Page 1

USER MANUAL

FGEN-AIM

st

AtIoNs

wIth MultIprotocol

FUNTIONALITY

Sense it! Connect it! Bus it! Solve it!

Page 2

All brand and produ

concerned.

ct names are trademarks or registered trade marks of the owner

Edition 10/2013

© Hans Turck GmbH, Muelheim an der Ruhr

All rights reserved, including those of

No part of this manual may be reproduced i

other process) or processed, duplicated or distributed by means of electronic systems without

written permission of Hans Turck GmbH & Co. KG, Muelheim an der Ruhr.

S

ubject to alterations without notice

the translation.

n any form (printed, photocopy, microfilm or any

Page 3

Table of contents

1About this manual

1.1 Documentation concept .................................................................................................................................1-2

1.2 Description of symbols used ..........................................................................................................................1-3

1.3 General .............................................................................................................................................................1-4

1.3.1 Prescribed use ......................................................................................................................................................................................... 1-4

1.3.2 Notes concerning planning/installation of this product ......................................................................................................... 1-4

1.4 List of revisions ................................................................................................................................................1-5

2 Multi-protocol functionality

2.1 General .............................................................................................................................................................2-2

2.1.1 Protocol dependent functions .......................................................................................................................................................... 2-2

3 FGEN – general technical properties

3.1 General .............................................................................................................................................................3-2

3.2 General information on FGEN ........................................................................................................................3-3

3.3 General technical data ....................................................................................................................................3-4

3.3.1 Technical data..........................................................................................................................................................................................3-4

3.3.2 Dimension drawings ............................................................................................................................................................................. 3-5

3.3.3 LED-displays .............................................................................................................................................................................................3-5

3.4 Connection possibilities..................................................................................................................................3-6

3.4.1 Ethernet .....................................................................................................................................................................................................3-6

3.4.2 Operating/load voltage .......................................................................................................................................................................3-6

3.4.3 Analog inputs and outputs ................................................................................................................................................................. 3-7

3.5 Address assignment ........................................................................................................................................3-8

3.5.1 Default setting of the gateway..........................................................................................................................................................3-8

3.5.2 Resetting the IP-address, switch position "000".......................................................................................................................... 3-8

3.5.3 Address setting via the rotary-mode .............................................................................................................................................. 3-9

3.5.4 Address setting via the mode BootP............................................................................................................................................... 3-9

3.5.5 Address setting via the mode DHCP ............................................................................................................................................ 3-10

3.5.6 Address setting via mode PGM ...................................................................................................................................................... 3-10

3.5.7 Addressing via mode PGM-DHCP ................................................................................................................................................. 3-11

3.5.8 F_Reset (Factory Reset) ..................................................................................................................................................................... 3-11

3.5.9 Addressing via I/O-ASSISTANT 3 (FDT/DTM) ............................................................................................................................. 3-12

3.5.10 Addressing via PGM-DHCP .............................................................................................................................................................. 3-15

3.6 SET-button .................................................................................................................................................... 3-15

3.7 Device configuration files ............................................................................................................................ 3-15

3.8 Web server - remote access/configuration................................................................................................. 3-16

3.8.1 IP address ............................................................................................................................................................................................... 3-16

3.8.2 Access rights ......................................................................................................................................................................................... 3-17

3.8.3 Login / password ................................................................................................................................................................................. 3-17

3.8.4 Network Configuration ..................................................................................................................................................................... 3-18

3.8.5 Station Configuration ........................................................................................................................................................................ 3-19

3.8.6 Station Diagnostics............................................................................................................................................................................. 3-19

D301271 1013 - FGEN - multi protocol

i

Page 4

3.8.7 Ethernet Statistics ................................................................................................................................................................................3-19

3.8.8 Links.......................................................................................................................................................................................................... 3-19

3.8.9 Change Admin Password..................................................................................................................................................................3-20

3.8.10 Parameters .............................................................................................................................................................................................3-21

3.9 Status and Control Word of the FGEN-stations .......................................................................................... 3-22

3.9.1 Status Word............................................................................................................................................................................................ 3-22

3.9.2 Control Word .........................................................................................................................................................................................3-22

4 Digital inputs FGEN-IM16-x001

4.1 FGEN-IM16-x001 ............................................................................................................................................. 4-2

4.1.1 Technical data ......................................................................................................................................................................................... 4-2

4.1.2 Wiring diagrams ..................................................................................................................................................................................... 4-2

4.1.3 Parameters ............................................................................................................................................................................................... 4-3

4.1.4 Diagnostic message of I/O-channels .............................................................................................................................................. 4-3

5 Digital outputs FGEN-OM16-x001

5.1 FGEN-OM16-x001 ........................................................................................................................................... 5-2

5.1.1 Technical data ......................................................................................................................................................................................... 5-2

5.1.2 Wiring diagrams ..................................................................................................................................................................................... 5-2

5.1.3 Parameters ............................................................................................................................................................................................... 5-3

5.1.4 Diagnostic messages ............................................................................................................................................................................ 5-3

6 Digital in-/outputs FGEN-IOM88-x001, FGEN-XSG16-x001

6.1 FGEN-IOM88-x001 .......................................................................................................................................... 6-2

6.1.1 Technical data ......................................................................................................................................................................................... 6-2

6.1.2 Wiring diagrams ..................................................................................................................................................................................... 6-3

6.1.3 Parameters ............................................................................................................................................................................................... 6-3

6.1.4 Diagnostic messages ............................................................................................................................................................................ 6-4

6.2 FGEN-XSG16-000x .......................................................................................................................................... 6-5

6.2.1 Technical data ......................................................................................................................................................................................... 6-5

6.2.2 Wiring diagrams ..................................................................................................................................................................................... 6-6

6.2.3 Parameters ............................................................................................................................................................................................... 6-7

6.2.4 Diagnostic messages ............................................................................................................................................................................ 6-8

7 Implementation of EtherNet/IP™

7.1 EtherNet/IP Communications Profile ............................................................................................................ 7-2

7.1.1 I/O Messages ........................................................................................................................................................................................... 7-2

7.1.2 Explicit Messages ................................................................................................................................................................................... 7-2

7.1.3 Communications profile of FGEN .................................................................................................................................................... 7-2

7.2 QC - QuickConnect .......................................................................................................................................... 7-4

7.2.1 General ...................................................................................................................................................................................................... 7-4

7.2.2 QuickConnect in FGEN......................................................................................................................................................................... 7-4

7.3 Classes and Instances of the EtherNet/IP™-stations .................................................................................... 7-6

7.3.1 EtherNet/IP™ Standard Classes ......................................................................................................................................................... 7-6

7.3.2 Identity Object (0×01) .......................................................................................................................................................................... 7-7

7.3.3 Assembly Object (0×04) ...................................................................................................................................................................... 7-9

7.3.4 Connection Manager Object (0×06) .............................................................................................................................................7-21

7.3.5 TCP/IP Interface Object (0×F5) ........................................................................................................................................................7-22

D301271 1013 - FGEN - multi protocolii

Page 5

7.3.6 Ethernet Link Object (0×F6)............................................................................................................................................................. 7-26

7.4 VSC-Vendor Specific Classes........................................................................................................................ 7-28

7.4.1 Class instance of the VSC .................................................................................................................................................................. 7-28

7.4.2 Gateway Class (VSC 100)................................................................................................................................................................... 7-29

7.4.3 Process Data Class (VSC102)............................................................................................................................................................ 7-31

7.4.4 Digital Versatile Module Class (VSC117) ..................................................................................................................................... 7-34

7.4.5 Miscellaneous Parameters Class (VSC 126) ................................................................................................................................ 7-35

7.5 Diagnostic messages via process data........................................................................................................ 7-36

7.5.1 Summarized Diagnostics .................................................................................................................................................................. 7-36

7.5.2 Scheduled Diagnostics (manufacturer specific diagnosis) .................................................................................................. 7-36

8 Application example: FGEN for EtherNet/IP™ with Allen Bradley PLC and RS Logix 5000

8.1 General .............................................................................................................................................................8-2

8.1.1 Used hard-/ software............................................................................................................................................................................. 8-2

8.2 Network configuration....................................................................................................................................8-3

8.2.1 Configuration of the network in "RS Logix 5000" .......................................................................................................................8-3

8.2.2 Downloading the I/O configuration................................................................................................................................................8-8

8.3 I/O data mapping.......................................................................................................................................... 8-10

8.4 Process data access ...................................................................................................................................... 8-11

8.4.1 Setting outputs .................................................................................................................................................................................... 8-11

8.4.2 Example program................................................................................................................................................................................ 8-11

8.5 Activating QuickConnect ............................................................................................................................ 8-13

9 Implementation of Modbus TCP

9.1 Common Modbus description ........................................................................................................................9-2

9.1.1 Protocol description ..............................................................................................................................................................................9-3

9.1.2 Data model ...............................................................................................................................................................................................9-4

9.2 Implemented Modbus functions....................................................................................................................9-6

9.3 Modbus registers.............................................................................................................................................9-7

9.3.1 Data width of the I/O-modules in the modbus-register area.............................................................................................. 9-10

9.3.2 Register mapping of the FGEN-stations......................................................................................................................................9-11

9.3.3 Register 100Ch: "Station status"..................................................................................................................................................... 9-16

