Page 1

DeviceNet™

Troubleshooting

FIELD GUIDE

G1001

Publised 11/11/2013

Page 2

SCOPE

he purpose of this troubleshooting guide is to direct qualied service personnel to the causes of network problems

and provide remedies. The primary goal of troubleshooting is to minimize network downtime. Test procedures

T

resistance of the physical media layer. It is usually sucient to have a true RSM multimeter, such as Fluke ® 87-3 Digital

Multimeter or similar to run tests and obtain reliable measurements. For information on designing DeviceNet™ systems,

refer to ODVA publication 27: “DeviceNet Planning and Installation Manual”.

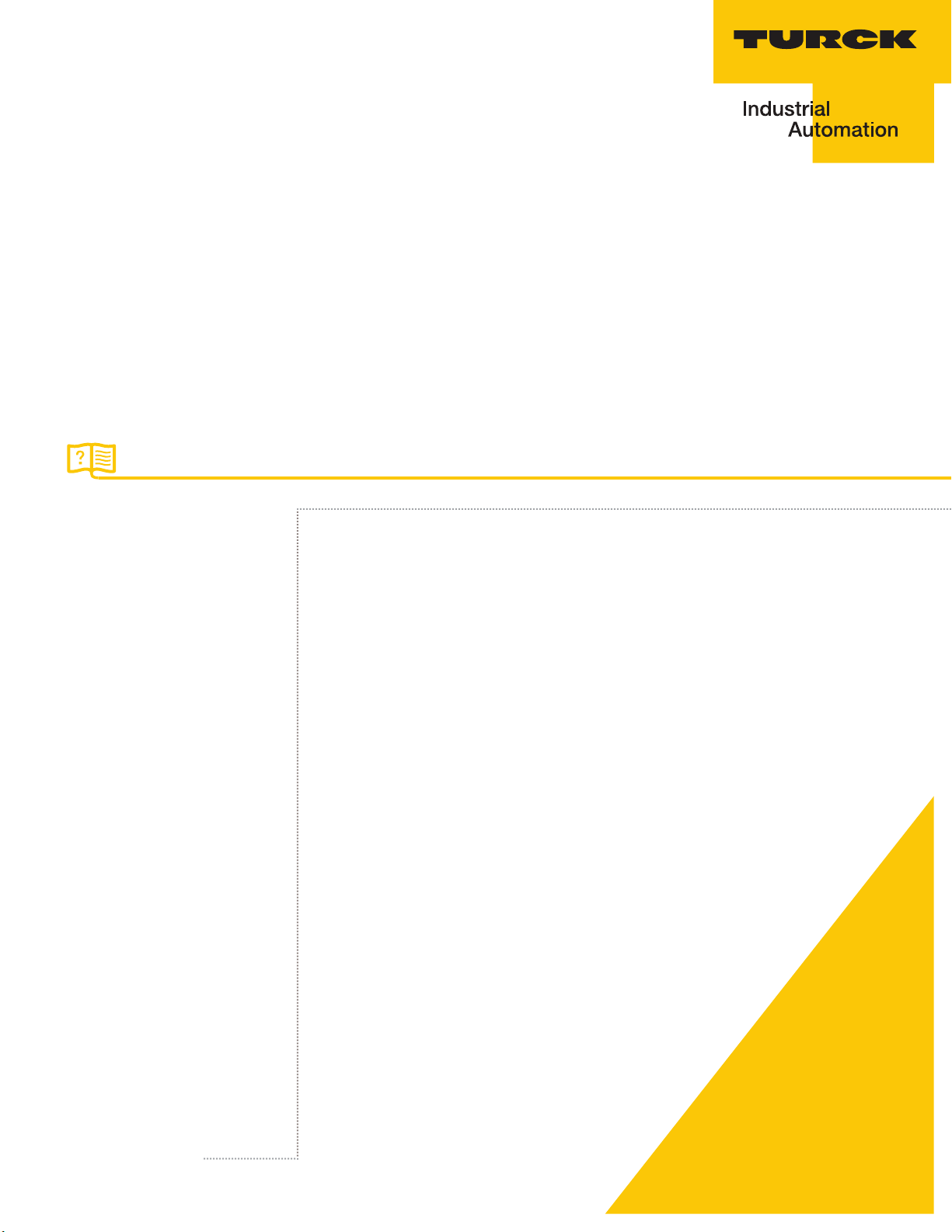

1.1 Network Components

DeviceNet uses a trunk line and drop line topology to connect nodes for communication. Here is an example:.

described in this Troubleshooting Guide require the use of test equipment to measure voltage, current, and

Trunk Line

TR

TR = Terminating Resistor

Component Description

Trunk Line The network cable between terminators. It is usually a

Drop Line The network cable between the trunk and nodes. Each

Tap A branching point from the trunk line. There may be one

Terminating Resistor The 121 Ohm resistor that is connected to the end of the

Node An addressable device that communicates on the

Power Supply The 24-volt DC source that powers network

NODE NODE

NODE

Drop Line

TapT ap

NODE NODE

Trunk Line

TR

POWER

SUPPLY

“thick” cable.

drop line may be no longer than 6 meters (20 feet)

node on a drop line, as with a tee tap, or multiple drop

lines, as with a multiport junction box.

