Turck BID2-G180-RP6/S212 Data Sheet

Inductive sensor

For high pressures

BID2-G180-RP6/S212

Type designation BID2-G180-RP6/S212

Ident-No. 1688010

Rated switching distance Sn 2 mm

Mounting conditions Flush

Secured operating distance

Correction factors St37 = 1; Al = 0.3; stainless steel = 0.7; Ms = 0.4

Repeat accuracy

Static pressure

Dynamic pressure

Admissible contact medium electrically non-conductive

Temperature drift

Hysteresis 3…15 %

Ambient temperature -25…+85 °C

Operating voltage 10…30 VDC

Residual ripple

DC rated operational current

No-load current I

Residual current

Isolation test voltage

Short-circuit protection yes/ Cyclic

Voltage drop at I

Wire breakage/Reverse polarity protection yes/ Complete

Output function 3-wire, NC contact, PNP

Switching frequency 2 kHz

0

e

ð (0,81 x Sn) mm

ð 2 % of full scale

ð 500 bar

ð 350 bar

ð ± 10 %

ð 10 % U

ss

ð 200 mA

ð 15 mA

ð 0.1 mA

ð 0.5 kV

ð 1.8 V

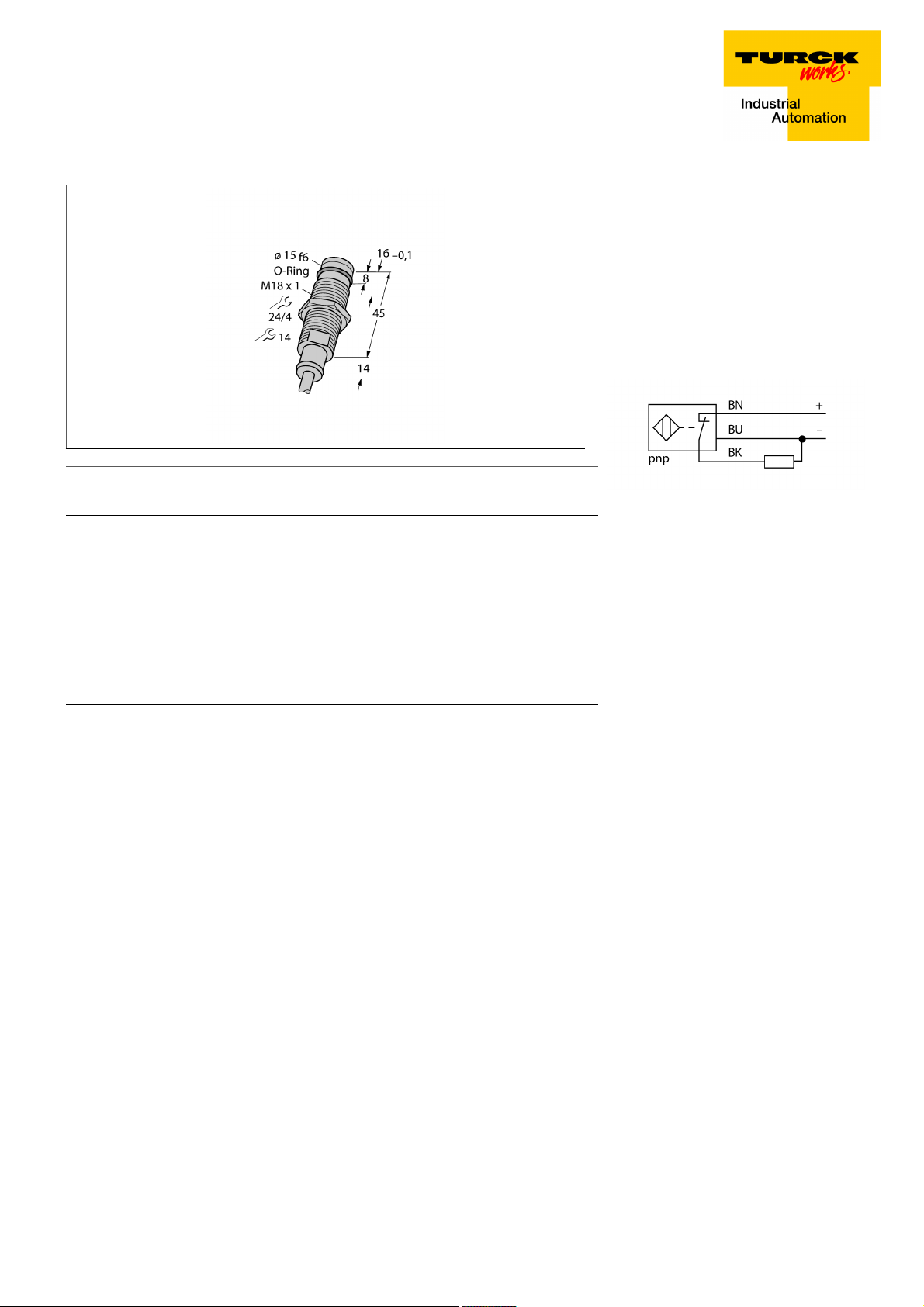

■ Threaded barrel, M18 x 1

■ Stainless steel, 1.4305

■ Admissible pressure static/dynamic

500/350 bar

■ DC 3-wire, 10…30 VDC

■ NC contact, PNP output

■ Cable connection

Wiring Diagram

Functional principle

Inductive sensors detect metal objects contactless and wear-free. For this purpose they

use a high-frequency electromagnetic AC

field that interacts with the target. The sensors

hosting a ferrite core coil generate the AC field

through an LC resonant circuit.

