powerfast Connectivity

Application Considerations

Installation Guidelines

Turck’s Powerfast products are easy to install by following a few simple guidelines:

• It is important to know the electrical requirements of the application and

to select a cordset that has the proper amperage and voltage ratings for

the application.

• Cables must be supported to prevent movement on the equipment. Per

NFPA 79, the cable must be supported every 12 inches in a non-vertical

run, every 36 inches in a vertical run and every 18 inches when

suspended in air. The cable should also be supported at any connection

points or terminations.

Note: Consult NFPA 79 (Electrical Standard for Industrial Machinery) for required over current protection of conductors and other selection and installation guidelines

for industrial machine applications.

• The cordsets are not intended for disconnection under load. Turck

oers Powerlok ttings that prevent the possibility of disconnection

These ttings are not required for use, but can be used as a

precautionary measure.

• Power should never be supplied from the male connector. The source of

power should always be supplied from the female connector.

• Use Turck closure caps to protect connectors from damage or dirt

when not connected.

Cable Options

Turck oers multiple cable options for the Powerfast products. The

majority of Turck’s Powerfast products use cables that carry a tray

rated, exposed run (TC-ER) approval. Select Turck Powerfast

products may carry an additional STOOW cable approval, although

versions that carry the STOOW and TC-ER approval are also available

as TC-ER only.

Both the STOOW/TC-ER cable and the TC-ER only cable version are

premium cable oerings. However, the TC-ER only version has a

slightly reduced cable outer diameter. This feature oers more

exibility and is a more cost eective solution. This cable option

can be designated by adding a “/S4000” to the end of the part

description where applicable.

