Page 1

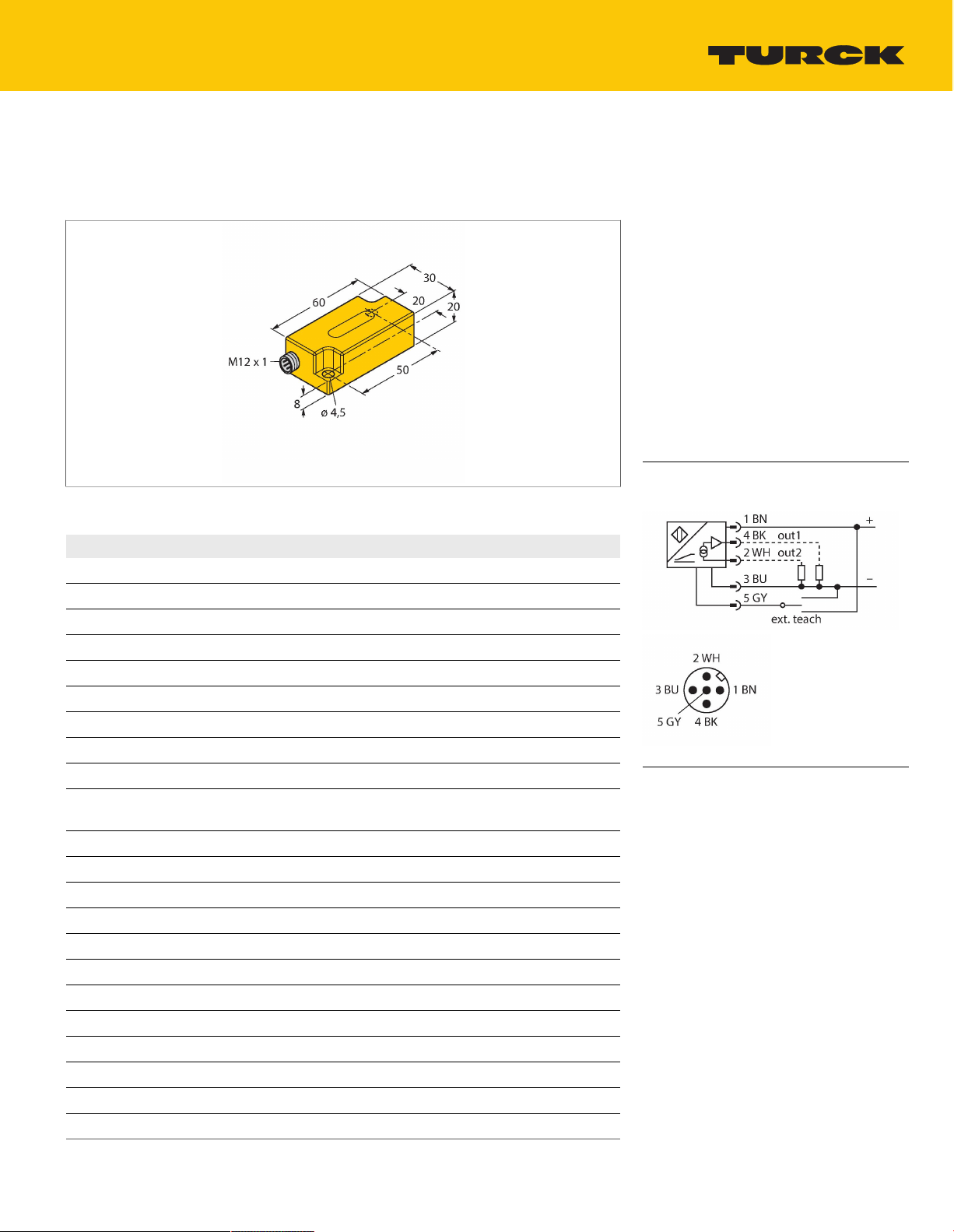

B1N360V-Q20L60-2UP6X3-H1151/3GD

Inclinometer – With two Programmable Switching Points

Features

Rectangular, height 20 mm

■

Plastic, PC

■

Indication of operating voltage and switching

■

state

Two programmable switching outputs

■

Switchpoints selectable in a range between

■

0° and 360°

DC 4-wire, 10…30 VDC

■

M12 x 1 male connector

■

ATEX category II 3 G, Ex zone 2

■

ATEX category II 3 D, Ex zone 22

■

Wiring diagram

Technical data

Type

Ident. no. 1534112

Measuring range 0…360°

Number of measuring axes 1

Mounting conditions Vertical

Repeat accuracy ≤0.2% of full scale

Absolute accuracy (at 25 °C) ±0.5°

Temperature coefficient typical 0.03°/K

Resolution ≤0.14°

Ambient temperature -30…+70°C

Operating voltage 10…30VDC

Residual ripple ≤10% U

Residual current ≤0.1mA

Isolation test voltage ≤0.5kV

Output current ≤500mA

Response delay 500ms

Dropout delay 350ms

Short-circuit protection yes / Thermal

Wire breakage/Reverse polarity protection yes / Complete

Output function 5-pin, NO/NC, 2 × PNP

Current consumption 35 mA

B1N360V-Q20L60-2UP6X3-H1151/3GD

For explosion hazardous areas see

instruction leaflet

ss

Surge protection from +Ub to (Ub - 40V)

Functional principle

Inclination is determined by a wear-free

semiconducting sensor element.

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

1|6

Page 2

Technical data

Approval acc. to ATEX declaration of conformity TURCK

Ex-12003H X

Device marking Ex II 3 G Ex nA IIC T5 Gc/II 3 D Ex tc IIIC

T85°C Dc

Design

Dimensions 60x30x20mm

Housing material Plastic, PC

Electrical connection Connector,M12 × 1

Vibration resistance 55Hz (1 mm)

Shock resistance 30g (11 ms)

