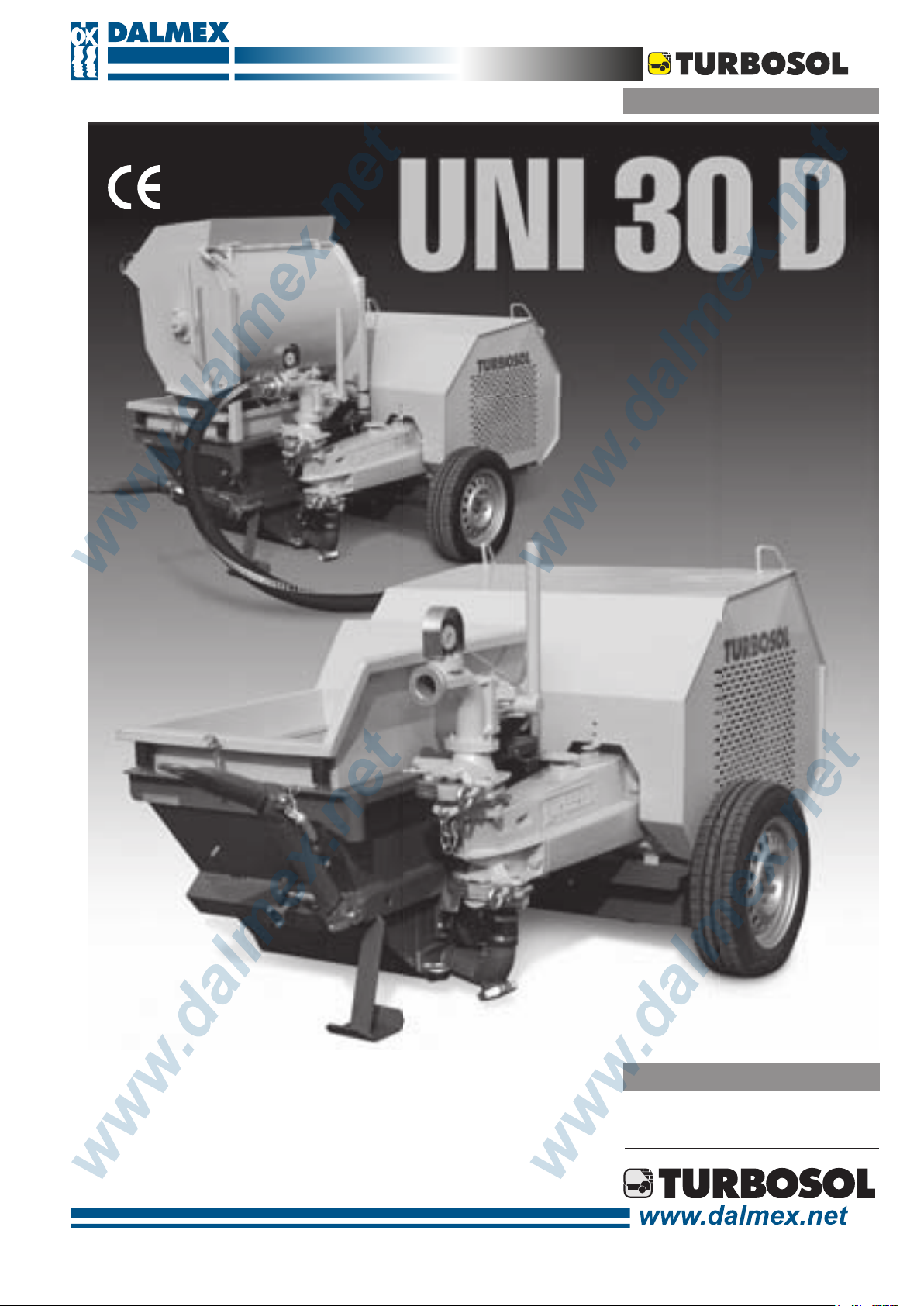

Turbosol UNI 30 D Instructions For Use And Maintenance Manual

ITALIANO

PU MP IN G S YS TE MS FOR THE BU IL DING IN DUST RY

ENGLISH

Serial number

CT. 200.359

IST R U CTIONS FOR USE AND MAINTE N A N CE

COM P R EHENSIVE CATAL O G U E & S PA RE PA RTS

INDEX

USE AND MAINTENANCE SPARE PARTS

1 - Use and maintenance 5

1.1 - Introduction 5

1.2 - General information 5

2 - Symbol key 6

3 - Caution and other hazards 7

3.1 - Caution and other hazards 7

4 - Description of the machine 8

4.1 - Type of the machine 8

Manufacturer’s registration plate 8

Manufacturer’s registration plate location 8

Machine’s serial number location 8

4.2 - Description of the machine 9

4.3 - Size of the machine 10

4.4 - Technical data 10

5 - Trasport 11

5.1 - Hoisting 11

6 - Use of the machine 12

6.1 - Operating principles 12

6.2 - Pumpable materials 13

6.3 - Preliminary operations 14

Positioning of the machine 14

Hoses 14

Anchoring the hoses 14

Couplings 15

Connections 15

6.4 - Starting the machine 16

Preliminary controls 16

Starting up 18

6.5 - Washing and stopping the machine 20

Stopping the machine 20

Cleaning 20

7 - Maintenance of the machine 22

7.1 - To be performed by the operator 22

Operations to be perfomed daily 22

At start 22

At the end of the working day 23

Every week 23

Machine not at work for long time 24

7.2 - Change of wear and tear parts by qualified

personnel 25

Change of the worn ball valves 25

Replace the gaskets of the inspection plugs 25

Changing the damaged valve’s seats 26

Change of the worn piston 26

Change of the teethed wheel

and the rubber ring of the centrifugal joint 27

7.3 - To be performed by qualified personnel 27

Operations to be performed every year or 100 h 27

Operations to be performed every 200 h 27

Operations to be performed every 6 m or 500 h 27

8 - Trouble shooting 28

8.1 - Mortar does not come out of the gun 28

Blockage of the spraygun. 28

Blockage of the mortar hoses. 28

Blockage of the valve’s group. 29

8.2 - Other inconvenients 29

Loose belt 29

8.3 - Works to be performed by the operator 30

8.4 - Works to be performed by the qualified

personnel 33

9 - Responsability of the operator 34

Tav. 1 - Chassis 36

Tav. 2 - Pump group 38

Tav. 3 - Gearbox group 42

Tav. 4 - Agitator 44

Tav. 5 - -Air system 46

Tav. 6 - Engine 48

Tav. 7 - Compressor 52

Tav. 8 - Mixer 54

Tav. 9 -Towbar - axle 58

Tav. 10 - Tool box cod. 201.145 60

Tav. 10 - Tool box cod. 201.145 62

Tav. 11 - Hoses 64

2

INSTRUCTIONS FOR USE AND MAINTENANCE

IMPORTANT

Read and carefully follow the instructions contained in

