TL SERIES

USER MANUAL

TL-1201

TL-1501

TL-1561

TL-1500

TL-1550

TL-1800

Turbosound Ltd.

Star Road, Partridge Green

West Sussex RH13 8RY England

Tel: +44 (0)1403 711447 Fax: +44 (0)1403 710155

web: www.turbosound.com

Issue 1.0 Copyright

2001 Turbosound Ltd.

user manual

TL series

Contents

Introduction ..................................................................................................................................3

Thanks......................................................................................................................................3

Unpacking the TL series loudspeaker ....................................................................................3

Features ........................................................................................................................................4

Product Range Summary............................................................................................................. 5

TL-1201.....................................................................................................................................5

TL-1501.....................................................................................................................................5

TL-1561.....................................................................................................................................6

TL-1500.....................................................................................................................................6

TL-1550.....................................................................................................................................7

TL-1800.....................................................................................................................................7

System requirements................................................................................................................... 8

Amplifier considerations.........................................................................................................9

Equalisation .............................................................................................................................9

Dispersion................................................................................................................................9

Mounting and Fixing..................................................................................................................11

Rigging hardware .................................................................................................................. 11

Choosing the best location ...................................................................................................12

Maintenance...............................................................................................................................13

Removal of the low frequency driver(s)...............................................................................13

Removal of the mid frequency driver...................................................................................13

Removal of the high frequency compression driver........................................................... 13

Appendix A.................................................................................................................................14

Use of thread locking compounds........................................................................................14

Appendix B ................................................................................................................................. 15

Spares and Accessories ........................................................................................................ 15

Flying Accessories.................................................................................................................15

Appendix C ................................................................................................................................. 16

Technical Specifications........................................................................................................16

Appendix D.................................................................................................................................18

Limited Warranty...................................................................................................................18

TL series manual

page 2

INTRODUCTION

Thanks

Thank you for choosing a TURBOSOUND TL series loudspeaker product for your application.

Please spare a little time to digest the contents of this manual, so that you can obtain the best

possible performance from this unit.

All TURBOSOUND products are carefully engineered for world class performance and reliability.

If you would like further information about this or any other TURBOSOUND product, please

contact us. Detailed product information is available on our web site at www.turbosound.com

We look forward to helping you in the near future.

Congratulations, you have just purchased a professional loudspeaker system from the renowned

Turbosound range, designed to give you the best in audio quality and many years of reliable,

trouble free operation. It offers superior audio quality, full technical documentation, and rigging

and flying hardware options. Please read through this manual carefully before you attempt to

operate the loudspeaker system. It contains valuable information enabling you to quickly and

easily set up and connect the loudspeakers, important system and set-up checks together with

positioning and mounting instructions.

user manual

TL series

Unpacking the TL series loudspeaker

After unpacking the unit please check carefully for damage. If damage is found, please notify the

carrier concerned at once. You, the consignee, must instigate any claim. Please retain all

packaging in case of future re-shipment.

TL series manual

page 3

user manual

TL series

FEATURES

•

Superb audio quality

Superb audio quality: carefully designed and matched loudspeaker drive units are used to

Superb audio qualitySuperb audio quality

give you exceptional performance and many years of reliable, trouble free operation.

•

High quality loudspeaker components

High quality loudspeaker components are used throughout the range. Low frequency drivers

High quality loudspeaker componentsHigh quality loudspeaker components

are specified for high sensitivity and durability, while high frequency drivers are selected for

consistent and reliable performance.

•

High frequency protection system

High frequency protection system: two-stage thermal overload circuits on all two way

High frequency protection systemHigh frequency protection system

products prevents damage to the HF drive units from both transient peaks and long term

heating effects.

•

Professional appearance

Professional appearance: TL series enclosures are equally suited to live sound as well as

Professional appearanceProfessional appearance

permanently installed applications.

•

Easy transportability

Easy transportability: comfortable, ergonomic flush handles are provided on all TL series

Easy transportabilityEasy transportability

enclosures for easy lifting and transportation in mobile sound reinforcement applications.

•

Wide dispersion

Wide dispersion: TL series enclosures are designed to give wide and even dispersion patterns

Wide dispersionWide dispersion

in order to maximise sound coverage over a given area from single loudspeakers.

•

Solid construction

Solid construction: all Turbosound TL series cabinets are built from high grade birch plywood

Solid constructionSolid construction

and are finished in a durable semi-matt textured paint.

•

Integral rigging points

Integral rigging points: fitted as standard, enabling use with optional M10 shoulder eyebolts

Integral rigging pointsIntegral rigging points

for many types of fixed installations. All models are type-tested for load rating to ensure safe

rigging.

•

Pole mount and tripod stand use

Pole mount and tripod stand use is facilitated by the provision of integral pole mount fittings

Pole mount and tripod stand usePole mount and tripod stand use

on all models with the exception of the TL-1561.

•

Speakon NL4MP connectors

Speakon NL4MP connectors are fitted to all TL series enclosures, enabling simple and easy

Speakon NL4MP connectors Speakon NL4MP connectors

hook-ups as well providing loop-in / loop-out facilities to additional enclosures.

