Page 1

TFS-780 Flashlight System

User Manual

Turbosound Ltd.

Star Road, Partridge Green

West Sussex RH13 8RY England

Tel: +44 (0)1403 711447 Fax: +44 (0)1403 710155

web: www.turbosound.com

Issue 1.4 © Turbosound Limited, October 2000

Page 2

user manual

TFS-780

TFS-780 user manual

Page 2

CONTENTS

Contents............................................................................................................................... 2

Introduction ......................................................................................................................... 4

Turbosound Flashlight & Floodlight System Concepts .................................................... 4

The Loudspeaker Management System (LMS) Concept ..................................................4

TFS-780................................................................................................................................ 4

TFS-780L ..............................................................................................................................5

TFS-780H.............................................................................................................................. 5

TFL-760H .............................................................................................................................. 6

TFL-760HM and TFL-760LM downfills................................................................................ 7

TFS-780HF long throw ........................................................................................................ 7

LMS-D6 ................................................................................................................................ 7

Flashlight Flying System..................................................................................................... 7

Flying and Stacking.............................................................................................................8

Overview.............................................................................................................................. 8

Setting Horizontal Angles................................................................................................. 12

Tilting................................................................................................................................. 12

Setting Vertical Angles ..................................................................................................... 15

Arraying............................................................................................................................. 16

Procedure for flying a Flashlight array ............................................................................ 17

Bass Enclosure arraying ................................................................................................... 23

Aiming - directivity of the stack ....................................................................................... 23

Ground Stacking................................................................................................................ 25

Vertical Dispersion Considerations.................................................................................. 25

Flown Systems.................................................................................................................. 26

LMS-D6 Loudspeaker Management System................................................................... 27

Introduction ....................................................................................................................... 27

General features & facilities ............................................................................................. 27

Unpacking.......................................................................................................................... 27

Mechanical Installation..................................................................................................... 27

Front Panel functions........................................................................................................ 28

Rear Panel functions ......................................................................................................... 29

Mains Power...................................................................................................................... 29

Voltage Setting.................................................................................................................. 30

Safety Earthing.................................................................................................................. 30

AC Power Fusing............................................................................................................... 30

Powering Up...................................................................................................................... 30

Audio Connections............................................................................................................ 31

Input and Output Connector Wiring................................................................................. 31

Time correction for loudspeaker driver placement......................................................... 31

AMP-780 - Flashlight System Amplification Rack ........................................................... 32

Racking, Cables and Connections .................................................................................... 32

Options ..............................................................................................................................33

Input Connections ............................................................................................................. 33

Output Connections ..........................................................................................................34

Remote Control Connections ........................................................................................... 34

Extension Cables............................................................................................................... 35

Mains Connections............................................................................................................ 36

TMC-750 and TMC-1250 High Efficiency Audio Power Amplifier .................................. 37

General Features & Facilities............................................................................................ 37

Page 3

user manual

TFS-780

TFS-780 user manual

Page 3

Front Panel Functions TMC-750 ....................................................................................... 38

Front Panel Functions TMC-1250 ..................................................................................... 39

Rear Panel Functions ........................................................................................................ 40

Mechanical Installation..................................................................................................... 41

Mains Power...................................................................................................................... 41

Powering Up...................................................................................................................... 41

Safety Earthing.................................................................................................................. 42

Internal Fuses.................................................................................................................... 42

Voltage Setting.................................................................................................................. 42

Voltage Range ...................................................................................................................42

Current Consumption ....................................................................................................... 42

Audio Connections & Controls......................................................................................... 43

Polarity............................................................................................................................... 43

Input Impedance................................................................................................................ 43

Muting................................................................................................................................ 44

Sensitivity.......................................................................................................................... 44

Attenuation & Gain Setting .............................................................................................. 44

Signal Metering.................................................................................................................44

Output Connections .......................................................................................................... 45

Damping Factor................................................................................................................. 45

Which speaker impedance?.............................................................................................. 45

Long Speaker Lines........................................................................................................... 45

The Cooling System.......................................................................................................... 46

Filter Inspection & Maintenance ......................................................................................46

Temperature Metering & Protection................................................................................ 46

Fan Speed Setting............................................................................................................. 47

Fault Modes....................................................................................................................... 47

Troubleshooting................................................................................................................ 48

Maintenance...................................................................................................................... 50

Gaining Access..................................................................................................................50

To withdraw one of the amplifier modules..................................................................... 50

Cleaning............................................................................................................................. 50

Routine Checks..................................................................................................................50

Cleaning heatsinks ............................................................................................................ 50

Spare Parts & Accessories................................................................................................ 51

Specifications.................................................................................................................... 51

Warranty............................................................................................................................ 52

Page 4

user manual

TFS-780

TFS-780 user manual

Page 4

INTRODUCTION

Turbosound Flashlight & Floodlight System Concepts

The TFS-780 has been designed as a complete system, with integrated loudspeakers, flying

hardware, amplifier racks, cabling and digital control system. It is designed for use in all

indoor and outdoor venues, from a small club audience up to the largest arena or stadium.

The Flashlight system concept benefits from the availability of a variety of purpose-designed

loudspeaker box types, forming a flexible kit of parts that are used to build up loudspeaker

arrays to cover specific audience spaces with precisely controlled high-fidelity sound

coverage.

The Turbosound TFL (Floodlight) loudspeaker system can be used on its own as a side or

front fill, as well as being part of the Turbosound Flashlight System. The Turbosound TFL760HM high-mid downfill and the TFL-760LM low-mid downfill enclosures contain the same

components as the TFL-760H, and are used to further enhance a Flashlight array, providing

near-field coverage for the nearest audience rows.

The TFS-780HF long-throw high-mid contains the same components as the TFL-760HM, and

is used for high end far-field coverage of the furthest audience areas.

The Loudspeaker Management System (LMS) Concept

The LMS-D6 Loudspeaker Management System is more than just an electronic crossover. It

provides full digital time alignment of all components in the Flashlight/Floodlight enclosures,

to ensure a coherent acoustic output. It also incorporates a number of features which

contribute to overall system reliability and ease of setting-up.

Because the power amplifiers are included as part of the Flashlight system, the LMS-D6 is

able to utilise output limiters which are precisely matched to the system requirements, being

pre-set to prevent the amplifiers from clipping. Inputs and outputs are fully balanced,

providing isolation between the LMS-D6 and the amplifier inputs. These factors contribute to

high reliability in the adverse circumstances often encountered under arduous touring

conditions.

Flashlight TFS-780

The Turbosound Flashlight system is a complete, fully integrated sound reinforcement

system comprising loudspeakers and all necessary drive and control equipment in an

extremely compact and manageable form.

By supplying the Flashlight only as an integrated package, Turbosound has ensured absolute

compatibility between users. All Flashlight systems are identical throughout the world, and

Page 5

user manual

TFS-780

TFS-780 user manual

Page 5

equipment from different sources may therefore be freely combined without difficulty. This

provides Flashlight system owners with a considerable competitive advantage in servicing

the requirements of international touring productions, and in co-operating with other

Flashlight suppliers within the worldwide network.

The system is supplied as multiples of a unit package comprising 12 enclosures (6 bass and 6

mid-high), a single rack of four dual-channel power amplifiers, two loudspeaker management

system controllers, flying hardware, and all the requisite cables and connectors. Two of

these packages (or 24 bass and 24 mid-highs) will provide a formidable system for distant

audience coverage in large arenas, and can be integrated with Turbosound Floodlight

enclosures for short and medium range coverage. This set of components also forms a

standard building block for the construction of spherical arrays.

The controller functions as an electronic loudspeaker management system, comprising a

24dB per octave crossover, with factory preset limiters matched to the power amplifiers,

digital time-alignment and electronically balanced inputs and outputs. The power amplifiers

are supplied as a set of four in a 19" rack with all necessary wiring and multi-pin connectors.

The loudspeakers are of six types, of compatible dimensions but with differing frequency

ranges, projection capabilities and dispersion patterns:

TFS-780L low frequency enclosure

The TFS-780L low frequency enclosure covers the sub-bass and bass ranges up to 150 Hz. It

contains a single 21" drive unit with a 6" voice coil, loaded with a TurboBass device. The

TFS-780L combines relatively compact dimensions and low weight with the ability to provide

beneficial low frequency coupling when used in multiples. The enclosure may be groundstacked or flown.

TFS-780H mid-high enclosure

The TFS-780H enclosure covers frequencies above 150 Hz and contains three drive units. A

large TurboMid device containing a very powerful 12" driver covers frequencies from 150Hz

to 1.3kHz. A smaller TurboMid device containing a specially developed 6½" cone driver

covers the range from 1.3kHz to 8kHz. The remaining frequencies above 8kHz are covered by

a 1” compression driver on a waveguide horn specifically designed for this purpose. All three

drive systems are designed to have a narrow dispersion angle of 25º horizontal x 25º vertical.

This high Q provides the projection necessary for true

long throw

applications such as large

arena and outdoor productions.

The TurboBass and TurboMid devices are unique to Turbosound and are covered by

principle patents world-wide. They utilise specialised forms of horn loading which provide

Page 6

user manual

TFS-780

TFS-780 user manual

Page 6

exceptionally low distortion and high efficiency from cone-type drive units. The subjective

effect of these devices is greater clarity and transparency of reproduction when compared

with conventional compression drivers and horns. All the cone drive units have been

designed specifically for the Flashlight system and are manufactured exclusively for

Turbosound.

The TFS-780H is fully equipped for all touring applications with a hinged rear access door,

integral multi-way speaker cable, keyhole flyplates, removable wheel board, ergonomically

placed flush handles, weatherised birch plywood construction and optimised truck-pack

dimensions. The TFS-780H enclosure is exactly the same size as, and of very similar weight

to, the TFS-780L.

TFL-760H mid-high

The TFL-760H is a three-way medium dispersion mid-high enclosure that gives outstanding

transient ability over a 50° horizontal coverage angle.

The use of specialised cone-type transducers, in combination with unique Axehead™

technology, results in high efficiency, accuracy, very low levels of distortion, even dispersion

and exceptional intelligibility, enabling it to be considered for a multitude of near and mid

field applications.