9.3.4 Register 1130h: „Modbus-Connection-Mode“.......................................................................................................................... 9-17

9.3.5 Register 1131h: „Modbus-Connection-Timeout“ .................................................................................................................... 9-17

9.3.6 Register 0×113C und 0×113D: „Restore Modbus-Connection-Parameters” ................................................................. 9-17

9.3.7 Register 0×113E und 0×113F: „Save Modbus-Connection-Parameters“ ........................................................................ 9-18

9.4 Bit areas: mapping of input-discrete- and coil-areas ................................................................................ 9-19

9.5 Error behavior of outputs (watchdog)........................................................................................................ 9-20

9.6 Parameters and diagnostic messages of the I/O channels ....................................................................... 9-21

10 Application example FGEN for Modbus TCP with CODESYS Win V3

10.1 Used hard-/ software.................................................................................................................................... 10-2

10.1.1 Hardware ................................................................................................................................................................................................ 10-2

10.1.2 Software.................................................................................................................................................................................................. 10-2

D301271 1013 - FGEN - multi protocol

iii

Page 6

10.2 Network configuration ................................................................................................................................. 10-3

10.3 Programming with CODESYS....................................................................................................................... 10-4

10.3.1 Predefined feature sets...................................................................................................................................................................... 10-4

10.3.2 Creating a new project ...................................................................................................................................................................... 10-5

10.3.3 Defining the communication settings ......................................................................................................................................... 10-7

10.3.4 Adding the Ethernet Adapter..........................................................................................................................................................10-9

10.3.5 Adding the Modbus master .......................................................................................................................................................... 10-10

10.3.6 Adding a Modbus TCP slave ......................................................................................................................................................... 10-11

10.3.7 Programming (example program) ............................................................................................................................................. 10-13

10.3.8 CODESYS: Global variables ............................................................................................................................................................ 10-14

10.3.9 Modbus channels.............................................................................................................................................................................. 10-15

10.3.10 Building, login and start ................................................................................................................................................................. 10-23

10.3.11 Reading out the process data ...................................................................................................................................................... 10-25

10.3.12 Evaluation of the status word of FGEN-XSG16-5001 (%IW1) ............................................................................................ 10-26

11 Implementation of PROFINET

11.1 FSU - Fast Start-Up (prioritized startup)..................................................................................................... 11-2

11.1.1 General ....................................................................................................................................................................................................11-2

11.1.2 FSU in FGEN ...........................................................................................................................................................................................11-2

11.2 GSDML-file..................................................................................................................................................... 11-3

11.3 PROFINET-Error Codes.................................................................................................................................. 11-4

11.4 Parameters .................................................................................................................................................... 11-5

11.4.1 General module parameters - parameters for slot 0 (turck-fgen) ...................................................................................... 11-5

11.4.2 Parameters for I/O channels ...........................................................................................................................................................11-5

11.5 Description of user data for acyclic services............................................................................................... 11-7

11.5.1 Description of the acyclic gateway user data............................................................................................................................ 11-7

11.5.2 Description of the acyclic I/O-channel user data ..................................................................................................................... 11-8

12 Application example: FGEN for PROFINET with a Siemens S7

12.1 Application example .................................................................................................................................... 12-2

12.1.1 General ....................................................................................................................................................................................................12-2

12.1.2 Example network ................................................................................................................................................................................. 12-2

12.1.3 New project in the Simatic Manager ............................................................................................................................................12-3

12.1.4 Setting the PG/PC-interface ............................................................................................................................................................. 12-3

12.1.5 Installation of the GSDML-files........................................................................................................................................................12-4

12.1.6 Adding PROFINET network nodes .................................................................................................................................................12-7

12.1.7 Scanning the network for PROFINET nodes............................................................................................................................ 12-10

12.1.8 Name assignment for FGEN-stations......................................................................................................................................... 12-11

12.1.9 PROFINET-neighborhood detection (LLDP)............................................................................................................................ 12-12

12.1.10 Online topology detection ............................................................................................................................................................ 12-15

12.1.11 Fast Start-Up - configuration of fieldbus nodes .................................................................................................................... 12-16

12.1.12 Diagnostics with Step 7 .................................................................................................................................................................. 12-18

13 Guidelines for Electrical Installation

13.1 General notes ................................................................................................................................................ 13-2

13.1.1 General ....................................................................................................................................................................................................13-2

13.1.2 Cable routing.........................................................................................................................................................................................13-2

13.1.3 Lightning protection ..........................................................................................................................................................................13-3

D301271 1013 - FGEN - multi protocoliv

Page 7

13.1.4 Transmission media............................................................................................................................................................................ 13-3

13.2 Potential relationships................................................................................................................................. 13-4

13.3 Electromagnetic compatibility(EMC ........................................................................................................... 13-5

13.3.1 Ensuring electromagnetic compatibility .................................................................................................................................... 13-5

13.3.2 Grounding of inactive metal components................................................................................................................................. 13-5

13.3.3 PE connection....................................................................................................................................................................................... 13-5

13.4 Shielding of cables ....................................................................................................................................... 13-6

13.5 Potential compensation............................................................................................................................... 13-7

13.5.1 Switching inductive loads ................................................................................................................................................................ 13-7

13.5.2 Protection against Electrostatic Discharge (ESD) .................................................................................................................... 13-7

14 Appendix

14.1 Changing the IP address of a PC/ network interface card ......................................................................... 14-2

14.1.1 Changing the IP address in Windows .......................................................................................................................................... 14-2

14.1.2 Changing the IP address via I/O-ASSISTANT V3 ....................................................................................................................... 14-4

14.2 Deactivating/ adapting the firewall in Windows ....................................................................................... 14-5

14.2.1 Addressing via DHCP ......................................................................................................................................................................... 14-7

15 Glossary

16 Index

D301271 1013 - FGEN - multi protocol

v

Page 8

D301271 1013 - FGEN - multi protocolvi

Page 9

1 About this manual

1.1 Documentation concept ............................................................................................................................ 1-2

1.2 Description of symbols used ..................................................................................................................... 1-3

1.3 General........................................................................................................................................................ 1-4

1.3.1 Prescribed use ...................................................................................................................................................................................1-4

1.3.2 Notes concerning planning/installation of this product ...................................................................................................1-4

1.4 List of revisions........................................................................................................................................... 1-5

D301271 1013 - FGEN - multi protocol 1-1

Page 10

About this manual

1.1 Documentation concept

This manual contains all information about the TURCK FGEN-product line in protection class IP67 with

multi-protocol function.

The following chapters contain:

the general technical data and station properties,

a description of the function and the assembly of the single devices in the product line,

a description of the stations' representation in the different Ethernet-protocols,

