Turbosound Flex Array TFA-600HW, Flex Array TFA-600HDP, Flex Array TFA-600L, Flex Array TFA-600B, Flex Array TFA-600HWDP User Manual

...Page 1

TFA-600H

TFA-600HW

TFA-600L

TFA-600B

TFA-600HDP

TFA-600HWDP

TFA-600LDP

TFA-600BD

USER MANUAL

Turbosound Ltd.

Star Road, Partridge Green

West Sussex RH13 8RY United Kingdom

Tel: +44 (0)1403 711447 Fax: +44 (0)1403 710155

web: www.turbosound.com

Issue 1.0 © Turbosound Ltd

Page 2

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 2

Contents

USER MANUAL ......................................................................................................................................................... 1

Contents ..................................................................................................................................................................... 2

Page 3

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 3

Page 4

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 4

Turbosound Limited ................................................................................................................................................ 83

Page 5

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 5

EC Declaration of Conformity

Manufacturer: Turbosound Ltd, Star Road, Partridge Green, West Sussex, RH13 8RY

Products:

TFA-600H

TFA-600L

TFA-600HDP

TFA-600LDP

T-25 Power Amplifier

T-45 Power Amplifier

T-475 Power Amplifier

LMS-D26 Controller

LMS-D24 Controller

Standards:

Safety EN60065:2003

Relevant Specifications used as basis for tests EN66103-1:1996

EN55103-2:1996

Category

Professional apparatus for use in Commercial Light Industrial and controlled EMC

environments.

CE Marking

All products are marked in accordance with the relevant statutory requirements.

Page 6

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 6

Introduction

Congratulations, you have purchased a professional loudspeaker product from the FLEX

ARRAY series of loudspeakers, designed to give you the best in audio quality and many years

of reliable, trouble-free operation. It offers excellent pattern control, safe and practical rigging

hardware, superior audio quality, proven reliability, self-powered options, full technical

documentation including EASE data, and the backing of a world leader in acoustics

technology including a comprehensive warranty against manufacturing defects. Please read

through this manual carefully before you attempt to operate the loudspeaker system. It

contains valuable information which will enable you to quickly and easily connect the

loudspeakers to your amplifiers and outboard equipment; important system and set-up

checks; and flying and stacking instructions.

Thanks

Thank you for choosing a TURBOSOUND loudspeaker product for your application.

By engaging in an on-going rigorous program of research and development all

TURBOSOUND products are carefully engineered for world class performance and reliability.

If you would like further information about this or any other TURBOSOUND product, please

contact us. Detailed product information is available on our web site at:

www.turbosound.com

We look forward to helping you in the near future.

Unpacking

After unpacking the unit please check carefully for damage. If damage is found, please notify

the carrier concerned at once. You, the consignee, must instigate any claim. Please retain all

packaging in case of future re-shipment.

Page 7

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 7

Flex Array Concepts

The Flex Array system is a modular flexible array loudspeaker system designed to deliver

extremely high fidelity audio in a range of medium scale fixed and portable sound

reinforcement applications.

Flex Array combines elements of line array theory and virtual point source theory in one

loudspeaker product, and for the first time offers virtually unlimited flexibility in adapting to a

huge variety of venue types and audience areas.

The Polyhorn™ Concept

The patented Polyhorn™ effectively solves several of the problems associated with

conventional exponential horns: namely the tendency to „beam‟ with increasing frequency;

and the undesirable comb filtering effects generated between adjacent devices due to the

variable curvature of the wavefront caused by the horn‟s geometry.

The Polyhorn™ is split into multiple cells, or individual „hornlets‟, which connect the

diaphragm to the horn mouth. Dividing the multi-cellular horn into multiple tapered

waveguides guarantees that the path length of each micro-horn is equal from the surface of

the driver diaphragm to the horn mouth, and ensures that all frequencies from all parts of the

diaphragm arrive at the horn mouth together. This provides the wavefront with uniformity of

phase.

The Polyhorn™ geometry ensures that the sound wave does not suffer from edge-diffraction

effects which have a tendency to confuse the directionality of the sound source.

Each cabinet in an array containing Polyhorn™ devices contributes to the generation of a

single, cohesive, and more or less continuous wavefront without noticeable comb-filtering

effects. In addition, the Polyhorn design offers the possibility of locating the acoustic centre

well behind the motor system and even the enclosure.

The Polyhorn™ devices exhibit a sharp cut-off at the edges of the dispersion pattern, making

it possible to achieve seamless coverage of a venue with minimal destructive interference

between elements, irrespective of how many individual enclosures are deployed in the

cluster. Because of the Polyhorn™ design‟s sharp cut-off, its array angle can in practice be

taken as being the same as the dispersion angle.

The Polyhorn™ design allows the extension of an application central to Turbosound‟s

philosophy – the use of cone drivers to cover mid-range (especially vocal) frequencies and

the freedom to apply relatively high crossover frequencies in order to minimise the distortion

common to metal-diaphragm compression drivers. The Polyhorn™ is employed in the high-

mid section of the Flex Array TFA-600H, loading a custom-designed 6.5” high power

neodymium drive unit.

Page 8

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 8

The Dendritic Horn

The patent-pending Dendritic HF horn utilises the same essential acoustic principle as is

employed in the Polyhorn: namely the application of equal path length hornlets to generate a

phase-coherent wavefront at the horn mouth. An extension of the principle allows the

Dendritic horn to act as the waveguide for a 1” throat compression driver, and key to the

operation of this new approach is the divide-by-two rule. Each section of the Dendritic

waveguide is split exactly two ways, ensuring that the signal in each leg is identical. In this

manner the output from a single compression driver is spread evenly across sixteen small

outputs.

Although adaptable to a range of output configurations, the Dendritic horn lends itself most

naturally to a slot output. By virtue of its tightly contorted pathways, the Dendritic creates a

very compact device, typically cutting 40% off the length of the external envelope.

The Flex Array Mid/High Waveguide

The Flex Array TFA-600 combines both Polyhorn and Dendritic horn technologies in a single,

physically aligned mid/high waveguide with equal path lengths, which produces a phasecoherent wavefront at the horn mouth. The Dendritic horn‟s compact dimensions allows the

high frequency driver to be located directly in front of, and mounted concentrically with, the

high-mid frequency driver. The horn‟s shallow geometry, comprising the combined horn and

the concentric mounting of the mid frequency and high frequency drivers, results in a very

compact enclosure with a depth of only 560mm (22”). This is beneficial both for keeping

cluster footprint small and is also a convenient dimension for trucking.

The combined waveguide is square in section, allowing it to be rapidly and easily removed

and rotated within the enclosure to suit the intended application. In this way the 75°

horizontal by 16° vertical coverage pattern can be readily transposed relative to the

orientation of the cabinet.

Page 9

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 9

The Loudspeaker Management System (LMS) Concept

Turbosound Loudspeaker Management Systems are more than just electronic crossovers. As

well as steep slope active filters and high performance limiters, they provide full digital

alignment of all components in the loudspeaker enclosures, to ensure coherent acoustic

output. They also incorporates a number of features which contribute to overall system

reliability and ease of setting-up and use.

All system parameters such as crossover frequencies, limiter settings, and equalisation can

be simply called up from a factory-preset menu, making it possible to maintain consistent

and repeatable system performance.

Because the power amplifiers can be included as part of the audio system, the controllers

utilise output limiters which are matched to the system requirements, being preset to prevent

the amplifiers from clipping under normal operating conditions. Inputs and outputs are fully

balanced, providing isolation between the controller and the amplifier inputs. These factors

contribute to high reliability in the adverse circumstances often encountered under arduous

touring conditions.

In addition, LMS-D2X series controllers are equipped with built-in network capability,

allowing maximum control and flexibility over the loudspeaker system‟s performance and

security.

LMS-D2x Loudspeaker Management Systems

Use of Turbosound loudspeaker management systems ensures accurate time-alignment of

the system drive units and also provides a facility for users to select additional delay, either

to compensate for physical displacement of ground-stacked bass enclosures relative to flown

high packs, or to provide full range delay for correct image localisation or use in distributed

systems.

Page 10

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 10

Power Amplifiers

In addition to the Turbosound T-series amplifiers recommended for use with Flex Array

systems, the following other power amplifier brands provide sufficient performance and

mechanical compatibility to perform well with Flex Array loudspeaker systems:

MC2 E series

Lab Gruppen FP series

Crest Pro series

QSC Powerlight II series

Digital Controllers

In addition to the Turbosound LMS-D24 and LMS-D26 loudspeaker management systems, the

following digital crossover has been tested and is recommended for use:

XTA 4 series controllers

Self-Powered Loudspeakers

Flex Array series cabinets are optionally available with integrated networkable Class D

amplifier modules in a self-powered format, taking consistent performance and ease of use

to a new level. Featuring lightweight high-power amplifiers using 96kHz DSP and operating

at better than 90% efficiency, self-powered Flex Array products eliminate the need for

separate amplifier racks and controllers, as well as the attendant cabling.

Due to their extremely high efficiency and modern, high performance power supplies, the

amplifier module only adds a few kilos to the overall net weight of the loudspeaker.

The sophisticated DSP allows multiple internal preset recall either via the rear panel or over a

remote link.

