Page 1

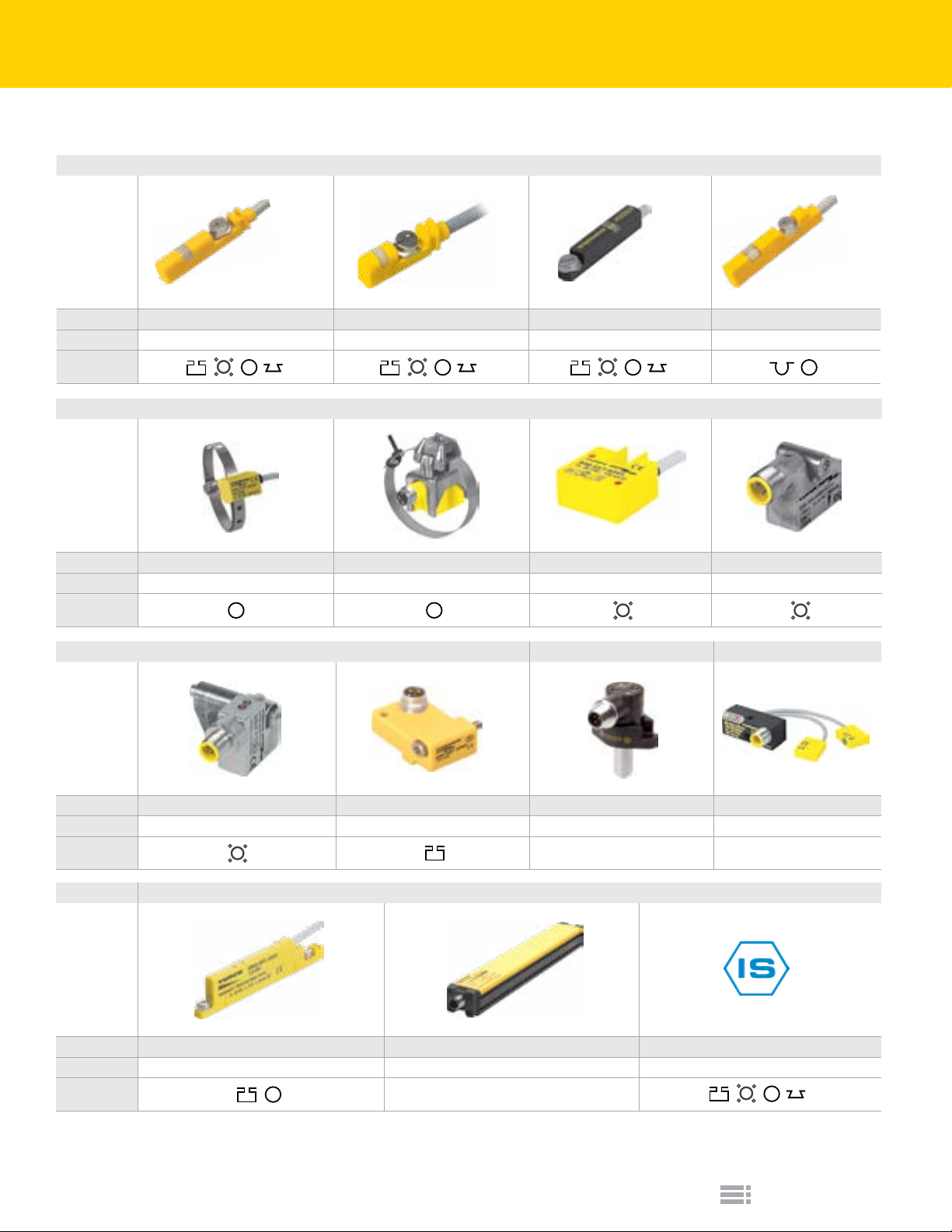

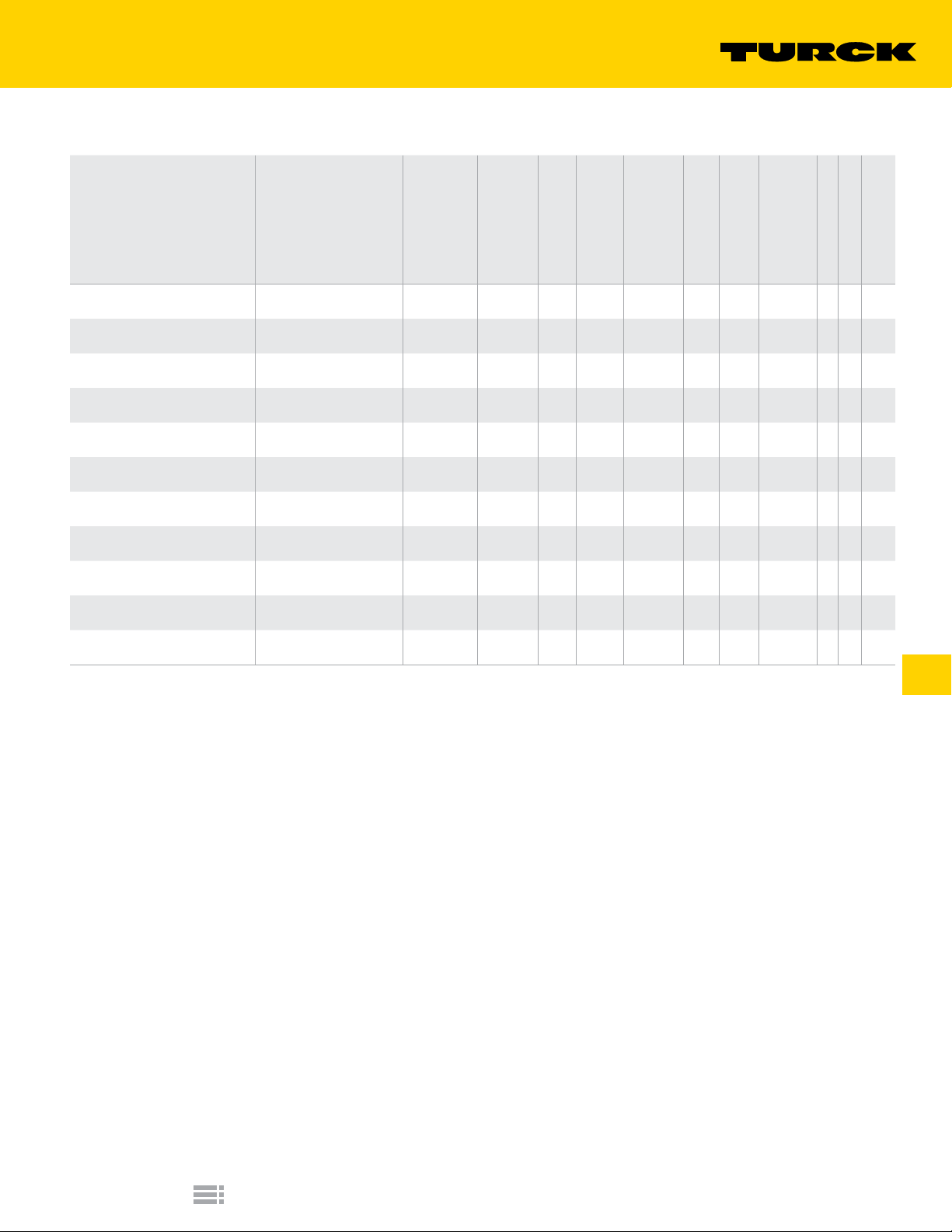

Cylinder Position Sensor Selection Guide

Cylinder Position Sensors

Housing UNT UNTK INT UNR

Pages G13 G15 G17 G19

Style of

Cylinder

Cylinder Position Sensors

Housing PST KST AKT IKE/IKT

Pages G21 G23 G25 G27

Style of

Cylinder

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors Inductive World Clamp Sensors

Housing IKM NST CRS Variable

Pages G29 G31 G33 - 36 G37 - 42

Style of

Cylinder

Magnetic Analog

Housing UNTL 25 mm Variable

Pages G43 G45 G47

Style of

Cylinder

G1

Turck Inc.

Page 2

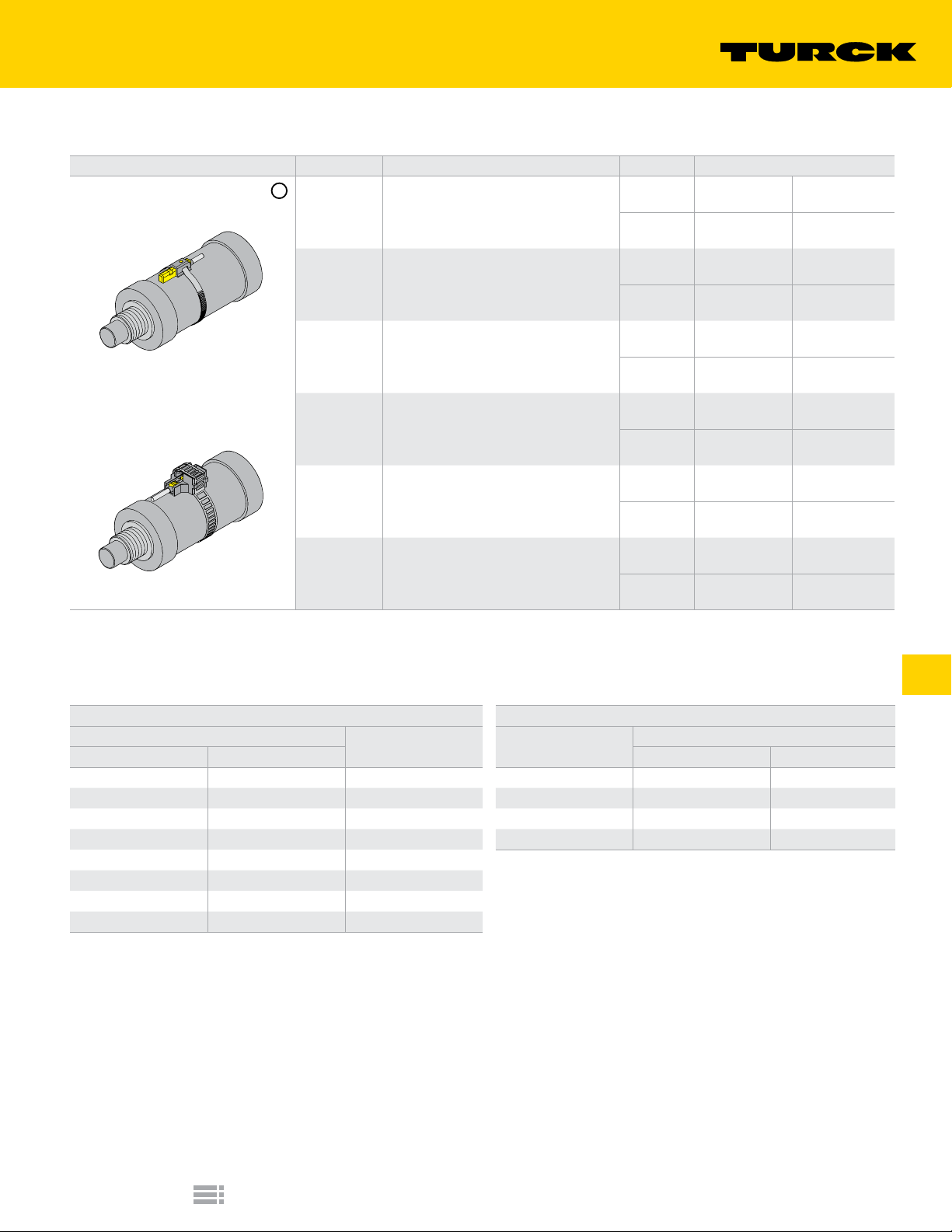

Cylinder Position Sensors

Drawing Manufacturer Cylinder Series Turck Sensor Turck Bracket

Parker P, SRM, SRDM, XLT, XLR, XKB, (S, SRD)