this booklet. You will thus help prevent accidents, be fully

covered by the manufacturer’s warranty, and will always

have available an equipment that is perfectly efficient

and ready to use.

Operations and maintenance of this equipment must be

performed only by skilled personnel who are well aware

of the dangers inherent to the machinery itself.

You must follow the regulations concerning the prevention

of work accidents as well current laws regarding safety in

the work place.

The manufacturer shall not be liable in any manner

whatsoever for injury or damage to persons and things,

resulting from unauthorized changes or modifications of

this equipment.

MACHINE FOR CONVEYING AND SPRAYING

TRADITIONAL, STRUCTURAL AND SPECIAL

MORTARS

UNI 30 D

The unit’s serial number:

You are strongly advised to enter your equipment’s

serial number in the space above, which must always be

referred to in order to facilitate the work of the personnel

in charge, and it must likewise be mentioned when

requesting service assistance or spare parts.

We reserve the right to make whatsoever technical

modifications in the interests of improving this

machinery, even if such modifications are not mentioned

in this booklet.

Written authorization from Turbosol must be obtained for

any and all full or partially reprinting or reproduction, of

the information contained in this booklet.

3

4

5

1 - GENERAL INFORMATIONS

1.1 - INTRODUCTION 1.2 - GENERAL INFORMATION

The UNI 30 mortar conveyor and sprayer machine can

be supplied with a variety of accessories. As a result,

some of the components and spare parts described

in this booklet may not be included with your own

equipment.

We have taken special care to clearly illustrate the

different variations in order to make it easier for you

to distinguish the use and maintenance instructions

applicable to your own machine.

Please read these instructions prior to starting up your

equipment and follow the instructions carefully.

For any other information you might require, TURBOSOL

PRODUZIONE S.P.A.’s customer service is at your

complete disposal.

TURBOSOL PRODUZIONE S.P.A.

Via Volta, 1

31030 Pero di Breda di Piave (TV) - ITALIA

Tel. 0039 - 0422 - 90.2.51

Fax 0039 - 0422 - 90.44.08

http://www.turbosol.it

e-mail: info@turbosol.it

TURBOSOL Machinery

This machinery is the product of our lengthy experience

and continuous development. The know-how thus

acquired, together with our stringent requirements

for high quality, constitutes the basic guarantee for

manufacturing low-wearing machinery which offers total

reliability at low servicing costs.

