Turbovex TX 350A, TX 75A Installation, Operation And Maintenance Manual

Page 1 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

Installation, operation and

maintenance guide

for window models

Rev. 2014.06.25

Page 2 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

Table of content

2.0.0 GENERAL INFORMATION...................................................................................................................... 3

2.1.0 P

REFACE

................................................................................................................................................ 3

2.2.0 A

REAS OF USE

........................................................................................................................................ 3

2.3.0 I

NCORRECT USE

...................................................................................................................................... 3

2.4.0 S

COPE OF DELIVERY

............................................................................................................................... 3

2.5.0 M

AIN COMPONENTS

: ............................................................................................................................... 4

F

IGURE 2: MAIN COMPONENTS

......................................................................................................................... 4

F

IGURE 3 MAIN COMPONENTS

.......................................................................................................................... 5

3.0.0 INSTALLATION OF UNIT ........................................................................................................................ 6

3.1.0. E

XTERNAL DIMENSIONS

.......................................................................................................................... 6

3.2.0 W

ALL/WINDOW INSTALLATION

.................................................................................................................. 7

4.0.0 PLACING THE UNIT .............................................................................................................................. 11

PLACING THE UNIT (CONT.) ........................................................................................................................ 12

5.0.0 SERVICE ................................................................................................................................................ 13

5.1.0 F

ILTER CHANGE

.................................................................................................................................... 13

5.2.0 R

EMOVING FILTERS AND EXCHANGER

..................................................................................................... 14

6.0.0 CONNECTING MAINS ELECTRICITY .................................................................................................. 17

6.1.0 C

ONNECTION

........................................................................................................................................ 17

6.2.0 W

IRING DIAGRAM

.................................................................................................................................. 18

7.0.0 TECHNICAL SPECIFICATIONS............................................................................................................ 19

7.1.0 S

OUND TEST

......................................................................................................................................... 20

8.0.0 PRINCIPLE OF OPERATION ................................................................................................................ 21

8.1.0 D

ESCRIPTION

....................................................................................................................................... 21

9.0.0 OPERATION .......................................................................................................................................... 22

9.1.0 R

EGULATING AIR VOLUME

...................................................................................................................... 22

9.2.0 R

EGULATING WARMTH

........................................................................................................................... 22

9.3.0 M

ASTER/SLAVE

..................................................................................................................................... 22

10.0.0 DECLARATION OF COMPLIANCE .................................................................................................... 23

Page 3 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

2.0.0 General information

Turbovex TX 350A and TX 75A are decentralized ventilation units with integrated heat

recovery.

2.1.0 Preface

This installation and operation guide contains technical information and details of

installation and maintenance of the unit.

2.2.0 Areas of use

Window models are designed for comfort ventilation for institutions, canteens, offices and

conference rooms etc.

2.3.0 Incorrect use

The window models are not designed for local exhaust ventilation, and are therefore not

suitable for this purpose.