TL series manual

page 4

PRODUCT RANGE SUMMARY

TL-1201

The TL-1201 is a compact trapezoidal passive two-way loudspeaker

enclosure designed for use in a wide variety of live sound

applications as well as in fixed installations ranging from cafes,

pubs, bars and restaurants to retail stores and houses of worship.

It consists of a 12” reflex-loaded low frequency driver and a 1” high

frequency compression driver in an optimally tuned, birch plywood

enclosure. These high-grade components are matched with an

internal second order passive crossover network.

Its wide dispersion pattern of 70°H x 40°V enables a variety of foreground sound applications,

including use as a delay speaker in distributed sound reinforcement system.

Two Neutrik Speakon NL4MP connectors provide input and loop in / loop out connections to the

enclosure. Internal threaded rigging points provided on the top and back are designed for use with

optional M10 shoulder eyebolts for rigging single enclosures in fixed installations. An integral

35mm pole mount is fitted for use with standard tripods and poles.

user manual

TL series

TL-1501

The TL-1501 is a trapezoidal passive two-way loudspeaker

enclosure designed for use in a wide variety of live sound

applications as well as in fixed installations ranging from

cafes, pubs, bars and restaurants to retail stores and houses of

worship.

It consists of a 15” low frequency driver and a 1” high

frequency compression driver in an optimally tuned, birch

plywood enclosure. These high-grade components are

matched with an internal second order passive crossover

network. The TL-1501 is designed to provide wide horizontal

coverage (70°H x 40°V) making it suitable for use in a variety of

foreground sound applications, including use as a delay speaker in distributed sound

reinforcement system.

Two Neutrik Speakon NL4MP connectors provide input and loop in / loop out connections to the

enclosure. Internal fixing points provided on the top and back can be used with optional M10

shoulder eyebolts for rigging single enclosures in fixed installations. An integral 35mm pole

mount is fitted for use with standard tripods and poles.

TL series manual

page 5

user manual

TL series

TL-1561

The TL-1561 is a trapezoidal passive three-way loudspeaker

enclosure designed for use in a wide variety of live sound

applications as well as in fixed installations ranging from cafes,

pubs, bars and restaurants to retail stores and houses of

worship.

It consists of a front-loaded 15” low frequency driver, a frontloaded 6.5" mid frequency driver and a 1” high frequency

compression driver on a 70°H x 40°V high frequency horn,

matched with an internal second order passive crossover

network.

The three-way design affords an increase in mid-range energy

when compared to its two-way counterpart, as well as

providing extended low frequency response due to the

increased enclosure size.

A rear panel connector plate carries two Neutrik Speakon NL4MP connectors for loop in / loop out

connections to additional enclosures. Flush handles are provided for easy lifting and carrying.

TL-1500

The TL-1500 is a trapezoidal 15” low frequency enclosure

designed to give low frequency support to TL-1201 or TL-1501

enclosures. As such it can be used in a wide variety of live

sound applications as well as in fixed installations ranging from

cafes, pubs, bars and restaurants to retail stores and houses of

worship.

It consists of a front-loaded 15” low frequency driver and an

internal high pass crossover network in an optimally tuned,

birch plywood enclosure. The cabinet is fitted with a pole mount socket in the top panel.

Two Neutrik Speakon NL4MP connectors provide input and high pass output connections to TL1201 or TL-1501 enclosures. Flush handles are provided for easy lifting and carrying.

TL series manual

page 6

TL-1550

The TL-1550 is a trapezoidal dual 15” low frequency enclosure

designed to give low frequency support to TL-1201 or TL-1501

enclosures. As such it can be used in a wide variety of live

sound applications as well as in fixed installations ranging from

cafes, pubs, bars and restaurants to retail stores and houses of

worship.

It consists of two front-loaded 15” low frequency drivers and an

internal high pass crossover network in an optimally tuned,

birch plywood enclosure. The cabinet is fitted with a pole

mount socket in the top panel.

Two Neutrik Speakon NL4MP connectors provide input and

high pass output connections to TL-1201 or TL-1501 enclosures.

Flush handles are provided for easy lifting and carrying.

user manual

TL series

TL-1800

The TL-1800 is a trapezoidal 18” low frequency enclosure

designed to give low frequency support to TL-1201 or TL1501 enclosures. As such it can be used in a wide variety of

live sound applications as well as in fixed installations

ranging from cafes, pubs, bars and restaurants to retail

stores and houses of worship.

It consists of a front-loaded 18” low frequency driver and

an internal high pass crossover network in an optimally

tuned, birch plywood enclosure. The cabinet is fitted with a

pole mount socket in the top panel.

Two Neutrik Speakon NL4MP connectors provide input and high pass output connections to TL1201 or TL-1501 enclosures. Flush handles are provided for easy lifting and carrying.