Precautions to be taken when the machine is operating

Maintenance or repair works must be carried out only

when the machine is turned off. Whatever safety devices

have been removed in order to complete such work, they

must be mounted again after maintenance has been

carried out.

Care and maintenance

Care and maintenance are vitally important in making it

possible for the machinery to operate as expected. It is

therefore essential that all maintenance will be performed

on schedule and will be carried out with extreme care.

Safety

This symbol marks each reference to safety in

this booklet, and it must be scrupulously observed.

The personnel in charge must be fully informed about

any safety regulations. Safety and accident-prevention

regulations currently in effect in your area or country

must likewise be observerd.

Training

This symbol indicates that the personnel operating

this machinery must have received special training in

regard to the correct manner in which such operation

must take place.

TURBOSOL SERVICE

For any problem related to trouble with this machinery or

when you need spare parts, contact your local Turbosol

dealer.

5

6

7

2 - SYMBOL KEY

OBLIGATION

PROHIBITION

It is compulsory to read this

maintenance booklet prior

to operating the machine

Lifting point

Warning:

machinery in operation

It is compulsory to read this

maintenance booklet with regard to

regular and general maintenance

It is compulsory to grease the

indicated point

3 - CAUTION AND OTHER HAZARDS

3.1 - CAUTION AND OTHER HAZARDS

A - Operate the unit only with the bonnet properly

closed.

B - Operate the unit only with the vibrating sieve proper-

ly positioned.

C - Check that the grill on the hopper is properly fixed.

For no reason the machine has to work without this

safety device.

D - The mixer is fixed with safety grill on top.

The opening of the above mentioned grill will

determine the immediate block of the mixer.

E - The machine must never pump material when not

connected to the hoses and to the spray gun.

F - Warning, check that no one is standing too close to

the air group valve.

A

B

G - The spray gun should not be directed towards

people. In case of blockage of the gun, no one

should look directly into the hose of the deflector.

The sudden exit of the blocked part or of mortar

under pressure, may cause problems to the sight.

H - Moving parts and hot parts are present inside the

canopy as well as battery acids.

I - Do not remove any protection.

L - Before disconnectiong the material hose couplings

or the spraygun, make sure that the pressure on

the pressure gauge is equal to 0 (zero) and that no

pressure is still present in the hoses.

M - Use gloves in nitrile for protection against cuts

and abrasions, preferably models with CE 940072

certificate and googles that can provide a total

protection to the eyes, with infrangible and

anti-fogging lenses (in policarbonate and vinyl

chloride).

C

D

H

L

B

F

I

H

E

I

G

7

8

9

E- m a i l : i n f o @ t u r b o s o l . i t - h t tp : / / w w w. tu r b o s o l . c o m/

