (for External Mounting) 17

5.2.2 Mounting Positioning Elements (for External Mounting) 17

6 Connection 18

6.1 Wiring Diagram 18

7 Commissioning 18

8 Operation 19

8.1 LED Display 19

9 Eliminating Interference 20

9.1 Replacing the Sensor Head and Measuring Element 20

10 Maintenance 20

11 Repair 20

11.1 Returning Devices 20

12 Disposal 20

13 Technical Data 21

13.1 Update Time 21

Contents

Page 4

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 5

5

2017/09

1 About these Instructions

These operating instructions describe the structure, functions and the use of the product, and

will help you to operate the product as intended. Read these instructions carefully before using the product. This is to avoid possible personal injury, or damage to property or the device.

Retain these instructions for future use during the service life of the product. If the product is

passed on, pass on these instructions as well.

1.1 Target Groups

These instructions are aimed at qualified personnel and must be carefully read by anyone

mounting, commissioning, operating, maintaining, dismantling or disposing of the device.

1.2 Explanation of Symbols

The following symbols are used in these instructions:

DANGER

DANGER indicates an imminently hazardous situation with a high risk of death or serious injury if it is not prevented.

WARNING

WARNING indicates a potentially hazardous situation with a moderate risk of death or

severe injury if not prevented.

CAUTION

CAUTION indicates a situation that may result in damage to property if it is not

prevented.

NOTE

NOTE indicates tips, recommendations and important information. The notes make

work easier, contain information on specific action steps and help prevent unnecessary

work due to incorrect processes.

CALL TO ACTION

This symbol identifies steps that the user has to perform.

ACTION RESULT

This symbol identifies relevant results of actions and action sequences.

1.3 Other Documents

Besides this document, the following material can be found on the internet at www.turck.com:

■

Data sheet

1.4 Feedback on these Instructions

We are committed to always keeping these instructions as informative and as clear as possible.

If you have any suggestions for improving the design or if some information is missing in the

document, please send your suggestions to techdoc@turck.com.

