Magnetic Field Sensor

for pneumatic cylinders

BIM-UNC-AN6X

Type designation BIM-UNC-AN6X

Ident-No. 100003138

■ For SMC C-groove cylinders without

mounting accessories

■ One-hand mounting possible

■ Stable mounting

■ Magneto-resistive sensor

■ DC 3-wire, 11…30 VDC

■ NO contact, NPN output

■ Cable connection

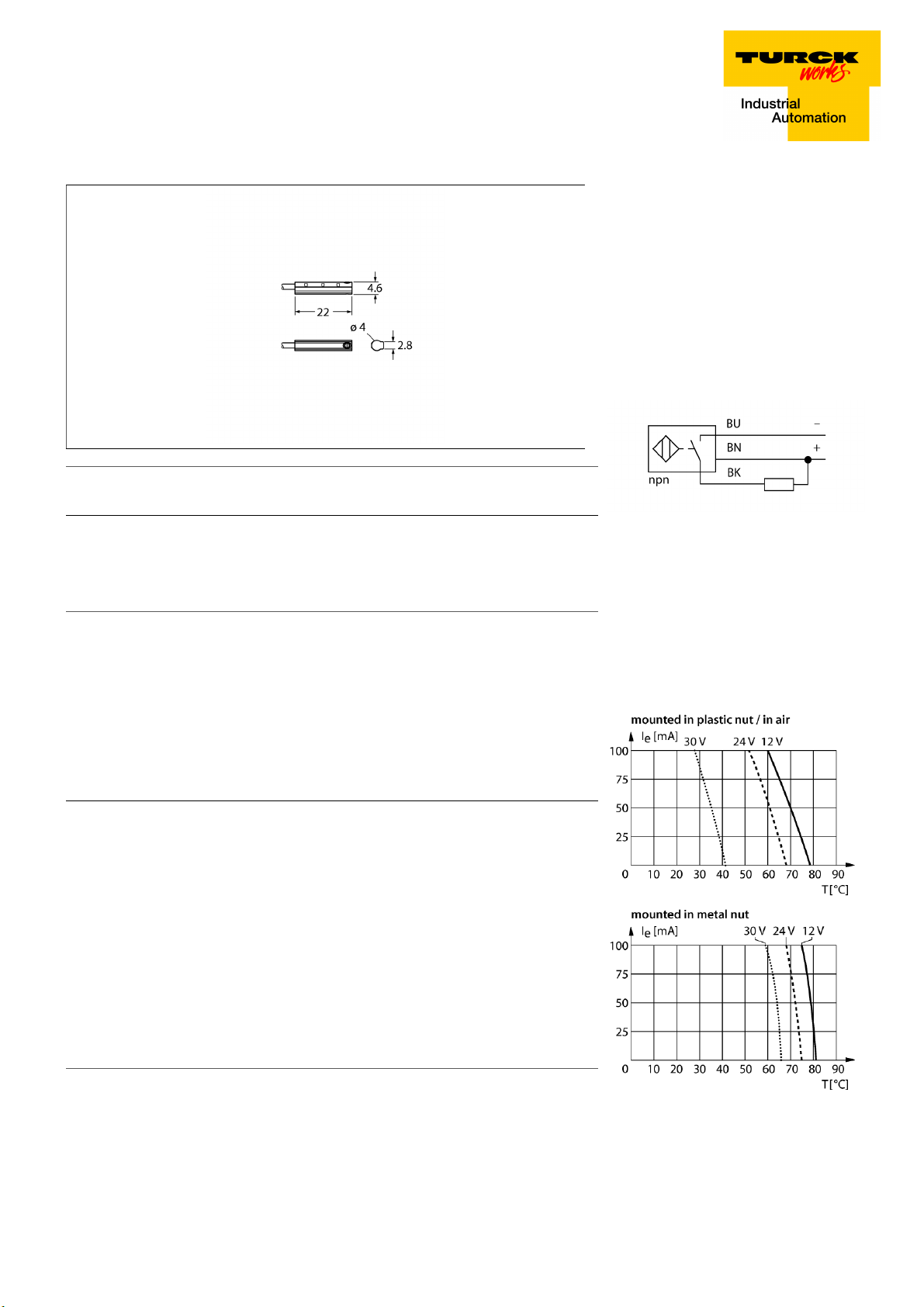

Wiring Diagram

Pass speed

Repeatability

Temperature drift

Hysteresis

Ambient temperature -25…+70 °C

Operating voltage 11…30 VDC

Residual ripple

DC rated operational current

No-load current I

Residual current

Isolation test voltage

Short-circuit protection yes/ Cyclic

Voltage drop at I

Wire breakage/Reverse polarity protection yes/ Complete

Output function 3-wire, NO contact, NPN

Switching frequency 0.3 kHz

Design Rectangular,UNC

Dimensions 22.1 x 4.6 mm

Housing material Plastic, PP-GF20

Active area material plastic, PP-GF20

Tightening torque fixing screw 0.1 Nm

Electrical connection Cables

Cable quality 2mm, Gray, Lif9Y-11Y, PUR, 2

Cable cross section

Litz wire 40x0.05mm

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP67

MTTF 2283 years acc. to SN 29500 (Ed. 99) 40 °C

Packaging unit 1

Mounting on the following profiles .