4 - DESCRIPTION OF THE MACHINE

4.1 - TYPE OF MACHINE

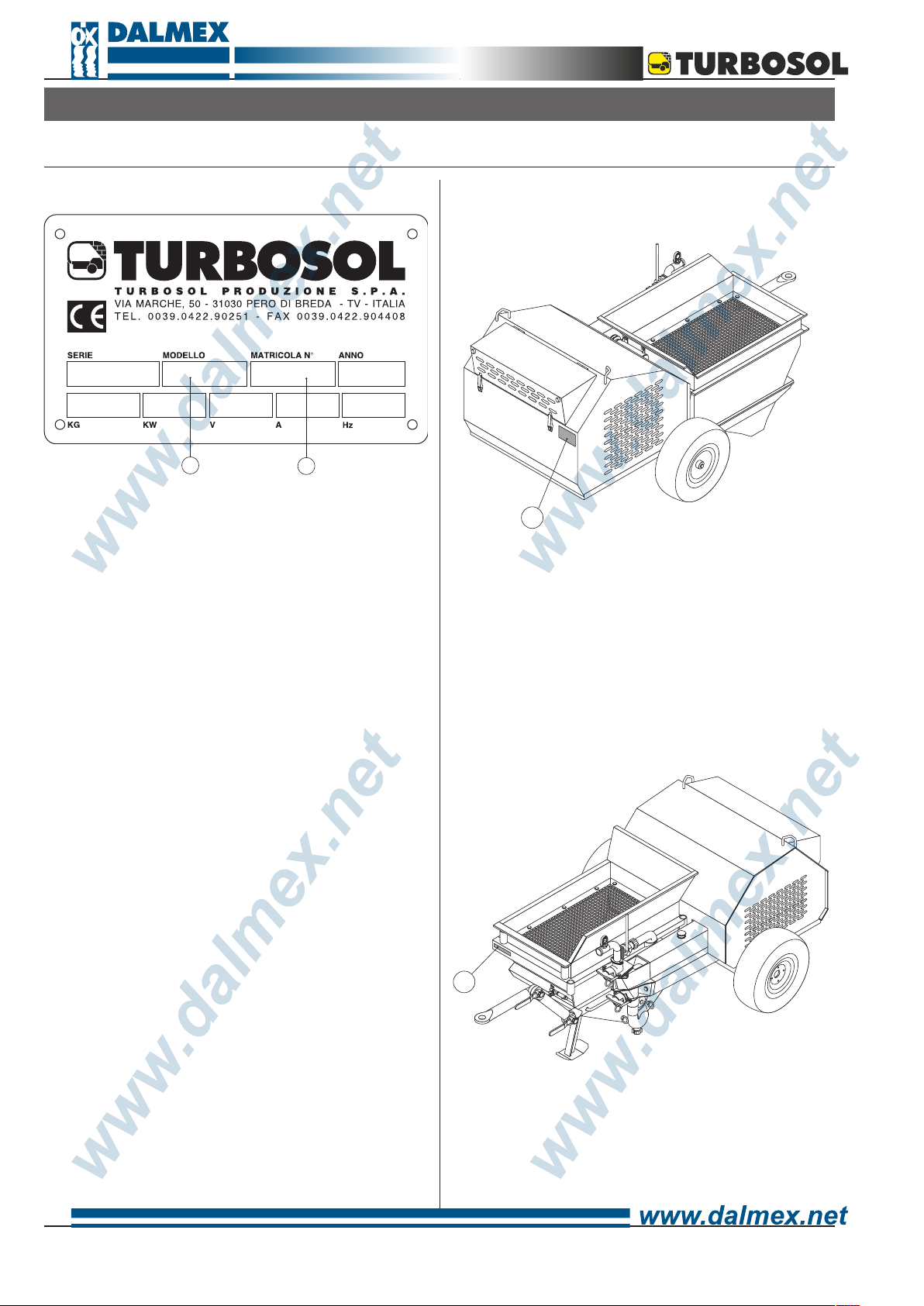

Manufacturer’s registration plate

A

The type of machine (A), its serial number (B), and

data on machine operating power are printed on the

manufacturer’s registration plate.

The meaning of the various symbols used is as follows.

(A) = Type of machine: UNI 30 D (S) (MF)

UNI 30 D = Machine with piston pump

traditional, structural, and special

mortars.

for pumping, conveying and spraying

B

Manufacturer’s registration plate location

1

The manufacturer’s registration plate (1) is attached to

the chassis of the machine.

S = Standard version.

MF = Version with fixed mixer.

(B) = Machine’s serial number: NNNNNN/AA

NNNNNN = The unit serial number.

/AA = Year of manufacture.

Machine’s serial number location

2

The machine’s serial number (2) is printed on the chassis

as well as on the manufacturer’s registration plate.

4.2 - DESCRIPTION OF THE MACHINE

Standard equipment:

• Protection frame for mechanical parts.

• Self-bearing frame with pneumatic wheels and

articulated draw-bar.

• Vibrating sieve with 8 mm mesh.

• Switch board built in accordance to EC norms.

•Piston pump with gravity ball valves.

•Mechanical gearbox with 2 speeds.

•Automatic mechanical safety device against

overpressure.

•Material recycling device

•Built-in air compressor of 270 l/m’ output.

•Positive action mixer of 180 l. (version MF).

•40 m (20+10 Ø 50 +10 Ø 40) of mortar rubber hoses

with cam-lock couplings.

•41 m (31 + 10) of air hose Ø 13 with quick couplings.

• Accessory box with spray gun and a series of nozzles.

• Technical literature.

11

Accessories upon request:

On line pressure gauge for hoses Ø 50.

Pumping nozzle for hoses Ø 40.

Pumping nozzle for hoses Ø 50.

Cement slurry injection device.

Hose extensions:

- Hose extensions of 10 m mortar/air (Ø 50 x 66 e Ø 13 x

19).

- Hose extensions of 20 m mortar/air (Ø 50 x 66 e Ø 13 x

19).