Page 6

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Notes on the Product

2 Notes on the Product

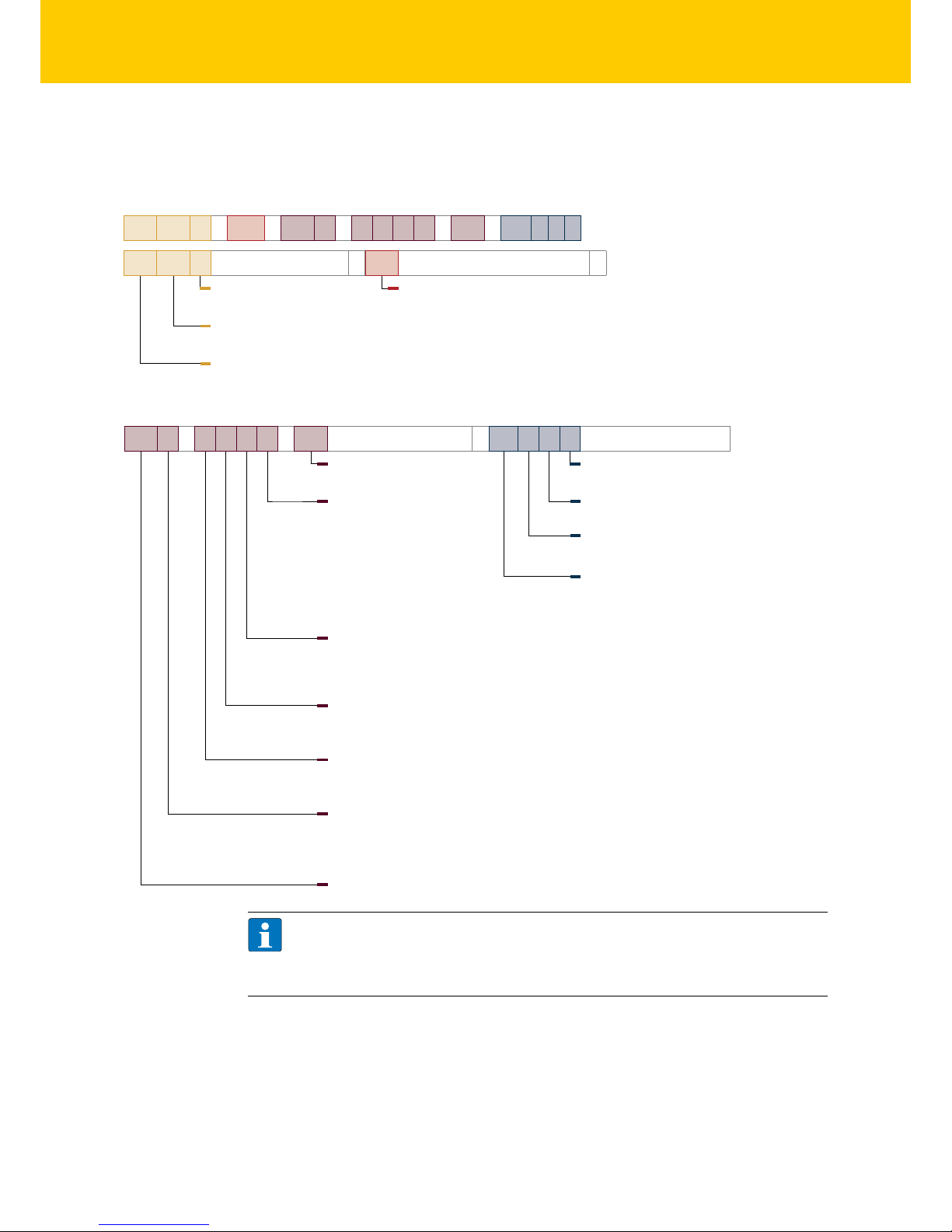

2.1 Product Identication

NOTE

■

Designs with manufacturer compatible connectors and models with enlarged blind

zones are available on request.

■

Device LTX…M-F10-SSI2-GAF1-X3-H1161 is the preferred type.

2.2 Scope of Delivery

Included in the scope of delivery:

■

Linear position sensor (without positioning element)

■

Quick start guide

LTX 100 M

Magnetostrictive

position sensor

–

Unit

M Millimeter

Measuring range

100 from 25 to 7500 mm

Operating principle

LTX Linear position sensor

LTX 100 M – F10 – SSI 2 – G A F 1 – X3 – H1 1 6 1

F10

Design

–

Design

F10 Flat face, rod Ø 10.3 mm,

aluminum*

R10 Raised face, rod Ø 10.3 mm,

aluminum

EF10 Flat face, rod Ø 10.3 mm,

stainless steel

ER10 Raised face, rod Ø 10.3 mm,

stainless steel

SSI 2 – G A F 1 – X3

Electrical version

–

Number of LEDs

X3 3-color LED

Resolution

1 0.005 mm*

2 0.01 mm

3 0.05 mm

4 0.1 mm

5 0.02 mm

6 0.002 mm

7 0.001 mm

Direction

F forward*

R backward

V velocity

Data type

S synchronous

A asynchronous*

Data format

B binary

G gray*

Data length

1 24 bit

2 25 bit*

3 26 bit

Data mode

H1161

Electrical connection:

Male

Assignment

1 Standard assignment

Number of contacts

6 6-pin

Connector type

1 straight

Connector type

H1 Male connector M12 x 1

* Preference type

Page 7

7

2017/09

2.3 Legal Requirements

The device is subject to the following EU directives:

■

2014/30/EU (electromagnetic compatibility)

■

2011/65/EU (RoHS 2)

2.4 Manufacturer and Service

Turck supports you with your projects, from initial analysis to the commissioning of your application. The Turck product database contains software tools for programming, configuration

or commissioning, data sheets and CAD files in numerous export formats. You can access the

product database at the following address: http://www.turck.de/products/

Should you have any further questions, please contact the sales and service team in Germany

on the following telephone numbers:

Sales: +49 208 4952-380

Technology: +49 208 4952-390

Outside Germany, please contact your Turck representative.