The TFL-760H is fully equipped for touring with a hinged rear access door, integral multi-way

speaker cable, heavy duty wheels, ergonomically placed flush handles, weatherised birch

plywood construction and optimised truck-pack dimensions. The TFL-760H shares the same

height and width as the Flashlight TFS-780H, and the positions of the keyhole fly plates allow

use of the highly advanced and well proven Flashlight flying systems. All of these features

combine to give a system unsurpassed in simplicity, ease and speed of handling and long

term durability.

The TFL-760H covers the frequency range from 180Hz upwards. The loudspeaker

complement consists of a very powerful low-mid 12" cone loudspeaker which, combined

with the Axehead wave guide, handles frequencies between 180Hz and 1.3kHz. The highmid band between 1.3kHz and 8kHz is covered by a similar combination based on a

specialised 6.5" loudspeaker. The remaining high frequency band, 8kHz to in excess of 20kHz,

is handled by a 1" HF compression driver. Perfect time alignment is achieved by the careful

positioning of these three components and their waveguides within the enclosure. The TFL760H is used to augment Flashlight systems where certain sections of a venue dictate wider

coverage and shorter throw.

The TFL-760H also makes an excellent flown or ground stacked stage side fill system due to

its tight vertical coverage.

Page 7

user manual

TFS-780

TFS-780 user manual

Page 7

TFL-760HM and TFL-760LM downfills

The downfill versions of Floodlight are used to provide near-field coverage as part of

Flashlight or Floodlight touring systems. The TFL-760HM is a trapezoidal high-mid section

incorporating the 6.5” and 1” components, whereas the TFL-760LM contains only the 12”

unit. Both downfill cabinets are exactly the same size and are fitted with Flashlight ‘keyhole’

flying points allowing these units to be flown as the bottom row of a PA cluster. A TFL760HM combined with a TFL-760LM contains exactly the same loudspeaker components as

the TFL-760H enclosure and is therefore electrically and acoustically equivalent. These two

units are also extremely useful as front fills or ground fills, either singly or combined

together.

TFS-780HF long throw mid-high

The TFS-780HF is a dedicated long-throw high frequency unit that is used to selectively boost

the high end at a distance without the need for an extra row of Flashlight boxes. It will

normally be flown as the top row of a Flashlight array. It is supplied in pairs with a

removable wheel dolly, matching the dimensions of a TFS-780H Flashlight enclosure. The

TFS-780HF is equipped with keyhole flyplates and hinged rear access door.

LMS-D6 Loudspeaker Management System

Use of the LMS-D6 loudspeaker management system ensures accurate time-alignment of the

system drive units and also provides a facility for users to select additional delay, either to

compensate for physical displacement of ground-stacked bass enclosures relative to flown

high packs, or to provide full range delay for correct image localisation or use in

distributed

systems. It should however be noted that the high-Q, and therefore long throw, properties of

the Flashlight generally eliminate the need for distributed delayed systems, even for very

large audiences.

Flashlight Flying System

To take full advantage of the precise dispersion properties of the Flashlight, a

complementary flying and lifting system has been developed. This is safe, flexible and

simple to use. It allows the creation of clusters and arrays with full control of the angles

between enclosures and of their vertical inclination, to suit a wide variety of requirements.

Adjustments may be easily made by one person whilst the system is in the air, with the array

always remaining in perfect physical balance.

Page 8

user manual

TFS-780

TFS-780 user manual

Page 8

FLYING AND STACKING

For Flashlight and Floodlight enclosures

Overview

The Flashlight system flying hardware is specifically designed to allow a wide range of

adjustment of the horizontal and vertical angles between adjacent enclosures, as well as the

overall vertical inclination of each column of enclosures. This means that arrays can easily be

optimised to suit the coverage requirements of any situation.

Sound radiating from adjacent cabinets will successfully blend over a range of included

angles, and this results in the ability to tailor both the overall coverage and the SPL at a given

distance. Most of the adjustments can be easily made whilst the system is in the air.

The flying bars consist as follows:

♦

Single bar - supports a vertical column of cabinets up to 5 deep.

♦

Twin bar - supports two single bars.

♦

Main bar - supports two twin bars, and may be lifted by either one motor (for arrays up

to three deep) or two motors for larger systems.

♦

Spacer bars - used to join and maintain the distance between flying bars.

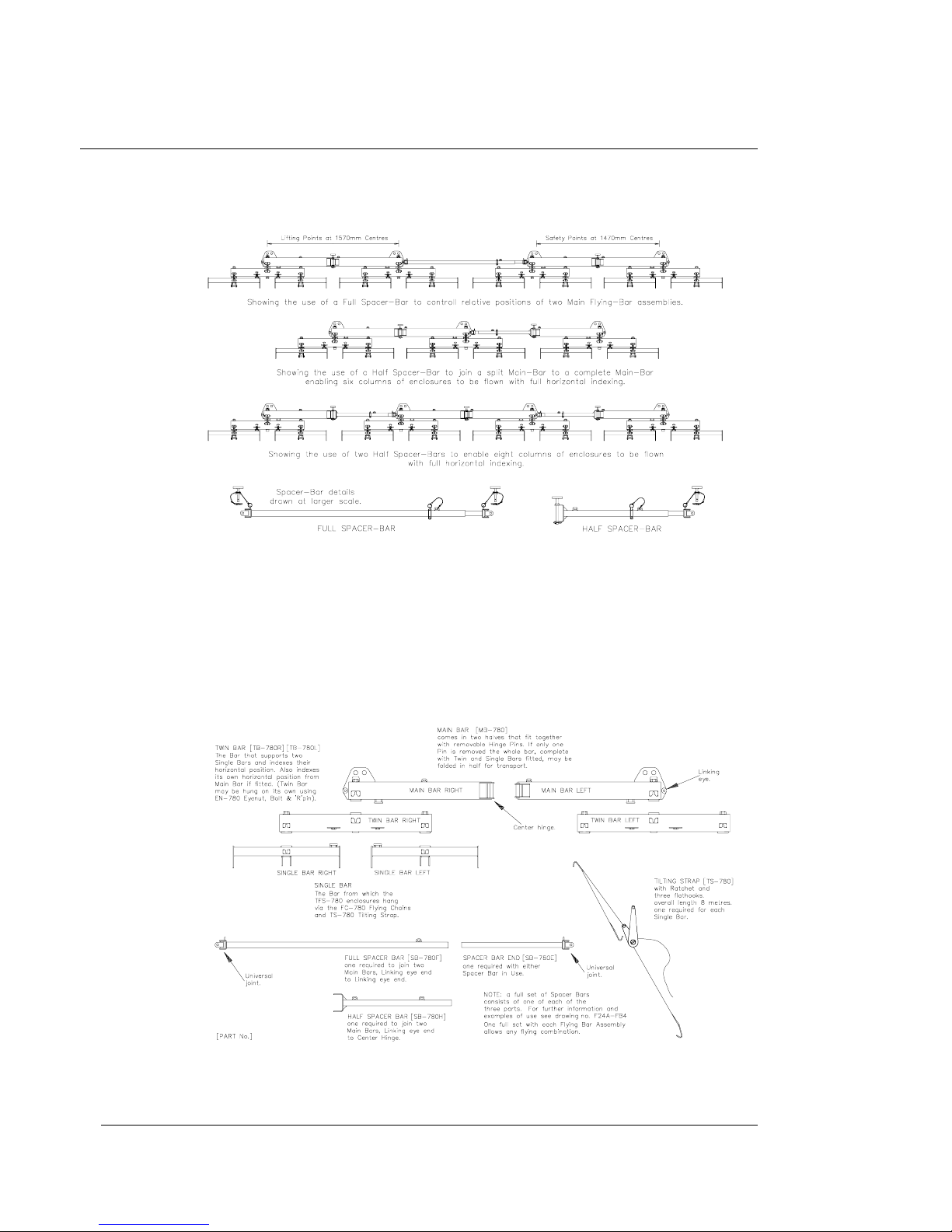

Configurations of these flying bars and spacers can be seen in Figure 3.