Festo

Bimba

SMC NCM, NCJ2, NCG, NCA1, CJ2, CM2, CG1, MGG

Norgren Round Line (RL)

Fabco-Air

CRDG, CRDSNU, CRDSW, DSNU, SDNUL, DSEU,

ESEU, ESNU, ESW, (DSN)

Original Line II (0L2), Original Line (M, MH, MNR,

MC, MRS), Doublle Wall (DW, DWD, DWN, DWM),

PC, Z Series (M04, M09, M17, M31),

Linear Thrusters (T, TE)

Pancake (X, XK, O, OP, XDR, XDRK, ODR),

Linear Slide (L, S, E,)

UNT Style KLRC-UNT*

UNR Style

UNT Style KLRC-UNT*

UNR Style

UNT Style KLRC-UNT*

UNR Style

UNT Style KLRC-UNT*

UNR Style

UNT Style KLRC-UNT*

UNR Style

UNT Style KLRC-UNT*

UNR Style

KLRC-2 with ASB

Clamp

KLRC-2 with ASB

Clamp

KLRC-2 with ASB

Clamp

KLRC-2 with ASB

Clamp

KLRC-2 with ASB

Clamp

KLRC-2 with ASB

Clamp

KLRC with ASB

Clamp

KLRC with ASB

Clamp

KLRC with ASB

Clamp

KLRC with ASB

Clamp

KLRC with ASB

Clamp

KLRC with ASB

Clamp

1. This Mounting is to be used only when “Switch Rail” is present on the cylinder.

2. ASB size is determined by the cylinder diameter. See Table 1. KLDT is required when the UNT sensor has integral quick disconnect.

3. These styles are not usually available with magnets.

4. Bracket size determined by the cylinder diameter. See Table 2.

UNT Housing with KLDT-UNT and ASB Style Strap UNT Housing with KLRC-UNT*

We reserve the right to make technical alterations without prior notice.

.276 - .433 7 - 11 ASB-1 KLRC-UNT1 .315 - .984 8 - 25

.433 - .748 11 - 19 ASB-2 KLRC-UNT2 .984 - 2.480 25 - 63

.709 - 1.142 18 - 29 ASB-3 KLRC-UNT3 2.480 - 5.118 63 - 130

1.102 - 1.535 28 - 39 ASB-4 KLRC-UNT4 5.118 - 9.843 130 - 250

1.496 - 1.929 38 - 49 ASB-5

1.890 - 2.323 48 - 59 ASB-6 Table 2

2.283 - 2.717 58 - 69 ASB-7

2.677 - 3.110 68 - 79 ASB-8

Cylinder Diameter Clamp

Inches Millimeters Inches Millimeters

Table 1

(Stainless Steel)

Part Number

Cylinder Diameter

Cylinder Position Sensors

Turck Inc.

G2

Page 3

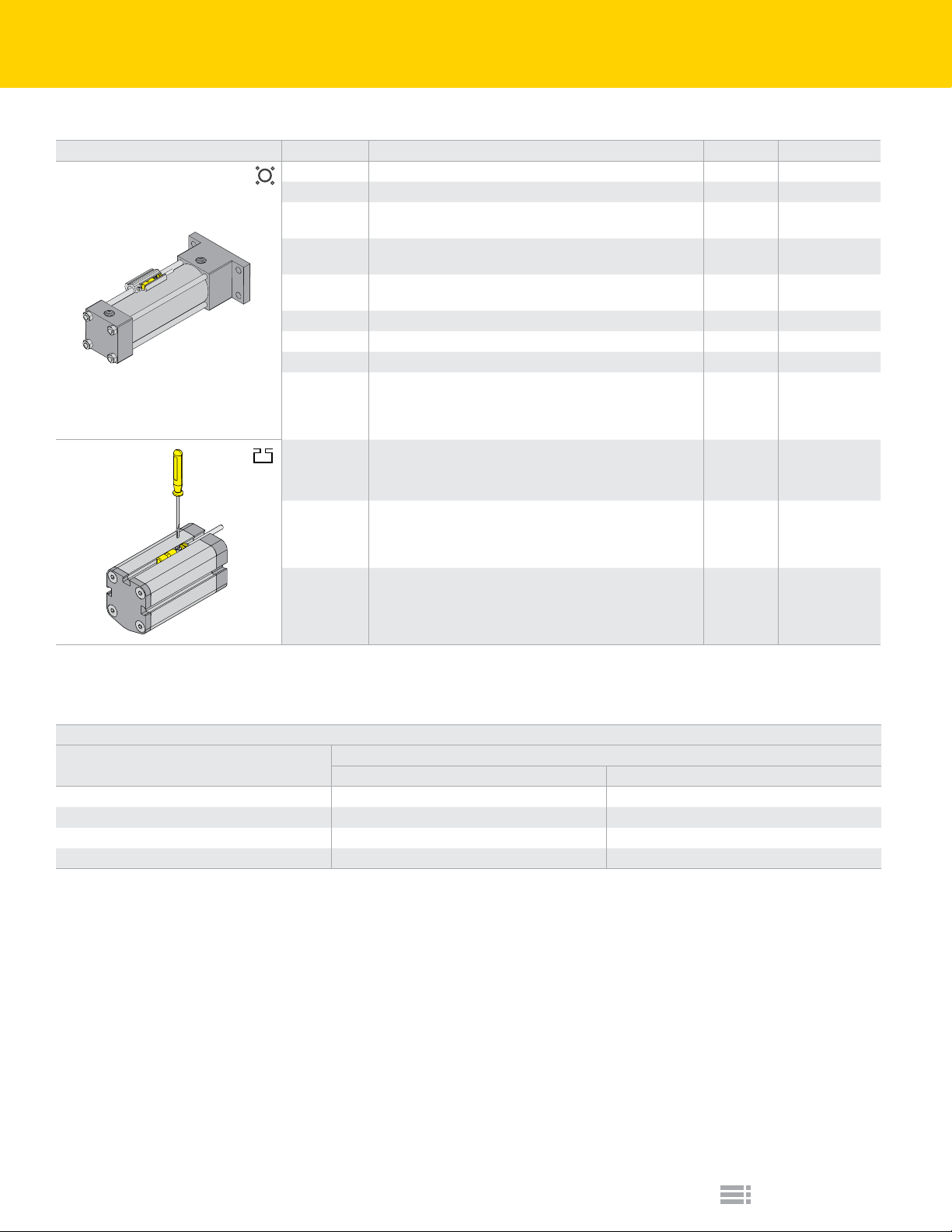

Cylinder Position Sensors

Drawing Manufacturer Cylinder Series Turck Sensor Turck Bracket

Tie Rod Style

KLZ* (Table 3)

T-Groove Style

Numatics A, E, S, L, B Square, VDMA-Z UNT Style KLZ Series Clamp

Parker P5E, HBT, LPM, (S, C, LP) UNT Style KLZ Series Clamp

PHD

Festo

Bimba

SMC ECQ2, MB, C95 UNT Style KLZ Series Clamp

Norgren A, EA, SS, N, J, EJ, 8000/M UNT Style KLZ Series Clamp

Turn-Act NFPA Series UNT Style KLZ Series Clamp

Fabco-Air

Parker P1M, P5T, SST UNT Style

A2, A3, AS, AV, AV2, A3V, AVS, HV, HV2, H3V, HVS, DAV, DHV, EA, EL, EH,

ES, NPG, NHG, NEAG, NEHG, TD, (A)

DNGU, DNGUL, DNGUT, DNU, DNUL, CRDNG, CRDNGS, DNG, DNGL,

DNGZK, DNGZL, DNGZS, DKE

Flat-I (FO, FOD, FOP, FOR, FOS, FS, FSD, FSR, FSS, F02, F03, F04),

Flat-II (FT, FST)

Long Stroke (321, 521, 721, 1221, S321, S521, S721, S1221),

Hi-Power (HP, THP, UHP),

Multi-Power (MP, BA, BP),

Linear Slide (SE, EZ, TS)

UNT Style KLZ Series Clamp

UNT Style KLZ Series Clamp

UNT Style KLZ Series Clamp

UNT Style KLZ Series Clamp

No Additional

Bracket Required

We reserve the right to make technical alterations without prior notice.

Festo

SMC CUJ, CXS, MGQ, MY1B, MHC, MHL2 UNT Style

1. When using KLZ Series Clamps, user must determine clamp size best suited for application.

2. These styles are usually not available with magnets.

3. Some of these may be equipped to handle 5, 8, or 12 mm inductive proximity sensors.

Part Number

KLZ1A-INT CLAMP .236 6.0

KLZ1M-UNT CLAMP .290 7.37

KLZ2M-UNT CLAMP .351 8.93

KLZ3M-UNT CLAMP .482 12.25

DNC, DNCT, DFM, DPZ, DPZJ, DZF, EZH,

ADVU, ADVULQ, ADVUL

UNT Sensor with KLZ* Mounting

Inches Millimeters

Table 3

UNT Style

Tie Rod Diameter Maximum

No Additional

Bracket Required

No Additional

Bracket Required

G3

Turck Inc.