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Mülheim an der Ruhr

Germany

3 For Your Safety

The product is designed to the latest standards. However, residual risks still exist. Observe the

following warnings and safety information to prevent personal injury or damage to property.

Turck accepts no liability for damage caused by failure to observe these warning and safety

instructions.

3.1 Intended Use

These devices are designed solely for use in industrial areas.

The magnetostrictive linear position sensors are used for contactless and wear-free linear

position detection. The devices are suitable for use in hydraulic cylinders. The devices can also

be used for level measurement through the use of float magnets (optionally available). The

measuring range is adjustable.

The devices must only be used as described in these instructions. Any other usage shall be considered improper and Turck shall not be held liable for any resulting damage.

3.2 General Safety Instructions

■

The devices are not safety components and may not be used for personal or property

protection.

■

The device must only be fitted, installed, operated, parameterized and maintained by trained

and qualified personnel.

■

The device only meets the EMC requirements for industrial areas and is not suitable for use in

residential areas.

Page 8

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

4 Product Description

The linear position sensors with SSI interface provide a serial synchronous interface output

signal (SSI) proportional to the position of the positioning element. Different device variants

enable the following measuring functions to be performed:

■

Position measurement, measuring direction forwards

■

Position measurement, measuring direction backwards

■

Speed measurement

The devices can be connected via a M12 plug connector. All devices feature a rod design with

IP68 protection. The devices operate without contact, which requires the use of a positioning

element approved by Turck (see Accessories).

The devices operate in absolute mode; voltage failures do not require renewed zero point adjustment or recalibration. All position values are determined as absolute values; reference runs

after a voltage drop are unnecessary.

4.1 Device Overview

Fig. 1: Device dimensions of LTX with standard blind zones (in mm)

4.1.1 Display Elements

Each device has a 3-color LED for indicating the operating state and for fault diagnostics (see

8.1 LED display).

24

44.5

ø 44.5

ø 10.3

10

M18 x 1.5 x 25

M12 x 1

81.3

L

63.5

Blind zone

50.8

Blind zone

Measuring

range

Page 9

9

2017/09

4.2 Properties and Characteristics

■

SSI output

■

Automatic signal control

■

7…30 VDC supply voltage

■

Low power consumption

■

High shock and vibration resistance

■

Protection class IP68

■

16 bit resolution

■

Status displayed via 3-color LED

■

Sensor and pressure pipe can be replaced separately

■

Male connector M12

4.3 Functional Principle

Operation of the Turck LTX sensors is based on the magnetostrictive principle. A “waveguide”

is located in the measuring probe of the linear position sensor. If a current signal generated at

the waveguide encounters the externally applied magnetic field of the positioning element,

mechanical feedback is produced in the waveguide. This feedback is evaluated in the sensor

head and output as position information.

4.4 Functions and Operating Modes

The devices have an SSI interface according to the RS422 standard. The process value is transferred via the interface either directly to the higher-level controller (with SSI card) or to a fieldbus device.

Fig. 2: Block diagram of the sensor control

The location of the positioning element on the sensor measuring probe is determined by

means of a propagation time measurement and transmitted to the controller via the SSI interface. All position values are determined as absolute values; reference runs after a voltage drop

are unnecessary.

+7…30 V

0 V

SSI Clock (+)

SSI Clock (–)

SSI Data (+)

SSI Data (–)

Input

Power

Supply

SSI Shift Register and Controller

Output Data Format Conversion

SSI Logic Diagram

Position Measurement

Page 10

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

New incoming position data is transferred via the data signal 605 ns after the rising edge of the

clock signal. This time frame, including the elapsed time caused by the length of the cable, must

be allowed for when defining the transmission rates.