a description of the devices' handling in the different PLC-applications,

D301271 1013 - FGEN - multi protocol1-2

Page 11

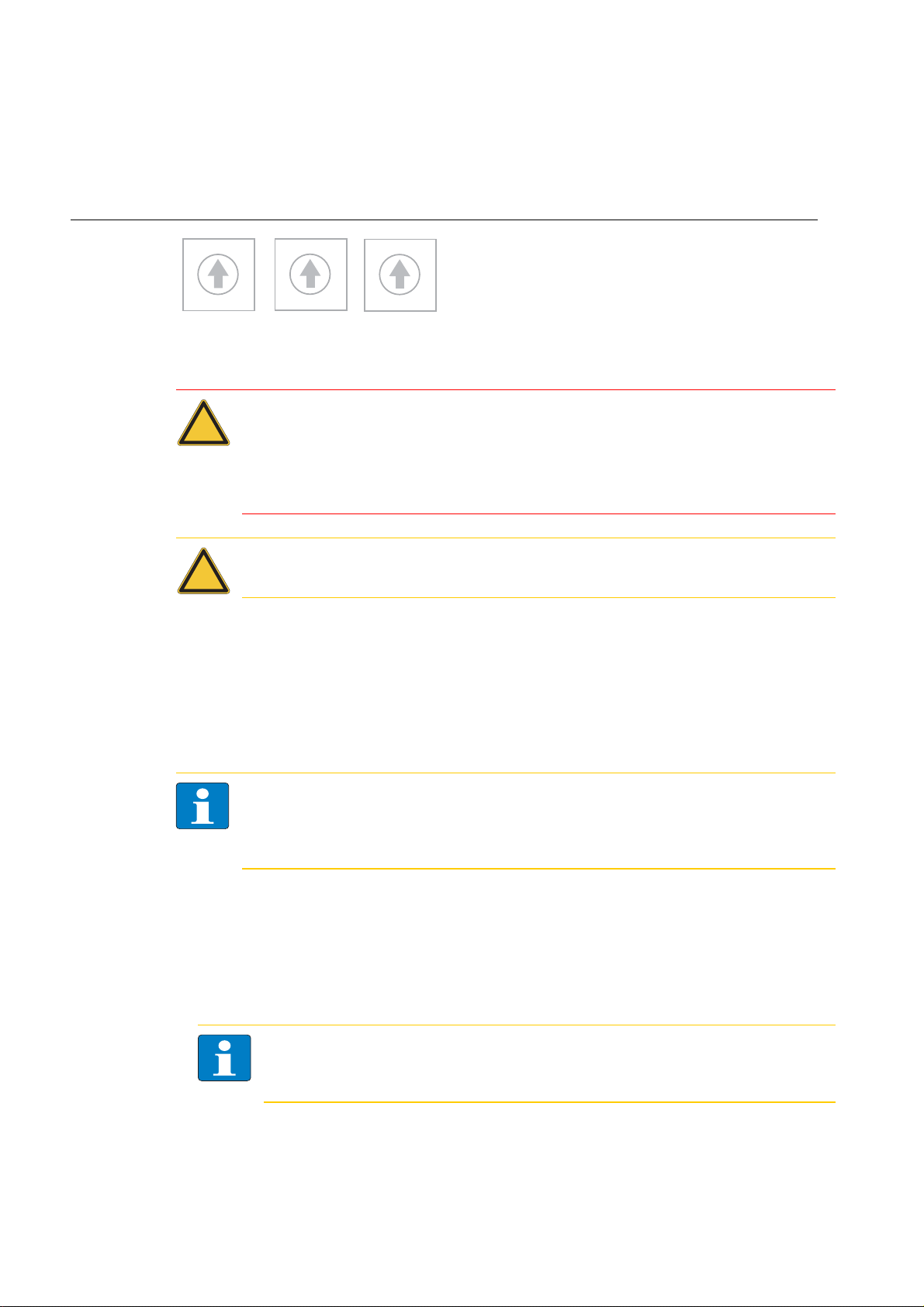

Description of symbols used

1.2 Description of symbols used

Warning

This sign can be found next to all notes that indicate a source of hazards. This can refer to

danger to personnel or damage to the system (hardware and software) and to the facility.

This sign means for the operator: work with extreme caution.

Attention

This sign can be found next to all notes that indicate a potential hazard.

This can refer to possible danger to personnel and damages to the system (hardware and

software) and to the facility.

Note

This sign can be found next to all general notes that supply important information about one

or more operating steps.

These specific notes are intended to make operation easier and avoid unnecessary work due

to incorrect operation.

D301271 1013 - FGEN - multi protocol

1-3

Page 12

About this manual

1.3 General

This manual includes all information necessary for the prescribed use of the FGEN-stations. It has been

specially conceived for personnel with the necessary qualifications.

1.3.1 Prescribed use

Attention

Please read this section carefully. Safety aspects cannot be left to chance when dealing with

electrical equipment.

Warning

The devices described in this manual must be used only in applications prescribed in this

manual or in the respective technical descriptions, and only with certified components and

devices from third party manufacturers.

Appropriate transport, storage, deployment and mounting as well as careful operating and thorough

maintenance guarantee the trouble-free and safe operation of these devices.

1.3.2 Notes concerning planning/installation of this product

Warning

All respective safety measures and accident protection guidelines must be considered

carefully and without exception.

D301271 1013 - FGEN - multi protocol1-4

Page 13

List of revisions

1.4 List of revisions

In comparison to the previous manual edition, the following changes/ revisions have been made:

Table 1-1:

List of revisions

Chapter Subject new changed

3 Web server - remote access/configuration (page 3-16) x

5 Changes in th technical data of module, page 5-2 x

6 Changes in th technical data of module, page 6-2 and page

x

6-5

7 EtherNet/IP Communications Profile (page 7-2) x

Note

The publication of this manual renders all previous editions invalid.

D301271 1013 - FGEN - multi protocol

1-5

Page 14

About this manual

D301271 1013 - FGEN - multi protocol1-6

Page 15

2 Multi-protocol functionality

2.1 General........................................................................................................................................... 2-2

2.1.1 Protocol dependent functions ....................................................................................................................................................2-2

– PROFINET ........................................................................................................................................................................................ 2-2

– EtherNet/IP™ ..................................................................................................................................................................................2-2

D301271 1013 - FGEN - multi protocol 2-1

Page 16

Multi-protocol functionality

2.1 General

The compact I/O-stations of the product line FGEN combine the three Ethernet protocols EtherNet/IP™,

Modbus TCP and PROFINET in one device.

A multi-protocol device can be operated without intervention of the user (which means, without

changes in the parameterization) in all of the three Ethernet protocols mentioned.

During the start-up after a power-on, the module runs in "snooping" mode and detects the Ethernet

protocol which requests a link connection by listening the traffic.

If a protocol is detected, the device automatically changes to the detected protocol and ignores the

telegrams of the other two.

2.1.1 Protocol dependent functions

PROFINET

Fast Start-UP (FSU)

Topology discovery

Address assignment via LLDP

EtherNet/IP™

QuickConnect (QC), see page 8-13

DLR (Device Level Ring)

D301271 1013 - FGEN - multi protocol2-2

Page 17

3 FGEN – general technical properties

3.1 General........................................................................................................................................................ 3-2

3.2 General information on FGEN ................................................................................................................... 3-3

3.3 General technical data ............................................................................................................................... 3-4

3.3.1 Technical data ...................................................................................................................................................................................3-4

3.3.2 Dimension drawings ....................................................................................................................................................................... 3-5

3.3.3 LED-displays .......................................................................................................................................................................................3-5

3.4 Connection possibilities ............................................................................................................................ 3-6

3.4.1 Ethernet ...............................................................................................................................................................................................3-6

– Ethernet-connection in QC-/FSU-applications.................................................................................................................. 3-6

3.4.2 Operating/load voltage ................................................................................................................................................................. 3-6

– Voltage supply via 7/8’’, 5-pole (FGEN-xxxxx-5xx1).........................................................................................................3-7

– Voltage supply via 7/8’’, 4-pole (FGEN-xxxxx-4xx1).........................................................................................................3-7

3.4.3 Analog inputs and outputs...........................................................................................................................................................3-7

3.5 Address assignment................................................................................................................................... 3-8

3.5.1 Default setting of the gateway....................................................................................................................................................3-8

3.5.2 Resetting the IP-address, switch position "000"....................................................................................................................3-8

3.5.3 Address setting via the rotary-mode ........................................................................................................................................3-9

3.5.4 Address setting via the mode BootP.........................................................................................................................................3-9

3.5.5 Address setting via the mode DHCP ...................................................................................................................................... 3-10

3.5.6 Address setting via mode PGM ................................................................................................................................................ 3-10

3.5.7 Addressing via mode PGM-DHCP ........................................................................................................................................... 3-11

– PROFINET ..................................................................................................................................................................................... 3-11

3.5.8 F_Reset (Factory Reset) ............................................................................................................................................................... 3-11

3.5.9 Addressing via I/O-ASSISTANT 3 (FDT/DTM)....................................................................................................................... 3-12

3.5.10 Addressing via PGM-DHCP ........................................................................................................................................................ 3-15

3.6 SET-button ................................................................................................................................................3-15

3.7 Device configuration files........................................................................................................................ 3-15

3.8 Web server - remote access/configuration ............................................................................................3-16

3.8.1 IP address ......................................................................................................................................................................................... 3-16

3.8.2 Access rights ................................................................................................................................................................................... 3-17

3.8.3 Login / password ........................................................................................................................................................................... 3-17

3.8.4 Network Configuration ............................................................................................................................................................... 3-18

3.8.5 Station Configuration .................................................................................................................................................................. 3-19

3.8.6 Station Diagnostics....................................................................................................................................................................... 3-19

3.8.7 Ethernet Statistics ......................................................................................................................................................................... 3-19

3.8.8 Links ................................................................................................................................................................................................... 3-19

3.8.9 Change Admin Password ........................................................................................................................................................... 3-20

3.8.10 Parameters....................................................................................................................................................................................... 3-21

3.9 Status and Control Word of the FGEN-stations .....................................................................................3-22

3.9.1 Status Word ..................................................................................................................................................................................... 3-22

– Meaning of the status bits ..................................................................................................................................................... 3-22

3.9.2 Control Word .................................................................................................................................................................................. 3-22

D301271 1013 - FGEN - multi protocol 3-1

Page 18

FGEN – general technical properties

3.1 General

This chapter contains all information about the hardware of the FGEN-stations, the general technical

data as well as the connection possibilities, the addressing,etc..

Note

Station-specific information can be found in the single station descriptions within the

respective chapters of this manual.

D301271 1013 - FGEN - multi protocol3-2

Page 19

General information on FGEN

3.2 General information on FGEN

The FGEN product family offers the following approved features:

direct connection of up to 16 digital in- and outputs to an Ethernet-network

Protocols: EtherNet/IP™, Modbus TCP and PROFINET RT in one single device

channel-related short-circuit diagnosis of outputs and slot-related short-circuit diagnosis of inputs

Ethernet-connection with two 4-pole, d-coded M12 x 1 round connectors

integrated Ethernet-switch for building up a line-topology

D301271 1013 - FGEN - multi protocol

3-3

Page 20

FGEN – general technical properties

3.3 General technical data

3.3.1 Technical data

Table 3-1:

Technical data

of the FGENstations

Power supply

Operating voltage U

Load voltage U

Internal current consumption (from U

(VI) 18 to 30 VDC

B

(VO) 18 to 30 VDC

L

) < 200 mA

B

Connectors

Ethernet 2 x M12-female (OUT), 4-pole, D-coded

Power supply

FGEN-xxxx-5001 7/8" connector, 5-pole

FGEN-xxxx-4001 7/8" connector, 4-pole

Inputs / Outputs M12 female, 5-pole

Isolation voltages

U

(UB against UL)none

BL

U

(supply voltage against Ethernet) 500 V AC

ETH

U

(ETH1 against ETH 2) 500 V AC

ETHETH

Housing Fibre-glass reinforced Polyamide (PA6-GF30)

Size 60.4 × 220.5 × 27 mm (B × L × H)

Mounting via 4 through-holes, Ø 4.4 mm

Mounting distance

station to station

≥ 50 mm

Valid for operation in the ambient temperatures

mentioned below, with sufficient ventilation as well

as maximum load (horizontal mounting).