Page 4

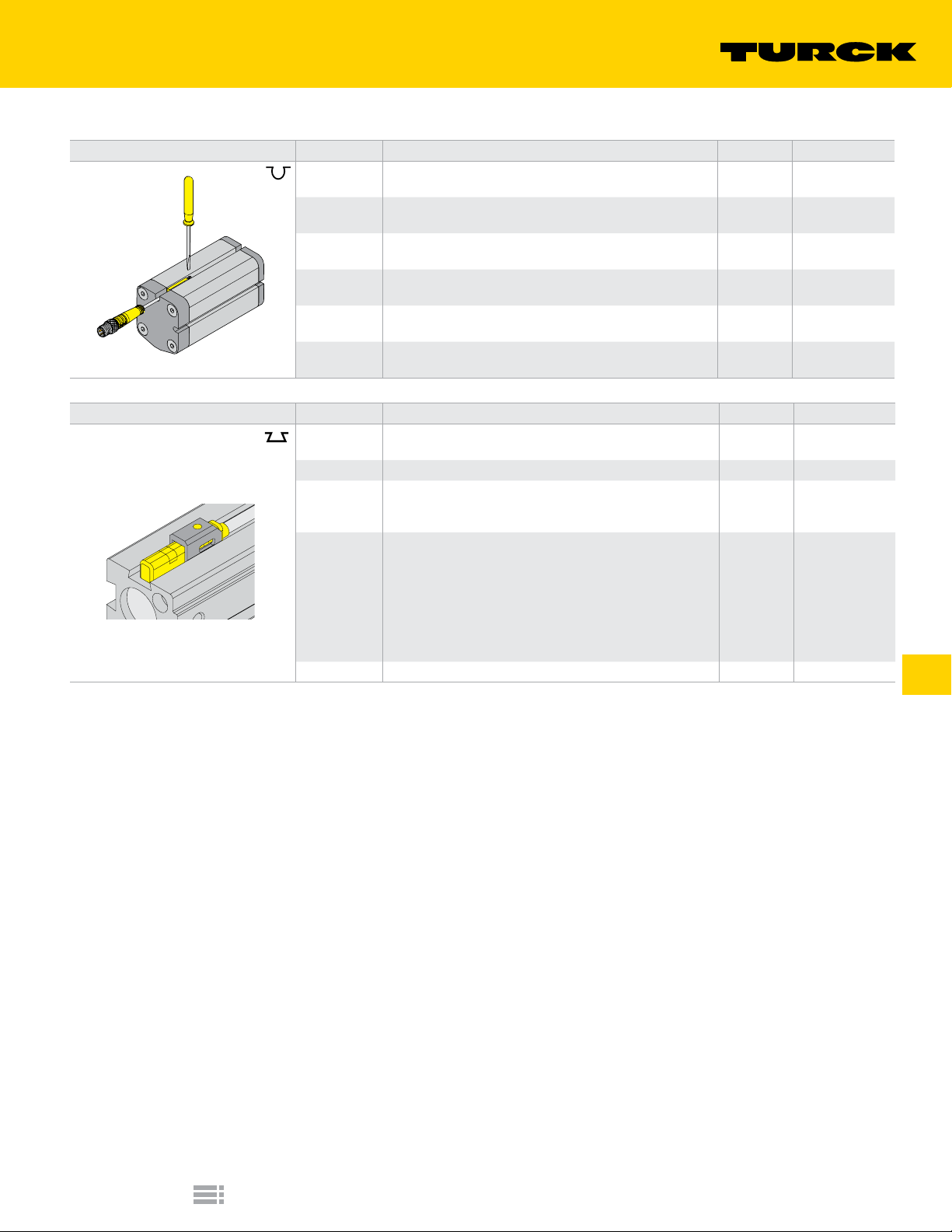

Cylinder Position Sensors

Drawing Manufacturer Cylinder Series Turck Sensor Turck Bracket

C-groove Style

Drawing Manufacturer Cylinder Series Turck Sensor Turck Bracket

Dovetail Style

Numatics K UNR Style

Festo ADVC UNR Style

Bimba

SMC

Compact Air B, C UNR Style

PHD

Numatics

Norgren 90000, 91000, 92000, 93000, Lite (A44000) UNT Style KLDT-UNT3

Fabco-Air

Compact Air

SMC CP95 UNT Style KLDT-UNT6

Twin Bore (TB, TBA, TBD), EF1 Series (EF, EFD, EFS, EFR), EF2 Series (EFT),

PneuMoment Series (PM)

(CQ2, CQs, NCDQ2, NCQ2), (CDQ2), CU, CUK, CUW, MU, MHF2, Air

Slides (MXQ)

CRH

O-groove

B,F, Compact C, Short Stroke, Rotary Actuator, Pee Wee (O, P, Q),

VDMA-V, Ring Series

Square 1 (SQ, SQF, SQL)

Pancake (X,XK, O, OP, XDR, XDRK, ODR)

Linear Slide1 (GB, L, S, E, SE, EZ, TS)

Inch Series (AB, AS, AR, AT)

Inch Series (B, R, S, T)

Ball Slide (BSC)

GC, CD, ACLA, ACLAD, (CLA, CLAD)

Metric Series (AWS, AWB, AWT)

Metric Series ( WS, WB, WT)

B/Base Mount, S/End Mount

R/ End Mount, (CSC, PSC, TCL)

UNR Style

UNR Style

UNR Style

UNT Style KLDT-UNT3

UNR Style KLFA-2UNR

UNT Style KLDT-UNT4

No Additional

Bracket Required

No Additional

Bracket Required

No Additional

Bracket Required

No Additional

Bracket Required

No Additional

Bracket Required

No Additional

Bracket Required

1. CQ2, NC(D) Q2, CQS, NCQ2 cylinders may have multiple grooves and may not be suited for the UNR style sensor.

2. This mounting is to be used only when dovetail style mounting rail is present on the cylinder.

3. These styles are usually not available with magnets.

We reserve the right to make technical alterations without prior notice.

4. This mounting is to be used only when sensor mounting rail is present on collet.

Cylinder Position Sensors

Turck Inc.

G4

Page 5

Cylinder Position Sensors

Drawing AKT Housing with KLA-1 Clamp

Cylinder Diameter

Rod Diameter

Clamp

Drawing AKT Housing with KLA-2 Clamp

Cylinder Diameter

Rod Diameter

Clamp

1.26 - 1.97 inches

32 - 50 mm

0.16 - 0.31 inches

4 - 8 mm

KLA-1

(Aluminum)

1.57 - 4.92 inches

40 - 125 mm

0.28 - 0.51 inches

7 - 13 mm

KLA-2

(Die-cast Zinc)

We reserve the right to make technical alterations without prior notice.

Drawing IKE, IKT, and IKM Housing with KLI-1 or KLI-3 Clamp

Cylinder Diameter

Rod Diameter

Clamp

Drawing IKE, IKT, and IKM Housing with KLI-5Z or KLI-6Z Clamp

Cylinder Diameter

Rod Diameter

Clamp

1.26 - 3.94 inches

32 - 100 mm

0.16 - 0.51 inches

4 - 13 mm

KLI-1

(Die-cast Zinc)

1.26 - 2.48 inches

32 - 63 mm

0.16 - 0.31 inches

4 - 8 mm

KLI-5Z

(Aluminum)

2.48 - 6.30 inches

63 - 160 mm

0.24 - 0.63 inches

6 - 16 mm

KLI-3

(Die-cast Zinc)

1.97 - 4.92 inches

50 - 125 mm

0.24 - 0.51 inches

6 - 13 mm

KLI-6Z

(Aluminum)

G5

Turck Inc.

Page 6

Cylinder Position Sensors

Drawing IKE, IKT, and IKM Housing with KLI-2 Clamp

Cylinder Diameter

Rod Diameter

Clamp

Drawing IKE, IKT, and IKM Housing with KLI-5 or KLI-6 Clamp

Cylinder Diameter

Rod Diameter

Clamp

1.26 - 3.94 inches

32 - 100 mm

0.35 - 0.79 inches

9 - 20 mm

KLI-2

(Die-cast Zinc)

1.26 - 1.97 inches

32 - 50 mm

0.31 - 0.55 inches

8 - 14 mm

KLI-5

(Aluminum)

1.97 - 3.94 inches

50 - 100 mm

0.43 - 0.75 inches

11 - 19 mm

KLI-6

(Aluminum)

Drawing IKE, IKT, and IKM Housing with KLI-CB64 or KLI-CB124 Clamp

Cylinder Diameter

We reserve the right to make technical alterations without prior notice.

Rod Diameter

Clamp

0.79 - 2.52 inches

20 - 64 mm

0.31 - 0.55 inches

8 - 14 mm

KLI-CB64

(Stainless Steel/Steel)

0.79 - 4.88 inches

20 - 124 mm

0.43 - 0.75 inches

11 - 19 mm

KLI-CB124

(Stainless Steel/Steel)

Cylinder Position Sensors

Drawing KST Housing with KST-SB170 and KST-SB335 Clamps

Cylinder Diameter

Strap

Mount

Screw Plate

0.31 - 0.99 inches

8 - 25 mm

KST-SB170

(Stainless Steel)

KST-MG

(Die-cast Zinc)

KST-SE

(Die-cast Zinc)

0.31 - 3.15 inches

8 - 80 mm

KST-SB335

(Stainless Steel)

Turck Inc.

G6

Page 7

Cylinder Position Sensors

Drawing PST Housing with KLP80-VA and KLP200-VA Clamps

Cylinder Diameter

Clamp

Drawing NST Housing with KLQ-1 or KLQ-2 Clamps

Cylinder Diameter

Cylinder

Manufacturer

Cylinder

Family

Clamp

0.31 - 3.15 inches

8 - 80 mm

KLP80-VA

(Stainless steel band,

brass nuts)

0.47 - 3.94 inches

12 - 100 mm

SMC

NCDQ2

SMC-325

(Anodized Aluminum)

3.15 - 7.87 inches

0 - 200 mm

KLP200-VA

(Stainless steel band,

brass nuts)

We reserve the right to make technical alterations without prior notice.

Drawing NST Housing with KLN-3 Clamp

Cylinder Diameter

Groove

Diameter

Clamp

*Accessory

0.47 - 3.94 inches

12 - 100 mm

0.20 - 0.53 (0.83) inches

5.2 - 13.5 (21)

KLN-3

(Anodized Aluminum)

Longer M5 x 35

set screw (A0050)

* mm

G7

Turck Inc.

Page 8

Cylinder Position Sensors

.290 [7.37]

.482 [12.25]

.351 [8.93]

UNT Mounting Clamps

KLDT-UNT2

KLRC-UNT2

Part Number “L” inches “L” mm UNT Housing with KLDT-UNT and ASB Style Strap

KLDT-UNT2 .276 7 Cylinder Diameter

KLDT-UNT3 .370 9.4 Inches Millimeters

(Stainless Steel)

KLDT-UNT4 .453 11.5 .276 - .433 7 - 11 ASB-1

KLDT-UNT5 .496 12.6 .433 - .748 11 - 19 ASB-2

KLDT-UNT6 .413 10.5 .709 - 1.142 18 - 29 ASB-3

KLDT-UNT7 .260 6.6 1.102 - 1.535 28 - 39 ASB-4

Note: For outside dimension of beveled ears add 1.6 mm to

bracket width listed.

1.496 - 1.929 38 - 49 ASB-5

1.890 - 2.323 48 - 59 ASB-6

Part Number Inches Millimeters

KLRC-UNT1 .315 - .984 8 - 25

KLRC-UNT2 .984 - 2.480 25 - 63

KLRC-UNT3 2.480 - 5.118 63 - 130

KLRC-UNT4 5.118 - 9.843 130 - 250

Clamp

KLZ1M-UNT CLAMP KLZ2M-UNT CLAMP KLZ3M-UNT CLAMP

We reserve the right to make technical alterations without prior notice.

APPROX.

1.575 [40.0]

APPROX.

1.575 [40.0]

APPROX.

1.575 [40.0]

KLZ1A-INT CLAMP

Cylinder Position Sensors

Turck Inc.