Trunk Line. There are two terminators per network.

network. There may be as many as 64 nodes per network.

communication. There may be multiple power supplies

on a network, located anywhere on the network.

Drop Line

2 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 3

Page 3

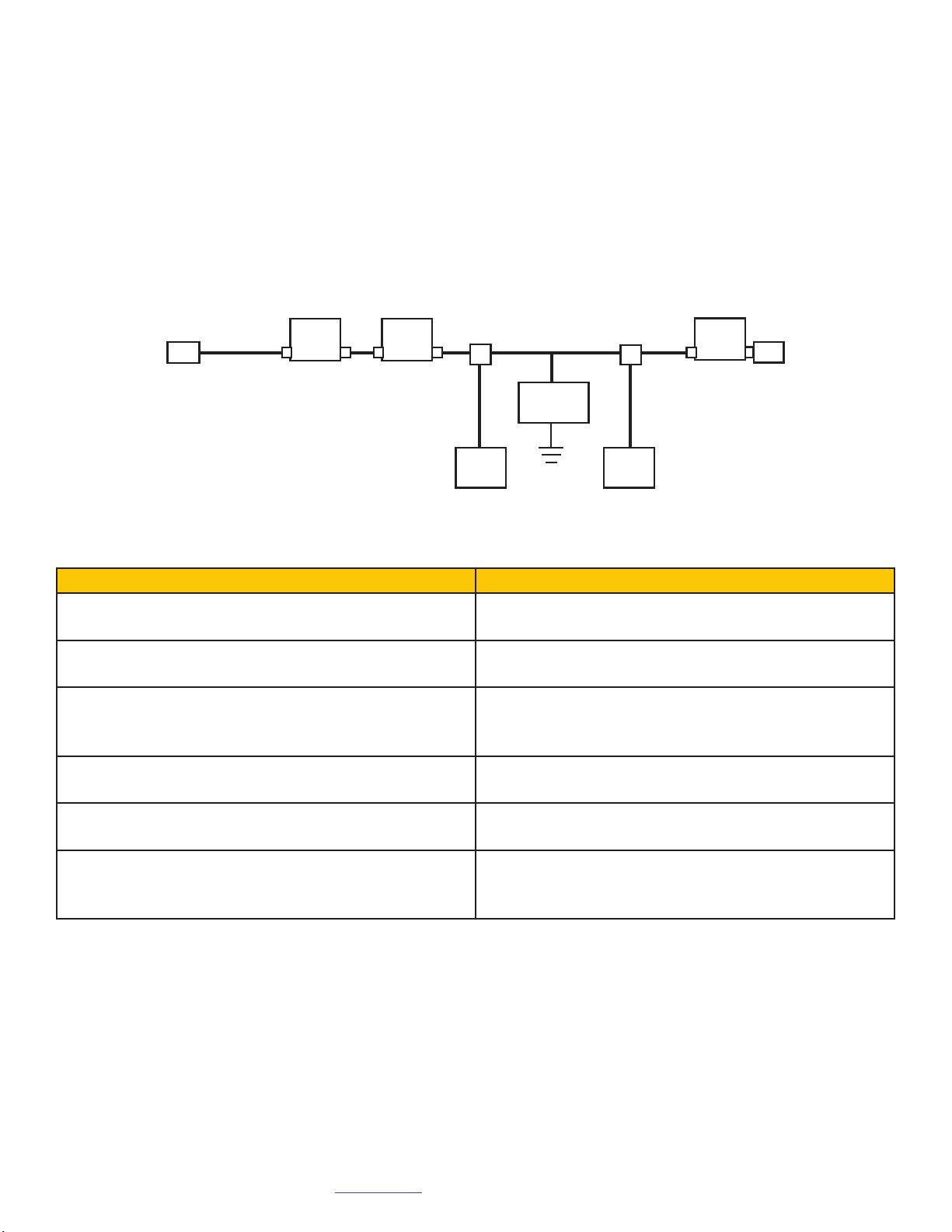

Wiring and Connector Pin Denitions

There are ve conductors in DeviceNet™ cables. There are three connector types commonly used on DeviceNet systems:

7/8 16 minifast ® (mini), M12 eurofast ® (micro), and screw terminal (open). Table I shows the connector pin denitions

and Table II shows the connector styles.

Name Wire Color Description

Shield Drain Bare Connection to the shields in the cable

V+ Red Connection to the bus 24 VDC supply

V- Black Connection to the bus supply common (0 VDC)

CANH Blue Data connection (high dierential)

CANL White Data connection (low dierential)

DeviceNet™ Cable Classication

Table I: Pin Denitions

Male mini

Connector

1 = Bare (Drain)

2 = Red (V+)

3 = Black (V-)

4 = White (CANH)

5 = Blue (CANL)

Table II: Connector Styles

Male Connectors

Female mini

Connector

minifast (mini) eurofast (micro) Open Style Front View

Male micro

Connector

1 = Bare (Drain)

2 = Red (V+)

3 = Black (V-)

4 = White (CANH)

5 = Blue (CANL)

Female micro

Connector

Open Female Connector

Rear View

5 = Red (V+)

4 = White (CANH)