Cylindrical design

0

e

ð 3 m/s

ð ± 0.1 mm

ð 0.3 mm

ð 1 mm

ð 10 % U

ss

ð 100 mA

ð 15 mA

ð 0.1 mA

ð 0.5 kV

ð 1.8 V

3 x 0.08 mm

M

2

Functional principle

Magnetic field sensors are activated by magnetic fields and are used, in particular, for the

detection of the piston position in pneumatic

cylinders. As magnetic fields can permeate

non-magnetizable metals, they detect a permanent magnet attached to the piston through

the aluminium cylinder wall.

Derating Curve

Switching state LED,Yellow

Included in delivery Cable clip

Edition • 2018-09-10T20:08:41+02:00

1 / 2 TURCK Inc.

Magnetic Field Sensor

for pneumatic cylinders

BIM-UNC-AN6X

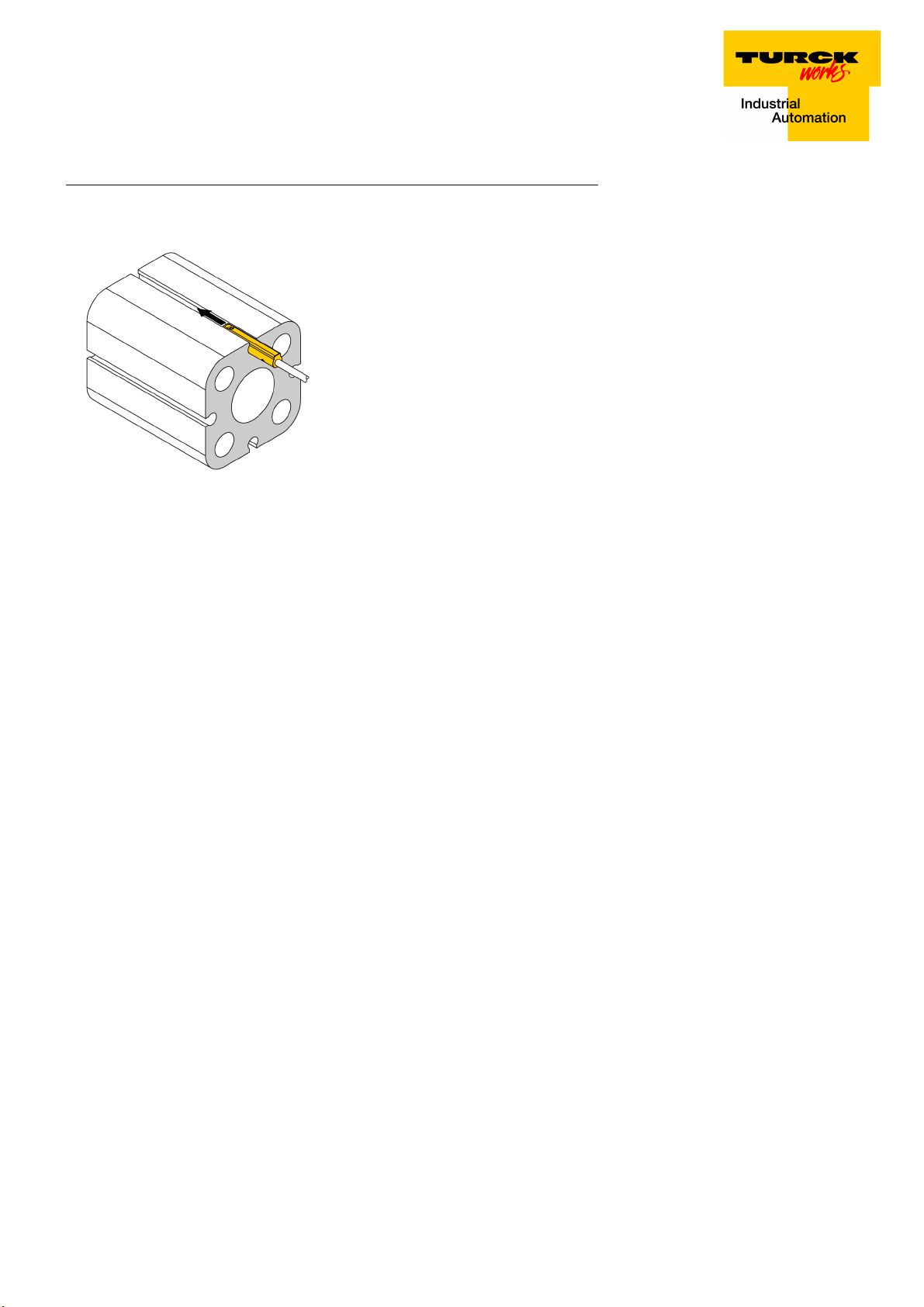

Mounting instructions/Description Mounting instructions

The sensor is mounted in the groove from the side.

If the screw is turned clockwise, it moves out of the

thread and pushes the sensor upwards towards the

cylinder. This fixes the sensor in place. A quarter turn

of the screw with a slotted screwdriver is sufficient to

fasten the sensor so that it doesn't vibrate. A tightening

torque of 0.1 Nm is sufficient for safe mounting without

damaging the cylinder. A cable clip is included in the

scope of delivery. It enables smooth cable routing in the

groove and ensures that the cable is fastened as se-

curely as possible. The corresponding accessories for

mounting on other cylindrical housings must be ordered

separately.

Edition • 2018-09-10T20:08:41+02:00

2 / 2 TURCK Inc.

Loading...

Loading...