turck BCT5-S18-UP6X2T-H1151, BCT10-S30-UN6X2T-H1151, BCT5-S18-UP6X2-H1151, BCT10-S30-UP6X2-H1151, BCT10-S30-UN6X2-H1151 Operating Instructions Manual

...Page 1

Your Global Automation Partner

Operating Instructions

BCT-…

Teachable Capacitive

Sensors

Page 2

2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 3

1 About These Instructions 5

1.1 Target groups 5

1.2 Explanation of symbols 5

1.3 Other documents 6

1.4 Feedback about these instructions 6

2 Notes on the Product 7

2.1 Product identication 7

2.2 Scope of delivery 7

2.3 Legal requirements 7

2.4 Manufacturer and service 8

3 For your safety 8

3.1 Intended use 8

3.2 Obvious misuse 8

3.3 General safety notes 8

4 Product description 9

4.1 Device overview 9

4.1.1 Indication elements 9

4.1.2 Operating elements 9

4.2 Properties and features 10

4.3 Operating principle 10

4.4 Functions and operating modes 10

4.4.1 Setting options 10

4.4.2 “Medium present” mode (Full teach) 10

4.4.3 “Medium not present” mode (Empty teach) 10

4.4.4 “Switch point between medium present and medium not present” mode

(Complete teach) 11

4.4.5 Internal voltage and temperature monitoring 11

4.5 Technical accessories 11

5 Mounting 13

6 Connection 14

6.1 Wiring diagrams 14

7 Commissioning 14

8 Operation 15

8.1 Operation in IO-Link mode – LED indication 15

9 Setting 16

9.1 Setting via the teach adapter 16

9.2 Setting by manual bridging (shorting) 17

9.3 Setting via pushbuttons 18

9.4 Setting via IO-Link 19

9.4.1 IO-Link parameters 20

9.5 Example of use: Adjust sensor for poorly detectable media 20

3

2016/09

BCT-... Capacitive Sensors

Page 4

10 Troubleshooting 21

11 Maintenance 21

12 Repair 21

12.1 Returning devices 21

13 Decommissioning 21

14 Disposal 21

15 Technical Data 22

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Page 5

5

2016/09

BCT-... Capacitive Sensors

1 About These Instructions

These instructions describe the setup, the functions and use of the device and help you to operate the product for its intended use. Read these instructions carefully prior to using the product.

Keep these instructions safe during the service life of the device. If the product is passed on,

pass on these instructions as well.

1.1 Target groups

This document is written for specially trained personnel and must be read carefully by anyone

who is charged with the mounting, commissioning, operation, maintenance, disassembly or

disposal of the device.

1.2 Explanation of symbols

The following symbols are used in these instructions:

DANGER

DANGER indicates a direct hazardous situation with the risk of death or serious injury if

it is not prevented.

WARNING

WARNING indicates a possible hazardous situation with the risk of death or serious

injury if it is not prevented.

NOTICE

NOTICE indicates a situation that may cause possible damage to property if it is not

prevented.

NOTE

NOTE indicates tips, recommendations and important information. The notes contain

information, particular operating steps that facilitate work and possibly help to avoid

additional work resulting from incorrect procedures.

➤

MANDATORY ACTION

This symbol denotes actions that the user must carry out.

➥

RESULT OF ACTION

This symbol denotes the relevant results of actions and procedures.

Page 6

6

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

About These Instructions

1.3 Other documents

Besides this document the following material can be found on the Internet at www.turck.com:

■

Data sheet of the particular device

■

IODD file

■

IO-Link Parameters Manual

All Turck software components and the IODD can be downloaded via the Turck

Software Manager. The Turck Software Manager can be downloaded free of charge at

www.turck.com.

1.4 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If you have any suggestions for improving the design or if some information is missing in

the document, please send your suggestions to techdoc@turck.com.

Page 7

7

2016/09

BCT-... Capacitive Sensors

2 Notes on the Product

2.1 Product identication

Teachable capacitive sensors

BCT5-S18-UP6X2T-H1151 BCT10-S30-UP6X2T-H1151

BCT5-S18-UN6X2T-H1151 BCT10-S30-UN6X2T-H1151

BCT5-S18-UP6X2-H1151 BCT10-S30-UP6X2-H1151

BCT5-S18-UN6X2-H1151 BCT10-S30-UN6X2-H1151

2.2 Scope of delivery

The scope of delivery consists of the device and two nuts for mounting.