In case of low simultaneity factors and low ambient

temperatures, mounting distances of < 50 mm may

be possible.

Protection class IP67

Vibration test to EN 60068-2-6, IEC 68-2-47

Shock test acc. to EN 60068-2-27

EMC acc. to EN 61131-2

Temperature range

– operating 0 °C to 55 °C (32 °F to 131 °F)

– Storage and transport temperature range -25 °C to 70 °C (-13 °F to 158 °F)

D301271 1013 - FGEN - multi protocol3-4

Page 21

General technical data

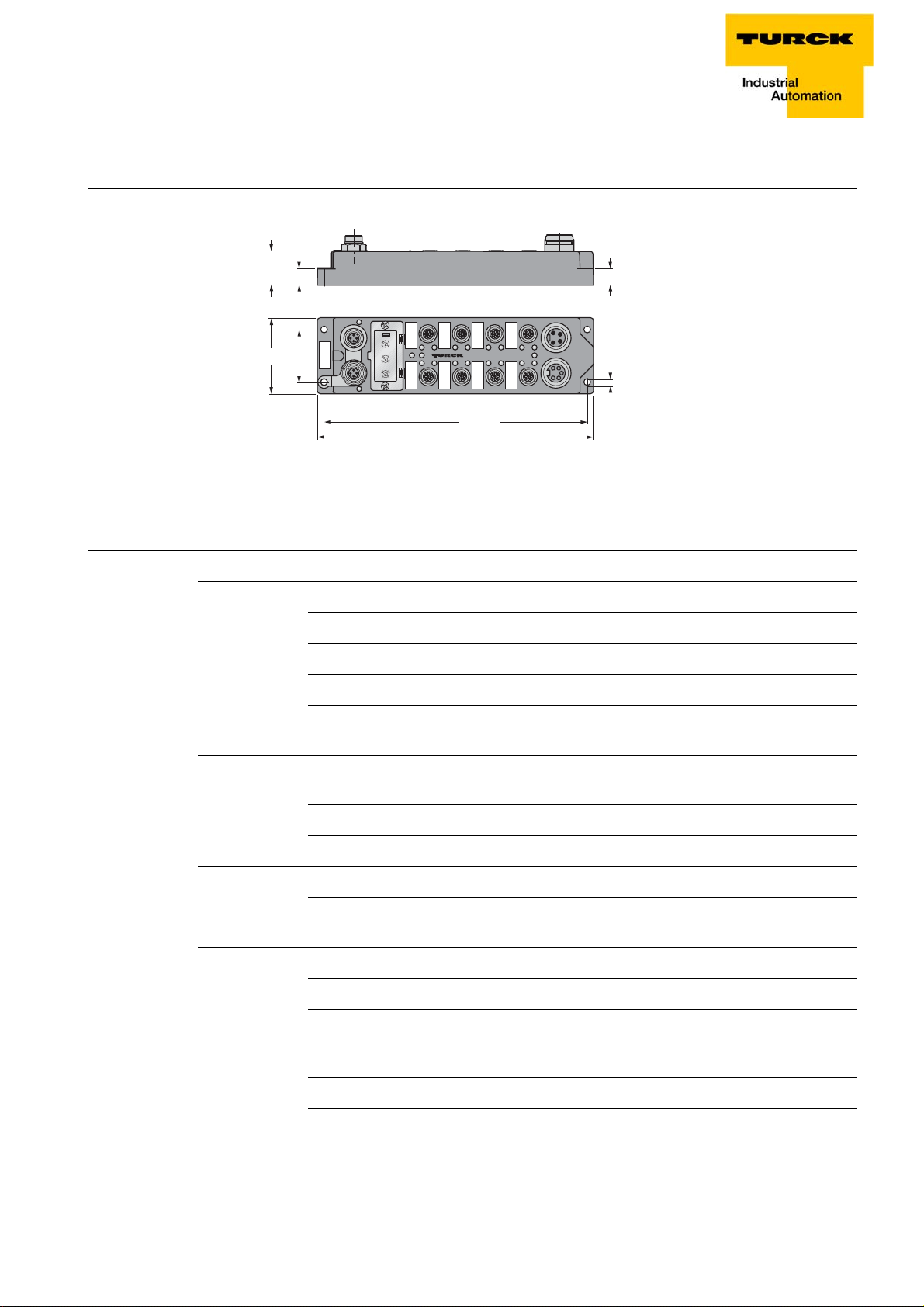

0

1

2

3

4

5

6

7

8

9

Power

U

i

U

o

0

1

4

5

37

Bus

ETH1

26

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

ETH2

210,5

220,5

C4C5

C6

C7

5,4

60,4 42

C0C1

C2

C3

13

27

13

C9

C8

C11

C10

3.3.2 Dimension drawings

Figure 3-1:

Dimensions for

the FGENstations

3.3.3 LED-displays

Table 3-2:

Dimensions for

the FGENstations

LED Display Meaning Remedy

ETHx green Link established,100 Mbps

Power off U

Ix/Ox green 24 V at input/ output

BUS green Active connection to a master -

green, flashing Ethernet traffic (100 Mbps)

yellow Link established,10 Mbps

yellow flashing Ethernet traffic (10 Mbps)

off No Ethernet link. Check the Ethernet-

connection.

< 18 V DC Check the connected

B

operating voltage.

green U

red U

and UL in the operating range

B

< 18 V DC Check the load voltage.

L

red Overcurrent at the output or at

the sensor supply

D301271 1013 - FGEN - multi protocol

green, flashing ready for operation -

red IP address conflict or restore

mode

red, flashing Blink-/wink-command active -

red/green Autonegotiation and / or

waiting for DHCP- / BootPaddress assignment.

Check the IP-addresses in

the network or wait until the

device is ready.

3-5

Page 22

FGEN – general technical properties

v

4

1

3

2

v

C10 C11

4

1

3

2

1 = TD + (YE)

2 = RD + (WH)

3 = TD (OG)

4 = RD (BU)

Power

U

i

U

o

04

3.4 Connection possibilities

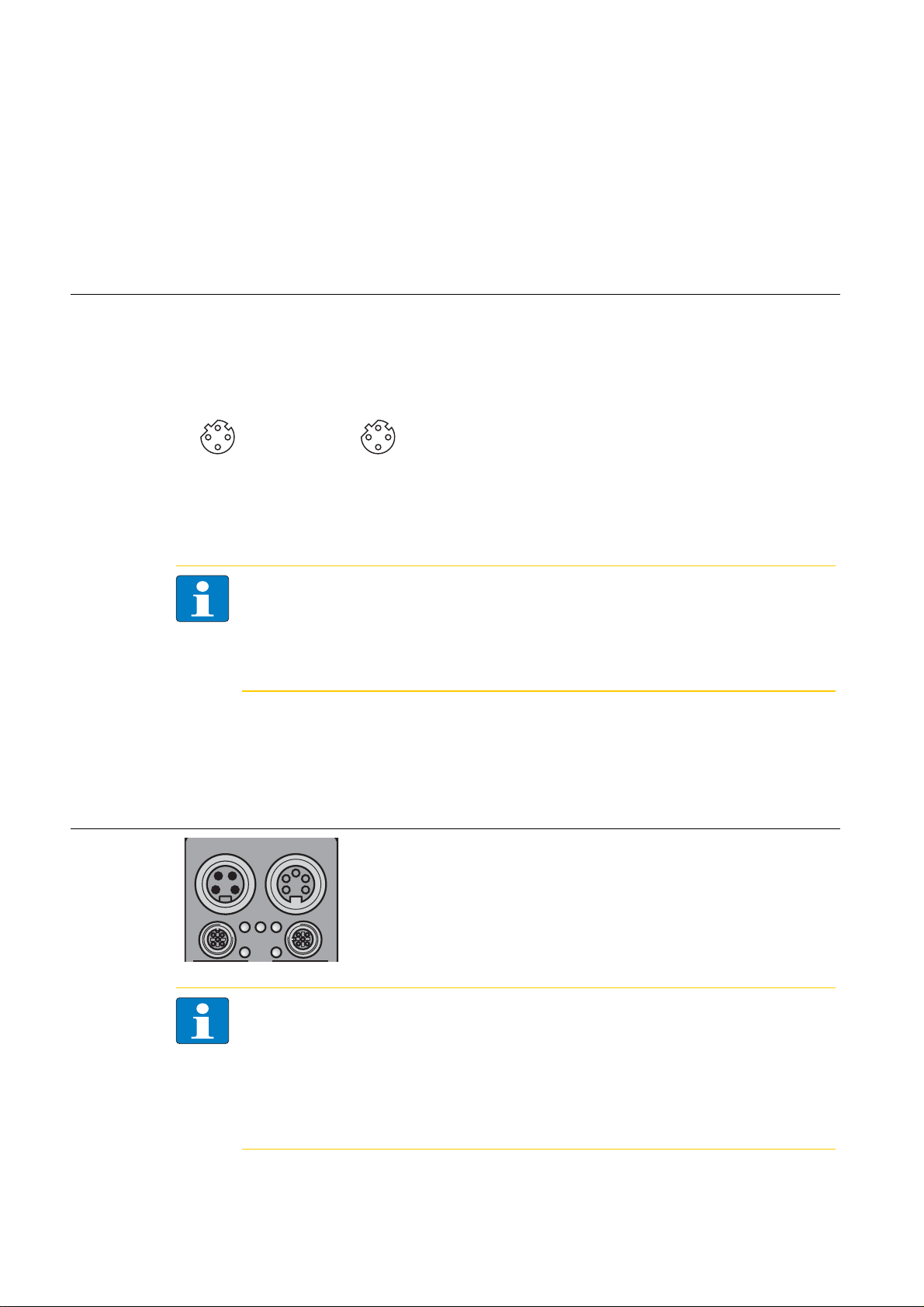

3.4.1 Ethernet

The connection to Ethernet via the integrated auto-crossing switch is done using two 4-pole, D-coded

M12 x 1-Ethernet-female connectors.

