Page 1

Your Global Automation Partner

PROFINET

Controller/Device

Commissioning in

CODESYS 3

Getting Started

Page 2

Page 3

Table of Contents

1 About these instructions 3

1.1 Target Groups 3

1.2 Explanation of Symbols 3

2 Creating a CODESYS Project and Configuring the Network 5

2.1 Installing a CODESYS package 5

2.2 Create CODESYS Standard Project with TBEN-L-PLC-

2.3 Configuring the Network 7

2.3.1 Configuring the Ethernet Interface 8

3 Using the Device as PROFINET Controller 11

3.1 Creating a CODESYS Project and Configuring the Network 11

3.2 Configuring the Device as PROFINET Controller 12

3.2.1 Adding the PROFINET Controller to the Project 12

3.2.2 PROFINET tasks in CODESYS 13

3.3 Configuring PROFINET Devices 14

3.3.1 Installing the GSDML-files 14

3.3.2 Scan Network for PROFINET Devices 15

3.3.3 Adding PROFINET Devices Manually 17

3.3.4 Configuring the BL20 station 19

3.3.5 Configuring the TBEN-S2-4IOL (IO-Link Master) 20

- Configuring the Empty Slots 2 – 5 (IO-Link-Ports) 21

- Configuring the Empty Slots 6 – 8 (Diagnostics, IO-Link-Events, Module Status) 25

3.4 Communication Settings for PROFINET Devices 29

3.4.1 Assigning the IP Address and the Station Name 29

3.4.2 Setting the communication parameters (Send Clock, Reduction Ratio, Phase) 30

3.5 Requesting the Device Status in the Program 31

3.6 Using IO-Link Function Blocks for CODESYS 32

4 Using the Device as PROFINET Device 35

4.1 Creating a CODESYS Project and Configuring the Network 35

4.2 Configuring the PROFINET Device 36

4.2.1 Adding the PROFINET Device to the Project 36

4.2.2 Configuring the PROFINET Device (CDS3 PN-Device) in TIA Portal 39

- Installing the GSDML-file 39

- Configuring the PROFINET parameters 40

- Configuring the in- and output data 41

2017/06

1

Page 4

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 5

1 About these instructions

These instructions describe the commissioning of the CODESYS 3 programmable Turck devices as

PROFINET Controller and PROFINET Device on the example of the compact controller TBEN-L…PLC-10.

The instructions are valid for the following devices:

PROFINET Controller

PROFINET Device

1.1 Target Groups

These instructions are aimed at qualified personnel and must be carefully read by anyone mounting, commissioning, operating, maintaining, dismantling or disposing of the device.

1.2 Explanation of Symbols

The following symbols are used in these instructions:

DANGER!

DANGER indicates an immediately dangerous situation, with high risk, the death or severe

injury, if not avoided.

WARNING!

WARNING indicates a potentially dangerous situation with medium risk, the death or

severe injury, if not avoided.

Compact controller

TBEN-L…-PLC-…

✔

✔ –

✔

– ✔

HMI/PLC

TX500 series

Programmable

gateways

BL20-PG-EN-V3/

BL67-PG-EN-V3

ATTENTION!

ATTENTION indicates a situation that may lead to property damage, if it is not avoided.

NOTE

In NOTES you find tips, recommendations and important information. The notes facilitate

work, provide more information on specific actions and help to avoid overtime by not following the correct procedure.

CALL TO ACTION

This symbol identifies steps that the user has to perform.

RESULTS OF ACTION

This symbol identifies relevant results of steps

2017/06

3

Page 6

About these instructions

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 7

2 Creating a CODESYS Project and Configuring the Network

Turck provides the CODESYS version actually released for the devices under www.turck.com. This

version contains the necessary Turck device packages.

Download CODESYS from www.turck.com and install it.

The installed CODESYS version contains all necessary CODESYS packages and device description

files.

