turck BI6U-MT12, BI20U-M30, BI10U-M18, BI10U-MT18, BI20U-MT30 Operating Instructions Manual

...Page 1

Your Global Automation Partner

Operating Instructions

Inductive Sensors

uprox®

with IO-Link Interface

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Contents

Page 3

3

2016/08

uprox® Sensors with IO-Link Interface

1 About this manual 5

1.1 Target groups 5

1.2 Explanation of symbols 5

1.3 Other documents 5

1.4 Feedback about these instructions 6

2 Notes on the product 7

2.1 Product identication 7

2.2 Scope of delivery 7

2.3 Legal requirements 8

2.4 Manufacturer and service 8

3 For your safety 9

3.1 Intended use 9

3.2 Obvious misuse 9

3.3 General safety instructions 9

4 Product description 10

4.1 Device overview 10

4.1.1 Indication elements 11

4.2 Properties and features 11

4.2.1 Properties and features – Rectangular design 11

4.3 Operating principle 11

4.4 Functions and operating modes 11

4.4.1 Sensor functions 11

4.4.2 Settable properties 13

4.4.3 Standard I/O mode (SIO mode) 16

4.5 Technical accessories 16

5 Mounting 17

5.1 Mounting cylindrical devices 17

5.1.1 Mounting cylindrical devices with a half-shell clamp 18

5.2 Mounting rectangular devices 19

5.2.1 Positioning the active face (Ni50U-QV40…) 21

5.2.2 Positioning the active face (NI50U-CK40…) 22

6 Connection 23

6.1 Wiring diagram 23

7 Commissioning 23

7.1 Setting IO-Link mode 23

7.2 Setting up SIO mode 23

8 Operation 24

8.1 LEDs 24

8.2 Operating devices in IO-Link mode 24

8.3 Operating devices in SIO mode 24

Contents

Page 4

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

9 Setting 24

9.1 Setting via IO-Link 24

9.1.1 IO-Link parameters 25

9.1.2 Parameter transfer with IO-Link call function block 25

9.1.3 Process data 25

9.2 Setting in SIO mode 26

9.2.1 Setting the device before initial commissioning 26

9.2.2 Setting devices after initial commissioning 26

10 Troubleshooting 26

11 Maintenance 26

12 Repair 26

12.1 Returning devices 26

13 Decommissioning 27

14 Disposal 27

15 Technical data 28

15.1 Technical data – Bi…U-M… 28

15.2 Technical data – BI…U-MT… 29

15.3 Technical data – Ni50U-… 30

Page 5

5

2016/08

uprox® Sensors with IO-Link Interface

1 About this manual

This manual describes the setup, the functions and use of the product and helps you to operate

the product for its intended use. Read these instructions carefully prior to using the product.

This will prevent the risk of personal injury and damage to property. Keep these instructions

safe during the service life of the product. If the product is passed on, pass on these instructions

as well.

1.1 Target groups

This document is written for specially trained personnel, and must be read carefully by anyone

who is charged with the mounting, commissioning, operation, maintenance, disassembly or

disposal of the device.

1.2 Explanation of symbols

The following symbols are used in these instructions:

DANGER

DANGER indicates an immediate hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a possible hazardous situation with the risk of death or serious

injury if it is not prevented.

NOTICE

NOTICE indicates a situation that may cause possible damage to property if it is not

prevented.

NOTE

NOTE indicates tips, recommendations and important information. The notes simplify

work, contain information on particular operating steps and help to avoid additional

work resulting from incorrect procedures.

MANDATORY ACTION

This symbol denotes actions that the user must carry out.

RESULT OF ACTION

This symbol denotes the relevant results of actions and procedures.

1.3 Other documents

Besides this document the following material can be found on the Internet at www.turck.com:

■

Data sheet of the respective device

■

IODD file

■

IO-Link parameter manual

All the required Turck software components and the IODD can be downloaded via the Turck

Software Manager. The Turck Software Manager can be downloaded free of charge from

www.turck.com.

Page 6

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

About this manual

1.4 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If you have any suggestions for improving the design or if some information is missing in

the document, please send your suggestions to techdoc@turck.com.

