Page 1

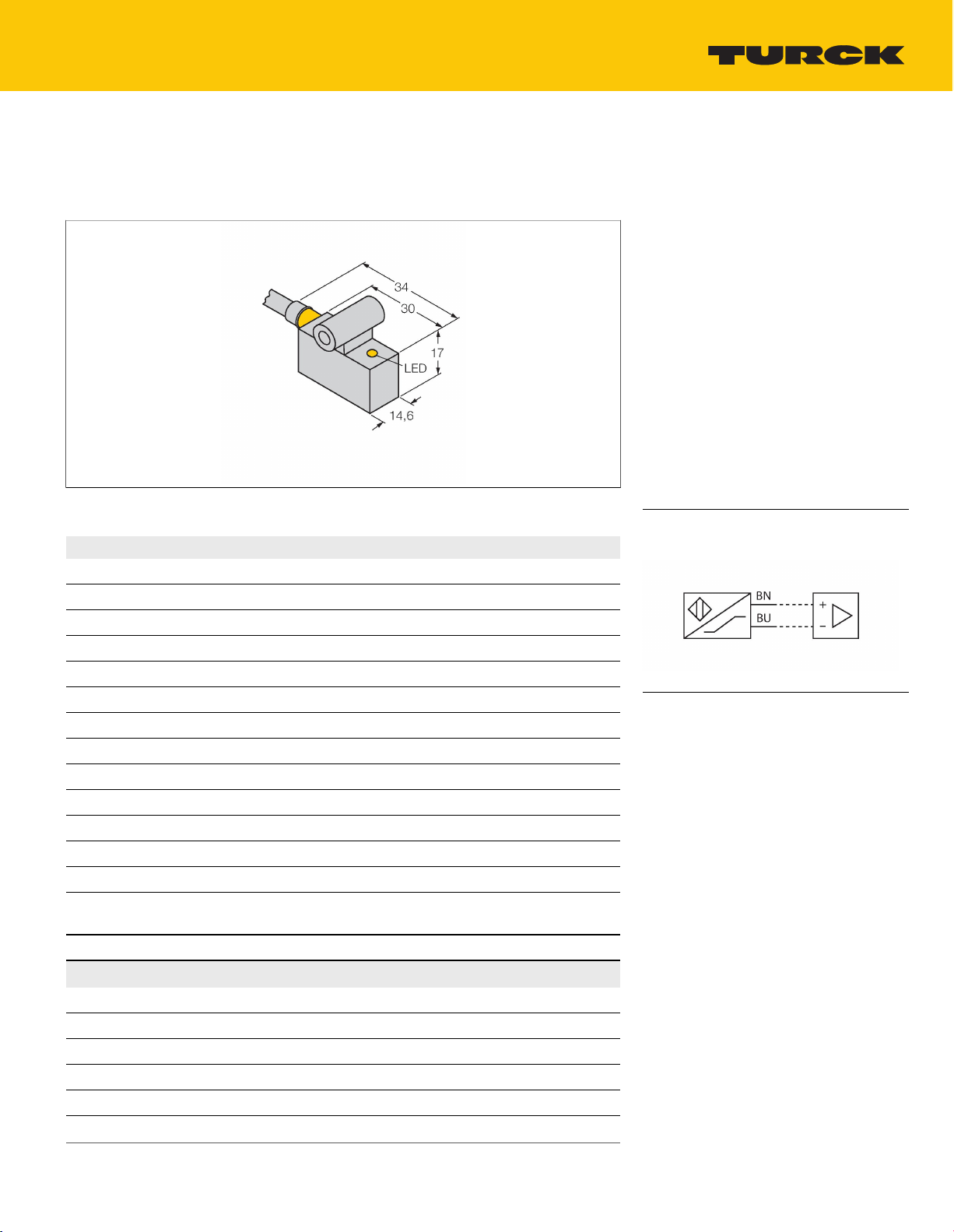

BIM-IKE-Y1X W/KLI3

Magnetic Field Sensor – for pneumatic cylinders

Features

Rectangular, height 17 mm

■

Active face in front

■

Metal, GD-Zn

■

Magnetic-inductive sensor

■

DC 2-wire, nom. 8.2 VDC

■

Output acc. to DIN EN 60947-5-6 (NAMUR)