TL series manual

page 7

user manual

TL series

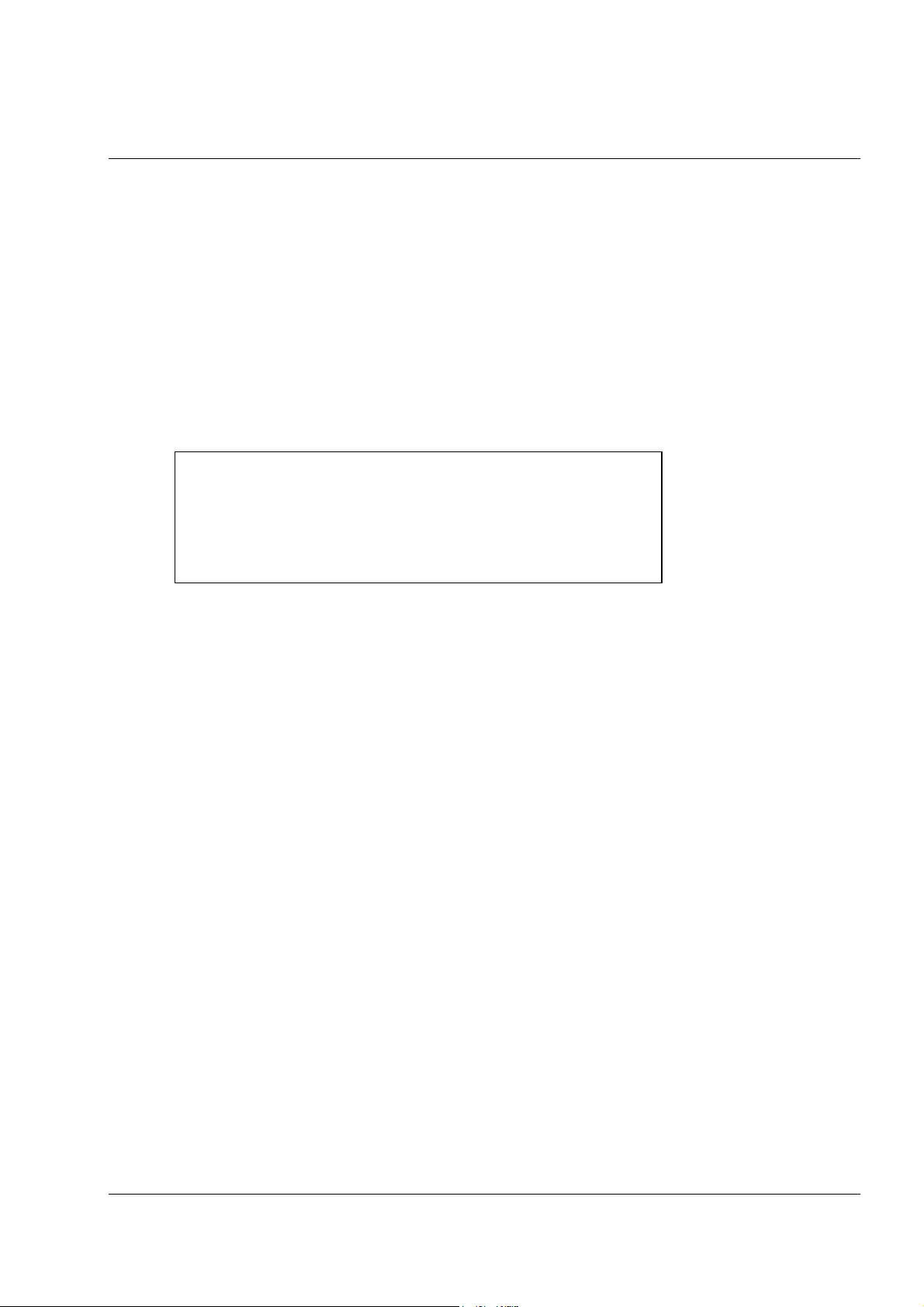

SYSTEM REQUIREMENTS

TL series enclosures are passive loudspeaker systems. This means that they require only one

amplifier channel for correct operation, the frequency splitting between the low frequency driver

and the high frequency driver or mid and high frequency driver in two-way and three-way

products being accomplished by the internal passive crossover network built into each enclosure.

If additional low frequency enclosures are used in conjunction with TL series two-way enclosures

to extend low frequency response, no additional amplifier channels or external electronic

crossovers are required. All TL series low frequency enclosures are equipped with internal high

pass crossover networks, splitting the full range signal and feeding the appropriate frequency

band to the two-way enclosure. Therefore a full range system consisting of, for example, a TL1201 and a TL-1500 can be powered from a single amplifier as shown below, thereby saving the

expense of additional amplifiers and external crossovers.

INPUT LINK

TL-1201

TL SERIES

INPUT LINK

AMPLIFIER

TL-1500

TL SERIES

LINKINPUT

INPUT LINK

1. Connect the amplifier output to the Speakon INPUT socket on the bass enclosure.

2. Then connect an additional speaker cable from the LINK socket on the bass cabinet to the

INPUT socket on the full range cabinet. Speakon pin connections are shown below.