Page 9

user manual

TFS-780

TFS-780 user manual

Page 9

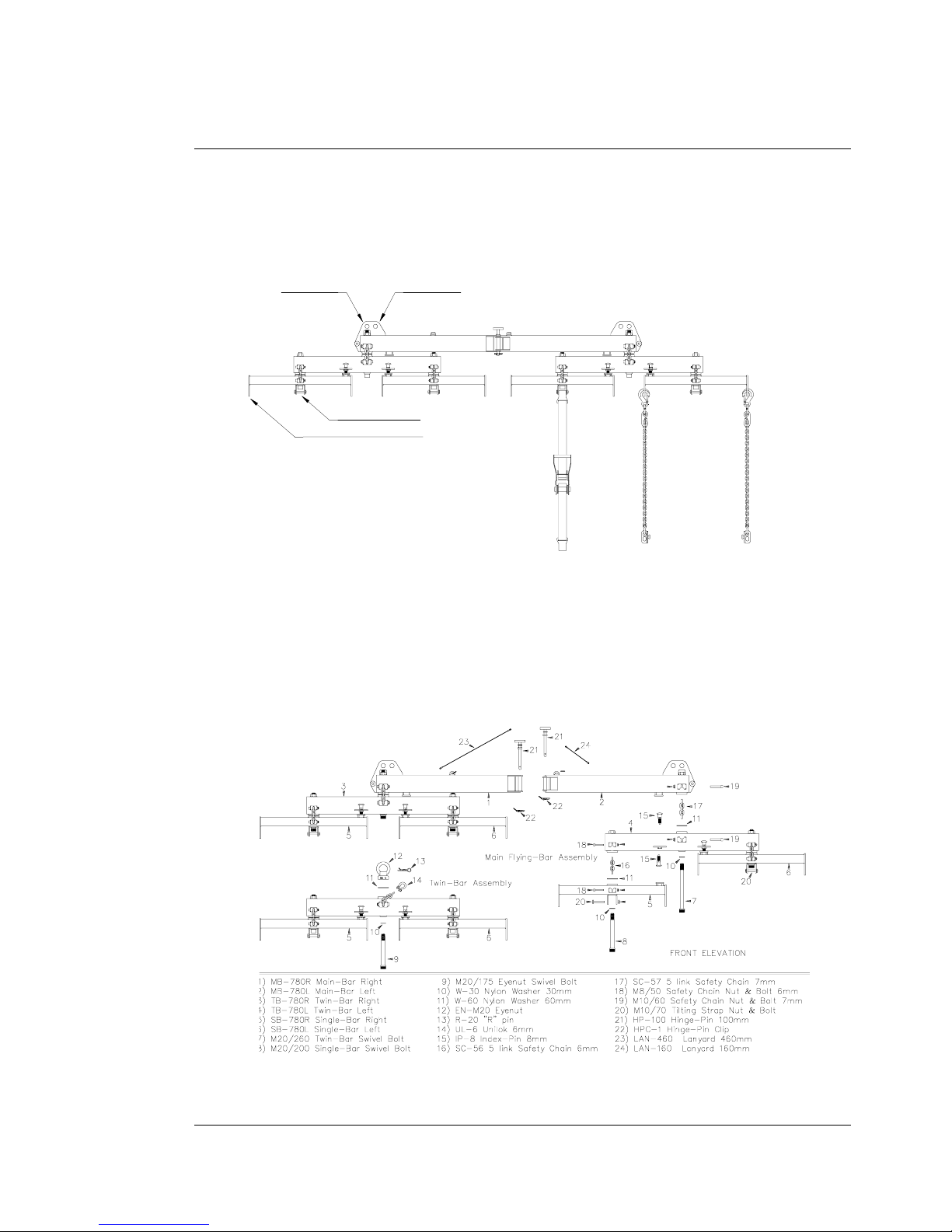

Figure 1. Flying Bar Assembly

Figure 2. Exploded Parts List

Lifting Point Safety P oint

Tilting Strap Point

Flying Chain Suspension Point

To suspend four columns of Flashlight

enclosures with indexed horizontal adjustment.

FC-780 FLYING CHAINS

one pair required

for each enclosure

to be flown.

TS-780 TILTING STRAP

one required

for each column

of enclosures.

(These are handed

left & right, the

left ones have RED

Shortening Hooks,

the right ones BLUE

Shortening Hooks).

FB-780A MAIN BAR

Page 10

user manual

TFS-780

TFS-780 user manual

Page 10

Figure 3. Flying Bars and Spacer Bar Configurations

Figure 4. Flying System Main Components

Page 11

user manual

TFS-780

TFS-780 user manual

Page 11

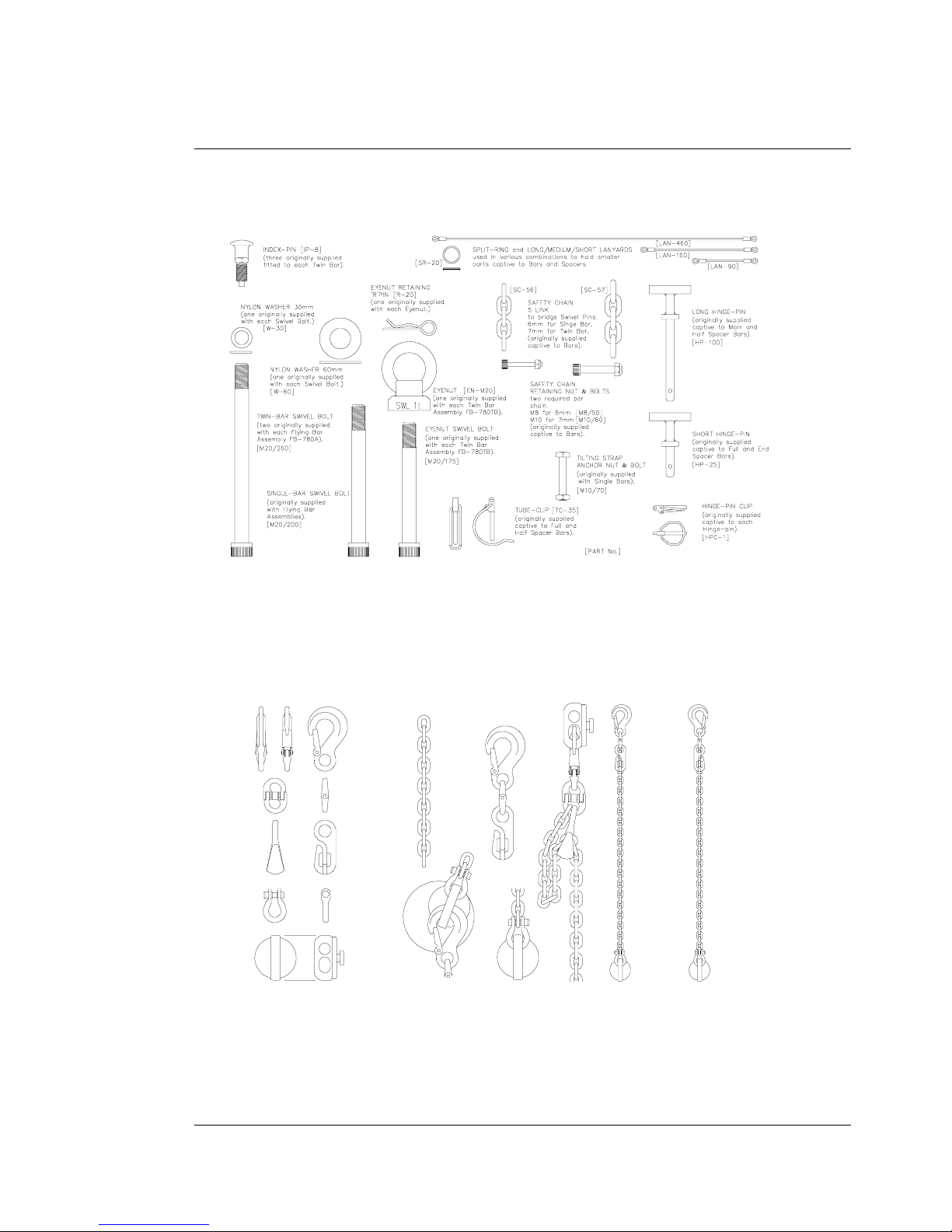

Figure 5. Flying System Small Components

Figure 6. Adjustable Chains

6mm Eye

Safety sling hook

6mm CONNEX

Connecti ng link

6mm

Shortening hook

6mm UNILOCK

'D'-Ring

6mm

Grade 80

Chain

Righthand

Chain (with

blue shortener)

Lefthand

Chain (with

red shortener)

Both Chains are

40 links long

Assembly examples

Page 12

user manual

TFS-780

TFS-780 user manual

Page 12

Setting Horizontal Angles

The Single Bars are pivoted on the Twin Bars which in turn are pivoted on the Main Bar. The

pivots include a nylon spacing washer to eliminate free play and allow for smooth operation.

A spring loaded Index Pin locates in one of a series of holes to secure the pivot at the desired

angle. A particular advantage of this pivot arrangement is that the horizontal splay of the

array may be adjusted whilst the system is in the air, and because the Single and Twin Bars

pivot about their centre points the array remains in perfect balance.

A secondary chain bypasses each pivot point to comply with safety requirements.

The Index Pin allows angles between columns of 0º to 40º to be set in 5º degree increments.

A minimum of 10º in the horizontal plane is recommended between Flashlight high packs to

ensure even coverage at the higher frequencies. Increased coupling is best achieved in the

vertical plane, as described in the next section.

Tilting

A high density white plastic locating tab

(biscuit)

is secured inside the door of each TFS780H. This is placed in the tilting bar slot at the top rear of the enclosure, and locates in the

enclosure above. These tabs act as simple and efective hinges, and ensure that the backs of

the enclosures stay in alignment with each other.

Page 13

user manual

TFS-780

TFS-780 user manual

Page 13

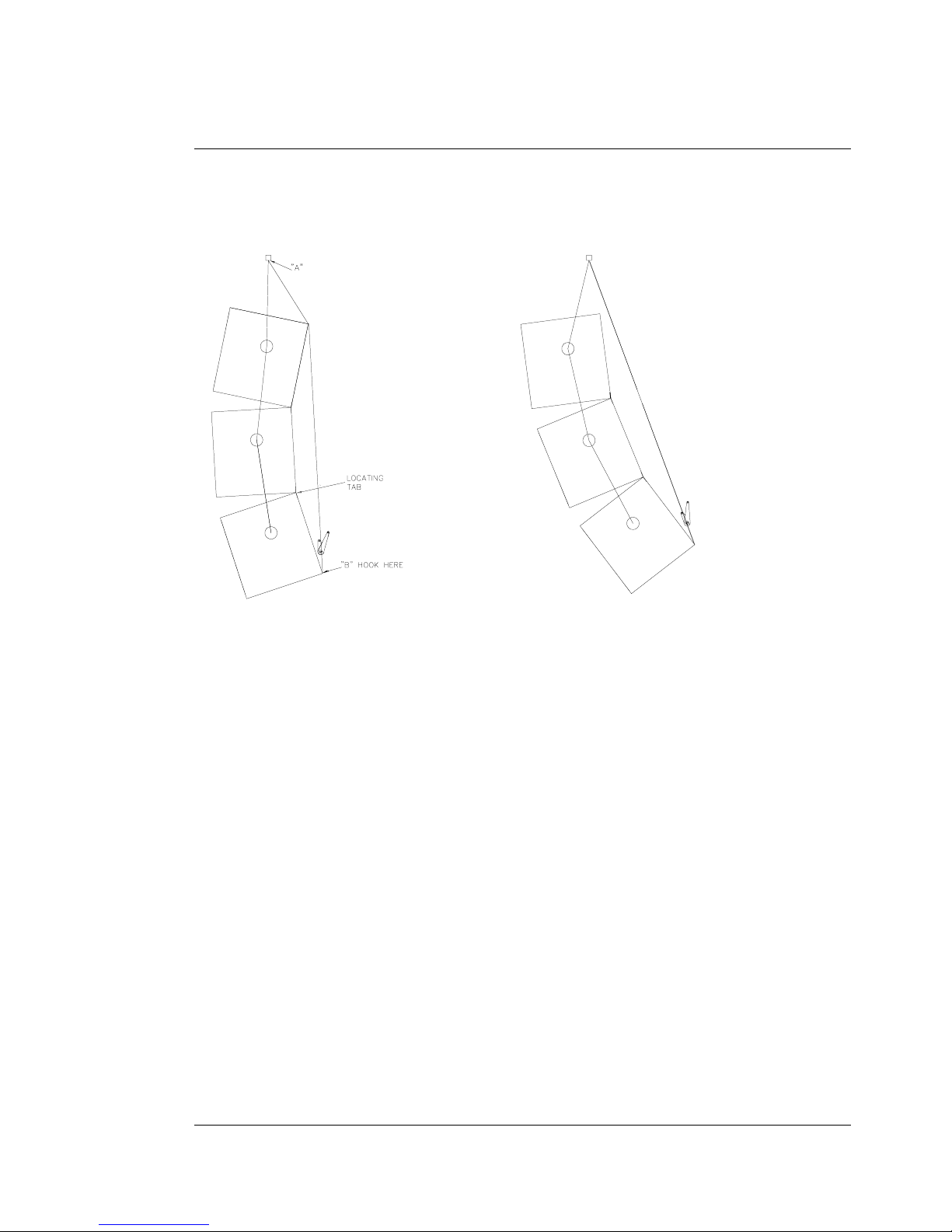

Figure 7. Tilting Strap Operation

The tilting strap, TS-780, is in two parts. The longer part is attached to the stirrup in the

