Page 1

user manual

Flashline

TFS-900 Flashline Loudspeaker System

User Manual

Flashline User Manual

page 1

Page 2

user manual

Flashline

CONTENTS

1. IMPORTANT SAFETY INSTRUCTIONS (AMPLIFIERS) .................................................................................................................... 4

1.1 Safety Instructions for 20000DP ................................................................................................................................................. 4

1.2 Standards ..................................................................................................................................................................................... 4

1.3 Explanation of Graphical Symbols ............................................................................................................................................ 5

1.4 Warning ........................................................................................................................................................................................ 5

1.5 Caution .........................................................................................................................................................................................5

1.6 FCC Compliance Notice (Radio Interference) ...........................................................................................................................5

1.7 User Responsibility .....................................................................................................................................................................6

2. WELCOME ..........................................................................................................................................................................................7

2.1 Introduction ................................................................................................................................................................................. 7

2.2 Thanks ..........................................................................................................................................................................................7

2.3 Unpacking ....................................................................................................................................................................................7

3. THE FLASHLINE SYSTEM .................................................................................................................................................................8

3.1 TFS-900H mid/high loudspeaker ................................................................................................................................................ 8

3.2 TFS-900B Subwoofer and TFS-900L Subwoofer ...................................................................................................................... 9

3.3 TFS-DOLLY and TFS-COVER ....................................................................................................................................................11

3.4 TFS-RACK ..................................................................................................................................................................................12

4. CONNECTING THE LOUDSPEAKERS ............................................................................................................................................14

4.1 Wiring convention ..................................................................................................................................................................... 14

4.2 Damping Factor in cable ........................................................................................................................................................... 14

4.3 Power Output Performance ...................................................................................................................................................... 14

5. SYSTEM CONFIGURATIONS .......................................................................................................................................................... 15

5.1 Suggested amplifier loading for the TFS-900H ...................................................................................................................... 15

5.2 Suggested amplifier loading for subwoofers ......................................................................................................................... 16

5.3 Suggested amplifier loading for subwoofers in cardioid mode ...........................................................................................17

5.4 Suggested amplifier loading for a 4-way Flex Array system ................................................................................................ 18

6. AMPLIFIER RACK ROUTING ........................................................................................................................................................... 19

6.1 TFS-RACK High output routing ................................................................................................................................................19

6.2 TFS-RACK Low output routing ................................................................................................................................................. 19

6.3 TFS-RACK Flex Array routing, TFA-600L/B ............................................................................................................................. 20

6.4 TFS-RACK Flex Array routing TSW-218 .................................................................................................................................. 20

7. RIGGING THE FLASHLINE SYSTEM ..............................................................................................................................................21

7.1 Overview ....................................................................................................................................................................................21

7.2 TFS-FT900 Fly Trunk ..................................................................................................................................................................21

7.3 Flying an Array ..........................................................................................................................................................................22

7.4 De-rigging the Array ................................................................................................................................................................. 29

7.5 Flex Array as Downfills ............................................................................................................................................................. 30

8. THE 20000DP AMPLIFIER ................................................................................................................................................................ 31

8.1 Main features ............................................................................................................................................................................. 31

8.2 Additional Documentation ....................................................................................................................................................... 32

9. AMPLIFIER INSTALLATION ............................................................................................................................................................. 33

Flashline User Manual

page 2

Page 3

user manual

Flashline

9.1 Unpacking ................................................................................................................................................................................33

9.2 Mounting .................................................................................................................................................................................33

9.3 Rear Mounting .........................................................................................................................................................................33

9.4 Cooling .....................................................................................................................................................................................35

9.5 Operating Voltage ...................................................................................................................................................................35

9.6 Grounding ................................................................................................................................................................................36

10. PRODUCT OVERVIEW .................................................................................................................................................................36

10.1 Front Panel Overview ...........................................................................................................................................................36

10.2 Back Panel Overview ............................................................................................................................................................38

11. SIGNAL FLOW AND LAKE PROCESSING ..................................................................................................................................41

11.1 Signal Flow ............................................................................................................................................................................41

11.2 Level Adjustments & Mute Points .......................................................................................................................................41

11.3 Power Output Section: Limiting and Sensitivity ................................................................................................................42

11.4 Lake Processing and Control ................................................................................................................................................43

11.5 Modules and Frames ............................................................................................................................................................43

11.6 LoadLibrary™ and Fingerprints ...........................................................................................................................................43

11.7 Super Modules ......................................................................................................................................................................44

11.8 Loudspeaker Crossover Configuration Overview ..............................................................................................................44

11.9 Files and Presets ...................................................................................................................................................................44

12. LAKE CONTROLLER SOFTWARE ...............................................................................................................................................46

12.1 Introduction ...........................................................................................................................................................................46

12.2 Lake Processing and Control ................................................................................................................................................46

12.3 Installing the Lake Controller Software ...............................................................................................................................46

12.4 Gain Structure .......................................................................................................................................................................47

12.5 Gain / Level Optimization .....................................................................................................................................................48

13. WARRANTY AND SUPPORT .......................................................................................................................................................49

13.1 General ...................................................................................................................................................................................49

13.2 International Warranties .......................................................................................................................................................49

13.3 Technical Assistance and Service ........................................................................................................................................49

14. MAINTENANCE ............................................................................................................................................................................50

14.1 Removal of the drive units ...................................................................................................................................................50

15. TECHNICAL SPECIFICATIONS ....................................................................................................................................................51

Flashline User Manual

page 3

Page 4

user manual

Flashline

1. Important Safety Instructions (Amplifiers)

Before using the device, be sure to carefully read the Safety Instructions. Keep this document with the

device at all times.

1.1 Safety Instructions for 20000DP

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Clean only with a dry cloth.

• Do not block any ventilation openings. Install in accordance

with the manufacturer’s instructions.

• Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including amplifiers) that

produce heat.

• Do not defeat the safety purpose of the polarized or groundingtype plug. A polarized plug has two blades with one wider than

the other. A grounding-type plug has two blades and a third

grounding prong. The wide blade or the third prong is provided

for your safety. If the provided plug does not fit into your outlet,

consult an electrician for replacement of the obsolete outlet.

• Protect the power cord from being walked on or pinched,

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

• Only use attachments/accessories specified by the

manufacturer.

• Unplug this apparatus during lightning storms or when unused

for long periods of time.

• Refer all servicing to qualified service personnel. Servicing is

required when the apparatus has been damaged in any way,

such as power-supply cord or plug is damaged, liquid has been

spilled or objects have fallen into the apparatus, the apparatus

has been exposed to rain or moisture, does not operate

normally, or has been dropped.

• Use the mains plug to disconnect the apparatus from the mains.

• WARNING: To reduce the risk of fire of electric shock, do not

expose this apparatus to rain or moisture.

• Do not expose this equipment to dripping or splashing and

ensure that no objects filled with liquids, such as vases, are

placed on the equipment.

• The mains plug of the power supply cord shall remain readily

operable.

• Do not connect the unit’s output to any other voltage source,

such as battery, mains source, or power supply, regardless of

whether the unit is turned on or off.

• Do not remove the top (or bottom) cover. Removal of the cover

will expose hazardous voltages. There are no user serviceable

parts inside and removal may void the warranty.

• An experienced user shall always supervise this professional

audio equipment, especially if inexperienced adults or minors

are using the equipment.

• The US National Differences clause 16.3 requires that network

cables must be flame rated VW-1.

• To prevent electric shock do not remove top or bottom covers.

No user serviceable parts inside, refer servicing to

qualified service personnel.

• à prévenir le choc électrique n’enlevez pas les couvercles.

Il n’y a pas des parties serviceable à l’intérieur, tous

reparations doit etre faire par personnel qualifié

seulment.

• To completely disconnect this equipment from the AC mains,

disconnect the power supply cord plug from the AC

receptacle. The mains plug of the power supply cord

shall remain readily operable.

• Pour démonter complètement l’équipement de l’alimentation

générale, démonter le câble d’alimentation de son

réceptacle. La prise d’alimentation restera aisément

fonctionnelle.

1.2 Standards

This equipment conforms to the

requirements of the EMC Directive 2004/108/

EC and the requirements of the Low Voltage

Directive 2006/95/EC. Standards applied:

EMC Emission, EN55103-1, E3, EMC Immunity EN551032, E3, with S/N below 1% at normal operation level.

Electrical Safety EN60065, Class I

This equipment is tested and listed according

to the U.S. safety standard ANSI/ UL 60065

and Canadian safety standard CSA C22.2 NO.

60065. Intertek made the tests and they are a Nationally

Recognized Testing Laboratory (NRTL).

Flashline User Manual

page 4

Page 5

user manual

Flashline

1.3 Explanation of Graphical Symbols

The lightning bolt triangle is used to alert the user to the presence of un-insulated “dangerous voltages”

within the unit’s chassis that may be of sufficient magnitude to constitute a risk of electric shock to humans.

The exclamation point triangle is used to alert the user to presence of important operating and service

instructions in the literature accompanying the product.

1.4 Warning

To reduce risk of fire or electric shock, do not expose this apparatus to rain or moisture.

Pour réduire les risques de blessure ou le choc électrique, n’exposez pas l’appareil à la pluie ou à l’humidité.

Do not expose this system/apparatus to dripping or splashing and ensure that no objects filled with liquids, such as

vases, are placed on the apparatus.