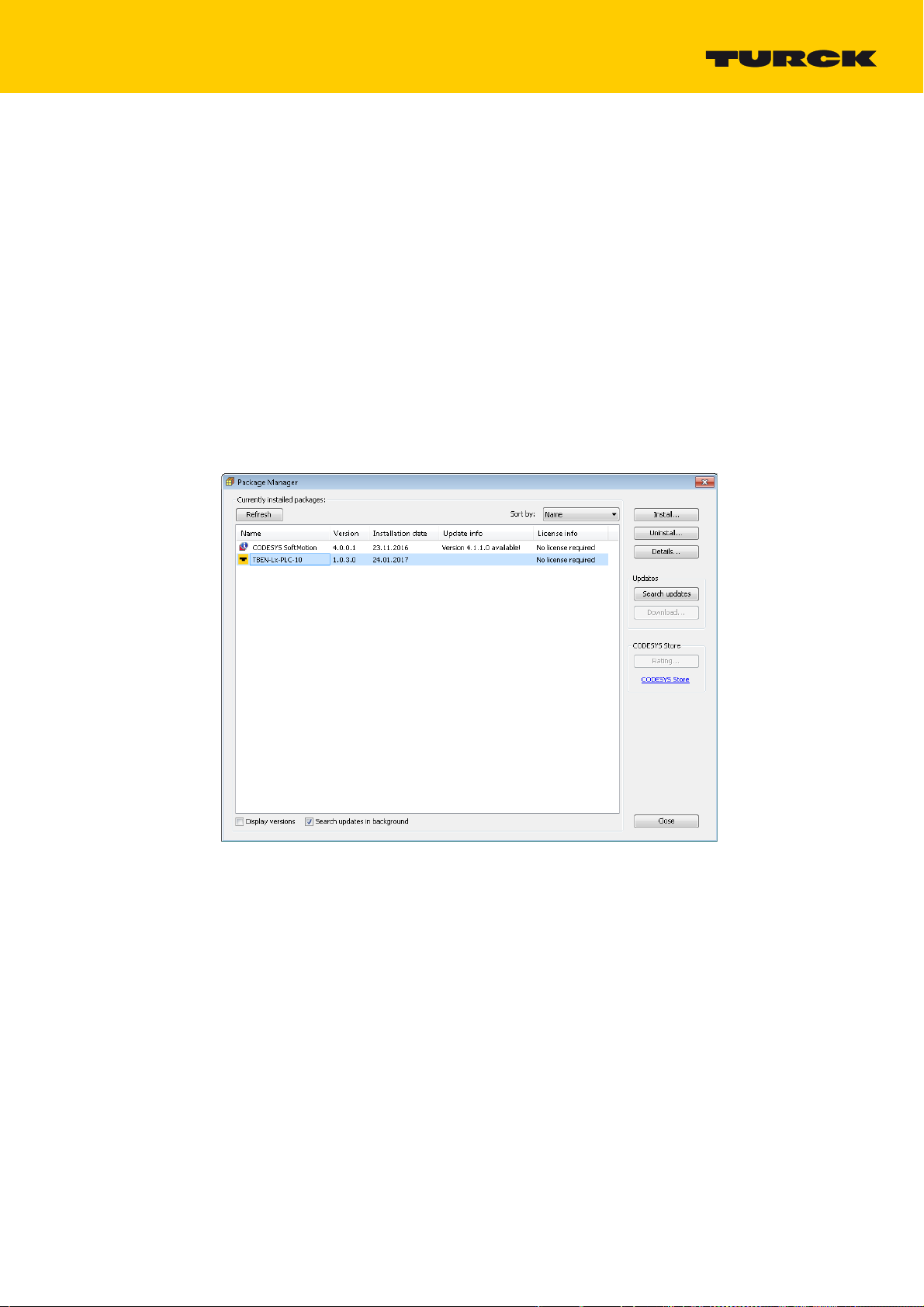

2.1 Installing a CODESYS package

If another CODESYS version is used, first of all the package for the used Turck device has to be

installed.

Download the CODESYS package for the used device under www.turck.com. In the following

example, the TBEN-L…-PLC-10 is used.

Install the package using the CODESYS Package Manager "Tools Package Manager".

2017/06

Fig. 1: Package Manager in CODESYS

The CODESYS package contains all necessary files:

CODESYS Device Description,

CODESYS libraries,

GSDML file,

EDS-file,

…

5

Page 8

Creating a CODESYS Project and Configuring the Network

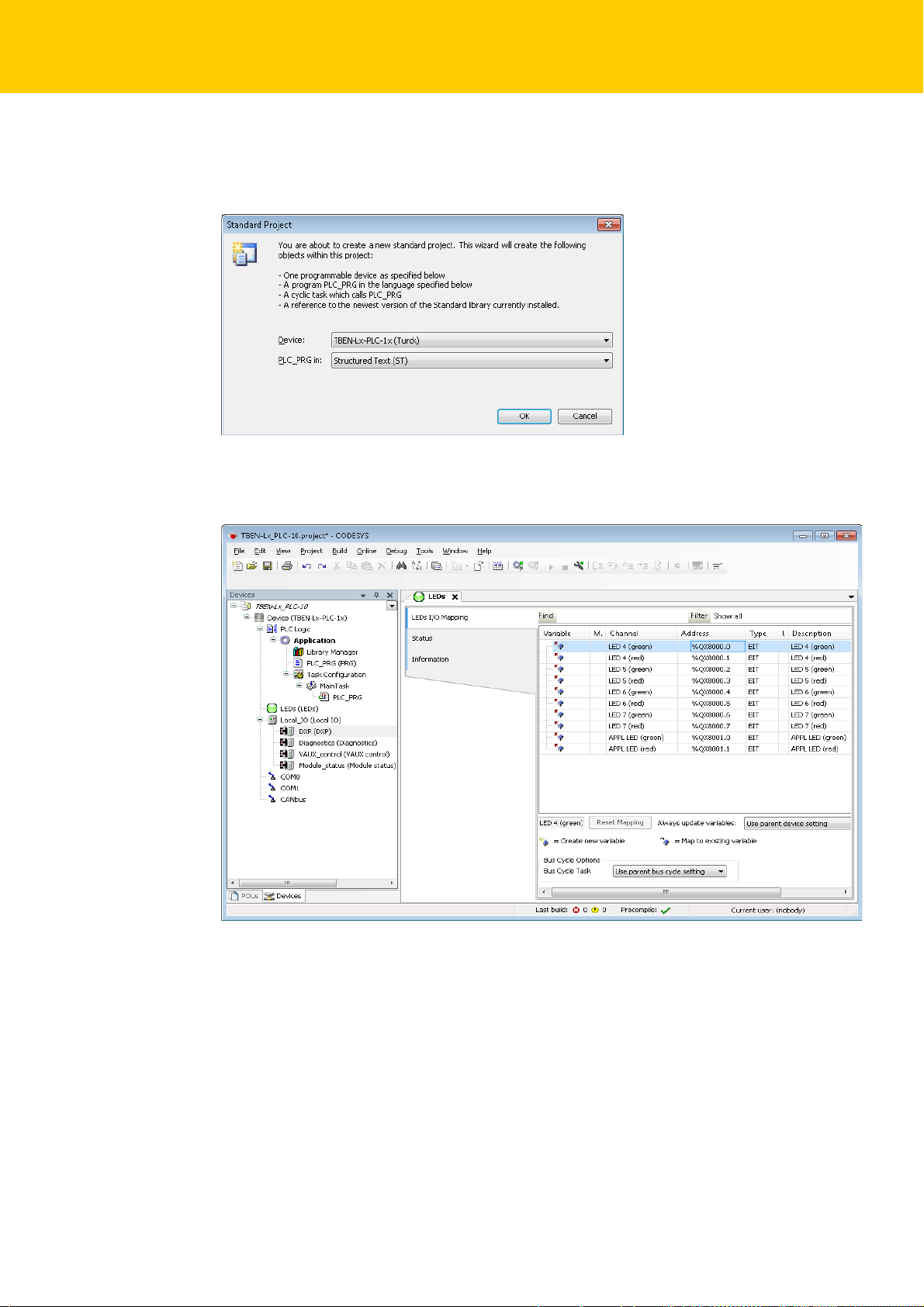

2.2 Create CODESYS Standard Project with TBEN-L-PLC-

Create a new standard project with TBEN-L-PLC- as CODESYS device.