centre of the flying bar at "A" using the hook at its end. The hook should face towards the

front of the cabinet. The other part of the strap with the ratchet is hooked into the lower slot

of the bottom enclosure at "B". The free end is then threaded through the ratchet and the

strap tightened to achieve the desired tilt.

WARNING

WARNINGWARNING

WARNING

If the strap is released suddenly, the row of enclosures may tend to swing violently forwards

and care must be taken to avoid danger to persons in the vicinity. It is essential to check that

nobody is standing immediately in front of the column, and to give a suitable warning,

before the strap is released. Ideally, two persons should support the row from the side whilst

the strap is released, or alternatively the bottom row may be returned to the ground before

release. In any event it is essential that all personnel in the vicinity are aware that the system

is about to move and that they must keep clear.

Page 14

user manual

TFS-780

TFS-780 user manual

Page 14

The Turbosound TFS-780 system has been designed and constructed to a high standard of

safety and tested to the most demanding of specifications. However, anyone involved in

flying ANY sound system, especially in a touring capacity, should take note of the following

advice:

The rigging of a flown sound system may be dangerous unless undertaken by qualified

The rigging of a flown sound system may be dangerous unless undertaken by qualifiedThe rigging of a flown sound system may be dangerous unless undertaken by qualified

The rigging of a flown sound system may be dangerous unless undertaken by qualified

personnel with the required experience to perform the necessary tasks. Fixing of hanging

personnel with the required experience to perform the necessary tasks. Fixing of hangingpersonnel with the required experience to perform the necessary tasks. Fixing of hanging

personnel with the required experience to perform the necessary tasks. Fixing of hanging

points in a roof should always be carried out by a professional rigger and in accordance with

points in a roof should always be carried out by a professional rigger and in accordance withpoints in a roof should always be carried out by a professional rigger and in accordance with

points in a roof should always be carried out by a professional rigger and in accordance with

the local rules of the venue. The house rigger and/or building manager must always be

the local rules of the venue. The house rigger and/or building manager must always bethe local rules of the venue. The house rigger and/or building manager must always be

the local rules of the venue. The house rigger and/or building manager must always be

consulted.

consulted.consulted.

consulted.

When initially ratcheting a column of speakers it is good to bear in mind the expected angle

of inclination so as to avoid ending up with too much of the strap left on the ratchet. This is

important because the ratchet can only take three complete turns before it releases itself.

It is recommended that you connect the hook to the bottom box, take up the slack in the

strap, and then fit the biscuits working up from the bottom. Initially when the system is hung

and the straps have been tightened just enough for the backs of the cabinets to touch, the

top box should point upwards as shown in Figure 7. When you increase the tension on the

strap the whole column will tilt around the centre of gravity of the column.

The system has been designed around an optimum setting so you must be aware that at

some point the backs of the bottom rows of cabinets will meet and limit any further

adjustment. To stop this you could try one or more of the following:

♦

Reduce the number of rows of cabinets.

♦

Use a smaller amount of horizontal splay.

♦

Use a smaller amount of vertical kelp.

Page 15

user manual

TFS-780

TFS-780 user manual

Page 15

Setting Vertical Angles

Vertical connection between enclosures and to the flying bars is achieved using the Q-D

Flying Plate and D-ring system originally developed for Turbosound's TMS-3 flying systems.

However, instead of fixed-length steel connections, an adjustable length chain is used.

(Figure. 6)

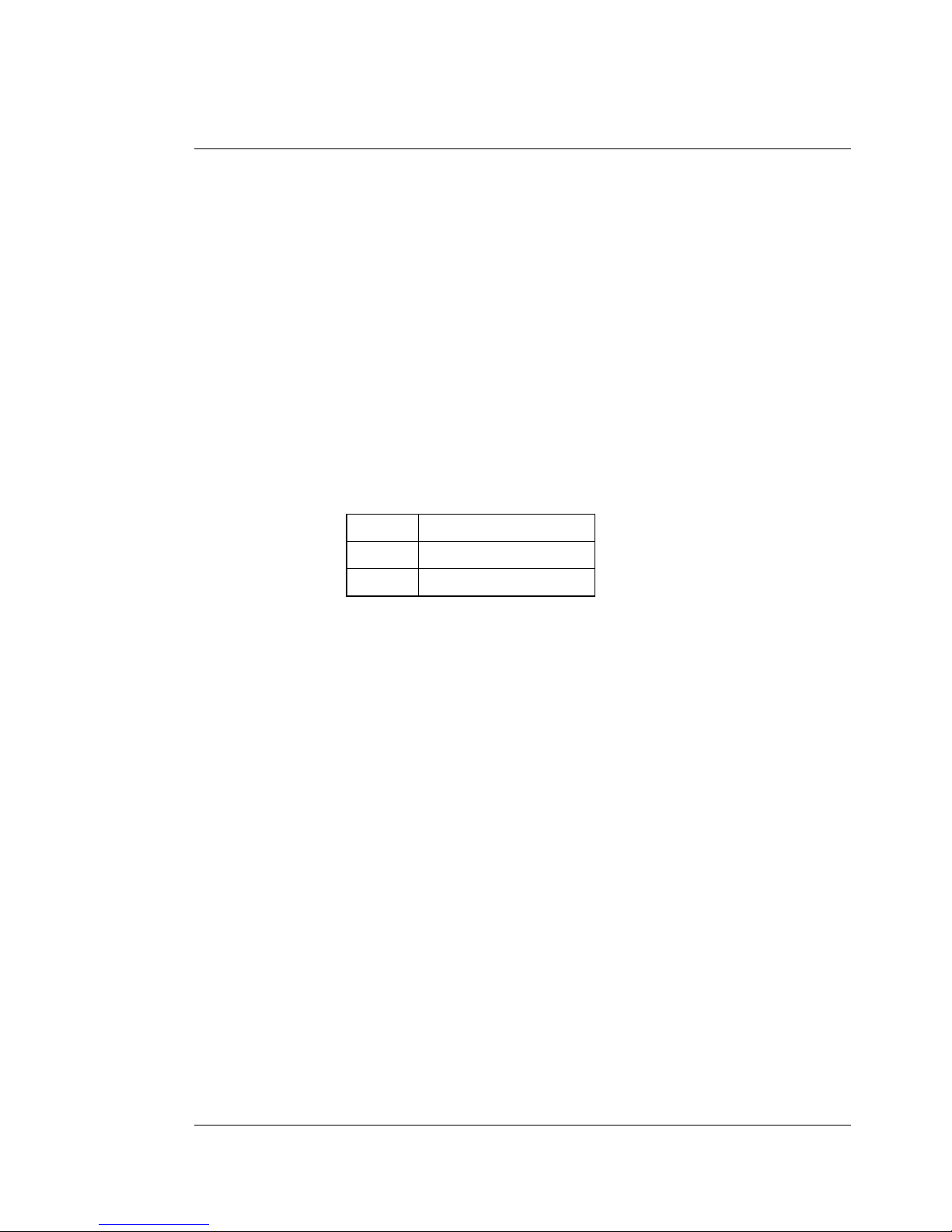

The vertical inter-cabinet angles available are as follows:

Chain

ChainChain

Chain

link in

link inlink in

link in

hook

hookhook

hook

780HF

780HF780HF

780HF

to

toto

to

780HF

780HF780HF

780HF

780HF

780HF780HF

780HF

to

toto

to

780H

780H780H

780H

780H

780H780H

780H

to

toto

to

780H

780H780H

780H

780H

780H 780H

780H

to

toto

to

760H

760H760H

760H

760H

760H760H

760H

to

toto

to

760H

760H760H

760H

Usage

UsageUsage

Usage

0 20º 22º ‡

!

4 3

°

17º 19º ‡

!

5 6

°

14º 14º 28º More

6 9

°

10º 10º 20º Vertical

7 12

°

6º 6º 12º Coverage

8 15

°

4º† 2º† 6º†

!

12 1.5

°

"

13 5

°

Higher Q

14 8

°

More

15 10.5

°

Coupling

16 15

°

"

17 17

°

"

† fit biscuit before chains ‡ greater than maximum length

The top chain from the flybar to the first cabinet can be adjusted to gain more height on the

system and also improve the looks. Alternatively if you are flying four or more cabinets deep

with a lot of kelp it is good to give the top chain some additional length as this makes

racheting easier.

When flying four Flashlight boxes deep the top biscuit can be difficult to fit depending on

how much vertical separation you have on the boxes. However if the top row consists of

bass cabinets where no vertical separation is required then you should use eight links

between the top two rows of cabinets, which requires you to fit the biscuits before fitting the

chains, thus locking the biscuits in place.