G8

Page 9

Cylinder Position Sensors

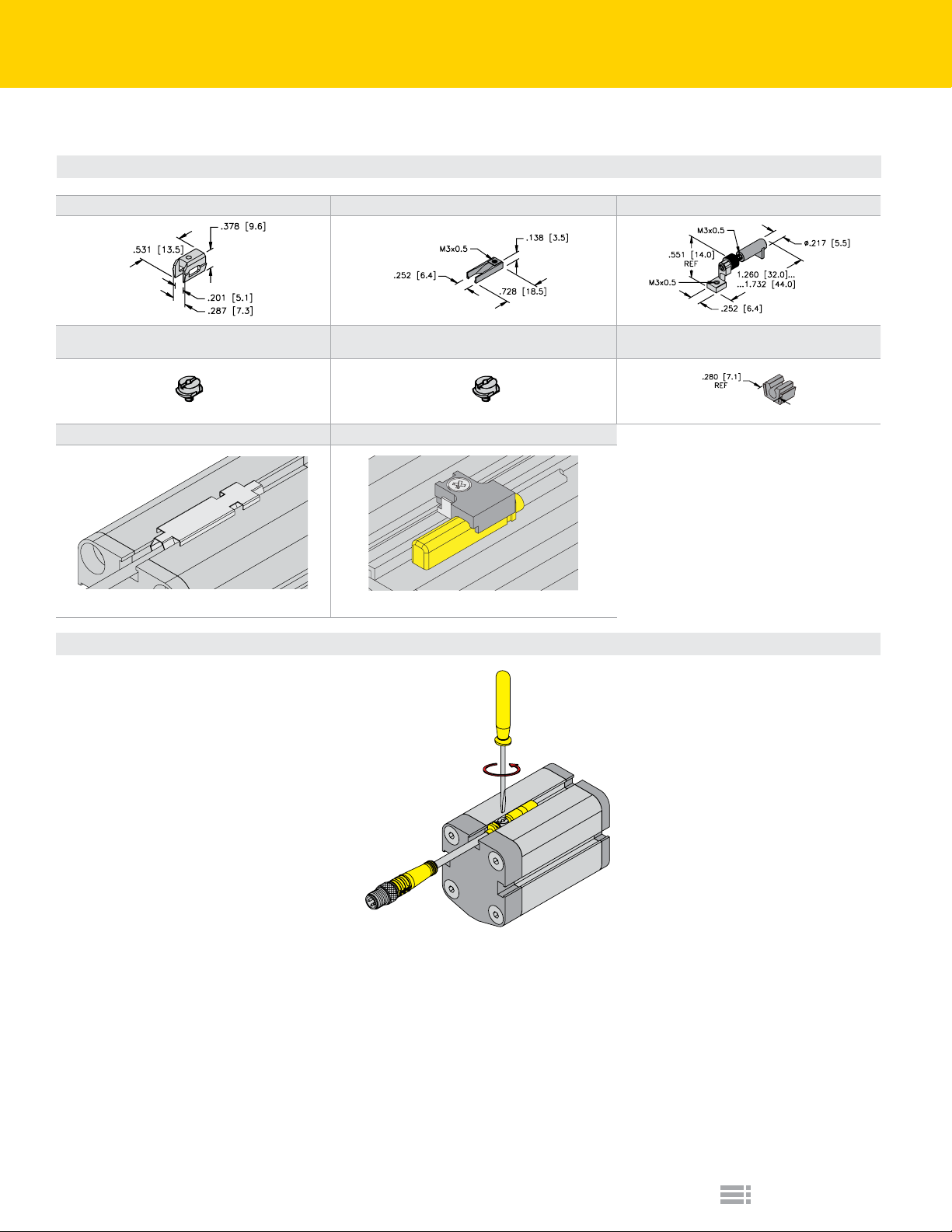

UNT Mounting Accessories

KLDT-UNT6 (6913355) UNT-Stopper (4685751) UNT-Adjusting Bracket (4685750)

UNT Mounting Screw, 2.5 mm

(6901056)

SG-UNT (A9800) KLT-UNT1 (6913377)

UNT Sensor Mounting

M2-BIM-UNT MTG SCRW. 1.5 mm

(6901050)

For use with SMC 325 Rail

UNT-Cable Clip

(6900456)

We reserve the right to make technical alterations without prior notice.

Note: Turn screw counter-clockwise to tighten.

G9

Turck Inc.

Page 10

Cylinder Position Sensors

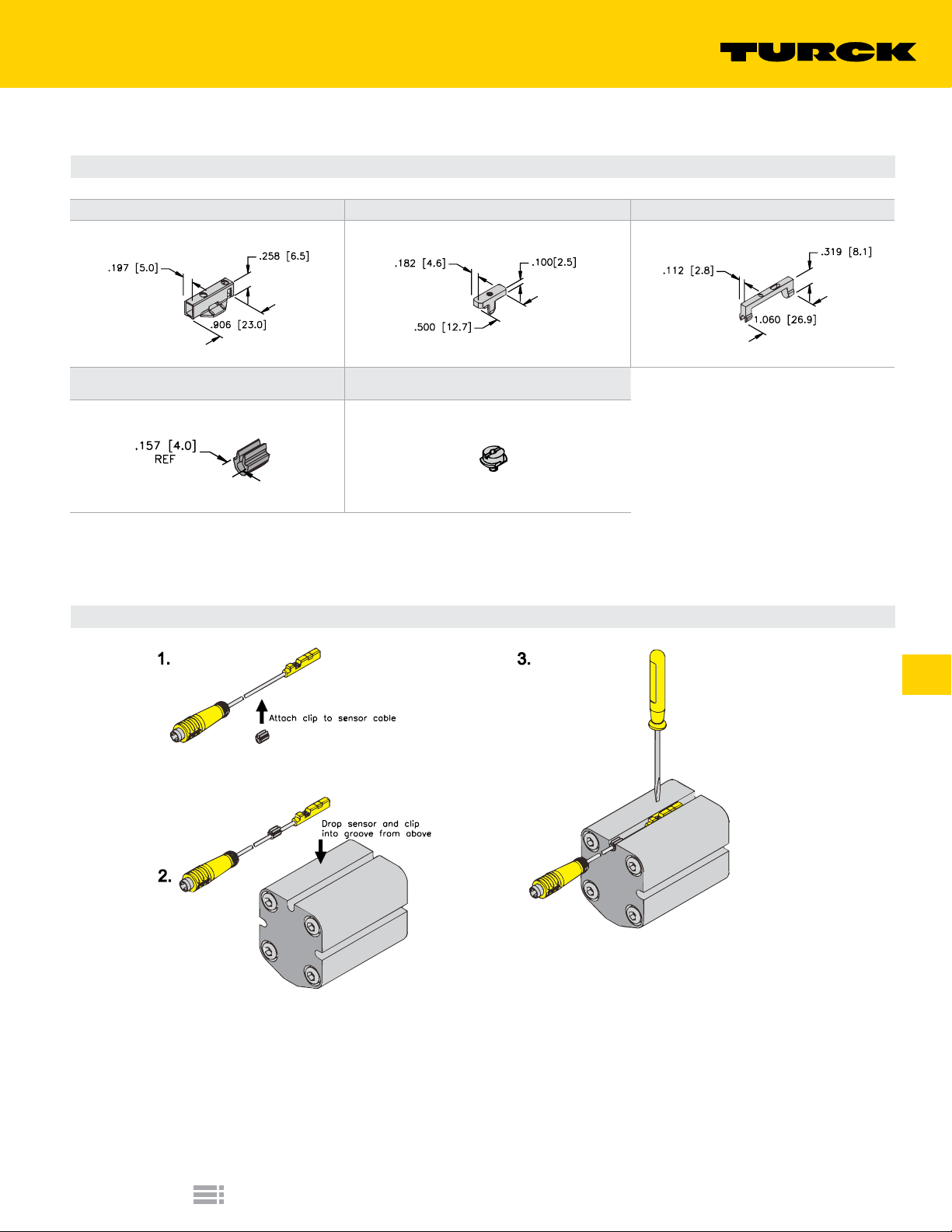

UNR Mounting Accessories

KLR-2 UNR KLFA-UNR KLTR-2 UNR

UNR Sensor Mounting

We reserve the right to make technical alterations without prior notice.

UNR Cable Clip

(6900428)

M1.6 BIM-UNR-MTG SCR. 1.3 mm

(6901055)

Note: Turn screw counter-clockwise to tighten. Use of mounting clip is optional.

Turck Inc.

Cylinder Position Sensors

G10

Page 11

Cylinder Position Sensors

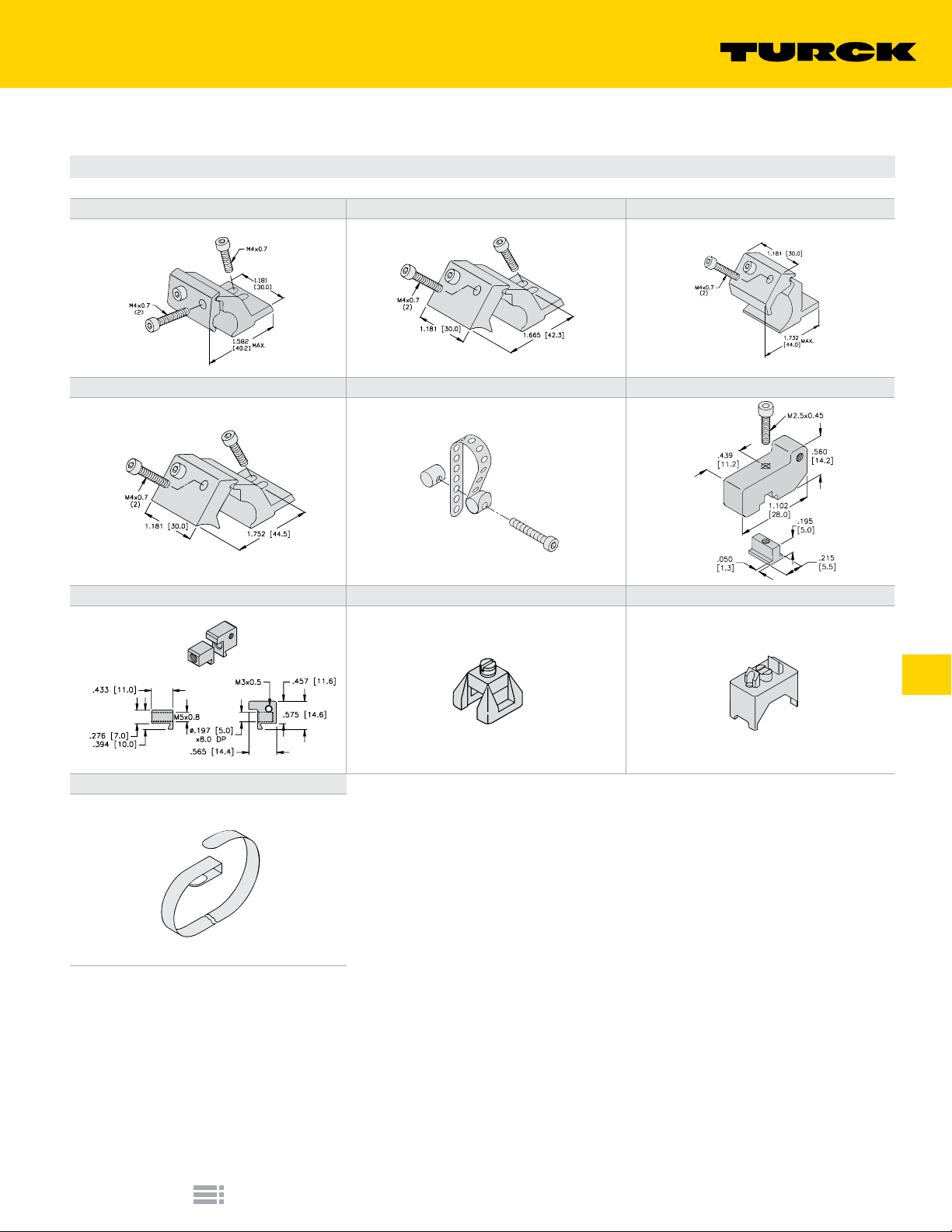

Mounting Clamps

KLA-1 KLA-3M KLA-2 KLI-1

KLI-3 KLI-2 KLI-CB64 and KLI-CB124

We reserve the right to make technical alterations without prior notice.