2.3 Legal requirements

The product is subject to the following EC directive:

■

2014/30/EC (EMC Directive)

The EC declaration of conformity is available for download from the Turck product database.

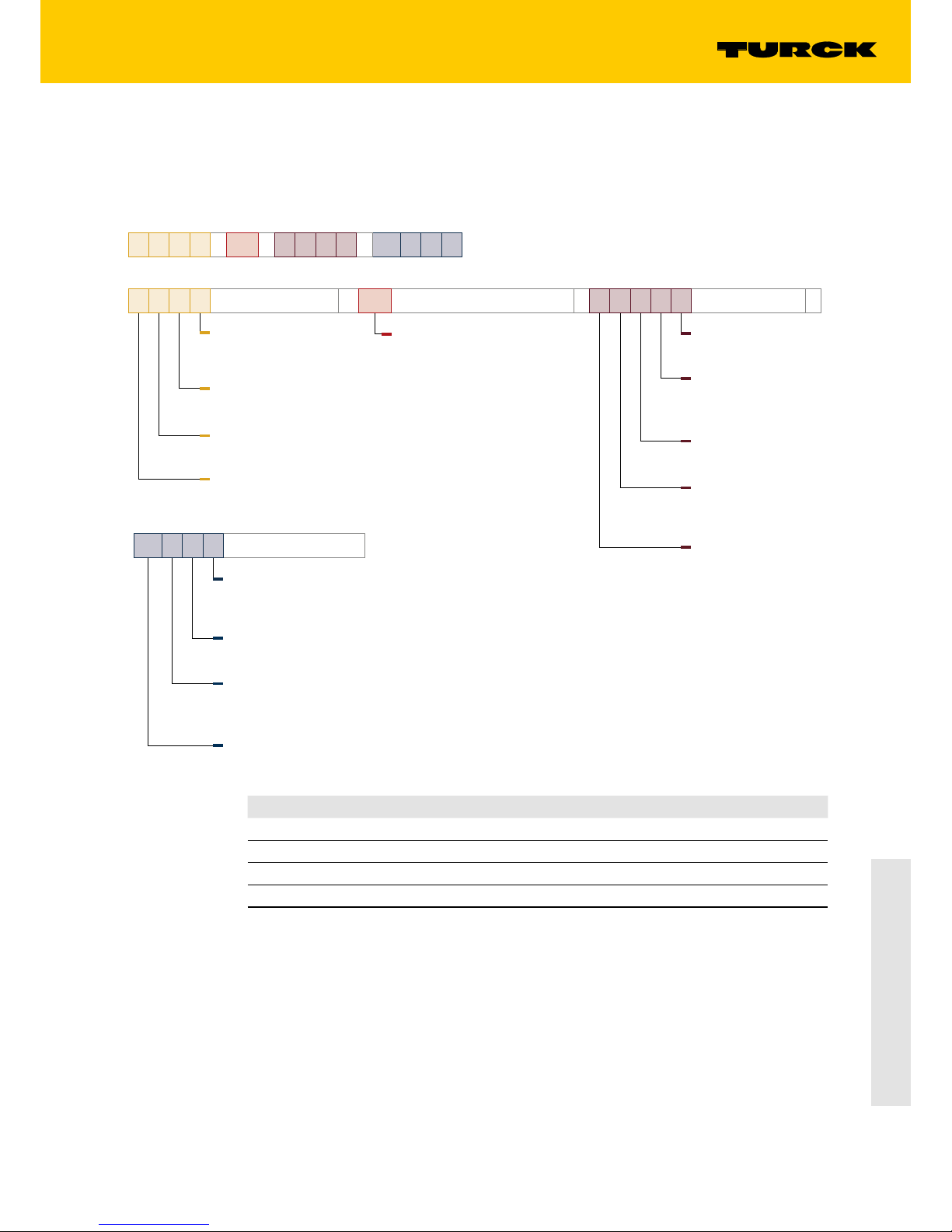

B C T 10 – S30 – U P 6 X2 – H1 1 5 1

B C T 10

Functional principle

–

Rated operating distance

… switching distance

Sn in [mm]