Fig. 2: Selecting the TBEN-L-PLC- as CODESYS device

The CODESYS project is created.

Fig. 3: CODESYS project

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 9

Additionally to the PLC logic, the project contains:

5 LEDs for free use in the program (LEDs)

– Each LED uses 2 bit in the process output data of the device. They are automatically mapped to

the output bits %QX8000.0 to QX8001.1 (see

Local IO (Local_IO)

– Process data and configuration of the device's local I/Os and the VAUX diagnostics

– Diagnostics of the local I/Os and module status.

2 serial interfaces (COM0 and COM1)

– Connection of RS232 and RS485 devices

1 CAN interface (CANbus)

– Use of the device as CANopen Device, CANopen Manager or as

SAE J1939 Manager

2.3 Configuring the Network

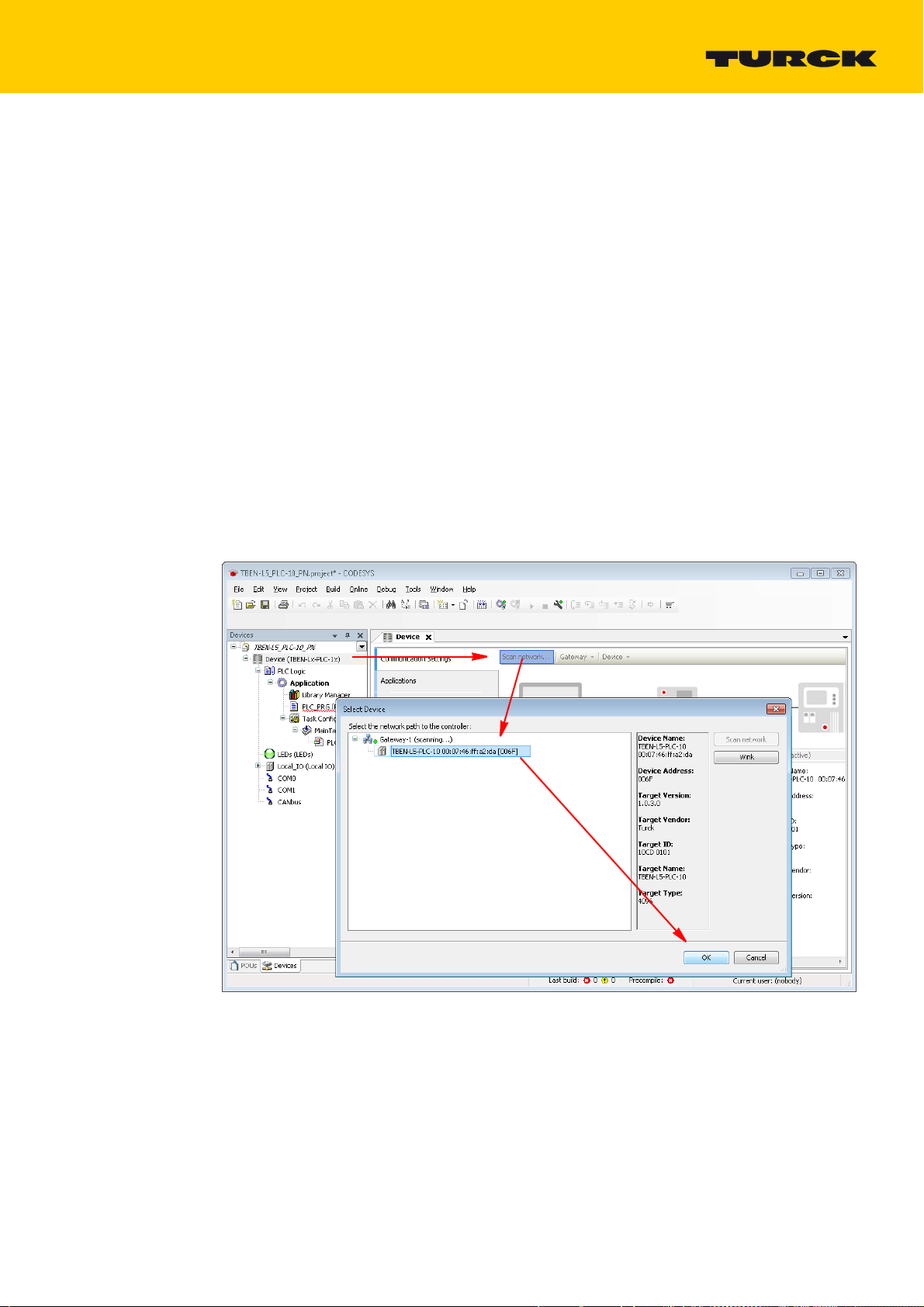

Double clicking the entry "Device (TBEN-Lx-PLC-1x)" opens the "device" tab.

Scan the network for TBEN-L…-PLC-10 via the "scan network…" button and select the device.

Fig. 3: CODESYS project (page 6)).