Page 7

7

2016/08

uprox® Sensors with IO-Link Interface

2 Notes on the product

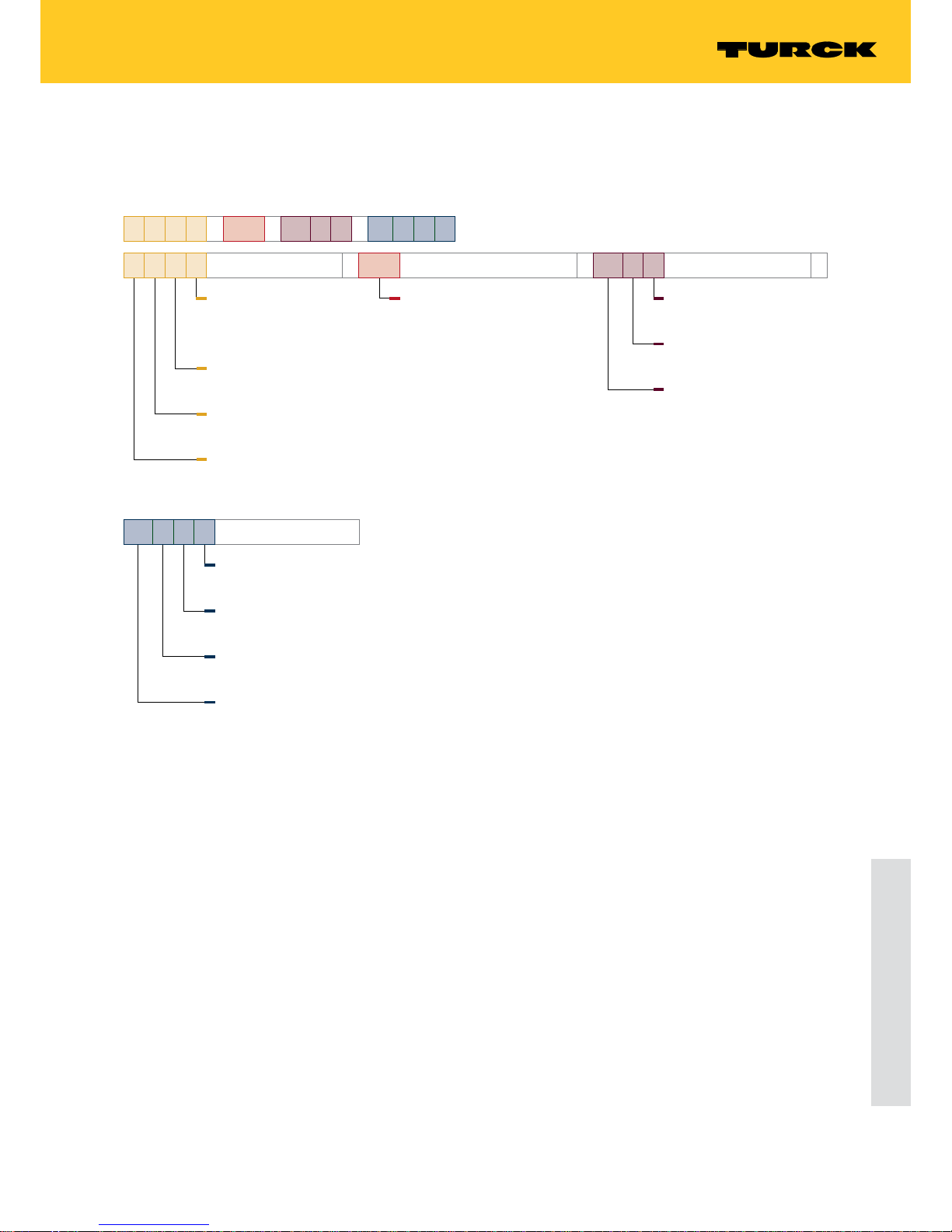

2.1 Product identication

2.2 Scope of delivery

The following are included in the scope of delivery:

■

Sensor

■

2 fixing nuts (with threaded barrel devices)

■

2 lock washers (with M12 and Bi…U-MT… design)

■

Mounting bracket BS4-CK40 (with Ni…U-CK40…)

■

Mounting block and mounting bracket (with Ni…U-QV40…)

■

Quick Start Guide

B i 10 U – M18 – IOL 6 X2 – H1141

B i 10 U

Functional principle

–

Special functions

U uprox® or uprox®+ or

uprox®3

Faktor 1 sensors

Rated switching distance

… Switching distance

Functional principle

i Inductive

Installation

B Flush

N Non-flush

M18

Design

–

Housing

M Threaded barrel, brass,

Ø in [mm]

MT Threaded barrel, brass,

PTFE coated, Ø in [mm]

CK40 Rectangular, variable orientation

of active face in 5 directions

QV40 Rectangular, variable orientation

of active face in 5 directions

IOL 6 X2

Electrical version

–

Indication

X2 Multicolor LED

Voltage range

6 10…30 VDC

Technology

IOL IO-Link

H1141

Electrical connection:

Connector

Assignment

1 Standard assignment

Number of contacts

4 Number of contacts

Connector design

1 Straight

Connector design

H1 Receptacle, M12 x 1

Page 8

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Notes on the product

2.3 Legal requirements

The device is subject to the following EC directives:

■

2014/35/EU (low voltage)

■

2014/30/EU (electromagnetic compatibility)

2.4 Manufacturer and service

Turck supports you in your projects – from the initial analysis right through to the commissioning of your application. The Turck product database offers you several software tools for programming, configuring or commissioning, as well as data sheets and CAD files in many export

formats. You can access the Product Database directly via the following address:

www.turck.de/products

For further inquiries in Germany contact the Sales and Service Team on:

Sales: +49 208 4952-380

Technical: +49 208 4952-390

For overseas inquiries contact your national Turck representative.

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Mülheim an der Ruhr

Germany

Page 9

9

2016/08

uprox® Sensors with IO-Link Interface

3 For your safety

The product is designed according to state of the art technology. Residual hazards, however,

still exist. Observe the following warnings and safety regulations in order to prevent danger to

persons and property. Turck accepts no liability for damage caused by failure to observe these

warnings and safety instructions.

3.1 Intended use

The devices are designed for installation in large-scale industrial plants and equipment and for

use in industrial automation applications.

The inductive sensors of the uprox® series enable the contactless and wear-free detection of

metallic objects. The factor 1 sensors have no reduction factor; the switching distance is the

same for all metals. The sensors are not susceptible to interference from strong magnetic fields.

The devices can be operated and set with IO-Link masters compliant with specification 1.1 via

an IO-Link interface. Process and diagnostics data can be exchanged during operation via IOLink with the higher controller level.