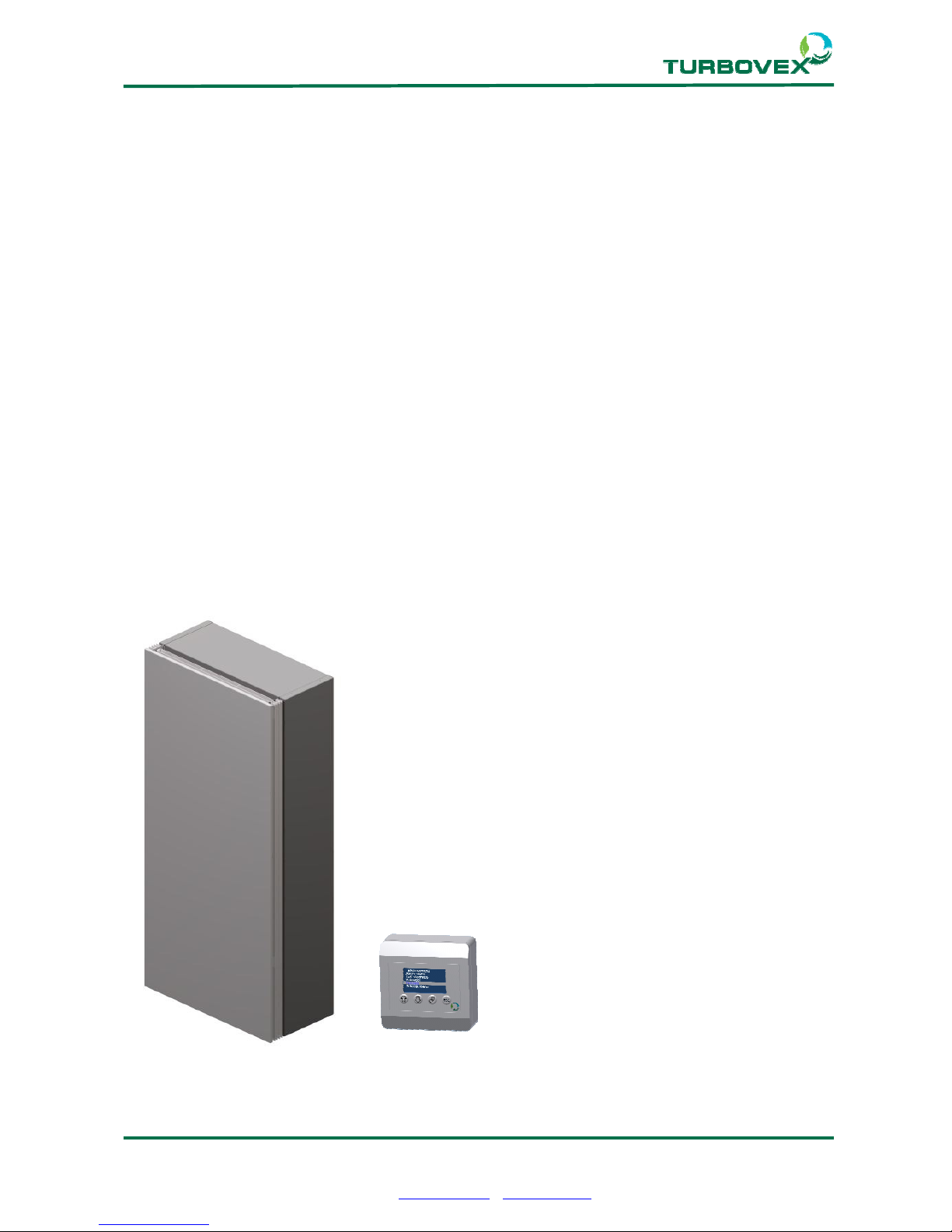

2.4.0 Scope of delivery

TX window models are supplied with the following main components:

