turck FXDP Series, FXDP-IM8-0001, FXDP-IM16-0001, FXDP-OM8-0001, FXDP-IOM88-0001 User Manual

...Page 1

FXDP –

USER MANUAL

Page 2

All brand and product names ar e trademarks or registered trade

marks of the owner concerned.

3rd, revised edition, 09/05

© Hans Turck GmbH & Co. KG, Mülheim an der Ruhr

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form (printed,

photocopy, microfilm or any other process) or processed, duplicated or distributed by means of electronic systems without written

permission of Hans Turck GmbH & Co. KG, Mülheim an der Ruhr.

Subject to alterations without notice.

Page 3

Warning!

Dangerous electrical voltage!

Before commencing the installation

Disconnect the power supply of the device.

Ensure that devices cannot be accidentally restarted.

Verify isolation from the supply.

Earth and short circuit.

Cover or enclose neighboring units that are live.

Follow the engineering instructions of the device concerned.

Only suitably qualified personnel in accordance with EN 50 110-

1/-2 (VDE 0 105 Part 100) may work on this device/system.

Before installation and before touching the device ensure that

you are free of electrostatic charge.

The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalization. The system installer is

responsible for implementing this connection.

Connecting cables and signal lines should be installed so that

inductive or capacitive interference do not impair the automation

functions.

Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire breakage

on the signal side does not result in undefined states in the auto

mation devices.

Ensure a reliable electrical isolation of the low voltage for the 24

volt supply. Only use power supply units complying with IEC 60

364-4-41 (VDE 0 100 Part 410) or HD 384.4.41 S2.

Deviations of the mains voltage from the rated value must not

exceed the tolerance limits given in the specifications, otherwise

this may cause malfunction and dangerous operation.

Emergency stop devices complying with IEC/EN 60 204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

-

I

Page 4

Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable units

must only be operated and controlled in enclosed housings.

Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time. If

necessary, emergency-stop devices should be implemented.

Wherever faults in the automation system may cause damage to

persons or property, external measures must be implemented to

ensure a safe operating state in the event of a fault or malfunction (for example, by means of separate limit switches, mechanical interlocks etc.).

The electrical installation must be carried out in accordance with

the relevant regulations (e. g. with regard to cable cross

sections, fuses, PE).

All work relating to transport, installation, commissioning and

maintenance must only be carried out by qualified personnel.

(IEC 60 364 and HD 384 and national work safety regulations).

All shrouds and doors must be kept closed during operation.

II

Page 5

Table of Contents

About this manual

Documentation concept................................................................................0-2

General Information. .....................................................................................0-3

Prescribed Use........................................................................................ 0-3

Notes Concerning Planning /Installation of this Product ........................0-3

Description of Symbols Used ......................................................................0-4

List of Revisions............................................................................................0-5

1 The FXDP product family

General information....................................................................................... 1-3

Product overview .........................................................................................1-4

The service module ................................................................................. 1-5

Connection to PROFIBUS-DP ......................................................................1-6

Addressing on PROFIBUS-DP ................................................................ 1-6

Transmission rates .................................................................................. 1-6

Bus termination ....................................................................................... 1-6

Configuration files ...................................................................................1-7

Connection possibilities................................................................................1-8

PROFIBUS-DP ........................................................................................ 1-8

Operating- / load voltage ........................................................................1-8

In-/ and outputs.......................................................................................1-9

General technical data ................................................................................ 1-10

Technical data.......................................................................................1-10

Dimension drawings..............................................................................1-12

LED indications .....................................................................................1-12

Diagnosis .................................................................................................... 1-13

2 Digital Input Modules

Digital input module, 8-channel....................................................................2-2

FXDP-IM8-0001....................................................................................... 2-2

Digital input module, 16-channel.................................................................. 2-6

FXDP-IM16-0001..................................................................................... 2-6

D300720 0905 - FXDP i

Page 6

3 Digital Output Modules

Digital output module, 8-channel.................................................................. 3-2

FXDP-OM8-0001.....................................................................................3-2

Digital output module, 16-channel................................................................3-6

FXDP-OM16-0001...................................................................................3-6

4 Digital Hybrid Modules

Digital hybrid module, 2 x 8-channel, I/I or O/O per connector.................... 4-2

FXDP-IOM88-0001..................................................................................4-2

Digital combined module, 2 x 8-channel, I/O per connector........................4-7

FXDP-CSG88-0001.................................................................................4-7

5 Universal Service Module

FXDP-XSG16-0001....................................................................................... 5-2

The service module ................................................................................. 5-2

Block diagram .........................................................................................5-4

Wiring diagrams ......................................................................................5-5

Technical data.........................................................................................5-6

Configuration options..............................................................................5-7

Parameterization .....................................................................................5-8

Diagnosis................................................................................................. 5-9

6 Connection to a Siemens PLC S7

General..........................................................................................................6-2

Reading- in the GSD File .............................................................................. 6-3

Selecting the FXDP Modules as Slaves........................................................6-5

Configuring the FXDP modules............................................................... 6-6

Diagnostic messages in the process image............................................ 6-7

Parameterization of the FXDP modules ........................................................6-8

Diagnosis evaluation on a S7-PLC ...............................................................6-9

Online diagnosis with die SIMATIC Manager.......................................... 6-9

Diagnosis via function block FB125...................................................... 6-12

7 Appendix

Declaration of conformity..............................................................................7-2

8Glossary

D300720 0905 - FXDPii

Page 7

9Index

D300720 0905 - FXDP iii

Page 8

D300720 0905 - FXDPiv

Page 9

About this manual

Documentation concept .................................................................... 2

General Information........................................................................... 3

Prescribed Use............................................................................................3

Notes Concerning Planning /Installation of this Product ............................3

Description of Symbols Used ............................................................ 4

List of Revisions ................................................................................ 5

D300720 0905 - FXDP 0-1

Page 10

About this manual

Documentation concept

This manual contains all information about the TURCK product

family FXDP in protection class IP67.

The following chapters contain exact information about the general

technical data and properties of each single module in the product

family, a description of the coupling to PROFIBUS-DP as well as

information about diagnosis and data mapping.

D300720 0905 - FXDP0-2

Page 11

General Information.

General Information.

Attention

Please read this section carefully. Safety aspects cannot be left to

chance when dealing with electrical equipment.

Prescribed Use

Warning

The devices described in this manual must be used only in applications prescribed in this manual or in the respective technical descriptions, and only with certified components and devices from

third party manufacturers.

Appropriate transport, storage, deployment and mounting as well as

careful operating and thorough maintenance guarantee the troublefree and safe operation of these devices.

Notes Concerning Planning /Installation of this Product

Warning

All respective safety measures and accident protection guidelines

must be considered carefully and without exception.

D300720 0905 - FXDP 0-3

Page 12

About this manual

Description of Symbols Used

Warning

This sign can be found next to all notes that indicate a source of ha zards. This can refer to danger to personnel or damage to the system

(hardware and software) and to the facility.

This sign means for the operator: work with extreme caution.

Attention

This sign can be found next to all notes that indicate a potential hazard.

This can refer to possible danger to personnel and damages to the

system (hardware and software) and to the facility.

Note

This sign can be found next to all general notes that supply important information about one or more operating steps. These specific

notes are intended to make operation easier and avoid unnecessary

work due to incorrect operation.

D300720 0905 - FXDP0-4

Page 13

List of Revisions

List of Revisions

In comparison to the previous manual edition, the following

changes/ revisions have been made

Table 1:

List of revisions

Chapter Subject/

new changed

Description

Chap. 5 – Example for wire break detection X

D300720 0905 - FXDP 0-5

Page 14

About this manual

D300720 0905 - FXDP0-6

Page 15

1 The FXDP product family

General information........................................................................... 3

Product overview .............................................................................. 4

The service module .....................................................................................5

Connection to PROFIBUS-DP............................................................. 6

Addressing on PROFIBUS-DP ....................................................................6

Transmission rates ......................................................................................6

Bus termination ...........................................................................................6

Configuration files .......................................................................................7

Connection possibilities .................................................................... 8

PROFIBUS-DP ............................................................................................8

Operating- / load voltage ............................................................................8

In-/ and outputs...........................................................................................9

General technical data .................................................................... 10

Technical data...........................................................................................10

Dimension drawings..................................................................................12

LED indications .........................................................................................12

Diagnosis ......................................................................................... 13

D300720 0905 - FXDP 1-1

Page 16

The FXDP product family

This chapter contains all information about the construction and the

general technical data of the FXDP modules as well as about the

their method of functioning.

Note

Please find all module-specific information in the module descriptions contained in the respective module chapters of the manual.