L’appareil ne doit pas être exposé à des egouttements d’eau ou des éclaboussures et de plus qu’aucun objet rempli

de liquide tel que des vases ne doit pas être placé sur l’appareil.

This apparatus must be connected to a mains socket outlet with a protective earthing connection.

Cet appareil doit être raccordé á une prise de courant qui est branchée à la terre.

The mains plug is used as a disconnect device and shall remain readily operable.

Lorsque la prise du réseau d’alimentation est utilisés comme dispositif de déconnexion, ce dispositif doit

demeuré aisément accessible.

1.5 Caution

To reduce the risk of fire or electric shock, do not remove screws. No user-serviceable parts inside.

Refer servicing to qualified service personnel.

Pour réduire le risque d’incendie ou de choc électrique, ne pas retirer les vis. Aucune pièce réparable par l’utilisateur.

Confier l’entretien àpersonnel qualifié.

1.6 FCC Compliance Notice (Radio Interference)

A sample of this product has been tested and complies with the limits for the European Electro Magnetic

Compatibility (EMC) directive. This equipment has also been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference from electrical equipment. This product uses radio frequency energy and if not used or

installed in accordance with these operating instructions, may cause interference to other equipment, such as radio

receivers.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment on

and off, the user is encouraged to try to correct the interference by one or more of the following measures:

• Re-orient or relocate the antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

Flashline User Manual

page 5

Page 6

user manual

Flashline

• Check if the affected unit complies with the EMC limits for immunity, (CE-labeled). If not, address the problem

with the manufacturer or supplier. All electrical products sold in the EC must be approved for immunity against

electromagnetic fields, high voltage flashes, and radio interference.

• Consult the dealer or an experienced radio/TV technician for help.

1.7 User Responsibility

1.7.1 Mains Connection Grounding

Your apparatus must be connected to a grounded socket outlet.

1.7.2 Speaker Output Hazard on Amplifiers

Amplifiers are capable of producing hazardous output voltages. To avoid electrical shock, do not touch any exposed

speaker wiring while the amplifier is operating. The external wiring connected to the speaker terminals shall be

installed by a qualified person, or ready-made leads or cords of appropriate capacity shall be used.

As the power output channels on amplifiers produce high voltage, do not connect or disconnect speaker cables

when the mains power is on.

1.7.3 Speaker Damage

Amplifier apparatus is very powerful and can be potentially dangerous to both loudspeakers and humans

alike. Many loudspeakers can be easily damaged or destroyed by overpowering them. Always check the

speaker’s continuous and peak power capabilities. Although the amplifiers attenuators can be used to reduce the

overall gain, an increase of the input signal can result in full output power, which may cause damage to connected

speakers.

1.7.4 Maintenance

For safe and reliable operation, the dust filter on should be removed and cleaned regularly to ensure maximum

airflow through the device. If the dust filters are not maintained there will be safety risks; for example, high internal

temperatures could ignite the dust and start a fire. There is also a risk that the unit will malfunction since it is

dependent on constant airflow from front to rear.

If the dust filters are not clean and the unit malfunctions, any resulting problems will not be covered by the

warranty.

Flashline User Manual

page 6

Page 7

user manual

Flashline

2. Welcome

2.1 Introduction

Congratulations, you have purchased a professional loudspeaker product from the Flashline series of products. If

you would like further information about this or any other TURBOSOUND product, please contact us on +44 (0)1403

711447.

Always check the Turbosound website for the latest updates on the technical documentation relating to this product

at www.turbosound.com

2.2 Thanks

Thank you for choosing a TURBOSOUND product for your application. By engaging in an ongoing rigorous process

of research and development all TURBOSOUND products are carefully engineered for world class performance and

reliability.

2.3 Unpacking

After unpacking the unit please check carefully for damage. If damage is found, please notify your supplier at once.

You, the consignee, must instigate any claim. Please retain all packaging in case of future re-shipment.

Flashline User Manual

page 7

Page 8

user manual

TFS-900H Butterfly plate

Flashline

3. The Flashline System

The Flashline TFS-900 System is a complete, fully integrated, large scale, five-way two-box line array sound

reinforcement system. It comprises mid/high and sub-bass loudspeakers, amplification and system control racks,

flying hardware, and transport cases in a very powerful and space-efficient format.

The Flashline system is designed to allow integration of systems around the world with guaranteed ‘out of the box’

compatibility.

3.1 TFS-900H mid/high loudspeaker

The TFS-900H is a four-way line array module covering the frequency range above 70Hz and containing three 1”

high frequency compression drivers loaded by Dendritic waveguides, two 6.5” high-mid cone transducers loaded by

Polyhorns, four 6.5” horn-loaded low-mid cone transducers, and two 12” horn-loaded low frequency transducers.

The rigging hardware is integrated into the end-cheeks on each side of the TFS-900H cabinet, which also provide

grab handle positions. Drop links at the front and rear of the box engage in the flygear of the box below it in the

array to give a range of inter-cabinet angles from 0° to 5°. TFS-900H cabinets are normally transported four-up

on the TFS-DOLLY and can be flown right off the dolly in blocks of four, with the rigging hardware already preconfigured for use. A simple TFS-GRID and TFS-TIP system is used to fly a typical array; no additional external parts

are required to fly the system.

The cabinet is finished in black TourTough finish.

TFS-900H Horn

TFS-900H Grilles

TFS-900H Endcheek

TFS-900H Flying pins

TFS-900H Handle

TFS-900H Flying pins

Flashline User Manual

page 8

TFS-900H Rear Drop link

TFS-900H Front Drop link

Page 9

TFS-900H Rear Droplink

TFS-900H NL8 Connectors

user manual

Flashline

TFS-900H Rear Doors

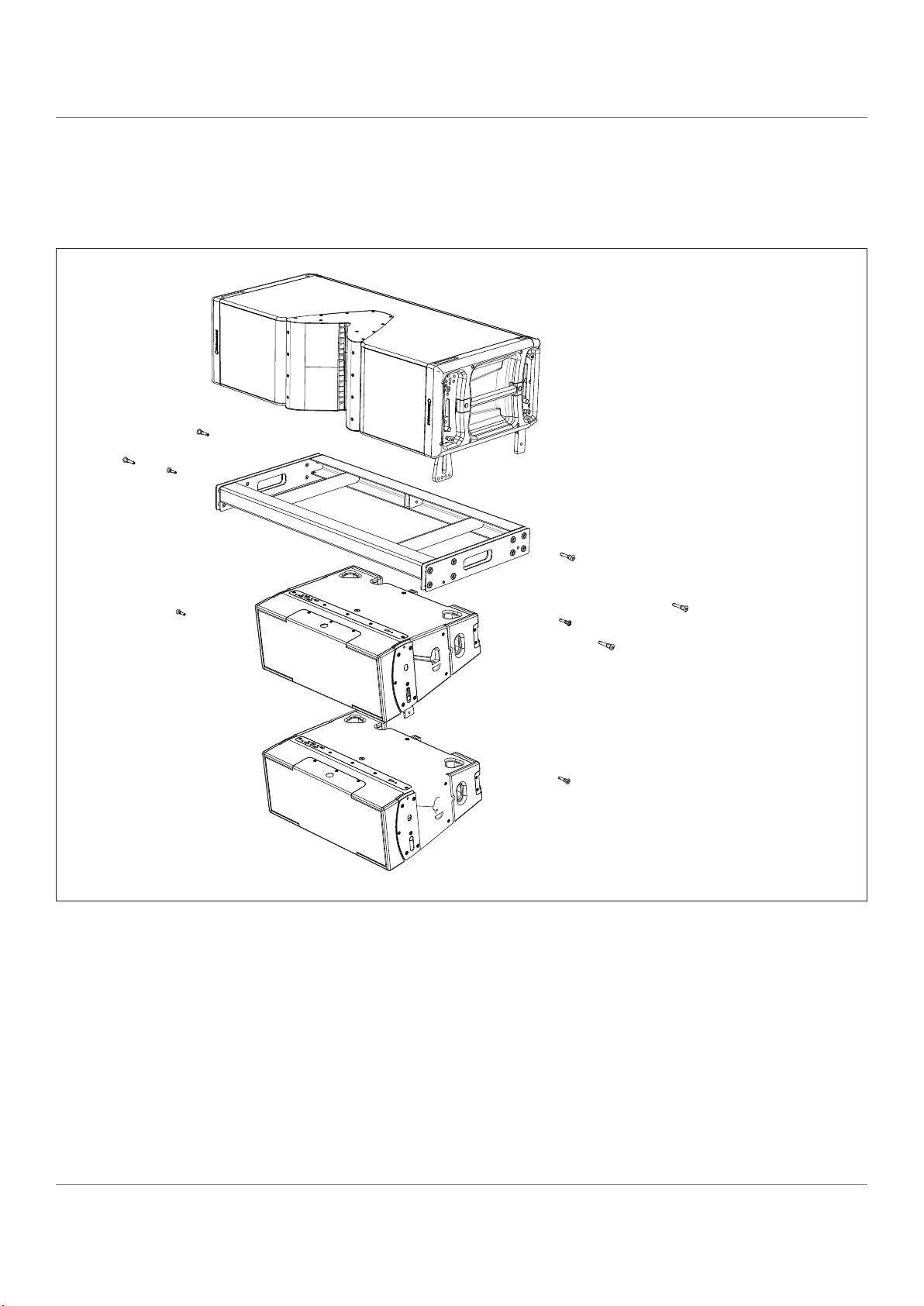

3.2 TFS-900B Subwoofer and TFS-900L Subwoofer

The TFS-900B is a dual 18” subwoofer employing hybrid loading techniques using the advantages of both bass

reflex loading and horn loading to develop extremely high levels of bass and sub-bass energy.