The devices must only be used as described in these instructions. Any other use is not in accordance with the intended use; Turck accepts no liability for any resulting damage.

3.2 Obvious misuse

■

The devices are not safety components and must not be used for the protection of persons or

property.

■

The listed switching distances are based on a standard target as specified in EN 609475-2:2012. Different targets (especially small targets) may cause changes in the switching

behavior.

3.3 General safety instructions

■

The device must only be fitted, installed, operated, parameterized and maintained by trained

and qualified personnel.

■

Only use the device in compliance with the applicable national and international regulations,

standards and laws.

Page 10

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

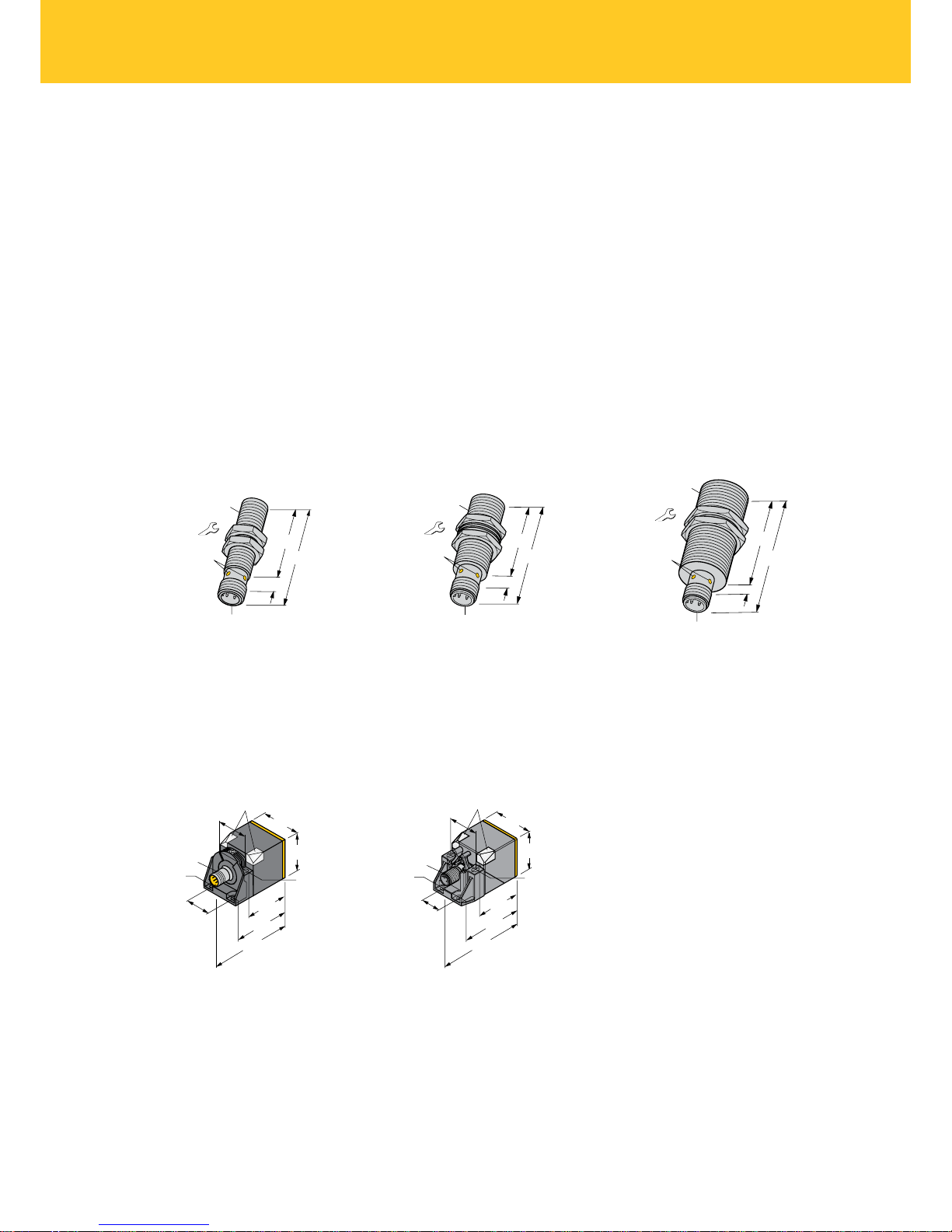

4 Product description

The cylindrical devices are provided with a metal housing with an M12, M18 or M30 male

thread with an LCP front cap. Variants with a PTFE-coated housing and PTFE-coated front cap

are also available. The active face can be installed flush with the surrounding area.

The rectangular devices are provided with a plastic housing. The active face of the NI…U-QV40

and NI…U-CK40 devices can be set in 5 positions. The active face can be installed flush, partially

flush or non-flush with the surrounding mounting area (see chapt. 5.2).

All devices are provided with a metal-bodied M12 connector (plug) for connecting the sensor

cable. The devices can be set and operated via an IO-Link interface.

The devices are provided with two outputs that can be set independently of each other. Output

1 can be operated either as a switching output or in IO-Link mode, output 2 is designed as a

switching output. The switching distance and other functions can be set for both outputs (see

chapter 4.4).

