Turbonics KWM6, KWM11 Installation Instructions Manual

Installation:

13

13

16

351mm

14

5

16

363mm

13

21

32

347mm

13

5

32

334mm

19

32

15mm

4

19

32

117mm

3

15

32

88mm

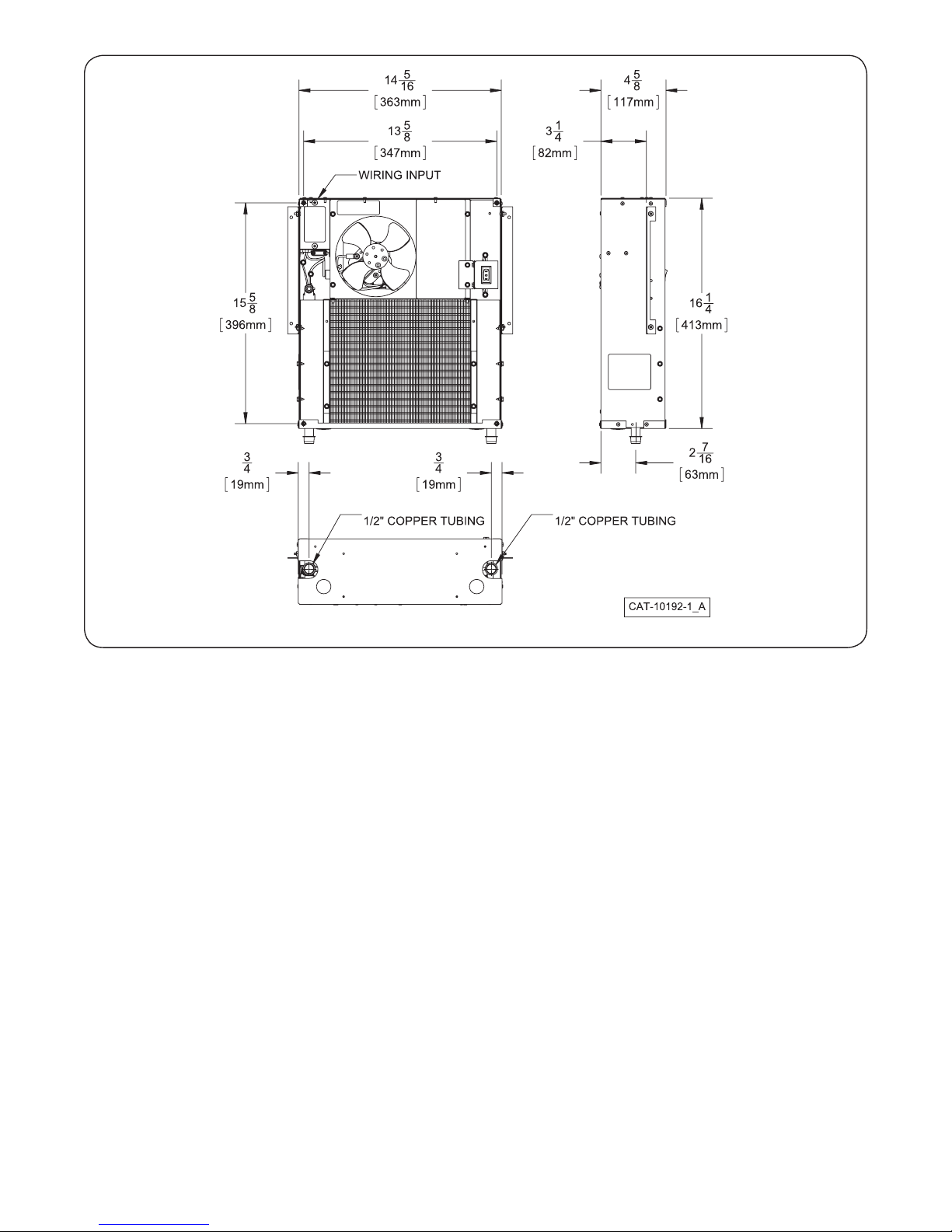

WIRING INPUT

INLET

1/2" COPPER TUBING

OUTLET

1/2" COPPER TUBING

CAT-09853-TUR

• Kickster Wall-Mount hydronic fan coils are suitable for

connection to a hot water supply at any pressure up to 300

psi with a maximum water temperature of 200°F.

• Building codes and plumbing regulations may vary.

Check local codes and regulations before determining

proper application and installation.

KWMIOM-3

Kickster Wall-Mount Fan Coil

Installation Instructions

Model KWM All Sizes

• Unit is designed to be mounted under sheetrock for proper

t of the cover. Install at least 6" - 8" above the oor for

best performance. Unit will t between standard 16" studs

on center.