The TFS-900B is designed for ground stacking in support of TFS-900H cabinets and includes stacking feet and

matching cabinet recesses to ensure stability. Heavy duty wheels are fitted for transportation.

The TFS-900L includes rigging hardware to allow it be flown in standard and cardioid configuration and it is

equipped with heavy duty wheels for transportation.

The TFS-900B and TFS-900L are both fitted with a pair of NL4 connectors. The drivers are wired independently in

order to benefit from the maximum power transfer from the 20000DP amplifiers. Both cabinets are finished in black

TourTough as standard.

TFS-900H Front Droplink

Flashline User Manual

page 9

Page 10

user manual

Flashline

TFS-900B driver access door

TFS-900B

stacking foot

TFS-900B driver

access door

TFS-900B stacking foot

TFS-900B NL4 connectors

Flashline User Manual

page 10

Page 11

user manual

Flashline

3.3 TFS-DOLLY and TFS-COVER

The TFS-DOLLY allows cabinets to be transported and loaded directly from truck to stage area in a venue in blocks of

four. The total weight of the stack and dolly including cover is 465.5kg.

The heavy duty TFS-COVER is designed to protect the cabinets during transit. The front and rear flaps are secured

with velcro and allow the fronts of the cabinets to be accessible.

Note that when transporting Flashline cabinets on

the TFS-DOLLY that four people are required for

handling the dolly in and out of trucks and stage

loading area.

Flashline User Manual

page 11

Page 12

user manual

Flashline

3.4 TFS-RACK

The TFS-Rack contains three 20000DP amplifiers configured to drive each of the four frequency bands in the TFS900H from its four output channels, or to drive subwoofers.

2 3

1

5

4

6

7

3.4.1 TFS-RACK panel connectors

1. A 19-pin female C mil connector provides multi-way signal connections to the rack. Mil C 5015 & VG 95234. The

mil-spec insert Number is 22-14

2. A 19-pin male C mil connector links out to additional racks

3. AES/EBU One male and one female connector, looped through

4. Ethernet and Dante connectors, looped through

5. Mains power to the rack is provided by a 32A three phase distro on a C-Form (EMEA) or Twist-Lock (USA)

connector.

6. Speaker outputs for the TFS-900H high packs are on three NL8 connectors, one per amplifier

7. Subwoofer outputs are on six NL4 connectors, two per amplifier.

Flashline User Manual

page 12

Page 13

3.4.2 Cable pin-outs

4+ High positive (+ve)

2 - Sub driver 2 negative (-ve)

The NL8 connectors are wired as follows:

4+

4-

1-

4

- High negative (-ve)

user manual

Flashline

1+

2-

2+

The NL4 connectors are wired as follows:

2+

1+

2-

3+

3-

3+ Mid positive (+ve)

3

- Mid negative (-ve)

2 - Low positive (+ve)

2 - Low negative (-ve)

1

- Bass positive (+ve)

1 - Bass negative (-ve)

2 + Sub driver 2 positive (+ve)

1-

1 - Sub driver 1 negative (-ve)

+ Sub driver 1 positive (+ve)

1

Flashline User Manual

page 13

Page 14

user manual

Flashline

4. Connecting the Loudspeakers

4.1 Wiring convention

CONFIGURED FOR TFS-900H CONFIGURED FOR 4-WAYCONFIGURED FOR TFS-900B/L

4.2 Damping Factor in cable

Turbosound recommends that for large scale PA use the total system damping factor should be 15 or greater. Longer

cables will reduce the overall damping factor of the system. In order to keep the damping factor over 15 it will be

necessary to increase the impedance of the load to keep the damping factor. Therefore for long runs Turbosound

recommends no more than two enclosures per amplifier. Turbosound recommends using 4mm2 cable as standard.

Cable size

2

mm

2.5 38 125 18 59 12 39

4 60 197 30 98 20 66

6 90 295 45 148 30 98

Length for 1 x TFS-900H (8 ohms)

m ft

Length for 2 x TFS-900H (4 ohms)

m ft

Length for 3 x TFS-900H (2.6 ohms)

m ft

4.3 Power Output Performance

Symmetrical Power

The 20000DP can deliver power as shown in the table below when all channels are driven equally.

Load Impedance (ohms) 2.0 2.7 4 8 16

20000DP Max power output (watts) 4800 5000 4440 2300 1150

Asymmetrical Power

Load Impedance (ohms) 2.0 2.7 4 8 16

20000DP Max power output (watts) 5000 5000 4500 2300 1150

Flashline User Manual

page 14

Page 15

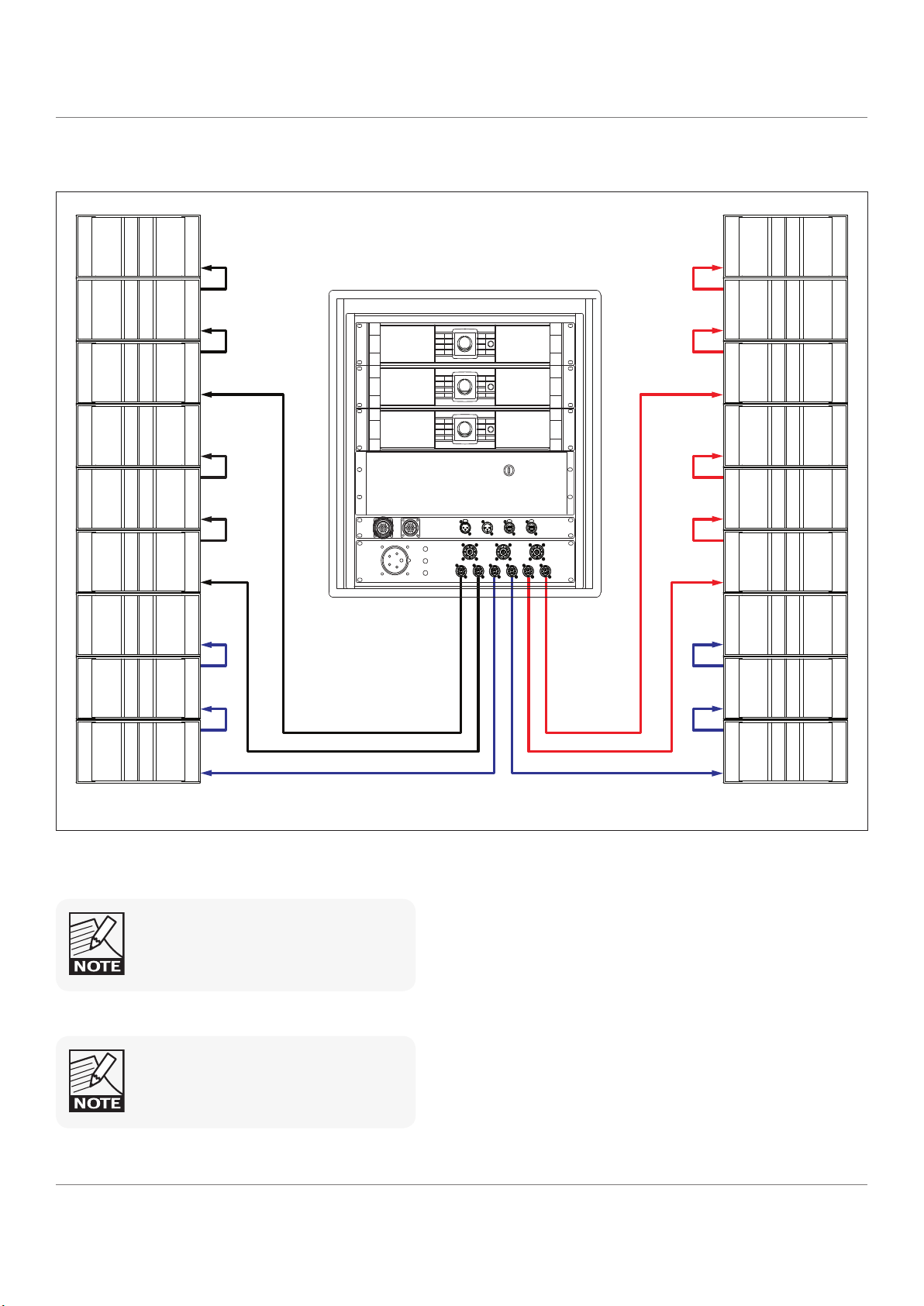

5. System Configurations

5.1 Suggested amplifier loading for the TFS-900H

user manual

Flashline

Each amplifier powers three enclosures. Whilst in theory the amplifier can power four enclosures this presents the

bass and low-mid with a 2 ohm load, which does not offer optimum performance.

BASS loading 2.6 ohms

LOW loading 2.6 ohms

MID loading 4 ohms

HIGH loading 6 ohms

Each amplifier is connected to one of the three

phases on the power supply. For optimum loading on

large systems it is good practice to load all phases

equally.