Main components:

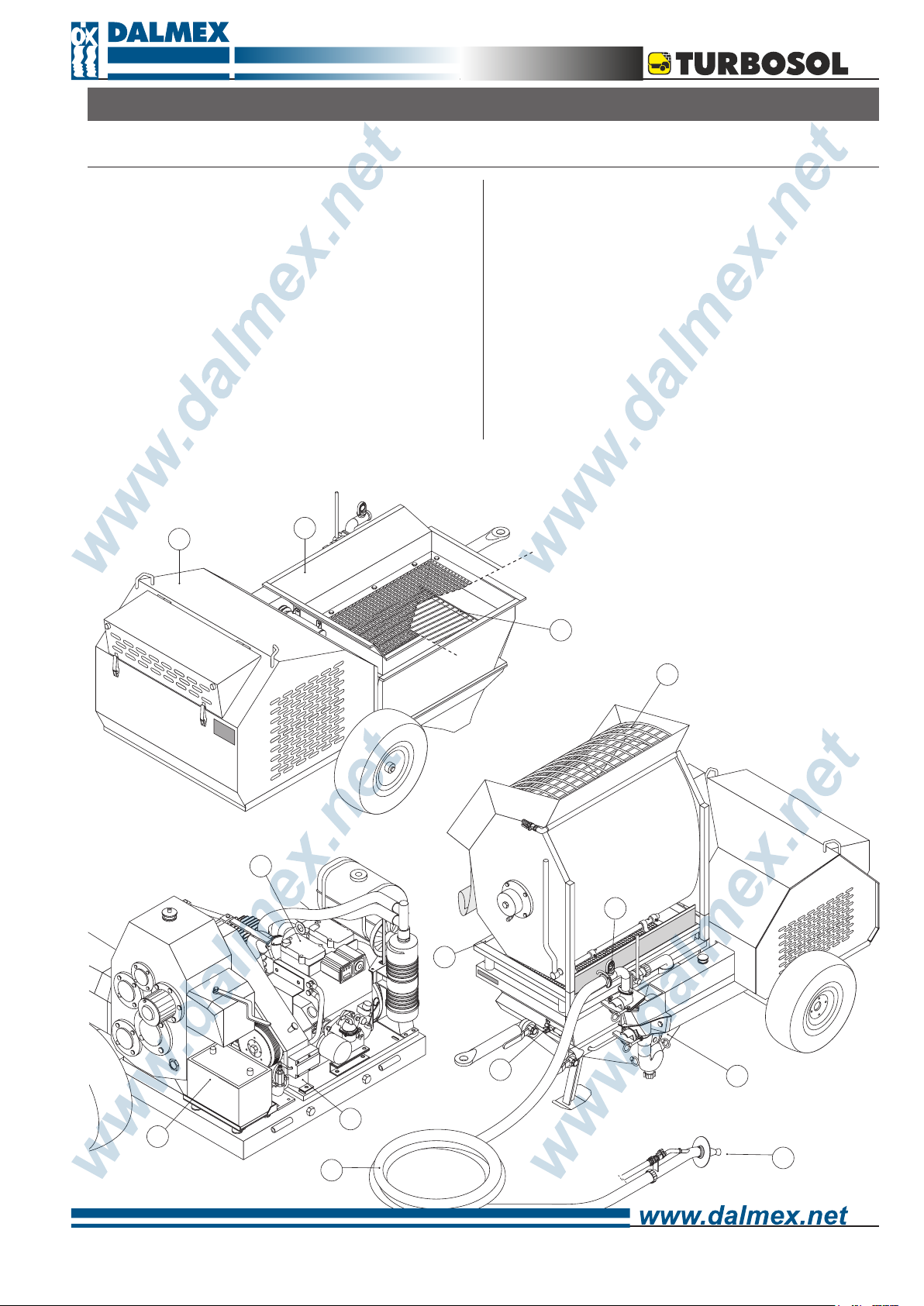

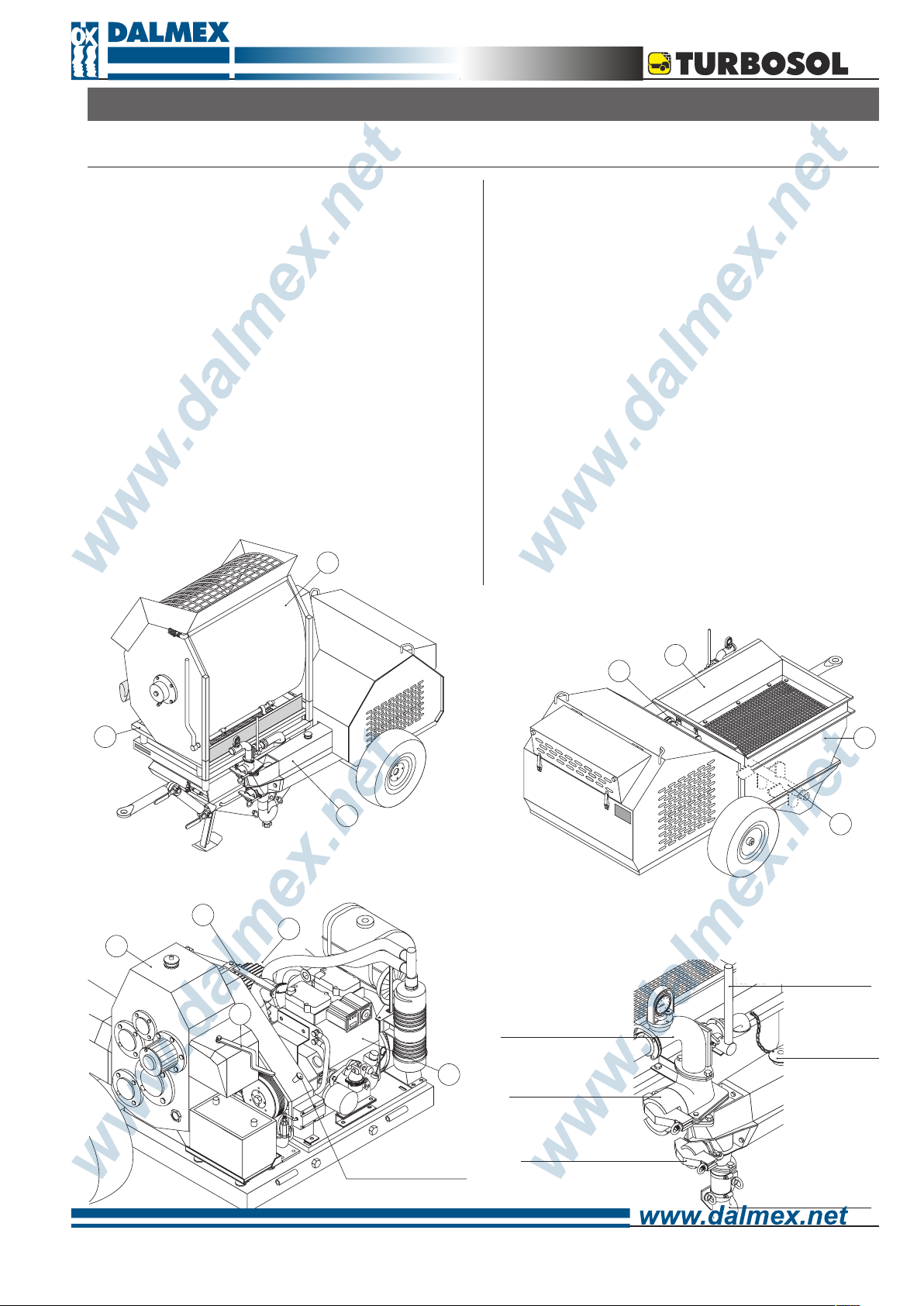

The machine is made up primarily of:

a hopper (3) an agitator (4),

a piston pump group (5),

a diesel engine (6) that operates a gearbox (7) with 2

speeds (7a) a safety device (7b) against overpressure,

a compressor (8),

a vibrating sieve (9) operated by a mechanical gearbox (10) and for the MF version: a fixed mixer (11).