3 = Bare (Drain)

2 = Blue (CANL)

1 = Black (V-)

Female Connectors

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 3

Page 4

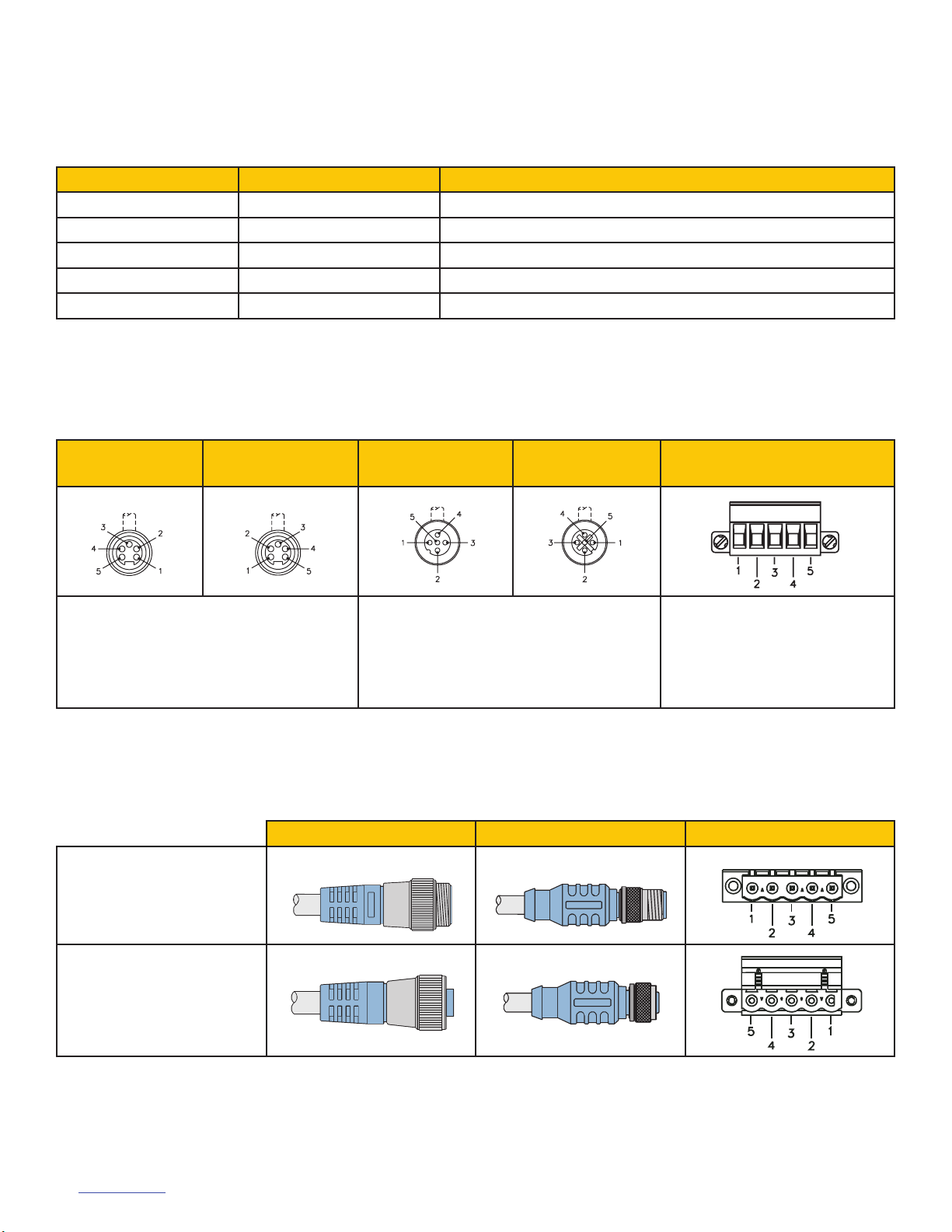

DeviceNet™ cables are classied according to DeviceNet Specication1 as:

Round Cables

• Thick Cable or Cable II

• Thin Cable or Cable I

Flat Cables

Table III: Cable Specications (provides data for each cable type listed in the DeviceNet Specication)

Data Pair Thick Cable Cable II Thin Cable Cable I Flat Cable

Min. Conductor Size:

#18 #18 #24 #24 #16

19 strands min.

Insulation Diameternominal 0.150 in 0.150 in 0.077 in 0.077 in 0.110 in

Color CAN_H White

CAN_L Light Blue

Impedance 120 Ohm +/- 10% @ MHz

Max. Propagation Delay 1.36 nSec/ft 1.36 nSec/ft 1.36 nSec/ft 1.36 nSec/ft 1.60 nSec/ft

