Inductive sensor

BI3U-EM12-AP6X/3D

■ ATEX category II 3 D, Ex-zone 22

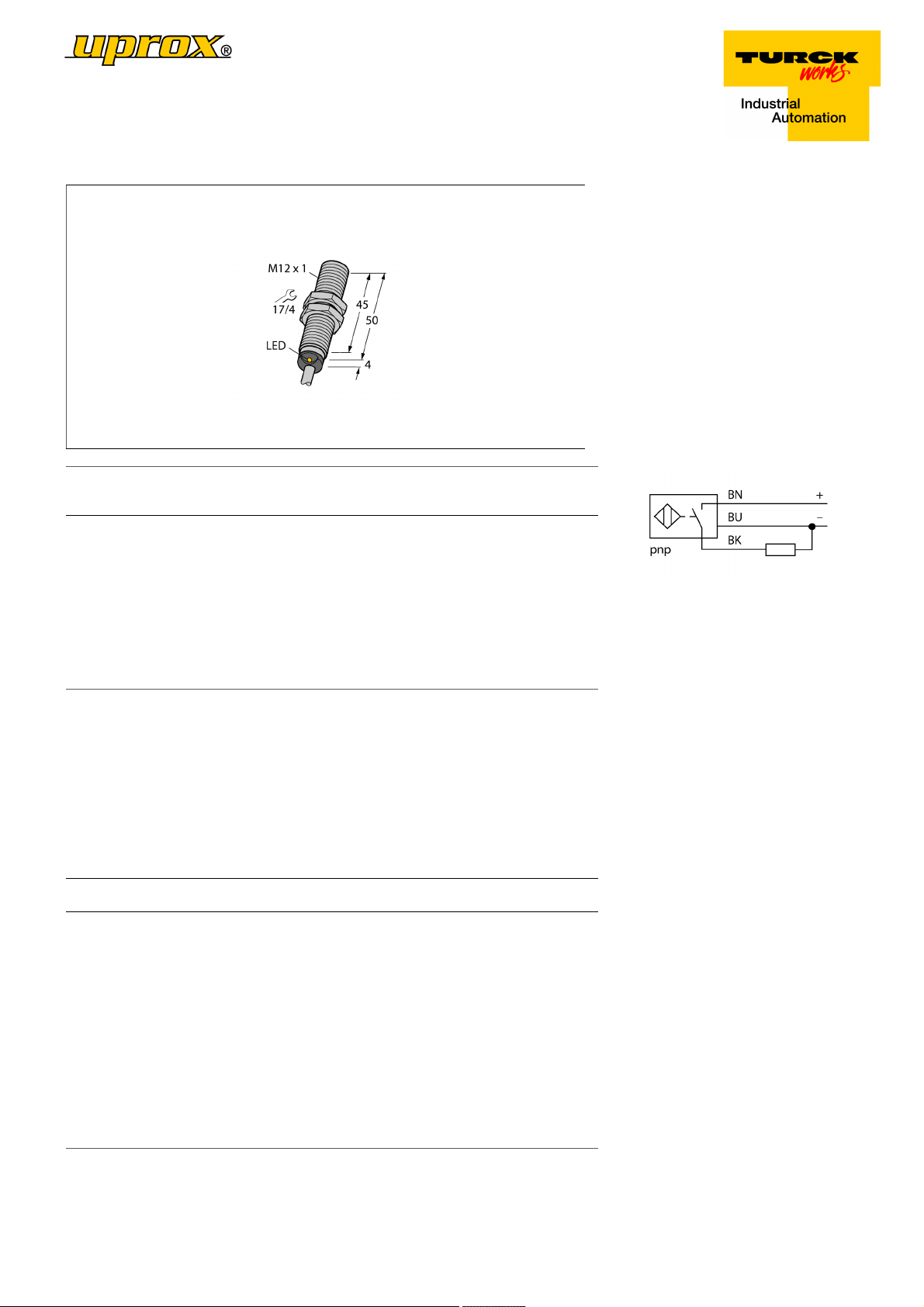

■ Threaded barrel, M12 x 1

■ Stainless steel, 1.4301

■ Factor 1 for all metals

■ Protection class IP68

■ Resistant to magnetic fields

■ Extended temperature range

■ High switching frequency

■ DC 3-wire, 10…30 VDC

■ NO contact, PNP output

■ Cable connection

Type designation BI3U-EM12-AP6X/3D

Ident-No. 1634305

Rated switching distance Sn 3 mm

Mounting conditions Flush

Secured operating distance

Repeat accuracy

Temperature drift

Hysteresis 3…15 %

Ambient temperature -30…+85 °C

Operating voltage 10…30 VDC

Residual ripple

DC rated operational current

No-load current I

Residual current

Isolation test voltage

Short-circuit protection yes/ Cyclic

Voltage drop at I

Wire breakage/Reverse polarity protection yes/ Complete

Output function 3-wire, NO contact, PNP

Switching frequency 3 kHz

Approval acc. to ATEX test certificate TURCK Ex-10002M X

0

e

ð (0,81 x Sn) mm

ð 2 % of full scale

ð ± 10 %

ð ± 15 %, ð -25 °C v ï +70 °C

For explosion hazardous areas see instruction

leaflet

ð 10 % U

ss

ð 200 mA

ð 20 mA

ð 0.1 mA

ð 0.5 kV

ð 1.8 V

Wiring Diagram

Functional principle

Inductive sensors detect metal objects contactless and wear-free. uprox® Factor 1 sensors have significant advantages due to their

patented ferrite-coreless multicoil system.

They detect all metals at the same large

switching distance and are resistant to magnetic fields.

Design Threaded barrel,M12 × 1

Dimensions 54 mm

Housing material Stainless steel, V2A (1.4301)

Active area material Plastic, PBT

End cap Plastic, EPTR

Max. tightening torque housing nut 10 Nm

Electrical connection Cable

Cable quality 5.2mm, LifYY, PVC, 2

Cable cross section

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP68

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Packaging unit 1

Switching state LED,Yellow

Edition • 2018-04-19T18:13:34+02:00

1 / 4 TURCK Inc.

