Magnetic Field Sensor

for pneumatic cylinders

BIM-UNT-AY1X/S1139

Type designation BIM-UNT-AY1X/S1139

Ident-No. 4685763

Pass speed

Repeatability

Temperature drift

Hysteresis

Ambient temperature -25…+70 °C

ð 10 m/s

ð ± 0.1 mm

ð 0.1 mm

ð 1 mm

■ ATEX category II 1 G, Ex Zone 0

■ ATEX category II 1 D, Ex Zone 20

■ For T-groove cylinders without mount-

ing accessories

■ Optional accessories for mounting on

other cylindrical housings.

■ One-hand mounting possible

■ Fine adjustment tool and stopper direct-

ly mountable on the sensor

■ Stable mounting

■ Long overtravel

■ For large cylinders

■ DC 2-wire, nom. 8.2 VDC

■ Output acc. to DIN EN 60947-5-6 (NA-

MUR)

■ Output with rectangular signal

■ NO contact

■ Cable connection

Wiring Diagram

Output function 2-wire, NAMUR

Switching frequency 1 kHz

Voltage Nom. 8.2 VDC

Current consumption non-actuated

Actuated current consumption

Approval acc. to KIWA 16 ATEX 0051 X

Design Rectangular,UNT

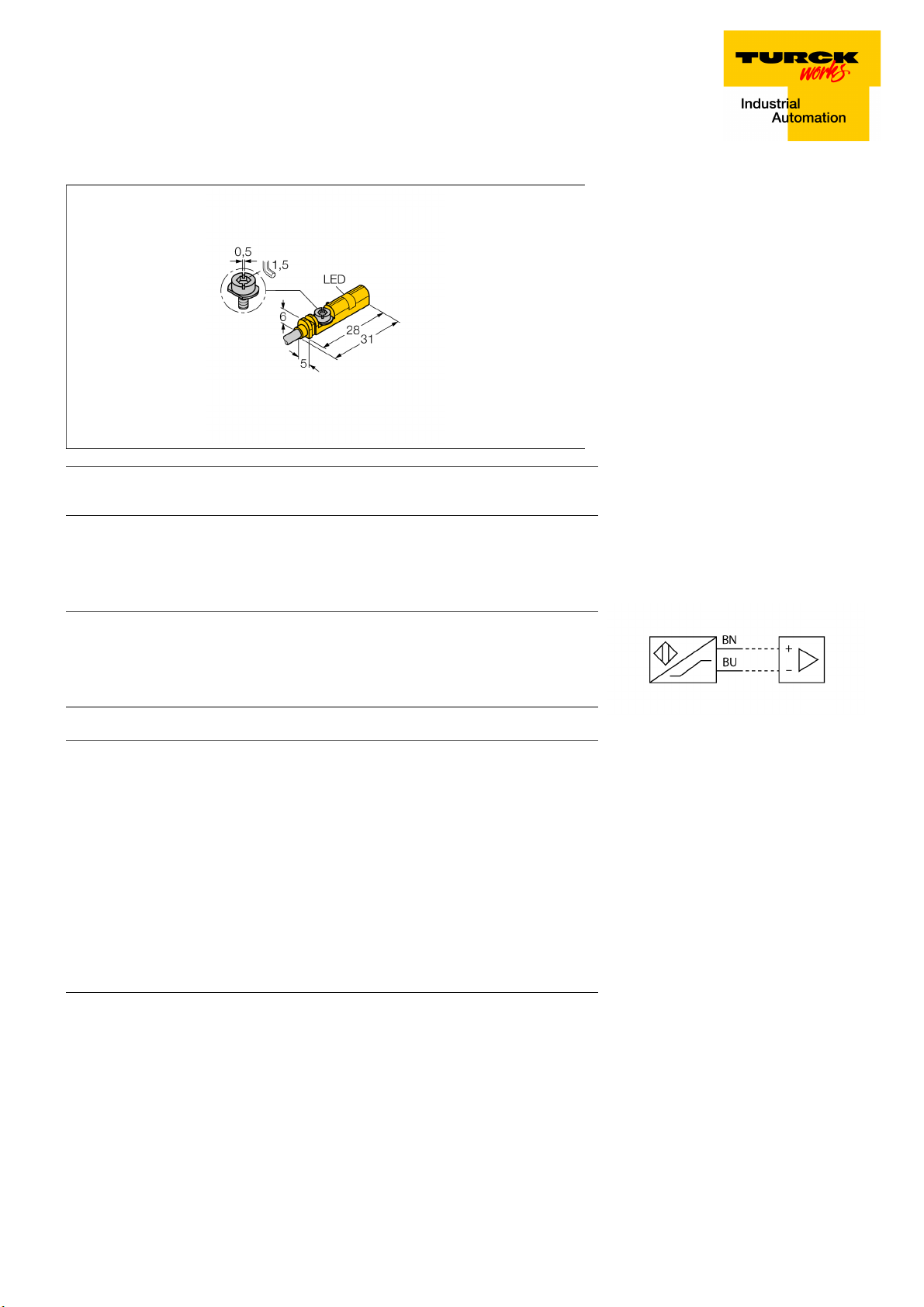

Dimensions 28 x 5 x 6 mm

Housing material Plastic, PP

Active area material Plastic, PP

Tightening torque fixing screw 0.4 Nm

Electrical connection Cable

Cable quality 3mm, Blue, Lif9YYW, PVC, 2

Cable cross section

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP67

MTTF 2283 years acc. to SN 29500 (Ed. 99) 40 °C

Packaging unit 1

Mounting on the following profiles .