Special functions

T teachable

Functional principle

C capacitive

Installation

B flush

S30

Design

–

Housing

S18 cylinder, plastic,

continuous thread Ø 18 mm

S30 cylinder, plastic,

continuous thread Ø 30 mm

U P 6 X2 T

Electrical version

–

Teach button

T teach button

Indication

X LED

2 number of LEDs

Voltage range

6 10…30 VDC

Output type

N NPN output

P PNP output

Output function

U NO/NC programmable

H1 1 5 1

Electrical connection

Assignment

1 standard assignment

or customized

Number of contacts

... number of contacts

Connector type

1 straight

3 straight, with adapter

Connector type

H1 M12 x 1 male

Page 8

8

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

For your safety

2.4 Manufacturer and service

Turck supports you in your projects – from the initial analysis right through to the commissioning of your application. The Turck product database offers you several software tools for programming, configuring or commissioning, as well as data sheets and CAD files in many export

formats. You can access the Product Database directly via the following address:

www.turck.de/products

For further inquiries in Germany contact the Sales and Service Team on:

Sales: +49 208 4952-380

Technical: +49 208 4952-390

For overseas inquiries contact your national Turck representative.

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Mülheim an der Ruhr

Germany

3 For your safety

The product is designed according to the latest state of the art technology. Residual hazards,

however, still exist.

Observe the following warnings and safety regulations in order to prevent danger to persons

and property.

Turck accepts no liability for damage caused by failure to observe these safety instructions.

3.1 Intended use

The devices are only designed for use in industrial applications.

The capacitive sensors are intended for the contactless detection of the presence of solid or liquid objects. Any other use is not in accordance with the intended use; Turck accepts no liability

for any resulting damage.

3.2 Obvious misuse

The devices are not safety components and must not be used for the protection of persons or

property.

3.3 General safety notes

■

The devices only meet the EMC requirements for industrial areas and are not suitable for use

in residential areas.

■

The device must only be fitted, installed, operated and maintained by trained and qualified

personnel.

■

Only use the device in compliance with the applicable national and international regulations,

standards and laws.

■

Not all objects are detected equally well by the sensor. Before regular operation check

whether the required object is detected.

Page 9

9

2016/09

BCT-... Capacitive Sensors

4 Product description

4.1 Device overview

The capacitive sensors have a cylindrical design with an M18 or M30 male thread. The device

front can be mounted flush with the surrounding area. All devices are provided with an M12

connector for connecting the sensor cable.

LED

Teach (T2)

Teach (T1)

24/8

50

87,3

M18 x 1

M12 x 1

LED

24/8

50

87,3

M18 x 1

M12 x 1

Fig. 1: Dimension drawings BCT5-S18-U*6X2T-H1151 (with teach button) and BCT5-S18-

U*6X2-H1151 (without teach button)

LED

Teach (T2)

Teach (T1)

36/10

50

87,3

M30 x 1,5

M12 x 1

LED

36/10

50

87,3

M30 x 1,5

M12 x 1

Fig. 2: Dimension drawings BCT10-S30-U*6X2T-H1151 (with teach button) and BCT10-S30-

U*6X2-H1151 (without teach button)

4.1.1 Indication elements

The capacitive sensors have a 2-color LED (green/yellow).

4.1.2 Operating elements

The capacitive sensors are available with and without integrated teach buttons. Refer to the

type code for the identification of the different device models.

Page 10

10

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

4.2 Properties and features

■

Threaded barrel M18 x 1 or M30 x 1.5

■

Flush mountable

■

Plastic, PA12-GF30, PEI

■

Setting via IO-Link, teach adapter, manual bridging or teach button

4.3 Operating principle

The sensors detect filling levels of liquids or solids - either in direct contact with the medium, or

through a non-metallic container wall. The capacitive sensors are also designed for the noncontact and wear-free detection of both metallic (electrically conductive) and non-metallic

(electrically non-conductive) objects.