9

10

9

5

3

4

7a

8

7

BY-PASS LEVER

7b

DELIVERY OUTLET WITH

PRESSURE GAUGE

6

INSPECTION PLUG FOR THE

DELIVERY VALVE

MUSHROOM SHAPED LID

FOR CYLINDER

ROD ENGINE STOP

INSPECTION PLUG FOR THE

SUCTION VALVE

SUCTION

COLLECTOR

9

10

11

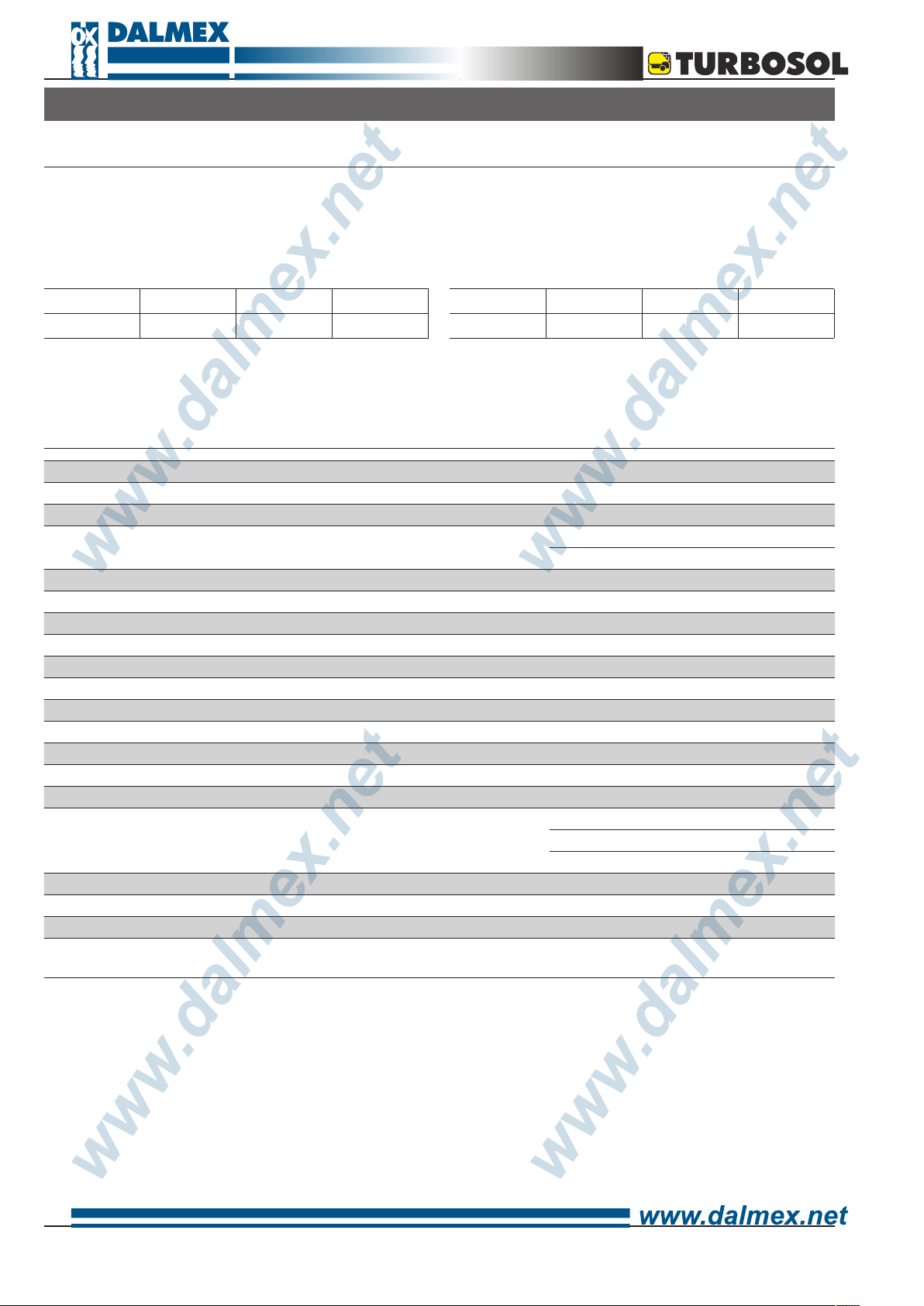

4.3 - SIZE OF THE MACHINE

Here are the size of the machine and its gross weight (ready for use).

Version DS Version DMF

LENGTH WIDTH HEIGHT W EIGHT

2150 mm 1500 mm 110 mm 810 kg

LENGTH WIDTH HEIGHT W EIGHT

2150 mm 1500 mm 1600 mm 1020 kg

4.4 - TECHNICAL DATA

Mortar pump pressure (indicative) 30 bar

Auxiliary circuits voltage 12 V

Engine power 14 kW

R.P.M.

max 2.600 R.P.M.

min 1.200 R.P.M.

Pilot valve fixed pressure max 4,5 bar

Compressor relief valve fixed pressure 6,5 bar

Compressor maximum valve pressure 6,5 bar

Compressor oil change (SHELL RIMULA EXTRA D 15W40) every 100 hours

Gearbox oil change (ELF POLYTELIS 100) every 500 hours

Engine oil change (diesel engine oil 15W40) check engine book

Mixer gearbox oil change (ELF Reductelf SP220) every 500 hours

Hopper capacity 200 l

Mixer capacity 180 l

Delivery distance (indicative) 200* m

Delivery height (indicative) 60* m

1° Part special Ø 50 x 69** mm

Delivery hoses

Extensions normal Ø 50 x 66 mm

Final Ø 40 x 53 mm

Maximum pumpable granulometry 8 mm

Temperature in the work environment from 5° to + 40° C

Sound power level (84/533/EEC) <100 dB(A)

N.B.: * Maximum distance and height cannot be reached at the same time.

** Use only hoses made specially for this machine.

For other data regarding the diesel engine please refer also to the attached engine booklet.