DCR - at 20 degrees C (max) 6.9 Ohms

/1000 ft

Tape Shield 2 mil/1 mil,

Al/Mylar

6.9 Ohms

/1000 ft

1 mil/1 mil,

Al/Mylar

6.9 Ohms

/1000 ft

2 mil/1 mil,

Al/Mylar

28 Ohms

/1000 ft

1 mil/1 mil,

Al/Mylar

4.9 Ohms

/1000 ft

N/A

Power Pair

Min. Conductor Size #15 #15 #22 #22 #160

Insulation Diameternominal 0.098 in 0.098 in 0.055 in 0.055 in 0.110 in

Color V+ Red

V- Black

DCR - at 20 degrees C 3.6 Ohms

/1000 ft

Tape Shield 1 mil/1 mil,

Al/Mylar

3.6 Ohms

/1000 ft

1 mil/1 mil,

Al/Mylar

17.5 Ohms

/1000 ft

1 mil/1 mil,

Al/Mylar

17.5 Ohms

/1000 ft

1 mil/1 mil,

Al/Mylar

4.9 Ohms

/1000 ft

N/A

General Specications

Outside Diameter 0.410 - 0.490” Specied by

Vendor

Bent Radius (d = diameter) 7 x d, xed

20 x d, ex

Suitable for

Application

0.240 - 0.280” Specied by

Vendor

7 x d, xed

20 x d, ex

Suitable for

Application

N/A

10 x

diameter

Drain Wire #18 #18 #22 #22 N/A

Agency Certication NEC (UL)

CL2/CL3 min.

Overall Shield Braid

36 AWG or

0.12 mm Cu

Compliant

w/ local gov’t

regulations

Braid

36 AWG or

0.12 mm Cu

NEC (UL)

CL2/CL3 min.

Tape

1 mil/1 mil,

Al/Mylar

Compliant

w/ local gov’t

regulations

Tape

1 mil/1 mil,

Al/Mylar

NEC (UL)

CL2 min.

N/A

4 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 5

Page 5

Thick Cable and Cable II

The maximum cable length used in trunk-drop topology depends on the data rate:

Table IV: Thick Cable and Cable II Topology

Communication Rate Network Length Trunk Length Maximum Drop Cumulative Drop

125 kb 500 m (1640ft) 500 m (1640 ft) 6 m (20ft) 156 m (512 ft)

250 kb 250 m (820 ft) 250 m (820 ft) 6 m (20 ft) 78 m (256 ft)

500 kb 100 m (328 ft) 100 m (328 ft) 6 m (20 ft) 39 m (128 ft)

The length of the network is the sum of the trunk length and cumulative drop length.

Thick Cable Capacity

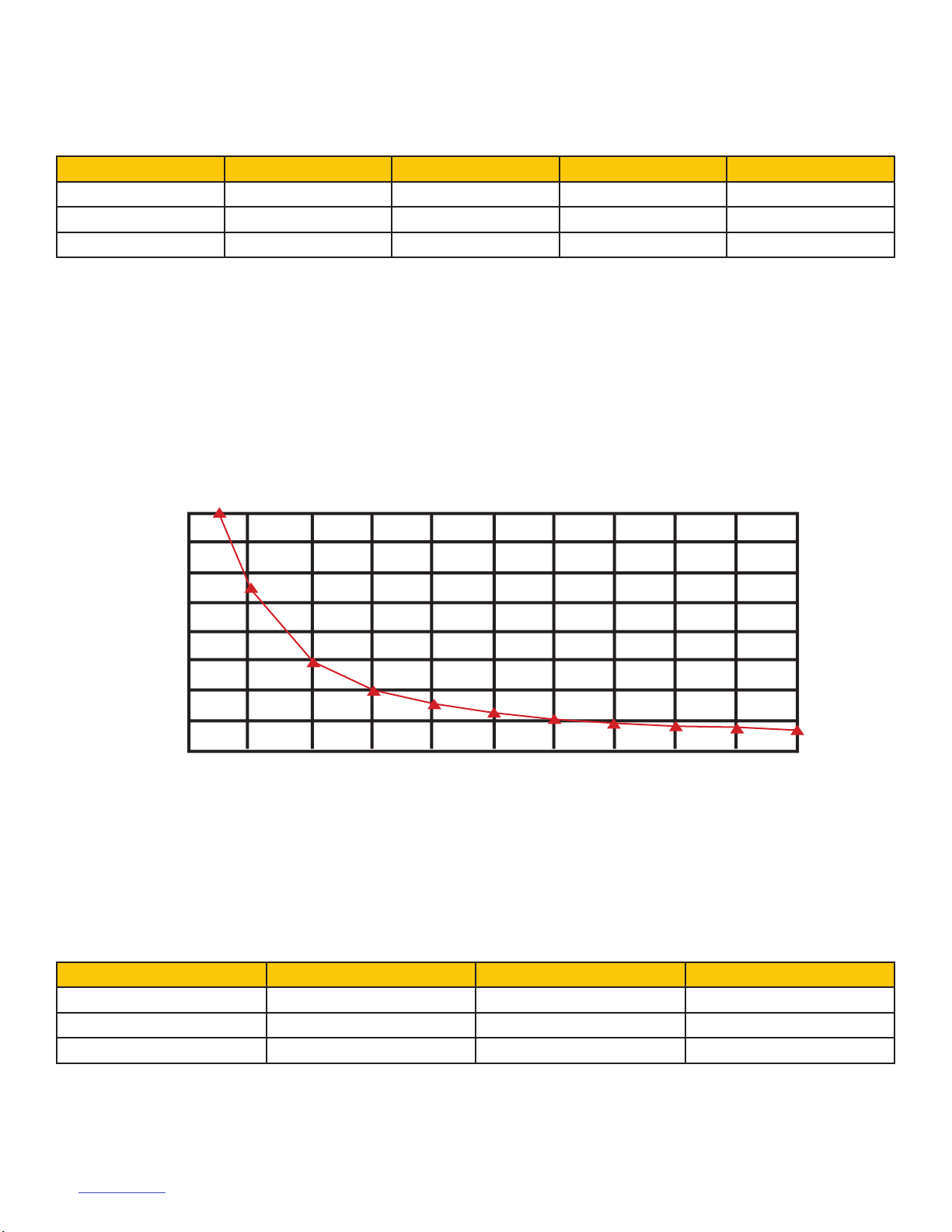

The power distribution chart, Figure 1, shows the maximum allowed current through the power conductors of the thick