Flashline User Manual

page 15

Page 16

user manual

Flashline

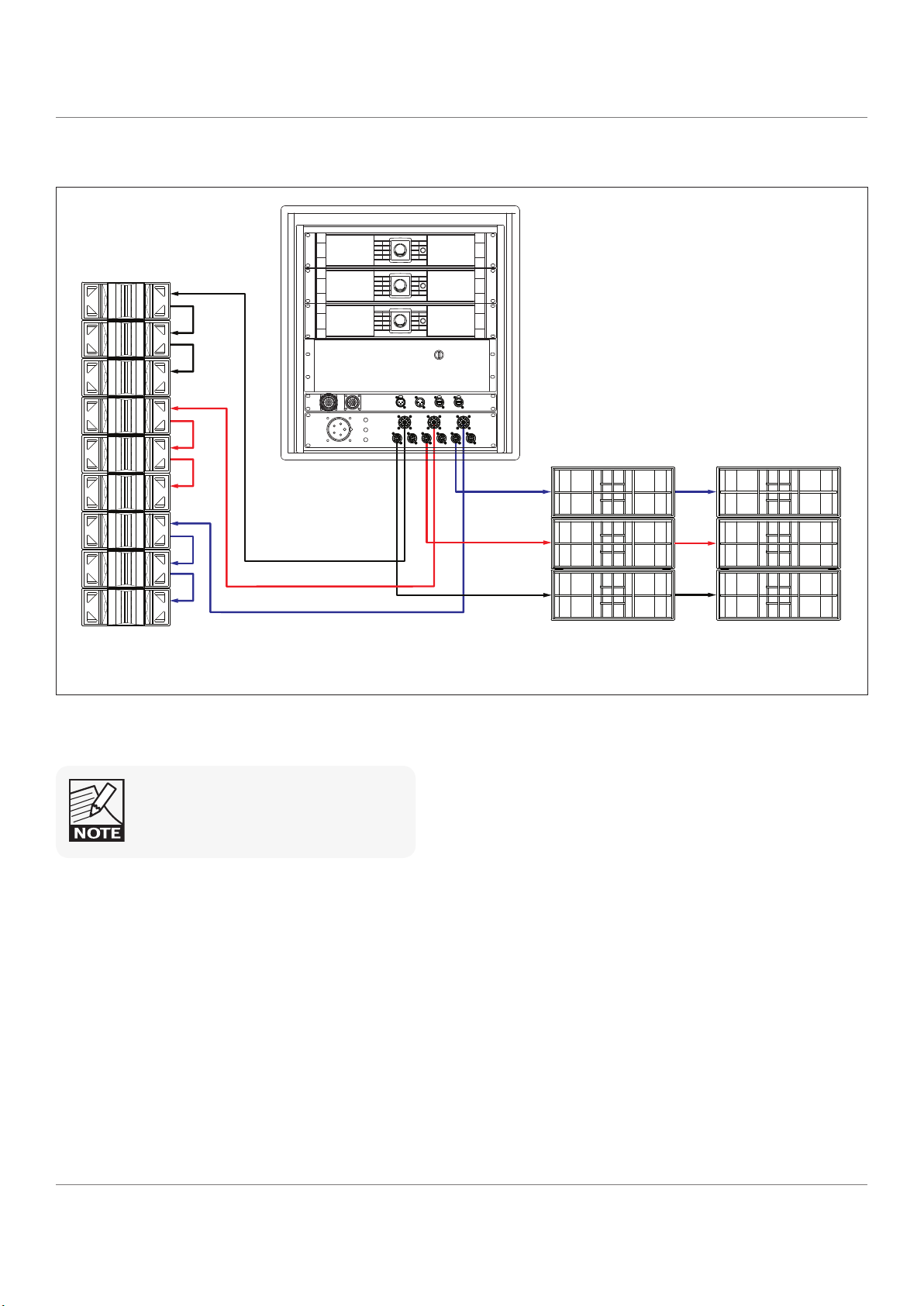

5.2 Suggested amplifier loading for subwoofers

Each amplifier powers up to six TFS-900B or TFS-900L enclosures. Each NL4 connector can power three

subwoofers. Each subwoofer has a drive unit wired to each pair of pins on the NL4 connectors.

Do not use the NL4 and NL8 connections

simultaneously on one amplifier.

In this configuration speaker cable lengths should not be greater than 20m due to damping factor considerations.

Each amplifier is connected to one of the three

phases on the power supply. For optimum loading on

large systems it is good practice to load all phases

equally.

Flashline User Manual

page 16

Page 17

Flashline

5.3 Suggested amplifier loading for subwoofers in cardioid mode

user manual

Each amplifier powers four TFS-900L or TFS-900B enclosures. The first NL4 on each amplifier powers the rear facing

cardioid unit, while the second NL4 powers the three forward facing units.

In this configuration speaker cable lengths should not be greater than 20m due to damping factor considerations.

Do not use the NL4 and NL8 connections

simultaneously on one amplifier.

Do not use the NL4 and NL8 connections

simultaneously on one amplifier.

Flashline User Manual

page 17

Page 18

user manual

Flashline

5.4 Suggested amplifier loading for a 4-way Flex Array system

Each amplifier powers three Flex Array TFA-600H cabinets and two TSW-218 subwoofers. In this instance the NL4 and

NL8 connections can be used simultaneously since the amplifier presets configure the outputs correctly.

Do not use the NL4 and NL8 connections

simultaneously on one amplifier.

Flashline User Manual

page 18

Page 19

Flashline

6. AMPLIFIER RACK ROUTING

6.1 TFS-RACK High output routing

AMP CHANNEL MAX NO OF ENCLOSURES CABINET DUTY NL8 NL8 PIN

20000DP - 1 CH1

20000DP - 1 CH2 TFS-900H 6.5” low 1 2+/2-

20000DP - 1 CH3 TFS-900H 6.5” mid 1 3+/3-

20000DP - 1 CH4 TFS-900H 1” high 1 4+/4-

20000DP - 2 CH1

20000DP - 2 CH2 TFS-900H 6.5” low 2 2+/2-

20000DP - 2 CH3 TFS-900H 6.5” mid 2 3+/3-

20000DP - 2 CH4 TFS-900H 1” high 2 4+/4-

20000DP - 3 CH1

20000DP - 3 CH2 TFS-900H 6.5” low 3 2+/2-

20000DP - 3 CH3 TFS-900H 6.5” mid 3 3+/3-

20000DP - 3 CH4 TFS-900H 1” high 3 4+/4-

3

3

3

TFS-900H 12” bass 1 1+/1-

TFS-900H 12” bass 2 1+/1-

TFS-900H 12” bass 3 1+/1-

user manual

6.2 TFS-RACK Low output routing

AMP CHANNEL MAX NO OF ENCLOSURES CABINET DUTY NL8 NL8 PIN

20000DP - 1 CH1

20000DP - 1 CH2 TFS-900L/B 18” driver 2 1 2+/2-

20000DP - 1 CH3 TFS-900L/B 18” driver 1 2 1+/1-

20000DP - 1 CH4 TFS-900L/B 18” driver 2 2 2+/2-

20000DP - 2 CH1

20000DP - 2 CH2 TFS-900L/B 18” driver 2 3 2+/2-

20000DP - 2 CH3 TFS-900L/B 18” driver 1 4 1+/1-

20000DP - 2 CH4 TFS-900L/B 18” driver 2 4 2+/2-

20000DP - 3 CH1

20000DP - 3 CH2 TFS-900L/B 18” driver 2 5 2+/2-

20000DP - 3 CH3 TFS-900L/B 18” driver 1 6 1+/1-

20000DP - 3 CH4 TFS-900L/B 18” driver 2 6 2+/2-

3

3

3

TFS-900L/B 18” driver 1 1 1+/1-

TFS-900L/B 18” driver 1 3 1+/1-

TFS-900L/B 18” driver 1 5 1+/1-

Flashline User Manual

page 19

Page 20

user manual

Flashline

6.3 TFS-RACK Flex Array routing, TFA-600L/B

AMP CHANNEL MAX NO OF ENCLOSURES CABINET DUTY NL8 NL8 NL4 NL4

20000DP - 1 CH1 3 TFA-600L/B 18” Sub 1 1+/1-

20000DP - 1 CH2

20000DP - 1 CH3 TFA-600H/HW 6.5” Himid 1 3+/3-

20000DP - 1 CH4 TFA-600H/HW 1” High 1 4+/4-

20000DP - 2 CH1 3 TFA-600L/B 18” Sub 3 1+/1-

20000DP - 2 CH2 TFA-600H/HW 10” Lomid 2 2+/2-

20000DP - 2 CH3 3 TFA-600H/HW 6.5” Himid 2 3+/3-

20000DP - 2 CH4 TFA-600H/HW 1” High 2 4+/4-

20000DP - 3 CH1 3 TFA-600L/B 18” Sub 5 1+/1-

20000DP - 3 CH2

20000DP - 3 CH3 TFA-600H/HW 6.5” Himid 3 3+/3-

20000DP - 3 CH4 TFA-600H/HW 1” High 3 4+/4-

3

3

TFA-600H/HW 10” Lomid 1 2+/2-

TFA-600H/HW 10” Lomid 3 2+/2-

6.4 TFS-RACK Flex Array routing TSW-218

AMP CHANNEL MAX NO OF ENCLOSURES CABINET DUTY NL8 NL8 NL4 NL4

20000DP - 1 CH1 1 TSW-218 18” Sub 1 1+/1-

20000DP - 1 CH2

20000DP - 1 CH3 TFA-600H/HW 6.5” Himid 1 3+/3-

20000DP - 1 CH4 TFA-600H/HW 1” High 1 4+/4-

20000DP - 2 CH1 1 TSW-218 18” Sub 3 1+/1-

20000DP - 2 CH2

20000DP - 2 CH3 TFA-600H/HW 6.5” Himid 2 3+/3-

20000DP - 2 CH4 TFA-600H/HW 1” High 2 4+/4-

20000DP - 3 CH1 1 TSW-218 18” Sub 5 1+/1-

20000DP - 3 CH2

20000DP - 3 CH3 TFA-600H/HW 6.5” Himid 3 3+/3-

20000DP - 3 CH4 TFA-600H/HW 1” High 3 4+/4-

3

3

3

TFA-600H/HW 10” Lomid 1 2+/2-

TFA-600H/HW 10” Lomid 2 2+/2-

TFA-600H/HW 10” Lomid 3 2+/2-

Flashline User Manual

page 20

Page 21

user manual

Flashline

7. Rigging the Flashline system

7.1 Overview

The rigging system consists of the following main components:

• TFS-GRID – a rectangular box section flying frame that supports a column of up to 20 cabinets

• TFS-TIP – a central bar which provides front and rear pick up points

• TFS-FT900 – the fly trunk houses two TFS-GRID flybars and associated parts such as shackles and locking bolts. It

is designed so as to allow the flybar to be connected and lifted out of the case with minimal manual handling

• Flex Array cabinets can be flown underneath as downfills using the CF-900 conversion frame

• RECLINE laser pointer allows remote monitoring of the vertical inclination of the array

7.2 TFS-FT900 Fly Trunk

TFS-FT900 Fly trunk lid

TFS-TIP tipper bar

TFS-GRID

TFS-FT900 Fly trunk

TFS-FT900 Fly trunk lid

Flashline User Manual

page 21

Page 22

user manual

Flashline

7.3 Flying an Array

• A single TFS-FT900 fly trunk contains two complete flybar assemblies and associated parts. Position the TFS-

FT900 fly trunk directly under the motors and tip it onto one side.

• Unlatch and remove the TFS-FT900 fly trunk lid to gain access to the TFS-GRID flybar, TFS-TIP tipper bar, and the

shackles and tipper bar retaining bolts stowed inside.

Flashline User Manual

page 22

Page 23

user manual

1 2 3

FRONT

CLUSTER POINTS UP CLUSTER LEVEL CLUSTER POINTS DOWN

FRONT FRONT

Flashline

• Lift the TFS-TIP tipper bar out from its stowed location in the fly trunk and slide it into position through the

central section of the TFS-GRID with the lifting eyes uppermost. The front of the TFS-GRID flybar is indicated by

the small cut-outs in the corners.

• Attach 3.75 tonne shackles to each end of the TFS-TIP tipper bar at the lifting points.

• Use a 1 metre steel lifting rope between the motor and the front pickup point to raise the front motor bag so

that it does not hang in front of the top cabinet.

• If using the RECLINE remote laser inclinometer system attach the sensor unit now to the front of the TFS-GRID.

• Lift the TFS-GRID flybar to above head height.

Flashline User Manual

page 23

Page 24

user manual

LOCK

LOCK

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

Flashline

• Release the TFS-GRID flybar drop links from the lock positions by removing the pins and allowing the drop

links to rotate down to their extended position. Stow the pins in the lock position.

• Wheel the first four TFS-900H boxes in on a TFS-DOLLY and position them under the flybar.

• Lower the TFS-GRID flybar slowly into position above the loudspeaker stack and guide the drop links into the

rigging hardware slots in the top of cabinet #1.

• Fit the top front pins on both sides of the cabinet into the holes marked GRID.

Flashline User Manual

page 24

Page 25

• Fit the top rear pins on both sides of the cabinet into the hole marked LOCK/GRID.

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

LOCK/ GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

LOCK

LOCK/STORE

LOCK/GRID

STORE

0

O

0.5

O

1

O

1.5

O

2

O

2.5

O

3

O

4

O

5

O

GRID

user manual

Flashline

• If the inter-cabinet angles have not already been set during warehouse preparation do this now. Set the angles

between cabinets with the front top pin on each cabinet by lifting the drop link of the cabinet above and inserting

the pin into one of the marked holes, reading the required angle settings from your EASE Focus2 prediction.

Ensure the pin is engaged in one of the four drop link holes and not in the central slot.

Flashline User Manual

page 25

Page 26

user manual

1

2

#1

#2

#3

#4

#1

#2

#3

#4

Flashline

• Check that the rear pins are engaged on both sides of the cabinet. Note: never lift the array without the rear

pins engaged. Regardless of how many people are rigging the array, it is one person’s job to always check that

the angles are set identically and correctly and that pins are fully engaged on both sides of each cabinet.

• The first block of four cabinets is now ready to lift. Check that all links are correctly fitted and secure. Take both

motors up together and lift the cluster clear of the TFS-DOLLY. The fronts of the cabinets will now open up as

the cluster lifts clear of the TFS-DOLLY depending on the angles set between them, creating a gradual smooth

curve to the front of the array.

• Fit the lower front pins on cabinets #1, #2 and #3 into the holes marked LOCK on both sides of the cabinets in

order to lock the array into a rigid structure. Do this now because if left until later it will not be possible to reach

them.

• A spanset and shackle can now be attached to the rear of the TFS-GRID flybar to feed the speaker cabling

through, allowing enough length to allow the cables to reach the lowest cabinet in the final cluster.

• Connect the first NL8 cable run to cabinet #1 and link down to the next two cabinets, making a total of three

cabinets on the first NL8 run. Connect the second NL8 cable run to cabinet #4.

Flashline User Manual

page 26

Page 27

user manual

Flashline

• Raise the cluster to above head height. Lower the rear motor only in order to bring the orientation of the lowest

cabinet back to almost horizontal so that the next block of cabinets will locate more easily.

• Wheel the next block of cabinets in underneath the cluster.

#1

#2

#3

#4

#5

#6

#7

#8

Flashline User Manual

page 27

Page 28

user manual

Flashline

• Release the drop links on cabinet #4 from their stowed positions by removing the bottom front and rear pins and

allowing the drop links to drop down to their extended position. Replace the pins in the front andf rear positions.

• Lower the cluster very slowly, allowing the drop links on cabinet #4 to locate into the channels of the flying

hardware on cabinet #5, eventually sitting flat on top of it.

#3

#4

#5

#6

• Locate the top rear pins on cabinet #5 in the LOCK/GRID position. Set the angles on cabinets #5, #6, #7 and #8

using the top front pins if these have not been done already. Take both motors up together and lift the second

block of cabinets off the TFS-DOLLY. As before the fronts of the cabinets will now open up depending on the

angles set between them.

• Fit the remaining lock pins to stabilise the array.

• Continue this procedure until the required number of cabinets are flown.

• Raise the array to the height specified by your EASE Focus2 prediction using a tape measure or laser system to

