Magnetic Field Sensor

Compact design for small hydraulic cylinders

BIM-UNTK-AP7X-0.3M-PSG 3M

■ For T-groove cylinders without mount-

ing accessories

■ Optionally available accessories for

mounting on other cylindrical housings.

■ Single-hand mounting

■ Tool for fine adjustments and stopper

directly mountable on the sensor

■ Stable mounting

■ Magneto-resistive sensor

■ DC 3-wire, 10…30 VDC

■ NO contact, PNP output

■ Pigtail with male end, M8 x 1

Type designation BIM-UNTK-AP7X-0.3M-PSG 3M

Ident-No. 4686011

Pass speed

Repeatability

Temperature drift

Hysteresis

Ambient temperature -25…+70 °C

Operating voltage 10…30 VDC

Residual ripple

DC rated operational current

No-load current I

Residual current

Isolation test voltage

Short-circuit protection no

Voltage drop at I

Wire breakage/Reverse polarity protection yes/ yes (voltage supply)

Output function 3-wire, NO contact, PNP

Switching frequency 0.3 kHz

Design Rectangular,UNTK

Dimensions 19.7 x 5 x 6 mm

Housing material Plastic, PP

Active area material Plastic, PP

Tightening torque fixing screw 0.4 Nm

Electrical connection Cable with connector, M8 × 1

Cable quality 3mm, Gray, Lif9Y-11Y, PUR, 0.3

Cable cross section

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP67

MTTF 2283 years acc. to SN 29500 (Ed. 99) 40 °C

Packaging unit 1

Mounting on the following profiles .

Cylindrical design

0

e

ð 3 m/s

ð ± 0.3 mm

ð 0.3 mm

ð 1 mm

ð 10 % U

ss

ð 100 mA

ð 10 mA

ð 0.1 mA

ð 0.5 kV

ð 1.4 V

Suited for E-ChainSystems® acc. to manufacturers

declaration H1063M

3 x 0.14 mm

E N K F

2

Wiring Diagram

Switching state LED,Yellow

Included in delivery Cable clip

Edition • 2018-03-27T22:12:41+02:00

1 / 4 TURCK Inc.