cable. Distance is measured from a single 24 VDC power source. If the maximum current exceeds the specied value

at any given point on the network, the power supply systems should be re-designed. Figure 1 provides thick cable

current ratings.

Figure 1: Current available through power conductors of thick cable

Maximum Current Capability (amps)

8.00

8

7

6

5

4

3

2

1

0

0

5.42

2.93

2.01

1.53

50 100 150 200 250 300 350 400 450 500

(164) (328) (492) (656) (820) (1984) (1148) (1312) (1476) (1640)

Length of Network in meters (feet)

1.23

1.03

0.89 0.78 0.69

Thin Cable and Cable I

The maximum cable length used in trunk-drop topology, based on the data rate is:

Table V: Thin Cable and Cable I Topology

Communication Rate Trunk Length Maximum Drop Cumulative Drop

125 kb 100 m (328 ft) 6 m (20 ft) 100 m (328 ft)

250 kb 100 m (328 ft) 6 m (20 ft) 78 m (256 ft)

500 kb 100 m (328 ft) 6 m (20 ft) 39 m (128 ft)

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 5

Page 6

Thin Cable Capacity

Power distribution chart: Figure 2,

shows the maximum allowed current

through the power conductors of the

Figure 1: Current available through power conductors of thick cable

3.00

3

thin cable. The distance is measured

from a single 24 VDC power source.

If the maximum current exceeds the

specied value at any given point

2

2.06

1.57

of the network, the power supply

system should be re-designed. Figure

1

2 provides thin cable current ratings.

0

01 02 03 04 06 07 09 0 10050 80

Maximum Current Capability (amps)

Length of Network in meters (feet)

Flat Cable

The maximum at cable length used in trunk topology, based on the data rate is:

Table VI: Flat Cable Topology

1.26

1.06

0.91

0.80

0.71

0.64

(262)(164) (328)(295)(230)(197)(131)(98)(66)(33)

Communication Rate Trunk Length Maximum Drop Cumulative Drop

125 kb 420 m (1378 ft) 6 m (20 ft) 156 m (512 ft)

250 kb 200 m (656 ft) 6 m (20 ft) 78 m (256 ft)

500 kb 100 m (328 ft) 6 m (20 ft) 39 m (128 ft)

Flat Cable Capacity

Figure 3: Current available through power conductors of at cable

9

8

7

6

5

4

3

2

1

Maximum Current Capability (amps)

0

0

12.52 55 0 100 150 200 250 300 350

(41) (82) (164) (328) (492) (656) (820) (984) (1148)

8.00

5.65

2.86

1.91

1.44

1.15

0.96

0.82

0.72

400

(1312)

0.69

420

(1378)

Length of Network in meters (feet)

6 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 7

Page 7

QUICK START

Know the Network Layout

An essential part of the troubleshooting process is knowing the layout of the network. Survey the network to determine

the location (or existence) of these components.

Network Topology

• The trunk cable connects nodes and taps. Look for a terminating resistor at each end.

• The drop lines are the non-terminated cables that connect nodes to the trunk.

Location of Nodes

• Count the nodes and note their location on the network.

Location of Power Supplies

• There may be more than one power supply on a network, located at the end, middle, or anywhere along the cable. Only one of

the power supplies must be the grounding point for network power.

When Things Go Wrong

The rst question is always “What has changed?” If you have added or replaced nodes, changed wiring, or congured

a scanner, start to look for a problem where you were working. If you cannot nd a problem there, you will need

to determine if the problem is caused by the physical media, a node communication fault, or the network power

distribution. It is sometimes dicult to determine the root problem, because there can be more than one network

problem. In general, check for physical media and node conguration problems before network power distribution or

isolating node communication faults.