Pressure resistant inductive sensors withstand pressures of up to 500 bar which makes

them perfectly suited for position control in hydraulic cylinders.

Design Threaded barrel,M18 × 1

Dimensions 58 mm

Housing material Metal, V2A (1.4305)

Active area material Plastic, PA12-GF30

Max. tightening torque housing nut 25 Nm

Electrical connection Cable

Cable quality 6.3mm, LiÖlflex, Ölflex®, 2

Cable cross section

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP67

Edition • 2018-04-23T15:46:52+02:00

1 / 2 TURCK Inc.

3 x 0.5 mm

2

Inductive sensor

For high pressures

BID2-G180-RP6/S212

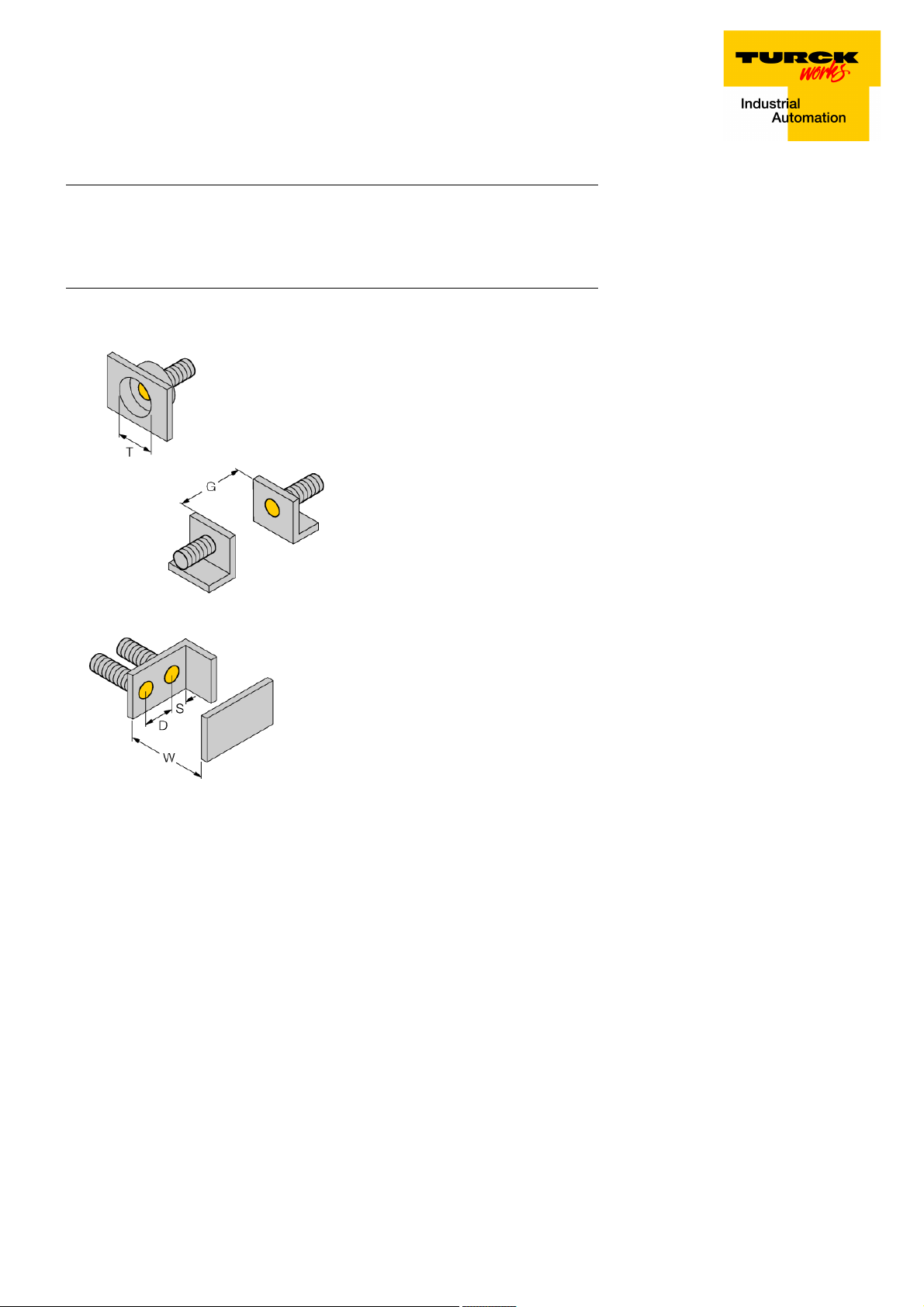

Distance D 2 x B

Distance W 3 x Sn

Distance T 3 x B

Distance S 1.5 x B

Distance G 6 x Sn

Diameter active area B Ø 18 mm

In order to protect the coil connections integrated in

■

the sensor head, it is required to ventilate the chamber of the oscillator coil.

For this the employed non-conductive and neutral

■

medium is filled into the cavity via the middle hole of

the sensor's active face, using a thin cannula.

Edition • 2018-04-23T15:46:52+02:00

2 / 2 TURCK Inc.

Loading...

Loading...