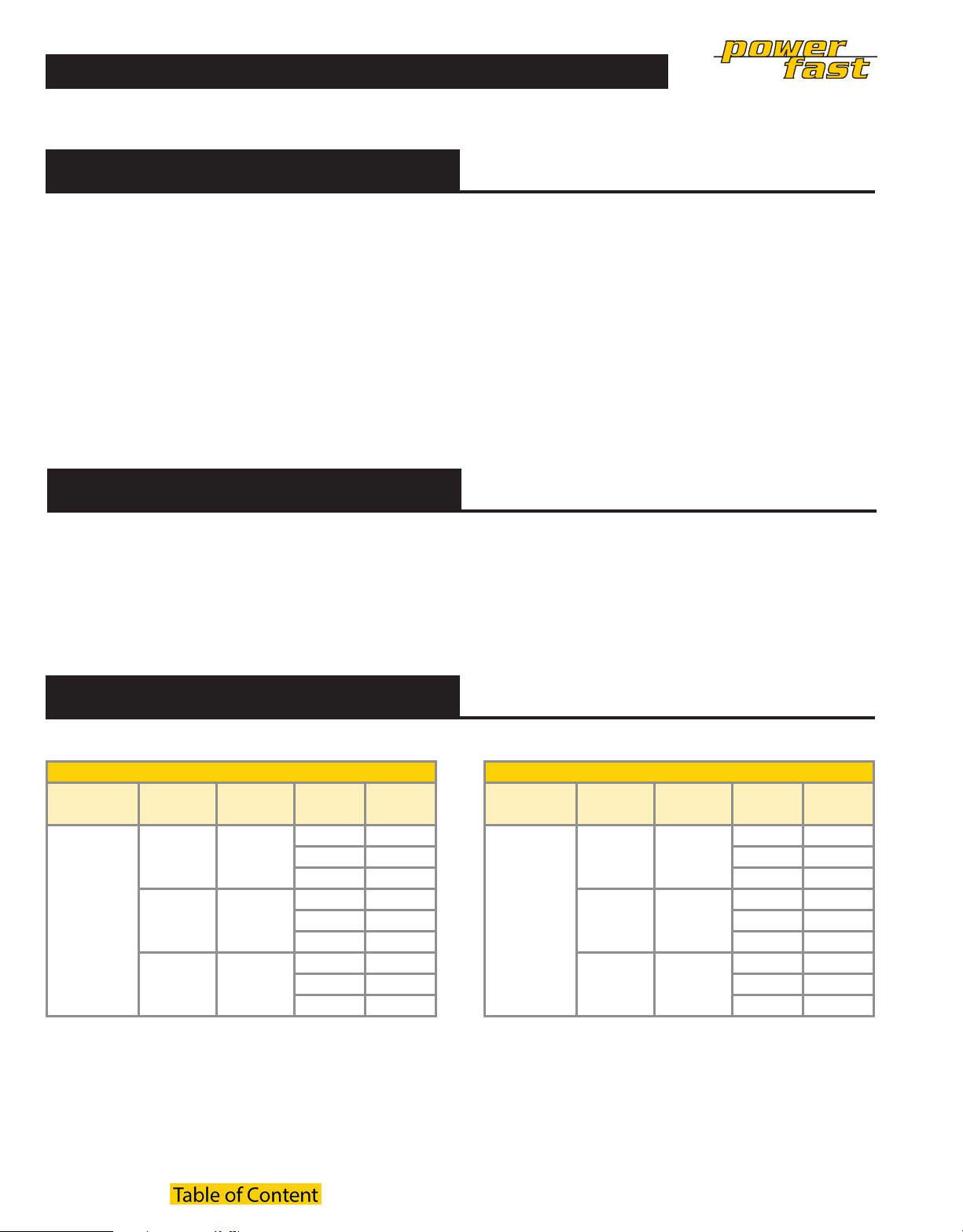

Estimated hp ratings for D-Size Powerfast

We reserve the right to make technical alterations without prior notice.

(Based on 85% motor eciency and 90% power factor.)

Single Phase (2 Current Carrying Conductors)

Pin Count AWG

10 AWG 30

3-pin

Note: These tables are theoretical values and are for reference only. Values will vary based on load conditions, as well as condition, age and type of motor.

Please consult a qualied electrician for specic product sizing requirements. Current limits for conductor gauge size taken from NFPA 79 2007 edition.

12 AWG 25

14 AWG 18

Current

(amps)

Voltage

(volts)

230 7

460 14

575 17

230 5

460 11

575 14

230 4

460 8

575 10

Power

(hp)

Three Phase (3 Current Carrying Conductors)

Pin Count AWG

10 AWG 25

4-pin

12 AWG 20

14 AWG 15

Current

(amps)

Voltage

(volts)

230 10

460 20

575 25

230 8

460 16

575 20

230 6

460 12

575 15

Power

(hp)