D300720 0905 - FXDP1-2

Page 17

General information

General information

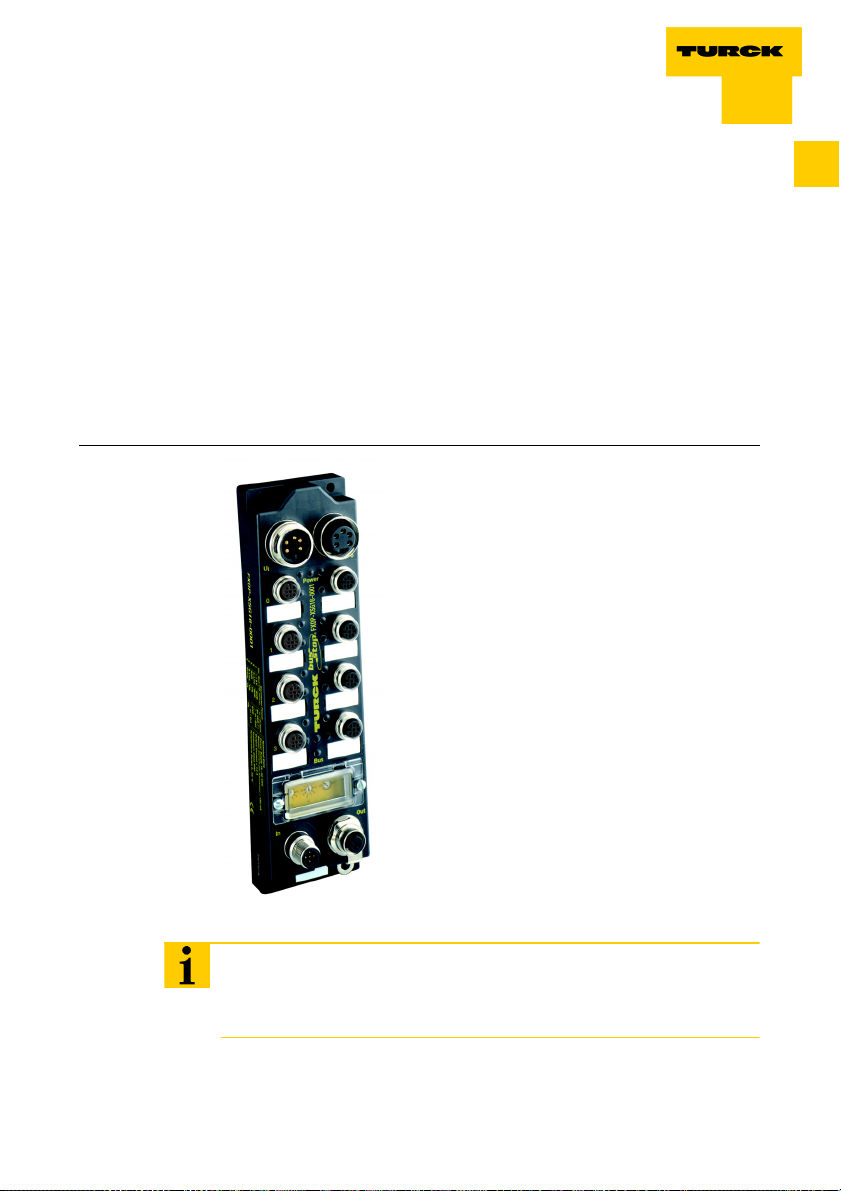

The new FXDP product family shows the following proven module

properties:

rugged PROFIBUS-DP module

glass-fibre reinforced plastic housing

fully encapsulated electronics

degree of protection IP67

galvanic channel isolation to the PROFIBUS-DP

short-circuit protected channels

Figure 1:

FXDP module

1

Note

All modules of the product family FXDP are approved for use in

Zone 2.

D300720 0905 - FXDP 1-3

Page 18

The FXDP product family

Product overview

Table 2:

Product overview

of the FXDP family

User data

section

8 Bit IN

16 Bit IN x x I/I per connector

8 Bit OUT x x O per connector

16 Bit OUT x x O/O per connector

8 Bit IN,

8 Bit OUT

8 Bit IN,

8 Bit OUT

8 Bit IN,

8 Bit DIAG

8 Bit OUT,

8 Bit DIAG

12 Bit IN,

4 Bit OUT

n Bit IN,

16-n Bit OUT

(AUTO Mode)

FXDP-IM8-0001

FXDP-IM16-0001

x

FXDP-OM8-0001

FXDP-OM16-0001

FXDP-IOM88-0001

x x I/I or O/O per

Comment

FXDP-CSG88-0001

FXDP-XSG16-0001

x I per connector

connector

x x I/O per connector

x I/DIAG per connector

x O/DIAG per

connector

x I/I or O/O per

connector

x outputs are read back

n Bit IN,

16-n Bit OUT

(PROG Mode)

AddOn:

Diag mapped

x channel as IN,

inverted IN, DIAG IN

or OUT

x x x x x x x diagnostics mapped

to user data section

D300720 0905 - FXDP1-4

Page 19

Product overview

The service module

Besides the typical FXDP properties like the extended diagnosis, the

possibility of diagnosis-data mapping into the user data as well as

the comfortable M12-I/O-connection technology, the service

module FXDP-XSG16-0001 provides the following additional

features:

Each single channel can be configured according to the applica-

tion via configuration software tools (e.g. SIMATIC Manager,

etc.). The required combination of in- and outputs can be exactly

planned to suit the customer’s needs. This thus ensures a 100%

technology utilization and a cost minimization.

Operating FXDP-modules can directly be replaced by the XSG-

module. Without any additional configuration, it can take-over

the function of the module that has to be replaced. The customer

only has to change the hardware, to set the previously config

ured PROFIBUS-DP address at the XSG-module and to execute

a voltage reset at the module.

Based on this fact, the module is universally applicable and can be

used to reduce inventory costs and system down-times - two

factors that are constantly gaining in importance in face of ever more

complex technical processes.

-

1

D300720 0905 - FXDP 1-5

Page 20

The FXDP product family

Connection to PROFIBUS-DP

Addressing on PROFIBUS-DP

The PROFIBUS-DP address (1 to 126) is set via three decimal rotary

coding switches located under a transparent protective cover.

Figure 2:

Setting the

PROFIBUS-DP

address

X 10

3

2

1

4

0

9

5

6

7

8

X 1

3

2

1

4

0

9

5

6

7

8

SF

X 100

1

0

SF

Transmission rates

The module supports transmission rates of up to 12 Mbps and

adjusts automatically to the transmission speed determined by the

master.

Bus termination

The bus termination is realized via an external terminating resistor at

Bus-OUT.

D300720 0905 - FXDP1-6

Page 21

Connection to PROFIBUS-DP

Table 3:

Configuration files

Configuration files

The configuration files for the software link are available via the

internet under

www.turck.com for download purposes.

The following table shows the corresponding configuration files for

each single module:

Module Configuration file

FXDP-IM8-0001 TU0_ff1f.gsd

FXDP-IM16-0001 TU1_ff1f.gsd

FXDP-OM8-0001 TU2_ff1f.gsd

FXDP-OM16-0001 TU3_ff1f.gsd

FXDP-IOM88-0001 TU4_ff1f.gsd

FXDP-CSG88-0001 TU5_ff1f.gsd

FXDP-XSG16-0001 TU6_ff1f.gsd

1

D300720 0905 - FXDP 1-7

Page 22

The FXDP product family

3

Connection possibilities

PROFIBUS-DP

Module connection to the PROFIBUS-DP is established via two

reverse-keyed M12 connectors.

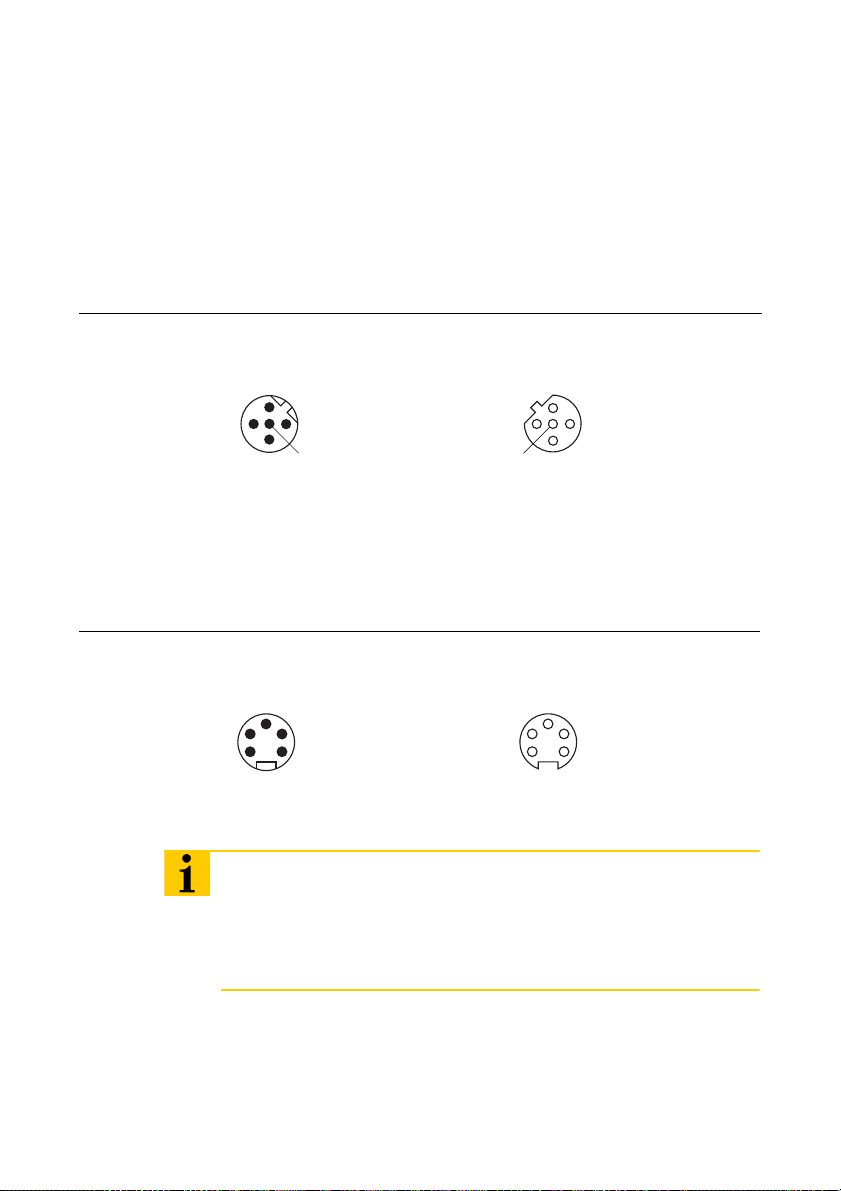

Figure 3:

M12x1-connector

for connection to

PROFIBUS-DP

Figure 4:

7/8” connector for

supplying and

feeding through of

supply voltage

Male (IN)

2

4

1 =N.N.