4.1 Device overview

M12 x 1

LED

17/4

36

52

M12 x 1

9

M12 x 1

36

52

9

LED

24/4

M18 x 1

36/5

46

62

M30 x 1.5

9

M12 x 1

LED

Abb. 1: Dimensions –

M12 design

Abb. 2: Dimensions –

M18 design

Abb. 3: Dimensions –

M30 design

40

40

30

M12 x 1

20

ø 5.3

46

5.3 x 7.3

65

60

LED

Abb. 4: Dimensions –

CK40 design

Abb. 5: Dimensions –

QV40 design

Page 11

11

2016/08

uprox® Sensors with IO-Link Interface

4.1.1 Indication elements

The devices with a cylindrical design are provided with a green and a yellow status LED. The

devices with a rectangular design are provided with 2 green and 2 yellow status LEDs.

4.2 Properties and features

■

Cylindrical and rectangular designs

■

Factor 1 for all metals

■

Degree of protection IP68

■

Resistant to magnetic fields

■

Large switching distance

■

DC 4-wire, 10…30 VDC

■

Male connector, M12 x 1

■

Communication via IO-Link V1.1 or via standard I/O

■

Electrical outputs that can be set independently of each other

■

Switching distance and hysteresis can be set

■

Identification via 32 byte memory

■

Temperature monitoring with settable limits

■

Various timer and diagnostic functions

4.2.1 Properties and features – Rectangular design

■

High luminance corner LEDs

■

Predamping protection based on self-compensation

■

Partially embedded mounting

■

Active face adjustable in 5 positions

4.3 Operating principle

Inductive sensors are used for the contactless and wear-free detection of metallic objects. To

do this, the devices generate an electromagnetic field which interacts with the detected object.

The sensors of the uprox® series have no reduction factor; the switching distance is the same for

all metals.

4.4 Functions and operating modes

The devices can be operated in IO-Link mode or in standard I/O mode (SIO mode). The devices

must be connected to an IO-Link master for operation in IO-Link mode.

IO-Link mode provides bidirectional IO-Link communication between an IO-Link master and

the sensors. For this the devices are integrated in the controller level via an IO-Link master.

The switching signals of the sensors are made available with the process data via the IO-Link

interface. Besides the switching information, diagnostics and identification messages can also

be queried via IO-Link.

Different sensor functions can be configured via the IO-Link interface.

4.4.1 Sensor functions

“One switch point”

The output configuration and the switching behavior can be set for one switch point. Switching

distance (in 20 % increments) and hysteresis are adjustable. With the “One switch point” function, output 2 can be used as a temperature indicator.

Page 12

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

“Two switch points”

Switching output 1 and switching output 2 can be used and set to separate switching distances

in 20% increments. A variable hysteresis cannot be set for the “Two switch points” function.

“Low resolution analog mode”

NOTE

The low resolution analog mode can only be used in operation on an IO-Link master.

In low resolution analog mode the switching states are sampled sequentially in 20% increments. This provides distance information which is output via Bit 2…Bit4 of the process data in

binary format.

Switching state indication (binary

coded)

not actuated

S

n

20 % 40 % 60 % 80 % 100 %

1st bit (Bit 4) 0 1 1 0 0 0

2nd bit (Bit 3) 0 0 0 1 1 0

3rd bit (Bit 2) 0 1 0 1 0 1

NOTE

Output 2 can be configured as required or can be used as a temperature indicator. The

maximum switching frequency is reduced to 7 Hz in low resolution analog mode.

“Rotational speed monitor”

The “Rotational speed monitor” enables the device to detect frequency values below and above

a specified frequency window. Upper and lower limit values of the frequency window can be

set between 0 and 30000 pulses per minute. The switching behavior is described in Fig. 6.

1

0

0f

minfmax

30000

Out1

Out2

f [Impulse/min]

Output f < f

minfmin

< f < f

max

f > f

max

Output 1 0 1 1

Output 2 0 1 0

Abb. 6: Output behavior (“Rotational speed monitor” sensor function)

The actual speed can be queried via the acyclic IO-Link parameter data. The tolerance is 3 %.

The switching distance is permanently set to Sn = 60 % in the “Rotational speed monitor” function. The output configuration can be selected as required.

Page 13

13

2016/08

uprox® Sensors with IO-Link Interface

“Pulse divider”

The “Pulse divider” function causes the device to output a signal pulse to the control level after

a specified number of actuation pulses. The number of actuation pulses (divider) can be set

between 1 and 128.

The following values can be set for the minimum duration of the signal pulse:

■

Target object ( 0 ms)

■

1 ms

■

10 ms

■

100 ms

NOTE

In the event of a voltage drop the number of actuation pulses is reset.

The output configuration can be selected as required.

4.4.2 Settable properties

Output conguration – Output 1

The following output configurations can be set for output 1:

■

PNP, NO contact

■

PNP, NC contact

■

NPN, NO contact

■

NPN, NC contact

■

Push-pull, non-inverted

■

Push-pull, inverted

Output conguration – Output 2

The following output configurations can be set for output 2:

■

PNP, NO contact

■

PNP, NC contact

■

NPN, NO contact

■

NPN, NC contact

■

Push-pull, non-inverted

■

Push-pull, inverted

■

Temperature indicator (not available in SIO mode and for the “Two switch points” function)

Switching distance

NOTE

The feature is only available for “One switch point” and “Two switch points” functions.

The switching distance can be set for both outputs to 20 %, 40 %, 60 %, 80 % and 100 % of the

maximum rated switching distance. Different switching distances can be set independently of

each other for output 1 and output 2. The switching distance of output 1 must be greater than

the switching distance of output 2; otherwise the switching distance for switching output 1

is set automatically to 20 % greater than the switching distance for switching output 2. If the

device automatically changes the switching distance for switching output 1, this is indicated by

a request for a new data update.