Symptoms of Physical Media Problems

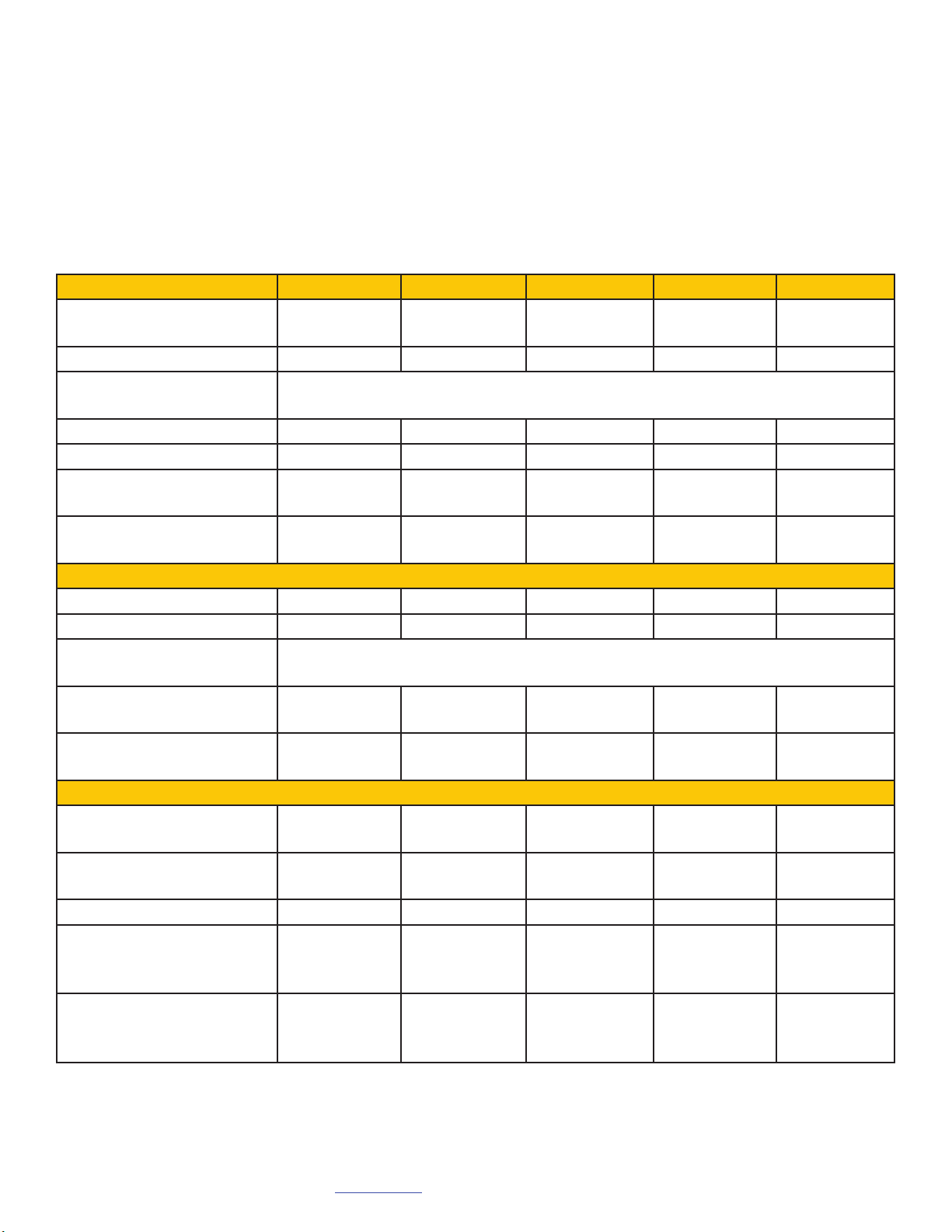

For This Symptom Take This Action See Procedure

All nodes on a trunk segment or

on a drop stop communicating

then may recover or go bus-o.

Nodes sporadically stop

communicating, and then recover.

The network communicates

only when the number of nodes

or trunk length is reduced.

Check all wiring and connectors on

the segment between the power

supply and the terminating power.

Check for loose wiring or a loose

connector leading to the node.

Check the resistance between

conductors on the bus cable,

CAN DC resistance, and

terminating resistor values.

3.1

3.1, 3.2, 3.3

3.3

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 7

Page 8

Symptoms of Node Problems

For This Symptom Take This Action See Procedure

Slave node is on-line, but the

scanner says it does not exist.

Slave node will not go on-line. Check CANH/CANL wiring.

Change the slave node address to

match scanner’s scan list.

3.6

3.4

Change the slave node data rate to

match the scanner’s data rate.

The network communicates only

when the node is removed.

The node is in the I/O timeout state. Reset the scanner and network power. 3.4

Check the node’s CAN transceiver. 3.4, 3.5

4

Symptoms of Network Power Distribution Problems

Network power distribution problems often produce sporadic or intermittent network failures.

For This Symptom Take This Action See Procedure

Nodes near the end of the

trunk stop communicating

after operating normally.

The scanner or multiple nodes

go to the bus-o state after

operating normally.

The scanner does not detect

properly congured slave nodes.

The network communicates only

when the number of nodes or

the trunk length is reduced.

Check the bus voltage at the node and the

common mode voltage at the ends of the bus.

Check common mode voltage and

power supply/shield grounding.

Check power supply/shield grounding

and common mode voltage.

Check the bus voltage at the node and . the

common mode voltage at the ends of the bus.

3.3 - 3.4

3.2 - 3.3

3.2 - 3.3

3.2

Network Failure

Network cannot go on-line, Bus-o condition (error 91).

For This Symptom Take This Action See Procedure

The network communicates only

when the number of nodes or

the trunk length is reduced.

Check bus voltage at node and common

mode voltage at ends of bus.

Check each node for Data Rate setting. 3.2 - 3.3

Check each node for CAN transceiver failure. 3.2 - 3.3

Check open style and eld wireable

connectors for proper wiring.