Magnetic Field Sensor

Compact design for small hydraulic cylinders

BIM-UNTK-AP7X-0.3M-PSG 3M

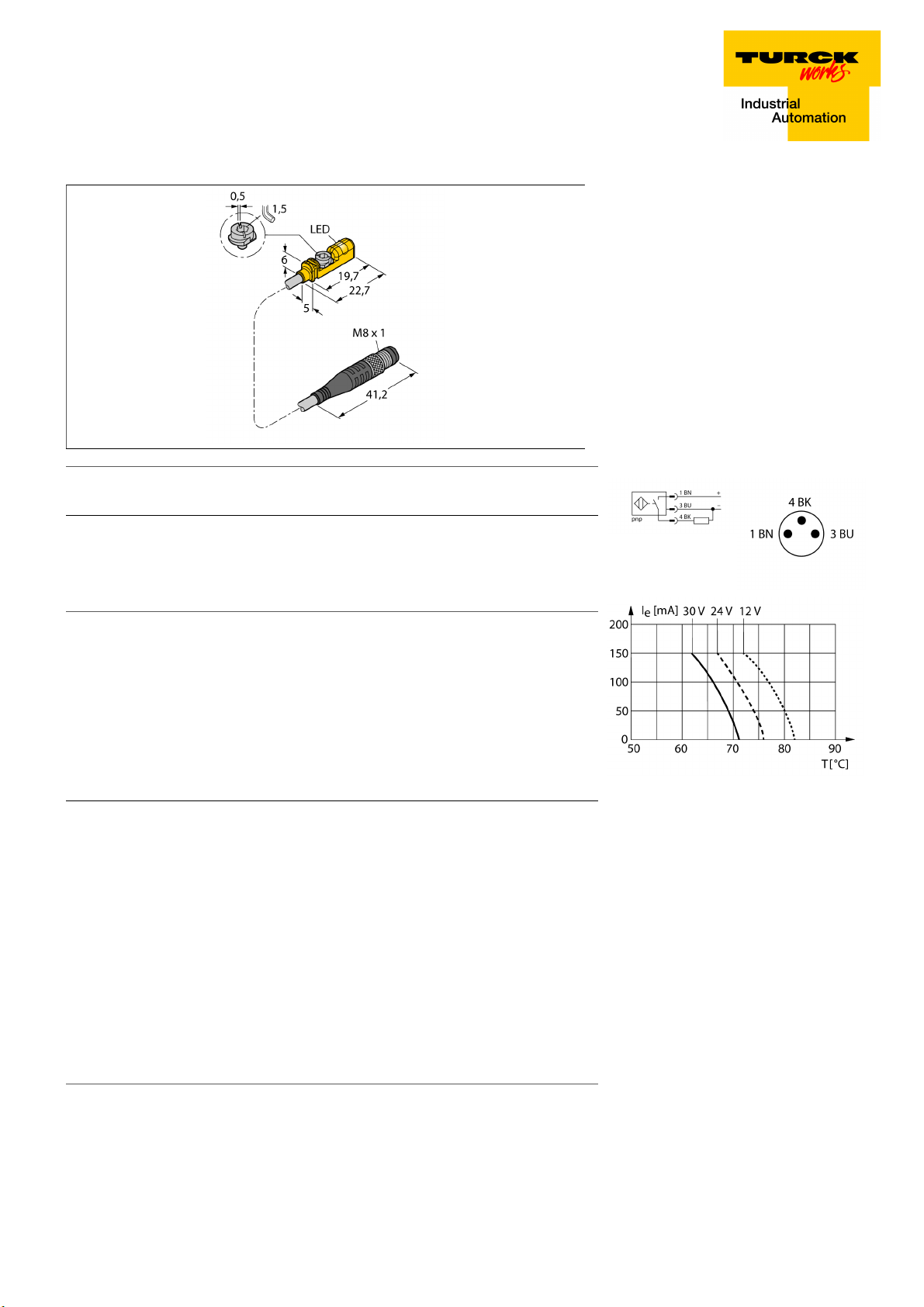

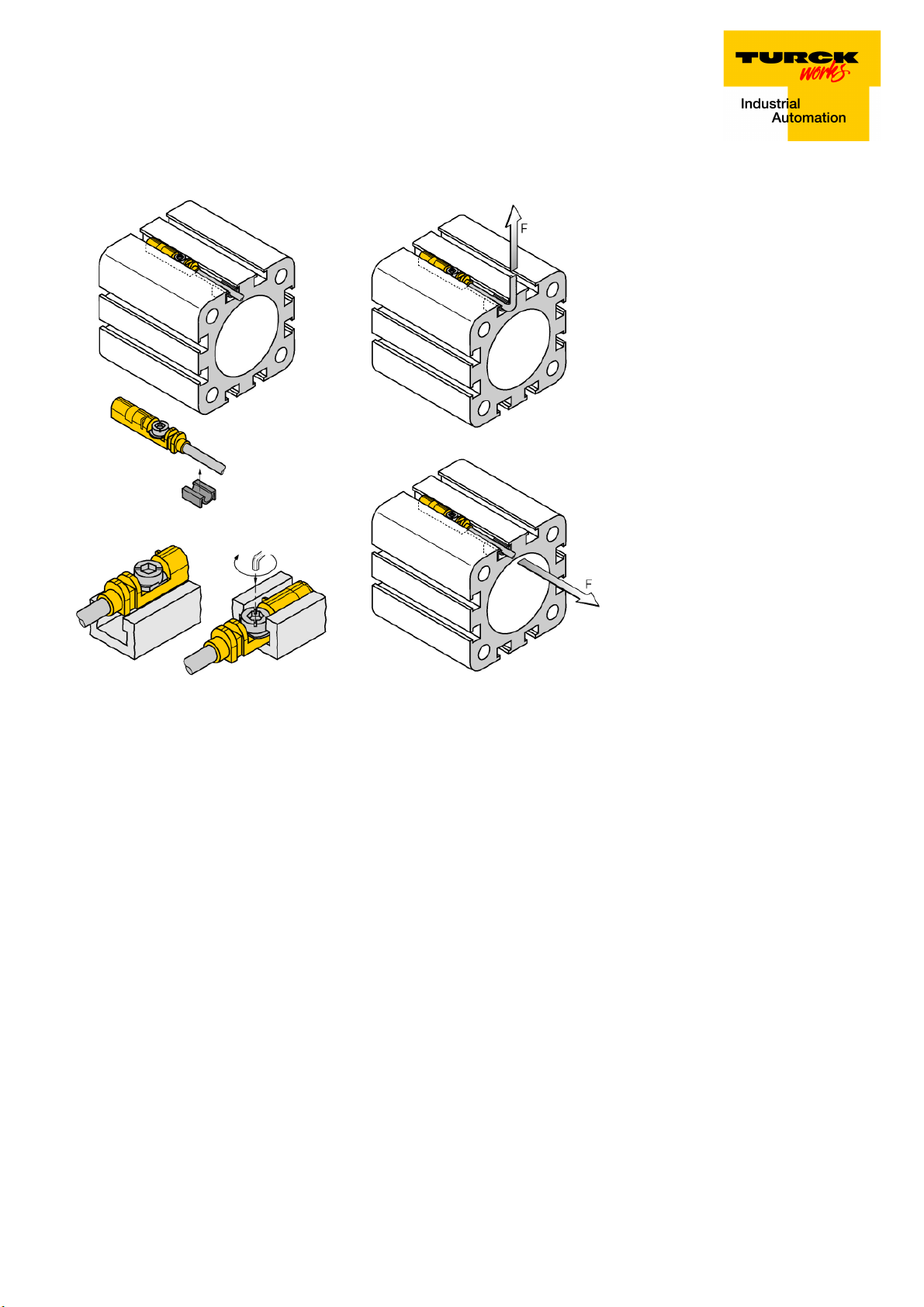

Thanks to the mounting lip, the sensor can be insert-

ed into the groove from above with one hand. Mount

the sensors as follows using the patented wing screw:

The wing screw and the female thread feature a left-

hand thread. Two small plastic lips keep the screw in

position, ready-to-install. Turn the screw clockwise.

The screw moves out of the thread and hits the upper

grooves with the wings. The sensor is thus pressed

down and locked in position. A few degrees up to ap-

proximately 1.5 turns of the screw with a slotted screw-

driver (blade width 0.5 mm) or a 1.5 mm Allen key are

sufficient to ensure vibration-proof fastening, depend-

ing on the shape of the slot. A tightening torque of 0.4

Nm is sufficient for safe mounting without damaging the

cylinder. The sensor can now withstand an axial and ra-

dial tensile load of F=100N applied on the cable. A ca-

ble clip is included in the scope of delivery. It enables

smooth cable routing in the groove and ensures that

the cable is fastened as securely as possible. The cor-

responding accessories for mounting on other cylindri-

cal housings must be ordered separately.

Edition • 2018-03-27T22:12:41+02:00

2 / 4 TURCK Inc.

Magnetic Field Sensor

Compact design for small hydraulic cylinders

BIM-UNTK-AP7X-0.3M-PSG 3M

Accessories