Self-powered loudspeakers can be conveniently controlled and monitored over a network

with a PC running TurboDrive™ software.

Class D amplifier modules can be retrofitted to non-powered enclosures in place of the

Speakon connector panel, providing a quick and effective upgrade path.

Page 11

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 11

Model Information

TFA-600H Three-Way Loudspeaker

The TFA-600H is a compact, trapezoidal, modular three-way switchable tri-amped/bi-amped

loudspeaker. It combines a patent-pending Dendritic HF waveguide and a patented midrange

Polyhorn™ in a single physically aligned waveguide. This geometry allows the enclosure‟s

dispersion to be easily adapted to line array or virtual point source implementation.

The loudspeaker‟s 75° horizontal dispersion pattern maximises the direct sound field while

reducing reverberant energy. Two Flex Array columns arrayed at 55° provide an ideal 130° of

horizontal coverage for wider auditoriums or outdoor events.

Neodymium drive units are used throughout the product in order to achieve exceptionally

low net weight, making it convenient to transport, handle and rig. In addition the drive units

are symmetrically located within the enclosure, which contributes to the smooth and

consistent horizontal coverage. The upper crossover point is positioned at 6kHz, giving the

legendary Turbosound midrange power and clarity that is only possible from a paper cone

type transducer.

The enclosure has both vertical and horizontal flying systems integrated into the cabinet. The

horizontal system uses a simple and effective drop link mechanism which permits easy

positioning and angling of each cabinet within any given line array configuration. Enclosures

are equipped with captive biscuits for use with chain links in virtual point source clusters, and

with a range of flying yokes for rigging enclosures in point source applications.

The 15mm birch plywood cabinet is equipped with a perforate steel grille with foam backing,

and recessed handles on the sides, rear, top and bottom. A recessed rear panel carries two

parallel-linked Speakon NL8 connectors for input and loop-through connections.

TFA-600HW Wide Dispersion Three-Way Loudspeaker

A wide dispersion version of the standard TFA-600H, but with a wider 100°h x 16°v coverage

pattern. The cabinet is identically sized and features the same integrated flygear - making it

possible to either integrate the TFA-600HW in a cluster of TFA-600H cabinets (for example as

downfills at the bottom of the hang), or to fly these on their own to simply achieve a wider

Page 12

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 12

coverage. This model is quickly identified by the „W‟ legend visible through the window on

each side of the cabinet.

The mid/high section is rotatable to allow a swap of the horizontal and vertical coverage

patterns, and in this configuration the TFA-600HW also works well as a stage lip infill cabinet.

TFA-600HDP Self-Powered Three-Way Loudspeaker

The TFA-600HDP is a networkable, digitally self-powered, bi-amplified, trapezoidal three-way

enclosure combining a patent-pending Dendritic HF waveguide and a patented midrange

Polyhorn™ in a single physically aligned waveguide.

It features a new generation of innovative lightweight Class D amplifiers, utilising

revolutionary 96kHz DSP technology to give operating efficiency in excess of 90%. Two

independent amplifier channels power the LF and MF/HF drivers separately. Neutrik™

Powercon connectors provide mains input and output to permit powering of two further

cabinets, while 3-pin XLRs are used for input and parallel link signal connections. RJ45

network connectors enable multiple loudspeakers to be controlled and monitored over a

BVNet network using TurboDrive™ software.

The enclosure has both vertical and horizontal flying systems integrated into the cabinet in

order to facilitate simple and intuitive rigging with a minimum of external parts. The

horizontal system is used to create flown or ground-stacked line array configurations. The

vertical rigging system is used for single box and virtual point source applications. This

flexibility of use is made possible by the rotatable mid/high section.

TFA-600HWDP Wide Dispersion Self-Powered Three-way Loudspeaker

The TFA-600HWDP is a wide dispersion networkable, digitally self-powered, bi-amplified,

trapezoidal three-way enclosure combining a patent-pending Dendritic HF waveguide and a

patented midrange Polyhorn™ in a single physically aligned waveguide.

It features two independent Class D amplifier channels powering the LF and MF/HF drivers

separately. Neutrik™ Powercon connectors provide mains input and output to permit

powering of two further cabinets, while 3-pin XLRs are used for input and parallel link signal

Page 13

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 13

connections. RJ45 network connectors enable multiple loudspeakers to be controlled and

monitored over a BVNet network using TurboDrive™ software.

The enclosure has both vertical and horizontal flying systems integrated into the cabinet in

order to facilitate simple and intuitive rigging with a minimum of external parts. The

horizontal system is used to create flown or ground-stacked line array configurations. The

vertical rigging system is used for single box and virtual point source applications. This

flexibility of use is made possible by the rotatable mid/high section.

Page 14

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 14

TFA-600L Compact Horn-loaded Subwoofer

The TFA-600L is a compact, horn-loaded subwoofer enclosure designed to be flown or

ground stacked with TFA-600H enclosures. It consists of a single 18” neodymium drive unit

loaded with a TurboBass™ device in a birch plywood cabinet. The TFA-600L utilises the same

drive unit as the larger TSW-218 horn-loaded subwoofer and employs the same loading

techniques, so these two bass enclosures can be freely mixed in any application. The

proprietary 18” drive unit is the result of a development project that has produced a unique

neodymium motor system. The magnet system drives a dual-spider, split 4” voice coil which

provides linear BL (magnetic force) with displacement, ensuring optimum control from the

motor assembly and very low harmonic distortion, even at the excursion limits. The 4” voice

coil also results in a lower system moving mass than equivalent 5” units, resulting in higher

sensitivity and exceptional response to fast transient peaks.

The enclosure is equipped with an integrated flying system which enables it to be flown at

the top of a column of Flex Array loudspeakers using a simple conversion frame between the

bass enclosures and mid/highs. The same conversion frame is used to create a stable Flex

Array ground stack. A pole mount socket is provided for use with flying yokes.

The 15mm birch plywood cabinet is equipped with a perforated steel grille with foam backing

and recessed handles on the sides and back, and is supplied with heavy duty wheels in order

to aid trucking and handling.

A recessed panel at the rear of the cabinet carries two parallel-linked Speakon NL4MP

connectors for input and loop-through connections.

Page 15

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 15

TFA-600LDP Compact Self-Powered Horn-loaded Subwoofer

The TFA-600LDP is a compact, networkable, digitally self-powered, horn-loaded subwoofer

enclosure designed to be flown or ground stacked with Flex Array TFA-600HDP mid/highs.

It features a new generation of innovative lightweight Class D amplifiers, utilising

revolutionary 96kHz DSP technology to give operating efficiency in excess of 90%. A

Neutrik™ Powercon connector provides mains input and 3-pin XLRs are used for input and

parallel link signal connections. RJ45 network connectors enable multiple loudspeakers to be

controlled and monitored over a BVNet network using TurboDrive™ software. The enclosure

is equipped with an integrated flying system which enables it to be flown at the top of a

column of Flex Array loudspeakers using a simple conversion frame between the bass

enclosures and mid/highs. The same conversion frame is used to provide a stable Flex Array

ground stack. A pole mount socket is fitted for use with flying yokes.

The 15mm birch plywood cabinet is equipped with recessed handles on the sides and back,

and is supplied with heavy duty wheels in order to aid trucking and handling.

Page 16

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 16

TSW-218 Horn-loaded Subwoofer

The TSW-218 is a horn-loaded subwoofer incorporating Turbosound's patented loading

principles, designed for use in applications requiring accurate and powerful reproduction of

low frequency energy at very high levels. Its ability to reproduce program material with such

integrity makes the TSW-218 applicable for both fixed or mobile systems which require

energetic low frequency response without stress or enclosure corrective equalisation.

The TSW-218 incorporates the TurboBass™ device, which employs a high-velocity partial

horn-loading technique, giving precise cone control at high power levels. The proprietary 18”

drive units are the result of a development project that has produced a unique neodymium

motor system. The magnet system drives a dual-spider, split 4” voice coil which provides

linear BL (magnetic force) with displacement, ensuring optimum control from the motor

assembly and very low harmonic distortion even at the excursion limits. The 4” coil also

means a lower system moving mass than equivalent 5” units, resulting in higher sensitivity

and exceptional response to fast transient peaks.

The TSW-218 is capable of outstanding electrical to acoustic power conversion. Optimisation

of the stepped horn flare produces a dramatic increase in sensitivity when multiple units are

coupled.

Page 17

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 17

TSW-218DP Self-Powered Horn-loaded Subwoofer

The TSW-218DP is a digitally self-powered horn-loaded subwoofer incorporating

Turbosound's patented loading principles, designed for use in applications requiring accurate

and powerful reproduction of low frequency energy at very high levels. Its ability to

reproduce program material with such integrity makes the TSW-218DP applicable for both

fixed or mobile systems which require energetic low frequency response without stress or

enclosure corrective equalisation.

The TSW-218DP features a lightweight Class D amplifier, utilising revolutionary 96kHz DSP

technology to give operating efficiency in excess of 90% and delivering 2500 watts in bridge

mode with abundant headroom into the two LF drivers. Four selectable presets provide a

choice of crossover points and delay settings depending on application. A Neutrik™

Powercon connector provides mains input and 3-pin XLRs are used for input and parallel link

signal connections. Two RJ45 network connectors are provided.