Mounting Brackets for Q25L Sensor

MB-Q21 MN-M5-Q25 MN-M4-Q25

Mounting Bracket Sliding block with M5 thread for the backside prole Sliding block with M4 thread for the backside prole

MB2.1-Q25 MB2.2-Q25 MB1-Q25

Mounting bracket for cylinders 40-60 mm Mounting bracket for cylinders 70-120 mm Mounting Clip

G11

Turck Inc.

Page 12

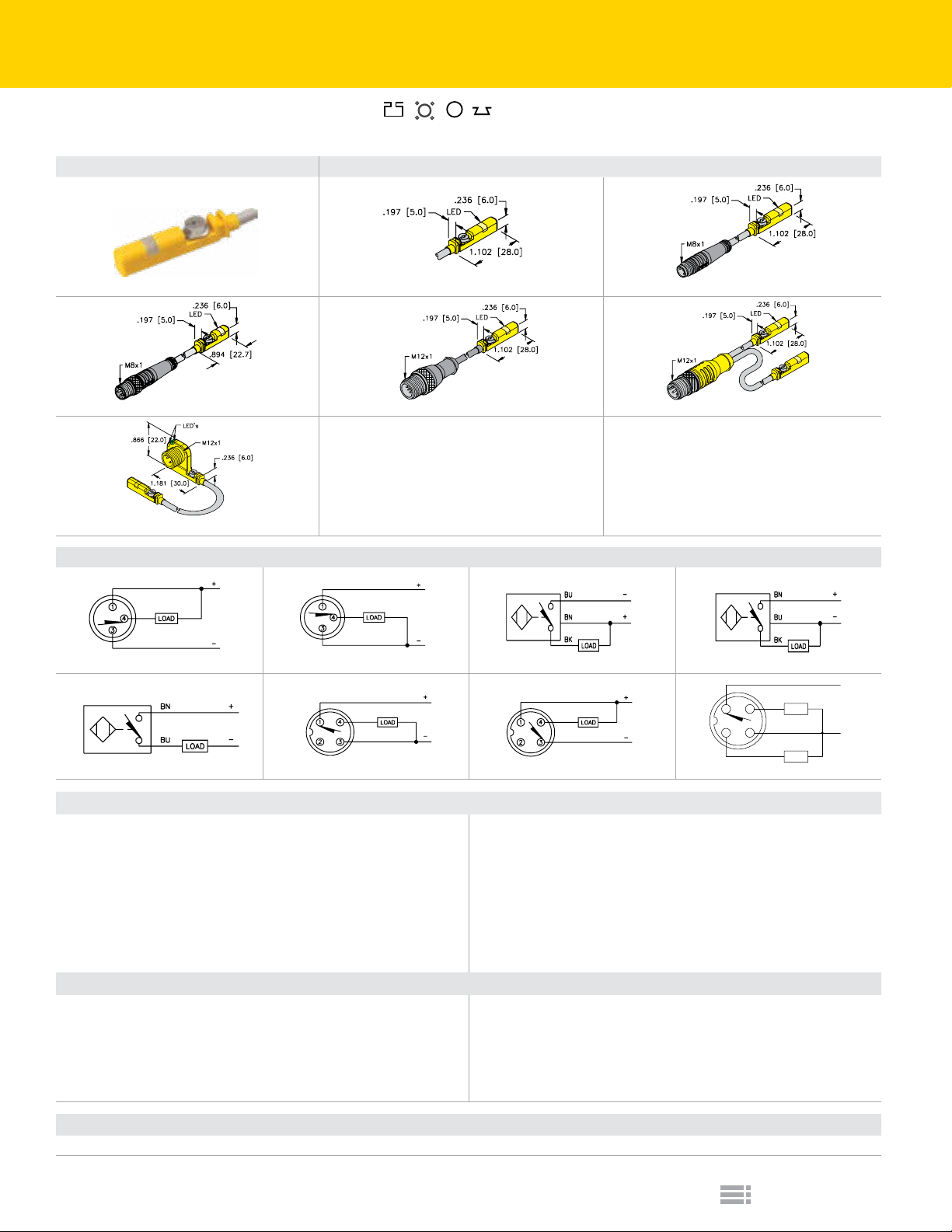

Cylinder Position Sensors

Mounting Clamps

KLI-5 KLI-5Z KLI-6

KLI-6Z KLP 80-VA and KLP 200-VA SMC-325

KLN-3 KST-SE (46736) KST-MG (46735)

We reserve the right to make technical alterations without prior notice.

KST-SB170 and KST-SB335

Cylinder Position Sensors

Turck Inc.

G12

Page 13

+

Cylinder Position Sensors | BIM-UNT

T-groove, C-groove, Tie-rod, and Round Cylinder Style

Housing Style Dimension Drawings

A

B

C

UNT - Picofast Quick Disconnect

F

UNT - Eurofast Quick Disconnect

1

Mating Cordset: PKG 3Z-*

5 6

D

UNT - Eurofast® Quick Disconnect

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: PKG 3Z-*; PKG 3M-*

Mating Cordset: RK 4T-*

UNT - Potted-In Cable

3 4

7

E

Mating Cordset: RK 4T-*

UNT - Picofast®Quick Disconnect

UNT - EurofastQuick Disconnect

8

S1

1 4

2

Mating Cordset: RK 4.4T-*; RKC 4.4T-*

LOAD

3

S2

LOAD

We reserve the right to make technical alterations without prior notice.

-

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

A14

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Pass Speed:

G13

Turck Inc.

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

2-wire DC - Magnetic (AD, AG)

≤10%

≤1 mm

Non-Polarized (AD) ≤4 V

Polarized (AG) ≤3.5 V

≥120 mA

≤3 ms, ≤10 ms (UNT)

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Off-State (Leakage) Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

≤0.8 mA

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm

Page 14

Cylinder Position Sensors | BIM-UNT

T-groove, C-groove, Tie-rod, and Round Cylinder Style

Part Number/

ID Number

BIM-UNT-AN6X

4685702

BIM-UNT-AP6X

4685741

BIM-UNT-AG41X/S1139/S1160

4685766

BIM-UNT-AN6X-0.3-PSG3S

4685705

BIM-UNT-AP6X-0.3-PSG3S

4685722

BIM-UNT-AP6X-0.3-PSG3M

4685723

BIM-UNT-AP6X-0.3-RS4T

46857260

BIM-UNT-AN6X-0.3-RS4T

4685792

BIM-UNT-0.3-UNT-2AP6X3-H1141

4685730

BIM-UNT-AP6X/S991

4685728

BIM-UNT-2AP6X-0.2-RSC4.4T

4685891

Features

Irradiated TPU Cable,

Wider Range

Fixed Coupling Nut

Fixed Coupling Nut

Rotating Coupling Nut

Dual Switch

Radial Magnetic Fields

Dual Switch

Output

3-wire DC,

NPN

3-wire DC,

PNP

2-wire DC

3-wire DC,

NPN

3-wire DC,

PNP

3-wire DC,

PNP

3-wire DC,

PNP

3-wire DC,

NPN

4-wire DC,

PNP

3-wire DC,

PNP

4-wire DC,

PNP

10-30

VDC

10-30

VDC

10-55

VDC

10-30

VDC

10-30

VDC

10-30

VDC

10-30

VDC

10-30

VDC

10-30

VDC

10-30

VDC

10-30

VDC

Voltage

Switching Freq. (Hz)

Operating Current (mA)

1000 ≤ 200 -25 to +70 IP67 PA 12 2M/TPU A 3 A13

1000 ≤ 200 -25 to +70 IP67 PA 12 2M/TPU A 4 A13

300 ≤ 100 -25 to +70 IP67 PA 12 2M/TPU A 5 A14

1000 ≤ 200 -25 to +70 IP67 PA 12 0.3M/TPU B 1 A13

1000 ≤ 200 -25 to +70 IP67 PA 12 0.3M/TPU B 2 A13

1000 ≤ 200 -25 to +70 IP67 PA 12 0.3M/TPU C 2 A13

1000 ≤ 200 -25 to +70 IP67 PA 12 0.3M/TPU D 6 A13

1000 ≤ 200 -25 to +70 IP67 PA 12 0.3M/TPU D 7 A13

1000 ≤ 150 -25 to +70 IP67 PP 0.3M/TPU F 8 A13

1000 ≤ 150 -25 to +70 IP67 PP 2M/TPU B 4 A13

1000 ≤ 150 -25 to +70 IP67 PP 0.2M/TPU E 8 A13

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G14

Page 15

Cylinder Position Sensors | BIM-UNTK

T-groove Short Cylinder Style

Housing Style Dimension Drawings

B

A

UNTK - Picofast Quick Disconnect

C

UNTK - EurofastQuick Disconnect

1

Mating Cordset: PKG 3Z-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

A17

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

Power-On Effect:

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: RK 4T-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

3-wire DC - Magnetic w/o Short Circuit Protection (AP7)

≤10%

≤1 mm

≤1.4 V

No

≤0.1 mA

≤10 mA;

≤3 ms

Per IEC 947-5-2

UNTK - Potted-In Cable

3 4

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

We reserve the right to make technical alterations without prior notice.

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

Incorporated

Incorporated

Per EN 60947-5-2

≤0.3 mm

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.3 mm

G15

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Turck Inc.

Page 16

Cylinder Position Sensors | BIM-UNTK

T-groove Short Cylinder Style

Part Number/

ID Number

BIM-UNTK-AP7X-0.3-PSG3M

4686011

BIM-UNTK-AP7X-0.3-RS4T

4686021

BIM-UNTK-AP7X

4686001

BIM-UNTK-AP6X

4686005

BIM-UNTK-AN6X

4686006

Features

Short Body 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU A 1 A17

Short Body 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU B 2 A17

Short Body 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 2M TPU C 3 A17

short Body 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP68 PP 2M TPU C 3 A13

Short Body 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP69 PP 2M TPU C 4 A13

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G16

Page 17

Cylinder Position Sensors | BR-INT

T-groove Cylinder Style or Universal Mount with Brackets

Housing Style Dimension Drawings

1

A3

Ripple:

Differential Travel (Hysteresis):

Maximum Switching Capacity:

Off-State (Leakage) Current:

Pass Speed:

Power-On Effect:

Transient Protection:

≤10%

≤1 mm (Depends on magnet)

≤10 W

0 mA

≤10 m/s

Per IEC 947-5-2

Per EN 60947-5-2

A

Wiring Diagrams/Mating Cordsets

2-wire Reed AC and DC (ADZ71)

INT - Picofast Potted-In Cable

Reverse Polarity Protection:

Shock:

Vibration:

Repeatability:

Temperature Drift:

Voltage Drop:

We reserve the right to make technical alterations without prior notice.

Yes

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥±0.1 mm

(constant temperature & voltage)

≤0.1 mm

≤0.5 V

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

G17

Turck Inc.

Page 18

Cylinder Position Sensors | BR-INT

T-groove Cylinder Style or Universal Mount with Brackets

Part Number/

ID Number

BR-INT-ADZ71X

4700510

Features

Reed Contact 2-wire AC/DC, Reed Contact 3-140 VAC/4-200 VDC 500 ≤ 500 -25 to +70 IP67 PA 12 2M/PVC A 1 A3

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G18

Page 19

Cylinder Position Sensors | BIM-UNR

+

C-groove Cylinder Style

Housing Style Dimension Drawings

A

B

UNR - Picofast Quick Disconnect

C

UNR - Eurofast Quick Disconnect

1

Mating Cordset: PKG 3Z-*

2

D

UNR - Eurofast Quick Disconnect

Wiring Diagrams/Mating Cordsets

Mating Cordset: PKG 3Z-*

5 6 7

3

Mating Cordset: RK 4T-*

1 4

2

3

Mating Cordset: RKC 4.4T-*

UNR - Potted-In Cable

We reserve the right to make technical alterations without prior notice.