2017/06

Fig. 4: Scan the network and select TBEN-L…-PLC-10 as device

7

Page 10

Creating a CODESYS Project and Configuring the Network

2.3.1 Configuring the Ethernet Interface

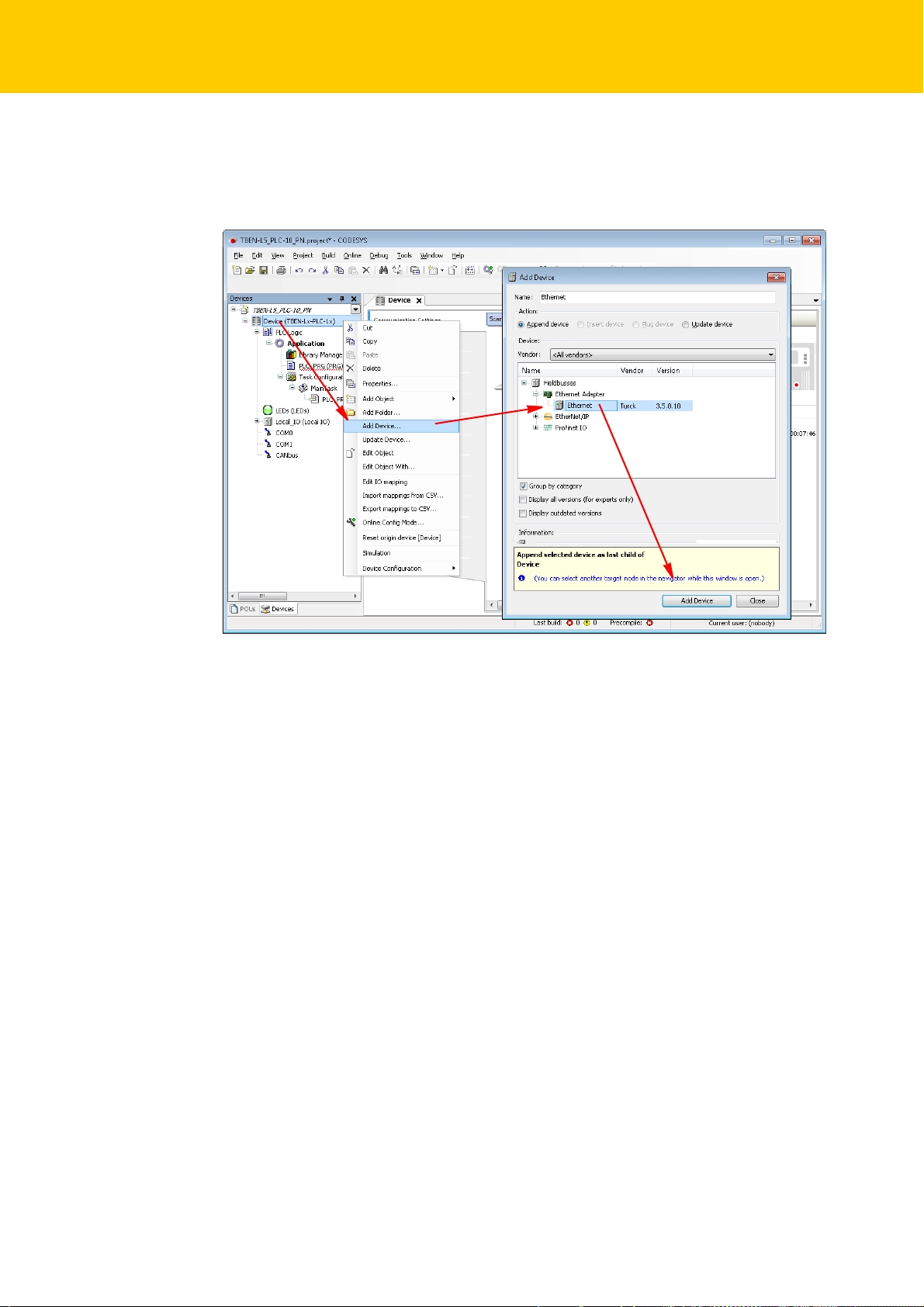

Right clicking the entry "Device (TBEN-Lx-PLC-1x)" opens context menu.

Add the Ethernet interface via the "Add device…" function.

Fig. 5: Adding the Ethernet interface

The Ethernet interface is added to the project tree.

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 11

Open the "Ethernet" tab by double clicking the Ethernet interface in the project tree.

Fig. 6: Configuring the Ethernet interface

The IP address of the network interface corresponds to the IP address of the TBEN-L-PLC-

Select "eth0" under "network interface".

The IP address is set automatically.

2017/06

9

Page 12

Creating a CODESYS Project and Configuring the Network

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 13

3 Using the Device as PROFINET Controller

Used Hardware

PLC:

–

TBEN-L5-PLC-10

I/Os:

–

TBEN-S1-8DXP

– TBEN-S2-4IOL with:

IO-Link port 1: Turck temperature sensor, TS-530-LI2UPN8X-H1141-L016, IO-Link V1.0

IO-Link port 2: generic port configuration, one bit each in- and output data

IO-Link port 3: Turck ultrasonic sensor, RU40U-M18E-LiU2PN8X2T-H1151, IO-Link V1.1

IO-Link port 4: generic port configuration, used as digital input

–

BL20-E-GW-EN with:

I/O module 1: BL20-E-2CNT-2PWM

I/O module 2: BL20-2DO-24VDC-0.5A-P

I/O module 3: BL20-2AI-I(0/4…20MA)

Used Software

CODESYS V3, 3.5.8.10

TBEN-L…-PLC-1…_V1.0.3.0.package

3.1 Creating a CODESYS Project and Configuring the Network

Create CODESYS project and configure the network according to Kapitel 2, Creating a CODE-

SYS Project and Configuring the Network.

2017/06

11

Page 14

Using the Device as PROFINET Controller

3.2 Configuring the Device as PROFINET Controller

Properties Compact controller

Max. number of devices 64 64

Min. cycle time 1 ms 1 ms

Max. number of devices at 1 ms

AThis information refers to standard PROFINET devices with up to 4 byte of process data as for example digital I/O

modules. For PROFINET devices with much more process data (50 …400 byte) as for example IO-Link, RFID or

serial COM interfaces, the cycle time has to be increased to 2, 4 or 8 ms.