Page 16

user manual

TFS-780

TFS-780 user manual

Page 16

Arraying

The concept of arraying the TFS-780 Flashlight system is to create part of the surface of a

sphere. A small part of a large sphere will form a high-directivity

(long-throw)

system with a

high SPL at a distance, whereas a large part of a small sphere will be of lower directivity

producing less SPL at a distance, but having a wider angle of coverage. This approach leads

to the creation of a virtual point source of sound somewhere behind the array.

There are some simple rules to follow to help achieve this goal:

♦

Never point two high packs in exactly the same direction.

♦

Try to obtain a smooth even curve in the horizontal plane.

♦

Use a similar amount of tilt on each column.

♦

Ensure that the bottom corners of each column are in line with each other.

Page 17

user manual

TFS-780

TFS-780 user manual

Page 17

Procedure for flying a Flashlight array

The following notes describe the procedure for flying left and right Flashlight arrays

designed to provide coverage of an outdoor area for approximately 15,000 people. The

configuration in this example is a six-wide Flashlight array, each side of the PA giving a

horizontal coverage angle of about 90°. This is made up of a 4-wide main bar assembly and a

twin bar assembly, requiring three lifting points. A half spacer bar connects the main bar and

twin bar, effectively continuing the curve of the array and setting the distance of the last two

columns, and hence the third lifting point.

1. Remove the flybars from the fly bar trunk

and set them out on the stage wings

according to the required configuration.

Splay all the bars out to form a smooth,

shallow curve by locating the springloaded index pins on each bar in the bar

locator holes. Normally you will want to

start with all the index pins in the fourth

index hole, giving a horizontal splay angle

of 15 degrees between each vertical

column.

2. Move the flybars into the approximate position on the stage wing where the PA is to be

flown, and check that the curve of the array is going give you the expected horizontal

coverage. Position the bars such that the break between the first and second on-stage

columns is pointing directly at the mix position – this works best when the mix position

is between 27.5m (90ft) and 43m (140ft)

from the stage – and make sure that the

off-stage column is giving you adequate

coverage of the bleachers or side-stage

seating. Sometimes you may want to

open up the angle of the two off-stage

columns to the next (fifth) index hole to

give a little more coverage of the offstage seating if it is particularly wide.

Once you are happy with the splay of the

bars, choose and fix your flypoints such that the chain drops fall exactly above, and in

line with, the pick up points on the flybar. Note:

Note: Note:

Note: the outer holes on the flybar are the

pickup points; the inner holes are the safety points. Take time to get the flypoints

positioned accurately, as it is much easier to do it now than later when the flybar is

under load.

Page 18

user manual

TFS-780

TFS-780 user manual

Page 18

3. If space permits, prepare the flown Flashlight high boxes by wheeling them into

position, in two rows six across, behind the flybar position. In this particular

configuration TFS-780HF long-throw mid-high boxes will form the top row of each

column, and for convenience these can be stacked on top of the first row of Flashlights

and wheeled in together. Loosen the camlocks securing the wheelboards to the

underside of the Flashlight cabinets, so that when the cabinets are hoisted the

wheelboards will remain on the ground. Open the access door of each cabinet, take out

the biscuit and allow this to hang outside the box on the captive string. It is better to

leave the EP6 cable inside for now, because once connected later on they should be

stowed inside the box to eliminate any possibility of becoming disconnected.

4. Attach chain motors to the three fly bar

lifting points with shackles and secure

them. Attach safeties if required. The

flybar assembly is now ready be hoisted

to accept the first row of cabinets. Attach

two 1 metre spansets to the cable drop

points on the flybars with shackles to act

as cable strain reliefs. It is a good idea to

have the bulk of the cables tied directly to

the bar as opposed to hanging below it –

in this way their weight is less likely interfere with the column’s centre of gravity. Raise

the flybar to about shoulder height, ensure that it is is level, and once more check the

horizontal coverage. Make any final adjustments to the flypoints now, if required, as the

weight of the flybars is not excessive and it is quite easy to lift the flybar, taking the load

off the chains as they are moved. A couple of inches forward or backwards may make a

significant difference to the way system hangs, so take time to get this right.

5. Attach flying chains to each of the single

bars. The chains are colour coded blue

for left, red for right, looking at the

enclosures from the front. It is a good

idea to count out and hang or lay the

correct number of flying chains out

beforehand in an easily accessible place –

such as on the edge of a fly bar trunk according to their colour: reds together

and blues together. This is a good

opportunity to remove links from the clutch and check their condition. All the hooks

should point outwards from the boxes, with the clutch facing to the front, since this

makes it easier to de-rig later on. This orientation is preferred because if during rigging

or de-rigging the box should come up and into contact with the hook, there is no

Page 19

user manual

TFS-780

TFS-780 user manual

Page 19

possibility of the safety clip being pushed open. Most importantly, all the chain hooks

must face the same way for an even hang.

6. The length of the top row of chains naturally determines the height of the PA, but also

affects the way it looks. A short top chain length results in a neater looking PA, with the

boxes flying closer to the flybars, albeit at the expense of more tension on the tilt strap.

Do this if you want to be able to point the top boxes upwards, i.e. to cover high

balconies. If left long, i.e. completely open, there will be minimum tension on the tilt

straps but the system will not look as neat. Leave the top chains long if you want a large

downward angle on the column. A good compromise and starting point for the top row

is with link number 9 in the clutch. Choosing an odd link number is very desirable

because the chain will automatically hang straight, without the possibility of a 90° twist.

This will also ensure the PA flies fairly close to the flybar. NOTE:

NOTE: NOTE:

NOTE: When on a long tour

and when the PA is flown repeatedly the same way for multiple shows, use tie wraps to

secure links in the shortening clutch to save time.

7. Position the first row of Flashlights,

with the long throw boxes stacked on

top, directly under the flybar assembly.

Open the access door of the long throw

box, fit the biscuit in to the kelping

brackets, and connect the cable. Stow

any excess cable inside the cabinet.

Allow the flying chains to hang freely

down the sides of the boxes. If the Dring does not naturally face the right

way,

do not rotate it

(which will cause a twist in the chain) to force it to face inwards,

simply flip the D-ring over so that it points in towards the fly point. NOTE:

NOTE: NOTE:

NOTE: later flying

chains, shipped after September 2000, are re-designed with two separate apertures in

the D-ring so that it cannot accidentally flip over; in this case simply allow the the chain

to hang freely and then rotate a quarter turn clockwise or counter-clockwise as

appropriate to point in towards the box. Snap the D-rings into the flyplates on the

cabinets by inserting and lifting sharply until you hear a solid click.

8. Attach the long part of the tilting straps

to the stirrup at the centre of each

single flybar, with the hook facing

forwards. Rather than letting the tilt

straps hang at the back of each box, it is

better to gather three to one side and

three to the other, to hang down at the

sides of the array until it is time to kelp

the boxes. This will avoid uneccessary

Page 20

user manual

TFS-780

TFS-780 user manual

Page 20

clutter when fitting biscuits and cables on subsequent rows of boxes.

9. Snap on the next row of flying chains, hooks facing forward, again observing the colour

coding – red for right, blue for left. The length of the flying chain will determine the

vertical angle between the first row and the second row of boxes. You will want the first

row of Flashlights to couple with the long throw boxes on the top row, so place link #27

in the clutch. This will result in a vertical angle of 3.5º between boxes.

10. Raise the PA about a further metre to

allow the third row of Flashlights to be

wheeled in underneath, having first

loosened the camlocks on the

wheelboards. Snap in a third row of

flying chains, again observing the colour

code. Shorten the chains by placing link

#7 in the clutch, which will result in a

vertical angle of 5° between boxes.

11. Raise the PA another metre or so, and

position downfill boxes face down on the

ground, or face down on a Flashlight

wheel board and roll into place

immediately below each column. There

are two types of downfill, a low-mid

(identified by the EP6 connector) and a

high-mid (identified by the XLR

connector). It is common to ‘chequerboard’ the downfills so that you end up

with a high-mid, low-mid, high-mid, low-mid, high-mid, low-mid arrangement left to

right across the PA. However there is often an exaggerated coupling of low-mid energy

from the PA and coming from the stage which, combined with the wider dispersion

created at lower mid frequencies, is sometimes undesirable. In this case try using all

high-mid downfills on the bottom row instead to clean up these frequencies close to the

stage.

12. Shorten each chain by placing link #10 in

the clutch and snap the D-rings into the

flyplates on the downfill boxes. Open the

access door, and take out the tilting strap.

The downfills are angled independently of

the main part of the array by means of

their own tilt straps, which are simply

Page 21

user manual

TFS-780

TFS-780 user manual

Page 21

secured to the Flashlight box above. Angle the downfills so that the top side is parallel to

the bottom of the cabinet above it. The exact angle will work out to be between 30° and

34° from the Flashlight box above it. For most applications this will give you the

optimum front fill coverage.

13. Attach a ratchet to the bottom kelping bracket on the lowest Flashlight box and feed the

free end of the tilting strap through the slot in the centre of the ratchet spindle. Place the

biscuits into the kelping bracket at the top of each box, and as you gradually pull

upwards on the strap guide the box above to allow the biscuit to settle into its lower

kelping bracket. The lower boxes will close up first as you continue to increase tension

on the tilt strap. When flying an array

with more than three Flashlight boxes

deep it is preferable that this procedure

be carried by two people, with one

person standing on a speaker box or

similar to be able to locate the highest

biscuit. When all the biscuits in the

column have positively located in the

kelping brackets, give the tilt strap one

more pull before beginning to ratchet

the column. If you leave too much slack at the free end of the strap the ratchet will not

be able to accommodate more than 2 or 3 layers of webbing without disabling the clutch

mechanism. At this stage do not put a lot of angle on the column, as it is much easier to

increase the amount of kelp than to decrease it. When using a chain length shorter than

link number seven in the clutch, a Flashlight box will naturally tend to hang pointing

slightly upwards, making the fitting of the biscuits very easy. However, if a shorter chain

is used (i.e. link number 8) you must fit the biscuit between boxes before attaching

chains to the lower box

.

14. Check the tilt of the boxes now with an inclinometer. Gradually ratchet the column until

you have achieved the required downward angle of the PA. Repeat for the remaining

columns.