Page 14

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

Switching hysteresis

NOTE

The switching hysteresis setting is only available for the “One switch point” function.

The switching distance hysteresis can be set to the 2 stages “Standard” and “small”.

NOTICE

“Small” hysteresis selected

Uncontrolled changing between the switching states

Set the switching distance and target in the application so that a setting to “small”

hysteresis is possible.

Switch-on delay

NOTE

The switch-on delay can only be set for the “One switch point” function.

If the switch-on delay Ton is activated, the switching pulse is generated after the actual sensor

actuation. The switch-on delay can be set between 0…60000 ms.

Abb. 7: Switch-on delay

The set output configuration is not changed. Switching pulses that are shorter than the set

switch-on delay are not transferred to the controller.

Switch-o delay

NOTE

The switch-off delay can only be set for the “One switch point” function.

If the switch-off delay T

off

is activated, the generation of the switch signal pulse is delayed by

the set time after sensor actuation.

Abb. 8: Switch-off delay

The set output configuration is not changed. Interruptions in switch pulses that are shorter

than the set switch-off delay are ignored at the output and are transferred with a switching

signal to the controller.

Page 15

15

2016/08

uprox® Sensors with IO-Link Interface

Temperature indicator

NOTE

The temperature indicator does not provide a highly precise value and does not show

the exact ambient temperature.

The device is provided with an integrated temperature indicator. The actual internal sensor

temperature can be read via the acyclic IO-Link parameter data. The application specific limit

values “Alarm undertemperature” and “Alarm overtemperature” can be set within the permissible temperature range. Values below and above the limit values are transferred to the controller via bit 6 and bit 7 of the process data. The acyclic parameter data enables the set limits to be

read out.

The temperature unit can be set to °C, °F or K. A temperature alarm can be set at output 2 for all

functions apart from the “Two switch points” function in SIO mode. The device switches when

the actual value is above or below the set limits.

Application specic marking

The device is provided with a 32 byte memory for application specific marking. The first byte of

the memory is transferred to the controller level via bit 8…bit 15 of the cyclic process data; up

to 256 devices can be identified via the process data. The acyclic parameter data enables the

memory to be completely read out.

Alternating oscillator frequency

NOTE

The “Alternating oscillator frequency” feature is only available for devices suitable for

non-flush mounting.

An alternating oscillator frequency reduces the lateral installation constraints between two

adjacently mounted devices. The alternating oscillator frequency is denoted as “F2” in the IODD.

LED mode

The LED settings can be adjusted as follows:

■

Only operating voltage indication: UB (green), output (yellow)

■

Only switching state: Output (yellow)

■

Off

LED temperature indication

The green LED can indicate values above or below the set temperature limits with a 1 Hz flash

signal. Both LEDs on the rectangular devices flash green.

Page 16

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

Start delay

NOTE

The “Start delay” function can only be set for the “Rotational speed monitor” function.

If the start delay is active, the switching signals are passed on to the controller once with a time

delay after each interruption of the power supply. The start delay can be set between 0…60000

ms. Output 1 and output 2 are switched during the set start delay, bit 5 of the process data is

set here to 1. The start delay bridges the start time of drives in order to prevent the output of

unwanted fault messages from the higher-level controller due to low speeds.

4.4.3 Standard I/O mode (SIO mode)

In standard I/O mode devices can be operated via a fieldbus device or a controller with digital

PNP, NPN or push-pull inputs. An IO-Link master is not required.

In SIO mode the device has 2 switching outputs. The following IO-Link communication cannot

be used:

■

Binary coded switching state information in low resolution analog mode

■

Temperature alarm for values above or below the set temperature limits

■

Application specific marking

■

Reading of IO-Link parameter data

All other sensor functions and settable features (see chapt. 4.4.1 and see chapt. 4.4.2) can be

used in SIO mode. The set functions can be evaluated via the switching signals of the particular

output.

Parameter changes made via IO-Link are also retained in the device after saving and after the

power supply is interrupted. Devices can be set via IO-Link and then operated at the digital

inputs with the appropriate settings in SIO mode.

4.5 Technical accessories

The following optional accessories are available for connection and parameter setting. Information on mounting accessories is provided on the relevant product data sheets. Accessories are

not supplied with the device.

Dimension drawing Type Description

41

24

54

M12 x 1

16

USB-Mini

IN-DC

LED:

CH1 (C/Q)

CH2 (DI/DO)

Error

LED: PWR

USB-2-IOL-0002 IO-Link adapter with integrated USB interface

L

42

11.5

ø 15

M12 x 1

M12 x 1ø 15

49.5

18.2

RKC4.4T-2-RSC4.4T/TEL Connection cable, M12 female connector, straight, 4-pole,

cable length: 2 m, sheathing material: PVC, black; cULus

approval; other cable lengths and types available, see

www.turck.com

Page 17

17

2016/08

uprox® Sensors with IO-Link Interface

5 Mounting

5.1 Mounting cylindrical devices

The sensors can be mounted in any position.

The following table shows the maximum tightening torque for fastening the sensor:

Type Max. tightening torque

BI6U-M12… 10 Nm

BI6U-MT12 7 Nm

BI10U-M18…/BI10U-MT18… 10 Nm

BI20U-M30…/BI20U-MT30… 50 Nm

Clean the mounting surface and the surrounding area.