A 81

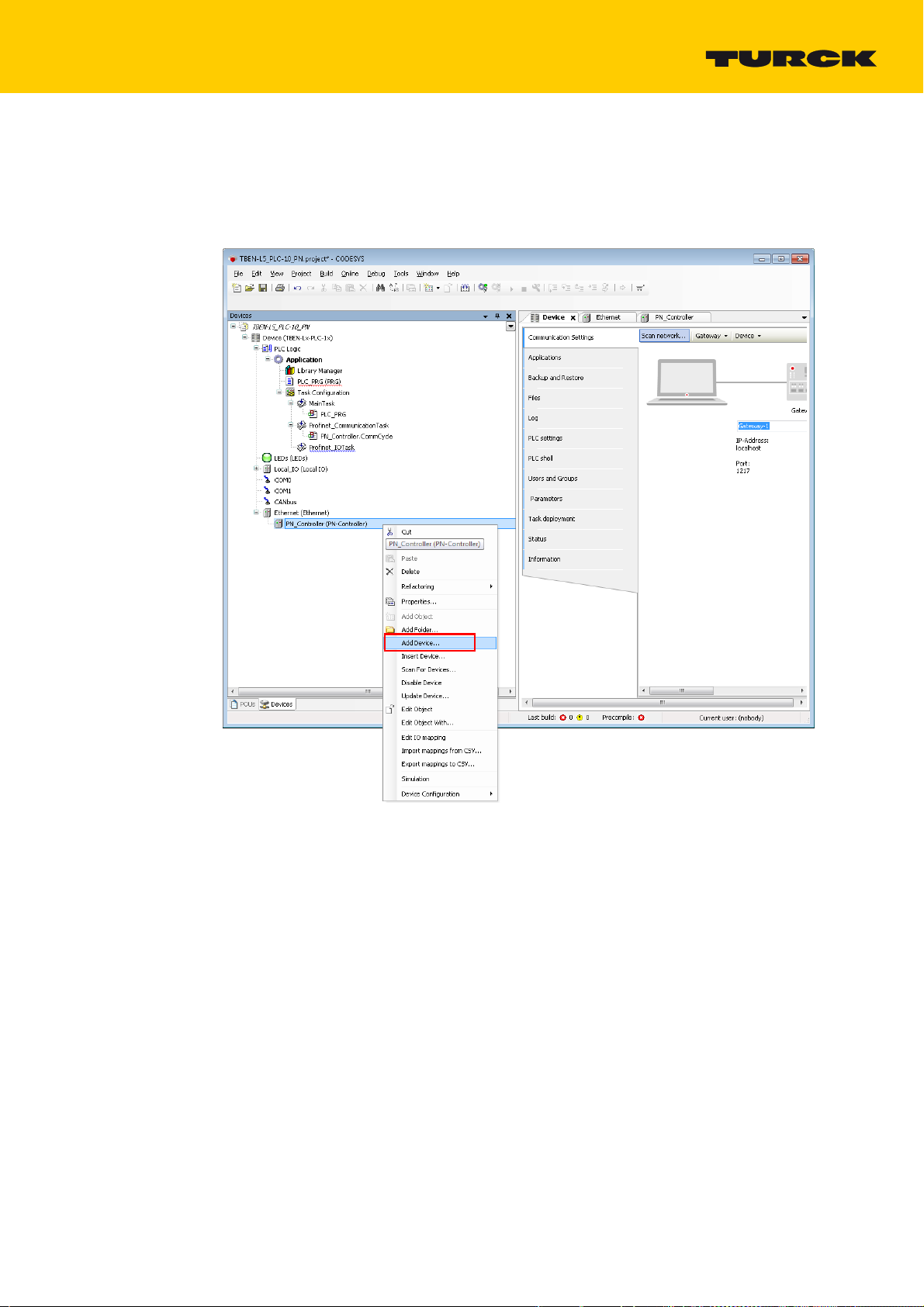

3.2.1 Adding the PROFINET Controller to the Project

The PN-Controller from 3S – Smart Software Solutions GmbH is used.

Add the PN-Controller to the Ethernet interface using the "Add device…" function.

TBEN-L…PLC-10

HMI/PLC

TX500

12

Fig. 7: Adding the PN-Controller

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 15

The PROFINET controller is added to the project tree.

Fig. 8: PN-Controller in project tree

NOTE

The Device addresses under "Default Slave IP Parameter" and the Ethernet interface of the

TBEN-L-PLC- have to be in the same subnet.

3.2.2 PROFINET tasks in CODESYS

The following PROFINET tasks are automatically added to the project as soon as a

PROFINET controller is added to the Ethernet interface.

Profinet_CommunicationTask

This task includes the acyclic communication services, such as establishing connections, configuration of slaves and diagnostics. These services are not time-critical due to very weak real-time

requirements. Therefore the task is low priority (default: priority 30, interval 10 ms). In applications with a large amount of slaves it can be necessary to extend the cycle time.

Profinet_IOTask

This task is responsible for the PROFINET IO real-time data exchange. It controls the PROFINETMaster-Stack. The task should be set to high priority (default: priority 1, interval 1 ms).

2017/06

13

Page 16

Using the Device as PROFINET Controller

3.3 Configuring PROFINET Devices

In this example, the following Turck multiprotocol devices are used as PROFINET devices:

–

TBEN-S1-8DXP

– TBEN-S2-4IOL

– BL20-E-GW-EN

3.3.1 Installing the GSDML-files

Download the GSDML files from www.turck.com and install them in the CODESYS Device

Repository.

14

Fig. 9: CODESYS Device Repository

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 17

3.3.2 Scan Network for PROFINET Devices

Start the device search via the "Scan for devices…" function at the PROFINET controller.

Fig. 10: Search devices

The found devices can either be selected separately or all found devices can be added to the

project via the "Copy All Devices to Project" button.

2017/06

15

Page 18

Using the Device as PROFINET Controller

Fig. 11: Searching devices

The devices are added to the project tree.

Modular Turck devices, as the BL20 station in the example, are added with all connected I/O

modules.

The configuration of the IO-Link ports of the TBEN-S2-4IOL in the example is done manually

afterwards (see Configuring the TBEN-S2-4IOL (IO-Link Master) (page 20)).

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 19

3.3.3 Adding PROFINET Devices Manually

As an alternative for the scanning of the network, PROFINET devices can also be add manually to

PROFINET.

Add external PROFINET devices using the "Add device…" function.

2017/06

Fig. 12: Adding external PROFINET devices

17

Page 20

Using the Device as PROFINET Controller

Select the PROFINET devices from the device catalog and add them to the project.

Fig. 13: Adding external PROFINET devices

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 21

3.3.4 Configuring the BL20 station

For modular PROFINET devices, first of all select the gateway (in this example the BL20-E- GW-

EN).

Right-click the gateway and use the "Add device" function to add the I/O modules in the order

in which they follow the gateway.