Page 22

user manual

TFS-780

TFS-780 user manual

Page 22

15. Attach the end of a long tape measure to the back corner of the lowest onstage

Flashlight cabinet. Raise the PA and note the exact height above the stage so that you

can mirror this vertical position to the other cluster. This will ensure that the both left

and right PA clusters are level.

16. When the flown arrays are in position, wheel in the Flashlight bass enclosures, and stack

them on the stage wings in three columns each of six cabinets. All the boxes are placed

on their sides, and mutual coupling is acheived by placing them ‘door to door’ so

forming a larger horn mouth. The two off-stage columns are stacked, with sides

touching and facing perpendicular to the stage edge, while the on-stage column is

angled inwards several degrees to point directly towards the mix position.

Page 23

user manual

TFS-780

TFS-780 user manual

Page 23

Bass Enclosure arraying

Flashlight bass enclosures are most efficient when ground stacked in a block. Not only do

they benefit from improved coupling when there are no air gaps between them, but they also

couple to the ground. However, some of this energy may be absorbed by nearby

obstructions such as barriers or a tightly-packed standing audience. Sound pressure levels

may also be excessive for members of the audience if they are able to get too close to the

enclosures. When stacking on the stage or on a platform, particularly outdoors, it is

preferable to close the gap between the platform and the floor with sheets of plywood. This

results in increased sound projection into the audience and less leakage backstage.

Aiming - directivity of the stack

The directivity of the bass stack will depend on its dimensions and curvature. A tall thin stack

will disperse a lot in the horizontal plane and become narrow in the vertical plane and

likewise a wide stack will narrow in the horizontal plane. There is usually an optimum

compromise between the two so that a smooth transition can be obtained between the effect

of the coupling of the two stacks down the centre line of the room and the effect of the

individual stacks beaming on their axis. Also adding some curvature to the stack will help to

increase the directivity of the stack especially in the higher frequencies.

Turbosound Flashlight bass bins can be stacked in various configurations, each giving a

certain emphasis which can be used to great advantage dependent on the room, situation

and type of music.

Stacking in pairs mouth to mouth (access panels outwards) helps the bins to couple giving a

wider mouth area and lower bass response. The example shown below will result in a strong

punchy low end partly due to the floor coupling. This configuration works well for rock

music, giving a solid low end. Stack two bass bins on their ends, with a Floodlight front fill

on top, between two columns of 4 high, 2 wide bass enclosures. Place the onstage columns

flush and parallel with the stage front, turning the offstage colum out towards the side.

Page 24

user manual

TFS-780

TFS-780 user manual

Page 24

An alternate arrangement is to stack the bass enclosures with a curve similar to the flown

array above it, giving a strong, punchy low end with even dispersion. The first row are

stacked door to the floor, with remaining bins alternately inverted in rows six across and

three high. The bass stack should be placed slightly apart from the stage, with the inside

column pointing directly at the mix position. The remaining columns are splayed evenly with

a 6” to 8” gap between each column. This arrangement works well for house and dance

music. A TFL-760HM placed on the stage edge gives excellent front fill coverage.

Tall, thin bass stacks work best, preferably in blocks of eight bins high by two wide. When

space permits use two of these blocks, the onstage block flush with and parallel to the stage,

with a second identical offstage block slightly separated from the first and angled outwards

by 10°.

Page 25

user manual

TFS-780

TFS-780 user manual

Page 25

STAGE

Ground stacking

In certain situations, indoors or outdoors, it may not be possible to fly any part of the system.

In this case, the same general rules apply as for flown arrays. High packs should be kept well

above head-height and angled carefully for even coverage. Small wood blocks may be used

to tilt cabinets upward for raised audience areas and downward for the floor areas, with the

locating biscuits being used for stability. Suitable wood blocks should always be carried for

this purpose.

In general, the wider dispersion Floodlight enclosures should be used for close range ground

stacked applications, i.e. to cover the nearest audience areas. Flashlight enclosures may be

used to cover the more distant areas from positions at the top of the stacks, where their high

Q (narrow dispersion) is ideal for

long throw

applications. Flashlight should not be stacked

directly on top of Floodlight as this arrangement is potentially unstable due to the difference

in cabinet sizes and centres of gravity.

Vertical Dispersion Considerations

Tightly coupling a pair of cabinets with the upper one inverted

to place the HF drivers close together will result in reduced

vertical dispersion and a higher level on axis which can improve

the projection in long throw situations, but this orientation is

normally unsatisfactory with Flashlight due to the asymmetric

nature of the cabinet. However experimentation with Floodlight

can produce acceptable results although a general degradation

in performance may be apparent. When stacking cabinets on top

of each other the right way up you should use a spacer in

between the fronts of each cabinet to introduce some vertical

angle in the stack. Care should be taken to ensure that the stack

remains stable and using the biscuit slots will help to prevent

cabinets from sliding around.

Page 26

user manual

TFS-780

TFS-780 user manual

Page 26

Flown Systems

For Flashlight in

short throw

use, the smoothest vertical dispersion is achieved with an

intercabinet angle of around 10° (with both cabinets the same way up). Reducing this angle

reduces vertical dispersion (increases the projection) but results in a less smooth dispersion

pattern. As these deviations in the vertical coverage are not normally perceptible to the

audience, smaller vertical cabinet angles may be safely selected to suit the projection or

throw

required. Angles greater than 15° will however result in a loss of coverage on axis and

should be avoided.

In most applications the upper rows of a cluster of cabinets will cover the more distant

sections of the audience, and the vertical intercabinet angles will therefore be progressively

smaller towards the top of the cluster.

Vertical: 10 degrees

between cabinets

Horizontal: 15 degrees

between columns

Page 27

user manual

TFS-780

TFS-780 user manual

Page 27

LMS-D6 LOUDSPEAKER MANAGEMENT SYSTEM

Introduction

This section is provided with the aim of assisting sound engineers, installers and consultants

to fully understand the LMS-D6, and to obtain the full benefit of its capabilities.

The LMS-D6 is a dedicated Loudspeaker Management System, specially configured for

Turbosound's Flashlight & Floodlight Systems, and to be used in conjunction with

Turbosound AMP-780 amplifier racks.

General features & facilities

Unpacking

As part of Turbosound's system of quality control, this product is carefully checked before

packing, to ensure flawless appearance. After unpacking the unit, please inspect for any

physical damage and retain the shipping carton and all relevant packing materials for use

should the unit need returning.

After unpacking the unit please check carefully for damage. If damage is found, please notify

the carrier concerned at once. You, the consignee, must instigate any claim. Please retain all

packaging in case of future re-shipment.

There will be a small packet of spare fuses with the unit. Please keep them in a safe place.

If any damage has occurred, please notify your dealer immediately, so that a written claim

for damages can be initiated. See the Warranty section at the end of this manual.

Mechanical Installation

A vertical rack space of 1U (44mm / 1.75") is required for each unit. If used in a mobile or

transportable system, the unit must be supported at the rear by additional bracing or

shelving, to prevent vibration-induced metal fatigue of the racking ‘ears’. Failure to do this

will impair reliability and invalidate the Warranty. The rack casing will need a depth of

425mm (minimum) to clear the connectors.

Adequate ventilation must be provided by allowing sufficient room around the sides and rear

of the unit to permit free circulation of air. Forced cooling is not required, a factor which aids

component longevity. The front of the unit should not be exposed to long term direct

sunlight as this can have a detrimental effect on the display lens.

Page 28

user manual

TFS-780

TFS-780 user manual

Page 28

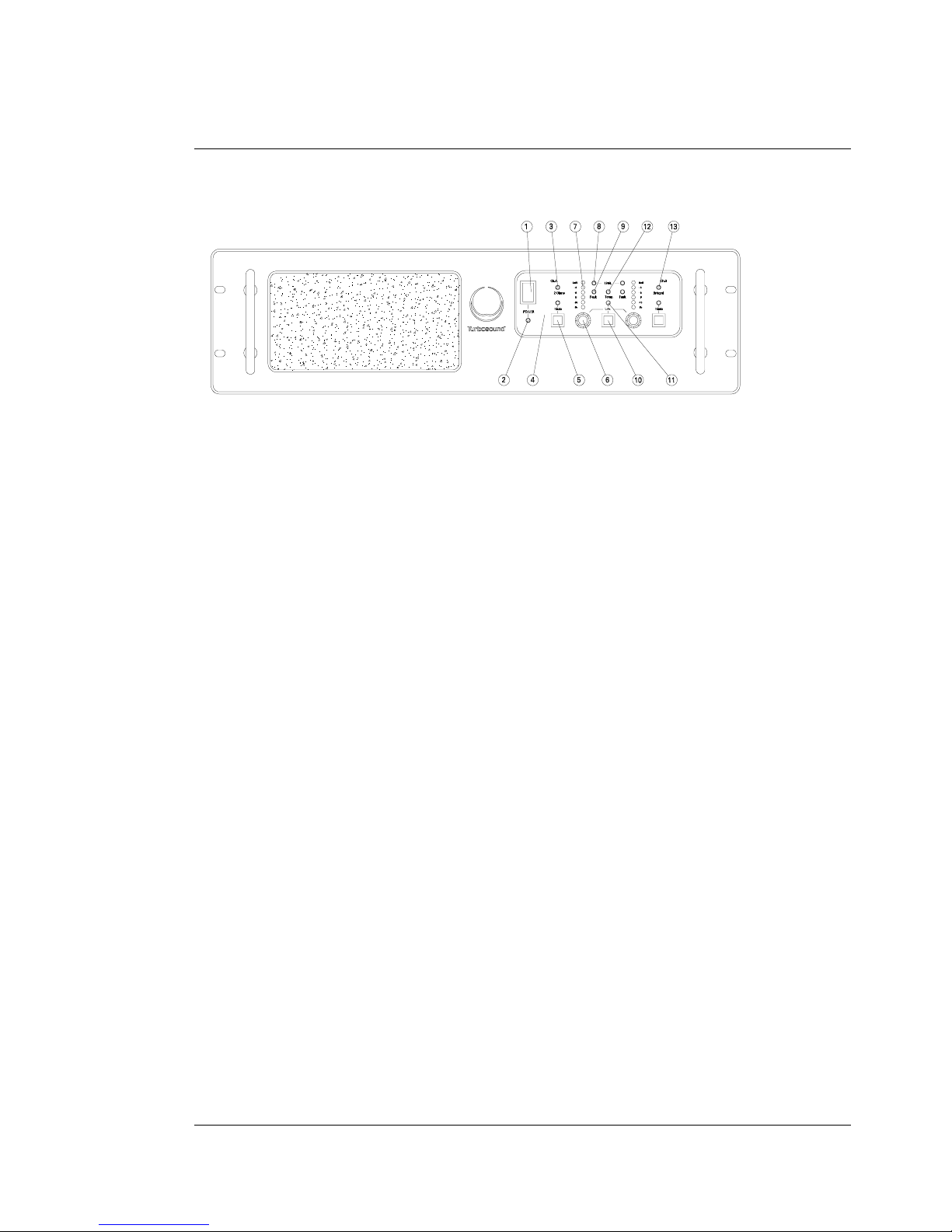

LMS-D6 Front Panel Functions

1. LCD Display

LCD Display LCD Display

LCD Display - Shows menu options, output information and parameters being adjusted.