The TSW-218DP incorporates the TurboBass™ device, which employs a high-velocity partial

horn-loading technique, giving precise cone control at high power levels. The proprietary 18”

drive units are the result of a development project that has produced a unique neodymium

motor system. The magnet system drives a dual-spider split 4” voice coil which provides

linear BL (magnetic force) with displacement, ensuring optimum control from the motor

assembly and very low harmonic distortion even at the excursion limits. The 4” coil also

means a lower system moving mass than equivalent 5” units, resulting in higher sensitivity

and exceptional response to fast transient peaks.

The TSW-218DP is capable of outstanding electrical to acoustic power conversion.

Optimisation of the stepped horn flare produces a dramatic increase in sensitivity when

multiple units are coupled.

Page 18

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 18

Network Capability

Self-powered Flex Array loudspeaker systems are supplied with built-in network functionality

– enabling fast, intuitive control and monitoring of all networked devices via the BvNet

protocol using Turbosound‟s TurboDrive™ software. Flex Array features brand new DSP,

offering multiple internal preset recall via the rear panel or by a remote link.

LMS-D2x series controllers are equipped with network cards as standard and are preconfigured with factory programs for all non-powered Flex Array models.

TurboDrive™ offers user control of input EQ, delay and mute, although key factory settings

such as limiting and driver correction are locked out on DP models to maintain consistent

voicing and driver protection while ensuring maximum flexibility of use.

Single controllers are connected via RS232, while multiple units (controllers or self-powered

loudspeakers) are connected to a PC via a simple BVNet USB adapter.

TurboDrive™ Quick Reference Setup

The following is a quick reference setup guide for networked systems. For more detailed

setup instructions please refer to the TurboDrive™ User Guide, available as a pdf download

from our ftp site ftp://ftp.turbosound.com/downloads/tech_data/software/turbodrive.

Computer System Requirements

Minimum system requirements are as follows:

PC with Pentium processor

Windows NT, 2000, XP or Vista

CD ROM or internet access

RS232 or USB port

The TurboDrive™ software is available from the CD supplied with your BvNet interface, or as

a download from our website at www.turbosound.com. We recommend that you always

check the website for the latest version of the software.

Hardware Requirements

In addition to a desktop PC or laptop as described above, the following equipment is required

in order to assemble a system network:

Linea Research USB & RS232 Interface (available from Turbosound, stock code

16F0005)

Linea Research Accessory Power Supply (optional, available from Turbosound, stock

code 15F0010)

Page 19

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 19

CAT5 type network cables

Self-powered loudspeaker(s) OR

Loudspeaker(s) AND LMS-D24 or LMS-D26 loudspeaker management system(s)

To create a network follow the steps below:

1. Install the TurboDrive™ software

from the CD supplied or download from the Turbosound website

ftp://ftp.turbosound.com/downloads/tech_data/software/turbodrive.

2. Install the drivers

If you are connecting via RS232 there is no need to install drivers. If you are

connecting via a USB port install the drivers which can be found on the CD that was

supplied with your Linea Research BvNet interface.

3. Connect a LMS-D2x loudspeaker management system to a PC

BvNet is the method of connecting multiple devices over a network, and this is done

with the Linea Research USB & RS232 Interface (available from Turbosound) which

enables devices to be connected either using RS232 or the RS485 standard carried

over CAT5-type cables.

Using RS232

Connect your computer to the RS232 port on the BvNet interface using a standard 9pin serial cable. External power is required for RS232 operation and this should be

supplied by the Linea Research Accessory Power Supply System.

MALE-FEMALE

SERIAL EXTENSION CABLE

RS-232

RS-232

BVNET INTERFACE POWER SUPPLY

CONTROLLER

CONTROLLER

USB

IN LINK

IN LINK

IN LINK

Page 20

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 20

4. Using USB

Connect your computer to the BvNet interface using a USB Type A to USB Type B

cable. External power is not required when using USB.

5. Connect network devices in a simple daisy-chain fashion with CAT5 type cables in

the order you want them to appear in the devices window.

6. Launch the TurboDrive™ software

On the first launch, the application will prompt for an authorisation code. The code

is PJLUWZ

7. Select the COM port from Network > Com Port

8. Click the Online toolbar button

9. Click on one of the devices that appear in the tree view to Launch the Panel

RS-232

USB

BVNET INTERFACE

CONTROLLER

CONTROLLER

USB

IN LINK

IN LINK

IN LINK

Page 21

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 21

GigMate™ Acoustic Simulation

While the Flex Array System is remarkably intuitive in terms of building arrays and aiming

them – and requires no theoretical calculations in order to achieve optimum coverage of a

room or audience space – there may well be situations where some prior knowledge of a

venue can save time in setting up and configuring the PA. In order to aid in this process,

Turbosound offers the GigMate™ software acoustic simulation package, a version of the

generic EASE Focus program that is based on current EASE 4.1 data.

GigMate™ provides an accurate elevation representation of sound pressure level and

coverage of a room, given the dimensions of the audience areas and location of available

rigging points in the venue. The database allows for the creation of flown clusters, or for

ground stacked arrays, of TFA-600H mid/high and TFA-600L bass enclosures.

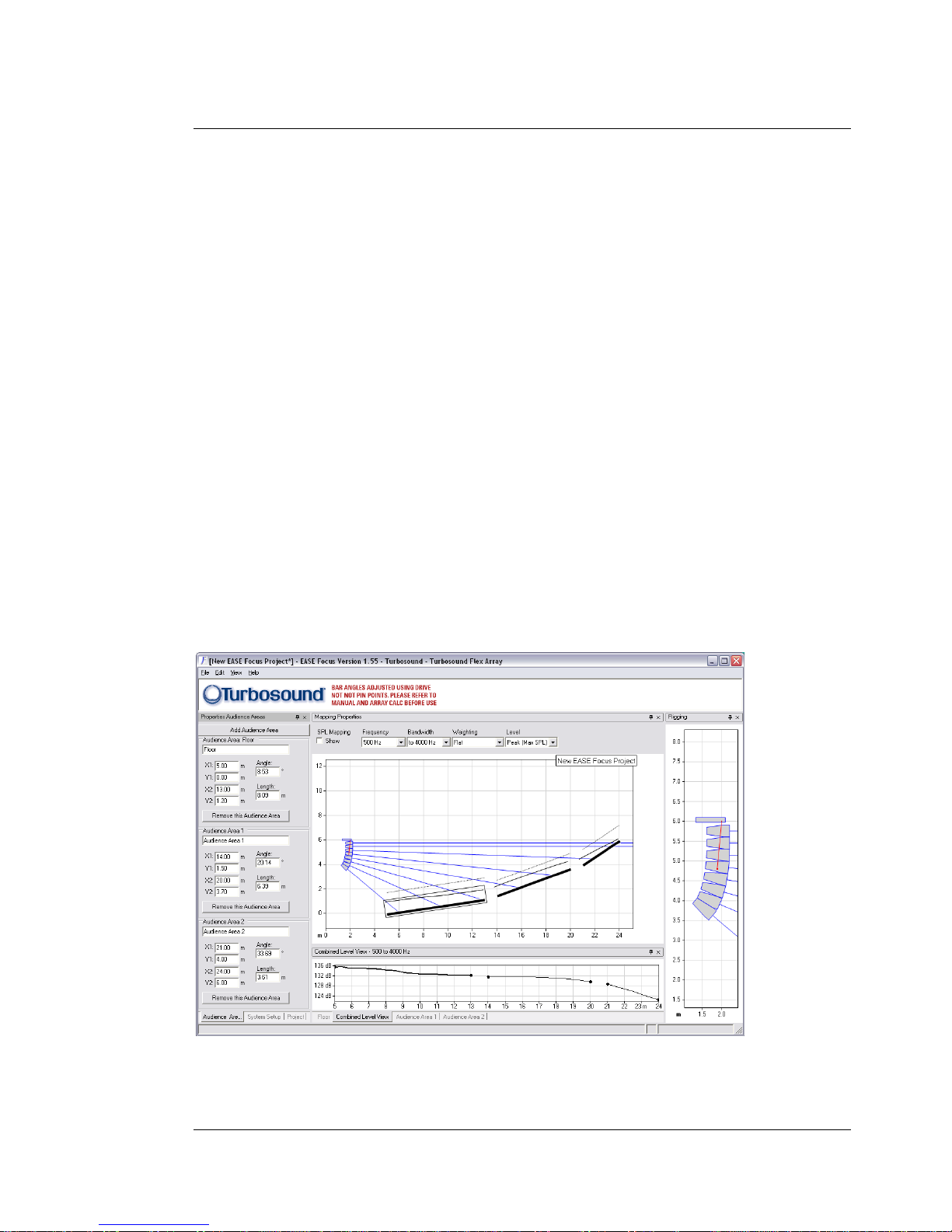

Setting up a Venue - Overview

The Audience Area window provides a way to add or remove Audience Areas and define

their location in the space. A venue can be selected from a range of standard venue presets,

or set up from scratch using the X and Y co-ordinates menus to define the location, size and

angle of the listening areas.

The PA is set up by choosing either a flown cluster or ground stack. Box count, cluster

position, tilt angle and splay angle can all be selected independently.