Figure 3-2:

Female connectors M12 x 1

Pin assignment

of the M12 x 1-

ETH1 ETH2

female connectors, 4-pole

Ethernet-connection in QC-/FSU-applications

Note

Please observe the following for QuickConnect (QC)- and Fast Start-Up (FSU)-applications:

– do not use a crossover-cable

– ETH1 = connector for incoming Ethernet-line

– ETH2 = connector for outgoing Ethernet-line

3.4.2 Operating/load voltage

The power supply is realized via 7/8" connectors on the module.

These connectors are designed either 4- or 5-pole.

Figure 3-3:

Power supply

Note

The operation voltage (U

voltage falls below the permissible voltage, the outputs are switched off.

U

in.

In case of an undervoltage at U

undervoltage at UB, the "POWER" LED is turned off.

UI = voltage IN

= voltage OUT for supplying the next node

U

O

) and the load voltage (UL) are fed and monitored separately. If the

B

can be switched off. In this case, the module still communicates and the inputs are still read

L

, the "POWER" LED changes from green to red. In case of an

L

D301271 1013 - FGEN - multi protocol3-6

Page 23

Connection possibilities

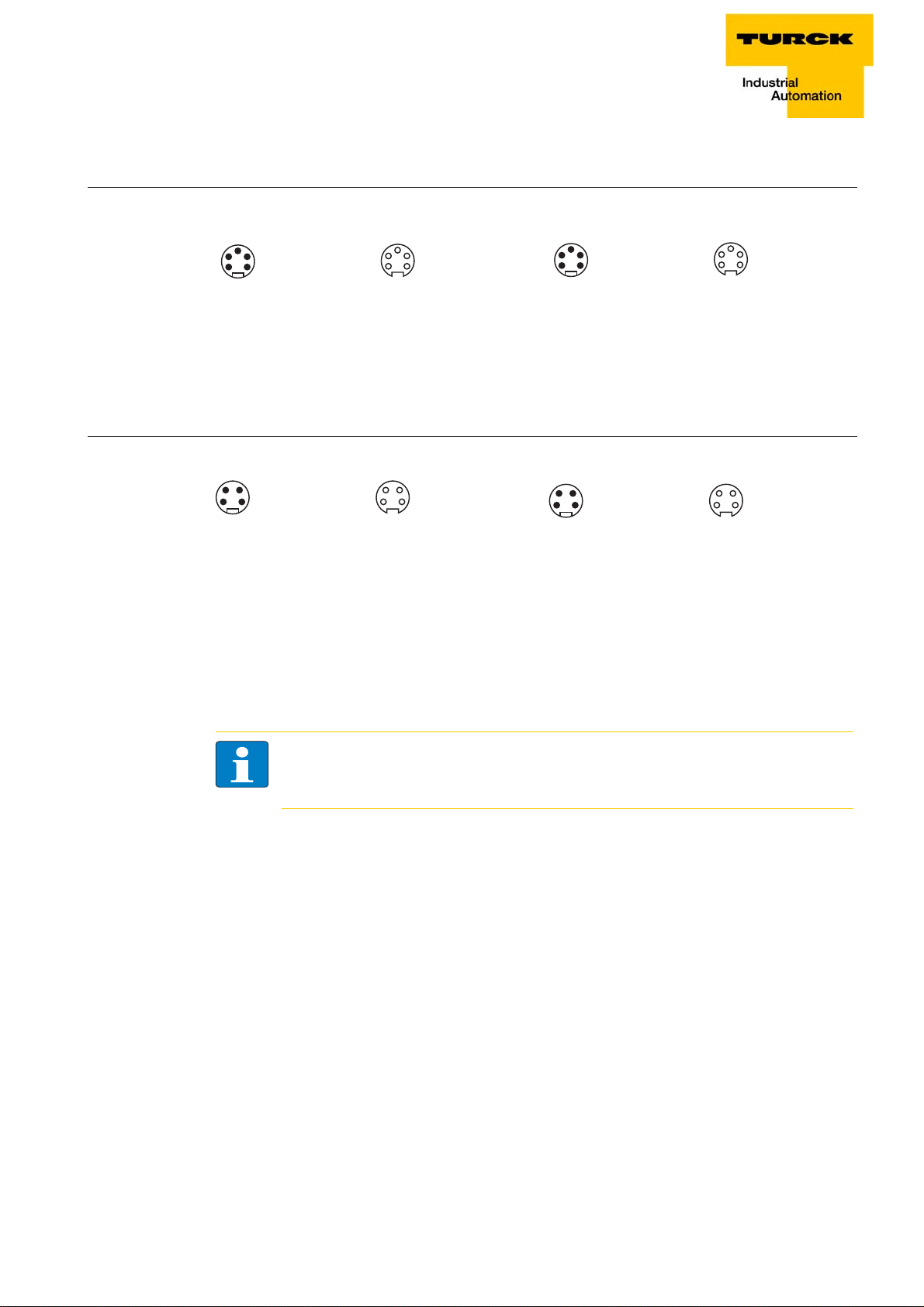

1 = GND

L

2 = GND

B

3 = PE

4 = U

B

5 = U

L

3

4

5

2

1

wv

3

4

5

2

1

1 = GND

L

2 = GND

B

3 = PE

4 = U

B

5 = U

L

3

4

5

2

1

wv

3

4

5

2

1

1 = GND

2 = GND

3 = FE

4 = U

B

5 = U

L

3

4

5

2

1

3

4

5

2

1

wv

1

2

3

4

1 = Aux +

2 = E +

3 = E

4 = Aux

1

2

3

4

1

2

3

4

1 = U

L

2 = U

B

3 = GND-B

4 = GND-L

1

2

3

4

wv

1

2

3

4

1 = Aux +

2 = E +

3 = E

1

2

3

4

1

2

3

4

1 = U

L

2 = U

B

3 = GND

4 = GND

1

2

3

4

Voltage supply via 7/8’’, 5-pole (FGEN-xxxxx-5xx1)

Figure 3-4:

7/8’’ male and

female,

5-pole

and UB galvanically isolated. No galvanic isolation of UL and UB at the

U

L

Voltage supply via 7/8’’, 4-pole (FGEN-xxxxx-4xx1)

Figure 3-5:

7/8’’ male and

female, 4-pole

FGEN-XSG16-5001

UL and UB galvanically isolated. No galvanic isolation of UL and UB at the

3.4.3 Analog inputs and outputs

The module is equipped throughout with metal M12 connectors for connection of the sensor/actuator

level.

Note

For the pin assignment of the M12-connectors, please refer to the wiring diagrams in the

station-specific chapters of this manual.

U

FGEN-XSG16-4001!

D301271 1013 - FGEN - multi protocol

3-7

Page 24

FGEN – general technical properties

x10

x1

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

000: 192.168.1.254

1 - 254: static rotary

300: BootP

400: DHCP

500: PGM

600: PGM-DHCP

900: F_Reset

x 100

3.5 Address assignment

Setting the address mode is done through the 3 rotary coding-switches on the gateway.

Figure 3-6:

Decimal rotary

coding-switches

for address

setting

Attention

The cover of the decimal rotary coding-switches must be closed by tightening the screw after

use.

The seal in the cover must not be damaged or slipped.

The protection class IP67 can only be guaranteed when the cover is closed correctly.

Note

After every change of the address-mode, a reset must be carried out.

3.5.1 Default setting of the gateway

The stations' default-settings are as follows:

IP-address 192.168.1.254

subnet mask 255.255.255.0

default gateway 192.168.1.1

Note

The stations can be reset by the user to these default settings at any time.

To reset the module, set the three coding-switches on the gateway to "000" followed by a

power-on reset.

3.5.2 Resetting the IP-address, switch position "000"

By setting the rotary coding switches to "000" followed by a voltage reset, the module is set to the

address 192.168.1.254 for IP-based services (seeDefault setting of the gateway (page 3-8)).

The I/O-ASSISTANT can, for example, communicate with the station in this switch position.