Fig. 3: SSI pulse diagram: Bitwise transmission from most significant bit (MSB) to least signifi-

cant bit (LSB)

4.4.1 Automatic Signal Control

The device is automatically adjusted to the signal strength of the positioning element as soon

as the sensor is supplied with power. The automatic signal control fully compensates for any

tolerances.

4.4.2 Update Mode

The devices can be operated in synchronous or asynchronous update mode. In asynchronous

mode, up to 2000 measurements (depending on length, see also the "Update time" section) can

be carried out per second to update the position values. In synchronous mode, the clock rate

for the update depends on the controller (max. 2000 measurements per second, depending on

length). In synchronous mode, if the controller queries the position data on the sensor faster

than the data is provided by the sensor, the sensor automatically switches to asynchronous

mode and continues to provide the latest position information to the controller.

NOTE

Turck recommends operating the device in asynchronous update mode, if no highly

dynamic control requirement is involved.

Fig. 4: Synchronous and asynchronous update mode

min. 16 µs

Clock (+)

Data (+)

Clock Interval

LSBMSB

SSI Clock

Synchronous

Asynchronous

Controller

Update

Internal

Repetition

Update

Position

Update

Position

Update

Position

Update

Position

Update

Position

Update

Position

Update

Position

Page 11

11

2017/09

Synchronous update mode

The clock pulse rate of the controller sets the frequency for reading the position data. The sensor transmits one position data bit to the controller with each pulse. The first clock edge of the

controller signals the sensor to carry out a new position measurement. The updated position

data is transferred in the next read cycle.

NOTE

In synchronous mode, the position data available to the controller is no more than one

update cycle old.

Asynchronous update mode

The sensor carries out position measurements according to a fixed internal request rate (sensorinternal measurement cycle) and provides the position information when requested by the

controller.

4.4.3 Measuring Functions

Different device variants are available for performing different measuring functions:

Device type Measuring function

LTX…SSI…F… Position, measuring direction

forwards

The position value is incremented during the

movement along the measuring probe starting

from the sensor head.

LTX…SSI…R… Position, measuring direction

backwards

The position value is incremented during the

movement in the direction of the sensor head

starting from the end of the measuring probe.

LTX…SSI…V… Speed measurement The sensor provides speed information directly.

4.4.4 Preferred Type LTX…M-F10-SSI2-GAF1-X3-H1161 – Measuring Range

Preferred types LTX…M-F10-SSI2-GAF1-X3-H1161 are available with the following measuring

lengths as standard:

Measuring range set

100…500 mm in 25 mm steps

500…2000 mm in 50 mm steps

2000…7600 mm in 500 mm steps

Page 12

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product Description

4.5 Technical Accessories

The following accessories are not included in the scope of delivery:

Dimension drawing Type Ident. no. Description

Positioning element

ø 32,8

ø 23,8

ø 4,7

ø 13,5

16,8

7,9

STM-AL-R10 6900409 Standard 4-hole positioning element, alu-

minum, suitable for installation in hydraulic

cylinders

ø 25,4

7,9

ø 13,5

CM-R10 6900416 Standard positioning element, suitable for

installation in hydraulic cylinders

LSPM-AL-R10 6900414 Ring-type positioning element with slot,

aluminum, can be used for external mounting with mounting clamp RB-R10

50,8

ø 14,1

ø 50,8

max.

ø 52,1

EF-R10 6900417 Float-positioning element, stainless steel,

specific weight 0.62 kg/m³, for external

mounting for level monitoring

Spacer

ø 32,8

ø 23,8

ø 4,7

ø 13,5

16,8

6,4

STS-R10 6900411 Standard spacer produced from non-ferritic

material for separating the positioning element from the ferritic base of the hydraulic