2 = A line

3 = GND

13

4 = B line

5 = Shield

5

Female (OUT)

1 = 5 VDC

2

2 = A line

1

3 = GND

4 = B line

5

4

5 = Shield

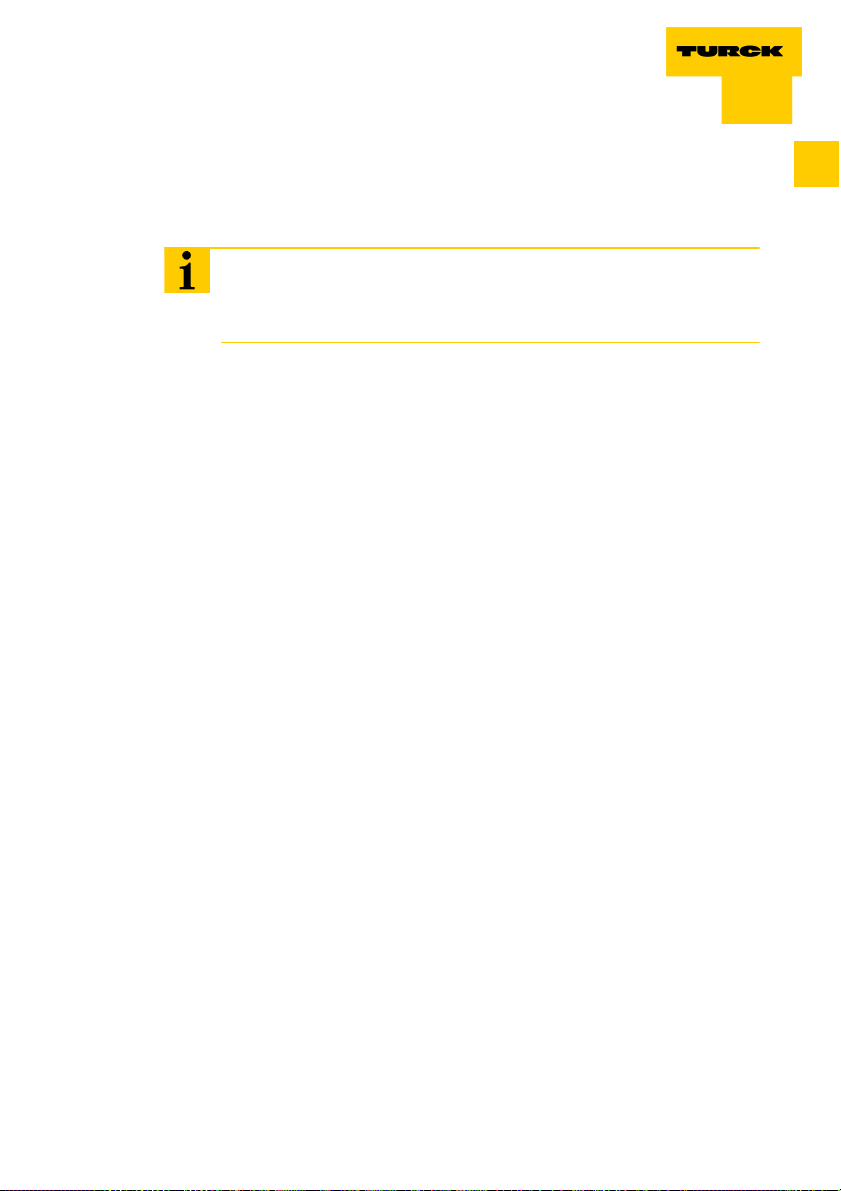

Operating- / load voltage

The module is powered via a 7/8” connector. The power is fed

through via a second 7/8” connector.

Male (Ui)

3

4

1 = GND

2

2 = GND

Female (Uo)

3

2

4

3 = PE

5

1

4 = U

5 = U

B

L

1

5

Note

The operational voltage is monitored internally. Supply failures of

less than 2.5 ms are compensated and thus do not lead to module

malfunction. It is also ensured that a voltage reset cannot lead to

generation of faulty signals.

D300720 0905 - FXDP1-8

Page 23

Connection possibilities

In-/ and outputs

The module is equipped throughout with 5-pole metal M12connectors for connection of the sensor/actuator level.

Note

For the pin assignment, please refer to the wiring diagrams in the

module-specific chapters of the manual.

1

D300720 0905 - FXDP 1-9

Page 24

The FXDP product family

General technical data

Technical data

Table 4:

General technical

data of FXDP

modules

A In case of low

simultaneity factors

and low ambient

temperatures,

mounting distances

of <

50mm may be

possible.

Power supply

Operational voltage UB24 VDC (18 ... 30 VDC)

Load voltage U

L

Internal current

consumption (via U

24 VDC (18 ... 30 VDC)

< 70 mA

)

B

Connections nickel-plated brass connectors

PROFIBUS-DP 1 x male M12 connector (IN),

1 x female M12 connector (OUT),

5-pole, reverse-keyed

Power supply 1 x 7/8” male connector (Ui),

1 x 7/8” female connector (Uo),

5-pole

Inputs/outputs female M12-connectors, 5-pole

Housing PA6-GF30

Dimensions 220,5 x 60,4 x 27 mm (H x B x T)

Mounting via 4 through-holes Ø 5.4 mm

Mounting distance

module/module

min. ≥ 50 mm A

Valid for operation in the ambient

temperatures mentioned below,

with sufficient ventilation as well

as maximum load (horizontal

mounting).

Degree of protection

IP67

(IEC 60529/EN 60529)

Vibration resistance test according to

EN 60068-2-6,

IEC 68-2-47

D300720 0905 - FXDP1-10

Page 25

General technical data

Shock resistance test according to

EN 60068-2-27

EMC according to

EN 61000-6-2,

EN 61000-6-4

Approval for use in

Zone 2

Temperature range

–Operating

temperature

– Storage and

transport

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

0 °C to +55 °C

(+32 °F to +131 °F)

-25 °C to +70 °C

(-13 °F to +158 °F)

1

D300720 0905 - FXDP 1-11

Page 26

The FXDP product family

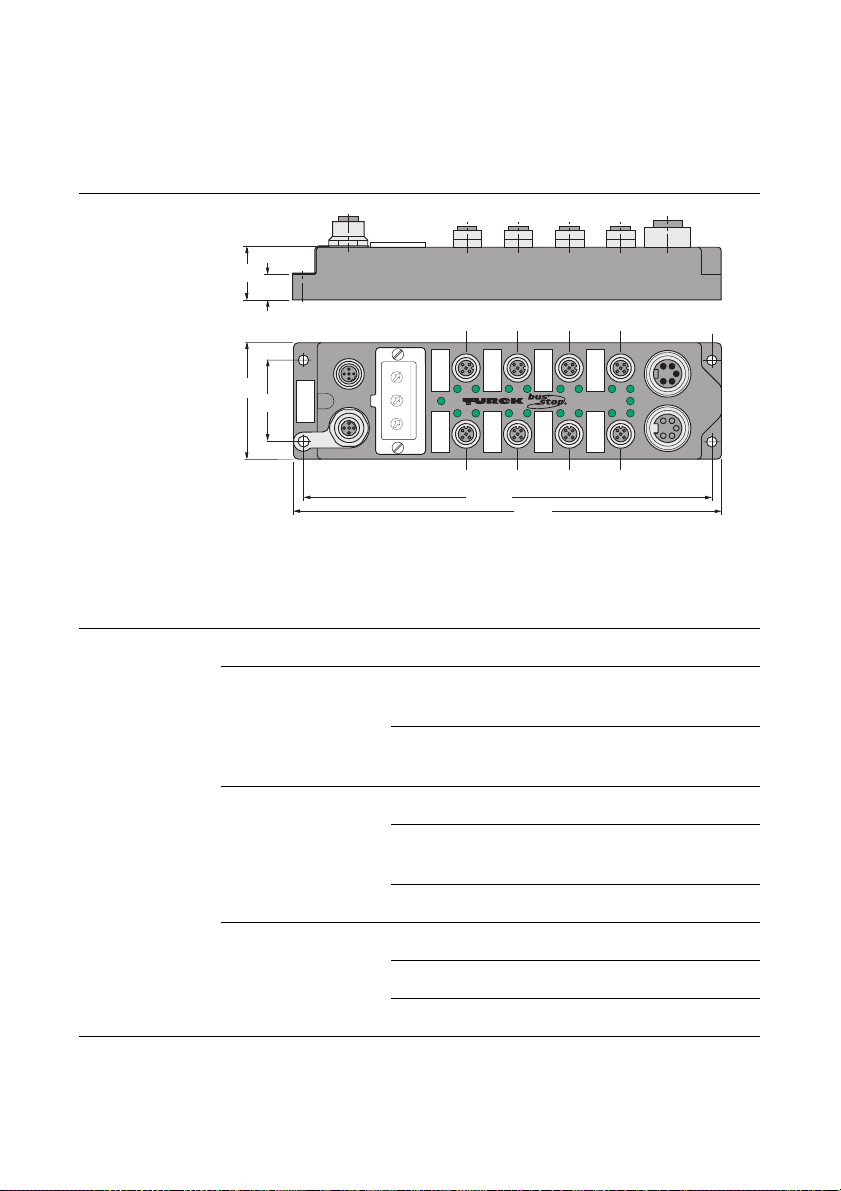

Dimension drawings

Figure 5:

FXDP moduledimensions

27

13

Table 5:

FXDP

LED indications

60,4

C3 C2 C1 C0

In

0

SF

1

SF

x100 x10 x1

0

1

9

Bus

2

8

7

3

4

6

42

5

0

1

9

8

2

7

3

4

6

5

Out

2

3

6

7

1

FXDP-CSG88-0001

5

0

Power

4

ø 5,4

U

i

U

0

C7 C6 C5 C4

210,5

220,5

LED indications

LED Color Meaning

Bus green communication with PROFIBUS-

DP running

red no communication to

PROFIBUS-DP

Power off UB < 18 VDC

green UB and UL,

within the operating range

red UL < 18 VDC

In-/ outputs off not actuated, inactive

green actuated, active

red channel overload

D300720 0905 - FXDP1-12

Page 27

Diagnosis

Diagnosis

1

These modules combine the advantages of channel diagnostics - as

known from the PDP series - with the favorable compact housing

dimensions of the FLDP series.

Output diagnostics are effective for each channel, whereas the

sensor supply is monitored separately for each connector.

Diagnostic data are also transferred to the PROFIBUS-DP and the

respective status is indicated via LEDs on the module individually for

each channel.

Diagnostic data can also be reproduced and transferred within the

user data area.

Note

Please read the corresponding sections in the module-specific

chapters for any information about the diagnosis mapping in the

process data image.

Channel-related diagnostics help increase system availability,

because the type of error and its location can be determined in

detail. According to PROFIBUS specifications, all diagnostic data

are transferred to the higher level control system via the PROFIBUSDP where these information can be evaluated by higher level

masters.

Chapter 6 of this manual „Connection to a Siemens PLC S7”

contains an example for plain-text diagnosis evaluation.

D300720 0905 - FXDP 1-13

Page 28

The FXDP product family

D300720 0905 - FXDP1-14

Page 29

2 Digital Input Modules

Digital input module, 8-channel......................................................... 2

FXDP-IM8-0001...........................................................................................2

– Wiring diagram ........................................................................................3

– Technical data .........................................................................................3

– Parameterization ......................................................................................4

– Diagnosis .................................................................................................5

Digital input module, 16-channel....................................................... 6

FXDP-IM16-0001.........................................................................................6

– Wiring diagram ........................................................................................7

– Technical Data .........................................................................................7

– Parameterization ......................................................................................8

– Diagnosis .................................................................................................9

D300720 0905 - FXDP 2-1

Page 30

Digital Input Modules

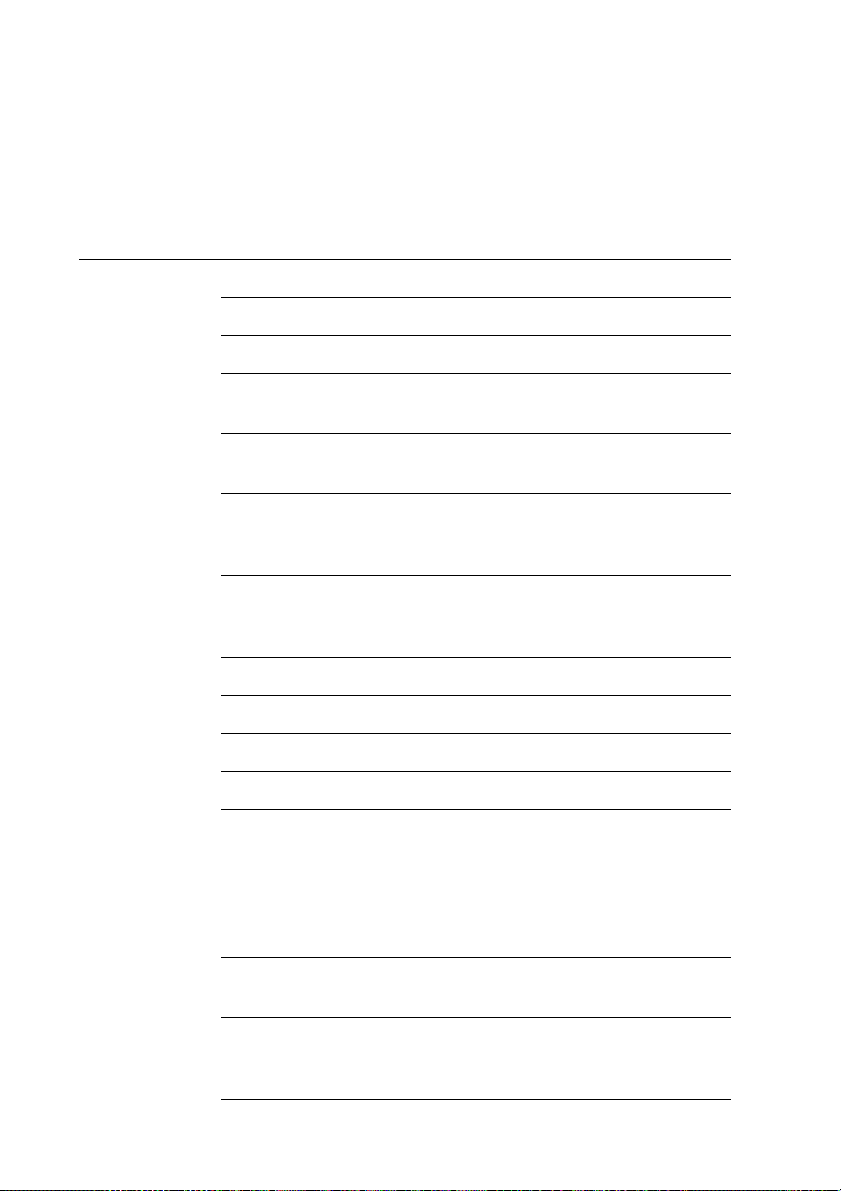

Digital input module, 8-channel

FXDP-IM8-0001

The busstop® input station FXDP-IM8-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

The module is suited for connection of up to eight 2/3 wire pnp

sensors or mechanical contacts.

Figure 6:

FXDP-IM8-0001

D300720 0905 - FXDP2-2

Page 31

Digital input module, 8-channel

Wiring diagram

Figure 7:

Wiring diagram

Table 6:

Technical data

FXDP-IM8-0001

3 () BU

5

PE

4 ( ) BK

1 (+) BN

2

Technical data

Type FXDP-IM8-0001

Configuration file TU0_ff1f.gsd

Inputs (8) 2/3 wire pnp sensors

Supply (via UB) 24 VDC (18 ... 30 VDC)

Supply current < 120 mA per connector,

short-circuit protected

Switching threshold

2 mA/4 mA

OFF/ON

Switching current

6 mA

limitation

Switch-on delay 2,5 ms

2

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to

PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP 2-3

Page 32

Digital Input Modules

Parameterization

Table 7:

parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 to 13 defined:

not parameterizable

1 input per connector

14 to 16 reserved -

D300720 0905 - FXDP2-4

Page 33

Digital input module, 8-channel

Diagnosis

diagnostic messages in the diagnosis telegram:

Table 8:

Diagnostic

messages

Diagnostic message Meaning

Short circuit Channel wise diagnosis for short circuits

Undervoltage Operating voltage UB < 18 VDC.

diagnosis in process data image

2

at the connected sensor

Table 9:

process data

Input Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P4 C6P4 C5P4 C4P4 C3P4 C2P4 C1P4 C0P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