TL series manual

page 8

Speakon Pin Wiring

Pin 1+ Positive

Pin 1- Negative

Pin 2+ No Connection

Pin 2- No Connection

1+

2-

1-

2+

Back Front

Amplifier considerations

Turbosound speaker enclosures should be driven by high quality power amplifiers designed for

true professional use. Such amplifiers will have balanced inputs, DC and RF fault protection, and

well-designed cooling systems for reliability. Turbosound power amplifiers such as the TMCT1000 are available and recommended for this purpose.

The program power listed in the loudspeaker’s technical specification is the best guide to the size

of amplifier required for general-purpose applications. The amplifier should therefore be capable

of delivering long term broadband power equal to the loudspeaker’s program power rating at the

loudspeaker’s stated nominal impedance. This approach allows sufficient headroom to generate

good dynamic range.

RECOMMENDED AMPLIFIER POWER RATINGS:

The amplifier's rated r.m.s. continuous power output (20Hz – 20kHz, per

channel) should be equal to the program power handling of the

loudspeaker at its nominal impedance.

user manual

TL series

In general, the more powerful the amplifier the better it will sound, provided that it is not driven

into sustained clipping. It should be understood that overdriving an insufficiently powered

amplifier is more likely to cause loudspeaker damage – the total energy in a heavily clipped signal

is far higher than in an unclipped signal – than operating a more powerful amplifier within its

ratings.

Equalisation

TL series enclosures are designed to provide smooth and even frequency response. They do not

need excessive amounts of external equalisation to overcome the sonic deficiencies often found in

many lesser designs.

In order to compensate for the room acoustics, TL series enclosures require only minimal

equalisation. As in any system, over-equalisation introduces phase shifts, distortion and a

reduction in headroom, usually causing more problems than it cures. Under most circumstances a

1/3 or 1/2 octave graphic equaliser will generally be adequate, with the fader settings applied

smoothly and as little as possible for the required room compensation. Most rooms will have

cut

resonances that will be excited at particular frequencies needing some

These problems are most pronounced at the lower frequencies where loudspeakers generally

exhibit very little directional control. If you find that the system needs a lot of

frequencies you may need additional sub-bass units. It is good practice to use as little equalisation

as possible, aiming to cut frequencies rather than adding large amounts of boost.

to help tame the sound.

boost

at lower

TL series manual

page 9

user manual

TL series

Dispersion

TL series enclosures are designed to provide relatively wide (70°) horizontal coverage. This allows

the majority of live sound applications to be covered with enclosures placed individually to take

advantage of this performance feature, for example either side of a stage in a pub or small club

environment as shown below. The loudspeakers should be either mounted on tripod stands or

supported on straight poles on top of TL-1500, TL-1550 or TL-1800 bass enclosures. In order to

optimise the sound coverage, point the loudspeakers inwards slightly, such that the centre lines

intersect at a distance approximately equal to twice the width of the stage.

STAGE

It is possible to array TL series loudspeakers in order to achieve wider horizontal coverage and in

these applications it is recommended that the cabinets be placed such that the trapezoidal sides

are touching to ensure that the appropriate splay angle is observed. For guidance when designing

a sound system, a 70º horizontal polar pattern equals an angle of 35º either side of the centre line

at which the sound pressure level is 6dB down with respect to centre, (averaged over the whole

frequency range of the loudspeaker). Thus a 40º vertical dispersion gives an angle of 20º above

and below the horizon.

TL series manual

page 10

MOUNTING AND FIXING

Rigging hardware

A versatile range of mounting hardware is available

that allows enclosures to be used in a variety of

ways, in either mobile sound reinforcement

applications or permanent installations.

A pole mount / tripod stand fitting

A pole mount / tripod stand fitting is fitted to the

A pole mount / tripod stand fittingA pole mount / tripod stand fitting

bottom of the TL-1201 and TL-1501 full range

cabinets. Use this pole mount facility with either

optional Turbosound PA-100 35mm diameter poles,

or conventional loudspeaker tripod stands. Doing so

will raise the TL-1201 or TL-1501 loudspeaker above

the heads of an audience, providing better sound

coverage from a single enclosure. A matching pole

mount socket is provided on the top of the TL-1500,

TL-1550 and TL-1800 low frequency enclosures to

accept the PA-100 pole.

user manual

TL series

All TL series cabinets, including low frequency enclosures, can be rigged in permanent

installations using optional M10 shoulder eyebolts

internal threaded rigging points, and a further rigging point is provided on the back panel, below

the connector plate, used to determine the amount of downward angle. As supplied, these rigging

points are fitted externally with M10 countersunk bolts. To facilitate rigging of the enclosure

simply remove these M10 bolts and replace them with M10 x 18mm shoulder eyebolts using a

suitable thread locking compound to avoid the possibility of loosening (please refer to Appendix

C: Use of thread locking compounds at the back of this manual). Note:

thread length of at least 18mm (3/4”).

optional M10 shoulder eyebolts. The top of the cabinet is provided with two

optional M10 shoulder eyeboltsoptional M10 shoulder eyebolts

Note: Eyebolts must have a

Note: Note:

TL series manual

page 11

user manual

TL series

NOTE:

NOTE: The rigging points are designed to suspend single enclosures only. There is no facility to

NOTE: NOTE:

hang an additional cabinet below a flown TL series enclosure.