3 x 0.34 mm

2

Inductive sensor

BI3U-EM12-AP6X/3D

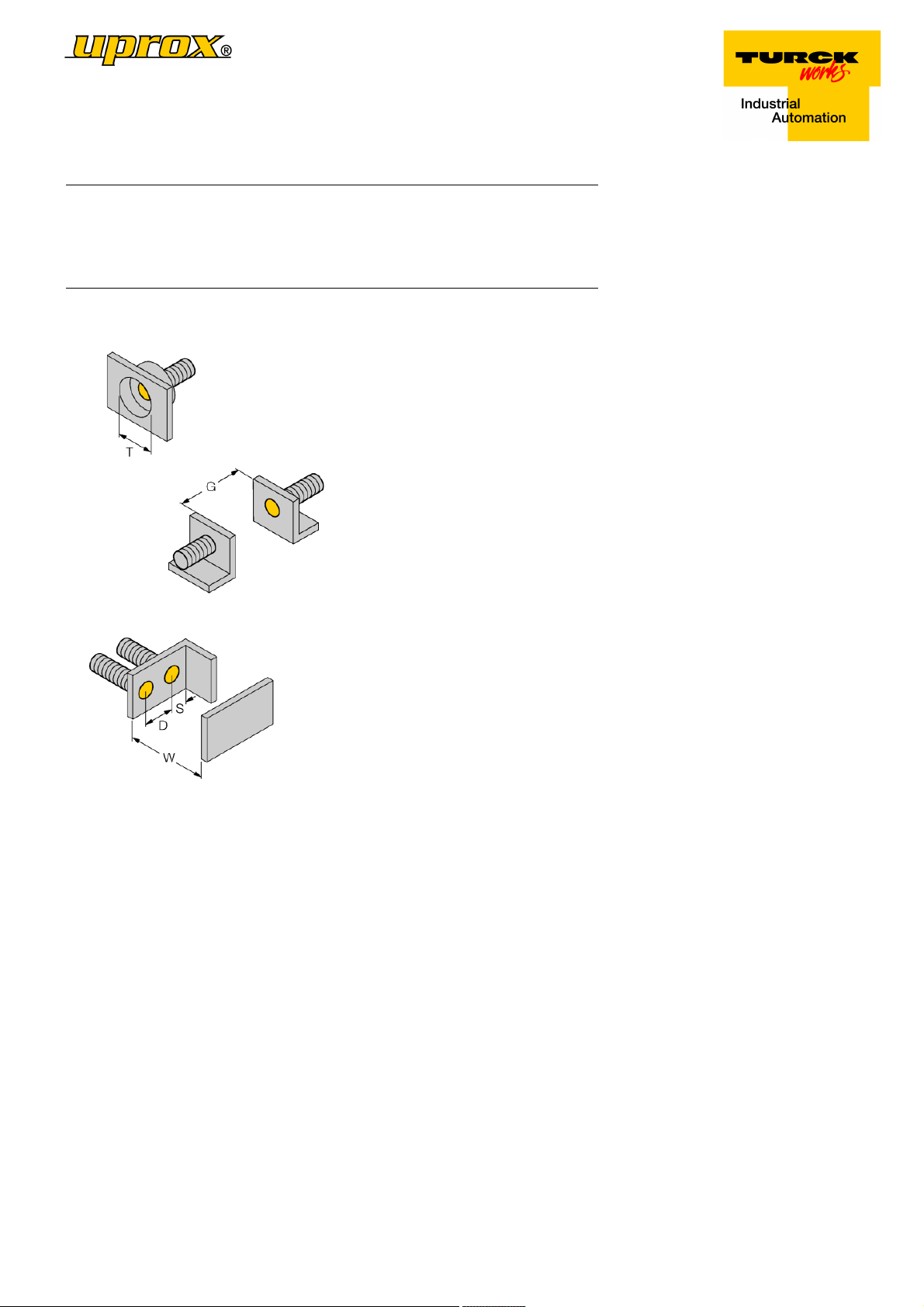

Distance D 2 x B

Distance W 3 x Sn

Distance T 3 x B

Distance S 1.5 x B

Distance G 6 x Sn

Diameter active area B Ø 12 mm

Edition • 2018-04-19T18:13:34+02:00

2 / 4 TURCK Inc.

Inductive sensor

BI3U-EM12-AP6X/3D

Accessories

Type code Ident-No. Description

BST-12B 6947212 Fixing clamp for threaded barrel devices, with dead-stop; ma-

terial: PA6

MW-12 6945003 Mounting bracket for threaded barrel devices; material: Stain-

less steel A2 1.4301 (AISI 304)

BSS-12 6901321 Mounting bracket for smooth and threaded barrel devices;

material: Polypropylene

Edition • 2018-04-19T18:13:34+02:00

3 / 4 TURCK Inc.

Inductive sensor

BI3U-EM12-AP6X/3D

Operating manual

Intended use

This device fulfills the directive 94/9/EC and is suited for use in explosion hazardous areas according to EN60079-0:2009 and EN61241-1:2004.

In order to ensure correct operation to the intended purpose it is required to observe the national regulations and directives.

For use in explosion hazardous areas conform to classification

II 3 D (Group II, Category 3 D, electrical equipment for dust atmospheres).

Marking (see device or technical data sheet)

É II 3 D Ex tD A22 IP67 T110°C acc. to EN 60079-0:2009 and EN 61241-1:2004

Local admissible ambient temperature

-25…+70 °C

Installation/Commissioning

These devices may only be installed, connected and operated by trained and qualified staff. Qualified staff must have knowledge of protection

classes, directives and regulations concerning electrical equipment designed for use in explosion hazardous areas.

Please verify that the classification and the marking on the device comply with the actual application conditions.

Installation and mounting instructions

Avoid static charging of cables and plastic devices. Please only clean the device with a damp cloth. Do not install the device in a dust flow and

avoid build-up of dust deposits on the device.

If the devices and the cable could be subject to mechanical damage, they must be protected accordingly. They must also be shielded against

strong electro-magnetic fields.

The pin configuration and the electrical specifications can be taken from the device marking or the technical data sheet.

In order to avoid contamination of the device, please remove possible blanking plugs of the cable glands or connectors only shortly before inserting the cable or opening the cable socket.

Special conditions for safe operation

For devices with M12 connectors please use the supplied safety clip SC-M12/3GD.

Do not disconnect the plug-in connection or cable under voltage.

Please attach a warning label permanently in an appropriate fashion in close proximity to the plug-in connection with the following inscription:

Nicht unter Spannung trennen / Do not separate when energized.

The device must be protected against any kind of mechanical damage and degrading UV-radiation.

Service/Maintenance

Repairs are not possible. The approval expires if the device is repaired or modified by a person other than the manufacturer. The most important

data from the approval are listed.

Edition • 2018-04-19T18:13:34+02:00

4 / 4 TURCK Inc.

Loading...

Loading...