check the height of the array

Flashline User Manual

page 28

Page 29

user manual

Flashline

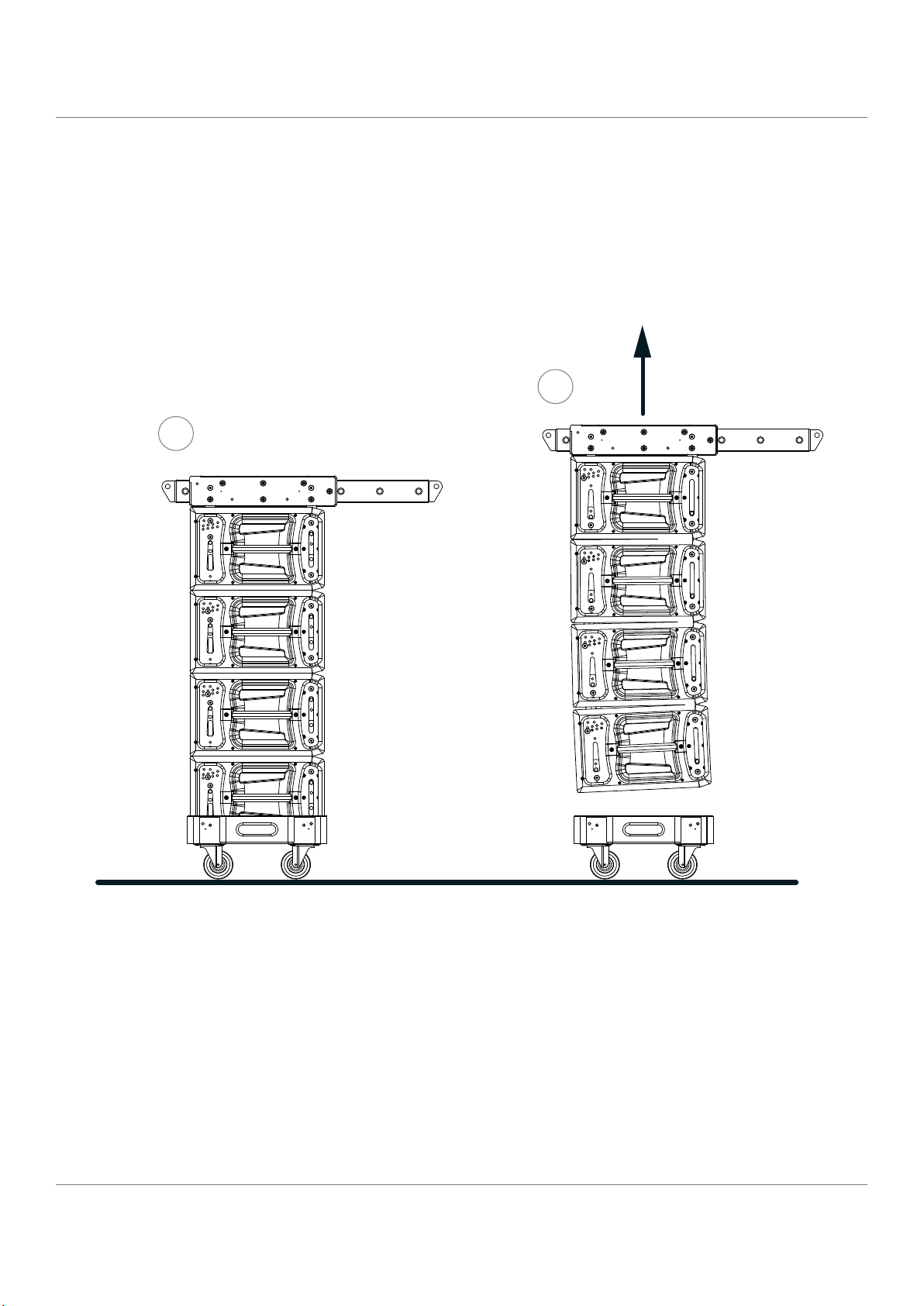

• The TFS-DOLLY wheelboards can be stacked using the woodwork rebates provided Fold the TFS-COVERS and

stack them on top of the wheelboards.

7.4 De-rigging the Array

• Taking the cluster down is a simple reversal of the rigging procedure. Bring the cluster down until the bottom

box is approximately a foot off the ground, and take the lock pins out at the front of the lowest four or more

boxes (depending on the curvature of the array) to allow the cabinets to close up, and place them in the stow

position. Lower the back motor gently to get the bottom box reasonably horizontal.

Make sure you always know the total weight of the

cluster. Never put more weight on a rigging point

than it is rated for, and always calculate how much

weight is on each rigging point.

• Carefully lower the cluster down onto a TFS-DOLLY. Disconnect the top pins from the fourth box.

• Carefully raise the array to free the lower four boxes.

• Ensure the drop link of the bottom box is up and into its locked position. Do not land the cluster on the drop

link or you will bend the rear hinge. Do not leave the front lock pins in for trucking, always put them in the store

position.

• Leave both pins in on the rear assembly because it is designed to allow the cabinets to touch each other in a

truck rather than the rigging hardware.

• Having de-rigged each block of cabinets onto a TFS-DOLLY one by one, put the covers on and stow the NL8

links in the cover.

• Finally lower the TFS-GRID flybar into the TFS-FT900 flytrunk in, disconnect the motors and lift the motors to a

safe position above head height.

• Stow the shackles in the trunk, slide the TFS-TIP tipper bar out, put the bolts back in the trunk and replace the

tipper bar in its stowed location.

Flashline User Manual

page 29

Page 30

user manual

CF-900

Conversion frame

Flex Array

TFA-600H

Flex Array

TFA-600H

Flashline

TFS-900H

Flashline

7.5 Flex Array as Downfills

Fles Array cabinets can be deployed at the bottom of a Flashline array as downfills using the CF-900 conversion

frame.

Flashline User Manual

page 30

Page 31

user manual

Flashline

8. The 20000DP AMPLIFIER

8.1 Main features

The 20000DP incorporates a number of sophisticated technologies to ensure the best possible performance

and many years of reliable operation. The following section summarizes the benefits of each feature; additional

information is available in the reference manuals.

8.1.1 Amplifier Platform

The 20000DP features extraordinary power density, patented Class TD® output stages, Regulated Switch Mode

Power Supply (R.SMPS™), the high-efficiency Intercooler® copper-finned cooling system, and a full suite of

protection features. Signal inputs are analog, AES digital, and Dante digital audio network; loop-through outputs or

redundant pairs are provided for each input type.

Please refer to the 20000DP Operation Manual for further information.

8.1.2 Amplifier DSP (Digital Signal Processing)

Various features are controlled by the on-board DSP, some of which are summarized in this section.

8.1.2.1 Input Gain (Sensitivity)

Input gain (sensitivity) is set in the digital domain, and may be controlled via the Lake Controller software or frontpanel interface.

8.1.2.2 ISVPL™

The Inter-Sample Voltage Peak Limiter (ISVPL) tailors each power output to the characteristics of the connected load.

Please refer to the 20000DP Operation Manual for further information.

8.1.2.3 Load Verification & Performance Monitoring

A comprehensive set of proprietary DSP-based tools are provided for load verification and real-time performance

monitoring. These functions utilize LoadLibrary, a comprehensive database for each loudspeaker component of the

connected load (usually one or more band-limited drivers in a multi-way system).

Using this data and a brief test signal, LoadSmart compares actual response to predicted response, identifying any

malfunctioning components or connection errors. During the performance, SpeakerSafe™ monitors real-time load

status, including temperatures of the amplifier stages as well as magnets and voice coils of connected loudspeakers.

This allows operators to avoid power compression and identify potential problems.

Please refer to the Lake Controller Operation Manual for detailed information on load verification and real-time

performance monitoring functionality.

8.1.3 Lake Processing and Controller

Flashline User Manual

page 31

Page 32

user manual

Flashline

The 20000DP integrates seamlessly into the Lake Processing environment. Two processing modules offer precise

settings for gain, delay, crossover settings, equalization and limiting. Lake processing features incorporated in each

module include Raised Cosine Equalization™, linear phase crossovers, and LimiterMax™ loudspeaker protection.

The Super Module feature allows hardware processing modules in two or more separate devices to function as

a single module in the Lake Controller software. Please refer to the Lake Controller Operation Manual for further

information.

8.1.4 Lake Analyzer Bridge

Lake Controller software provides integration with third-party real-time analyzers, providing simultaneous

measurement display and EQ adjustment via the Lake Controller. The third-party measurement tools that can be

integrated via the Analyzer Bridge include:

• Smaart Live Version 5.4

• Live-Capture Light / Live-Capture Pro

Smaart, distributed and supported by Rational Acoustics, provides real-time sound system measurement,

optimization and control. Smaart combines several powerful audio frequency measurement and analysis tools.

Live-Capture, created by WaveCapture, offers easy-to-use software and measurement tools for sound engineers,

installers, consultants and designers. The Lake Analyzer Bridge in conjunction with Live-Capture Light provides a

completely free spectrum analyzer via your Lake Controller software interface.

8.1.5 Dante™ Audio Network

The 20000DP includes Dante digital audio networking as standard. Utilizing the latest advances in Ethernet

technology, Dante offers simplified system configuration and extremely low latency while delivering very high

quality uncompressed digital audio across the Lake network. The Zen™ automatic configuration feature enables

plug-and-play setup without third-party DHCP or DNS servers. Dante is compatible with high-bandwidth networks,

allowing large numbers of audio channels to be distributed alongside control and analyzer data.

8.2 Additional Documentation

This document, the 20000DP Quick Start & Field Reference Guide, serves as a basic introduction to the installation

and operation of the 20000DP Powered Loudspeaker Management system. More detailed information is available

in the comprehensive 20000DP Operation Manual, which serves as the primary reference source for detailed

information on the installation and operation of the 20000DP Powered Loudspeaker Management system.

If you intend to use the device as part of a networked system, or access features via the Lake Controller, please refer

to the various supporting documents which can be located via these methods:

• Start > Programs > Lake Controller > Documentation (after installing Lake Controller software)

• On the Installer CD-ROM or the downloaded software installer

• Online at: http://labgruppen.com/index.php/products/documentation/

Flashline User Manual

page 32

Page 33

user manual

Flashline

9. Amplifier Installation

9.1 Unpacking

Carefully open the shipping carton and check for any damage to the device or the supplied accessories. Every

Turbosound product is tested and inspected before leaving the factory and should arrive in perfect condition. If any

damage is discovered, please notify the shipping company immediately. Only the consignee may initiate a claim

with the carrier or their insurers for damage incurred during shipping. Save the carton and packing materials for the

carrier’s inspection.

In addition to the 20000DP amplifier, the shipping carton include the following items:

• 20000DP Quick Start & Field Reference Guide

• AC mains lead (power cable) with Neutrik® powerCON® connector

• Rear brackets for additional rack support (pair) along with associated mounting hardware

• Software Installer and Documentation CD-ROM

Please keep the original carton and associated packaging to facilitate shipping of the device should the need arise.

9.2 Mounting

Airflow for cooling the 20000DP is from front panel (intake) to rear panel (exit). Please ensure that no object, such as

rack doors or lids are placed at the front or rear of the rack to ensure that airflow is maximized. This device has no

top or bottom vents and therefore may be stacked directly on top of each other. Sufficient space should be available

at the front of the rack to accommodate the handles, and at the rear to accommodate connectors and cables;

allowance must be made for cable or loom bends within a rack.

9.3 Rear Mounting

Two rear support brackets along with associated mounting hardware are included with the 20000DP, as shown in

Figure 1; it is recommended that these are used wherever possible. Fit the brackets to the vertical rails at the rear of

the rack. Figure 2 and Figure 3 show the fitting options for fixed and removable installation. The support brackets

are reversible and may be fitted to point either to the front or rear of the rack; the orientation used depends on the

rack depth and position of the rear rack rails. Two mounting methods are possible; note that the method shown in

Figure 2 additionally provides extra security against unauthorized removal. For situations where rapid removal and

replacement is required, the method shown in Figure 3 should be used.