The mapping properties allow the user to select frequency bands from 125Hz to 8kHz, and

also bandwidth from one-third octave to broadband. Weighting and level can also be

selected here.

Once mapped to achieve satisfactory room coverage and level, results can be saved and

printed as a .rtf file. The program will also calculate the total weight of the cluster as well as

its overall physical size.

Page 22

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 22

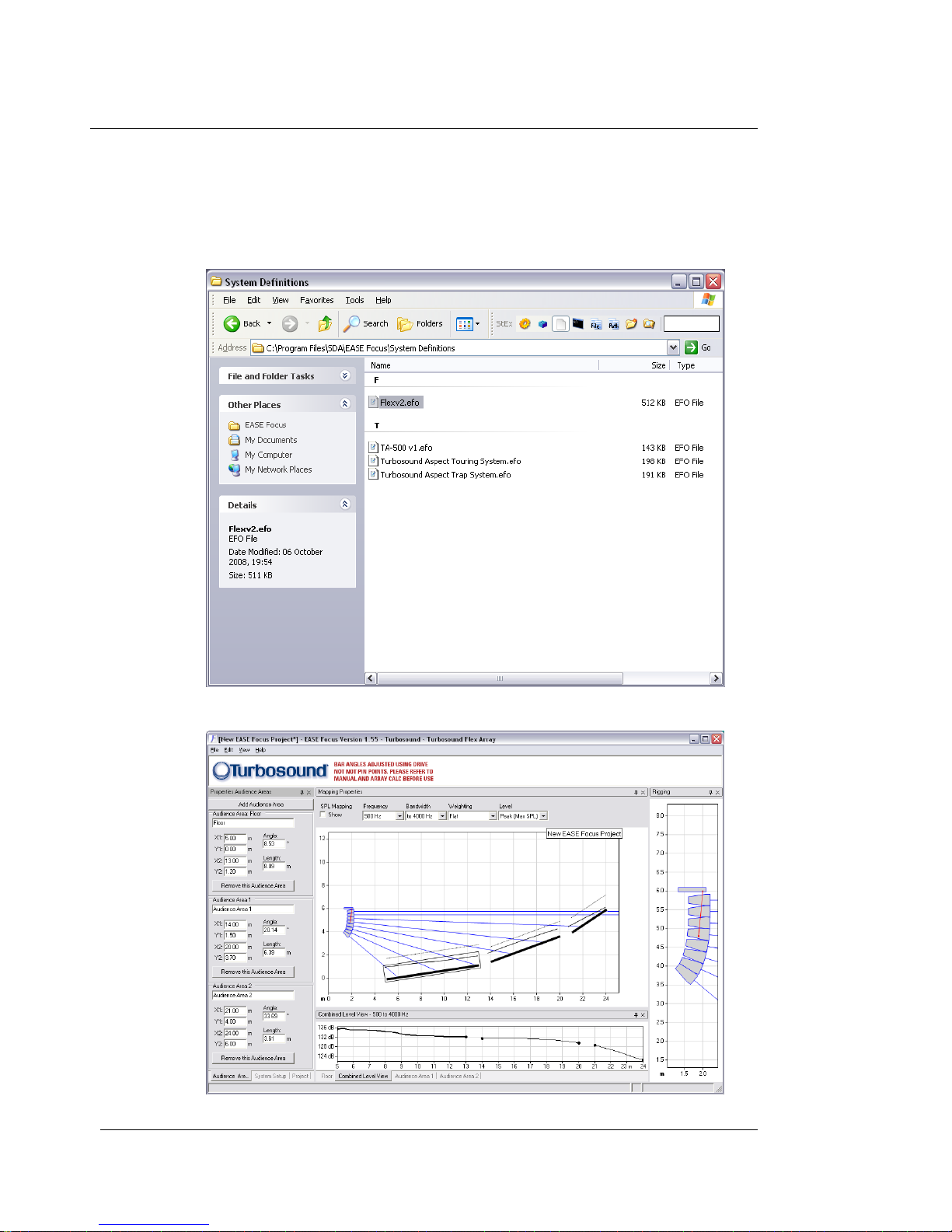

Running Turbosound GigMate™ for the first time:

When you first start the program you must set the system file that it is to use. The installation

files include the Flex Array file, as well as the Aspect TA-500 file and two Turbosound Aspect

TA-890 Touring System files as shown below:

Select the Flexv2.efo file . You will now be presented with the GigMate™ main screen:

Page 23

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 23

The screen is split into four main areas:

System Setup

The left hand side of the screen is where you define the system, auditorium and project. Tabs

on the bottom of this window allow you to toggle between the three modes.

Mapping Properties

This is the main window which will display the system as configured in the System Setup

window, along with the audience areas and mappings.

Audience Area

Beneath the main Mapping Properties window this graphically displays the SPL on each

audience area, or across a combination of audience areas.

Rigging

The far right window shows the detail of the system configuration, and is especially useful in

larger venues where the speakers shown in the main window become very small.

Designing a System

To design a system begin by defining the venue/audience areas by clicking on the “Audience

Area” tab in the bottom left of the screen.

Within this window you can edit or remove existing audience areas, and create new ones.

Page 24

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 24

There are two methods of defining an audience area. In either case you must define the

X1/Y1 coordinate of the start of the area; you can then either enter the X2/Y2 points or its

length and angle.

As you create audience areas they are shown graphically in the main window.

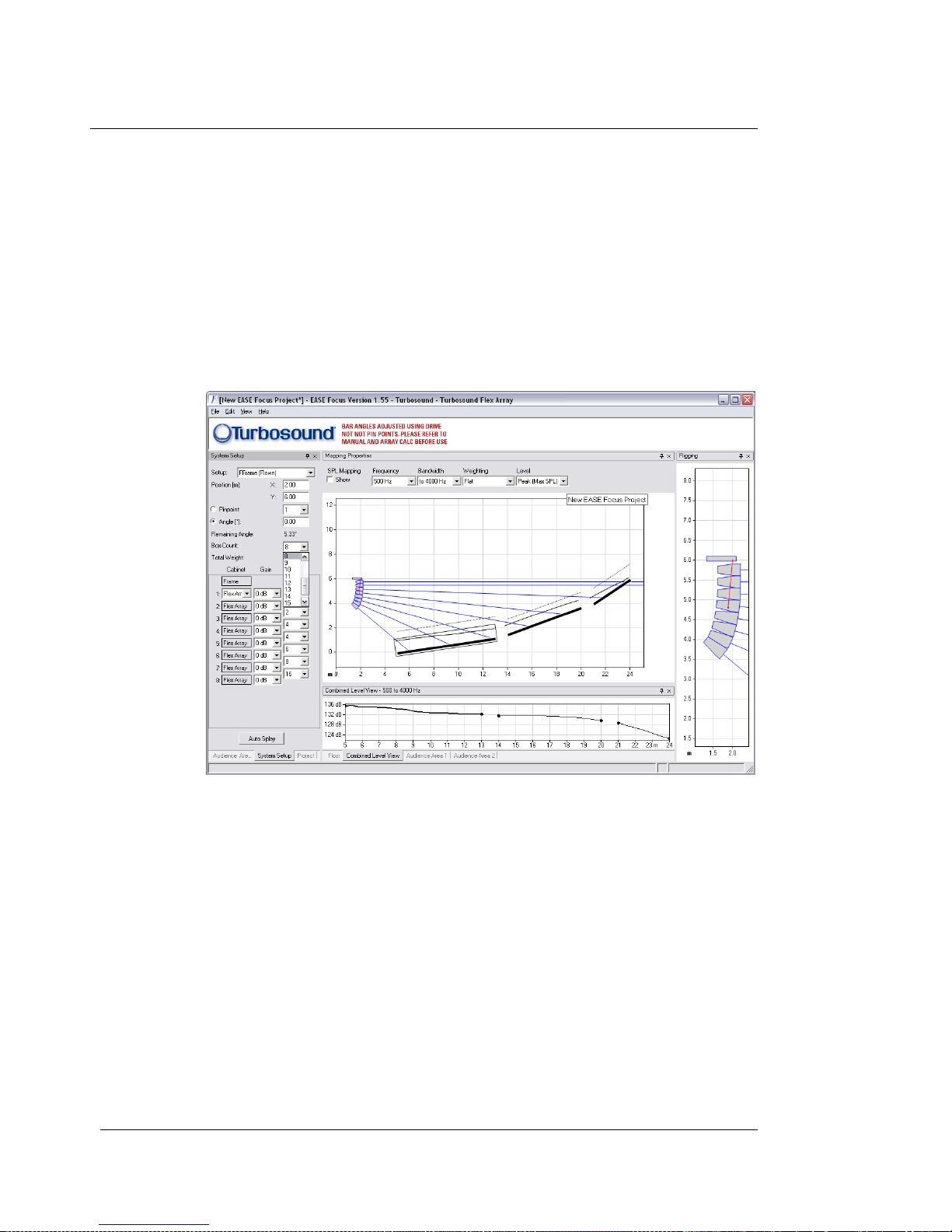

Desiging the Loudspeaker Array

The next step is to design the loudspeaker array using the “System Setup” window. Select

the “System Setup” tab in the bottom left of the screen and begin by choosing the desired

flybar or ground stack in the drop down box at the top left of the window.