Install the sensor in a fixture (mounting bracket or fixing clamp) if necessary.

Install the sensor or the mounting fixture at the intended location. Observe the minimum

mounting distances.

Distance BI6U-M12-…/

BI6U-MT12-…

BI10U-M18-…/

BI6U-MT18-…

BI20U-M30-…/

BI20U-MT30-…

T 3 × W 3 × W 3 × W

G 6 × S

n

6 × S

n

6 × S

n

W 3 × S

n

3 × S

n

3 × S

n

D 24 mm 36 mm 60 mm

S 1.5 × W 1.5 × W 1.5 × W

Abb. 9: Minimum mounting distances

Page 18

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

5.1.1 Mounting cylindrical devices with a half-shell clamp

NOTICE

Mounting with a half-shell clamp

Device damage due to faulty mounting

Align the uprox marking on the front cap of the sensor horizontally in relation to the

half-shell clamp (see Fig. 3).

Observe maximum tightening torque of the half-shell clamp (see data sheet).

Abb. 10: Aligning the sensor in the mounting bracket

Page 19

19

2016/08

uprox® Sensors with IO-Link Interface

5.2 Mounting rectangular devices

The sensors can be mounted in any position.

A 4-side flush mounting is possible. The switching distance is reduced if the device is mounted

from the rear or with a protrusion.

Clean the mounting surface and the surrounding area.

Install the sensor in a fixture (mounting bracket or fixing clamp) if necessary.

Install the sensor or the mounting fixture at the intended location. Observe the minimum

mounting distances and mounting conditions.

Distance Ni50U-… in rectangular design

D 240 mm

W 105 mm

S 60 mm

G 300 mm

N 30 mm

B 40 mm

Abb. 11: Minimum mounting distances

Page 20

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

Mounting condition Distance Sr

1-side flush D 240 mm 35 mm

2-side flush D 240 mm 35 mm

3-side flush D 80 mm 20 mm

4-side flush D 60 mm 17 mm

Recessed mounting on metal X 10 mm 20 mm

X 20 mm 20 mm

X 30 mm 20 mm

X 40 mm 20 mm

Protruded on metal Y 10 mm 40 mm

Y 20 mm 50 mm

Y 30 mm 50 mm

Y 40 mm 50 mm

Mounting in aperture plate I 150 mm

Installation with twisted mounting position, on metal

50 mm

Mounting with twisted mounting position, on metal, one side

wall

25 mm

Mounting with twisted turning

angle, on metal, 2 side walls

15 mm

Mounting with twisted mounting position, on metal, 3 side

walls

Abb. 12: Mounting conditions

Page 21

21

2016/08

uprox® Sensors with IO-Link Interface

5.2.1 Positioning the active face (Ni50U-QV40…)

The active face is can be set in 5 directions:

■

Active face front (as supplied)

■

Active face left

■

Active face right

■

Active face up

■

Active face down

Gently press together the fixing clamp on the mounting bracket to release the device from

the mounting bracket.

Turn the active face to the side.

Insert the device into the mounting bracket until the fixing clamp snaps into position.

optional: turn the active face left, right, up or down.

Abb. 13: Positioning the active face

Page 22

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Mounting

5.2.2 Positioning the active face (NI50U-CK40…)

The active face is can be set in 5 directions:

■

Active face front (as supplied)

■

Active face left

■

Active face right

■

Active face up

■

Active face down

Undo the locking screw (B) and pull the sensor from the mounting bracket (A).

Undo the screws to (E).

Remove the adapter bracket (D), rotate 180° and re-tighten the screws (E).

Fit the sensor and the mounting bracket (A) and tighten the locking screw (B).

Abb. 14: Positioning the active face

Page 23

23

2016/08

uprox® Sensors with IO-Link Interface

6 Connection

Connect the open end of the connection cable as shown in Fig. 5 and the terminal layout of

the particular connected device to the IO-Link master, fieldbus device or controller with the

corresponding inputs.

Connect the female connector of the connection cable to the male connector at the rear of

the sensor.

6.1 Wiring diagram

Pin Pin assignment Wiring diagram

Pin 1 U

B

4 BK

1 BN3 BU

2 WH

1 BN +

3 BU –

2 WH Out2

4 BK Out1 / IO-Link

Pin 2 Out 2

Pin 3 GND

Pin 4 Out 1/IO-Link

Abb. 15: Wiring diagram

7 Commissioning

The device is operational automatically 18 ms after the cables are connected and the power

supply is switched on. If the device is connected to an IO-Link master, IO-Link communication

starts automatically. For this the IO-Link master sends a wakeup request to the device.

7.1 Setting IO-Link mode

Set a cycle time of at least 8 ms on the IO-Link master.

The device is operational.

7.2 Setting up SIO mode

Connect the device to a standard I/O port.

The device is operational after a delay of 500 ms.

The delay is necessary in SIO mode for the operation of preactuated sensors so that the sensor

can exclude being connected to an IO-Link master. The operation delay has no effect on any

potential IO-Link communication.

Page 24

24

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Operation

8 Operation

8.1 LEDs

The devices are provided with a green and a yellow status LED.

NOTE

The switching state of the device is only indicated via the LEDs in SIO mode. In IO-Link

mode the green LED flashes (1 s on, 0.1 s).