IMPORTANT:

IMPORTANT: Any installation, whether temporary or permanent, must be securely attached to the

IMPORTANT: IMPORTANT:

structure of the building using chain, steel wires or web straps which are certified and load rated

for the purpose. The combined weight of the sound system, its cables and the rigging system

must be safely carried by the points at which attachment is made to the building or structure.

Great care must be taken in selecting the attachment points and methods, being absolutely sure of

the load carrying capacity of points chosen.

NOTE

NOTE: The rigging of loudspeaker systems is an extremely serious matter with potentially lethal

NOTENOTE

consequences should anything go wrong. It is of vital importance that you, or other people rigging

the system, are suitably qualified to do so and have a full understanding of all the factors involved

with safety as a number one priority. Turbosound accepts no responsibility for any accident,

damage or failure of any rigged system. This rigging information is specifically related to the

requirements of TL series enclosures only. For more detailed information on the whole topic of

rigging various handbooks are available. If you are in any doubt contact your Turbosound dealer

who will be able to refer you to an experienced rigging company.

Choosing the best location

When using any TL series system, certain room parameters will affect the resultant sound quality

and coverage. For example, any boundary like a wall or floor will lift certain frequencies. If you are

placing the unit in a corner then a lift at the bass end is to be expected and it may sound rather

boomy. This can be compensated for moving the speaker or cutting low frequencies with a

graphic equaliser.

When speakers are flown in free space then boundary effects are minimised. The result is a

smooth frequency response without any boost at odd frequencies, but the bass end may appear

subjectively light. In this case increase the sub-bass level to bring the low end up.

The relationship between sound pressure level and distance is an “inverse square law” so

remember that every time the distance from the sound source is doubled the sound level

decreases by 6dB. For every 3dB increase of speaker output you need a doubling of input power

and you can work out the wattage input needed to give the required SPL levels at various

distances from the loudspeaker(s).

TL series manual

page 12

MAINTENANCE

If any of the drive units in your TL series cabinet should cease functioning and need a replacement

recone or diaphragm, you are advised to remove the faulty unit from the cabinet and send it to a

professional service centre authorised to recone and repair Turbosound loudspeakers.

Removal of the low frequency driver(s)

The perforated steel loudspeaker grille is held in place under tension only, fitting into slots at

either side of the baffle. There are no screws or other fixings holding the grille in place.

1. Lay the cabinet on its back and, using two small screwdrivers inserted through the mesh of

the grille, firmly pull the grille away from the slot at one side of the baffle until it is free. Set

the grille aside for later re-assembly.

2. Undo the four screws holding the driver(s) in place and carefully lift it out and away from the

cabinet. Make a note of the driver polarity for later reconnection. Disconnect the cables from

the drive unit and completely remove the driver from the cabinet.

user manual

TL series

3. To reinstate the driver(s) simply reverse the above procedure, making sure you observe the

correct polarity when reconnecting the cables back into the terminals of the drive units.

Removal of the mid frequency driver

1. Remove the loudspeaker grille as described above and set the grille aside for later re-fitting.

2. Undo the four screws holding the driver(s) in place and carefully lift it out and away from the

cabinet. Make a note of the driver polarity for later reconnection. Disconnect the cables from

the drive unit and completely remove the driver from the cabinet. To reinstate the driver

simply reverse the above procedure, making sure you observe the correct polarity when

reconnecting the cables back into the terminals of the drive units.

Removal of the high frequency compression driver

1. Remove the loudspeaker grille as described above and set the grille aside for later re-fitting.

2. Remove the horn/driver assembly by unscrewing the four screws holding the flange in place.

Lift it out and away from the cabinet.

3. The high frequency driver can now be disassembled from the HF horn.

4. To reinstate the high frequency horn and compression driver, simply reverse the above

procedure making sure you observe the correct polarity when reconnecting the cables back

into the terminals of the drive unit.

TL series manual

page 13

user manual

TL series

APPENDIX A

Use of thread locking compounds

When assembling flying hardware to TL series loudspeaker enclosures it is advisable to use

thread-locking compounds to eyebolts and other bolts in order to avoid any possibility of

loosening.

The recommended thread-locking compound is Loctite 222.

The threaded rigging points used in TL series enclosures are manufactured from zinc-plated mild

steel. Therefore, and additionally if the external bolts used are zinc-plated, zinc-passivated,

stainless steel or anodised (as the majority are), then the corresponding activator, Loctite 7471,

should be used to achieve 100% performance.

Application:

Application: Spray Loctite 7471 into the thread holes and allow to evaporate. Apply Loctite 222

Application: Application:

thread locking compound to the bolts prior to fitting, allowing sufficient to fill all the engaged

threads. Assemble components and tighten as necessary.

The parts may be disassembled by hand if required.