Now select the number of cabinets deep that you wish to hang or stack from the “Box Count”

drop-down menu. Trim height or PA wing height can now be set in the “Position” field.

If a mix of Low and High cabinets are to be used then select in the “Cabinet” window the

type and location in the array of each box. The angle between cabinets can now be set in the

“Angle” list. Each cabinet has an aiming line that can be used to determine the centre of each

cabinet‟s dispersion. Adjust the trim height, top angle and inter-cabinet angle to achieve

optimum coverage.

Page 25

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 25

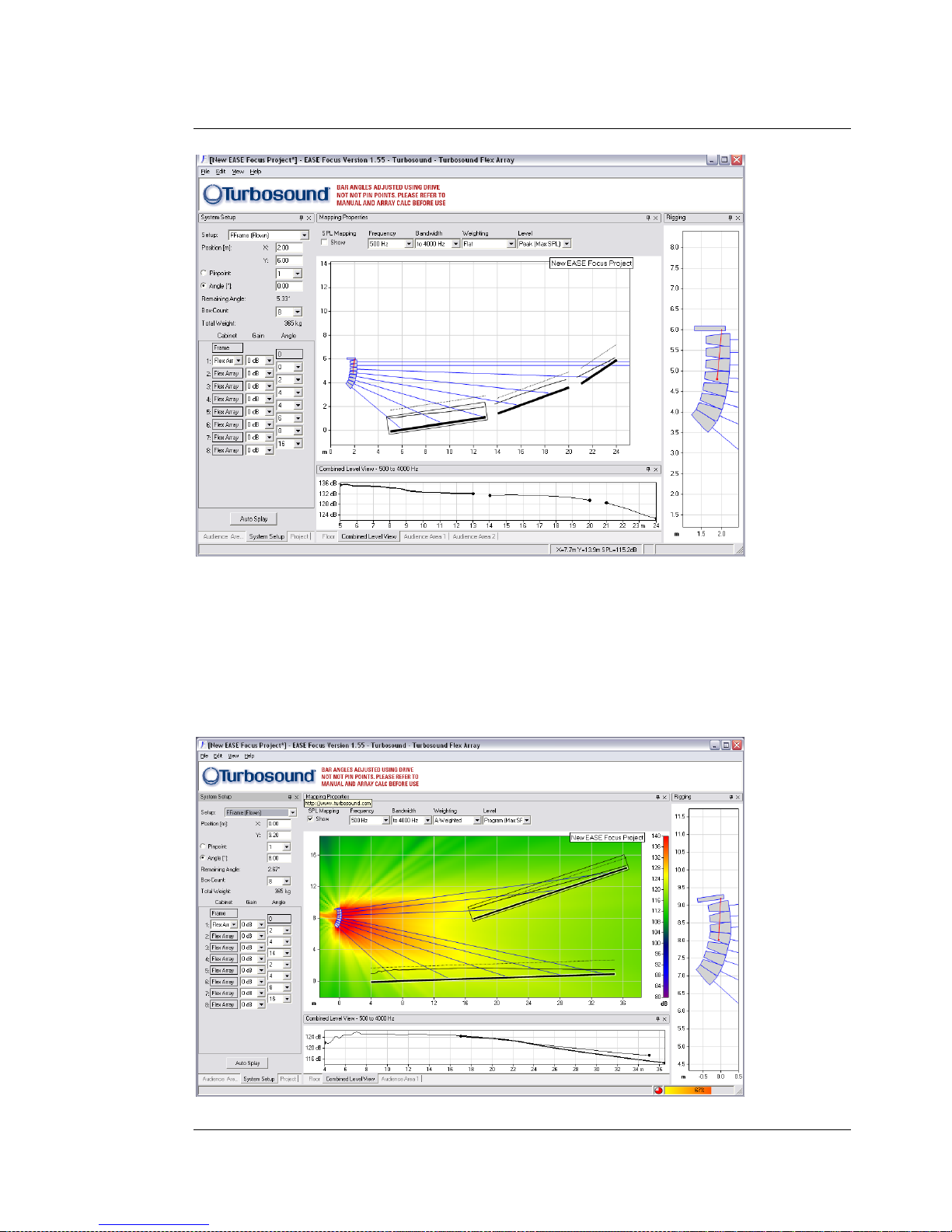

Now that the general design has been established the system performance must be mapped.

At the top of the main window there is an “SPL Mapping” checkbox. This will map the

system output at the frequency and bandwidth selected in the adjacent dropdown boxes. For

most applications a one-third octave weighted mapping gives realistic and useful data.

System Mapping Performance

Page 26

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 26

The Audience Area graph at the bottom of the window shows the SPL, as specified in the SPL

Mapping lists, on the selected Audience Area. The selected area is highlighted in the main

window and the graph is repeated onto each area. Selecting the “Combined Level View” tab

will show the SPL across all areas simultaneously.

Now that the system is mapped, the inter-cabinet angles or row attenuation may be trimmed

to provide the smoothest coverage. Typically the bottom cabinets of the system will require

some attenuation and should be on their own “Amp way” to achieve this.

Changing the System

GigMate™ currently includes Flex Array TFA-600 systems, as well as Aspect Touring TA-890

series, trapezoidal TA-880 series and TA-500 wide dispersion series products. To switch

between systems use Edit/Change System on the menu bar and select from the list.

Page 27

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 27

Some typical examples are shown here.

Theatre-style venue

Ground stacked system with bass enclosures

Page 28

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 28

Flown system with bass enclosures

Festival system

Page 29

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 29

Tri-amp / bi-amp configuration

TFA-600H enclosures can be configured either in fully tri-amped mode, or bi-amped with

passive HF. They are shipped from the factory as standard in tri-amped mode, although

changing from one to the other is a simple case of changing the position of a jumper located

behind the connector panel.Please note that the rear flygear must be removed in order to

access the conector panel.

1. Remove the four M6 button-head screws securing the rear panel.

2. The default jumper position as shipped from the factory is TRI-AMP (as shown above

right).

3. For TFA-600HW wide dispersion products relocate the jumper from the TRI-AMP PCB

header to the centre position (BI-AMP „HW‟ HORN) as shown below left.

4. For TFA-600H narrow dispersion products relocate the jumper to the extreme left position

(BI-AMP „H‟ HORN) as shown above right.

5. Replace the rear panel, replace the flygear and phase check the cabinet before operating.

Page 30

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 30

Transportation

FT-600/3 Transport Case

The FT-600/3 transport case allows a block of three TFA-600H speaker cabinets to be

conveniently transported in a pre-rigged configuration, and is recommended as the most

efficient way to truck and handle the cabinets. The transport case is wide enough to allow the

ball-lock pins to be inserted in the flygear whilst in the case – and therefore makes it possible

to lift the block of three cabinets together – while still being dimensioned to fit three-across in

a standard truck.

Cabinets must be set with 0° intercabinet angle while in the case for

transportation, although the desired

cluster angles may be easily set

once the block of cabinets is lifted

out of the case. The use of the FT600/3 makes for a very quick and

repeatable set up.

Page 31

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 31

Flying and Stacking

Overview

To take full advantage of the extremely flexible properties of the Flex Array system, two

modes of rigging system have been developed and are both fully integrated into the

enclosure. The two rigging systems allow either line arrays or virtual point source clusters to

be assembled – intuitively, quickly and easily, and with an absolute minimum of additional

external parts to suit the coverage requirements of a huge variety of professional sound

reinforcement situations.

The flying systems are inherently safe, flexible, self-contained and simple to use. The load is

taken entirely through the flygear and not through the cabinet‟s woodwork. The rigging

design allows the creation of clusters and arrays that can be assembled quickly and with a

minimum number of crew, and with full control of the vertical angles between enclosures

and the overall cluster inclination.

Safety Notes on Rigging

The Turbosound rigging system has been designed and constructed to a high

standard of safety, and tested to the most demanding of specifications. In order

to ensure the highest safety standards, the information following on the

assembly and safe use of rigging accessories must be carefully understood and followed.

Only use Turbosound recommended rigging accessories, which are specifically designed for

their intended purpose. Do not use Turbosound rigging with other types or brands of

loudspeakers. This practice may compromise safety standards and Turbosound will not be

responsible for damage or injury so caused.

Do not modify the rigging accessories, or use them in any other way than that described in

this user manual. Rigging components supplied as part of a complete assembly are noninterchangeable and must not be exchanged with the component parts of any other

assembly.

The component parts of a Turbosound rigging accessory must only be assembled using the

fasteners and methods of assembly recommended in this manual. The use of fasteners and

methods of assembly not specified or approved by Turbosound may result in an unsafe

rigging assembly. Welding, or any other means of permanently fixing rigging components to

each other or to cabinet fixing points, is not allowed.

Page 32

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 32

Rigging assemblies must only be assembled using the appropriate parts and fixings as

specified in this manual using the specific mounting instructions. Rigging components or

assemblies must only be fixed to Turbosound loudspeaker cabinets using the cabinet fixing

points, assembly methods and fasteners specified in this manual and the specific mounting

instructions.

Walls, floors or ceilings must be capable of safely and securely supporting the actual load.

The rigging accessory used must be safely and securely fixed both to the loudspeaker and to

the wall, floor or ceiling.