1. Turbovex TX window model

2. TX electronic controller

Figure 1 Deliverables

Page 4 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

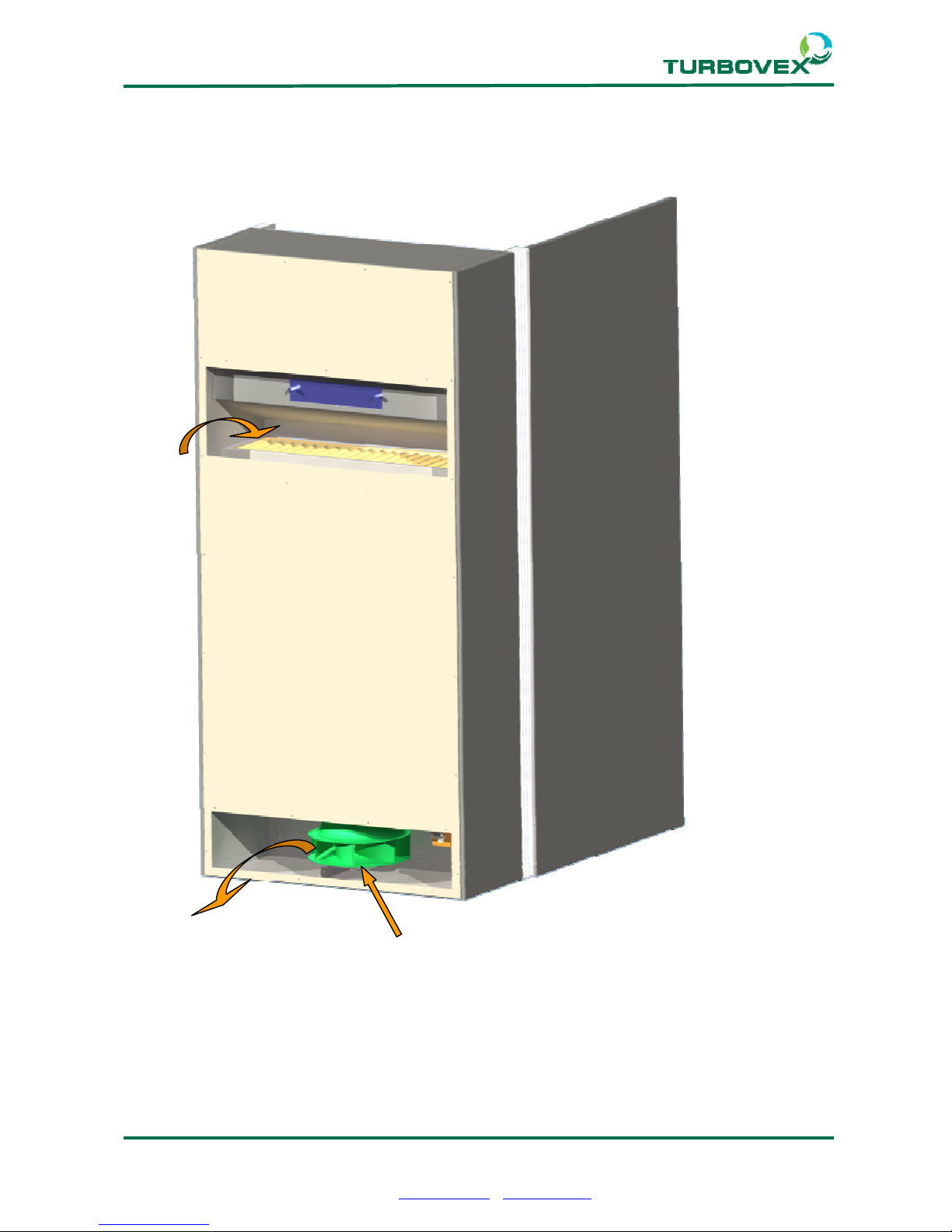

2.5.0 Main components:

Figure 2: Main components

1. Intake Air

2. Exhaust Air

3. Extract Air

4. Supply Air

5. Counterflow heat exchanger

6. Supply Air Fan

7. Extract Air Fan

8. Bypass Damper

9. Electrical heater