Protection class IP68 / IP69K

MTTF 399years acc. to SN 29500 (Ed. 99) 40

Power-on indication

Switching state 2 × LEDs,Yellow

Included in delivery Security clip SC-M12/3GD, SC-M12/3GD

Rectangular,Q20L60

°C

LED,Green

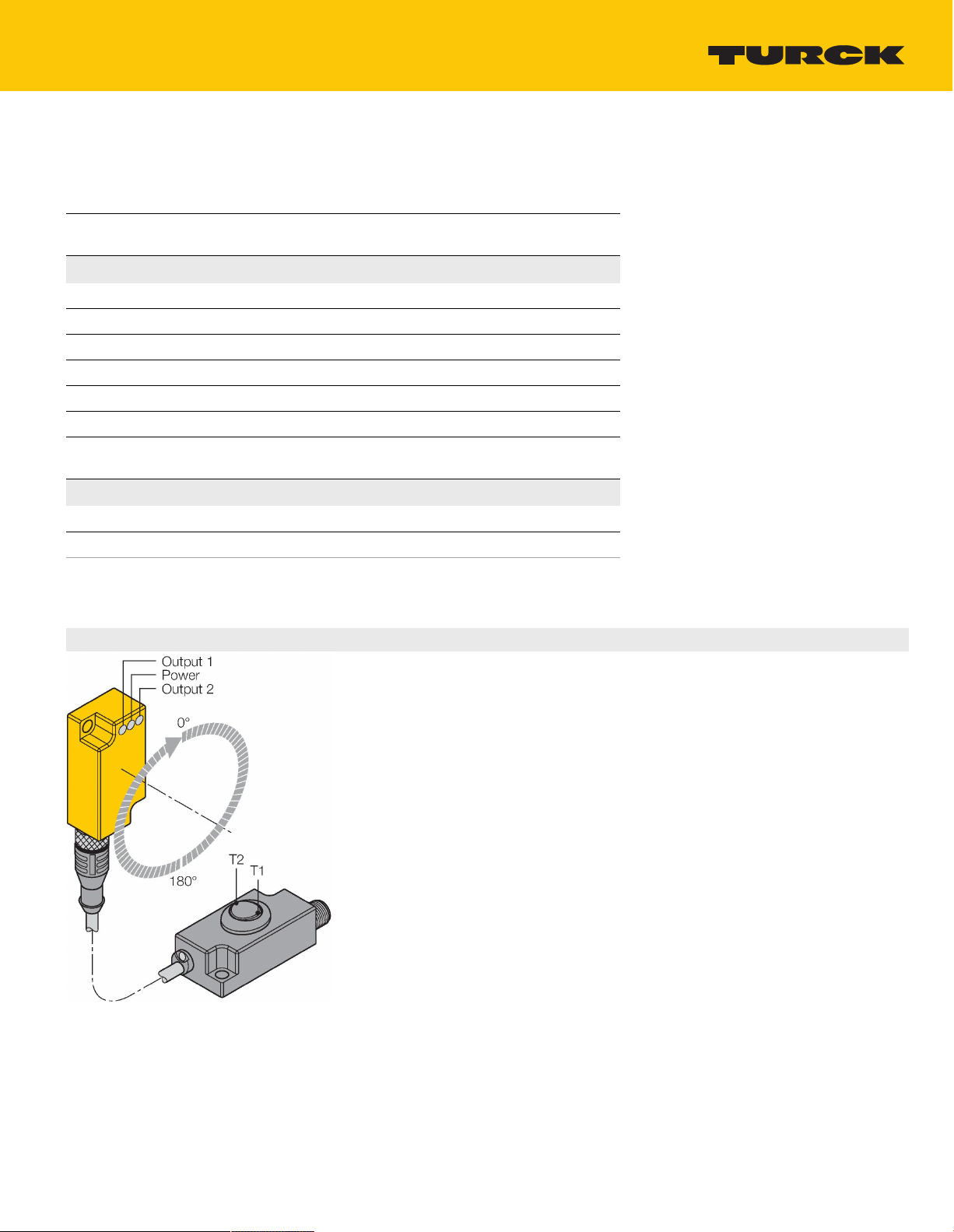

Mounting instructions

Mounting instructions/Description

The switchpoints are set with the TX1-Q20L60

teach adapter

By actuating the toggle switch T1 (OUT 1), a

bridge is formed between GND and pin 5.

By actuating the toggle switch T2 (OUT 2), a

bridge is formed between UB and pin 5.

The switch-on and off points are freely

selectable within 360° degrees.

You can teach-in the switching points either

clockwise or counter-clockwise.

Before programming the wanted switch-on and

off points, move the sensor in start position. For

details on programming, please see next page.

Should you wish to set the switch-off point

yourself, the sensor must also be positioned

at this point. The sensor must be installed in

vertical position.

A further programming method has already a

preset range of 180°. Here, only the switch-on

point must be set.

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

2|6

Page 3

Accessories

GUARD-Q20L60 A9684

Protective housing for Q20L60

inclinometers for protecting against

mechanical impact; material:

Stainless steel

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

3|6

Page 4

Operating Instructions

Switchpoint adjustable as NO contact counter-clockwise or as NC contact clockwise

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 1 s to set the switch-on point

Power LED and Output 1 (2) LED flash

Place the sensor in the wanted end position

Press T1 (T2) for 3 s to set the switch-off point

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact clockwise or as NC contact counter-clockwise

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 3 s to set the switch-on point

Power LED and Output 1 (2) LED flash fast

Place the sensor in the wanted end position

Press T1 (T2) for 1 s to set the switch-off point

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact counter-clockwise or as NC contact clockwise (180° default

setting)

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 1 s to set the switch-on point

Power LED and Output 1 (2) LED flash

Press T1 (T2) for 1 s to set the travel path 180 ° and the hysteresis 1 °

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact clockwise or as NC contact counter-clockwise (180° default

setting)

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 3 s to set the switch-on point

Power LED and Output 1 (2) LED flash fast

Press T1 (T2) for 3 s to set the travel path 180 ° and the hysteresis 1 °

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

T1 = Switching output 1; T2 = Switching output 2

Default settings:

Hysteresis 1°

Intended use

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

4|6

Page 5

This device fulfills the directive 2014/34/EC and is suited for use in explosion hazardous areas according to

EN60079-0:2009, EN60079-15:2010 and EN60079-31:2009In order to ensure correct operation to the intended purpose it is

required to observe the national regulations and directives.