Cylindrical design

Switching state LED,Yellow

Included in delivery cable clip

ð 1.2 mA

ï 2.1 mA

2 x 0.14 mm

E N K F

2

Functional principle

Magnetic field sensors are activated by magnetic fields and are especially suited for piston position detection in pneumatic cylinders.

Based on the fact that magnetic fields can

permeate non-magnetizable metals, it is possible to detect a permanent magnet attached

to the piston through the aluminium wall of the

cylinder.

Edition • 2018-03-19T20:41:18+01:00

1 / 6 TURCK Inc.

Magnetic Field Sensor

for pneumatic cylinders

BIM-UNT-AY1X/S1139

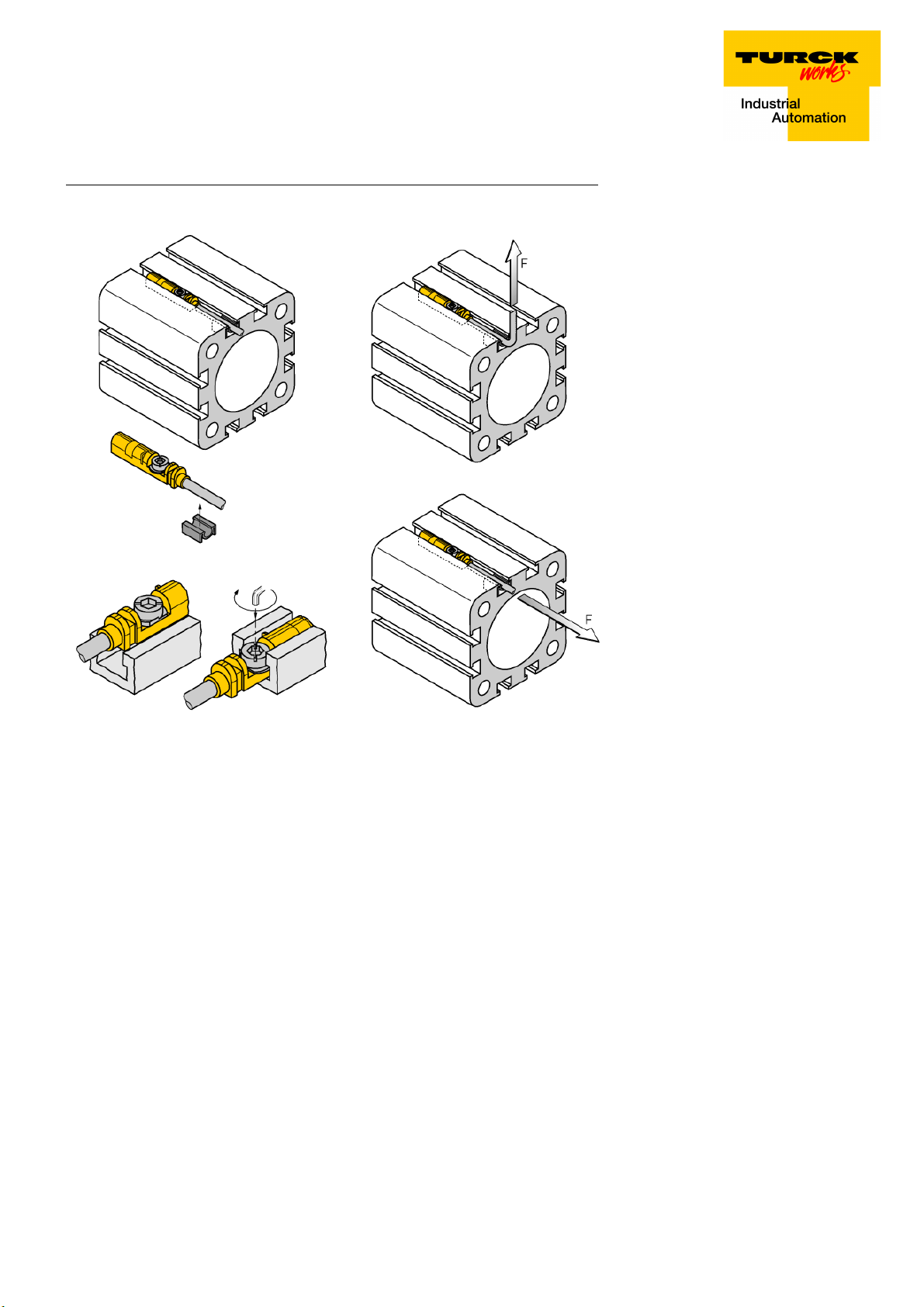

Mounting instructions/Description Mounting instructions

Thanks to the mounting lip, the sensor can be insert-

ed into the groove from above with one hand. Mount

the sensors as follows using the patented wing screw:

The wing screw and the female thread feature a left-

hand thread. Two small plastic lips keep the screw in

position, ready-to-install. Turn the screw clockwise.

The screw moves out of the thread and hits the upper

grooves with the wings. The sensor is thus pressed

down and locked in position. A few degrees up to ap-

proximately 1.5 turns of the screw with a slotted screw-

driver (blade width 0.5 mm) or a 1.5 mm Allen key are

sufficient to ensure vibration-proof fastening, depend-

ing on the shape of the slot. A tightening torque of 0.4

Nm is sufficient for safe mounting without damaging the

cylinder. The sensor can now withstand an axial and ra-

dial tensile load of F=100N applied on the cable. A ca-

ble clip is included in the scope of delivery. It enables

smooth cable routing in the groove and ensures that

the cable is fastened as securely as possible. The cor-

responding accessories for mounting on other cylindri-

cal housings must be ordered separately.

Edition • 2018-03-19T20:41:18+01:00

2 / 6 TURCK Inc.

Loading...

Loading...