2. Gain Keys

Gain KeysGain Keys

Gain Keys - Two input and six-output ‘gain’ keys allow instant access to the gain screen for

each channel. Pressing a second time selects the last function edited.

3. Next Key

Next KeyNext Key

Next Key - Moves the display forwards through the list of available parameters for the

current input or output channel.

4. Back Key

Back KeyBack Key

Back Key - Moves the display backwards through the list of available parameters for the

current input or output channel.

5. Menu Key

Menu KeyMenu Key

Menu Key - Activates the main menu on the LCD display. Pressing a second time selects the

last menu edited. Different menus are selected by pressing the

‘BACK’

and

‘NEXT’

keys or

using the

‘FREQ’

control.

6. Enter Key

Enter KeyEnter Key

Enter Key - Enters the chosen menu and confirms menu selections.

7. OUT Key

OUT KeyOUT Key

OUT Key - Exits the menu.

8. Bypass Key

Bypass KeyBypass Key

Bypass Key - Allows the currently displayed parametric section to be bypassed. (Note: The

Highpass / Lowpass filters and limiters can not be bypassed.)

9. Parameter Controls

Parameter ControlsParameter Controls

Parameter Controls - The three velocity sensitive rotary encoders allow the relevant

parameter, on the LCD screen, to be adjusted.

10. Input Meters

Input MetersInput Meters

Input Meters - Displays available headroom before input clipping occurs. The bottom green

LED is set at -24dB, with the orange 0dB LED set at 3dB below clipping. The top, red LED

displays digital overflow and can therefore light without all the other LEDs becoming

illuminated.

11. Output Meters

Output MetersOutput Meters

Output Meters - Displays headroom before limiting occurs. The bottom green LED is set at 24dB, with the orange ‘LIM’ LED set at the limiter threshold for that channel. The top, red

LED indicates 4dB of limiting.

12. Mute Keys

Mute KeysMute Keys

Mute Keys – One mute key per output channel.

5 4 3 6 9 10 11 12

1 8 7 2

'Q'

3

LIM

-3

-24

LIM

-3

-24

LIM

-3

-24

MENU

BYPASS

ENTER

OUT

FREQ 'Q' GAIN

CLIP

-6

-24

GAIN GAIN GAIN GAIN GAIN GAIN GAIN GAIN

MUTE MUTE MUTE

AB 12 456

DIGITAL LOUDSPEAKER MANAGEMENT SYSTEM

LMS-D6

LIM

-3

-24

LIM

-3

-24

TQ-440

Page 29

user manual

TFS-780

TFS-780 user manual

Page 29

LMS-D6 Rear Panel Functions

1. Power Switch

Power SwitchPower Switch

Power Switch.

2. Mains Fuse

Mains FuseMains Fuse

Mains Fuse - Located in a finger-proof fuseholder adjacent to the mains inlet. Always

replace this fuse with the correct type as shown on the rear panel legend. (N.B. A spare

fuse is located in this holder.)

3. Mains Power

Mains PowerMains Power

Mains Power - Connected via a standard IEC socket. A compatible power cord is

supplied with the unit.

4. External

ExternalExternal

External - RS232 via a 9-pin DIN DEE socket, for connection to a PC.

5. XLR Inputs and Outputs

XLR Inputs and OutputsXLR Inputs and Outputs

XLR Inputs and Outputs - 3 pin XLR connectors are provided for each audio input and

output. All terminations are fully balanced, pin 2 Hot, pin 3 Cold and pin 1 not connected.

Mains Power

The LMS-D6 must always be connected to a 3 wire grounded AC supply. It is supplied with a

standard IEC power cord with conductors as follows:

BROWN Power line Live (Phase)

BLUE Power line Neutral

GREEN/YELLOW Safety Earth and ground connection

Units supplied to the North American market are fitted with an integral moulded 3 pin

connector, which is provided to satisfy UL & CSA safety standards.

1 2 3 4 5

INPUT B INPUT A

CUSTOM MAD E FOR TURBOSOUND

IN THE UK BY XTA ELECTRONICS

PROTECTION AGAINST FIRE

REPLACE ONLY WITH THE

SAME TYPE T1A, 250V FUSE

RS232

DATA IN PUT

PIN1=SHIELD

PIN2=H OT

PIN3=COLD

THIS EQUIPMENT MUST BE EARTHED

RISQUE DE CHOC E LECT RIQUE - NE PAS OUVR IR

WARNING / AVIS

OUTPUT 6 OUTPUT 5 OUTPUT 4 OUTPUT 3 OUTPUT 2 OUTPUT 1

DO NOT EXPOSE TO RAIN OR MOISTURE

SHOCK HAZARD – DO N OT REMO VE COVERS

Page 30

user manual

TFS-780

TFS-780 user manual

Page 30

Voltage Setting

The LMS-D6 is provided with an auto-seeking power supply, and therefore requires no

external adjustment for correct operation with international AC line voltages ranging from 60

to 250 volts.

Safety Earthing

The green/yellow wire of mains cord must always be connected to the electrical installation's

Safety Earth or Ground. It is essential for personal safety, as well as proper operation of the

unit.

The green/yellow wire is internally connected to all exposed metal surfaces. Any rack

framework which this unit might be mounted into is assumed to be connected to the same

grounding circuit. The LMS-D6 has balanced audio connections and does not require

disconnection of this or any other safety earth for the avoidance of hum loops. If any

problems are experienced with hums or buzzes, careful attention to the signal cable

grounding will effect a cure.

AC Power Fusing

The incoming mains power fuseholder is mounted on the rear panel. If the fuse needs to be

replaced it must be properly rated as follows: 20mm 1A 250 V type T. It is important for

continued safety that this specification is adhered to. It is very unlikely that this fuse will fail

during normal use, and such a situation must be treated with some caution as to the cause.

Powering Up

When the LMS-D6 is switched on by operating the power on-off switch located on the rear

panel, the internal circuitry carries out a series of routine diagnostic tests.

After the switch-on cycle, the screen will revert to displaying the delay program name that

was in use when the unit was last powered down.

The internal memory automatically saves all settings when the unit is switched off, so there

is no need to re-load delay and temperature information every time the system is poweredup. The memory contents are retained indefinitely without the need for an internal backup

battery.

Page 31

user manual

TFS-780

TFS-780 user manual

Page 31

Audio Connections

The LMS-D6 audio inputs are RFI filtered and electronically balanced. The outputs are

electronically balanced and fully floating. Overall, the unit is designed to operate at any

signal levels ranging -10dBu up to +20dBu. The outputs will drive into loads of 600 Ohms or

greater and both inputs and outputs are intended to be 'fuss free', regardless of an

installation's complexity.

The connector wiring is as follows:

Input Output

Pin 1 n/c Pin 1 n/c

Pin 2 hot (+) Pin 2 hot (+)

Pin 3 cold (-) Pin 3 cold (-)

Input and Output Connector Wiring

Balanced Wiring

Whether a system is wired to a 'pin 3 hot' or a 'pin 2 hot' convention will not matter as long

as the wiring of hot & cold phases to both the input and output XLR connectors is the same.

At the LMS-D6 input, the convention is 'screen goes forward with the signal'. Input cable

screening therefore needs to be connected at and derived from the signal source end, as pin

1 on the input XLR is not connected to the LMS-D6 chassis nor signal ground.

Time correction for loudspeaker driver placement

When a loudspeaker sound system is constructed which utilises different loudspeaker drivers

for separate frequency bands, it is inevitable that the sound sources are non-coincident. The

effect of this is that phase and time differences occur, producing a substantial cancellation of

the signal around the crossover region. There is also a general lack of transient clarity or

smearing

of the sound, resulting from an inaccurate combining of the wavefront. The LMSD6 provides and maintains the optimum signal delay between the HF and HMF drivers and

the LMF driver in the TFS-780H when the unit is switched to Flashlight mode, and in

Floodlight mode the three drivers in the TFL-760H are physically aligned so inter-driver time

delays are switched out.

Page 32

user manual

TFS-780

TFS-780 user manual

Page 32

AMP-780.2 FLASHLIGHT SYSTEM AMPLIFICATION RACK

Racking, Cables and Connections

The AMP-780.2 Flashlight amplification system comprises a complete amplifier rack,

flightcase and cabling system which can power the recommended system configuration of

six TFS-780H and six TFS-780L, although each rack is capable of powering up to eight TFS780H and eight TFS-780L enclosures if required.

The rack contains TMC series amplifiers designed and developed in England for Turbosound

by MC

2

Audio Ltd.

Input and output connectors are mounted on a single 2U 19" panel at the rear of the rack.

The amplifier rack is supplied with the facility to monitor and control certain amplifier

functions remotely via a simple 2-wire connection using the loop-in and loop-out XLR

connectors provided on the rear panel to a laptop or desktop computer.

The rack itself is a space frame, fabricated from rectangular steel sections with all necessary

mounting points welded in. The top and side apertures are fitted with panels which may be

supplied in a variety of different finishes to blend with any particular packaging. These are

secured with Velcro to allow easy access to the amplifiers and cabling.