4

Mating Cordset: RK 4T-*

S1

LOAD

-

S2

LOAD

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

G19

Turck Inc.

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

Page 20

Cylinder Position Sensors | BIM-UNR

C-groove Cylinder Style

Part Number/

ID Number

BIM-UNR-AN6X-0.3-PSG3S W/M

4685848

BIM-UNR-AP6X-0.3-PSG3S W/M

4685843

BIM-UNR-AN6X-0.3-RS4 W/M

4685850

BIM-UNR-AP6X-0.3-RS4 W/M

4685845

BIM-UNR-AN6X W/M

4685847

BIM-UNR-AP6X W/M

4685842

BIM-UNR-2AP6X-0.2-RSC4.4T

4685899

Features

Fixed Coupling Nut 3-wire DC, NPN 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU A 1 A13

Fixed Coupling Nut 3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU A 2 A13

Dual Switch 4-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.2M/TPU D 7 A13

Output

3-wire DC, NPN 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU C 3 A13

3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 0.3M/TPU C 4 A13

3-wire DC, NPN 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 2M/TPU B 5 A13

3-wire DC, PNP 10-30 VDC 300 ≤ 100 -25 to +70 IP67 PP 2M/TPU B 6 A13

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G20

Page 21

Cylinder Position Sensors | BIM-PST

Round Cylinder Style

Housing Style Dimension Drawings

A

B

1

Mating Cordset: PKG 3Z-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

PST - Picofast Quick Disconnect

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: PKG 3Z-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

Magnetic Actuation Strength (Gauss): 20-350

3 4

Additional Specications

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

PST - Potted-In Cable

We reserve the right to make technical alterations without prior notice.

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

G21

Turck Inc.

Page 22

Cylinder Position Sensors | BIM-PST

Round Cylinder Style

Part Number/

ID Number

BIM-PST-AN6X-V1131 W/KLP-80

4625190

BIM-PST-AP6X-V1131 W/KLP-80

4625090

BIM-PST-AN6X W/KLP-80

4624191

BIM-PST-AP6X W/KLP-80

4624090

Features

KLP-80 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- A 1 A13

KLP-80 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- A 2 A13

KLP-80 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 2M/PVC B 3 A13

KLP-80 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 2M/PVC B 4 A13

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G22

Page 23

Cylinder Position Sensors | BIM-KST

Round Cylinder Style

Housing Style Dimension Drawings

A

B

1

Mating Cordset: PKG 3Z-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

KST - Picofast Quick Disconnect

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: PKG 3Z-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

Magnetic Actuation Strength (Gauss): 20-350

3 4

Additional Specications

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

KST - Potted-In Cable

We reserve the right to make technical alterations without prior notice.

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

G23

Turck Inc.

Page 24

Cylinder Position Sensors | BIM-KST

Round Cylinder Style

Part Number/

ID Number

BIM-KST-AN6X-V1131

46743

BIM-KST-AP6X-V1131

46742

BIM-KST-AN6X

46741

BIM-KST-AP6X

46740

Features

KST SB170 and KST SB335

Straps Included

KST SB170 and KST SB335

Straps Included

KST SB170 and KST SB335

Straps Included

KST SB170 and KST SB335

Straps Included

Output

3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- A 1 A13

3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- A 2 A13

3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc

3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

2M/

PVC

2M/

PVC

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

B 3 A13

B 4 A13

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G24

Page 25

Cylinder Position Sensors | BIM-AKT

Tie-rod Cylinder Style

Housing Style Dimension Drawings

A

B

1

Mating Cordset: RK 4.2T-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

A14

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Pass Speed:

AKT - Eurofast Connector

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: RK 4T-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

≤10%

≤1 mm

Non-Polarized (AD) ≤4 V

Polarized (AG) ≤3.5 V

≥120 mA

≤3 ms, ≤10 ms (UNT)

3 4

2-wire DC - Magnetic (AD, AG)

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Off-State (Leakage) Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

AKT - Potted-In Cable

We reserve the right to make technical alterations without prior notice.

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

≤0.8 mA

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm

G25

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Turck Inc.

Page 26

Cylinder Position Sensors | BIM-AKT

Tie-rod Cylinder Style

Part Number/

ID Number

BIM-AKT-AD4X-H1141 W/KLA-1

4480290

BIM-AKT-AP6X-H1141 W/KLA-1

4675290

BIM-AKT-AD4X W/KLA-1

4480090

BIM-AKT-AP6X W/KLA-1

4675090

Features

KLA-1 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 PA 12 -- A 1 A14

KLA-1 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- A 2 A13

KLA-1 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 PA 12 2M/PVC B 3 A14

KLA-1 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 2M/PVC B 4 A13

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G26

Page 27

Cylinder Position Sensors | BIM-IKE/IKT

Tie-rod Cylinder Style

Housing Style Dimension Drawings

B

A

IKE/IKT - Potted-In Cable

C

We reserve the right to make technical alterations without prior notice.

IKE/IKT - Picofast Quick Disconnect

Wiring Diagrams/Mating Cordsets

IKE/IKT - Eurofast Quick Disconnect

1 2 3 4

5

Mating Cordset: PKG 3Z-*

A13

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

A14

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Pass Speed:

Ripple:

Ripple:

6

Mating Cordset: RK 4.2T-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

≤10%

≤1 mm

Non-Polarized (AD) ≤4 V

Polarized (AG) ≤3.5 V

≥120 mA

≤3 ms, ≤10 ms (UNT)

7

Mating Cordset: RK 4T-*

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

2-wire DC - Magnetic (AD, AG)

Off-State (Leakage) Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

Mating Cordset: PKG 3Z-*

8

Mating Cordset: RK 4T-*

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

≤0.8 mA

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm

G27

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Turck Inc.

Page 28

Cylinder Position Sensors | BIM-IKE/IKT

Tie-rod Cylinder Style

Part Number/

ID Number

BIM-IKE-AD4X W/KLI-3

4421490

BIM-IKT-AD4X W/KLI-3

4482090

BIM-IKE-AN6X W/KLI-3

4621590

BIM-IKT-AN6X W/KLI-3

4620190

BIM-IKE-AP6X W/KLI-3

4621490

BIM-IKT-AP6X W/KLI-3

4620090

BIM-IKE-AN6X-V1131 W/KLI-3

4621795

BIM-IKT-AN6X-V1131 W/KLI-3

4622195

BIM-IKE-AP6X-V1131 W/KLI-3

4621695

BIM-IKT-AP6X-V1131 W/KLI-3

4622095

BIM-IKE-AD4X-H1141 W/KLI-3

4421690

BIM-IKT-AD4X-H1141 W/KLI-3

4482290

BIM-IKE-AN6X-H1141 W/KLI-3

4621790

BIM-IKT-AN6X-H1141 W/KLI-3

We reserve the right to make technical alterations without prior notice.

4621190

BIM-IKE-AP6X-H1141 W/KLI-3

4621690

BIM-IKT-AP6X-H1141 W/KLI-3

4621090

Features

KLI-3 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 Zinc 2M/PVC A 1 A14

KLI-3 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 Zinc 2M/PVC A 1 A14

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc 2M/PVC A 2 A13

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc 2M/PVC A 2 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc 2M/PVC A 3 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc 2M/PVC A 3 A13

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- B 4 A13

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- B 4 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- B 5 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- B 5 A13

KLI-3 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 Zinc -- C 6 A14

KLI-3 Included 2-wire DC 10-65 VDC 300 ≤ 100 -25 to +70 IP67 Zinc -- C 6 A14

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- C 7 A13

KLI-3 Included 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- C 7 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- C 8 A13

KLI-3 Included 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 Zinc -- C 8 A13

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

Turck Inc.

Cylinder Position Sensors

G28

Page 29

Cylinder Position Sensors | BIM-IKM

Tie-rod Cylinder Style

Housing Style Dimension Drawings

B

A

IKM - Eurofast Connector

C

IKM - Microfast® Connector

1

Mating Cordset: RK 4T-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

A15

Line Frequency:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Continuous Load Current:

Off-State (Leakage) Current:

Minimum Load Current:

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: KB 3T-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

2-wire AC w/o Short-Circuit Protection - Magnetic (AZ)

≥50... ≤60 Hz

≤1 mm

≤6.0 V

AC: ≤500 mA

≤1.7 mA

≥5.0 mA

IKM - Potted-In Cable

3

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Pass Speed:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

We reserve the right to make technical alterations without prior notice.

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

≤1 ms

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≥± 0.1 mm

G29

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Turck Inc.

Page 30

Cylinder Position Sensors | BIM-IKM

Tie-rod Cylinder Style

Part Number/

ID Number

BIM-IKM-AP6X2-H1141/S34W/KLI-3

4627290

BIM-IKM-AZ3X2-B3131 W/KLI-3

1347190

BIM-IKM-AZ3X2 W/KLI-3

1347290

Features

KLI-3 Included, WFI 3-wire DC, PNP 10-30 VDC 20 ≤ 200 -25 to +70 IP67 Zinc -- A 1 A13

KLI-3 Included 2-wire AC 20-250 VAC 20 ≤ 500 -25 to +70 IP67 Zinc -- B 2 A15

KLI-3 Included 2-wire AC 20-250 VAC 20 ≤ 500 -25 to +70 IP67 Zinc 2M/PVC C 3 A15

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G30

Page 31

Cylinder Position Sensors | BIM-NST

T-groove or Slot Style

Housing Style Dimension Drawings

B

A

NST - Picofast Connector

C

NST - Picofast Connector

1

Mating Cordset: PKG 3Z-*

A13

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

Pass Speed:

Wiring Diagrams/Mating Cordsets

2

Mating Cordset: RK 4T-*

3-wire DC - Magnetic (AN, RN, AP, RP)

≤10%

≤1 mm

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA;

≤10 ms; ≤3 ms (UNR)

Magnetic Actuation Strength (Gauss): 20-350

3

Additional Specications

Mating Cordset: RK 4T-*

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Repeatability:

NST - Potted-In Cable

4

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤0.1 mm, ≤0.3 mm (UNR)

Shock:

Vibration:

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm, ≥± 0.3 mm (UNR)

We reserve the right to make technical alterations without prior notice.

G31

Turck Inc.

Page 32

Cylinder Position Sensors | BIM-NST

T-groove or Slot Style

Part Number/

ID Number

BIM-NST-AP6X-V1131

4685800

BIM-NST-AN6X-H1141

4685500

BIM-NST-AP6X-H1141/S34

4685401

BIM-NST-AP6X-H1141

4685400

BIM-NST-AP6X

4685600

Features

w/o Bracket 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- A 1 A13

w/o Bracket 3-wire DC, NPN 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- B 2 A13

w/o Bracket, WFI 3-wire DC, PNP 10-30 VDC 20 ≤ 200 -25 to +70 IP67 PA 12 -- B 3 A13

w/o Bracket 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 -- B 3 A13

w/o Bracket 3-wire DC, PNP 10-30 VDC 1000 ≤ 200 -25 to +70 IP67 PA 12 2M/PVC C 4 A13

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G32

Page 33

Cylinder Position Sensors | CRS

In-Cylinder Position Sensors

Housing Style Dimension Drawings

1

A

Wiring Diagrams/Mating Cordsets

2

CRS - Eurofast Connector

We reserve the right to make technical alterations without prior notice.