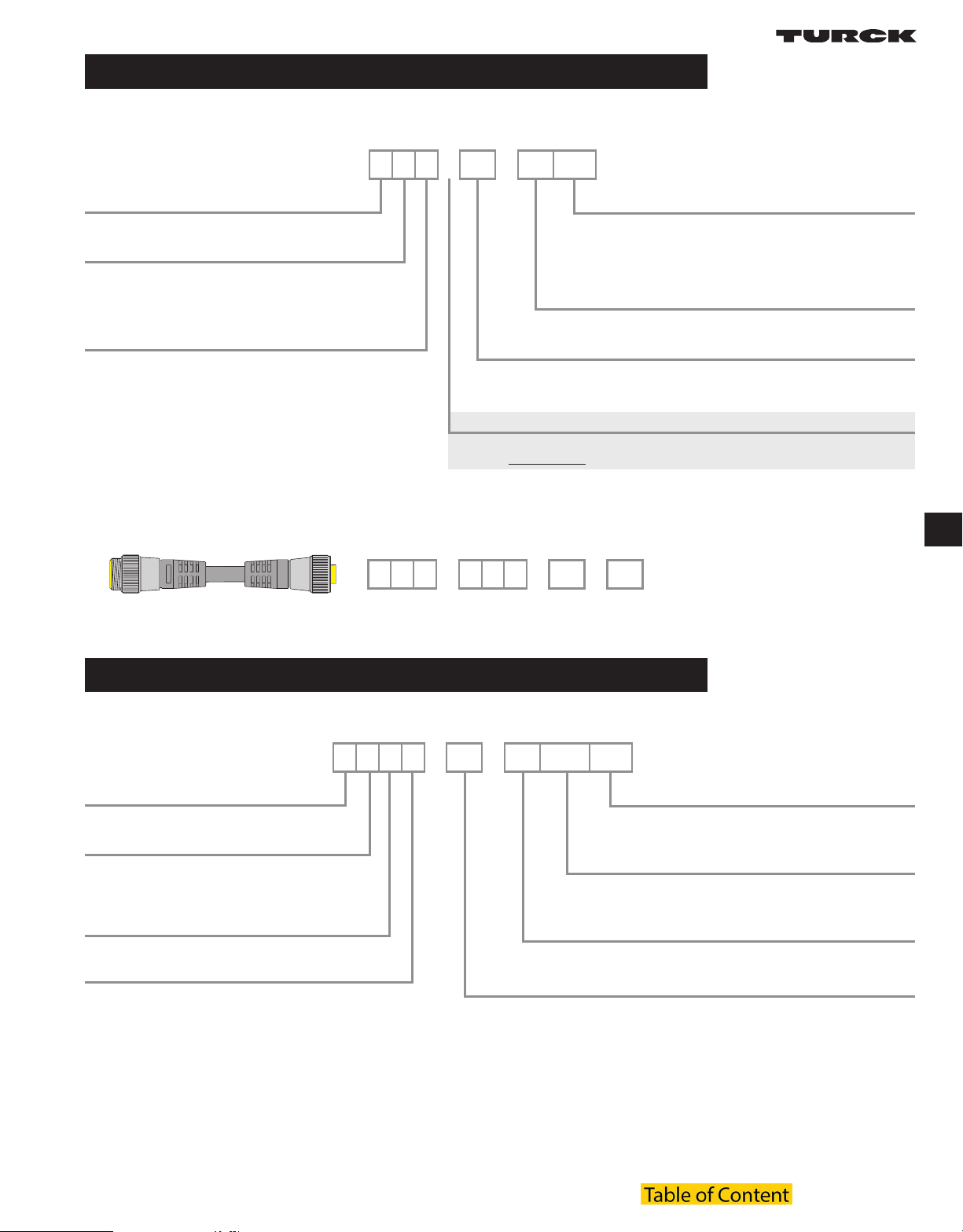

A-Size 7/8” powerfast Connectivity

2 and 3-Wire Receptacles, Front Mount, 1/4-18 NPT Threads

Part Number Keys are to assist in IDENTIFICATION ONLY. Consult factory for catalog items not identied.

R K M 34 - *M /S..

M23 Multifast® Receptacle

Gender

K = female connector, female threads

S = male connector, male threads

Y = male connector, female threads

Coupling Nut Material

(blank) = nylon

M = nickel plated brass

V = 316 stainless steel (hex)

Extension Examples

Varieties

(blank) = TC-ER STOOW PVC cable jacket

/S4000 = TC-ER PVC cable jacket

/S .. = consult factory, special

/CS .. = consult factory, special

Length in Meters

Number of Wires / AWG / Color Codes

34 = 3x14 AWG GN, BK, WH

44 = 4x14 AWG BK, WH, RD, GN

Insertion Point of Extension Cable Second Prex*

* Male connector listed rst, female connector second

Example: RSM RKM 44-2M

R S M R K M 44 - *M

A-Size 7/8” Powerfast Receptacle Part Number Key

R K F V 34 - *M /NPT /S..

A-Size 7/8” Powerfast Receptacle

Gender

K = female connector, female threads

S = male connector, male threads

X = female connector, male threads

A-Size 7/8” Powerfast Receptacle

Housing Material

(blank) = nickel plated brass

K = nylon

V = 316 stainless steel

Number of Wires / AWG / Color Codes

34 = 3x14 AWG GN, BK, WH

44 = 4x14 AWG BK, WH, RD, GN

A-Size 7/8” powerfast

Varieties

/S .. = consult factory, special

/CS .. = consult factory, special

Connection Thread

/NPT = ½-14 NPT threads

/M20 = M20 x 1.5 threads

Length in Meters

B2007 J3

A-Size 7/8” powerfast Connectivity

A-Size 7/8” Powerfast Cordset Specications

Mechanical Electrical

Mold material/color: PVC/Black

Contact carrier material: PVC Contact material: Brass or copper with gold plating

Coupling nut material: Cable jacket material/color:

Standard: Nickel plated brass Standard: TC-ER STOOW TPE/Black

Additional options: Nylon

316 stainless steel

Environmental protection: NEMA 1, 3, 4, 6P and IEC IP67 Ratings: 15 Amps, 600 VAC

Temperature rating: -40 °C to +90 °C (-40 °F to +194 °F)

A-Size 7/8” Powerfast Receptacle Part Number Key

Mechanical Electrical

Contact carrier material: PVC Contact material: Brass or copper with gold plating

Housing material/plating: Cable jacket material/color: PVC

Standard: Nickel plated brass

Additional options: Nylon

316 stainless steel

Environmental protection: NEMA 1, 3, 4, 6P and IEC IP67

Temperature rating: -40 °C to +105 °C (-40 °F to +221 °F)

Additional options: TC-ER TPE or

TC-ER PVC/Black (/S4000 version)

Ratings: 15 Amps, 600 VAC

We reserve the right to make technical alterations without prior notice.