TL series manual

page 14

APPENDIX B

Spares and Accessories

CD-106 1” HF compression driver

RD-106 Replacement diaphragm for CD-106

LS-6504 6.5” MF loudspeaker

RC-6504 Recone kit for LS-6504

LS-1211 12” LF loudspeaker

RC-1211 Recone kit for LS-1211

LS-1514 15” LF loudspeaker

RC-1514 Recone kit for LS-1514

LS-1807 18" LF loudspeaker

RC-1807 Recone kit for LS-1807

MG-1201 Metal grille for TL-1201

MG-1501 Metal grille for TL-1501

MG-1561 Metal grille for TL-1561

MG-1500 Metal grille for TL-1500

MG-1550 Metal grille for TL-1550

MG-1800 Metal grille for TL-1800

PX-1201 Passive crossover network for TL-1201

PX-1501 Passive crossover network for TL-1501

PX-1561 Passive crossover network for TL-1561

PX-1500 Passive crossover network for TL-1500

PX-1550 Passive crossover network for TL-1550

PX-1800 Passive crossover network for TL-1800

user manual

TL series

Flying Accessories

EB-10 M10 x 18mm shoulder eyebolt

PA-100 35mm straight pole

TL series manual

page 15

user manual

TL series

APPENDIX C

Technical Specifications

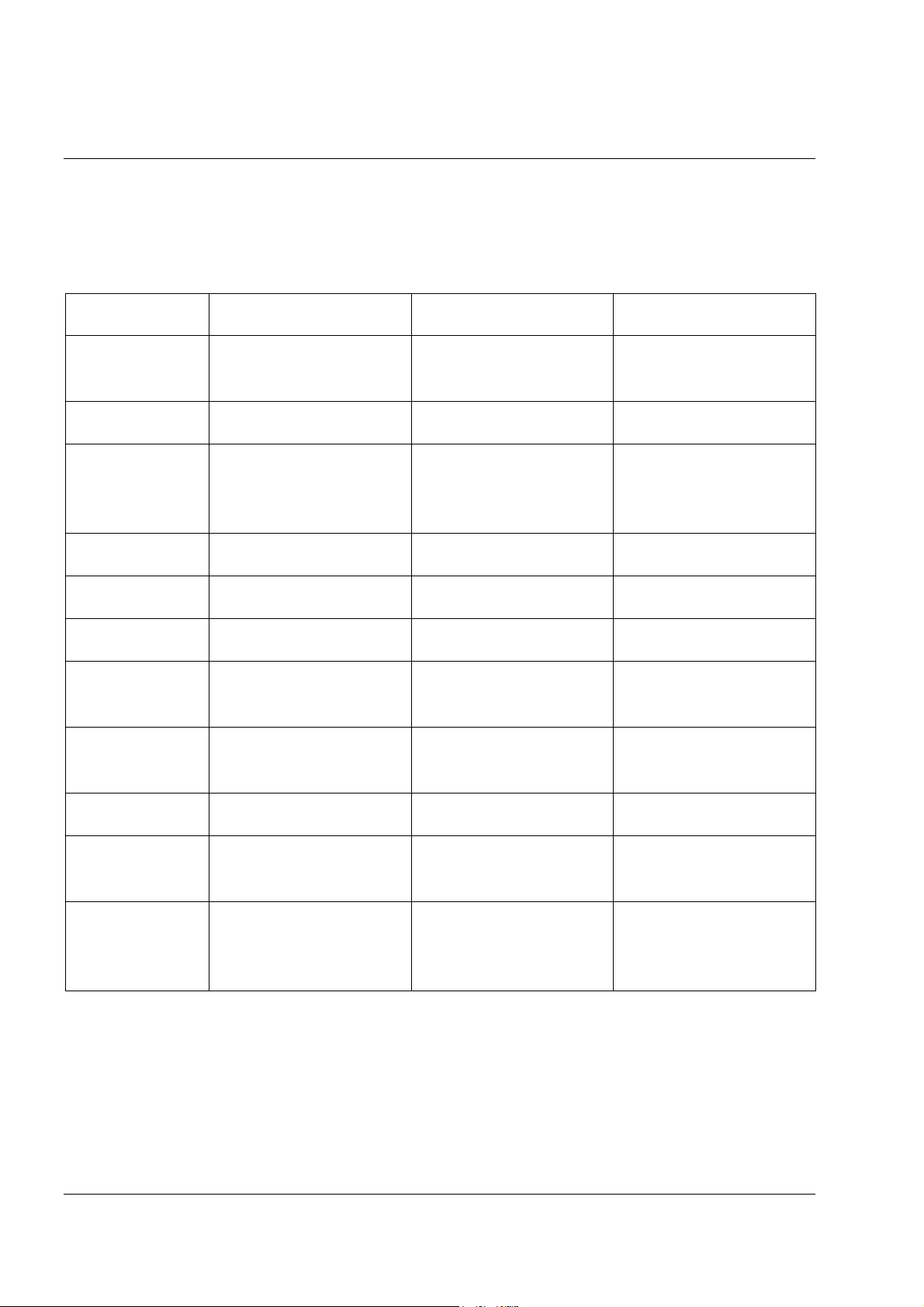

TL-1201

TL-1201 TL-1501

TL-1201TL-1201

TL-1501 TL-1561

TL-1501TL-1501

TL-1561

TL-1561TL-1561

Dimensions

(H x W x D)