Flashline User Manual

page 33

Page 34

user manual

Flashline

Figure 1: Rear Support Bracket and Mounting Hardware

Figure 2: Use washer for permanent installation

Figure 3: Use tube for slide-on installation

Flashline User Manual

page 34

Page 35

user manual

Flashline

9.4 Cooling

9.4.1 Overview

The 20000DP uses a forced-air cooling system with airflow from front to rear, allowing high continuous power levels

without thermal problems. Front-to-rear airflow is preferable as air at the front of a rack is cooler than that at the

rear in nearly all situations; never attempt to reverse the airflow. The operation of the cooling system is dependent

on front-to-rear airflow; it will not function effectively with external airflow in the opposite direction.

Make sure an adequate air supply is provided in front of the 20000DP, and that the rear of the amplifier has sufficient

space to allow air to escape. If the amplifier is rack-mounted, never operate the unit with any front or rear rack doors

or covers in position. It is recommended to keep the ambient temperature around the amplifier as cool as possible.

An increased temperature can have a significant negative impact on the expected lifetime on the components inside

the amplifier.

Fit solid blanks (not ventilation blanks) to unused rack

spaces to ensure effective air circulation. Leaving

gaps in between items of equipment degrades the

effectiveness of forced-air cooling.

If installing one or more 20000DP amplifier in a rack with other fan-cooled equipment, be sure that all the other

equipment also uses front-to-rear airflow for cooling. If this precaution is not observed, there is a risk of overheating,

as units with the reverse airflow will be drawing in air which has already been heated by the amplifiers.

9.4.2 Temperature Sensing and Protection

The 20000DP is equipped with a sophisticated temperature sensing system which protects it from any overheating

which may occur as a result of inadequate ventilation.

9.5 Operating Voltage

The 20000DP is equipped with a universal power supply operating from 80 to 265 V. Only connect the mains cable

(AC cord) to an AC source of the voltage shown on the label. The 20000DP uses primary switching, which means the

mains power is rectified on the primary side of the transformer. This makes the power supply insensitive to mains

frequency variation, and it will operate normally on line frequencies from 45 to 75 Hz. If the mains plug (AC plug)

fitted to the mains cable (AC cord) is not appropriate for your country, it can be removed and a locally-sourced one

fitted instead, observing the color coding in the table below:

PowerCON Pin 230V version 115V version

L Brown Black

N Blue White

E Green/Yellow Green

If you are not 100% confident of your competence to replace the mains plug (AC plug), the task should be carried

out by qualified personnel.

Once a suitable AC power supply is connected, the device can be turned on using the front panel power button.

When turned on, a diagnostic routine is performed and the power button LED changes from red (Standby) to green

(Active).

Flashline User Manual

page 35

Page 36

user manual

Flashline

In-rush current is controlled and limited during the

soft-start sequence. This enables multiple amplifiers

on the same AC mains circuit to be turned on

simultaneously.

9.6 Grounding

Analog inputs feature Iso-Float™ ground isolation, a technology which combines the benefits of transformercoupled isolation with the advantages of clean, direct-coupled inputs. The audio converters are galvanically isolated,

and not connected to the main ground. High-speed transformers and opto-isolators create a barrier between the

device and the outside electrical environment.

The Iso-Float feature is activated by default, but may

be disabled via the Lake Controller software, or via

the front panel menu.

Use correctly-shielded balanced audio input connections to minimise hum and interference. NEVER disconnect the

earth (ground) pin on the mains cable (AC power cord).

10. Product Overview

10.1 Front Panel Overview

The front panel controls are clustered around a daylight readable LCD, allowing adjustment and monitoring of

the majority parameters and meters. The two clusters of controls on either side of the LCD include five dedicated

function buttons, eight dynamic function buttons with embedded LEDs and a rotary data encoder .

Figure 4: Front Panel Overview

10.1.1 Handles

Flashline User Manual

page 36

Page 37

user manual

Flashline

Two sturdy metal handles are fitted to the front panel. The handles should be used when carrying the device, and

when fitting it in or removing it from a rack. Ensure that any door or removable rack front cover has sufficient depth

to clear the handles.

10.1.2 Dust Filters

Two dust filters are fitted behind metal covers. To remove the covers, loosen the thumbscrews located behind the

handles. Once detached, the dust filter elements can be removed for cleaning.

NEVER operate this device without the dust filters in

place.

10.1.3 Display

The display illuminates when the device is on. The LCD, function buttons, and the rotary encoder provide realtime control and monitoring of most parameters. The LEDs embedded in the function buttons indicate available

menu options, provide confirmation of Controller communication, and indicate various faults and warnings. The

brightness and contrast of the display and front panel LEDs can be adjusted via the front panel menu.

10.1.4 Standby

The 20000DP is powered on and to standby using the top-left button, or via the Lake Controller.

10.1.5 Mute Enable

Select MUTE ENABLE to allow the dynamic function buttons to operate as mute controls for the Module inputs and

power output channels. The MUTE ENABLE button flashes when the mode is selected; a subsequent press deselects

this mode. If left activated, MUTE ENABLE mode will automatically disable two minutes after the last mute action.

10.1.6 Meter

The METER button scrolls through four alternative meter views: Home View, Module View, Temperature View and

Input View. Pressing METER from Menu Mode returns the screen to Meter Mode with Home View displayed.

10.1.7 Menu

After pressing the MENU button, the LCD will display the top level menu. In Menu Mode the function buttons enable

access to various information and functions.

10.1.8 Dynamic Function Buttons with LEDs (Left of LCD)

The function of these buttons change according to the currently selected view or menu.

• In Menu Mode they are set for menu navigation and for parameter selection

• In Meter Mode they provide Module input mute/unmute functionality in conjunction with MUTE ENABLE

The LED in the top button provides Frame fault and warning indications. The middle two buttons provide Module

input mute functionality, mute indication and faults and warning indications relating to the 20000DP inputs. The

bottom button is used only in Menu Mode or to lock the front panel buttons.

Flashline User Manual

page 37

Page 38

user manual

Flashline

Please refer to the Operation Manual for further details.

10.1.9 Dynamic Function Buttons with LEDs (Right of LCD)

The function of these buttons change according to the currently selected view or menu.

• In Menu Mode they are used for menu navigation and for parameter selection

• In Meter Mode they provide output mute/unmute functionality in conjunction with MUTE ENABLE

All LEDs provides mute, clip, fault and warning indications for the power outputs channels.

10.1.10 Communication LED

The high-intensity white LED illuminates white to indicate that the Module/Frame is selected in the Lake Controller;

it flashes white to indicate communication with the Lake Controller. The brightness of the LCD and communications

LED can be adjusted in the Frame page of the Main Menu on the front panel.

10.1.11 Rotary Encoder

The rotary encoder is used to modify various parameters (e.g. input level) via the menu. When a menu item is

selected that permits adjustment of parameter values, the ring around the rotary encoder illuminates. In Home View

the encoder can be used to scroll through the Meter Views.

10.1.12 Exit

The EXIT button is used primarily while navigating the menu system in Menu Mode; pressing EXIT will return the

menu up one level. In Meter Mode, pressing EXIT returns the metering display to the default Home View.

10.2 Back Panel Overview

5 1 324 6 7 8

LINK SEC PRIM ACT LINK ACT

SWITCHED 10/100 Base-TX

100/240V 2400/2950W

50-60Hz

Must be grounded/earthed

Made in Sweden

CLASS 2 WIRING

1+/- CH 1+/2+/- CH 2+/-

Ser. N:o

SPEAKER OUTPUTS

1+/- CH 1+/2+/- CH 2+/-

Removed!

3+/- CH 3+/4+/- CH 4+/-

1+/- CH 3+/2+/- CH 4+/-

INPUT 1 INPUT 2 LINK

ANALOG WITH ISO-FLOAT

1 LINK 2

PIN 1: SCRN 2: POS 3: NEG

TM

INPUT 1-2 LINK 1-2

AES/EBU

Figure 5: Back Panel Overview

Flashline User Manual

page 38

Page 39

user manual

Flashline

10.2.1 Connectors

10.2.1.1 Analog Inputs

Analog inputs are available on two standard XLR3F latching connectors. The inputs are electronically balanced and

feature Lake Iso-Float circuitry. The impedance is 20 kohms, and the inputs can accept a maximum input level of +26

dBu.

10.2.1.2 Analog Links

Two latching XLR3M connectors are fitted adjacent to the analog input connectors. These are paralleled to the input

connectors to provide an unprocessed analog loop-through to feed additional amplifiers, or other equipment.

10.2.1.3 AES3 Input

A latching XLR3F connector is provided which accepts an AES3 digital audio signal. Input impedance is 110 ohms,

please ensure that 110 ohm digital audio cables are used; standard XLR microphone cables are rarely suitable for

reliable digital audio transmission.

AES3 is a stereo digital format, and therefore both

PLM inputs are fed via a single connector. Selection of

the analog or digital inputs is made via the front panel

display or control software.

10.2.1.4 AES3 Link

A latching XLR3M connector is fitted adjacent to the AES3 input connector. This is paralleled to the input connector

to provide an unprocessed AES3 loop-thru to feed further amplifiers, or other equipment. An AES3 110 ohm

termination load is enabled by default when the amplifier is the last unit connected within an AES3 daisy-chained

system. The termination may be disabled, if desired, via the front panel menu and within the Lake Controller

software.