4.4 Functions and operating modes

When delivered, the device functions as a proximity switch with a rated operating distance of 5

mm (BCT5-S18- ...) or 10 mm (BCT10-S30 ...). Additional functions can be taught by the user.

4.4.1 Setting options

The devices can be set via IO-Link with FDT tools such as PACTware™ or via the PLC software.

The capacitive sensors are also provided with additional setting options:

■

Setting via teach adapter (optional accessories, not included)

■

Settings made via manual bridging via pin 5 to UB or pin 5 to GND

■

Setting via pushbuttons (for models with teach buttons)

4.4.2 “Medium present” mode (Full teach)

In “Medium present” (Full teach) mode, the device operates with minimum sensitivity. This is

useful for applications with easy to detect media. A switch point is taught for when a medium

or an object is present in the sensing range of the sensor.

The switch threshold for the “Medium present” mode is automatically set so that a safety reserve is produced for the switchoff limit. The safety reserve can be set via FDT/IODD. The switch

point is below the measured capacitance. Environmental factors such as temperature deviations, condensation, the formation of film or pollution have less effect on the signal in “Medium

present” mode. The switch point can be set with the “Medium present” teach button. The interval between two teach operations can be set to any length as required.

4.4.3 “Medium not present” mode (Empty teach)

In “Medium not present” (Empty teach) mode the device operates at maximum sensitivity. Possible uses include applications in which pre-actuation by the environment must be prevented.

The switch point is taught when no medium or object is present in the detection range of the

sensor.

The switch threshold is automatically set for the “Medium not present” mode so that there is a

safety reserve for the switchoff limit. The safety reserve can be set via FDT/IODD. In this case, the

switch point is above the measured capacitance. Environmental factors such as temperature

deviations, condensation, the formation of film or pollution have less effect on the signal in

“Medium present” mode. The “Medium not present” teach enables the switch point to be set.

The interval between two teach operations can be set to any length as required.

Page 11

11

2016/09

BCT-... Capacitive Sensors

4.4.4 “Switch point between medium present and medium not present” mode (Complete teach)

“Switch point between medium present and medium not present” mode is suitable for applications with difficult environmental conditions or media with little contrast. This requires the

“Medium present” and “Medium not present” teach operations to be carried out in succession.

The switch point is in the middle of the capacitances measured with the two teach operations.

In “Switch point between medium present and medium not present” mode, the difference

between the full and empty state of a container can be detected.

4.4.5 Internal voltage and temperature monitoring

The device is provided with internal voltage and temperature monitoring. The monitoring function provides information to determine the load and failure probability of the sensor.

4.5 Technical accessories

The accessories are not supplied with the device and must be ordered.

Item designation Description Figure

TX1-Q20L60 Teach adapter

60

30

50

20

M12 x 1

M12 x 1

42.5

ø 15

ø 4.5

8

USB-2-IOL-0002 IO-Link adapter V1.1 with integrated

USB port

41

24

54

M12 x 1

16

USB-Mini

IN-DC

LED:

CH1 (C/Q)

CH2 (DI/DO)

Error

LED: PWR

RKC4.5T-2-RSC4.5T/

TEL

Connection cable between sensor

and USB-2-IOL-002, 2 m long

42

11.5

ø 15

M12 x 1

L

M12 x 1

49.5

18.2

ø 15

Page 12

12

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Product description

Item designation Description Figure

RKC4.5-5T-2/TEL Female connector, straight, with 2 m

PVC cable, open end

42

11.5

ø 15

M12 x 1

L

WKC4.5-5T-2/TEL Female connector, angled, with 2 m

PVC cable, open end

26.5

M12 x 1

ø 15

32

L

In addition to the above-mentioned connection cables,Turck also offers other cable types for

specific applications with the correct terminals for the capacitive sensors. More information on

this is available from the Turck product database at http//www.turck.de/products in the Connectivity area.

Page 13

13

2016/09

BCT-... Capacitive Sensors

5 Mounting

The sensors can be mounted in any position (orientation). The maximum tightening torque for

fastening the sensors is 2Nm (BCT5-S18-…) or 5Nm (BCT10-M30-…).

➤ Clean the mounting surface and the surrounding area.

➤ When using a mounting bracket: Fasten the sensor in the mounting bracket.