■

Cable connection

■

ATEX category II 2 G, Ex zone 1

■

ATEX category II 1 D, Ex zone 20

■

SIL2 (Low Demand Mode) acc. to IEC 61508,

■

PL c acc. to ISO 13849-1 at HFT0

SIL3 (All Demand Mode) acc. to IEC 61508,

■

PL e acc. to ISO 13849-1 with redundant

configuration HFT1

Technical data

Wiring diagram

Type

Ident. no. 1056490

Pass speed ≤10m/s

Repeatability ≤ ±0.1mm

Temperature drift ≤0.1mm

Hysteresis ≤1mm

Ambient temperature -25…+70°C

Output function 2-wire, NAMUR

Switching frequency 1kHz

Voltage Nom.8.2VDC

Current consumption non-actuated ≤1.2mA

Actuated current consumption ≥2.1mA

Approval acc. to KEMA 02 ATEX 1090X

Internal capacitance (Ci)/inductance (Li) 150 nF/150 µH

Device marking

Design

Dimensions 30x14.6x17mm

Housing material Metal, GD-Zn

Active area material Plastic, PA12-GF30

Electrical connection Cable

Cable quality Ø5.2mm, Blue, Lif9YYW, PVC, 2m

Core cross-section

BIM-IKE-Y1X W/KLI3

É II 2 G Ex ia IIC T6 Gb / II 1 D Ex ia IIIC

T95 °C Da

(max. Ui = 20 V, Ii = 60 mA, Pi = 200 mW)

Rectangular,IKE

2x0.25mm

2

Functional principle

Magnetic field sensors are activated by

magnetic fields and are especially suited

for piston position detection in pneumatic

cylinders. Based on the fact that magnetic

fields can permeate non-magnetizable metals,

it is possible to detect a permanent magnet

attached to the piston through the aluminium

wall of the cylinder.

BIM-IKE-Y1X W/KLI3 | 12/03/2020 06-34 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

1|4

Page 2

Technical data

Vibration resistance 55Hz (1 mm)

Shock resistance 30g (11 ms)