Net weight 21kg (46.2lbs) 26kg (57.2lbs) 32kg (70.4lbs)

Components 1 x 12” LF driver

Frequency response 54Hz – 20kHz ±6dB 46Hz – 20kHz ±6dB 42Hz – 20kHz ±6dB

Nominal dispersion 70°H x 40°V @-6dB pts 70°H x 40°V @-6dB pts 70°H x 40°V @-6dB pts

Sensitivity 98dB, 1 watt @ 1metre 99Db, 1 watt @ 1metre 98dB, 1 watt @ 1 metre

Power handling 250 watts r.m.s.

Maximum SPL 122dB continuous

550mm x 395mm x 383mm

(21.6” x 15.5” x 15”)

1 x 1” HF compression driver

500 watts program

128dB peak

635mm x 480mm x 465mm

(25” x 18.9” x 18.3”)

1 x 15” LF driver

1 x 1” HF compression driver

300 watts r.m.s.

600 watts program

124dB continuous

130dB peak

810mm x 480mm x 465mm

(31.9” x 18.9” x 18.3”)

1 x 15” LF driver

1 x 6.5” MF driver

1 x 1” HF compression driver

300 watt r.m.s.

600 watts program

123dB continuous

129dB peak

Construction 15mm (5/8”) birch plywood 15mm (5/8”) birch plywood 15mm (5/8”) birch plywood

Grille Powder coated perforated steel

mesh

Connectors (2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

Due to continuing product improvement the above specifications are subject to change.