Bit is not used

D300720 0905 - FXDP 2-5

Page 34

Digital Input Modules

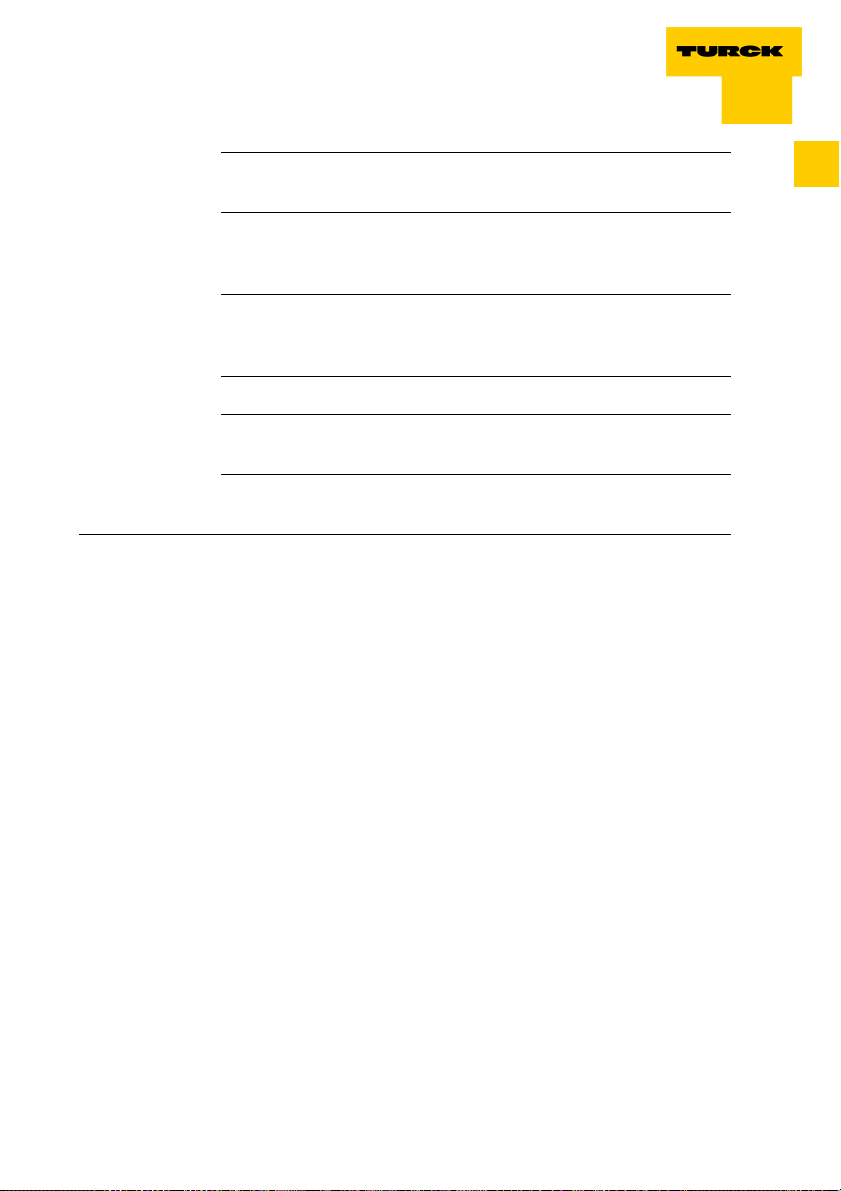

Digital input module, 16-channel

FXDP-IM16-0001

The busstop® input station FXDP-IM16-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

The module is suited for connection of up to sixteen 2/3 wire pnp

sensors or mechanical contacts.

Figure 8:

FXDP-IM16-0001

D300720 0905 - FXDP2-6

Page 35

Digital input module, 16-channel

Wiring diagram

Figure 9:

Wiring diagram

Table 10:

technical Data

FXDP-IM16-0001

3 BU –

5 PE

4 BK

1 BN +

2 WH

3 BU –

Technical Data

Type FXDP-IM16-0001

Configuration file TU1_ff1f.gsd

Inputs (16) 2/3 wire pnp sensors

Supply (via UB) 24 VDC (18 ... 30 VDC)

Supply current < 120 mA per connector,

short-circuit protected

Switching threshold

2 mA/4 mA

OFF/ON

Switching current

6 mA

limitation

Switch-on delay 2,5 ms

2

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to

PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP 2-7

Page 36

Digital Input Modules

Parameterization

Table 11:

parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to

PROFIBUS-DP standard

7 to 9 Standard DPV1 parameters according to

PROFIBUS-DP standard

10 to 13 defined:

not parameterizable

2 inputs per connector

14 to 16 reserved -

D300720 0905 - FXDP2-8

Page 37

Digital input module, 16-channel

Diagnosis

diagnostic messages in diagnosis telegram:

Table 12:

Diagnostic

messages

Diagnostic message Meaning

Short circuit Channel wise diagnosis for short circuits

Undervoltage Operating voltage UB < 18 V.

diagnosis in process data image

2

at the connected sensor

Table 13:

process data

Input Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P4 C6P4 C5P4 C4P4 C3P4 C2P4 C1P4 C0P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL < 18 VDC

Bit is not used

D300720 0905 - FXDP 2-9

Page 38

Digital Input Modules

D300720 0905 - FXDP2-10

Page 39

3 Digital Output Modules

Digital output module, 8-channel ...................................................... 2

FXDP-OM8-0001.........................................................................................2

– Wiring diagram ........................................................................................3

– Technical data .........................................................................................3

– Parameterization ......................................................................................4

– Diagnosis .................................................................................................5

Digital output module, 16-channel .................................................... 6

FXDP-OM16-0001.......................................................................................6

– Wiring diagram ........................................................................................7

– Technical data .........................................................................................7

– Parameterization ......................................................................................8

– Diagnosis .................................................................................................9

D300720 0905 - FXDP 3-1

Page 40

Digital Output Modules

Digital output module, 8-channel

FXDP-OM8-0001

The busstop® output station FXDP-OM8-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

Up to eight DC actuators with a maximum output current of 1.4 A

per output can be connected.

Figure 10:

FXDP-OM8-0001

D300720 0905 - FXDP3-2

Page 41

Digital output module, 8-channel

Wiring diagram

Figure 11:

Wiring diagram

Table 14:

Technical data

FXDP-OM8-0001

5

PE

4 (+) BK

1

2

3 () BU

Technical data

Type FXDP-OM8-0001

Configuration file TU2_ff1f.gsd

Outputs (8) DC-actuators

Load supply (via UL) 24 VDC (18 ... 30 VDC)

Output current 1,4 A, short-circuit protected

(ON period = 50 %)

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to

PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

3

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP 3-3

Page 42

Digital Output Modules

Parameterization

Table 15:

Parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 to 13 defined:

not parameterizable

1 output per connector

14 and 15reserved -

16 UL diagnosis

Activation of UL diagnosis

00 = diagnosis is not transferred via the bus

01 = diagnosis is transferred via the bus

D300720 0905 - FXDP3-4

Page 43

Digital output module, 8-channel

Diagnosis

diagnostic messages in diagnosis telegram:

Table 16:

Diagnostic

messages

Table 17:

process data

Diagnostic message Meaning

Short circuit Channel wise diagnosis for short circuits

at the connected actuator.

Undervoltage Operation voltage UB missing or

<

18 VDC

Load voltage missing Load voltage UL missing or < 18 VCD

diagnosis in process data image

Output Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P4 C6P4 C5P4 C4P4 C3P4 C2P4 C1P4 C0P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area

.

3

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

Bit is not used

D300720 0905 - FXDP 3-5

Page 44

Digital Output Modules

Digital output module, 16-channel

FXDP-OM16-0001

The busstop® output station FXDP-OM16-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

Up to sixteen DC actuators with a maximum output current of 1.4 A

per output can be connected.

Figure 12:

FXDP-OM16-0001

D300720 0905 - FXDP3-6

Page 45

Digital output module, 16-channel

Wiring diagram

Figure 13:

Wiring diagram

Table 18:

Technical data

FXDP-OM16-0001

5 PE

4 BK +

1

2 WH +

3 BU –

Technical data

Type FXDP-OM16-0001

Configuration file TU3_ff1f.gsd

Outputs (16) DC-actuators

Load supply (via UL) 24 VDC (18 ... 30 VDC)

Output current 1,4 A, short-circuit protected

(ON period = 50 %)

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to

PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

3

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP 3-7

Page 46

Digital Output Modules

Parameterization

Table 19:

Parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 to 13 defined:

not parameterizable

2 Outputs per connector

14 and 15reserved -

16 UL diagnosis

Activation of UL diagnosis

00 = diagnosis is not transferred via the bus

01 = diagnosis is transferred via the bus

D300720 0905 - FXDP3-8

Page 47

Digital output module, 16-channel

Diagnosis

diagnostic messages in the diagnosis telegram

Table 20:

Diagnostic

messages

Table 21:

process data

Diagnostic message Meaning

Short circuit Channel wise diagnosis for short circuits

at the connected actuator.

Undervoltage Operation voltage UB missing or

<

18 VDC

Load voltage missing Load voltage UL missing or < 18 VDC

diagnosis in process data image

Output Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C3P2 C3P4 C2P2 C2P4 C1P2 C1P4 C0P2 C0P4

Byte 1 C7P2 C7P4 C6P2 C6P4 C5P2 C5P4 C4P2 C4P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

3

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area

.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

Bit is not used

D300720 0905 - FXDP 3-9

Page 48

Digital Output Modules

D300720 0905 - FXDP3-10

Page 49

4 Digital Hybrid Modules

Digital hybrid module, 2 x 8-channel, I/I or O/O per connector ......... 2

FXDP-IOM88-0001......................................................................................2

– Wiring diagrams .......................................................................................3

– Technical data .........................................................................................4

– Parameterization ......................................................................................5

– Diagnosis .................................................................................................5

Digital combined module, 2 x 8-channel, I/O per connector ............. 7

FXDP-CSG88-0001.....................................................................................7

– Wiring diagram ........................................................................................8

– Technical data .........................................................................................9

– Parameterization ....................................................................................10

– Diagnosis ...............................................................................................10

D300720 0905 - FXDP 4-1

Page 50

Digital Hybrid Modules

Digital hybrid module, 2 x 8-channel, I/I or O/O per connector

FXDP-IOM88-0001

The busstop® input/output station FXDP-IOM88-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

Up to eight 2/3 wire pnp sensors and eight DC actuators with a

maximum output current of 1.4 A per output can be connected.