A fully shock mounted road case with four heavy duty castors completes the system, which

is designed to fit four across in a standard width truck.

ΡΕΜΟΤΕ ΧΟΝΤΡΟΛ ∆ΑΤΑ

ΒΟΤΗ ΧΗΑΝΝΕΛΣ.

ΙΝΠΥΤ

ΑΝ∆

ΛΙΝΚ

ΛΟΩ ΟΥ ΤΠΥΤΣ

ΙΝΠΥΤ

ΟΡ

ΛΙΝΚ

ΣΙΓΝΑΛ

ΗΙΓΗ ΟΥΤΠΥΤΣ

ΑΜΠ−780.2

Page 33

user manual

TFS-780

TFS-780 user manual

Page 33

Options

The rack is supplied fitted with four amplifiers as standard. The two top amplifiers are TMC750 models, and power the high frequency and high-mid frequency sections respectively,

while the two bottom amplifiers are TMC-1250 models and power the low-mid frequency and

low frequency sections respectively. Separate adjustment of the levels of left and right sides

of the rack is possible on all frequency bands. Furthermore, the rack may be operated in twochannel or stereo mode by removal of the link plug (dongle) located under the top panel.

Input Connections

As will be seen from the wiring schedule below, the incoming 11 pin Lemo socket is

connected via the mono/stereo linking connector to the adjacent link-out Lemo and to the

XLR male cable plugs which connect LF, LMF, HMF and HF feeds to the amplifiers in the rack.

In two-channel mode, the second Lemo socket becomes the input connector for the second

channel.

Figure 1. Amplifier Rack Signal Wiring

Page 34

user manual

TFS-780

TFS-780 user manual

Page 34

Output Connections

The amplifier outputs are wired to two 19-way CEEP (Socapex compatible) output sockets,

rated at 20 Amperes per contact, which drive the TFS-780L and TFS-780H respectively.

The output wiring has been arranged to preclude accidental connection of the LF output to

anything other than the TFS-780L, preventing any risk of drive-unit damage.

Mated connectors are screw-locked, ensuring reliability.

In addition, there are two EP6 and two XLR outputs for running small systems not requiring

multicore loudspeaker extension cables.

Two 4 metre fanouts are supplied to take the 19-way cable outputs to the speakers. The Low

fanout is fitted with six female XLR connectors and the High fanout with four EP6 connectors.

The cables are labelled to indicate which amplifier channels they relate to.

Remote Control Connections

Two 3-pin XLR connectors are provided on the rear to enable the external remote control and

monitoring of certain amplifier functions such as power on/off, temperature and gain. All that

is required to enable this facility is a 2-wire connection via a RS232 to RS485 adapter to a

laptop or desktop computer. The software is supplied free of charge as a download from the

Turbosound web site at www.turbosound.com. The remote control facility is able to maintain

control of a virtually unlimited number of amplifiers, and can group amplifiers or amplifier

racks into zones if required.

Page 35

user manual

TFS-780

TFS-780 user manual

Page 35

Extension Cables

19-way extension cables are available to order in 25, 50 and 100 metre lengths (EX-780) for

flying and/or remote positioning of amplifier racks. These cables utilise 2.5 mm

2

conductors

for low line resistance and are black in colour to minimise visibility to the audience.

Figure 2. Multiway Outputs.

Figure 3. Auxiliary Outputs.

Page 36

user manual

TFS-780

TFS-780 user manual

Page 36

Figure 4. Multiway to EP6 Fan-Out.

Figure 5. Multiway Cables.

Mains Connections

Incoming mains power may be connected by one of a variety of

C Form

connectors,

depending on the power system specified when the rack was ordered. Typical supply

configurations are as follows:

110 V star-wired (3 phase) 110 V parallel (1 phase)

220/240 V (3 phase) 220/240 V (1 phase)

The mains power wiring utilises Wago distribution blocks with spring-loaded screwless

connectors. The power wiring may therefore be quickly and easily reconfigured should the

need arise, for example if conversion from single to three phase operation is required. We

recommend you consult a qualified electrician in cases of uncertainty.

Page 37

user manual

TFS-780

TFS-780 user manual

Page 37

TMC-750 AND TMC-1250 HIGH EFFICIENCY AUDIO POWER AMPLIFIERS

General Features & Facilities

The TMC-750 and TMC-1250 are highly efficient, rugged high power amplifiers, with many

original features developed to meet the requirements of modern professional sound

reinforcement, for both touring and fixed installations. They have been designed with audio

quality ranking equal first alongside utility and ruggedness.

♦

Two independently controlled and powered channels.

♦

High continuous power, in excess of 750 watts per channel into 4 ohms (TMC-750) and

1250 watts per channel into 4 ohms (TMC-1250).

♦

A 10kΩ actively balanced, fully floating input is fitted as standard.

♦

Bargraph meter display of output headroom.

♦

LED display of output device temperature.

♦

High damping factor, >400 below 1kHz.

♦

Complementary class AB bipolar outputs, with unique floating drive stage for optimum

audio performance.

♦

Sophisticated monitoring of load and temperature.

♦

Low noise vari-speed fans for quiet operation.

♦

User selectable clip limiter with ‘tight’ and ‘easy’ settings which track the supply voltage.

♦

Front-panel accessible filter for improved dust collection.

♦

Fully functional bi-directional remote control via RS485.

♦

Consistent reliability and easy serviceability through solid, lightweight construction and

modular packaging.

Page 38

user manual

TFS-780

TFS-780 user manual

Page 38

Front Panel Functions TMC-750

1. Mains power rocker switch

Mains power rocker switchMains power rocker switch

Mains power rocker switch – applies AC mains power to the amplifier.

2. Mains power LED

Mains power LED Mains power LED

Mains power LED – illuminates when AC power is applied to the amplifier.

3. Low impedance 2 Ohm LED

Low impedance 2 Ohm LED Low impedance 2 Ohm LED

Low impedance 2 Ohm LED – indicates when the 2 Ohm load setting is selected.

4. Mute LED

Mute LED Mute LED

Mute LED – illuminates when the channel is muted.

5. Mute switch

Mute switch Mute switch

Mute switch – disconnects the output of the relevant channel from the loudspeaker

load.

6. Gain

Gain Gain

Gain – rotary encoder which allows the gain of the channel to be adjusted.

7. LED ladder

LED ladder LED ladder

LED ladder – displays that channel’s output drive level. The bottom (green) LED is set at

–25dB, and the top (red) LED is set at 0.25dB below true clip level.

8. Limit LED

Limit LED Limit LED

Limit LED – illuminates when the channel is clipping.

9. Fault LED

Fault LED Fault LED

Fault LED – indicates when the DC and/or short circuit protection has been activated.

10. Link switch

Link switch Link switch

Link switch – connects the inputs of channel A and channel B together.

11. Link LED

Link LED Link LED

Link LED – illuminates when channels a and B are linked.

12. Temp LED

Temp LED Temp LED

Temp LED – illuminates when the temperature of the output devices exceeds 90° C. At

the sme time the channel output will be reduced by 3dB.

13.

Bridged LED –

Bridged LED – Bridged LED –

Bridged LED – indicates when the amplifier bridged mode is selected.

Page 39

user manual

TFS-780

TFS-780 user manual

Page 39

Front Panel Functions TMC-1250

1. Mains power rocker switch

Mains power rocker switchMains power rocker switch

Mains power rocker switch – applies AC mains power to the amplifier.

2. Mains power LED

Mains power LED Mains power LED

Mains power LED – illuminates when AC power is applied to the amplifier.

3. Low impedance 2 Ohm LED

Low impedance 2 Ohm LED Low impedance 2 Ohm LED

Low impedance 2 Ohm LED – indicates when the 2 Ohm load setting is selected.

4. Mute LED

Mute LED Mute LED

Mute LED – illuminates when the channel is muted.

5. Mute switch

Mute switch Mute switch

Mute switch – disconnects the output of the relevant channel from the loudspeaker load.

6. Gain

Gain Gain

Gain – rotary encoder which allows the gain of the channel to be adjusted.

7. LED ladder

LED ladder LED ladder

LED ladder – displays that channel’s output drive level. The bottom (green) LED is set at

–25dB, and the top (red) LED is set at 0.25dB below true clip level.

8. Limit LED

Limit LED Limit LED

Limit LED – illuminates when the channel is clipping.

9. Fault LED

Fault LED Fault LED

Fault LED – indicates when the DC and/or short circuit protection has been activated.

10. Link switch

Link switch Link switch

Link switch – connects the inputs of channel A and channel B together.

11. Link LED

Link LED Link LED

Link LED – illuminates when channels a and B are linked.

12. Temp LED

Temp LED Temp LED

Temp LED – illuminates when the temperature of the output devices exceeds 90° C. At

the sme time the channel output will be reduced by 3dB.

13. Bridged LED

Bridged LEDBridged LED

Bridged LED – indicates when the amplifier bridged mode is selected.

O

I

Page 40

user manual

TFS-780

TFS-780 user manual

Page 40

Remote

Input Output

Fuse 10 Amp Anti-surge

Bridged

WARNING

Replace fuse with same

Do not expose this unit

Stereo

Channel AInputOutput Channel B

Pin.2.

Pin 3

Pin 2

Pin 3

+

-

+

_

+

_

+

_

2/4

4/8

Link Link

o

a

d

L

ohms

ohms

Volts.AC

Pin 1 GND. Pin 1 GND.

Made in EnglandMC 2Audio Ltd

This unit must be earthed.

Shock hazard - do not

to moisture.

type only.

remove covers.

(mono)

Serial No.

2(4)

+

-

Reset

B

230VAc

OUTPUT

+

-

Channel B

LINKED INPUTS

MC AUDIO LTD

2

Do not expose this unit to moisture.

Shock hazard - do not remove covers.

This unit must be earthed.

WARNING

MADE IN ENGLAND

LINKED INPUTS

Channel A

bridged mode, value in brackets ().

NOTE: Impedanc es double in

ohms

4(8)

ohms

Bridged

(mono)

Stereo

O

A

D

L

+

A

Remote

OUTPUT

+

-

Rear Panel Functions

1. Loudspeaker terminals