➤ Install the sensor or the mounting fixture at the intended location.

➤ Make sure that the connector on the rear of the sensor remains accessible.

➤ Observe the minimum mounting distances.

BCT5-S18-… BCT10-S30-…

Distance D 36 mm 60 mm

Distance W 15 mm 30 mm

Distance S 27 mm 45 mm

Distance G 30 mm 60 mm

Fig. 3: Minimum installation distances

➤ When using more than one sensor in the application: Avoid the overlapping of the electrical

fields. This overlap can occur if two sensors are mounted less than 36mm (for BCT5-S18-…)

or 60mm (for BCT10-S30-…) apart.

Page 14

14

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Connection

6 Connection

➤ Connect the female connector of the connection cable to the male connector of the sensor.

➤ Connect the open end of the connection cable to the power supply and/or the processing

units.

6.1 Wiring diagrams

Pin Pin assignment Wiring diagram

Pin 1 U

B

4 BK

1 BN3 BU

2 WH

5 GY

+

–

1

3

4

5teach

pnp

IO-Link

Pin 3 GND

Pin 4 IO-Link output and switch

output

Pin 5 Teach-in

Fig. 4: Sensor wiring diagram (BCT…-UP…)

Pin Pin assignment Wiring diagram

Pin 1 U

B

4 BK

1 BN3 BU

2 WH

5 GY

–

+

3

1

4

5teach

npn

IO-Link

Pin 3 GND

Pin 4 IO-Link output and switch

output

Pin 5 Teach-in

Fig. 5: Sensor wiring diagram (BCT…-UN…)

7 Commissioning

The device is operational automatically once the cables are connected and the power supply is

switched on.

Page 15

15

2016/09

BCT-... Capacitive Sensors

8 Operation

WARNING!

The devices are not safety devices.

Risk of injury due to misuse!

➤ Do not use sensors for the protection of personnel and machinery

On delivery, the switching distance of the sensor Sn is (see sect. “Technical Data”). The output

function is NO (normally open).

Operation as a diuse mode sensor

In diffuse mode operation the LEDs have the following indication function:

LED indication Meaning

Yellow lit Sensor actuated

Green lit Sensor not actuated

Flashes momentarily Teach button feedback signal

Goes out for about 0.5 s Teach operation successful. The sensor switches to normal operation.

Green fast flashing for approx.

1 s

Teach operation failed

8.1 Operation in IO-Link mode – LED indication

In IO-Link mode the LEDs have the following indication function:

LED indication Meaning

Green, lit with short

interruptions

IO-Link mode started

Page 16

16

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting

9 Setting

The capacitive sensor has a switching output with an adjustable switch point. After successful

teach-in the sensor automatically runs in the normal operating mode. The interval between two

teach operations can be set to any length as required.

NOTE

If a determined switch point is outside of the saved switching interval, the taught

value is rejected. The device indicates a fault and returns to normal operation without

any changes.

Teach in the devices as follows:

Switch point: Medium

present

1

Switch point: Medium

not present

1

Change NC/NO Reset

IO-Link All operating modes are teachable via FDT/IODD.

Teach adapter Press and hold down

the pushbutton on

the adapter to U

B

for

2…9 s

Press and hold down

the pushbutton on

the adapter to GND

for 2…9 s

Press and hold down

the pushbutton on the

adapter to U

B

for more

than 10 s

Press and hold down

the pushbutton on

the adapter to GND

for more than 10 s

Teach buttons T1/T2 Press and hold down

T1 for 2…9 s

Press and hold down

T2 for 2…9 s

Press and hold down

T1 for > 10 s

Press and hold down

T2 for > 10 s

Manual bridging (pin 5) Connect to U

B

for

2…9 s

Connect to GND for

2…9 s

Connect to UB > 10 s Connect to GND for

> 10 s

1.

Set the switch point centrally between “Medium present” and “Medium not present”: Teach both medium states in sequence.

The TX1-Q20L60 teach adapter is not supplied with the device and must be ordered additionally. To use the teach adapter connect it between the sensor and the connection cable.

9.1 Setting via the teach adapter

“Medium present” teach

➤ Connect the TX1-Q20L60 teach adapter between the sensor and the connection cable.