Mating Cordset: RK 4T-*

A4

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

3 and 4-wire DC - (AN, RN, AP, RP, VN, VP)

≤10%

3-15% (5% typical)

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA (Ferrite, Uprox)

≤20 mA (Uprox+, Uprox 3)

Mating Cordset: RK 4T-*

Time Delay Before Availability:

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

≤8 ms

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤±10%

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≤2% of Rated Operating Distance

G33

Turck Inc.

Page 34

Cylinder Position Sensors | CRS

In-Cylinder Position Sensors

Part Number/

ID Number

Bi2-CRS260-AN4X2-H1141/S34

4580004

Bi2-CRS317-AN4X2-H1141/S34

4580093

Bi2-CRS343-AN4X2-H1141/S34

4571890

Bi2-CRS524-AN4X2-H1141/S34

4568096

Bi2-CRS232-AP4X2-H1141/S34

4570492

Bi2-CRS260-AP4X2-H1141/S34

4570890

Bi2-CRS287-AP4X2-H1141/S34

4571290

Bi2-CRS317-AP4X2-H1141/S34

4571690

Bi2-CRS343-AP4X2-H1141/S34

4571800

Bi2-CRS476-AP4X2-H1141/S34

4580091

Bi2-CRS524-AP4X2-H1141/S34

4580090

Bi2-CRS603-AP4X2-H1141/S34

4580096

Bi2-CRS705-AP4X2-H1141/S34

4580089

Bi2-CRS730-AP4X2-H1141/S34

We reserve the right to make technical alterations without prior notice.

4580003

Bi2-CRS959-AP4X2-H1141/S34

4571891

Bi2-CRS1159-AP4X2-H1141/S34

4570899

Bi1.5-CRS524C-AP6X2-H1141

4279091

Bi1.5-CRS260C-AP6X2-H1141

4279092

Features

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

WFI; 1,500 PSI

Operating

High Pressure; 3,000

PSI Operating

High Pressure; 3,000

PSI Operating

Output

3-wire DC, NPN 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 1 A4

3-wire DC, NPN 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 1 A4

3-wire DC, NPN 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 1 A4

3-wire DC, NPN 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 1 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-65 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-30 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

3-wire DC, PNP 10-30 VDC 30 ≤ 200 -25 to +70 IP67 Zinc A 2 A4

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Dimension Drawings

Wiring Diagrams

Spec List

Cylinder Position Sensors

Bi *-CRS-XXXX-.. = Length of probe in mm. Example: CRS260 = 26.0 mm

Turck Inc.

G34

Page 35

Cylinder Position Sensors | CRS

In-Cylinder Position Sensors

Housing Style Dimension Drawings

B

A

CRS - Microfast Connector

We reserve the right to make technical alterations without prior notice.

CRS - Minifast® Connector

1

Mating Cordset: KB 3T-*

A5

Line Frequency:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Continuous Load Current:

Off-State (Leakage) Current:

Wiring Diagrams/Mating Cordsets

2

2-wire AC/DC w/ Short-Circuit Protection - (ADZ, RDZ, FDZ, VDZ)

≥50... ≤60 Hz

3-15% (5% typical)

≤6.0 V

AC: ≥440 mA; DC: ≥330 mA

AC: ≥120 mA; DC: ≥120 mA

AC: ≤400 mA; DC: ≤300 mA

AC: ≤100 mA; DC: ≤100 mA

≤1.7 mA (AC)

≤1.5 mA (DC)

Mating Cordset: RKM 311-*M

Minimum Load Current:

Inrush Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

≥3.0 mA

≤3 A (≤20 ms, max 5 Hz)

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤2% of Rated Operating Distance

G35

Turck Inc.

Page 36

Cylinder Position Sensors | CRS

In-Cylinder Position Sensors

Part Number/

ID Number

Bi2-CRS232-ADZ30X2-B3131/S34

4275093

Bi2-CRS260-ADZ30X2-B3131/S34

4275493

Bi2-CRS317-ADZ30X2-B3131/S34

4276293

Bi2-CRS476-ADZ30X2-B3131/S34

4276693

Bi2-CRS524-ADZ30X2-B3131/S34

4277093

Bi2-CRS730-ADZ30X2-B3131/S34

4278293

Bi2-CRS959-ADZ30X2-B3131/S34

4279093

Bi2-CRS1159-ADZ30X2-B3131/S34

4279493

Bi2-CRS232-ADZ30X2-B1131/S34

4270093

Bi2-CRS260-ADZ30X2-B1131/S34

4270493

Bi2-CRS317-ADZ30X2-B1131/S34

4271293

Bi2-CRS343-ADZ30X2-B1131/S34

4271493

Bi2-CRS476-ADZ30X2-B1131/S34

4271693

Bi2-CRS524-ADZ30X2-B1131/S34

4272093

We reserve the right to make technical alterations without prior notice.

Bi2-CRS603-ADZ30X2-B1131/S34

4272493

Bi2-CRS705-ADZ30X2-B1131/S34

4272893

Bi2-CRS730-ADZ30X2-B1131/S34

4273293

Bi2-CRS959-ADZ30X2-B1131/S34

4274093

Bi2-CRS1159-ADZ30X2-B1131/S34

4274493

Bi1.5-CRS959C-ADZ30X2-B1131

4279094

Bi1.5-CRS730C-ADZ30X2-B1131

4279095

Bi1.5-CRS260C-ADZ30X2-B1131

4279096

Bi1.5-CRS232C-ADZ30X2-B1131

4279097

Bi1.5-CRS524C-ADZ30X2-B1131

4279098

Bi1.5-CRS317C-ADZ30X2-B1131

4279099

Features

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

WFI; 1,500 PSI Operating 2-wire AC/DC

High Pressure; 3,000 PSI

Operating

High Pressure; 3,000 PSI

Operating

High Pressure; 3,000 PSI

Operating

High Pressure; 3,000 PSI

Operating

High Pressure; 3,000 PSI

Operating

High Pressure; 3,000 PSI

Operating

Output

2-wire AC/DC

2-wire AC/DC

2-wire AC/DC

2-wire AC/DC

2-wire AC/DC

2-wire AC/DC

Voltage

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

20-250 VAC/10-

300 VDC

Switching Freq. (Hz)

Operating Current

(mA)

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc A 1 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

20 ≤ 400/300 -25 to +70 IP67 Zinc B 2 A5

Operating Temp. (°C)

Protection

Housing

Dimension Drawings

Wiring Diagrams

Spec List

Cylinder Position Sensors

Bi *-CRS-XXXX-.. = Length of probe in mm. Example: CRS260 = 26.0 mm

Turck Inc.

G36

Page 37

+

+

Cylinder Position Sensors | Q6.5

Power Clamp Position Sensors

Housing Style Dimension Drawings

B

A

Q6.5 - Eurofast Connector

C

We reserve the right to make technical alterations without prior notice.

Q6.5 - Microfast Connector

1

1

2

LOAD

3

S2

LOAD

S1

4

Mating Cordset: RK 4.4T-*

A4

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

A5

Line Frequency:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Continuous Load Current:

Off-State (Leakage) Current:

2

-

≤10%

3-15% (5% typical)

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA (Ferrite, Uprox)

≤20 mA (Uprox+, Uprox 3)

2-wire AC/DC w/ Short-Circuit Protection - (ADZ, RDZ, FDZ, VDZ)

≥50... ≤60 Hz

3-15% (5% typical)

≤6.0 V

AC: ≥440 mA; DC: ≥330 mA

AC: ≥120 mA; DC: ≥120 mA

AC: ≤400 mA; DC: ≤300 mA

AC: ≤100 mA; DC: ≤100 mA

≤1.7 mA (AC)

≤1.5 mA (DC)

Wiring Diagrams/Mating Cordsets

1 4

2

S1

LOAD

3

S2

-

LOAD

Mating Cordset: RK 4.4T-*

3 and 4-wire DC - (AN, RN, AP, RP, VN, VP)

Time Delay Before Availability:

Reverse Polarity Protection:

Minimum Load Current:

Q6.5 - Eurofast Connector

3

Power-On Effect:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Inrush Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

Mating Cordset: KB 5T-*

≤8 ms

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤±10%

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≤2% of Rated Operating Distance

≥3.0 mA

≤3 A (≤20 ms, max 5 Hz)

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤2% of Rated Operating Distance

G37

Turck Inc.

Page 38

Cylinder Position Sensors | Q6.5

Power Clamp Position Sensors

Part Number/

ID Number

Ni2-Q6.5-AN6-0.1-FS4.4X3/S304

1650079

Ni2-Q6.5-AN6-0.16-FS4.4X3/S304

1650085

Ni2-Q6.5-AP6-0.1-FS4.4X3/S304

1650048

Ni2-Q6.5-AP6-0.16-FS4.4X3/S304

1650086

Ni2-Q6.5-AP6-0.2-FS4.4X3/S304

1650047

Ni2-Q6.5-0.1-BDS-2AP6X3-H1141/S34

1650098

Ni2-Q6.5-0.16-BDS-2AP6X3-H1141/S34

1650110

Ni2-Q6.5-ADZ32-0.1-FSB5.4X4/S304

4200204

Ni2-Q6.5-ADZ32-0.16-FS 5.4X4/S304

4200203

Features

WFI 4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.1M/TPU C 2 A4

WFI 4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.16M/TPU C 2 A4

Output

4-wire DC, NPN 10-30 VDC 30 ≤ 500 -25 to +70 IP67 PBT 0.1M/TPU A 1 A4

4-wire DC, NPN 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.16M/TPU A 1 A4

4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.1M/TPU A 2 A4

4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.16M/TPU A 2 A4

4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.2M/TPU A 2 A4

4-wire, VAC/DC 20-250 VAC/10-300 VDC 30 ≤ 100 -25 to +70 IP67 PBT 0.1M/TPU B 3 A5

4-wire, VAC/DC 20-250 VAC/10-300 VDC 30 ≤ 100 -25 to +70 IP67 PBT 0.16M/TPU B 3 A5

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G38

Page 39

+

Cylinder Position Sensors | Q9.5

Power Clamp Position Sensors

Housing Style Dimension Drawings

B

A

Q9.5 - Eurofast Connector

C

We reserve the right to make technical alterations without prior notice.

Q9.5 - Eurofast Connector

1

1 4

2

3

Mating Cordset: RK 4.4T-*

A4

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

A5

Line Frequency:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Continuous Load Current:

Off-State (Leakage) Current:

S1

LOAD

-

S2

LOAD

≤10%

3-15% (5% typical)

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA (Ferrite, Uprox)

≤20 mA (Uprox+, Uprox 3)

2-wire AC/DC w/ Short-Circuit Protection - (ADZ, RDZ, FDZ, VDZ)

≥50... ≤60 Hz

3-15% (5% typical)

≤6.0 V

AC: ≥440 mA; DC: ≥330 mA

AC: ≥120 mA; DC: ≥120 mA

AC: ≤400 mA; DC: ≤300 mA

AC: ≤100 mA; DC: ≤100 mA

≤1.7 mA (AC)

≤1.5 mA (DC)

Wiring Diagrams/Mating Cordsets

2

3 and 4-wire DC - (AN, RN, AP, RP, VN, VP)

Time Delay Before Availability:

Reverse Polarity Protection:

Minimum Load Current:

Q9.5 - Microfast Connector

Mating Cordset: KB 5T-*

Power-On Effect:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

Inrush Current:

Power-On Effect:

Transient Protection:

Shock:

Vibration:

Repeatability:

≤8 ms

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤±10%

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≤2% of Rated Operating Distance

≥3.0 mA

≤3 A (≤20 ms, max 5 Hz)

Per IEC 947-5-2

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤2% of Rated Operating Distance

G39

Turck Inc.