10. Filter

11. Main PCB

12. TX Controller

11

3

4

5

6

9

10

8

10

12

3

Page 5 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

Figure 3 Main components

1

2

7

Page 6 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

3.0.0 Installation of unit

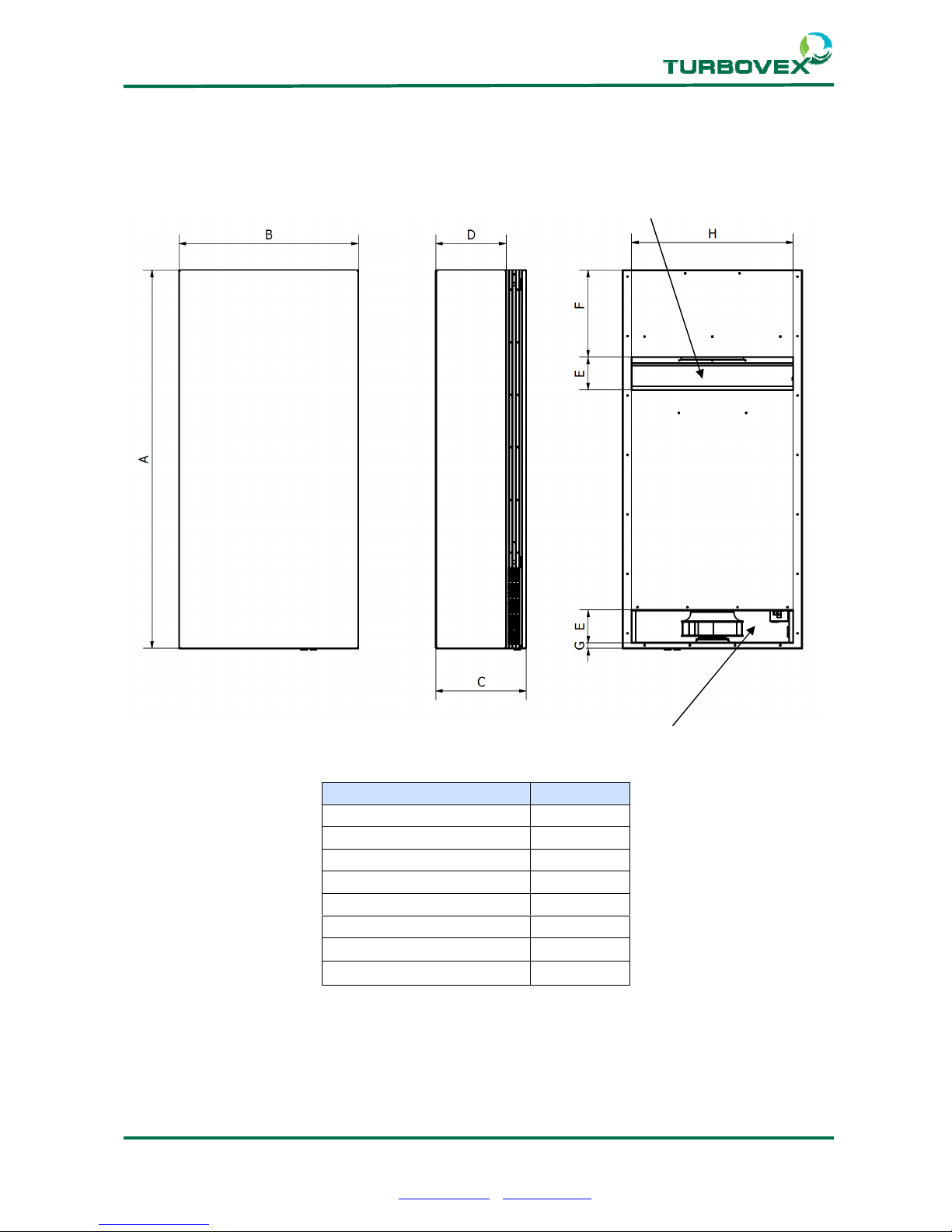

3.1.0. External dimensions

Intake zone

Minimum required distance to walls, floor and ceiling is 70 mm.