When mounting rigging components on walls, floors or ceilings ensure that all fixings and

fasteners used are of an appropriate size and load rating. Wall and ceiling claddings, and the

construction and composition of walls and ceilings, all need to be taken into account when

determining whether a particular fixing arrangement can be safely employed for a particular

load. Cavity plugs or other specialist fixings, if required, must be of an appropriate type, and

must be fitted and used in accordance with the maker‟s instructions.

Use only the rigging accessory fixing holes indicated in this manual and the specific

mounting instructions to fix Turbosound rigging accessories to walls, floors or ceilings.

Where specified, the recommended maximum torque settings for screw fasteners must be

strictly complied with.

Secondary Safeties

Best practice dictates that all loudspeakers flown in theatres, studios or other places of work

and entertainment should (and where local laws apply), in addition to the principle load

bearing means of suspension, be provided with an independent, properly rated and securely

attached secondary safety.

Only steel wire ropes or steel chains of an approved construction and load rating may be

used as secondary safeties. Plastic covered steel wire ropes are not permitted for use as

secondary safeties.

Safety Inspections

Carefully inspect rigging systems components and cabinets for defects or signs

of damage before proceeding to assemble a flown array. If any parts are

damaged or suspect, DO NOT USE THEM.

Regular and more rigorous test and inspection of rigging components must also be carried

out. Safety legislation, and test and inspection requirements, will vary from country to

country. In most cases, annual independent test and inspection by a suitably approved and

Page 33

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 33

qualified inspector will be required. Users must ensure compliance with all applicable safety

requirements.

Turbosound recommends regular safety inspections and further recommends that a logbook

be kept detailing the test and inspection history of each Turbosound rigging accessory.

Turbosound has adopted the following load safety factors:

12 x load safety factor: Chains, ropes, shackles, eyebolts, straps and hooks.

5 x load safety factor: Accessories generally employed in fixed, permanent

installations.

Always wear protective headwear, footwear, and eye protection in accordance with local

regulations. Anyone involved in flying ANY sound system, especially in a touring capacity,

should take note of the following advice:

The rigging of a flown sound system may be dangerous unless undertaken by qualified

personnel with the required experience and certification to perform the necessary tasks.

Fixing of hanging points in a roof should always be carried out by a professional rigger and

in accordance with the local rules of the venue. The house rigger and/or building manager

must always be consulted.

Flying System components have been individually tested in accordance with

the following UK/EU regulations:

The Health and Safety at Work Act 1974

The Supply of Machinery (Safety) Regulations 1992

The Lifting Operations and Lifting Equipment Regulations 1998

Each component is covered by a Record of Load Test Certificate, which may be obtained on

request from Turbosound, quoting the identifying number(s) from the flying equipment.

Page 34

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 34

Rigging Hardware

Horizontal (‘A’ mode) Rigging System

Page 35

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 35

Rigging Components

The Flex Array „A‟ mode, or horizontal, rigging system includes all the necessary hardware

to enable vertical suspension of TFA-600 series cabinets from a single rigging point and

using only a single motor rated at 1 tonne.

The FB-600 adjustable lift point flybar supports the entire weight of the loudspeaker cluster

by engaging into the steel flygear rebated into the short sides of the loudspeaker enclosures,

whose integrated drop links locate into the flyware of the cabinet directly underneath to form

the pivot points about which cabinets are angled vertically. The drop links are secured in

position with captive ball-lock pins that stow into cabinet recesses for transportation. The

cabinet‟s rear drop link pivots down to engage in the clevis connection plate of the cabinet

below in several positions, which permits a range of inter-cabinet angle adjustment, in 2°

increments, from 0° to 16°.

FB-600 Adjustable Lift Point Flybar

The FB-600 is a T-shaped flybar that enables the suspension of TFA-600H mid/high and TFA600L low frequency loudspeakers up to an SWL of 700kg, and is used for the creation of

flown Flex Array line arrays. The frame is constructed from rectangular box steel section with

a unique formed rear spine containing a channel in which the lift point is located.

The movable lift point can be traversed along the length of the spine from front to rear by

means of a screw thread, which is turned by a 22mm (7/8”) socket driven by a speed brace or

hand held electric drill. The screw is located in polymer-sealed bearings requiring no

maintenance under normal operating conditions, and is designed to last the lifetime of the

product.

Page 36

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 36

Turning the drive nut on the end of the shaft tilts the load by varying the position of the

motor connection point relative to the centre of mass of the loudspeaker column. The lift

point position can be altered even when under load in order to obtain the desired final cluster

inclination.

The flybar‟s rear spine is provided with multiple locating holes along its length based on a

vernier scale adjustment. A captive 100mm (4”) ball-lock pin is used to lock the lift point‟s

position when one of the two holes in the lift point aligns with a fly bar locating hole.

Floating drop links at each end of the box section engage into the flygear of the TFA-600H

mid/high cabinet or TFA-600L low frequency cabinet, and are secured with captive 15mm

(5/8”) ball-lock pins.

Two cabinet connection drop link positions are provided at the rear of the flybar at the

correct spacing for attachment to either TFA-600L low frequency cabinets or TFA-600H

mid/highs.

The net weight of the FB-600 flybar is 25 kgs.

Important Safety Notes

To ensure continued safe operation of the FB-600 flybar the following points should be noted:

The BLP-10/100 100mm (4”) locking pin should always be fitted to lock the lift point

before lifting the flybar

Four ball-lock pins must be fitted to ensure the safe lifting of the cluster

Under no circumstances should hands be placed in the open top of the spine when the

flybar is in use

Two safety lug points are provided for attaching wire safety rope. No other part of the

flybar can be used for this purpose

Any components that are damaged should be repaired or replaced by qualified service

personnel only

In the extremely unlikely event of failure of the screw the safety and operation of the

flybar is not compromised

Page 37

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 37

BLP-600 Ball-lock Pins

These are provided in three sizes depending on application.

The BLP-8/15 is used to lock cabinets together at the side pivot points and, in

conjunction with the rear links, to set the vertical angles between cabinets

The BLP-10/35 is used to locate the rear drop links in the cabinet‟s clevis connection

plate

The BLP-10/100 locks the position of the lift point on the FB-600 flybar

Ball-lock pins are held captive by a lanyard either on the flybar or cabinet, and are normally

parked in a recess in the cabinet side, or on the flybar, when not in use to avoid the

possibility of losing them. They can only be used to engage with the box above, or with an

inter-cabinet coupler.

Rear Drop Link

These are supplied with each mid/high cabinet, and are used to set the inter-cabinet angle by

engaging in the clevis connection plate of the cabinet below. When not in use the rear drop

Page 38

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 38

link is stowed conveniently within the rear cabinet recess.

Page 39

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 39

CF-600 Conversion Frame

Used to interface between bass cabinets and mid/high cabinets in a flown column of Flex

Array loudspeakers. The conversion frame has a SWL of 520kg which enables a column of up

to a maximum of 12 TFA-600H cabinets to be suspended below it.

The CF-600 conversion frame also functions as a ground stacking frame, interfacing between

ground stacked TFA-600L bass cabinets and the mid-high cabinets positioned on top.

The net weight of the conversion frame is 11kg (24.2lbs)

Page 40

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 40

CF-600 Conversion Frame in a Flown Column

The conversion frame is fitted underneath the lowest TFA-600L low frequency cabinet in a

flown column as shown in the diagram below. TFA-600H cabinets are suspended from the

conversion frame using the captive ball-lock pins

Page 41

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 41

Connection to the first TFA-600H cabinet is made via two 10mm ball-lock pins which are

engaged into the rear spine of the mid/high cabinet (one pin is located on the loudspeaker

and one pin is located on the conversion frame).

The drop link from the TFA-600L low frequency cabinet is released by removing one of the

pins and pivoting the link into the conversion frame.

The drop link from the conversion frame locates into the clevis connection plate of the top

mid/high cabinet in one of several predetermined locations, which allows for a range of intercabinet angles.

Page 42

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 42

Ground Stacking with the CF-600 Conversion Frame

In this application the conversion frame locates on the top of a ground stacked bass

cabinet(s) and engages into the flygear of the first mid/high cabinet. The system allows for

the lowest mid/high cabinet to be tilted down by approximately 8°.

Page 43

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 43

Procedure for Flying a Column of Flex Array Loudspeakers

As described previously, the task of flying Flex Array cabinets is greatly simplified by the use

of the FT-600/3 transport case which allows three mid/high cabinets to be transported, prerigged and lifted out of the case in one block.

1. Having established the location of the rigging points, position the FB-600 flybar directly

underneath a fly point and check that the intended position of the cluster will give the

required coverage. Attach a chain motor to the lift point using the shackle provided. At

this point the lift point should be traversed so that it is approximately within the front half

of its travel.

2. Lift the flybar and position a FT-600/3 transport case underneath. Engage the flybar drop

links into the flygear of the first mid/high cabinet. Secure the drop links with the ball-lock

pins that are attached to each side of the first loudspeaker cabinet.

3. Lift the flybar together with the first three cabinets sufficiently to allow a further FT-600/3

transport case with three mid/high cabinets to be positioned underneath.

4. Locate the third cabinet‟s drop links into the flygear of the fourth cabinet and secure with

two BLP-8/15 ball-lock pins. Secure the rear drop link with a BLP-10/35 ball-lock pin.