piston rod, suitable for installation in hydraulic cylinders

Page 13

13

2017/09

Dimension drawing Type Ident. no. Description

Accessories for external mounting

#6-32

ø 7,1

31,7

23,8

50,8

76,2

25,4

15,7

50,8

ø 14,2

MMB-R10 6900004 Mounting clamp for positioning element, for

external mounting, with screws and standard

STS-R10 spacer

50,8

19,3

12,7

ø 12,2

ø 10,5

50,8

26,2

ø 7,1

ø 7,1

31,7

50,8

76,2

25,4

15,7

50,8

ø 19,5

MB-R10 6900419 Mounting clamp for sensor head and rod, for

external mounting, with screws

50,8

19,3

12,7

ø 12,2

ø 10,5

50,8

26,2

ø 7,1

RB-R10 6900420 Mounting clamp for rod, for external mount-

ing, with screws

Page 14

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

5 Mounting

The device can be mounted in a hydraulic cylinder or externally with a mounting bracket.

CAUTION

Incorrect mounting

Risk of damage to the sensor

Only fasten the device in place using the hexagon nut on the sensor head (max.

tightening torque: 50Nm).

Do not fasten by turning the sensor head itself.

Ensure that the positioning element is guided centrally over the pressure pipe along

the entire measuring length (deviation < 0.5 mm).

Fig. 5: Side view of LTX-R10 with dimensions in mm [in] (design with raised face)

Fig. 6: Design with flat face (F10) – Housing nut with thread,

dimensions in mm [in]

Fig. 7: Design with raised face (R10) – Housing nut with thread,

dimensions in mm [in]

81.3 [3.20]

2.5 [.10]

7.1 [.28]

ø 25.4 [1.00]

ø 44.5 [1.75]

7.9

[.31]

ø 10.3 [.405]

32.8 [1.28]

M12 x 1

3-color LED

LTX…M: M18x1.5-6gx25mm thread

w/jam nut

LTX…E: 3/4-16x1.00 thread

w/jam nut

Viton O-ring

for 1/2“ dia

tube boss seal

Span

63.5 [2.50] Dead band

50.8 [2.00] Null

Standard 4-hole positioning element

(STM-AL-R10)

9.6

[.38]

2.5 [.10]

7.1 [.28]

ø 25.4 [1.00]

Page 15

15

2017/09

5.1 Mounting the Device in a Hydraulic Cylinder

CAUTION

Incorrect mounting

Risk of damage to the hydraulic cylinder

Observe cylinder manufacturer instructions and hydraulic cylinder specifications.

The devices can be mounted directly in a hydraulic cylinder. To do so, the cylinder piston rod

must have a bore hole with a recommended diameter of 13.5 mm (depending on the cylinder

design). To fasten the device, the end cap of the hydraulic cylinder must have an M18×1.5

threaded bore in accordance with ISO 6149-1.

5.1.1 Mounting the Sensor

Loosen and remove the hexagon nut on the sensor from the thread on the sensor head.

Ensure that the O-ring is located on the sensor head for pressure sealing.

Mount the non-ferrite spacer between the positioning element and base of the piston rod.

Mount the positioning element. Observe a minimum distance of 51 mm between the posi-

tioning element and sensor head with the piston rod in the retracted position. If the mini-

mum distance cannot be observed, sink the positioning element in the cylinder piston.

Recommended for sensors with measuring probe lengths ≥ 1500 mm: use protecting ring,

e.g. made of polymer (see Fig. 8, Item 2). The protecting ring prevents mechanical wear on

positioning elements by the pressure pipe when the piston is fully extended.

Fasten the positioning element and spacer with non-ferrite screws.

Remove protective cap on the hydraulic cylinder (if present). The bore hole in the cylinder

piston rod should have a diameter of at least 13.5 mm.

Insert the sensor pressure pipe into the cylinder piston.

Screw the sensor into the M18 × 1.5 threaded bore of the hydraulic cylinder using the thread

of the sensor head (max. tightening torque: 50Nm).