Dimensions (mm) TX350A

A (Height) 1400

B (Width) 662

C (Depth) 334

D (Mounting Dimension) 260

E (Hole Height) 122

F (Hole Distance Upper) 322

G (Hole Distance Lower) 20

H (Hole Width) 597

Exhaust Zone

Page 7 of 23

Turbovex A/S

Industrivej 45, DK – 9600 Aars

Tel: +45 96 98 14 62 – Fax: +45 98 96 42 24

e-mail: info@turbovex.dk – www.turbovex.dk

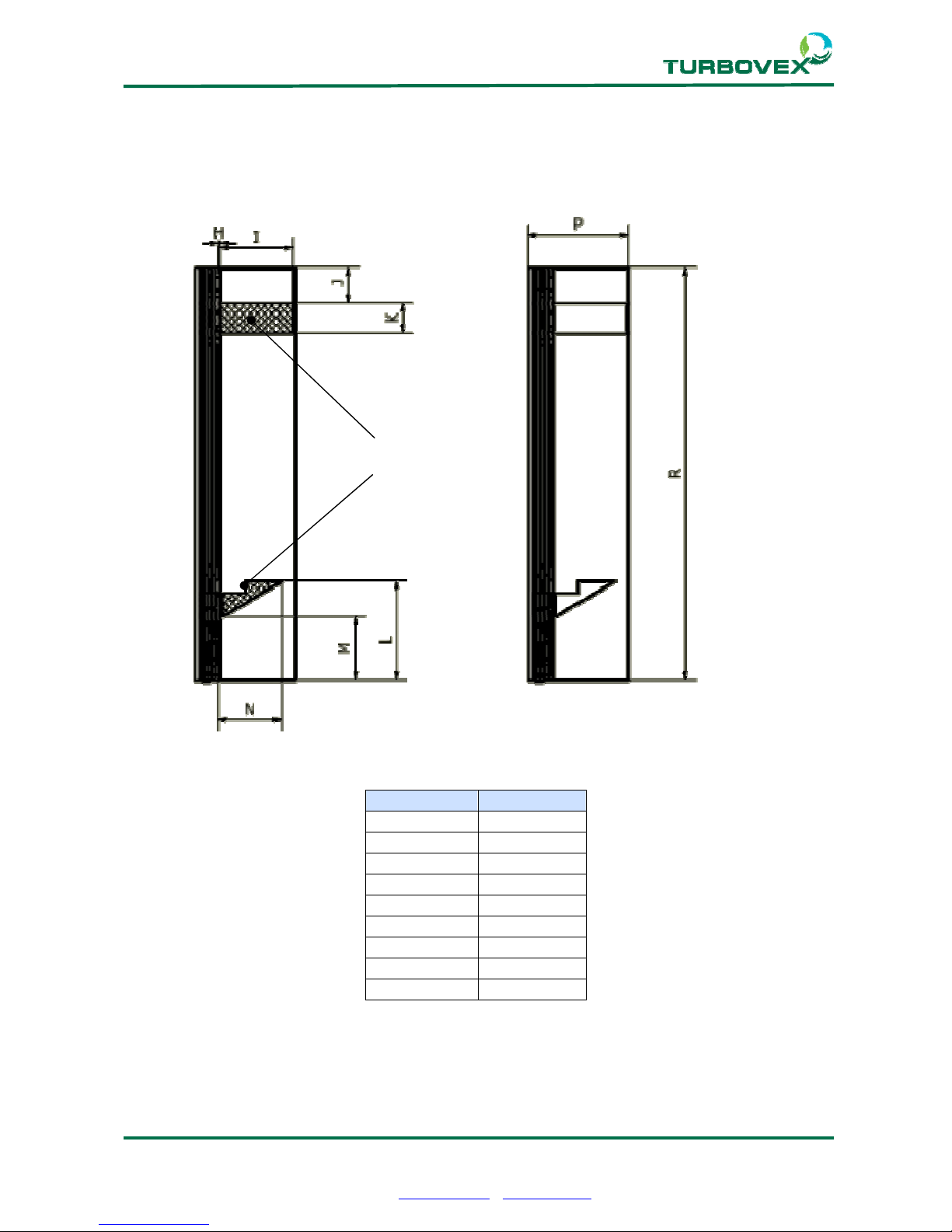

3.2.0 Wall/window installation

Internal reinforcement is built into the sides within the marked areas. Holes can be drilled

in these areas as required for installation.

Dimensions: TX350A

H 10

I 235

J 105

K 90

L 335

M 220

N 205

P 336

R 1400

Safe area

for holes

Loading...

Loading...