The inputs and outputs are provided equidirectionally via four

connectors.

Figure 14:

FXDP-IOM88-0001

D300720 0905 - FXDP4-2

Page 51

Digital hybrid module, 2 x 8-channel, I/I or O/O per connector

Wiring diagrams

Figure 15:

Wiring diagrams

5 PE

5 PE

3 BU –

4 BK

1 BN +

2 WH

3 BU –

4 BK +

1

2 WH +

3 BU –

4

D300720 0905 - FXDP 4-3

Page 52

Digital Hybrid Modules

Technical data

Table 22:

Technical data

FXDP-IOM88-0001

Type FXDP-IOM88-0001

Configuration file TU4_ff1f.gsd

Inputs (8) 2/3 wire pnp sensors

Supply (via UB) 24 VDC (18 ... 30 VDC)

Supply current < 120 mA per connector,

short-circuit protected

Switching threshold

2 mA/4 mA

OFF/ON

Switching current

6 mA

limitation

Switch-on delay 2,5 ms

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Outputs (8) DC-actuators

Load supply (via UL) 24 VDC (18 ... 30 VDC)

Output current 1.4 A, short-circuit protected

(ON period = 50 %)

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP4-4

Page 53

Digital hybrid module, 2 x 8-channel, I/I or O/O per connector

Parameterization

Table 23:

Parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 and 1100, 00

not parameterizable

12 and 13AA, AA

The connectors 0-3 are

defined as inputs, the

connectors 4-7 are

defined as outputs.

not parameterizable

14 and 15reserved -

16 UL diagnosis

Activation of UL diagnosis

00 = diagnosis is not transferred via the bus

01 = diagnosis is transferred via the bus

Diagnosis

diagnostic messages in the diagnosis telegram:

4

Table 24:

Diagnostic

messages

Diagnostic

message

Meaning

Short circuit Channel wise diagnosis for short circuits at

the connected sensor/ actuator.

Undervoltage Operation voltage UB missing or < 18 VDC

Load voltage

Load voltage UL missing or < 18 VDC

missing

D300720 0905 - FXDP 4-5

Page 54

Digital Hybrid Modules

diagnosis in process data image

Table 25:

process data

Input Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C3P2 C3P4 C2P2 C2P4 C1P2 C1P4 C0P2 C0P4

Output Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P2 C7P4 C6P2 C6P4 C5P2 C5P4 C4P2 C4P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area

.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

Bit is not used

D300720 0905 - FXDP4-6

Page 55

Digital combined module, 2 x 8-channel, I/O per connector

Digital combined module, 2 x 8-channel, I/O per connector

FXDP-CSG88-0001

The busstop® input/output station FXDP-CSG88-0001 is a modular

PROFIBUS-DP slave in a compact housing design.

Up to eight 2/3 wire pnp sensors and eight DC actuators with a

maximum output current of 1.4 A per output can be connected.

The inputs and outputs are provided in combination by eight

connectors.

Figure 16:

FXDP-CSG88-0001

4

D300720 0905 - FXDP 4-7

Page 56

Digital Hybrid Modules

Wiring diagram

Figure 17:

Wiring diagram

PE

3 () BU

5

4 ( ) BK

1 (+) BN

2

D300720 0905 - FXDP4-8

Page 57

Digital combined module, 2 x 8-channel, I/O per connector

Technical data

Table 26:

Technical data

FXDP-CSG88-0001

Type FXDP-CSG88-0001

Configuration file TU5_ff1f.gsd

Inputs (8) 2/3 wire pnp sensors

Supply (via UB) 24 VDC (18 ... 30 VDC)

Supply current < 120 mA per connector,

short-circuit protected

Switching threshold

2 mA/4 mA

OFF/ON

Switching current

6 mA

limitation

Switch-on delay 2,5 ms

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Outputs (8) DC-actuators

Load supply (via UL) 24 VDC (18 ... 30 VDC)

Output current 1.4 A, short-circuit protected

(ON period = 50 %)

4

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP 4-9

Page 58

Digital Hybrid Modules

Parameterization

Table 27:

Parameter data

assignment

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 and 1188, 88

not parameterizable

12 and 1388, 88

Pin 2 of the connectors is

defined a output, pin 4 as

input.

not parameterizable

14 and 15reserved -

16 UL diagnosis

Activation of UL diagnosis

00 = diagnosis is not transferred via the bus

01 = diagnosis is transferred via the bus

Diagnosis

diagnostic messages in the diagnosis telegram:

Table 28:

Diagnostic

messages

Diagnostic

Meaning

message

Short circuit Channel wise diagnosis for short circuits at

the connected sensor/ actuator.

Undervoltage Operation voltage UB missing or < 18 VDC

Load voltage

Load voltage UL missing or < 18 VDC

missing

D300720 0905 - FXDP4-10

Page 59

Digital combined module, 2 x 8-channel, I/O per connector

diagnosis in process data image

Table 29:

process data

Input Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P4 C6P4 C5P4 C4P4 C3P4 C2P4 C1P4 C0P4

Output Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C7P2 C6P2 C5P2 C4P2 C3P2 C2P2 C1P2 C0P2

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area

.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

Bit is not used

4

D300720 0905 - FXDP 4-11

Page 60

Digital Hybrid Modules

D300720 0905 - FXDP4-12

Page 61

5 Universal Service Module

FXDP-XSG16-0001 ............................................................................ 2

The service module .....................................................................................2

Block diagram .............................................................................................4

Wiring diagrams ..........................................................................................5

Technical data.............................................................................................6

Configuration options..................................................................................7

Parameterization .........................................................................................8

Diagnosis.....................................................................................................9

– Diagnostic messages in the diagnosis telegram .....................................9

– Diagnosis in the process data image ....................................................10

D300720 0905 - FXDP 5-1

Page 62

Universal Service Module

FXDP-XSG16-0001

The busstop® input/output station FXDP-XSG16-0001 is a modular

PROFIBUS-DP slave in a compact housing design. The module is

equipped with sixteen channels, which can be configured differently

depending on the specific application requirements. Up to sixteen

2/3 wire pnp sensors or sixteen DC actuators with a maximum

output current of 1.4 A per output can be connected.

The service module

Besides the typical FXDP properties like the extended diagnosis, the

possibility of diagnosis-data mapping into the user data as well as

the FIXCON

FXDP-XSG16-0001 provides the following additional features:

Each single channel can be configured according to the applica-

tion via configuration software tools (e.g. SIMATIC Manager,

etc.). The required combination of in- and outputs can be exactly

planned to suit the customer’s needs. The device’s configuration

options enable the user to operate the module in the “AUTO

mode” or to use the individual channels as an input, as an

inverted input, as a diagnostic input or as an output. This thus

ensures a 100% technology utilization and a cost minimization.

Operating FXDP-modules can directly be replaced by the XSG-

module. Without any additional configuration, it can take-over

the function of the module that has to be replaced. The customer

only has to change the hardware, to set the previously config

ured PROFIBUS-DP address at the XSG-module and to execute

a voltage reset at the module.

Based on this fact, the module is universally applicable and can be

used to reduce inventory costs and system down-times - two

factors that are constantly gaining in importance in face of ever more

complex technical processes.

®

I/O-connection technology, the service module

-

D300720 0905 - FXDP5-2

Page 63

FXDP-XSG16-0001

Figure 18:

FXDP-XSG16-0001

5

D300720 0905 - FXDP 5-3

Page 64

Universal Service Module

Block diagram

Figure 19:

Block diagram

FXDP-XSG16-0001

Figure 20:

Setting the loop

for wire break

detection

A

2

U (24 V)

B

A

Wire-break detection via external bridge between PIN 2

and U . Only realizable with the parameterization of

13

5

B

GND

4

Input

Invert. Input

Diag. Input

Output

Input

Invert. Input

Output

as “Diag. Input”.