Page 40

Cylinder Position Sensors | Q9.5

Power Clamp Position Sensors

Part Number/

ID Number

Ni2-Q9.5-AP6-0.1-FS4.4X3/S304

1650060

Ni2-Q9.5-0.1-BDS-2AP6X3-H1141/S34

1650099

Ni2-Q9.5-ADZ32-0.1-FSB5.4X4/S304

4200210

Features

WFI 4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.1M/TPU B 1 A4

Output

4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.1M/TPU A 1 A4

4-wire, VAC/DC

20-250 VAC/10-300

VDC

Voltage

Switching Freq. (Hz)

Operating Current (mA)

20 ≤ 100 -25 to +70 IP67 PBT 0.1M/TPU C 2 A5

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G40

Page 41

Cylinder Position Sensors | ISI

Power Clamp Position Sensors

Housing Style Dimension Drawings

1

A

ISI - Eurofast Connector

Wiring Diagrams/Mating Cordsets

We reserve the right to make technical alterations without prior notice.

Mating Cordset: RK 4.4T-*

A4

Ripple:

Differential Travel (Hysteresis):

Voltage Drop Across Conducting Sensor:

Trigger Current for Short Circuit Protection:

Off-State (Leakage) Current:

No-Load Current:

3 and 4-wire DC - (AN, RN, AP, RP, VN, VP)

≤10%

3-15% (5% typical)

≤1.8 V

≥220 mA on 200 mA Load Current

≥170 mA on 150 mA Load Current

≥120 mA on 100 mA Load Current

≤0.1 mA

≤15 mA (Ferrite, Uprox)

≤20 mA (Uprox+, Uprox 3)

Time Delay Before Availability:

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Temperature Drift:

Shock:

Vibration:

Repeatability:

≤8 ms

Per IEC 947-5-2

Incorporated

Incorporated

Per EN 60947-5-2

≤±10%

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≤2% of Rated Operating Distance

G41

Turck Inc.

Page 42

Cylinder Position Sensors | ISI

Power Clamp Position Sensors

Part Number/

ID Number

Ni2-ISI-0.1-BDS-2AP6X3-H1141/S34

1650133

Features

WFI 4-wire DC, PNP 10-30 VDC 30 ≤ 150 -25 to +70 IP67 PBT 0.1M/TPU A 1 A4

Output

Voltage

Switching Freq. (Hz)

Operating Current (mA)

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G42

Page 43

Cylinder Position Sensors | WIM

Power Clamp Position Sensors

Housing Style Dimension Drawings

B

A

23 mm - Embeddable, T-groove Pneumatic Cylinders Picofast Quick Disconnect

C

We reserve the right to make technical alterations without prior notice.

23 mm - Embeddable, T-groove Pneumatic Cylinders Eurofast Quick Disconnect

1

Mating Cordset: RK 4.4T-*; PKG 4M-*

A7

LIU5:

LIU2:

≤10%

≤8.0 mA

0-10 V/R

≥4.7 kΩ

L

0-20 mA/R

±0.06% / °C

4-20 mA, 0-10 V

4-20 mA, 2-10 V

≤0.4 kΩ

L

Ripple:

No-Load Current:

Load Resistance Voltage Output:

Load Resistance Current Output:

Temperature Drift:

A8

Ripple:

No-Load Current:

Load Resistance Voltage Output:

Temperature Drift:

Reverse Polarity Protection:

Transient Protection:

≤10%

≤8.0 mA

0-10 V/R

≥4.7 kΩ

L

±0.06% / °C

Incorporated

Per EN 60947-5-2

23 mm - Embeddable, T-groove Pneumatic Cylinders EurofastQuick Disconnect

Wiring Diagrams/Mating Cordsets

2

3 and 4-wire DC Analog - (LIU, SIU)

3 and 4-wire DC Analog - (LU)

Mating Cordset: RK 4.4T-*

Transient Protection:

Shock:

Vibration:

Repeatability:

Short-Circuit Protection:

Reverse Polarity Protection:

Short-Circuit Protection:

Wire-Break Protection:

Shock:

Vibration:

Repeatability:

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤1% of measuring range |A-B|

(0.5% after 30 min. warm up)

Yes

Incorporated

Yes

Yes

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤1% of measuring range |A-B|

(0.5% after 30 min. warm up)

G43

Turck Inc.

Page 44

Cylinder Position Sensors | WIM

Power Clamp Position Sensors

Part Number/

ID Number

WIM45-UNTL-LIU5X2-0.3-PSG4M

1536620

WIM45-UNTL-0.3-BIM-UNT-LUAP6X4-H1141

1536623

WIM45-UNTL-LIU5X2-0.3-RS4

1536621

Linear Operating

Distance (mm)

45 10 bit

45 10 bit

45 10 bit

Resolution

4-wire DC, Current

and Voltage

4-wire DC, Current

and Voltage

4-wire DC, Current

and Voltage

Output

Voltage

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 PA 12 0.3M/TPU A 1 A7

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 PA 12 0.3M/TPU B 2 A8

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 PA 12 0.3M/TPU C 1 A7

Output Voltage/

Current

Operating Temp. (°C)

Protection

Housing

Cable Length/Jacket

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G44

Page 45

Cylinder Position Sensors | WIM

Magnetic Linear Position Sensors

Housing Style Dimension Drawings

1

A

25 mm - Embeddable, Eurofast Quick Disconnect

Wiring Diagrams/ Mating Cordset

We reserve the right to make technical alterations without prior notice.

Mating Cordset: RK 4.4T-*

A7

No-Load Current:

Load Resistance Voltage Output:

Load Resistance Current Output:

Temperature Drift:

For mounting accessories see page G9

Ripple:

LIU5:

LIU2:

≤10%

≤8.0 mA

0-10 V/R

≥4.7 kΩ

L

0-20 mA/R

±0.06% / °C

4-20 mA, 0-10 V

4-20 mA, 2-10 V

≤0.4 kΩ

L

3 and 4-wire DC Analog - (LIU, SIU)

Short-Circuit Protection:

Reverse Polarity Protection:

Additional Specications

Magnetic Actuation Strength (Gauss): 50-100

Transient Protection:

Shock:

Vibration:

Repeatability:

Per EN 60947-5-2

30 g, 11 ms

55 Hz, 1 mm Amplitude, in all 3 Planes

≤1% of measuring range |A-B|

(0.5% after 30 min. warm up)

Yes

Incorporated

G45

Turck Inc.

Page 46

Cylinder Position Sensors | WIM

Magnetic Linear Position Sensors

Part Number/

ID Number

WIM100-Q25L141-LIU5X2-H1141

1536630

WIM125-Q25L166-LIU5X2-H1141

1536631

WIM160-Q25L201-LIU5X2-H1141

1536632

WIM200-Q25L241-LIU5X2-H1141

1536633

Linear Operating

Distance (mm)

100 10 bit

125 10 bit

160 10 bit

200 10 bit

Resolution

4-wire DC, Current and

4-wire DC, Current and

4-wire DC, Current and

4-wire DC, Current and

Output

Voltage

Voltage

Voltage

Voltage

Voltage

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 AL PC-GF20 A 1 A7

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 AL PC-GF20 A 1 A7

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 AL PC-GF20 A 1 A7

15-30 VDC 0-10 V/4-20 mA -25 to +70 IP67 AL PC-GF20 A 1 A7

Output Voltage/

Current

Operating Temp. (°C)

Protection

Housing

Face

Dimension Drawings

Wiring Diagrams

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G46

Page 47

Cylinder Position Sensors | Namur

Intrinsically Safe

A

Dimension Drawings

B

UNT - Potted-In Cable

C

INT - Eurofast Quick Disconnect

E

AKT - Eurofast Connector

G

NST - Potted-In Cable

D

F

H

INT - Picofast Potted-In Cable

PST - Potted-In Cable

We reserve the right to make technical alterations without prior notice.

AKT - Potted-In Cable

IKE/IKT - Eurofast Quick Disconnect

I

IKE/IKT - Potted-In Cable

Wiring Diagrams/Mating Cordsets

1 2

A16

Differential Travel (Hysteresis):

Nominal Voltage:

Load Resistance:

Non-activated Current Consumption:

Activated Current Consumption:

Recommended Switching Point for

Remote Amplifier:

G47

Turck Inc.

≤1 mm

8.2 VDC (EN60947-5-6)

1000 Ω

≤1.2 mA

≥2.1 mA

>1.2 to <2.1 mA,

typ. 1.55 mA ON/1.75 mA OFF

2-wire DC NAMUR - Magnetic (Y0 and Y1)

Additional Specications

Magnetic Actuation Strength (Gauss): 20-350

Mating Cordset: RK 4.21T-*

Power-On Effect:

Reverse Polarity Protection:

Wire-Break Protection:

Transient Protection:

Shock:

Vibration:

Repeatability:

Pass Speed:

Realized in Amplifier

Incorporated

Realized in Amplifier

Realized in Amplifier

30 g, 11 ms

55 Hz, 1 mm Amplitude in all 3 Planes

≥± 0.1 mm

≤10 ms

Page 48

Cylinder Position Sensors | Namur

Intrinsically Safe

Part Number/

ID Number

BIM-UNT-AY1X/S1139

4685763

BIM-INT-Y1X

1056800

BIM-INT-Y1X-0.2-RS4.21T

1056892

BIM-PST-Y1X W/KLP-80

1057090

BIM-AKT-Y1X-H1141 W/KLA-1

1055290

BIM-AKT-Y1X W/KLA-1

1055090

BIM-IKE-Y1X W/KLI-3

1056490

BIM-IKE-Y1X-H1141 W/KLI-3

1056690

BIM-NST-Y1X

1058400

Features

Wider Range

KLP-80 Included

KLA-1 Included

KLA-1 Included

KLI-3 Included

KLI-3 Included

w/o Bracket

Output

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-wire DC

NAMUR

2-Wire DC

NAMUR

Voltage

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67

8.2 VDC nominal 1000 Remote -25 to +70 IP67 Zinc N/A YE

8.2 VDC nominal 1000 Remote -25 to +70 IP67 Zinc N/A YE -- H 2 A16

8.2 VDC nominal 1000 Remote -25 to +70 IP67

Switching Freq. (Hz)

Operating Current

(mA) VAC/VDC

Operating Temp. (°C)

Protection

Housing

Power LED

Output LED

Cable Length/Jacket

PA

N/A YE

12

PA

N/A YE

12

PA

N/A YE

12

PA

N/A YE

12

PA

N/A YE -- E 2 A16

12

PA

N/A YE

12

PA

N/A YE

12

2M/

PVC

2M/

PVC

0.2M/

PVC

2M/

PVC

2M/

PVC

2M/

PVC

2M/

PVC

Dimension Drawings

Wiring Diagrams

A 1 A16

B 1 A16

C 2 A16

D 1 A16

F 1 A16

I 1 A16

G 1 A16

Spec List

We reserve the right to make technical alterations without prior notice.

Cylinder Position Sensors

Turck Inc.

G48

Loading...

Loading...