Fig. 14: Adding I/O modules to the BL20 gateway

2017/06

19

Page 22

Using the Device as PROFINET Controller

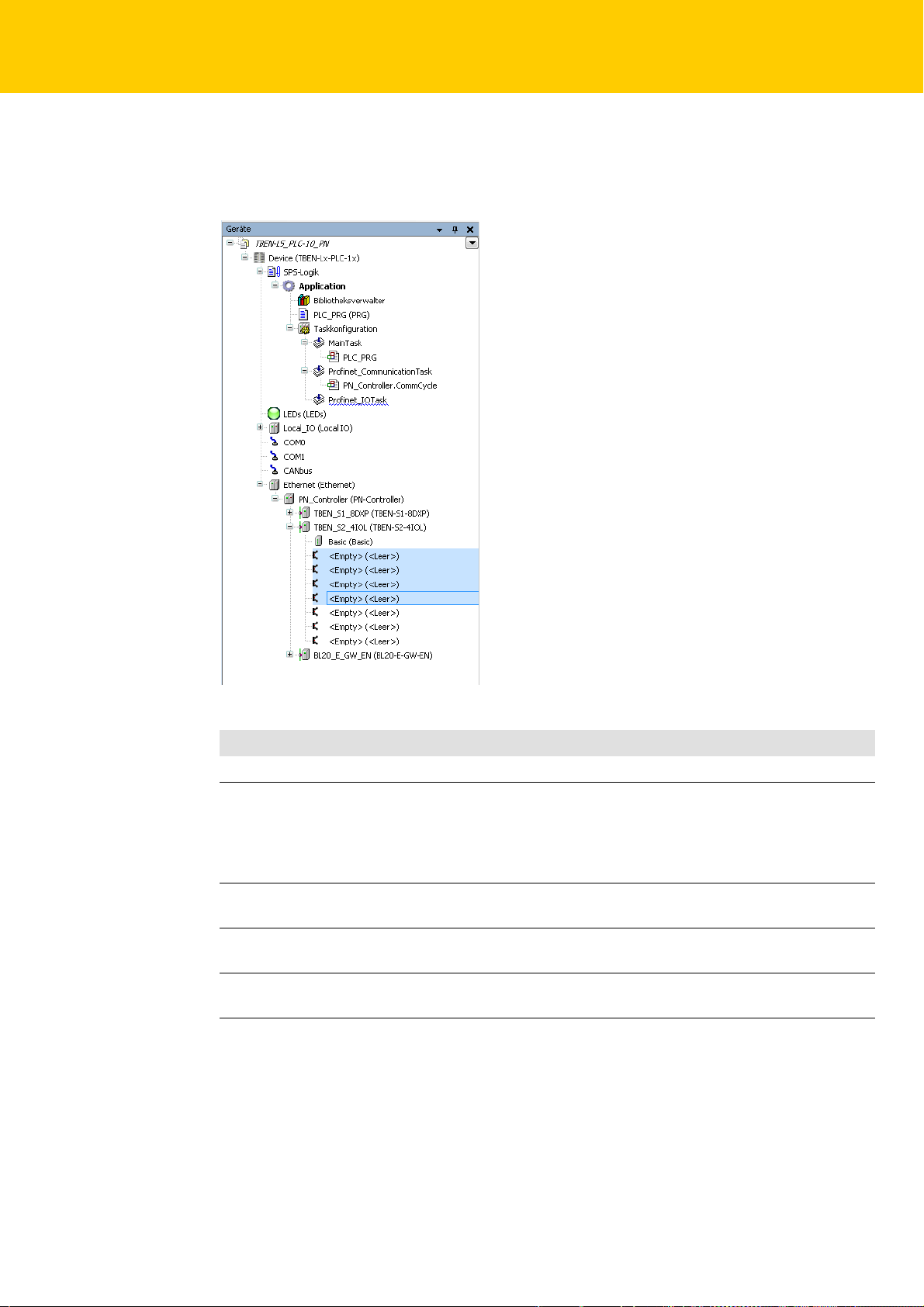

3.3.5 Configuring the TBEN-S2-4IOL (IO-Link Master)

The TBEN-S2-4IOL is shown in the project tree as a modular slave with one basic slot and seven

empty slots.

Fig. 15: TBEN-S2-4IOL in the project tree

Slot/empty slot Meaning

1

2 - 5 IO-Link ports For the configuration of the four

6 Diagnostics Optional mapping of the diagnostics (IO-Link and

7 IO-Link Events Optional mapping of the diagnostics (IO-Link and

8 Module status Optional mapping of the diagnostics (IO-Link and

Basic

DXP-channels of the device (DXP 2, 4, 6, and 8)

IO-Link ports.

Specific or generic configuration of the IO-Link

ports (see Configuring the Empty Slots 2 – 5 (IO-

Link-Ports) (page 21)).

DXP-diagnostics) into the master's process image.

DXP-diagnostics) into the master's process image.

DXP-diagnostics) into the master's process image.

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 23

Configuring the Empty Slots 2 – 5 (IO-Link-Ports)

Device configuration in the example:

TBEN-S2-4IOL with:

IO-Link port 1: Turck temperature sensor, TS-530-LI2UPN8X-H1141-L016, IO-Link V1.0

IO-Link port 2: generic port configuration, one bit each in- and output data

IO-Link port 3: Turck ultrasonic sensor, RU40U-M18E-LiU2PN8X2T-H1151, IO-Link V1.1

IO-Link port 4: generic port configuration, used as digital input

Use the "Plug device…" function to select an IO-Link device for the respective empty slot.

The configuration is either done via SIDI (Simple IO-Link Device Integration) or as generic configuration. In this example port 1 and 3 are used with a specific sensor, port 2 with a generic sensor with

one byte IO-Link input data and one byte IO-link output data. Port 4 is configured generically as digital input.

NOTE

By means of the "Simple IO-Link Device Integration (SIDI)", Turck IO-Link devices can

directly be selected from the device GSDML in PROFINET.

2017/06

Fig. 16: TBEN-S2-4IOL, "Plug device…" and select port configuration

21

Page 24

Using the Device as PROFINET Controller

Select the entry of the temperature sensor "TS-530-LI2UPN8X-family" under "Port configuration

generic" and plug the device.