2

3

4

5

1

1 Viton O-ring

2 Protecting ring

(optional)

3 4-hole positioning

element

4 Spacer for positioning

element

5 13.5 mm bore hole in

the cylinder piston rod

Fig. 8: Mounting the Device in a Hydraulic Cylinder

Page 16

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

5.2 Fastening the Device Externally with Mounting Bracket

CAUTION

Magnetization of metal in close proximity with the measuring probe

Inaccurate measurements

Mount the sensor measuring probe at least 7 mm away from ferromagnetic material.

NOTE

Non-ferrous materials, such as brass, copper, aluminum, demagnetized stainless steel

or plastic do not impair the function of the sensor.

Loosen the hexagon nut on the thread of the sensor head.

Guide the mounting bracket over the pressure pipe up to the sensor head.

If the mounting bracket has an M18 × 1.5 threaded hole, screw the sensor tight directly.

Fasten the mounting bracket.

Re-fasten the hexagon nut on the sensor head.

Fig. 9: Mounting device with mounting brackets (dimensions in mm)

ø 7.1

32

25.4

7 x 26

11

50.8

50.8

MB-R10

MMB-R10

RB-R10

Page 17

17

2017/09

5.2.1 Mounting Additional Mounting Elements (for External Mounting)

On devices over 750 mm in length, additional mounting elements (RB-R10) increase protection

against mechanical stresses such as impacts and vibrations. The mounting elements must be

made from non-ferrite material.

When using additional mounting elements, use a ring-type positioning element with slot as

the positioning element.

Fit mounting elements made from ferromagnetic (already magnetized) material at least 7 mm

away from both the blind zone and the active measuring range of the sensor.

Sensors with measuring probe lengths of 750…1800 mm: Fit additional mounting elements

as per Fig. 10:

Sensors with measuring probe lengths > 1800 mm: Fit mounting elements at distances of

1200 mm.

5.2.2 Mounting Positioning Elements (for External Mounting)

Observe a distance of 7 mm between the positioning element and ferrite material. Use a

spacer if necessary.

Observe a distance of 7 mm between the end of the measuring probe and ferrite material.

The positioning element must not touch the sensor along the entire measuring range.

When using ring-type positioning elements with slot: Observe ≤ 5 mm distance between the

positioning element and measuring probe (nominal distance: 1.5 mm).

Push the positioning element into the active measuring range of the sensor.

Fasten the positioning element with non-ferrite screws.

50,8

31,8

25,4

11

7,1

25,4

26,2

16,9

36

25,4

15,7

ø 7,1 (2x)

31,8

50,8

50,8

50,8

ø 7,1 (2x)

1

2

3

4

6

Dead bandStrokeNull

1 Sensor

2 Mounting element for

sensor head

3 4-hole positioning ele-

ment (aluminum)

4 Spacer for positioning

element

5 Mounting element for

positioning element

6 Mounting element for

measuring probe

Fig. 10: Mounting the positioning element (dimensions in mm)

Page 18

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Connection

6 Connection

NOTE

Turck recommends keeping the length of the connection lines as short as possible.

The running lengths of the connection lines are limited and depend on the SSI clock frequencies. Different clock rates are recommended depending on the length of the connection lines.

Clock rate and data frame lengths are set by the master.

Line length [m] Baud rate

< 3 1 MBd

< 50 < 400 kBd

< 100 < 300 kBd

< 200 < 200 kBd

< 360 < 100 kBd

Connect the coupling of the connection cable to the connector of the device.

Connect the sensor to the higher level as per the connector pin assignment (Fig. 11).

6.1 Wiring Diagram

NOTE

The following figure details the usual wire colors. In exceptional cases, this color allocation may differ.

Pin Pin assignment Wiring Diagram

Pin 1 U

B

+

Pin 2 Data +

Pin 3 GND

Pin 4 Data -

Pin 5 Clock -

Pin 6 Clock +

Fig. 11: Wiring Diagram

7 Commissioning

Once the cables and the supply voltage are connected, the device automatically goes into

operation. To ensure the correct calibration of the automatic signal control, the positioning element must be located in the active measuring range of the sensor when the supply voltage is

connected.