LED indication Meaning

green flashing (1 s on, 0.1 s off) IO-Link communication

green Device is operational

yellow Switching output 1 actuated

yellow flashing (approx. 1Hz) Switching output 2 actuated

yellow flashing (approx. 4Hz) Temperature indicator

green/yellow flashing Fault in SIO mode

8.2 Operating devices in IO-Link mode

IO-Link mode provides different sensor functions and adjustable features. The bidirectional

IO-Link communication enables all the parameters to be changed by the controller during commissioning as well as during operation.

NOTE

The change of the output configuration is only updated after a voltage reset or after

switching to SIO mode.

8.3 Operating devices in SIO mode

In SIO mode the device operates according to the last setting made in IO-Link mode. Not all

sensor functions and settable features of the device are available for use in SIO mode. The following functions can be set as standard:

■

“One switch point” sensor function

■

Output 1: PNP (NO contact), output 2: PNP (NC contact)

■

Switching distance: 100 %

■

Both LEDs on

9 Setting

The device has two outputs which can be set independently of each other. Output 1 can be

operated either as a switching output or as an interface for IO-Link communication, output 2 is

designed as a switching output.

9.1 Setting via IO-Link

The devices can be parameterized via the IO-Link communication interface within the limits of

their technical specifications (see data sheet). For further information on IO-Link see the IO-Link

commissioning manual (D900634).

Page 25

25

2016/08

uprox® Sensors with IO-Link Interface

9.1.1 IO-Link parameters

Different parameter settings for the particular application are made via the IO-Link interface.

For further information on the functions and IO-Link parameters see chapter 4.4.1 and the IOLink parameter manual of the device.

9.1.2 Parameter transfer with IO-Link call function block

Due to the range of functions available with the devices, the parameter subindexes described

in the IO-Link parameter manual cannot be addressed with an IO-Link call function block compliant with the IO-Link specification. To transfer parameters the entire data string of the parameter index must be transferred in binary format from the controller to the device. The subindex

“0” referring to the entire string must be set in the IO-Link call function block. A separation of

subindexes is not possible.

9.1.3 Process data

Bit Function Meaning/bit information

0 Output 1 0: Output 1 not actuated

1: Output 1 switches (depending on the sensor function

and the output configuration)

1 Output 2 0: Output 2 not actuated

1: Output 2 switches (depending on the sensor function

and the output configuration)

1: Output 2 is not set as a temperature indicator (“One

switch point” sensor function)

2 Switch point 2

0

3-bit coding for the set switching distance (3rd bit)

3 Switch point 2

1

3-bit coding for the set switching distance (2nd bit)

4 Switch point 2

2

3-bit coding for the set switching distance (1st bit)

5 Start delay 1: Start delay switched on and activated after a voltage

reset (for “Rotational speed monitor” sensor function)

6 Undertemperature 1: Temperature indicator detects value below the set tem-

perature limits

7 Overtemperature 1: Temperature indicator detects value above the set tem-

perature limits

8…15 Application specific marking A 32 byte memory is provided for application specific

marking. The first byte of the memory is transferred cyclically to the controller.

If the sensor is actuated, bits 0…4 show the switching state according to the actual settings.

Example: “One switch point” sensor function, 100% switching distance, output 2 not set as a

temperature indicator.

Bit State Meaning

0 1 Output 1 switches

1 1 Output 2 is not set as a temperature indicator

2 1

3-bit coding for the set switching distance (100%), see chap. 4.4.13 0

4 0

Page 26

26

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Troubleshooting

9.2 Setting in SIO mode

Various sensor functions and settable features (see chapt. 4.4.1 and see chapt. 4.4.2) can be

used in SIO mode. The set functions can be evaluated via the switching signals of the particular

output.

9.2.1 Setting the device before initial commissioning

Set the sensor functions and features via an IO-Link master or IO-Link USB adapter (see chap-

ter 4.5) using a configuration tool.

The selected settings are saved and are available after the device is mounted in the

installation.

9.2.2 Setting devices after initial commissioning

Disconnect the device from the controller.

Set the sensor functions and features via an IO-Link master or IO-Link USB adapter using a

configuration tool.

The selected settings are saved and are applicable after the device is refitted in the

installation.

10 Troubleshooting

If possible use the device at another location in the application.

The sensor has a fault if it is still present.

Take the device out of service and replace it with one of the same type.

If the device operates trouble-free at the different location in the application, the fault is caused

by the application.

Check the environment of the device for metallic foreign objects in the metal free zones.

Check the environment of the device for EMC interference sources.

11 Maintenance

The good condition of the sensor connections and cables must be checked regularly.

The devices are maintenance-free, clean dry if required.

12 Repair

The device must not be repaired by the user. The device must be decommissioned if it is faulty.

Observe our return acceptance conditions when returning the device to Turck.

12.1 Returning devices

If a device has to be returned, bear in mind that only devices with a decontamination declaration will be accepted. This is available for download at

http://www.turck.de/static/media/downloads/01_Declaration_of_Decontamination_EN.pdf

and must be completely filled in, and affixed securely and weather-proof to the outside of the

packaging.

Page 27

27

2016/08

uprox® Sensors with IO-Link Interface

13 Decommissioning

Remove the connection cable from the power supply and/or the processing units.

Remove the connection cable from the device.

Undo the connections of the device or if necessary the mounting aid for the mounting area.

Undo if necessary the connection of the device to the mounting aid.

14 Disposal

The devices are designed for installation in large-scale industrial installations and equipment.