Protection class IP67

MTTF 6198years acc. to SN 29500 (Ed. 99) 40

°C

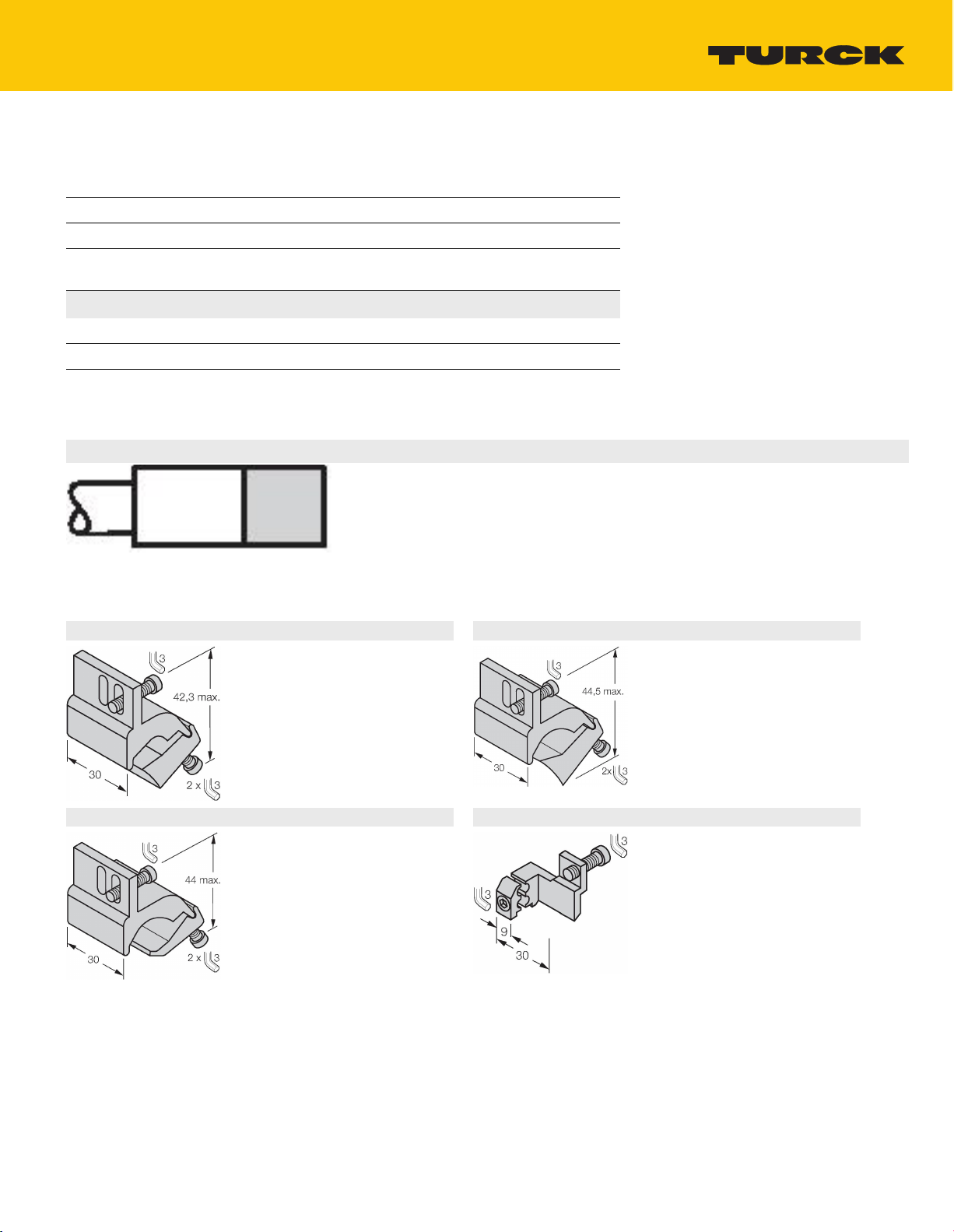

Mounting on the following profiles

Cylindrical design

F # #

Switching state LED,Yellow

Mounting instructions

Mounting instructions/Description

Accessories

KLI5Z 6971803

Mounting bracket for mounting

magnetic field sensors on tie-rod

cylinders; cylinder diameter: 32…63

mm; material: Aluminum

KLI6 6971805

Mounting bracket for mounting

magnetic field sensors on profile

cylinders; cylinder diameter: 50…100

mm; material: Aluminum

KLI6Z 6971806

Mounting bracket for mounting

magnetic field sensors on tie-rod

cylinders; cylinder diameter: 50…125

mm; material: Aluminum

KLI7 6971810

Mounting bracket for mounting

magnetic field sensors on profile

cylinders with external dovetail guide;

cylinder diameter: 32…200 mm;

material: Aluminum

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

BIM-IKE-Y1X W/KLI3 | 12/03/2020 06-34 | technical changes reserved

2|4

Page 3

KLI1 69710

Mounting bracket for mounting

magnetic field sensors on tie-rod

cylinders; cylinder diameter: 32…100

mm; material: Die-cast Zinc

KLI3 69712

Mounting bracket for mounting

magnetic field sensors on tie-rod

cylinders; cylinder diameter: 63…160

mm; material: Die-cast Zinc

KLI5 6971802

Mounting bracket for mounting

magnetic field sensors on profile

cylinders; cylinder diameter: 32…50

mm; material: Aluminum

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

BIM-IKE-Y1X W/KLI3 | 12/03/2020 06-34 | technical changes reserved

3|4

Page 4

Operating Instructions

Intended use

This device fulfills the directive 2014/34/EC and is suited for use in explosion hazardous areas according to EN

60079-0:2012 + A11 and EN 60079-11:2012.Further it is suited for use in safety-related systems, including SIL2 as per IEC

61508.In order to ensure correct operation to the intended purpose it is required to observe the national regulations and

directives.

For use in explosion hazardous areas conform to classification

II 2 G and II 1 D (Group II, Category 2 G, electrical equipment for gaseous atmospheres and category 1 D, electrical equipment for

dust atmospheres).

Marking (see device or technical data sheet)

É II 2 G and Ex ia IIC T6 Gb and É II 1 D Ex ia IIIC T95 °C Da acc. to EN 60079-0, -11

Local admissible ambient temperature

-25…+70 °C

Installation/Commissioning

These devices may only be installed, connected and operated by trained and qualified staff. Qualified staff must have

knowledge of protection classes, directives and regulations concerning electrical equipment designed for use in

explosion hazardous areas.Please verify that the classification and the marking on the device comply with the actual

application conditions.

This device is only suited for connection to approved Exi circuits according to EN 60079-0 and EN 60079-11. Please

observe the maximum admissible electrical values.After connection to other circuits the sensor may no longer be

used in Exi installations. When interconnected to (associated) electrical equipment, it is required to perform the "Proof

of intrinsic safety" (EN60079-14).Attention! When used in safety systems, all content of the security manual must be

observed.

Installation and mounting instructions

Avoid static charging of cables and plastic devices. Please only clean the device with a damp cloth. Do not install the

device in a dust flow and avoid build-up of dust deposits on the device.If the devices and the cable could be subject to

mechanical damage, they must be protected accordingly. They must also be shielded against strong electro-magnetic

fields.The pin configuration and the electrical specifications can be taken from the device marking or the technical data

sheet.

Service/Maintenance

Repairs are not possible. The approval expires if the device is repaired or modified by a person other than the

manufacturer. The most important data from the approval are listed.

BIM-IKE-Y1X W/KLI3 | 12/03/2020 06-34 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

4|4

Loading...

Loading...