5. Lift the flybar and continue to add cabinets either in blocks of three or singly as required

to complete the specified loudspeaker cluster.

6. Adjust the angles of the lower cabinets as you go, according to the cluster design; it is

much easier to do it now (lifting the weight of one or two cabinets by hand in order to

release the drop link and change its position) rather than trying to adjust cabinets in the

middle of a larger cluster.

7. Connect the NL8 speaker cables up the cabinets as you go along as well; they may not be

reachable later on. The cables will run neatly into the cable recesses in each speaker

cabinet.

8. The lowest cabinet‟s drop link is not used and should be parked in the rear woodwork

recess with a captive ball-lock pin as shown here.

Page 44

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 44

9. Adjust the overall inclination of the cluster using a speed brace or electric drill applied to

the 22mm (7/8”) drive nut at the rear of the flybar. An inclinometer may be used on the

flybar or the top cabinet to obtain a consistent angle between the left and right PA

clusters.

10. Lock the lift point with BLP-10/100 100mm (4”) locking pin before lifting the flybar into its

final position.

Page 45

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 45

LMS series Loudspeaker Management Systems

Introduction

This section is provided with the aim of assisting sound engineers, installers, and consultants

to fully understand Turbosound Loudspeaker Management Systems, and to obtain the full

benefit of their capabilities.

The Turbosound LMS-D26 and LMS-D24 are recommended for use with Flex Array

loudspeaker systems, offering varying features and facilities depending on the specific

application.

Unpacking

As part of Turbosound's system of quality control, the product is carefully checked before

packing, to ensure flawless appearance. After unpacking the unit, please inspect for any

physical damage. If any damage has occurred, please notify your dealer immediately, so that

a written claim for damages can be initiated. You, the consignee, must instigate any claim.

Please retain all packaging in case of future re-shipment.

There will be a small packet of spare fuses with the unit. Please keep them in a safe place.

Mechanical Installation

A vertical rack space of 1U (44mm / 1.75") is required for each unit. If used in a mobile or

transportable system, the unit must be supported at the rear by additional bracing or

shelving, to prevent vibration-induced metal fatigue of the racking „ears‟. Failure to do this

will impair reliability and invalidate the Warranty. The rack casing must have a depth of

425mm (minimum) to clear the connectors.

Adequate ventilation must be provided by allowing sufficient room around the sides and rear

of the unit to permit free circulation of air. Forced cooling is not required, a factor which aids

component longevity. The front of the unit should not be exposed to long term direct

sunlight as this can have a detrimental effect on the display lens.

Page 46

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 46

LMS-D24 and D26 Loudspeaker Management Systems

Features

Minimal signal path design, providing exceptional audio quality with carefully

optimised processing and high performance converters for a full >111dB dynamic

range, 96kHz sampling rate and minimal filtering. Audio-grade capacitors are used

in the analogue signal path.

Sonically superb ADC / DAC combination; a carefully matched pairing of the best

devices from Burr Brown and Wolfson.

Newly released family of Analogue Devices SHARC DSP.

Extended bandwidth; 96kHz sampling frequency provides for a nominally flat

response to 40kHz.

Front panel parameter rotary encoder provides a familiar and easy to use control

format with all filter information displayed simultaneously on a backlit LCD display.

Page 47

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 47

Front Panel Functions

2x 24 character

LCD

Input Signal

Indicators

Store and

Recall buttons

Channel Select

buttons

Parameter Edit

Encoders

Output Mute

buttons

Limiter

Indicators

Edit Parameter

Select buttons

Input Signal Indicators – A set of three pairs of LED‟s indicate signal present, +4dBu and input

clip for both channels. The signal present LED‟s operate at approximately –40 dBu, giving a

useful indication of even relatively low input signal levels. The +4 dBu LED‟s are intended to

show nominal operating level and can also be useful for setting system gain structure. Clip

LEDs warn the user of input overload and operate at +19 dBu.

Program Store and Recall – these controls provide access to 45 presets. Pressing the store

button allows the user to name a preset and choose which memory location it will be held in.

Pressing store button again completes the process. The Recall function operates in a similar

way, pressing the recall button allows the user to select which preset they require, pressing

the button for a second time, then confirming, recalls the new DSP settings. The unit allows

the user to set up user programs with full access to all parameters.

Note that presets cannot be stored or recalled when secure mode is activated.

Channel Selection Buttons – the currently selected channel is displayed on the top left hand

corner of the LCD. Pressing the channel buttons scrolls through the available input and

output channels and finally through the utility functions and back to the default screen. If

operating a stereo-linked preset the channel name will indicate the channel pairing. For

example „A+B‟ means both input A and B parameters. The name of the output will be shown

briefly at the top of the display when stepping onto an output.

Edit Select Buttons – the currently selected edit parameter is displayed on the bottom left

corner of the LCD. Pressing the edit select buttons moves through the available parameters

for the current input or output.

Page 48

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 48

Text display – preset, channel, parameter and status information is shown on the 2x 24character text display. In most screens the currently selected channel is displayed on the

upper line and the edit parameter on the lower line. To simplify the display and enhance

security, some parameters or parameter pages are omitted when not relevant.

Parameter Knobs – three velocity sensitive parameter knobs are used to adjust parameters

shown on the display. Up to three parameters are displayed on the screen. The parameter

name is shown above the parameter value in each of the three screen sections. The

parameter knobs have a fixed association with the screen sections; the rightmost parameter

knob adjusts the rightmost parameter and so on.

Output signal and limiter indication – two LED‟s are provided for each output channel. These

show the signal level relative to the limiter threshold. The yellow LED will light when the

signal is 6dB below the threshold and the red warning LED will light when the limiter

threshold is reached.

Mute buttons and status LED‟s – each output has a mute button and associated mute status

LED. Pressing the button toggles the mute on and off.

Note that the mute buttons do not function when the Secure Mode is activated.

Secure Button (on the rear) – a momentary button is fitted behind the rear panel, between

the output XLRs and the RS232 port. When activated, this will disable all the front panel

controls so they cannot affect the signal path, making the unit secure against tampering.

When in secure mode, the indicators still operate normally.

Note that the communications port is still active in secure mode.

Page 49

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 49

Rear Panel Functions

Power Inlet

Network Card

Audio Output

Connectors

Audio Input

Connectors

Secure Mode

Switch

Serial Comms

Port

Power Inlet – provides connection to a suitable mains electricity supply using the cable

supplied. The controller has a switch mode power supply that is capable of operating with a

nominal mains voltage of 80 to 240v, 50/60Hz without re-configuration.

Network card – connects to a PC via a BvNet interface to enable network control of the

loudspeaker system.

Audio Input connectors – these are fully balanced and are wired pin 1 ground, pin 2 hot and

pin 3 cold. The two inputs have pin 1 connected directly to the chassis and feed the signal

processing chains. If an unbalanced source is used, a connection should be made between

the pin 3 „cold‟ signal and the ground connection of the unbalanced source.

Audio Output connectors – the processed outputs are impedance balanced, and are wired

pin 1 ground, pin 2 hot and pin 3 cold. An unbalanced input may be driven by connecting pin

3 „cold‟ signal to the ground connection of the unbalanced destination input. Note that output

pin-1s are ground lifted at audio frequencies but connected to ground at RF for good EMC

performance. The intention being that the amplifiers the processor is driving should be

responsible for the grounding of their input cable shields.

Communications port connector – the unit may be controlled entirely from another

controller (typically a Personal Computer), running an application that is compliant with the

ObCom standard. Connection will normally be made to the controller via this serial port

connector. This port is also used for updating the firmware in the unit.

Note: The communications port is NOT disabled when the front panel is made secure using

the secure button.

Page 50

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 50

Operating the LMS-D24 and D26

Starting up

The unit will energise as soon as power is applied to the IEC inlet; there is no power switch.

During the start up process the firmware application model number and version numbers are

displayed and the outputs are muted until the unit has completed its internal checks. Once

the start-up routines are complete and the unit is ready to pass audio, the DSP signal path

will be restored to the current settings when it was last powered down and the audio signal

is gradually ramped up to its correct level.

Selecting a Factory Preset

There is a library of thirty Factory Presets to suit a range of Turbosound enclosures.

Factory Presets contain some parameters that are fixed and hidden from view; the remainder

of the DSP parameters are available for user manipulation. The number and type of hidden

parameters is dependant on the Factory Preset, typically crossover frequencies, output delay

and some EQs are hidden; those settings that are a function of the loudspeaker cabinet

design and should not require adjustment for different applications.

To recall a Factory Preset for a particular cabinet or system, press Recall and use the left hand

parameter knob A to scroll through the available factory preset locations (as indicated by a

box symbol after the preset number). Once the appropriate preset has been selected press

recall again, at which point you will be asked to confirm the action by pressing recall for a

third time. This is to guard against accidental recall of Presets.

Factory Presets are locked so they cannot be over-written. The user can, however, store an

edited version of a Factory Preset in any free preset location.

Details of all the Factory Presets can be found in Appendix A.

Creating a Crossover

In addition to the Factory Presets the unit has two further „Base Presets‟; mono and stereo.

These Base Presets are stored in locations 1 and 2 respectively, they can be used to develop

settings for any loudspeaker combination and are recalled in the same way as the Factory

Presets described above. These Presets are also locked but the user can name and store their

own edited versions in any free preset location.