Note

Setting "000" is no operation mode! Please set the device to another mode after having

reset the IP address to the default values.

D301271 1013 - FGEN - multi protocol3-8

Page 25

Address assignment

3.5.3 Address setting via the rotary-mode

switch position: 001 - 254

When using the rotary-mode, the last byte of the station’s IP address can be set via the rotary coding

switches.

Addresses in the range from 0 to 255 can be allocated, whereas 1 is normally reserved for the defaultgateway. 0 and 255 are reserved for broadcast messages in the subnet.

Note

We therefore recommend addresses in the range of 2-254.

3.5.4 Address setting via the mode BootP

switch position: 300

Address setting is carried out by a BootP-server in the network after the start-up of the gateway.

Note

The IP address, as well as the default subnet mask assigned to the station by the BootP-server,

are stored in the station’s EEPROM.

If the station is subsequently switched to rotary- or PGM-mode, the settings carried out via

BootP (IP address, subnet mask, etc) will be read from the module’s EEPROM.

PROFINET

Please assure, that in PROFINET -applications, the address assigned via a BootP-server corresponds to

the address, which is assigned in the configuration tool.

D301271 1013 - FGEN - multi protocol

3-9

Page 26

FGEN – general technical properties

3.5.5 Address setting via the mode DHCP

switch position: 400

Address setting is carried out by a BootP-server in the network after the start-up of the gateway.

Note

The IP address, as well as the default subnet mask assigned to the station by the DHCP-server,

are stored in the station’s EEPROM.

If the station is subsequently switched to rotary- or PGM-mode, the settings carried out via

BootP (IP address, subnet mask, etc) will be read from the module’s EEPROM.

DHCP supports three mechanisms for IP address allocation:

In "automatic allocation", the DHCP-server assigns a permanent IP address to a client.

In "dynamic allocation", DHCP assigns an IP address to a client for a limited period of time. After this

time, or until the client explicitly relinquishes the address, the address can be re-assigned.

In "manual allocation", a client's IP address is assigned by the network administrator, and DHCP is

used simply to convey the assigned address to the client.

PROFINET

Please assure, that in PROFINET -applications, the address assigned via a BootP-server corresponds to

the address, which is assigned in the configuration tool.

3.5.6 Address setting via mode PGM

switch position: 500

The PGM-mode enables access of the software I/O-ASSISTANT to the module’s network settings.

Note

In the PGM-mode, all network settings (IP address, subnet mask, etc.) are send to the module’s

internal EEPROM and stored permanently.

D301271 1013 - FGEN - multi protocol3-10

Page 27

Address assignment

3.5.7 Addressing via mode PGM-DHCP

switch position: 600

The device sends DHCP-requests until a IP-address is assigned (DHCP-server, PROFINET-controller).

The assigned IP-address is stored to the device and the DCHP-client is stopped.

Even after a restart of the device, the device sends no further DHCP-requests.

PROFINET

This mode assures a PROFINET-compliant operation of the modules.

Note

If a DHCP-server is used within the network, problems may occur during IP-assignment.

In this case, both, the DHCP-server as well as the PROFINET-controller (vie DCP), try an IPaddress-assignment.

3.5.8 F_Reset (Factory Reset)

switch position: 900

Setting 900 sets all device-settings back to the default values and deletes all data in the device's internal

flash.

Note

Setting 900 is no operation mode! Please set the device to another mode after having reset

the IP address to the default values.