10.2.1.5 SpeakON Connectors

The 20000DP is provided with Neutrik speakON® power output connectors, and allows for Bridge Mode operation

which is activated from the Lake Controller software. Please refer to the Lake Controller Operation Manual and the

20000DP Operation Manual for further information on Bridge Mode.

The power outputs are simultaneously available on a single 8-pole speakON connector, and on two 4-pole speakON

connectors. The two 4-pole connectors carry the outputs of channels 1 & 2 and 3 & 4 respectively.

Bridge Mode can be enabled via the Lake Controller software, please refer to the Lake Controller Operation Manual

and to section 8.1.2 of this Operation Manual for further details on standard and Bridge Mode wiring for speakON

connectors.

10.2.1.6 Primary Network Connector

The primary Neutrik RJ45 etherCON® con nection provides integration into an Ethernet control network which

may include other Lake Processors and the Lake Controller software. Network connection permits full control of all

functions along with real-time metering from a remote position. This device supports the Dante audio networking

protocol, which allows transmission of multichannel, high-definition digital audio over the same Ethernet

connection.

Flashline User Manual

page 39

Page 40

user manual

Flashline

Use the primary connector when using a star network topology, consisting of individual Cat-5e connections between

the devices and an Ethernet switch. Alternatively this connection can be used to daisy chain directly to another Lake

Processor. The daisy chain topology should not be used with Dante.

For a technical reference of the Ethernet Port, please refer to the 20000DP Operation Manual. Additional information

is available in the Lake Network Configuration Guide.

The Ethernet ports operate at the Ethernet data rate of

100 Mbps, and allow straight or crossed network

cables. Two LEDs above each port indicate valid

network connection (LINK) and network activity (ACT).

10.2.1.7 Secondary Connector

The secondary network connector can be used to daisy-chain multiple 20000DPs, LM 26 and legacy Lake devices.

Alternatively, a Dante dual-network topology can be created by connecting all secondary network connectors to a

separate Ethernet switch, ensuring full redundancy in the event of a network component failure.

Additional processor configuration is required for a

dual redundant network setup. See the Lake

Controller Operation Manual for further details.

For a technical reference of the Ethernet Port, please refer to the 20000DP Operation Manual. Additional information

is available in the Lake Network Configuration Guide.

When connecting multiple devices to an Ethernet

network, care must be taken NOT to create a closed

loop which causes network malfunction.

10.2.1.8 Mains Power Connector

The mains power AC input is via a Neutrik powerCON connector, rated at 32 A. The power supply must be

connected to AC mains using a power cable with a correctly wired plug for the country of operation.

Flashline User Manual

page 40

Page 41

user manual

Module Output:

Gain/Delay

Phase Rev

Mute

Module Output:

Gain/Delay

Phase Rev

Mute

Module Output:

Gain/Delay

Phase Rev

Mute

Module Output:

Gain/Delay

Phase Rev

Mute

Module Output:

Gain/Delay

Phase Rev

Mute

Module Output:

Gain/Delay

Phase Rev

Mute

Flashline

11. Signal Flow and Lake Processing

11.1 Signal Flow

Figure 5-1 and Figure 5-2 depict the audio signal flow inside a 20000DP. It is worth noting that this sophisticated

device provides seven points in the signal chain where the signal level can be adjusted, muted or disconnected.

Important information regarding correct setting of the gain structure can be found in the 20000DP Operation

Manual.

Output EQ

Analog 1/2

AES 1

AES 2

Dante X

Dante Y

Analog 1/2

AES 1

AES 2

Dante X

Input

Router

1

(Mute)

Input

Router

2

(Mute)

Input

Mixer A

Input

Mixer B

Module:

Gain

Phase Rev

Mute

Module:

Gain

Phase Rev

Mute

EQ Delay

EQ Delay

Dante Y

Figure 6: Signal Flow Diagram

11.2 Level Adjustments & Mute Points

Input Router Stage – Input selection and MUTE

Input Mixer Stage – Router ON/OFF connection to mixer and gain settings

Module Input Stage – Mute and gain settings

Output EQ

Output EQ

Crossovers

Output EQ

Output EQ

Output EQ

Module Output Stages – Mute and gain settings

Output Router Stage – Output ON/OFF routoing connections

Attenuation Stage – Power output channel mute and attenuation settings

Amp Gain Stage – Amplifier gain control

Flashline User Manual

page 41

Page 42

user manual

Output Routing

AMP

Attenuator

Mute

Phase Rev

Attenuator

Mute

Phase Rev

Attenuator

Mute

Phase Rev

LoadSmart

SpeakerSafe

LoadSmart

SpeakerSafe

LoadSmart

SpeakerSafe

LoadSmart

SpeakerSafe

Amp Gain

Amp Gain

Amp Gain

Amp Gain

Attenuator

Mute

Phase Rev

AMP

AMP

AMP

ISVPL

ISVPL

ISVPL

ISVPL

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

LimiterMax

RMS / Peak

Module Output:

Gain/Delay

Phase Rev

Mute

Flashline

If the required audio signal is not passing

correctly, verify the connection, mute and

volume settings at all seven stages.

11.3 Power Output Section: Limiting and Sensitivity

The Current Peak Limiter (CPL) dynamically limits the drive to the power stage based on three parameters: sensed

output current level, feedback from the output stage, and sensed voltage clip from the ISVPL. This ensures that

power output is maintained within the design limits of the amplifier.

The adjustable Inter-Sample Voltage Peak Limiter (ISVPL) sets the 20000DP’s maximum output voltage and therefore

also the maximum output power. The ISVPL setting is made via MENU > MODULE > LIMITERS > ISVPL, and can also

be set from the Lake Controller software.

The sophisticated output section monitors faults and generates warnings when appropriate; warnings are displayed

on the front panel of the 20000DP and also sent as messages over the control network. In the rare event that

maximum ratings are significantly exceeded, the amplifier will shut down until the condition has been rectified

or the incorrect setting has been readjusted. Sensing circuits also transmit local output power stage temperature,

processor card temperature, and PSU temperature to the appropriate protection circuits. The table below lists

analog input sensitivity in dBu and Vrms for various Amp Gain settings and maximum/minimum ISVPL settings,

assuming an analog input headroom of 26 dBu.

Flashline User Manual

page 42

Figure 7: Signal Flow Diagram (part 2)

Page 43

user manual

Flashline

INPUT SENSITIVITY

ISVPL SETTING 194V 193V 153V 17.8V

GAIN (dB) dBu Vrms dBu Vrms dBu Vrms dBu Vrms

+44 +1.0 0.87 +0.9 0.86 -1.1 0.68 -19.8 0.08

+41 +4.0 1.22 +3.9 1.22 +1.9 0.96 -16.8 0.11

+38 +7.0 1.73 +6.9 1.72 +4.9 1.36 -13.8 0.16

+35 +10.0 2.44 +9.9 2.43 +7.9 1.92 -10.8 0.22

+32 +13.0 3.45 +12.9 3.43 +10.9 2.71 -7.8 0.32

+29 +16.0 4.87 +15.9 4.84 +13.9 3.84 -4.8 0.45

+26 +19.0 6.88 +18.9 6.84 +16.9 5.42 -1.8 0.63

+22 +23.0 10.90 +22.9 10.84 +20.9 8.59 +2.2 1.00

11.4 Lake Processing and Control

As outlined in section 2.2.3, this device integrates seamlessly into the Lake Processing environment, providing all

features, functionality and connectivity associated with all Lake Processors. The internal Lake Processing includes

programmable crossovers, EQ, dynamics and other functions, and can be fully controlled via the supplied Lake

Controller software. Additionally, many functions can be controlled or accessed directly via the front panel.

The Lake Controller Operation Manual and Lake Network Configuration Guide are supplied on the accompanying

CD-ROM and additional documentation is available from the Start Menu after software installation.

11.5 Modules and Frames

11.5.1 Overview

A Frame represents one physical Lake Processor (e.g. a 20000DP). A maximum of two Modules are contained within

each Frame; these are referred to as Module A and Module B. The number of Modules shown in a given Frame is

dependent upon the signal processing configuration of that Frame.

Each Module can be configured as a Classic Crossover (Bessel, Butterworth, Linkwitz-Riley), as a Linear Phase

Crossover, or as multiple full bandwidth Auxiliary Outputs. The default configuration is 2 x 2-Auxiliary Output

Modules, providing a total of four module outputs.

11.6 LoadLibrary™ and Fingerprints

In addition to the standard loudspeaker presets (Module files), the Lake Controller also includes a set of enhanced

Module files specifically for use with the 20000DP.

These supplementary Module files, known as the LoadLibrary, incorporate both Lake DSP parameters along with

20000DP specific data; LoadLibrary Module files include parameter settings for the 20000DP’s Amplifier Gain

and ISVPL limiter. Additionally, LoadLibrary loudspeaker types may also include data relating to the electrical

characteristics of a particular loudspeaker.

Flashline User Manual

page 43

Page 44

user manual

Flashline

Electrical characteristic data is used to enable load verification (LoadSmart) and monitoring facilities (SpeakerSafe)

to be performed on the 20000DP. This data set is termed a Fingerprint. When a 20000DP-specific loudspeaker type is