Page 51

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 51

Navigation and Viewing Parameters

(Note: The LMS-D26 is shown in all the following screen shots; however the features and

parameters apply equally to the LMS-D24)

Many of the processing elements in each input and output path have features that may be

controlled by the user, such as gain, frequency or limiter threshold. We call these adjustable

features parameters.

A parameter may be adjusted when it is displayed by turning one of the three-parameter

knobs. Each of the three-parameter knobs is associated with a zone on the display. Adjusting

the leftmost parameter knob will change the value of the parameter showing in the leftmost

zone of the display and so on. Turn a knob clockwise to increase the value of a parameter, or

anti-clockwise to decrease it. The knobs are velocity-sensitive so turning a knob rapidly will

cause the action to „accelerate‟, so the value changes more rapidly.

Page 52

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 52

Navigation

The DSP parameters are organised by channel. The currently selected channel is shown in

the top left hand corner of the display. You can navigate between the channels by pressing

the channel buttons. Pressing the channel buttons will scroll through the channels, utilities

and back to the default screen. When using a Preset that is stereo linked, the channel

selection will reflect this. For example „1&4‟ indicates outputs 1 and 4. When navigating onto

an output channel, the usage of the output, as define in the factory preset, will be shown

briefly at the top of the screen.

Pressing the edit navigation buttons gives access to the various pages of parameters

available for each channel. The currently selected page is shown in the bottom left hand

corner of the display; this is omitted on some pages where the function is obvious. The

screen shows up to three (normally related) parameters for a given part of the processing

functions on a given channel.

The edit buttons allow you to scroll, in either direction, through the different processing

pages for a given Channel. When you go past the last page, you will be returned to the

default page.

The channel buttons allow you to scroll, in either direction, through the input and output

channels, whilst trying to maintain the currently viewed processing block. If the channel you

scroll to does not have the currently viewed processing block, the next one will be shown

instead.

NB. When the unit powers-up, the settings will be the same as those when the unit was last

switched off.

Page 53

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 53

Presets

The device contains a total of forty-five user and Factory Presets. The user cannot overwrite

the basic mono, basic stereo or Factory Preset programs.

Preset Recall

To select an existing Preset, press the Recall Button so the indicator above it illuminates.

Turn parameter knob A until the required Preset number is shown on the display. Factory

presets are indicated by a box symbol appearing after the preset number. Press the Recall

Button again to activate the Preset. Pressing any other button will cancel the operation.

Users can develop their own Preset based on one of the basic or Factory Presets stored

within the device. Once a basic or user Preset has been recalled, a user has complete

freedom to adjust any or all of the parameters. Factory Presets can be used as the basis for

user Presets but they have some parameters that are predefined as a function of the

loudspeaker system. These parameters are „hidden‟ from the user, as they should be constant

regardless of application.

Page 54

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 54

Preset Store

To store the current Preset in a user location, press the Preset Store Button so the indicator

above it illuminates. Turn the first parameter knob until the required Preset location number

is show on the display. A Preset name of up to 12 characters in length can be entered using

parameter knobs B and C. Pressing the Store Button again completes the process and stores

the Preset. As with Preset Recall, pressing any other button cancels the operation.

The user can overwrite non-protected Presets only; if an attempt is made to save a Preset in a

location already occupied by a basic or Factory Preset a „LOCKED PRESET‟ message is

displayed.

Page 55

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 55

DSP Processing Layout

Input DSP block diagram

Input A

Input

LED’s

Input

Gain

Delay

4th Order

HPF

Low

Shelf EQ

Six Band

PEQ

High

Shelf EQ

Routing

Input B

SUM - 6dB

NB. Channel B processing is

identical to Channel A but for

clarity it is not shown

Output DSP block diagram

Routing

Delay

8th Order

HPF

8th Order

LPF

Low

Shelf EQ

Six Band

PEQ

High

Shelf EQ

Output

Gain

Mute Limiter

Metering

Stereo / Mono Formats

There is only one „standard‟ layout of the processing blocks, but flexible routing and control

linking allows this layout to be adapted to a wide variety of applications.

There are two „Formats‟, Mono or Stereo. With the Mono format, all outputs have unique

parameter settings, and all outputs are identical in terms of processing functions and routing

capability. This is the most flexible Format.

Stereo format pairs the inputs and outputs for stereo operation, the parameters of each

member of the pair being identical. The routing of inputs to outputs is fixed. This format is

intended for symmetrical stereo operation, eliminating the need to make identical parameter

adjustments for each channel.

The channel pairing is:

Left and Right Inputs

Outputs 1 (routed from L input) and 3 (routed from R input) [1 and 4 for LMS-D26]

Outputs 2 (routed from L input) and 4 (routed from R input) [2 and 5 for LMS-D26]

Outputs 3 (routed from L input) and 6 (routed from R input) – LMS-D26 only]

Page 56

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 56

DSP processing

Input Channels

Gain

Knob A: Gain, adjustable in 0.2dB steps from –80 dB to +20dB

Delay

Knob A: Delay, adjustable in variable steps from 0 to 400ms

The delay parameter is adjustable in fine steps at low values; the adjustment becomes

progressively coarser as the value increases. The velocity sensitive Parameter Knobs

therefore provide accurate setting of driver offset delays (typically below 10ms) and rapid

setting of longer system alignment delays.

Page 57

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 57

High Pass Filter

Knob A: Frequency, out (off), 10.0Hz to 25.6kHz in variable steps

Knob B: high pass filter type

System high pass filtering is provided for the input signal. This is the preferred location for

high pass filtering as it affects all outputs and can therefore improve inter-band phase

relationships. Filter type is selectable from Butterworth, Bessel, Linkwitz-Riley and Hardman.

Filter slopes of up to 4th order or 24dB / octave are provided. Not all filter types are available

in all slopes. For example 18dB / octave Linkwitz-Riley filters do not exist.

The Hardman type filter is always described by its‟ order as the filter becomes progressively

steeper rather than following a linear slope so a dB/octave description is not accurate.

Page 58

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 58

Parametric Equalisation

Eight sections of equalisation are provided, two shelving filters and six fully variable

parametric sections.

High and Low shelving filters

Knob A: Frequency, 10.0Hz to 25.6kHz in variable steps

Knob B: Slope, 6 to 12dB / octave in 1dB steps

Knob C: Gain, +/-15dB in 0.2dB steps

The frequency is specified as point where the filter deviates by 3dB from the gain value.

Parametric filters

Knob A, Centre Frequency, 10.0Hz to 25.6kHz in variable steps

Knob B, Width, display selectable, Q or BW (Bandwidth)

BW adjustable from 0.05 to 5 octaves in variable steps

Q adjustable from 14.2 to 0.2 in variable steps

Knob C, Gain, +/-15dB in 0.2dB steps

Page 59

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 59

Output Channels

Gain and Polarity

Knob A: Gain, adjustable in 0.2dB steps from –80 dB to +20dB

Knob B: Polarity, selectable, normal or reversed with reference to other outputs

Delay

Knob A: Adjustable in variable steps from 0 to 80ms

As for input delay, velocity sensitive Parameter Knobs provide finer adjustment at low levels

and rapid selection of higher values.

Page 60

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 60

High and Low Pass Filters

Knob A: Frequency, <<out, 10.0Hz to 25.6kHz, out>>

Knob B: high pass filter type

Filter type is selectable from Butterworth, Bessel, Linkwitz-Riley and Hardman. Filter slopes of

up to 8th order or 48dB / octave are provided. Not all filter types are available in all slopes.

For example 18dB / octave Linkwitz-Riley filters do not exist.

The Hardman type filter is always described by its‟ order as the filter becomes progressively

steeper rather than following a linear slope so a dB/octave description is not accurate.

Page 61

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 61

Parametric Equalisation

Eight sections of equalisation are provided in a similar format to the input channel

equalisation; two shelving filters and six parametric.

Knob A: Frequency, 10.0Hz to 25.6kHz in variable steps

Knob B: Slope, 6 to 12dB / octave in 1dB steps

Knob C: Gain, +/-15dB in 0.2dB steps

The frequency is specified as point where the filter deviates by 3dB from the gain value.

Knob A, Centre Frequency, 10.0Hz to 25.6kHz in variable steps

Knob B, Width, display selectable, Q or BW (Bandwidth)

BW adjustable from 0.05 to 5 octaves in variable steps

Q adjustable from 14.2 to 0.2 in variable steps

Knob C, Gain, +/-15dB in 0.2dB steps

Page 62

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 62

Limiters

Knob A: Threshold, -40dBu to 20dBu in 0.2dB steps

A high performance, low distortion limiter is provided on each output. Threshold is user

adjustable; all other parameters are carefully calculated dependant on configuration to

provide clean and effective control of signal dynamics.

Routing

Knob A: Output source, selectable; Input A, Input B or Sum A+B

Configures the routing from input to output. This function is only available in mono format

Presets.

Page 63

user manual

FLEX ARRAY

FLEX ARRAY user manual

Page 63

Utilities

Utility functions

Two utility functions are provided to adjust screen contrast and the display units used for

parametric equalisation bandwidth.

The device automatically adjusts for the variations in display contrast as the temperature of