The devices must be disposed of correctly and must not be included in normal household

garbage.

Page 28

28

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical data

15 Technical data

15.1 Technical data – BI…U-M…

Technical data BI6U-M12-… BI10U-M18-… BI20U-M30…

Rated operating distance S

n

6 mm 10 mm 20 mm

Mounting condition flush

Assured switching distance ≤ (0.81 × S

n

) mm

Repetition accuracy ≤ 2 % of full scale

Temperature drift ≤ ± 10 %

Hysteresis 3…15 %

Ambient temperature -25…+70 °C

Operating voltage 10…30 VDC

Ripple ≤10 % U

SS

DC rated operational current ≤ 150 mA

No-load current I

0

≤ 20 mA

Residual current ≤ 0.1 mA

Rated insulation voltage ≤ 0.5 kV

Short-circuit protection Yes/cyclic

Voltage drop at I

e

≤ 1.8 V

Wire breakage / reverse polarity

protection

yes/completely

Output function 4-wire, NO contact/N/O contact, PNP/NPN/Push-pull/IO-Link

Output 1 Switching output or IO-Link mode

Output 2 Switching output

Switching frequency max. 0.5 kHz

IO-Link specification IO-Link specified according to version 1.1 and V1.0 (separate IODD)

Port class Class A

Transfer rate COM 2/38.4 Kbit/s

Process data width 16-bit

Switching point information 2 bit

Frame type 2.2

Design Threaded barrel, M12 × 1 Threaded barrel, M18 × 1 Threaded barrel, M30 × 1.5

Dimensions 52 mm 52 mm 62 mm

Housing material Metal, CuZn, chrome-plated

Material of active face Plastic, LCP

Max. tightening torque of housing

nuts

10 Nm 10 Nm 50 Nm

Connection Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Type of protection IP68

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Page 29

29

2016/08

uprox® Sensors with IO-Link Interface

15.2 Technical data – BI…U-MT…

Technical data BI6U-MT12-… BI10U-MT18-… BI20U-MT30…

Rated operating distance S

n

6 mm 10 mm 20 mm

Mounting condition flush

Assured switching distance ≤ (0.81 × S

n

) mm

Repetition accuracy ≤ 2 % of full scale

Temperature drift ≤ ± 10 %

Hysteresis 3…15 %

Ambient temperature -25…+70 °C

Operating voltage 10…30 VDC

Ripple ≤10 % U

SS

DC rated operational current ≤ 150 mA

No-load current I

0

≤ 20 mA

Residual current ≤ 0.1 mA

Rated insulation voltage ≤ 0.5 kV

Short-circuit protection Yes/cyclic

Voltage drop at I

e

≤ 1.8 V

Wire breakage / reverse polarity

protection

yes/completely

Output function 4-wire, NO contact/N/O contact, PNP/NPN/Push-pull/IO-Link

Output 1 Switching output or IO-Link mode

Output 2 Switching output

Switching frequency max. 0.5 kHz

IO-Link specification IO-Link specified according to version 1.1 and V1.0 (separate IODD)

Port class Class A

Transfer rate COM 2/38.4 Kbit/s

Process data width 16-bit

Switching point information 2 bit

Frame type 2.2

Design Threaded barrel, M12 × 1 Threaded barrel, M18 × 1 Threaded barrel, M30 × 1.5

Dimensions 52 mm 52 mm 62 mm

Housing material Metal, CuZn, PTFE-coated

Material of active face Plastic, LCP, PTFE-coated

Max. tightening torque of housing

nuts

7 Nm 10 Nm 50 Nm

Connection Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Type of protection IP68

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Page 30

30

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical data

15.3 Technical data – NI50U-…

Technical data NI50U-CK40-… NI50U-QV40

Rated operating distance S

n

50 mm

Mounting condition Non-flush, flush mounting possible

Assured switching distance ≤ (0.81 × S

n

) mm

Repetition accuracy ≤ 2 % of full scale

Temperature drift ≤ ± 10 %

≤ ± 20 % ≤ -25 °C v ≥ +70 °C

Hysteresis 3…15 %

Ambient temperature -30…+85 °C

Operating voltage 10…30 VDC

Ripple ≤10 % U

SS

DC rated operational current ≤ 150 mA

No-load current I

0

≤ 20 mA

Residual current ≤ 0.1 mA

Rated insulation voltage ≤ 0.5 kV

Short-circuit protection Yes/cyclic

Voltage drop at I

e

≤ 1.8 V

Wire breakage / reverse polarity

protection

yes/completely

Output function 4-wire NO contact/N/O contact, PNP/NPN, Push-pull/IO-Link

Output 1 Switching output or IO-Link mode

Output 2 Switching output

Switching frequency 0.5 kHz 0.25 kHz

IO-Link specification IO-Link specified according to version 1.1

Port class Class A

Transfer rate COM 2/38.4 Kbit/s

Process data width 16-bit

Switching point information 2 bit

Frame type 2.2

Design Rectangular, CK40 Rectangular, QV40

Dimensions 65 × 40 × 40 mm

Housing material Plastic, PBT-GF20-V0 Plastic, PBT-GF30-V0

Connection Male connector, M12 x 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Type of protection IP68

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Page 31

31

2016/08

uprox® Sensors with IO-Link Interface

Page 32

D102217 | 2016/08

*D102217ßß1608*

28 subsidiaries and over

60 representations worldwide!

www.turck.com

Loading...

Loading...