For use in explosion hazardous areas conform to classification

II 3 G and II 3 D (Group II, Category 3 G, electrical equipment for gaseous atmospheres and category 3 D, electrical equipment for

dust atmospheres).

Marking (see device or technical data sheet)

Ex II 3 G Ex nA IIC T5 Gc acc .to EN 60079-0:2009 and EN 60079-15:2010 and Ex II 3 D Ex tc IIIC T85°C Dc acc. to EN

60079-0:2009 and EN 60079-31:2009

Local admissible ambient temperature

-30…+70 °C

Installation/Commissioning

These devices may only be installed, connected and operated by trained and qualified staff. Qualified staff must have

knowledge of protection classes, directives and regulations concerning electrical equipment designed for use in

explosion hazardous areas.Please verify that the classification and the marking on the device comply with the actual

application conditions.

Installation and mounting instructions

Avoid static charging of cables and plastic devices. Please only clean the device with a damp cloth. Do not install the

device in a dust flow and avoid build-up of dust deposits on the device.If the devices and the cable could be subject to

mechanical damage, they must be protected accordingly. They must also be shielded against strong electro-magnetic

fields.The pin configuration and the electrical specifications can be taken from the device marking or the technical

data sheet.In order to avoid contamination of the device, please remove possible blanking plugs of the cable glands or

connectors only shortly before inserting the cable or opening the cable socket.

Special conditions for safe operation

For devices with M12 connectors please use the supplied safety clip SC-M12/3GD. The safety clips SC-M12/3GD are

not required when using the protective housing SG-Q20L60.Do not disconnect the plug-in connection or cable under

voltage.Please attach a warning label permanently in an appropriate fashion in close proximity to the plug-in connection

with the following inscription: Nicht unter Spannung trennen / Do not separate when energized.The device must be

protected against any kind of mechanical damage and degrading UV-radiation. On selecting the approval-relevant

accessories, always ensure that they are installed conform to the application.Load voltage and operating voltage of this

equipment must be supplied from power supplies with safe isolation (IEC 30 364/UL508), to ensure that the rated voltage

of the equipment (24 VDC +20% = 28.8 VDC) is never exceeded by more than 40%.

Service/Maintenance

Repairs are not possible. The approval expires if the device is repaired or modified by a person other than the

manufacturer. The most important data from the approval are listed.

Operating Instructions

Switchpoint adjustable as NO contact counter-clockwise or as NC contact clockwise

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 1 s to set the switch-on point

Power LED and Output 1 (2) LED flash

Place the sensor in the wanted end position

Press T1 (T2) for 3 s to set the switch-off point

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact clockwise or as NC contact counter-clockwise

Press T1 (T2) for 5 s

Power LED flashes

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

5|6

Page 6

Place the sensor in the wanted start position

Press T1 (T2) for 3 s to set the switch-on point

Power LED and Output 1 (2) LED flash fast

Place the sensor in the wanted end position

Press T1 (T2) for 1 s to set the switch-off point

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact counter-clockwise or as NC contact clockwise (180° default setting)

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 1 s to set the switch-on point

Power LED and Output 1 (2) LED flash

Press T1 (T2) for 1 s to set the travel path 180 ° and the hysteresis 1 °

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

Switchpoint adjustable as NO contact clockwise or as NC contact counter-clockwise (180° default setting)

Press T1 (T2) for 5 s

Power LED flashes

Place the sensor in the wanted start position

Press T1 (T2) for 3 s to set the switch-on point

Power LED and Output 1 (2) LED flash fast

Press T1 (T2) for 3 s to set the travel path 180 ° and the hysteresis 1 °

Power LED and Output 1 (2) LED flash for 3 s then turn steady

Teach process completed, sensor ready for operation.

T1 = Switching output 1; T2 = Switching output 2

Default settings:

Hysteresis 1°

TURCK Inc. | 3000 Campus Drive Minneapolis, MN 55441-2656 | Phone: 763-553-7300 | Application Support: 1-800-544-7769 | Fax 763-553-0708 | www.turck.com

B1N360V-Q20L60-2UP6X3-H1151/3GD | 12/03/2020 07-32 | technical changes reserved

6|6

Loading...

Loading...