➤ Specify object/level for switch point.

➤ Press and hold down the pushbutton on the adapter to U

B

for 2…9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% below the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

“Medium not present” teach

➤ Connect the TX1-Q20L60 teach adapter between the sensor and the connection cable.

➤ Specify object/level for switch point.

➤ Press and hold down the pushbutton on the adapter to GND for 2…9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% above the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Page 17

17

2016/09

BCT-... Capacitive Sensors

Inverting the output function (NO/NC)

➤ Connect the TX1-Q20L60 teach adapter between the sensor and the connection cable.

➤ Specify object/level for switch point.

➤ Press and hold down the pushbutton on the adapter to U

B

for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Reset to factory settings

➤ Connect the TX1-Q20L60 teach adapter between the sensor and the connection cable.

➤ Press and hold down the pushbutton on the adapter to GND for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Set the switch point between “Medium present” and “Medium not present”

➤ Reset sensor to factory settings.

➤ Carry out “Medium present” teach.

➤ Carry out “Medium not present” teach.

➥ The switch point is in the middle of the measured capacitances measured at teaches “Medium

present” and “Medium not present”.

NOTE

The “Medium present” and “Medium not present” teaches can be made in any order

and with any time interval.

9.2 Setting by manual bridging (shorting)

“Medium present” teach

➤ Specify object/level for switch point.

➤ Pin 5 to U

B

for 2 ... 9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% below the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

“Medium not present” teach

➤ Specify object/level for switch point.

➤ Hold pin 5 to GND for 2 ... 9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% above the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Page 18

18

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting

Inverting the output function (NO/NC)

➤ Specify object/level for switch point.

➤ Hold pin 5 to U

B

for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Reset to factory settings

➤ Specify object/level for switch point.

➤ Hold pin 5 to GND for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Set the switch point between “Medium present” and “Medium not present”

➤ Reset sensor to factory settings.

➤ Carry out “Medium present” teach.

➤ Carry out “Medium not present” teach.

➥ The switch point is in the middle of the measured capacitances measured at teaches “Medium

present” and “Medium not present”.

NOTE

The “Medium present” and “Medium not present” teaches can be made in any order

and with any time interval.

9.3 Setting via pushbuttons

“Medium present” teach

➤ Specify object/level for switch point.

➤ Press and hold down pushbutton 1 for 2…9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% below the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

“Medium not present” teach

➤ Specify object/level for switch point.

➤ Press and hold down pushbutton 2 for 2…9 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed. In this case, the switch point is 20% above the

capacitance measured in the teach mode.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Page 19

19

2016/09

BCT-... Capacitive Sensors

Inverting the output function (NO/NC)

➤ Specify object/level for switch point.

➤ Press and hold down pushbutton 1 for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Reset to factory settings

➤ Specify object/level for switch point.

➤ Press and hold down pushbutton 2 for more than 10 s.

➥ If the LED goes out for about 0.5 s and the sensor returns to normal operation, the teach

operation has been successfully completed.

➥ If the green LED flashes rapidly for about 1 s, the teaching process has failed and must be

repeated.

Set the switch point between “Medium present” and “Medium not present”

➤ Reset sensor to factory settings.

➤ Carry out “Medium present” teach.

➤ Carry out “Medium not present” teach.

➥ The switch point is in the middle of the measured capacitances measured at teaches “Medium

present” and “Medium not present”.

NOTE

The “Medium present” and “Medium not present” teaches can be made in any order

and with any time interval.

9.4 Setting via IO-Link

The following components are required for setting the device via IO-Link:

Hardware Software Documentation

USB IO-Link adapter USB-2-IOL-0002 PACTware™ parameter software System start manual IO-Link (D900063)

DTM IODD Interpreter

IODD configuration file for BCT… capacitive sensors

Refer to the IO-Link parameter manual for further information on operating modes and parameters in IO-Link mode.

Page 20

20

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Setting

9.4.1 IO-Link parameters

Different parameters can be set for the specific application via the IO-Link interface.

Parameter Meaning

Memory Use IO-Link data retention mode: Transfer param-

eter data from the device to the IO-Link master. If

a device is replaced, the data can be transferred

from the master to the new device.