Select "TS-530-LI2UPN8X-family" and "Plug device…".

Fig. 17: Select TS-530-LI2UPN8X-family

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 25

Configure port 2 generically and select the entry "IN 1 BYTE/OUT 1 BYTE".

Fig. 18: Generic port configuration

Select the entry of the ultrasonic sensor "RU40U-M18E-LiU2PN8X2T-H1151" under "Port config-

uration specific" and plug the device.

2017/06

23

Page 26

Using the Device as PROFINET Controller

Configure port 4 generically and select the entry "DI".

Fig. 19: IO-Link Port Configuration

24

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 27

Configuring the Empty Slots 6 – 8 (Diagnostics, IO-Link-Events, Module Status)

The empty slots 6 to 8 allow the mapping of channel diagnostics, IO-Link Events and the modules

status to the process image of the IO-Link master.

Select the entry for the respective empty slot using the "Plug device…" function.

2017/06

Fig. 20: TBEN-S2-4IOL: Add diagnostics, IO-Link Events and module status

25

Page 28

Using the Device as PROFINET Controller

Diagnostics

Fig. 21: TBEN-S2-4IOL: Diagnostics in the process image

26

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 29

IO-Link Events

Fig. 22: TBEN-S2-4IOL: IO-Link Events in the process image

2017/06

27

Page 30

Using the Device as PROFINET Controller

Module status

Fig. 23: TBEN-S2-4IOL: Module status in the process image

28

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 31

3.4 Communication Settings for PROFINET Devices

Open the device's configuration tab by double clicking the entry of the respective PROFINET

device in the project tree.

3.4.1 Assigning the IP Address and the Station Name

Assign a PROFINET device name and an IP address and, if necessary, adapt the parameters "Send

Clock", "Reduction Ratio2 and "Phase" to the application.

NOTE

Assigning an IP address or a station name to the devices is not necessary if the devices

have been automatically read in using the "Scan for Devices" function (see Scan Network

for PROFINET Devices (page 15)).

2017/06

Fig. 24: Configuring external PROFINET devices

NOTE

The IP addresses of the PROFINET Devices and the PN Controller have to be in the same

subnet.

29

Page 32

Using the Device as PROFINET Controller

PROFINET Update Time

Reduction Ratio = Anzahl der Phasen

Send Clock

Phase 1 Phase 2 Phase 3 Phase 4

3.4.2 Setting the communication parameters (Send Clock, Reduction Ratio, Phase)

Send Clock (ms):

Send clock time in milliseconds

Reduction Ratio:

Scaling factor

The transmission interval results from the Send Clock × Reduction Ratio. Therefore, a Send Clock

of 1ms and a Reduction Ratio of 4 means that I/O data is sent every 4 ms.

Phase:

With a Reduction Ratio of n, the transmission interval is subdivided into phases 1 to n (where

transmission is in one phase only). The phase for transmission can be determined for the purpose

of load distribution.

Fig. 25: PROFINET Update Time

Fig. 26: Settings for the PROFINET device

With the settings "Send Clock" = 1 ms and "Reduction Ratio" = 4 the PROFINET Cycle Time (or Update

Time) is divided into four phases of 1 ms each. A PROFINET device with these settings is updated

every 4 ms. The PROFINET Update Time is thus the result of the multiplication of "Send Clock" and

"Reduction Ratio".

PROFINET Update Time = Send Clock × Reduction Ratio

The parameter "Phase" defines in which phase this PROFINET device is updated. In PROFINET networks with several devices the devices can be split to the different phases. This helps the master to

optimize the PN data transfer.

30

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 33

3.5 Requesting the Device Status in the Program

The device status can be requested in the program by entering the PROFINET device instance and

the requested function.

Instance.Status;

Example:

Request, if the device is in cyclic data exchange:

tben_s2_4IOL.xRunning;

2017/06

Fig. 27: Requesting the device status in the program

31

Page 34

Using the Device as PROFINET Controller

3.6 Using IO-Link Function Blocks for CODESYS

For acyclic access to the Turck IO-Link master devices (in the example TBEN-S2-4IOL) as well as to

the connected IO-Link devices, Turck offers the following function blocks:

IOL_CALL (in accordance with IO-Link specification)

single acyclic accesses

IOL_WriteParamterList:

sending a parameter list for e. g. initial parameterization of IO-Link devices

The function blocks are part of the turck CODEYS library "IO-Link CALL PROFINET", V1.0.2.0 or higher.

Further information about the function blocks and their usage can be found in the operating

instructions of the Turck IO-Link master or in the function block description in CODESYS.

Fig. 28: Function block IOL_CALL

32

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 35

Fig. 29: Function block IOL_WriteParameterList

2017/06

33

Page 36

Using the Device as PROFINET Controller

34

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 37

4 Using the Device as PROFINET Device

Properties

max. number of I/O data 1024 byte in total

(512 IN + 512 OUT)

Used Hardware

Controller.

–

Siemens CPU 1515-2 PN

Device:

–

TBEN-L5-PLC-10

Used Software

CODESYS V3, 3.5.8.10

TBEN-L…-PLC-1…_V1.0.3.0.package

TIA Portal V13

GSDML-V2.3-TURCK-CDS3_PN_Device-20151208-010322.xml

4.1 Creating a CODESYS Project and Configuring the Network

Create CODESYS project and configure the network according to Kapitel 2, Creating a CODE-

SYS Project and Configuring the Network.

2017/06

35

Page 38

Using the Device as PROFINET Device

4.2 Configuring the PROFINET Device

4.2.1 Adding the PROFINET Device to the Project

The Turck PROFINET Device is used.

Add the Profinet_Device to Ethernet using the "Add Device" function.

Fig. 30: Add PROFINET Device

36

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 39

Configure the in- and output data lengths which have to be exchanged with the higher-level

PROFINET Master. Therefore add the respective process data entries.

Fig. 31: Configuring the PROFINET Device

NOTE

Please observe the following for the configuration of the I/O data:

The CODESYS input data have to be have to be configured as output data in the PROFINET

Controller configuration, the CODESYS output data have to be configured as input data.