Powder coated perforated steel

mesh

(2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

Powder coated perforated steel

mesh

(2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

TL series manual

page 16

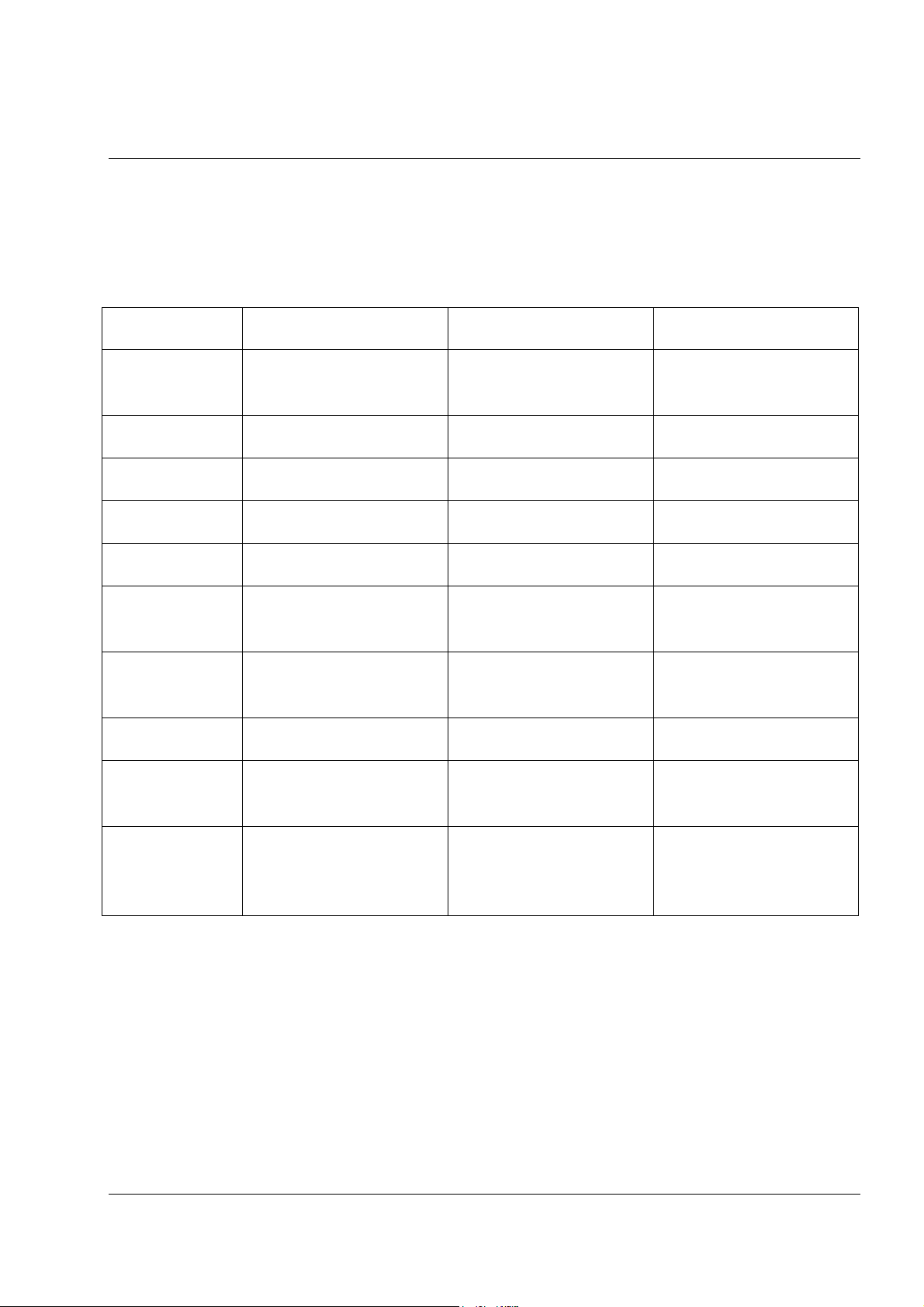

TL-1500

TL-1500 TL-1550

TL-1500TL-1500

TL-1550 TL-1800

TL-1550TL-1550

TL-1800

TL-1800TL-1800

user manual

TL series

Dimensions

(H x W x D)

Net weight 23kg (50.6lbs) 37kg (81.4lbs) 26kg (57.2lbs)

Components 1 x 15” LF driver 2 x 15” LF drivers 1 x 18” LF driver

Frequency response 50Hz – 225Hz ±6dB 50Hz – 225Hz ±6dB 42Hz – 225Hz ±6dB

Sensitivity 99dB, 1 watt @ 1metre 101dB, 1 watt @ 1metre 97dB, 1 watt @ 1 metre

Power handling 300 watts r.m.s.

Maximum SPL 122dB continuous

Construction 15mm (5/8”) birch plywood 15mm (5/8”) birch plywood 15mm (5/8”) birch plywood

Grille Powder coated perforated steel

530mm x 480mm x 465mm

(20.9” x 18.9” x 18.3”)

600 watts program

128dB peak

mesh

875mm x 480mm x 465mm

(34.4” x 18.9” x 18.3”)

600 watts r.m.s.

1200 watts program

124dB continuous

130dB peak

Powder coated perforated steel

mesh

600mm x 500mm x 485mm

(23.6” x 19.7” x 19”)

350 watt r.m.s.

700 watts program

123dB continuous

129dB peak

Powder coated perforated steel

mesh

Connectors (2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

(2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

Due to continuing product improvement the above specifications are subject to change.

(2) Speakon NL4MP wired

pin 1+ positive,

pin 1- negative

TL series manual

page 17

user manual

TL series

APPENDIX D

Limited Warranty

This Turbosound loudspeaker product is warranted to the original end-user purchaser and all

subsequent owners for a period of two (2) years from the original date of purchase.

Warranty Coverage

Warranty Coverage

Warranty CoverageWarranty Coverage

Warranty coverage includes defects in materials and workmanship. It does not include:

•

damage caused by accident, misuse, abuse, neglect or modification by any person other than

an authorised Turbosound representative,

•

damage caused by failure to operate the product in accordance with the instructions

contained in the user manual,

•

damage occurring during shipment in transit,

•

claims based on any misrepresentation by the seller,

•

products which do not have the original components as specified in the product engineering

information,

•

products on which the serial number has been removed or defaced.

Shipping

Shipping

ShippingShipping

Should any fault develop with a component of your Turbosound system, please return the

product, freight pre-paid, in its original packing carton, along with proof of purchase such as the

original bill of sale or receipted invoice, and a description of the suspected fault to Turbosound

Ltd. (Att: Customer Service), Star Road, Partridge Green, West Sussex RH13 8RY, England, or your

local authorised Turbosound representative. The product serial number must be quoted in all

correspondence relating to the claim. Insurance is recommended, as Turbosound or its

representatives are not liable for loss or damage in transit. Turbosound will pay for return freight

costs should repairs be covered under warranty.

TL series manual

page 18

Incidental and consequential damages

Incidental and consequential damages

Incidental and consequential damagesIncidental and consequential damages

Turbosound's liability is limited to the repair or replacement, at our option, of any defective

product, and shall not be liable for any incidental and consequential damages including, without

limitation, injury to persons or property or loss of use.

Limitation of implied warranties

Limitation of implied warranties

Limitation of implied warrantiesLimitation of implied warranties

All implied warranties, including warranties of merchantability and fitness for a particular

purpose, are limited in duration to the length of this warranty.

This warranty is in addition to, and in no way detracts from, your statutory rights as a consumer.

No other warranty is expressed or implied.

Please record your purchase information below for future reference:

Dealer Name _______________________________________________________________________

Dealer Address ____________________________________________________________________

user manual

TL series

___________________________________________________________________________________

___________________________________________________________________________________

Post / Zip Code _____________________________________________________________________

Dealer telephone / fax ______________________________________________________________

Invoice number ____________________________________________________________________

Date of purchase ___________________________________________________________________

Unit serial number _________________________________________________________________

TL series manual

page 19

Turbosound Ltd.

Star Road, Partridge Green

West Sussex RH13 8RY England

Tel: +44 (0)1403 711447 Fax: +44 (0)1403 710155

web: www.turbosound.com

Loading...

Loading...