3.3 - 3.4

3.2

8 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 9

Page 9

NETWORK TESTS

Termination Test

Description Termination is used to match the impedance of a node to the impedance of the

transmission line being used. When impedances are mismatched, the transmitted

signal is not completely absorbed by the load and a portion is reected back

into the transmission line. If the source, transmission line and load impedance

are equal, these reections are eliminated. This test measures series resistance

of DeviceNet™ data pair conductors and attached terminating resistors.

Procedure 1. Turn all network power supplies o..

2. Measure and record DC resistance between CANH and

CANL at the middle and end of the network.

If Measured

Values are:

<50 Ohms Check for more than two terminating resistors.

Check for short-circuit between CANH and CANL wiring.

Check nodes for faulty transceivers (refer to CAN Transceiver Resistance Test).

60 Ohms Normal - do nothing.

71-121 Ohms Check for open circuits in CANH or CANL wiring..

Check for one missing terminating resistor.

Problem Resolution • Split the network down the middle into two segments.

• Check resistance of each segment - should be 121 Ohm since only a single.

• terminating resistor is present on each segment.

• Mark a break point and leave it disconnected.

• At least one segment will show resistance = to 121 Ohm.

• Split a bad segment into two sections and add, temporarily, a terminating resistor.

• to the non-terminated section. Mark the location of the break point and temporary.

• terminating resistor.

• Check the resistance of each section - should be 121 Ohm.

• Continue splitting the network until the problem is located and repaired.

• Remove all temporary resistors and bring network back to original state.

• Verify once again that the assembled network has 60 Ohm resistance.

The same procedure is used to locate connector shorts or faulty transceivers.

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 9

Page 10

Power Supply Ground Test

Description The shield and V- of the DeviceNet™ cable system must be grounded at a single

location as shown in Figure 4, preferably near the physical center of the network. If

multiple power supplies are present, ground only at the power supply closest to the

middle of the network. This test will indicate if multiple grounds are connected.

Procedure 1. Turn o all network power supplies..

2. Disconnect V- and Shield wires are from earth ground and from each other.

3. Measure and record the DC resistance between Shield and

earth ground at the far most ends of the network..

4. Connect the V- and Shield wires to earth ground.

If Measured

Values are:

Note: Grounding wire could be up to 10-ft long. Grounding is done with:

<1 M Ohm Check for additional grounded V- or Shield wires

>1 M Ohm Normal Range

• 1” copper braid, or

• #8 AWG copper wire up to 10-ft long

Figure 4: Network Grounding

CAN_H

CAN_L

SHIELD/DRAIN

V-

V+

Power Tap

FUSE FUSE

SCHOTTKY

DIODE

Power Supply

Cable

#15AWG

GND V- V+

Network PS

10 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 11

Page 11

Power Common Mode Voltage Test

Description When the current is drawn through the power pair on the DeviceNet™ trunk line, the

resistance of the power pair conductors produces the common mode voltage drop.

The eect of the common mode voltage is that the V+ line decreases from the 24 VDC

at the power supply as you move farther from the power supply. More signicantly,

the V- line increases from the 0 VDC value at the power supply along the length of the

trunk line. This test assumes that V+ decreases and V- increases are equal. Since CANH

and CANL both are referenced to the V- wire, if the voltage on the V- line varies more

than 4.65 VDC at any two points the CAN transceivers will fail to operate properly.

Procedure 1. Turn all network power supplies on.

2. Congure all nodes for their maximum current draw from network

power. Turn on outputs that use network power.

3. Measure and record DC voltage between V+ and V- where

each power supply connects to the trunk.

4. Measure and record DC voltage between V+ and V- at the ends of the network.

If the dierence

between any

two measured

values is:

<9.3 Volts Normal Range

>9.3 Volts Network will not operate properly. Possible solutions:

• Shorten overall length of the network cable

• Move power supply in direction of overloaded section

• Move nodes from overloaded section to less loaded section

• Move high current loads close to the power supply

• Add a second power supply

• Break the network into two separate networks

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 11

Page 12

CANH/CANL Voltage Test

Description Each node contains a CAN transceiver that generates dierential signals onto the data

conductors. When the network communication is idle, the CANH and CANL voltages

are approximately 2.5 volts. Faulty transceivers can cause the idle voltages to vary and

disrupt network communication. Although this test indicates that faulty transceivers

may exist on a network, it will not indicate which node has the faulty transceiver. If a

node with a faulty transceiver is found, perform the CAN Transceiver Resistance Test.

Procedure 1. Turn all network power supplies on.

2. Congure all nodes for their maximum current draw from network

power. Turn on outputs that use network power.

3. Measure and record DC voltage between V+ and V- where

each power supply connects to the trunk.

4. Measure and record DC voltage between V+ and V- at the ends of the network.

If CANH and/or

CANL are:

<2/0 Volts • CANH/CANL conductor has

intermittent short to shield or V-.

• Check all open style and eld wireable connectors.

• Check CANH and CANL conductors for continuity.

• Possible faulty transceiver on one or mode

nodes (refer to CAN Transceiver).

2.0 - 3.0 Volts Normal Range.