Pin 2 = channel 1, 3, 5,... (all impair channel numbers)

Pin 4 = channel 0, 2, 4 ...(all pair channel numbers)Figure

Example for wire break detection:

3 BU –

5 PE 4 BK

1 BN +

2WH

3 BU –

Loop for wire break detection

PIN 2

input A

(actuator)

D300720 0905 - FXDP5-4

Page 65

FXDP-XSG16-0001

Wiring diagrams

Figure 21:

Wiring diagrams

Connection of 2 actuators:

5 PE

4 BK +

1

2 WH +

3 BU –

Connection of 2 sensors:

3 BU –

5 PE

4 BK

1 BN +

2 WH

3 BU –

Combinations of sensor and actuator:

3 () BU

5

PE

5

PE

4 ( ) BK

1 (+) BN

2

3 () BU

4 (+) BK

1 (+) BN

2 ( ) WH

5

D300720 0905 - FXDP 5-5

Page 66

Universal Service Module

Technical data

Table 30:

Technical data

FXDP-XSG16-0001

Type FXDP-XSG16-0001

Configuration file TU6_ff1f.gsd

Inputs (configurable) ((n) 2/3 wire pnp sensors (n = 0...16)

Supply (via UB) 24 VDC (18 ... 30 VDC)

Supply current < 120 mA per connector, short-circuit

protected

Switching threshold

2 mA/4 mA

OFF/ON

Switching current

6 mA

limitation

Switch-on delay 2,5 ms

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Outputs (configurable) (16-n) DC actuators (n = 0...16)

Load supply (via UL) 24 VDC (18 ... 30 VDC)

Output current 1.4 A, short-circuit protected (ON

period = 35 %)

Switching frequency < 250 Hz

Galvanic isolation galvanic isolation to PROFIBUS-DP

Housing

EMC to EN 61000-6-2,

EN 61000-6-4;

EN 61326/1999; A1/1999

Approval for use in

Zone 2

to EN 50014/2000,

EN 50021/2000 /

É II 3 G EEx nA IIC T4 X

D300720 0905 - FXDP5-6

Page 67

FXDP-XSG16-0001

Configuration options

Table 31:

´Configuration

options for the

universal service

module

User data

area

FXDP-IM8-0001

FXDP-IM16-0001

FXDP-OM8-0001

FXDP-OM16-0001

FXDP-IOM88-0001

FXDP-CSG88-0001

Comment

FXDP-XSG16-0001

8 Bit IN x x I per connector

16 Bit IN x x I/I per connector

8 Bit OUT x x O per connector

16 Bit OUT x x O/O per connector

8 Bit IN,

8 Bit OUT

8 Bit IN,

x x I/I bzw. O/O per

connector

x x I/O per connector

8 Bit OUT

8 Bit IN,

8 Bit DIAG

8 Bit OUT,

8 Bit DIAG

12 Bit IN,

4 Bit OUT

n Bit IN,

16-n Bit OUT

x I/DIAG per

connector

x O/DIAG per

connector

x I/I bzw. O/O per

connector

x outputs are read

back

(AUTO Mode)

5

n Bit IN,

16-n Bit OUT

(PROG Mode)

x channel config-

urable as IN,

inverted IN,

DIAG IN or OUT

AddOn:

Diag mapped

x x x x x x x diagnostics mapped

to user data area

D300720 0905 - FXDP 5-7

Page 68

Universal Service Module

Parameterization

Table 32:

Parameter data

assignment

A The parameterization of the input as diagnostic

input can only be

realized if the in

put is connected

to Pin

2

-

Param.-

Parameter Meaning

Byte

0 to 6 Standard DP parameters according to PROFIBUS-

DP standard

7 to 9 Standard DPV1 parameters according to PROFIBUS-

DP standard

10 Channel-parameter [0]

00 = input

01 = inverted Input

10 = output

Channel-function

(Channel 0-3)

2 Bit define the function of

the respective channel.

11 = diagnostic input A

11 Channel-parameter [1]

00 = input

01 = inverted Input

10 = output

Channel-function

(Channel 4-7)

2 Bit define the function of

the respective channel.

11 = diagnostic input A

12 Channel-parameter [2]

00 = input

01 = inverted Input

10 = output

Channel-function

(Channel 8-11)

2 Bit define the function of

the respective channel.

11 = diagnostic input A

13 Channel-parameter [3]

00 = input

01 = inverted Input

10 = output

Channel-function

(Channel 12-15)

2 Bit define the function of

the respective channel.

11 = diagnostic input A

14 reserved -

15 reserved -

16 UL diagnosis

00 = diagnosis is not transferred via the bus

01 = diagnosis is transferred via the bus

Activation of UL diagnosis

D300720 0905 - FXDP5-8

Page 69

FXDP-XSG16-0001

Diagnosis

Diagnostic messages in the diagnosis telegram

Table 33:

diagnostic

messages

Diagnostic message Meaning

Short circuit Channel wise diagnosis for short circuits

at the connected sensor/ actuator.

Wire-break Indication of a wire-break in the sensor- /

or actuator line (please read the following

„Note“).

The wire-break indication is inverted:

diagnostic bit = 0 → no diagnosis

diagnostic bit = 1 → wire-break at Diag.IN

Undervoltage Operation voltage UB missing or

<

18 VDC

Load voltage missing Load voltage UL missing or < 18 VDC

Note

The Pin 2-diagnosis „wire-break“ can only be realized with the module FXDP-XSG-0001 configured as „IM8D8“, „OM8D8“ or

„XSG16: 16 IN/ 16 OUT (Prog. Mode)“ (see „Configuration options”,

Page 5-7).

Note

A wire-break can only be detected if Pin 1 (UB - supply) and Pin 2 are

bridged at the sensor or at the actuator.

5

D300720 0905 - FXDP 5-9

Page 70

Universal Service Module

Diagnosis in the process data image

Table 34:

process data

Input Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C3P2 C3P4 C2P2 C2P4 C1P2 C1P4 C0P2 C0P4

Byte 1 C7P2 C7P4 C6P2 C6P4 C5P2 C5P4 C4P2 C4P4

Output Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 C3P2 C3P4 C2P2 C2P4 C1P2 C1P4 C0P2 C0P4

Byte 1 C7P2 C7P4 C6P2 C6P4 C5P2 C5P4 C4P2 C4P4

Diagn. A Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 U

U

B

SC

L

Byte1 SC 7 SC 6 SC 5 SC 4 SC 3 SC 2 SC 1 SC 0

Byte2 SC 15 SC 14 SC 13 SC 12 SC 11 SC 10 SC 9 SC 8

Byte3 Con 7 Con 6 Con 5 Con 4 Con 3 Con 2 Con 1 Con 0

A Depending on the configuration, the manufacturer specific diagnosis

data can be mapped into the user data area.

CxPy Status: connector x, pin y

SC Common short-circuit indication

SCx Short-circuit indication channel x

Conx Overload sensor voltage: connector x

U

B

U

L

UB < 18 VDC

UL <18 VDC

D300720 0905 - FXDP5-10

Page 71

6 Connection to a Siemens PLC S7

General .............................................................................................. 2

Reading- in the GSD File.................................................................... 3

– Reading-in the GSD files before starting the software ............................3

– Reading-in the GSD files after starting the software ...............................3

Selecting the FXDP Modules as Slaves ............................................. 5

Configuring the FXDP modules...................................................................6

Diagnostic messages in the process image................................................7

Parameterization of the FXDP modules ............................................. 8

Diagnosis evaluation on a S7-PLC ..................................................... 9

Online diagnosis with die SIMATIC Manager..............................................9

Diagnosis via function block FB125..........................................................12

D300720 0905 - FXDP 6-1

Page 72

Connection to a Siemens PLC S7

General

The software „SIMATIC Manager“ V 5.1 with Service Pack 6 from

Siemens is used to configure the connection of FXDP modules with

the Siemens S7 PLC.

The CPU used in the S7 in the following example was a

CPU 315-2AF02-0AB0 with firmware version 3.

D300720 0905 - FXDP6-2

Page 73

Reading- in the GSD File

Reading- in the GSD File

The GSD files for FXDP must be read into the software before you

can begin with the initial configuration. There are two procedures

possible for reading-in the files:

Reading-in the GSD files before starting the software

Copy the GSD files „TUx_ff1f.gsd“ for the FXDP into the

„Step7\S7data\GSD“ directory.

Copy the icon files (*.bmp) into the „Step7\S7data“ directory.

Start the „SIMATIC Manager“ software.

The FXDP modules will automatically be entered into the hard-

ware overview following correct installation of the files. The hardware overview can be accessed using the <Insert → Hardware

Catalog> command.

Reading-in the GSD files after starting the software

Proceed as follows to read-in the above GSD files, if you have

already started the software.

Create a new or open an existing project.

Open the hardware configuration software.

Copy the required GSD file using the <Options → Install New

*.GSD...> command.

6

Figure 21:

Reading-in the

GSD files using

„Install New

*.GSD...“

D300720 0905 - FXDP 6-3

Page 74

Connection to a Siemens PLC S7

Select the GSD file from the corresponding source directory.

Figure 22:

Selection of the

GSD files from the

corresponding

source directory

The GSD files are listed as separate entries in the hardware

catalog following correct installation.

Figure 23:

FXDP modules in

the hardware

catalog

Note

The exact configuration procedure can be found in the operators

manual, which is supplied with the software.

D300720 0905 - FXDP6-4

Page 75

Selecting the FXDP Modules as Slaves

Selecting the FXDP Modules as Slaves

To insert a FXDP module as a slave, select the required entry from

the hardware catalog.

Figure 24:

Inserting a FXDP

module as a slave

6

D300720 0905 - FXDP 6-5

Page 76

Connection to a Siemens PLC S7

Configuring the FXDP modules

After the selection of a module as modular slave, the function of the

module has to be defined.

Please choose one of the module’s configuration options from the

hardware catalog.

Figure 25:

Configuration of

the slave

D300720 0905 - FXDP6-6

Page 77

Selecting the FXDP Modules as Slaves

Diagnostic messages in the process image

The FXDP modules offer the possibility to map the diagnosis data

into the process image.

This can be achieved by adding the function „Add On: Diagnosis in

I/O-Data“ to the module’s configuration.