5 - TRANSPORT

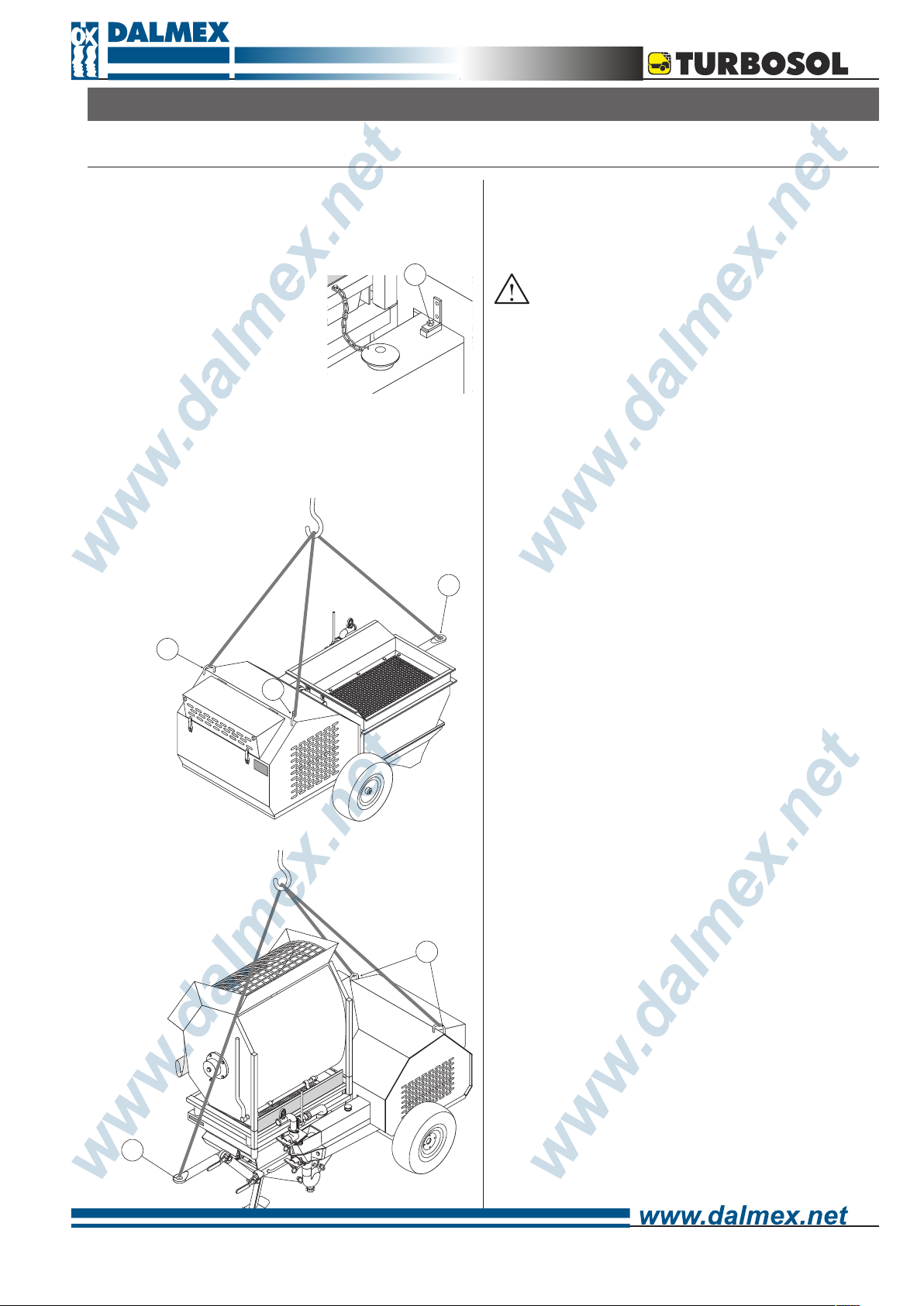

5.1 - HOISTING

In order to lift the machine hook the cables up to the

handles (12) of the bonnet (make sure first that the

hooks are closed) and to the tow bar (13).

Use only hoisting equipment, hooks and ropes that have

been tested and approved for lifting at least 1000 kg.

14

• Make sure that the safety screw

(14) that blocks the bonnet is

correctly fixed.

Avoid hoisting the machine with a fork-lift.

Minimum length of the ropes:

- 1,00 m. for the ropes to be connected to the handles.

- 1,30 m. for the ropes to be connected to the tow bar.

13

12

12

Before lifting up the machine, make sure that no one is

standing too close to it.

The mortar mixed separately with whatever kind

of mixer or prepared with the built-in mixer (MF

version), will be discharged on the vibrating sieve of the

machine.

13

12

11

Loading...

Loading...