>3.0 Volts • CANH/CANL conductor has intermittent short

to V+. Network in bus-o state (error 91). Check

all open style and eld wireable connectors.

• Check for excessive common mode voltage

(refer to Power Common Mode Voltage Test).

CAN Levels Parameter Range

Recessive CANH

CANL

CANH - CANL

Dominant CANH

CANL

CANH - CANL

2.0 - 3.6

2.0 - 3.6

0.45 maximum

2.75 - 5.1

0.5 - 2.86

0.95 minimum

12 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 13

Page 13

CAN Transceiver Resistance Test

Description The CAN transceivers used in DeviceNet™ nodes have one circuit that controls CANH and another

circuit that controls CANL. Experience shows that electrical damage to one or both circuits

may increase the leakage current in these circuits. This test uses an ohm/meter to measure the

current leakage through the CAN circuits. Note: The reference values listed below are derived

from tests with Philips Model PCA82C251 CAN transceivers and Fluke® multimeter Models

77 and 87. Other combinations of transceivers and multimeters may yield dierent results.

Procedure 1 1. Disconnect the node from the network. Leave the node unpowered.

2. Measure and record the DC resistance between CANH and V-.

3. Measure and record the DC resistance between CANH and V+.

4. Measure and record the DC resistance between CANL and V-.

5. Measure and record the DC resistance between CANL and V+.

If Measured

Values are:

Procedure 2 Measure resistance between CANH (signal probe) and CANL (common probe)

If Measured

Values are:

<1 M Ohms Faulty CAN transceiver

4 M - 6 M Ohms Normal Range

>6 M Ohms Faulty CAN transceiver

<36 Kohms Faulty or deteriorated CAN transceiver

36> Kohms <39 Normal Range

ESD Discharge Test

Description The following test shows if power and communication lines are aected by an electrostatic

discharge. ESD may cause damage to the nodes and disrupt network communication. Every

node is aected by discharge and in the long run most components will deteriorate, thus

reducing network performance and reliability. A repeated node failure in the same production

area indicates that an ESD discharge is above the components ratings. Transceiver PCA82C251

is rated for +/- 250 VDC ESD discharge, classication B, machine model: C=100 pF, R=0 Ohm.

Tektronix ® scope model THS730A, 200 Mhz, 1 GSs, or similar may be used for ESD test.

Procedure 1 1. Connect Channel 1 to CANH and set voltage reference to 500 V.

2. Connect Channel 2 to CANL and set voltage reference to 500 V.

3. Set dierential signal CANH - CANL.

4. Set time reference to 200 nsec.

5. Set trigger point at CH 1, at 250 V.

6. Measure voltage and adjust reference levels as required.

If CANH

Measured

Values are:

<200 VDC

>200 VDC

Acceptable ESD discharge

Control systems must be grounded

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 13

Page 14

SETTING NODE ADDRESS AND COMMUNICATION RATE

The methods described below are used on TURCK and DeviceNet™ products and may be dierent than other vendors’

implementations. The default node address is 63 and the communication rate is set at 125 kbps (kilobits per second). The

node address and communication rate parameters can be set in hardware or software. The factory default is Software

Conguration. Changes to DIP switch settings take eect the next time the device is powered up or when the device

receives a software reset.

Hardware Address/Comm Rate Conguration

Hardware conguration of node addresses and communication rates is

accomplished using DIP switches located under the device cover. Switches

S7 and S8 adjust the communication rate and switches S1-S6 set the node

address using binary code. Switch S1 is the least signicant bit and switch

S6 is the most signicant bit.

Software Address/Comm Rate Conguration

Software conguration of node addresses and communication rates is active

when DIP switches S7 and S8 are ON. The node address and communication

rates are stored in nonvolatile memory. Changes to the node address and

communication rate require the use of a DeviceNet conguration tool.

Switches S1-S6 are ignored when in software conguration mode.

Rotary Switches

Rotary switches provide a more convenient and reliable way of setting the

node address or data rate.

OFF

S1 - S6 Set

Node Address

7

8

125 kbps 250 kbps

OFF

1

2

3

4

5

6

7

8

S7 - S8 Set

Comm Rate

7

500 kbps

8

1

2

3

7

S7 - S8 are

switched ON

4

5

6

7

8

8

14 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 15

Page 15

The MSD (the Most Signicant Digit) switch sets a tenth

digit and the LSD (the Least Signicant Digit) sets a single

digit. The valid address range is 0-63.

The MSD switch set to the PGM (programmable) position

allows use of node commissioning or software setup of

the node address.

The Data Rate switch, when available, is used for the

Node Address (00-63)

23

1

0

PGM

4

MSD

1

5

0

9

6

23

8

LSD

4

5

6

7

Data Rate

Auto

500

250

125

PGM

selection of a pre-dened communication speed. In

“Auto” position, the node detects the Data Rate through

“Autobaud”. It usually takes several poll messages to be transmitted for the node to “lock” in the appropriate Data Rate.

In addition to these four predened positions, the Data Rate switch can be set to “PGM” (programmable mode). The PGM

position is any nonpredened position.

Changes to the rotary switch settings take eect the next time the device is powered up or when the device receives a

software reset.

www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 15

Loading...

Loading...