Figure 26:

Add on: Diagnosis

in I/O-Data

6

D300720 0905 - FXDP 6-7

Page 78

Connection to a Siemens PLC S7

Parameterization of the FXDP modules

If parameterizable modules have been chosen, the slave properties

can be opened with a double click on the respective module.

Figure 27:

Parameterizing a

FXDP module

D300720 0905 - FXDP6-8

Page 79

Diagnosis evaluation on a S7-PLC

Diagnosis evaluation on a S7-PLC

In the following example, a S7 PLC with the CPU 315-2AF02-0AB0,

firmware version 3, is used for diagnosis evaluation.

Note

A correct diagnosis-data evaluation cannot be guaranteed if S7

PLCs with older hard- or firmware-version are used.

The diagnosis evaluation of the FXDP modules can be done either

via the online diagnosis in the hardware configurator of the SIMATIC

software or via the Siemens function block FB125. This function

block enables the visualization of plain text diagnosis on systems of

different manufacturers.

Online diagnosis with die SIMATIC Manager

For the online diagnosis you have to go online with the configured

FXDP station in the hardware catalog.

A pending diagnosis is shown in the software with a red symbol at

the module image . A double click on the module opens the window

„Object

properties...“.

The register „DP Slave Diagnostics...“ shows the plain text diagnostic message, the slot number which accords to the connector’s

number on the FXDP modules and the channel number.

Note

The plain text diagnosis is an evaluation of standardized error

codes, which are sent by the FXDP modules.

According to the PROFIBUS-DP standard, the meanings of the error

codes 1-11 are defined (i.e. 1 = „Short circuit“, 6 = „Wire break“).

All other error codes may differ in their interpretation, always depending on the programming software that is used.

6

D300720 0905 - FXDP 6-9

Page 80

Connection to a Siemens PLC S7

The button „Hex Format...“ opens the window „Diagnosis in Hexadecimal Format“ which shows the module’s entire diagnosis telegram.

Figure 28:

Module

information

Note

The software „SIMATIC Manager“ only interprets the standardized

error codes in the online diagnosis.

D300720 0905 - FXDP6-10

Page 81

Diagnosis evaluation on a S7-PLC

The following example shows a simulated failure in the load voltage

supply (U

). The software can not interpret the diagnostic message

L

„No encoder voltage or load voltage“ (error code 17), because it is

not standardized.

Figure 29:

Error code 17 (not

standardized)

6

D300720 0905 - FXDP 6-11

Page 82

Connection to a Siemens PLC S7

Diagnosis via function block FB125

The following description shows the diagnosis with function block

125 version V4.5. You can download the actual version of the func

tion block directly from the Siemens homepage.

Note

Please read the function block’s description from Siemens for all information about structure and handling of FB 125.

In order to use the FB125, all „software blocks“ and „symbols“ of

the function block have to be copied into the project.

Figure 30:

Project with

FB125

-

Online-access to the modules’ diagnostic messages is possible via

the variable table VAT125 or the data block DB125.

D300720 0905 - FXDP6-12

Page 83

Diagnosis evaluation on a S7-PLC

The following example shows a diagnostic message with error

6 („Wire break“) at station 22, channel 0.

code

Figure 31:

VAT125 with diagnostic message

6

The function block FB125 transmits the diagnostic messages to

higher-level operating panels which interpret the error codes and

display them as plain text diagnosis.

D300720 0905 - FXDP 6-13

Page 84

Connection to a Siemens PLC S7

D300720 0905 - FXDP6-14

Page 85

7 Appendix

Declaration of conformity .................................................................. 2

D300720 0905 - FXDP 0-1

Page 86

Appendix

Declaration of conformity

Figure 32:

Declaration of

conformity

D300720 0905 - FXDP7-2

Page 87

8 Glossary

Acknowledge

A

Acknowledgment of a signal received.

Active metal component

Conductor or conducting component that is electrically live during operation.

Address

Identification number of, e.g. a memory position, a system or a module within

a network.

Addressing

Allocation or setting of an address, e. g. for a module in a network.

Analog

Infinitely variable value, e. g. voltage. The value of an analog signal can take on

any value, within certain limits.

Automation device

A device connected to a technical process with inputs and outputs for control.

Programmable logic controllers (PLC) are a special group of automation

devices.

Baud

B

Baud is a measure for the transmission speed of data. 1 Baud corresponds to

the transmission of one bit per second (Bit/s).

Baud rate

Unit of measurement for measuring data transmission speeds in Bit/s.

Bidirectional

Working in both directions.

D300720 0905 - FXDP 8-1

Page 88

Glossary

Bus

Bus system for data exchange, e. g. between CPU, memory and I/O levels. A

bus can consist of several parallel cables for data transmission, addressing,

control and power supply.

Bus cycle time

Time required for a master to serve all slaves or stations in a bus system, i. e.

reading inputs and writing outputs.

Bus line

Smallest unit connected to a bus, consisting of a PLC, a coupling element for

modules on the bus and a module.

Bus system

All units which communicate with one another via a bus.

Capacitive coupling

C

Electrical capacitive couplings occur between cables with different potentials.

Typical sources of interference are, for example, parallel-routed signal cables,

contactors and electrostatic discharges.

Coding elements

Two-piece element for the unambiguous assignment of electronic and base

modules.

Configuration

Systematic arrangement of the I/O modules of a station.

CPU

Central Processing Unit. Central unit for electronic data processing, the

processing core of the PC.

Digital

D

A value (e. g. a voltage) which can adopt only certain statuses within a finite set,

mostly defined as 0 and 1.

DIN

German acronym for German Industrial Standard.

D300720 0905 - FXDP8-2

Page 89

EIA

E

Electronic Industries Association – association of electrical companies in the

United States.

Electrical components

All objects that produce, convert, transmit, distribute or utilize electrical power

(e. g. conductors, cable, machines, control devices).

EMC

Electromagnetic compatibility – the ability of an electrical part to operate in a

specific environment without fault and without exerting a negative influence on

its environment.

EN

German acronym for European Standard.

ESD

Electrostatic Discharge.

Field power supply

F

Voltage supply for devices in the field as well as the signal voltage.

Fieldbus

Data network on sensor/actuator level. A fieldbus connects the equipment on

the field level. Characteristics of a fieldbus are a high transmission security and

real-time behavior.

GND

G

Abbreviation of ground (potential „0“).

Ground

Expression used in electrical engineering to describe an area whose electrical

potential is equal to zero at any given point. In neutral grounding devices, the

potential is not necessarily zero, and one speaks of the ground reference.

Ground connection

One or more components that have a good and direct contact to earth.

8

D300720 0204 - FXDP 8-3

Page 90

Glossary

Ground reference

Potential of ground in a neutral grounding device. Unlike earth whose potential

is always zero, it may have a potential other than zero.

GSD

Acronym for Electronic Device Data Sheet which contains standardized

PROFIBUS DP station descriptions. They simplify the planning of the DP

master and slaves. Default language is English.

Hexadecimal

H

System of representing numbers in base 16 with the digits 0 ... 9, and further

with the letters A, B, C, D, E and F.

Hysteresis

A sensor can get caught up at a certain point, and then “waver“ at this position.

This condition results in the counter content fluctuating around a given value.

Should a reference value be within this fluctuating range, then the relevant

output would be turned on and off in rhythm with the fluctuating signal.

I/O

I

Input/output.

Impedance

Total effective resistance that a component or circuit has for an alternating

current at a specific frequency.

Inactive metal components

Conductive components that cannot be touched and are electrically isolated

from active metal components by insulation, but can adopt voltage in the event

of a fault.

Inductive coupling

Magnetic inductive couplings occur between two cables through which an

electrical current is flowing. The magnetic effect caused by the electrical

currents induces an interference voltage. Typical sources of interference are for

example, transformers, motors, parallel-routed network and HF signal cables.

D300720 0905 - FXDP8-4

Page 91

Intelligent modules

Intelligent modules are modules with an internal memory, able to transmit

certain commands (e. g. substitute values and others).

Load value

L

Predefined value for the counter module with which the count process begins.

Lightning protection

All measures taken to protect a system from damage due to overvoltages

caused by lightning strike.

Low impedance connection

Connection with a low AC impedance.

LSB

Least Significant Bit

Mass

M

All interconnected inactive components that do not take on a dangerous touch

potential in the case of a fault.

Master

Station in a bus system that controls the communication between the other

stations.

8

Master/slave mode

Mode of operation in which a station acting as a master controls the communication between other stations in a bus system.

Module bus

The module bus is the internal bus in a BL20 station. The BL20 modules

communicate with the gateway via the module bus which is independent of the

fieldbus.

MSB

Most Significant Bit

D300720 0204 - FXDP 8-5

Page 92

Glossary

Multi-master mode

Operating mode in which all stations in a system communicate with equal

rights via the bus.

NAMUR

N

German acronym for an association concerned with standardizing measurement and control engineering. NAMUR initiators are special versions of the

two-wire initiators. NAMUr initiators are characterized by their high immunity to

interference and operating reliability, due to their special construction (low

internal resistance, few components and compact design).

Overhead

O

System administration time required by the system for each transmission

cycle.

PLC

P

Programmable Logic Controller.

Potential compensation

The alignment of electrical levels of electrical components and external