D301271 1013 - FGEN - multi protocol

3-11

Page 28

FGEN – general technical properties

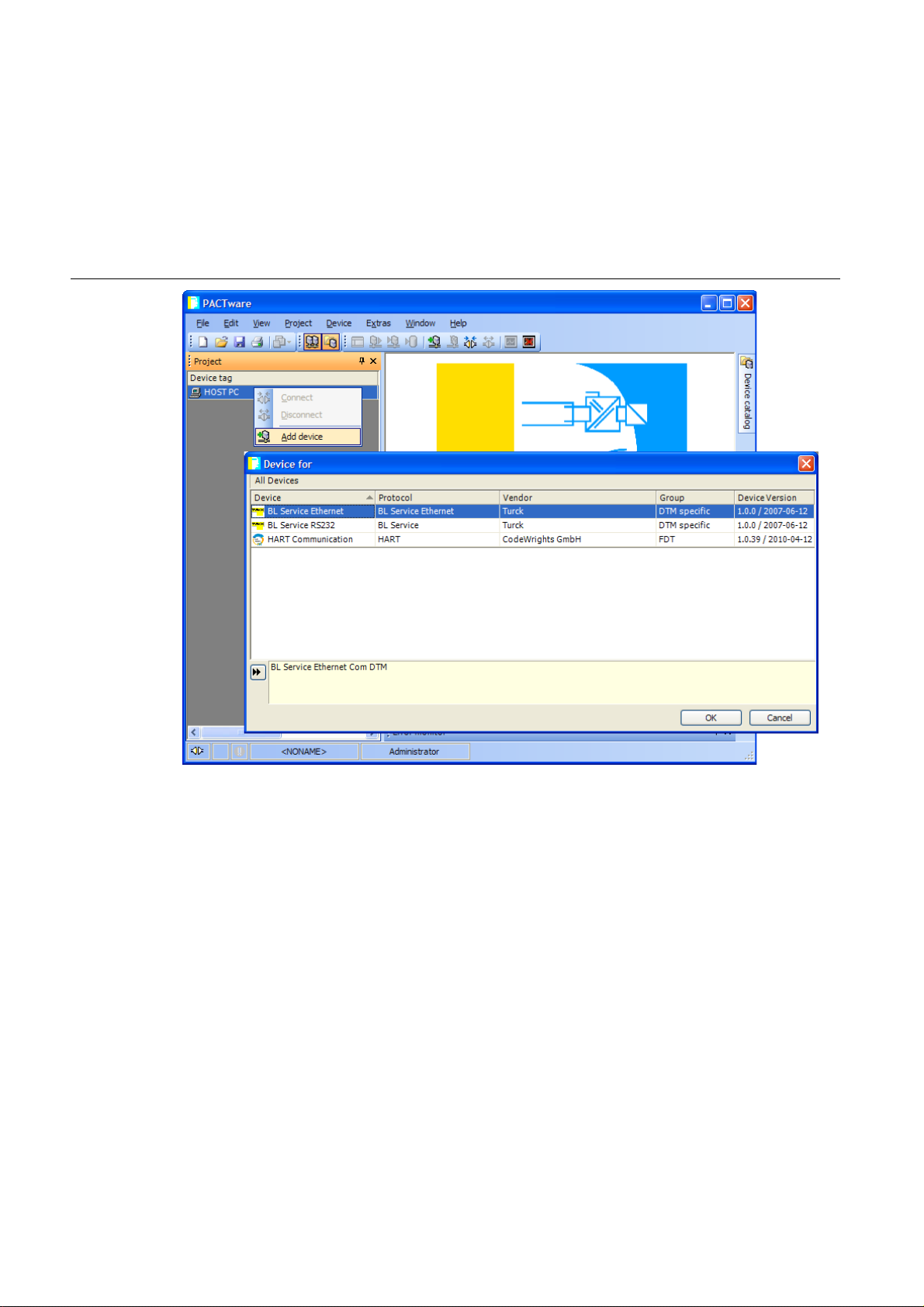

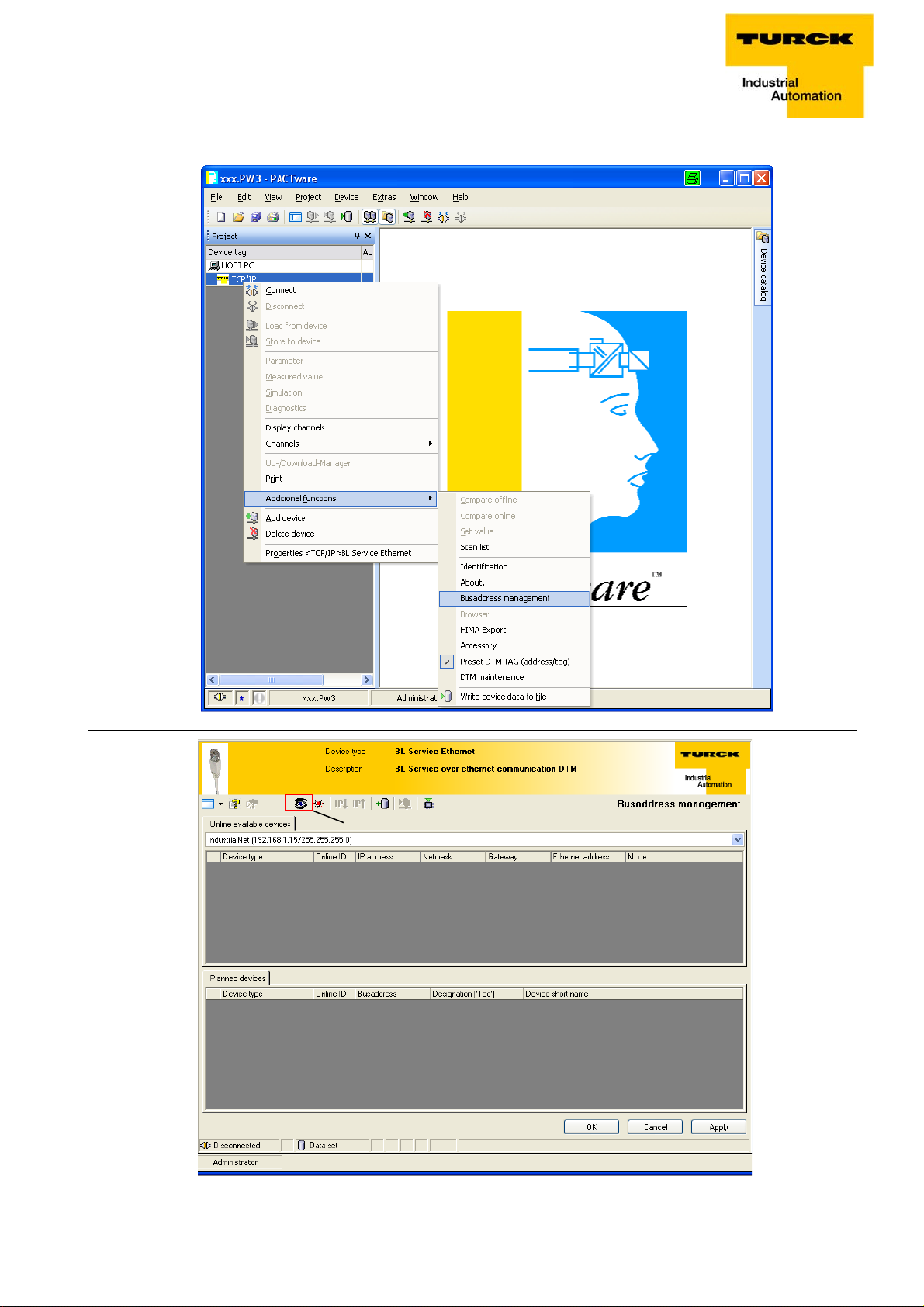

3.5.9 Addressing via I/O-ASSISTANT 3 (FDT/DTM)

The software-tool I/O-ASSISTANT enables direct access to the Ethernet-network via the Ethernet cable.

The IP address, as well as the subnet mask of the TURCK Ethernet stations, can be changed according

to the application by using the Busaddress Management function of the BL Service Ethernet interface

(TCP/IP) in the software I/O-ASSISTANT.

Figure 3-7:

BL Service

Ethernet

D301271 1013 - FGEN - multi protocol3-12

Page 29

Address assignment

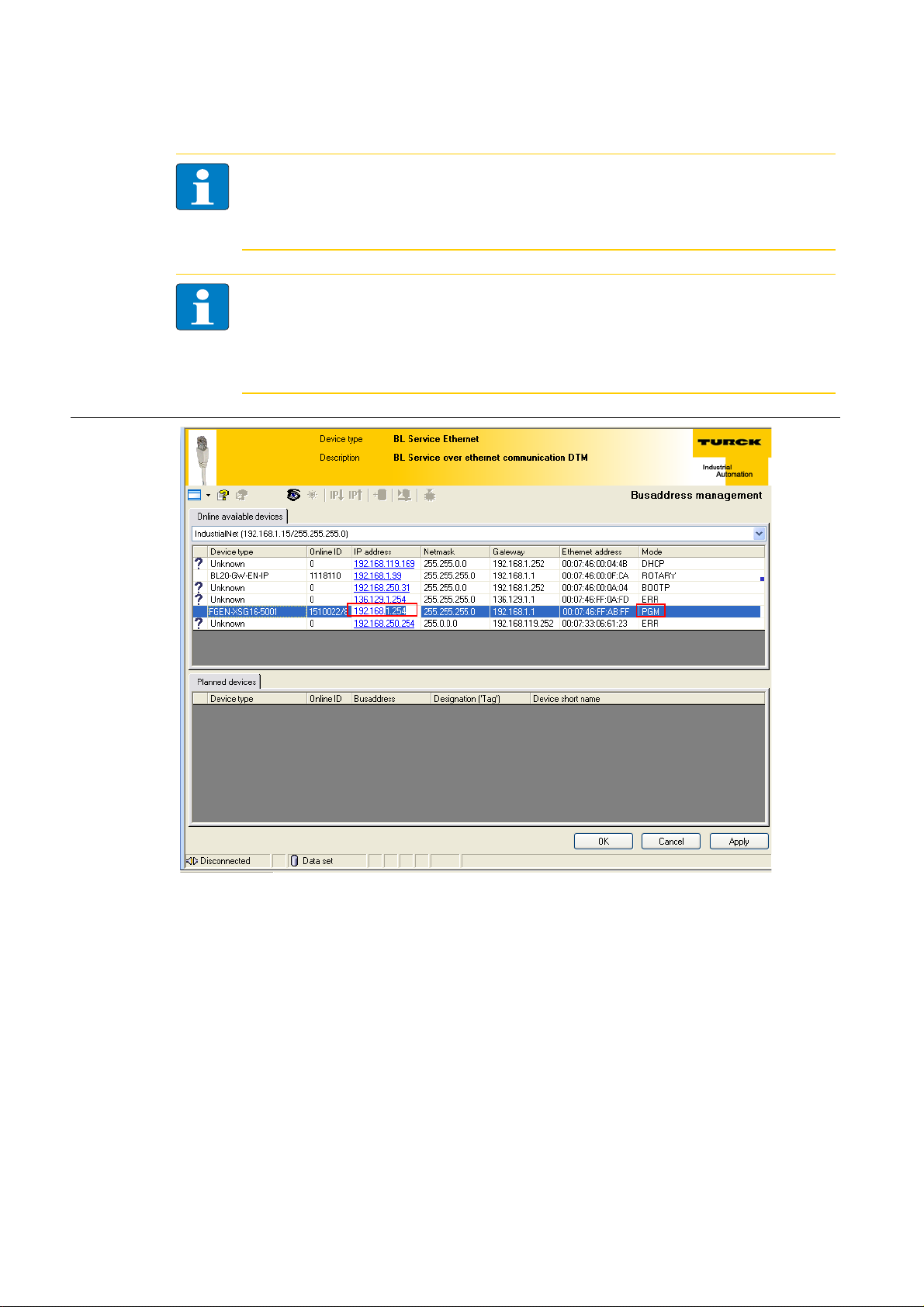

A

Figure 3-8:

Busaddress

management

Figure 3-9:

Searching

networkNodes in the

Busaddress

management

A Search function

in the Busaddress management

D301271 1013 - FGEN - multi protocol

3-13

Page 30

FGEN – general technical properties

Note

The access of the IO-ASSISTANT to the station is only possible, if the station already has an IPaddress and if it is operated in switch position 500 = PGM or 600 = PGM-DHCP-mode (see also

Address assignment (page 3-8)).

Note

When using Windows XP as operating system, difficulties may occur with system-integrated

firewall.

It may inhibit the access of PACTware™ (I/O-ASSISTANT V3) to the Ethernet-network. In this

case, please adapt your firewall respectively or deactivate it.

Figure 3-10:

Specify IP

address

change

D301271 1013 - FGEN - multi protocol3-14

Page 31

SET-button

3.5.10 Addressing via PGM-DHCP

The device's network settings can be changed under "Network Configuration" only by users having

administrator rights.

Further information concerning the web server of the FGEN-devices and it's use can be found under

Web server - remote access/configuration (page 3-16).

Note

The access of the IO-ASSISTANT to the station is only possible, if the station already has an IPaddress and if it is operated in switch position 500 = PGM or 600 = PGM-DHCP-mode (see also

Address assignment (page 3-8)).

Figure 3-11:

Web server with

Network

Configuration

3.6 SET-button

Pushing the SET-button causes a device-restart.

3.7 Device configuration files

The actual device configuration files for the stations can be downloaded from the TURCK-home page

www.turck.com.

D301271 1013 - FGEN - multi protocol

3-15

Page 32

FGEN – general technical properties

3.8 Web server - remote access/configuration

Note

When working with the webserver of the module, it should be assured, that the browser

always reloads the HTML-pages from the module‘s webserver (forced reload). The data

should not be loaded from the browser‘s cache memory.

This guarantees that the data to be shown are always acutal (module type, module status

etc.).

Short-cuts for browser:

Internet Explorer: Shift + F5

Mozilla Firefox: Ctrl + F5

Figure 3-12:

Web server of

the FGENstation

3.8.1 IP address

Open the web server by entering the device's IP-address in your web browser.

IF no IP-address is assigned to the device (DHCP-, BootP-server etc.), then the web server can be opened

using the default IP-address 192.168.1.254.

D301271 1013 - FGEN - multi protocol3-16

Page 33

Web server - remote access/configuration

3.8.2 Access rights

Without administrator rights, data as general product data and diagnosis data are read only.

In order to achieve administrator rights, please log-on to the web server, see Login / password (page

3-17).

3.8.3 Login / password

Login to the web server by using the default-password "password".

The default-password can be changed by the administrator at every time under Change Admin

Password (page 3-20) .

Note

A reset of the device to the default-settings using the switch position

900 "F_Reset" also causes a reset of the password to "password".

Figure 3-13:

Web server

"Home" screen

D301271 1013 - FGEN - multi protocol

3-17

Page 34

FGEN – general technical properties

3.8.4 Network Configuration

On the "Network Configuration"-page, network-relevant settings can be changed.