Data memory lock Locking and unlocking the data memory

Local parameter setting lock Lock and unlock the pushbuttons on the sensor

Switch point Set the safety reserve between the measured

capacitance and the taught switch point

Sensor teach state Indicates which teach operation was last carried

out

Switch point behavior

Output function Invert the output function (NO/NC)

Mode selection Choose between one switch point (single mode)

and two switch points (window mode)

Hysteresis value Fixed default value for hysteresis

9.5 Example of use: Adjust sensor for poorly detectable media

In this example, the sensor for detecting poorly detectable media (e.g. sticky adhesive liquids)

in a tank has to be taught. For this a switch point must be taught between “Medium present”

and “Medium not present”.

➤ Reset sensor to factory settings.

➤ Level detection - Teach the sensor when the tank is full: Carry out “Medium present” teach.

➤ Level detection - blank out the wall when tank is empty: Carry out “Medium not present”

teach.

➥ The switch point is in the middle of the measured capacitances measured at teaches “Medium

present” and “Medium not present”.

NOTE

The “Medium present” and “Medium not present” teaches can be made in any order

and with any time interval.

Page 21

21

2016/09

BCT-... Capacitive Sensors

10 Troubleshooting

If the device does not function as expected, first check whether ambient interference is present.

If there is no ambient interference present, check the connections of the device for faults.

If there are no faults, there is a device malfunction. In this case, decommission the device and

replace it with a new device of the same type.

11 Maintenance

The proper condition of the connectors and cables must be checked regularly.

The devices are maintenance-free, if necessary, clean with a damp cloth.

12 Repair

The device must not be repaired by the user. The device must be decommissioned if it is faulty

and sent to Turck. Also observe here the specific warranty conditions agreed with the shipment.

12.1 Returning devices

If a device has to be returned, bear in mind that only devices with a decontamination declaration will be accepted. This is available for download at

http://www.turck.de/static/media/downloads/01_Declaration_of_Decontamination_EN.pdf

and must be completely filled in, and affixed securely and weather-proof to the outside of the

packaging.

13 Decommissioning

➤ Remove the connection cable from the power supply and/or processing units.

➤ Remove the connection cable from the sensor.

➤ Undo the connections of the sensor or the mounting bracket from the mounting area.

➤ If necessary, undo the connection of the sensor to the mounting bracket.

14 Disposal

The devices must be disposed of correctly and must not be included in normal household

garbage.

Page 22

22

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com

Technical Data

15 Technical Data

BCT5-S18-… BCT10-S30-…

Nominal switching distance (flush) 5 mm 10 mm

Nominal switching distance (non-flush) 7.5 mm 15 mm

Assured switching distance ≤ (0.75 × Sn) mm

Hysteresis 2 ... 20%

Temperature drift typ. 20 %

Repeat accuracy ≤ 2% of full scale

Ambient temperature -25…+70°C

Operating voltage 10…30 VDC

Residual ripple ≤ 10 % U

ss

DC rated operational current ≤ 200 mA

No-load current I

0

≤ 15 mA

Residual current ≤ 0.1 mA

Switching frequency 10 Hz

Rated insulation voltage ≤ 0.5 kV

Output function 5-wire, programmable, PNP (UP), NPN (UN), IO-Link

Short-circuit protection yes, cyclic

Voltage drop at 200 mA ≤ 2.4 V

Wire breakage / reverse polarity protection yes, complete

Design Threaded barrel, M18 x 1 Threaded barrel, M30 x 1.5

Housing material Plastic, PA 12-GF30, PEI

Material active face Plastic, PA12-GF30

Admissible pressure on front cap ≤ 6 bar ≤ 3 bar

Max. tightening torque of housing nut 2 Nm 5 Nm

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection type IP67

MTTF 1080 years acc. to SN 29500, Ed. 99, 40 °C

Switching status display 2-color LED (green / yellow)

Page 23

23

2016/09

BCT-... Capacitive Sensors

Page 24

...with 28 subsidiaries and over

60 representations worldwide!

www.turck.com

D102274 | 2016/09

*D102274ßß1609*

Loading...

Loading...