Page 19

19

2017/09

8 Operation

8.1 LED Display

Color/status Meaning

off No power supply present

Illuminated in green Positioning element signal detected in taught range, SSI clock signal

operational

Illuminated in yellow No SSI clock signal detected

Illuminated in red No positioning element signal detected

Red flashing/red-green

flashing

Internal error

Green with brief yellow

flashing (1 s to 0.12 s)

Data not synchronous with controller (only in synchronous mode)

Yellow with brief red flashing

(1 s to 0.12 s)

SSI clock pulses do not match the SSI data length

Proceed as follows if no positioning element signal is detected (red LED lit):

Place the positioning element in the active measuring range of the device.

Reset the voltage.

The device is automatically adjusted to the signal strength of the positioning element.

If, in synchronous mode, the data is not synchronized with the controller (LED green with brief

yellow flashing, 1 s to 0.12 s), proceed as follows:

Increase the update time via the module settings of the SSI master.

Page 20

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Eliminating Interference

9 Eliminating Interference

If the device does not function as expected, check the LED feedback (see section “LED display”).

Check whether ambient interference is present. If there is no ambient interference, check the

connections of the device for faults.

If there are no errors, there is a device malfunction. In this case, decommission the device and

replace it with a new device of the same type.

9.1 Replacing the Sensor Head and Measuring Element

WARNING

Overpressure at the sensor head

Risk of injury through uncontrolled ejection of sensor head

In pressurized systems, ensure that the pressure pipe is undamaged and

pressure-proof.

NOTE

The system does not have to be depressurized for a fluid cylinder application.

The sensor head and measuring element can be replaced independently of the pressure pipe.

Loosen the screws on the sensor head.

Pull the sensor head and measuring element out of the housing.

Insert a new sensor head and measuring element into the housing.

Secure the screws, e.g. with Loctite 243.

Fasten the screws on the sensor head (max. tightening torque < 1 Nm).

10 Maintenance

Ensure that the plug connections and cables are always in good condition. The devices are

maintenance-free; if necessary clean dry.

11 Repair

The device is not intended for repair by the user. The device must be decommissioned if it is

faulty. Please refer to our terms and conditions of return when returning devices to Turck.

11.1 Returning Devices

If a device has to be returned, bear in mind that only devices with a decontamination declaration will be accepted. This is available for download at

http://www.turck.de/de/produkt-retoure-6079.php

and must be filled in completely and affixed to the outside of the packaging such that it is

secure and cannot be impaired by adverse weather.

12 Disposal

Devices must be properly disposed of and must not be included in general household

waste.

Page 21

21

2017/09

13 Technical Data

Technical Data LTX-R10…/LTX-F10… LTX-ER10…/LTX-EF10…

Measuring range specications

Blind zone (connector end) 50.8mm

Blind zone (end) 63.5mm

Resolution selectable, see type code

Linearity ≤ 0.01% full scale

Operating temperature, rod -40 °C … +105 °C

Operating temperature, electronics -40 °C … +85 °C

Temperature drift ≤ 10 ppm/°C

Electrical data

Operating voltage 7…30 VDC

Current consumption ≤ 100 mA/15 VDC

Short-circuit protection yes/cyclic

Output function 6-wire, SSI

Design

Design Cylindrical/smooth

Housing material Metal, aluminum, black Metal, stainless steel, 304

Material, active face Metal, stainless steel, 316

Vibration resistance 30 Hz (1 mm)

Shock resistance 100 g (11 ms)

Pressure resistance (temporary) 680 bar

Pressure resistance (permanent) 340 bar

Protection class IP68

13.1 Update Time

Measuring length Update time

300mm 500 µs

750mm 850 µs

1000mm 1 ms

2000mm 2 ms

5000mm 4 ms

Page 22

D101914 | 2017/09

*D101914*

Over 30 subsidiaries and over

60 representations worldwide!

www.turck.com

Loading...

Loading...