Figure 3-14:

Web server

"Network

Configuration"

D301271 1013 - FGEN - multi protocol3-18

Page 35

Web server - remote access/configuration

3.8.5 Station Configuration

The "Station Configuration"-page serves for parameterizing the device's fieldbus interface.

Figure 3-15:

Web server

"Station

Configuration"

3.8.6 Station Diagnostics

Diagnostic messages of the device are displayed on the "Station Diagnostics"-page.

3.8.7 Ethernet Statistics

The page "Ethernet Statistics" shows information like the port-status, telegram and error counters etc.

The page can above all be useful for analyzing network problems.

3.8.8 Links

This page contains for example a link to the product page on the TURCK-homepage.

D301271 1013 - FGEN - multi protocol

3-19

Page 36

FGEN – general technical properties

3.8.9 Change Admin Password

Please define an individual password for administrator rights.

Default-password: „password“

Note

A reset of the device to the default-settings using the switch position

900 "F_Reset" also causes a reset of the password to "password".

Figure 3-16:

Change Admin

Password

D301271 1013 - FGEN - multi protocol3-20

Page 37

Web server - remote access/configuration

3.8.10 Parameters

The "Parameters"-page is used to parameterize the station's I/O-channels.

Figure 3-17:

Web server

"Parameters"

D301271 1013 - FGEN - multi protocol

3-21

Page 38

FGEN – general technical properties

3.9 Status and Control Word of the FGEN-stations

The Status as well as the Control Word are mapped into the station's process data.

EtherNet/IP™

In EtherNet/IP™, the mapping can be disabled, see Gateway Class (VSC 100), GW Status register

(page 7-30) and GW Control Register (page 7-30).

Modbus TCP

→ see Register 100Ch: "Station status" (page 9-16)

PROFINET

→ see PROFINET-Error Codes (page 11-4)

3.9.1 Status Word

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Status 0

1 - FCE - - CFG COM U

U

L

------

Diag

Warn

B

-

Meaning of the status bits

Table 3-3:

Name Meaning

Meaning of the

status bits

DiagWarn Summarized diagnosis of the device. At least 1 channel sends diagnostics.

U

L

U

B

COM I/O Communication Lost Error

CFG I/O CfgModified Error

FCE Force Mode Active Error

3.9.2 Control Word

The Control Word has no function at the moment, it is reserves for further use.

Load voltage not within the permissible range (18 to 30 V)

System voltage not within the permissible range (18 to 30 V)

No Communication on the module bus.

The I/O-configuration has be changed and is no longer compatible.

The Force Mode is activated, which means, the actual output values may no match the

ones defined and sent by the field bus.

D301271 1013 - FGEN - multi protocol3-22

Page 39

4 Digital inputs FGEN-IM16-x001

4.1 FGEN-IM16-x001 ........................................................................................................................................ 4-2

4.1.1 Technical data ...................................................................................................................................................................................4-2

4.1.2 Wiring diagrams ...............................................................................................................................................................................4-2

– Ethernet ...........................................................................................................................................................................................4-2

– Power supply ................................................................................................................................................................................. 4-2

– Input M12x1 ...................................................................................................................................................................................4-2

4.1.3 Parameters..........................................................................................................................................................................................4-3

4.1.4 Diagnostic message of I/O-channels.........................................................................................................................................4-3

D301271 1013 - FGEN - multi protocol 4-1

Page 40

Digital inputs FGEN-IM16-x001

5 PE

4 BK

1 BN +

3 BU

3 BU

2 WH

v

C0...C7

4.1 FGEN-IM16-x001

The station offers 16 digital inputs for 3-wire pnp sensors.

4.1.1 Technical data

Table 4-1:

Technical data

FGEN-IM16x0001

Type designation FGEN-IM16-x001

Number of channels (16) 3-wire pnp-sensors

Supply (via U

) 18 ... 30 VDC from operating voltage

B

Supply current < 120 mA per connector, short-circuit protected

Switching threshold OFF/ON 2 mA / 4 mA

Low level signal voltage -3 to 5 VDC (EN 61131-2, type 1 and 3)

High level signal voltage 11 to 30 VDC (EN 61131-2, type 1 and 3)

Max. input current 6 mA

Switch-on delay 2.5 ms

Switching frequency

Potential isolation galvanic isolation against U

≤ 500 Hz

and Ethernet

L

Note

General technical data for the products of the FGEN-product line can be found in chapter 3.

4.1.2 Wiring diagrams

Ethernet

→ Ethernet (page 3-6)

Power supply

→ Operating/load voltage (page 3-6)

Input M12x1

Figure 4-1:

Wiring diagram,

input M12x1

D301271 1013 - FGEN - multi protocol4-2

Page 41

FGEN-IM16-x001

4.1.3 Parameters

Table 4-2:

Parameters

A default

setting

Parameter name Value Description

Digital input

(Inv. DIx)

Further information about the parameter data mapping can be found in the fieldbus specific chapters.

EtherNet/IP™: chapter 7.4.4, Digital Versatile Module Class (VSC117) (page 7-34) ff.

Modbus TCP: chapter 9.3.2, Register mapping of the FGEN-stations (page 9-11) ff.

PROFINET: chapter 11.4, Parameters (page 11-5)

0 = normal A

1 = inverted Inverts the digital input signal.

4.1.4 Diagnostic message of I/O-channels

Table 4-3:

Diagnostic

messages

Diagnostics Description

SCSx Short circuit at sensor supply of the respective channel

Further information about the diagnostic data mapping can be found in the fieldbus specific chapters.

EtherNet/IP™: chapter 7.4.4, Process Data Class (VSC102) (page 7-31)

Modbus TCP: chapter 9.3.2, Register mapping of the FGEN-stations (page 9-11) ff.

PROFINET: chapter 11.3, PROFINET-Error Codes (page 11-4)

D301271 1013 - FGEN - multi protocol

4-3

Page 42

Digital inputs FGEN-IM16-x001

D301271 1013 - FGEN - multi protocol4-4

Page 43

5 Digital outputs FGEN-OM16-x001

5.1 FGEN-OM16-x001 ....................................................................................................................................... 5-2

5.1.1 Technical data ...................................................................................................................................................................................5-2

5.1.2 Wiring diagrams ...............................................................................................................................................................................5-2

– Ethernet ...........................................................................................................................................................................................5-2

– Power supply ................................................................................................................................................................................. 5-2

– Input M12x1 ...................................................................................................................................................................................5-2

5.1.3 Parameters..........................................................................................................................................................................................5-3

5.1.4 Diagnostic messages ......................................................................................................................................................................5-3

D301271 1013 - FGEN - multi protocol 5-1

Page 44

Digital outputs FGEN-OM16-x001

5 PE

4 BK +

1

2 WH +

3 BU

v

C0...C7

5.1 FGEN-OM16-x001

The station offers 16 digital inputs for DC actuators.

5.1.1 Technical data

Table 5-1:

Technical data

FGEN-OM16x001

Type designation FGEN-OM16-x001

Number of channels (16) DC actuators

Output voltage 18…30 V DC from load voltage

Output current per channel 2.0 A, short-circuit proof

Load type resistive, inductive, lamp load

Simultaneity factor 0.25 for complete module,

Potential isolation galvanic isolation against U

Note

General technical data for the products of the FGEN-product line can be found in chapter 3.

5.1.2 Wiring diagrams

Ethernet

→ Ethernet (page 3-6)

Power supply

1 × 2 A or 2 × 1 A per connector,

but only max. 9 A total current per module

and Ethernet

B

Figure 5-1:

Wiring diagram,

output M12x1

→ Operating/load voltage (page 3-6)

Input M12x1

D301271 1013 - FGEN - multi protocol5-2

Page 45

FGEN-OM16-x001

5.1.3 Parameters

Table 5-2:

Parameters

A default

setting

Parameter name Value Description

Output on

overcurrent

(SROx)

Further information about the parameters can be found in the fieldbus specific chapters.

EtherNet/IP™: chapter 7.4.4, Digital Versatile Module Class (VSC117) (page 7-34) ff.

Modbus TCP: chapter 9.3.2, Register mapping of the FGEN-stations (page 9-11) ff.

PROFINET: chapter 11.4, Parameters (page 11-5)

5.1.4 Diagnostic messages

Table 5-3:

Diagnostic

messages

Diagnostics Description

SCOx Short circuit at output of the respective channel

0 = activated A The output switches on automatically after an overload.

1 = deactivated The output is switched-off after an overload until a new set-

command is given (fall and rise).

Further information about the diagnostic data mapping can be found in the fieldbus specific chapters.

EtherNet/IP™: chapter 7.4.3, Process Data Class (VSC102) (page 7-31) ff.

Modbus TCP: chapter 9.3.2, Register mapping of the FGEN-stations (page 9-11) ff.

PROFINET: chapter 11.3, PROFINET-Error Codes (page 11-4)

D301271 1013 - FGEN - multi protocol

5-3

Page 46

Digital outputs FGEN-OM16-x001

D301271 1013 - FGEN - multi protocol5-4

Page 47

6 Digital in-/outputs FGEN-IOM88-x001, FGEN-XSG16-x001