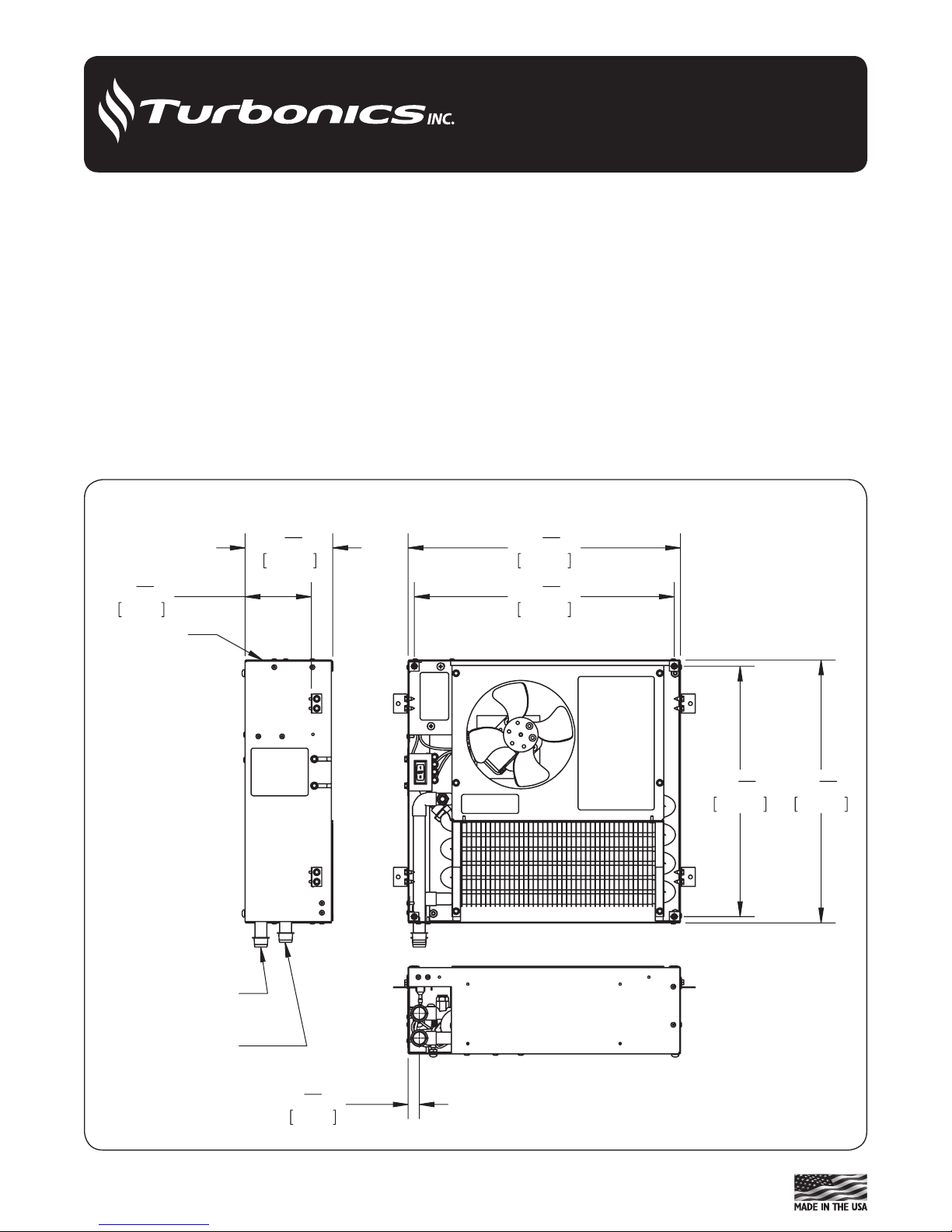

• For unit dimensions on the KWM6 refer to Figure 1, 3 & 6.

For KWM11 refer to Figure 2, 4 & 7.

• Examine unit for shipping damage.

Figure 1 - KWM6

• Secure unit in proper position. Unit must be level to assure

proper drainage and operation.

1

OUTLET

INLET

Figure 2 - K WM11

Piping

• e piping on the unit will usually be copper or any other

locally approved piping. Accessible ½” sweat ttings are

provided on the unit itself. An optional exible stainless

steel connector kit with shut-o valves is available for

connecting the unit to any type of piping system and can

be used with an optional valve control box.

• All piping systems should be designed by a technician

with experience in the various piping arrangements that

work with this type of unit.

• As with any system employing circulated water, the pipes

passing through unheated spaces should be insulated.

NOTE: When using mono-flo or “venturi” fittings, we

suggest placement of a ball valve just after the supply

take-off and before the return is connected.

Piping: Hot Water Boiler

• e unit supply line should be taken from the boiler side

beyond any o-control valve. If the system being used is

a gravity-ow or cast iron hot water system, a separate

circuit must be installed.

Piping: Water Heater

• To install correctly, a technician with knowledge of piping

arrangements and back-o valves must design the piping

system.

Wiring the Unit

• A eld wiring connection is provided on the unit (see

gure 5). Connect wires at this point only.

• e unit is manufactured with a built-in factory wired

aquastat with a set point of 140°F on and 110°F o. e

aquastat may be disabled in the eld if not required (see

application manuals).

Loading...

Loading...