Type code Ident-No. Description

UNT-STOPPER 4685751

KLZ1-INT CLAMP 6970410 Accessories for mounting the sensors BIM-INT and BIM-UNT

Accessories for finetuning the switchpoint on N T-groove

cylinders; snap-locked in the BIM-UNT fixture; suited for mul-

tiple use; material: plastic

on tie-rod cylinders; Cylinder diameter: 32…40 mm; material:

Aluminium; Further mounting accessories for other cylinder

diameters on request

KLZ2-INT CLAMP 6970411 Accessories for mounting the sensors BIM-INT and BIM-UNT

on tie-rod cylinders; Cylinder diameter: 50…63 mm; material:

Aluminium; Further mounting accessories for other cylinder

diameters on request

UNT-ADJUSTING

BRACKET

KLDT-UNT2 6913351 Accessories for mounting the BIM-UNT sensor on dovetail

4685750

Accessories for finetuning the switchpoint on N T-groove

cylinders; snap-locked in the BIM-UNT fixture; suited for mul-

tiple use; material: metal/plastic

cylinders; groove width: 7 mm; material: PPS

Edition • 2018-03-27T22:12:41+02:00

3 / 4 TURCK Inc.

Magnetic Field Sensor

Compact design for small hydraulic cylinders

BIM-UNTK-AP7X-0.3M-PSG 3M

Accessories

Type code Ident-No. Description

KLDT-UNT3 6913352

Accessories for mounting the BIM-UNT sensor on K dove-

tail groove cylinders; groove width: 9.4 mm; material: PPS

KLDT-UNT6 6913355

Accessories for mounting on K dovetail groove cylinders;

groove width: 7.35 mm; material: PPS

Edition • 2018-03-27T22:12:41+02:00

4 / 4 TURCK Inc.

Loading...

Loading...