The data thus have to be configured in reverse order in the PROFINET Controller configuration (see also Configuring the in- and output data (page 41)).

2017/06

37

Page 40

Using the Device as PROFINET Device

Which data will be mapped into the configured input and output data, depends on assignments in

the PLC program or in the I/O mapping of the TBEN-L-PLC-.

Fig. 32: PROFINET Device data mapping

NOTE

The PROFINET Device shows an error as long as a connection to the PROFINET Controller

is established.

38

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 41

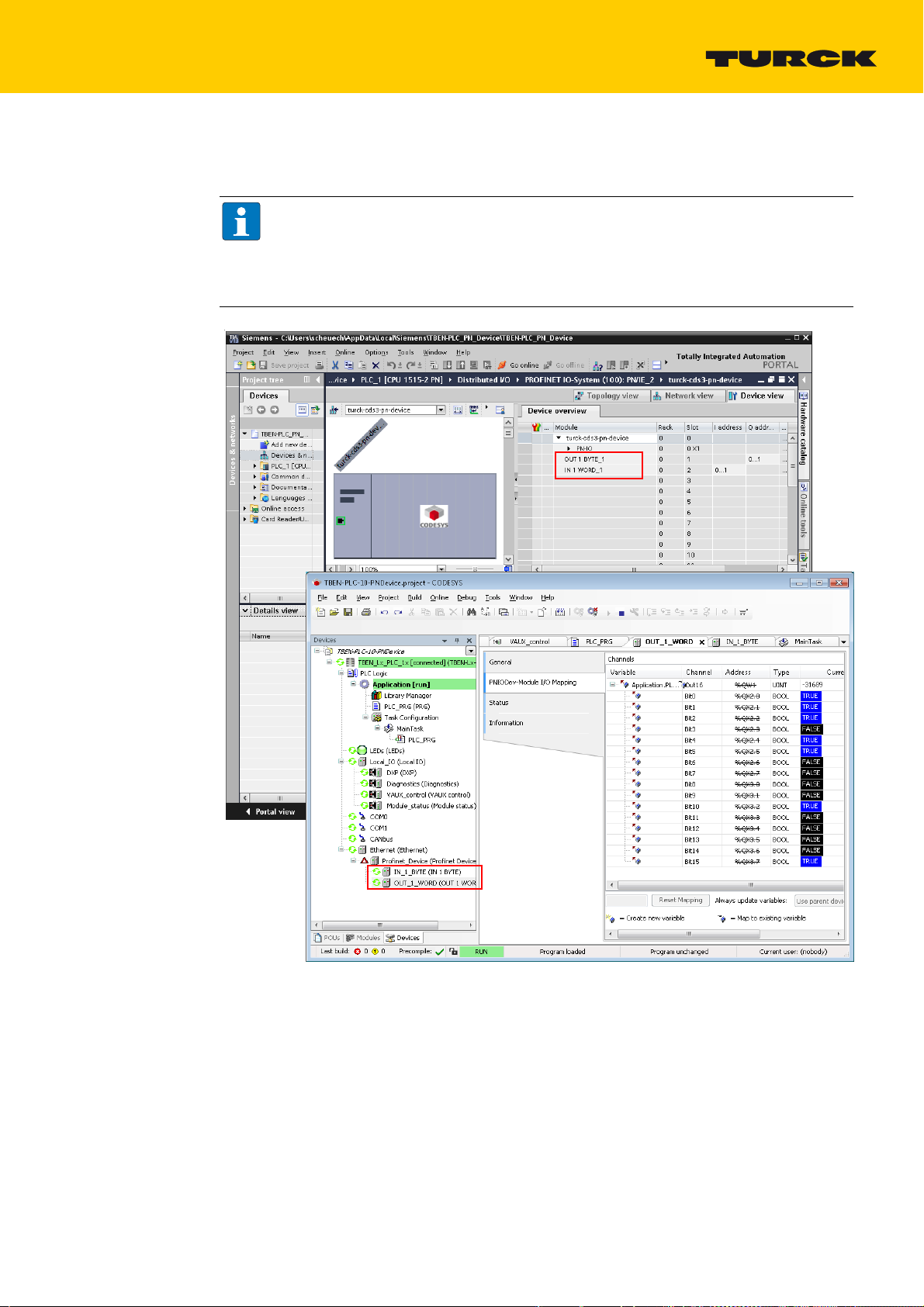

4.2.2 Configuring the PROFINET Device (CDS3 PN-Device) in TIA Portal

The following example shows the CDS3 PN-Device configuration in TIA Portal V13 from Siemens.

The PROFINET-CODESYS-device is configured as standard PROFINET Device in TIA Portal.

Installing the GSDML-file

Install the device's GSDML-file (GSDML-V2.3-TURCK-CDS3_PN_Device--.xml) in TIA Portal. It

can be downloaded at the respective product fromwww.turck.com.

The device is added to the hardware catalog "CDS 3 PN Device".

Fig. 33: Configuring the PROFINET Device in TIA Portal

2017/06

39

Page 42

Using the Device as PROFINET Device

Configuring the PROFINET parameters

Like for all other PROFINET Device, the PROFINET-interface has to be configured for the CDS3 PNDevice" in the project.

Set all necessary IP-settings and assign a PROFINET Device name or use the device name which

has already been assigned to the device.

Fig. 34: Settings PROFINET-interface (CDS3 PN Device)

40

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 43

Configuring the in- and output data

Configure the in- and output data, which have to be exchanged with the CODESYS-device.

NOTE

The configuration of the data in TIA Portal has to be done in reverse order compared to

the configuration in CODESYS. Input data in TIA Portal are output-data in CODESYS, and

vice versa.

The configured data lengths have to match.

2017/06

Fig. 35: Configuration of in- and output data in TIA Portal/CODESYS

41

Page 44

Using the Device as PROFINET Device

After configuring the PROFINET Device in TIA Portal and starting the PN controller, the CODESYS

application with the PROFINET Device is running error free.

Fig. 36: CODESYS application with PROFINET Device

42

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 45

100000538 2017/06

28 subsidiaries and over

60 representations worldwide!

*100000538*

www.turck.com

Loading...

Loading...