A-Size 7/8” Powerfast Cordset Selection Matrix

1 2 3 4

Straight Female Straight Male Right Angle Female Right Angle Male

Pins AWG Current Rating TC-ER STOOW TC-ER STOOW TC-ER STOOW TC-ER STOOW

3 14 15 RKM 34-*M RSM 34-*M

4 14 15 RKM 44-*M RSM 44-*M

Pins AWG Current Rating TC-ER TC-ER TC-ER TC-ER

3 14 15 RKM 34-*M/S4000 RSM 34-*M/S4000 WKM 34-*M/S4000 WSM 34-*M/S4000

4 14 15 RKM 44-*M/S4000 RSM 44-*M/S4000 WKM 44-*M/S4000 WSM 44-*M/S4000

A-Size 7/8” Powerfast Receptacle Selection Matrix

5 6 7 8

Female Male Female Male

Pins AWG Current Rating 1/2-14 NPT Mounting Thread 1/2-14 NPT Mounting Thread M20 Mounting Thread M20 Mounting Thread

3 14 15 RKF 34-*M/NPT RSF 34-*M/NPT RSF 34-*M/M20 RKF 34-*M/M20

4 14 15 RKF 44-*M/NPT RSF 44-*M/NPT RSF 44-*M/M20 RKF 44-*M/M20

J4 B2007 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • Turck • Minneapolis, MN 55441 B2007 J5

1/2-14NPT

1.000 [25.4]

.650 [16.5]

1.181 [30.0]

1/2-14NPT

1.150 [29.2]

.500 [12.7]

1.000 [25.4]

1.000 [25.4]

.618 [15.7]

1.154 [29.3]

1.000 [25.4]

.618 [15.7]

1.268 [32.2]

A-Size 7/8” powerfast Connectivity

A-Size 7/8” Powerfast Cordset and Receptacle Dimensions

1 RKM.. 2 RSM..

3 WKM.. 4 WSM..

5 RKF..*/NPT.. 6 RSF..*/NPT..

Ă.988 [25.1]

7/8-16UN

Ă1.142 [29.0]

Ă.988 [25.1]

7/8-16UN

7 RKF..*/M20.. 8 RSF..*/M20..

M20x1.5

Ă.988 [25.1]

7/8-16UN

M20x1.5

Ă1.134 [28.8]

Ă.988 [25.1]

7/8-16UN

A-Size 7/8” Powerfast Cordset and Receptacle Pinouts

3-Pin Pinouts 4-Pin Pinouts

Female Male Female Male

Ă1.142 [29.0]

A-Size 7/8” powerfast

Ă1.134 [28.8]

B2007 J5

1. GN

2. BK

3. WH

1. BK

2. WH

3. RD

4. GN

A-Size 7/8” powerfast Connectivity

A-Size 7/8” Powerfast Closure Cap Selection Matrix

9 10 11 12 13 14

Mates to male

cordsets and

receptacles

Material Thread

Nickel Plated Brass 7/8-16 UN RKM-CC RSM-CC RKF-CC RSF-CC RKF-MC RSF-MC

Stainless Steel 7/8-16 UN RKMV-CC RSMV-CC RKFV-CC RSFV-CC RKFV-MC RSFV-MC

6” SS Loop

Lanyard

Mates to female

cordsets and

receptacles

6” SS Loop

Lanyard

Mates to male

receptacles

6” SS Lanyard

with Eyelet

Mates to female

receptacles

6” SS Lanyard

with Eyelet

Mates to male

cordsets and

receptacles

No Lanyard No Lanyard

A-Size 7/8” Powerfast Closure Cap Dimensions

9 RKM-CC 10 RSM-CC

Mates to female

cordsets and

receptacles

11 RKF-CC 12 RSF-CC

13 RKF-MC 14 RSF-MC

J6 B2007 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • Turck • Minneapolis, MN 55441 B2007 J7

A-Size 7/8” powerfast Connectivity

A-Size 7/8” Powerlok

Part Number Application A-Size Powerlok Open A-Size Powerlok Closed

LOCK-A POWER

Nylon locking guard for straight

A-Size Powerfast connectors

A-Size Powerfast Disconnect Switch Selection Matrix

We reserve the right to make technical alterations without prior notice.

Pins AWG Current Rating Standard M12 Auxilary Output

3 14 15 Amps RSF RKF 34/DS RSF RKF 34/DS/AUX

4 14 15 Amps RSF RKF 44/DS RSF RKF 44/DS/AUX

A-Size 7/8” powerfast

B2007 J7

Loading...

Loading...