Turbonics Kickster KWM Series, Kickster KWM6 VCB, Kickster KWM11 VCB Installation Instructions Manual

Installation:

• Kickster Wall Mount hydronic fan coils with VCB

are suitable for connection to a hot water supply at any

pressure up to 300 psi with a maximum water temperature

of 200°F.

VCBIOM-1

Kickster Wall Mount Fan Coil

Installation Instructions

Model KWM All Sizes with

Valve Control Box (VCB)

• Unit is designed to be mounted under sheetrock for proper

t of the cover. Install at least 6" - 8" above the oor for

best performance. Unit will t between standard 16" studs

on center.

• Building codes and plumbing regulations may vary.

Check local codes and regulations before determining

proper application and installation.

• Examine unit for shipping damage.

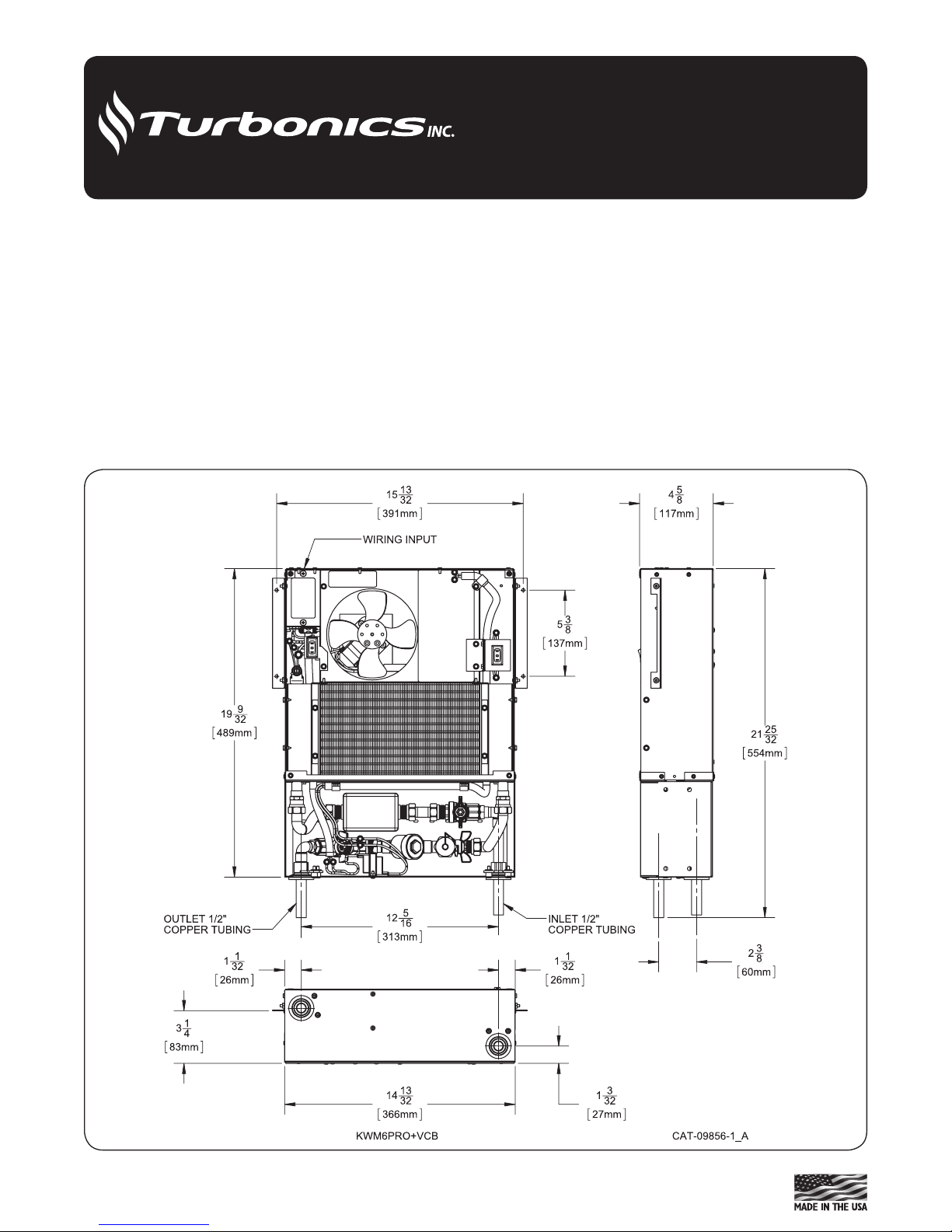

Figure 1 - KWM6 VCB

• For unit dimensions on the KWM6 refer to Figure 1 & 3.

For KWM11 refer to gure 2 & 4.

• Secure unit in proper position. Unit must be level to assure

proper drainage and operation.

1

14

13

32

366mm

1

1

32

26mm

1

1

32

26mm

1

3

32

27mm

3

1

4

83mm

KWM11PRO+VCB

22

9

32

566mm

12

5

16

313mm

15

13

32

391mm

7

1

2

191mm

INLET 1/2"

COPPER TUBING

OUTLET 1/2"

COPPER TUBING

WIRING INPUT

24

25

32

630mm

4

19

32

117mm

2

3

8

60mm

CAT-09856-2_A

Figure 2 - KWM11 VCB

Piping

• e piping on the unit will usually be copper or any other

locally approved piping. Accessible ½” sweat ttings are

provided on the unit itself. For VCB component listing

see Figure 3.

• All piping systems should be designed by a technician

with experience in the various piping arrangements that

work with this type of unit.

• As with any system employing circulated water, the pipes

passing through unheated spaces should be insulated.

NOTE: When using mono-flo or “venturi” fittings, we

suggest placement of a ball valve just after the supply

take-off and before the return is connected.

Piping: Hot Water Boiler

• e unit supply line should be taken from the boiler side

beyond any o-control valve. If the system being used is

a gravity-ow or cast iron hot water system, a separate

circuit must be installed.

Piping: Water Heater

• To install correctly, a technician with knowledge of piping

arrangements and back-o valves must design the piping

system.

Purge and Flush Instructions

After the unit is connected to the water system, verify that

there are no leaks.

1. Close the ball valve on the outlet pipe

2. Open the ball valve on the inlet pipe

3. Remove the brass cap on the purge/flush valve

4. Connect a garden hose to the purge/flush valve and make

sure you are running the hose into a drain or large bucket

5. Open the purge/flush valve. This will purge air from the

system.

6. Continue to flush the system until all air and foreign

matter is removed.

7. Close the purge/flush valve and replace the brass cap

8. Open the ball valve on the outlet pipe.

Prior to Zone valve actuator installation both ball valves

must be open as pressure is applied to the system.

Wiring the Unit

• A eld wiring connection is provided on the unit.

Connect wires at this point only.

• e unit is manufactured with a built-in factory wired

aquastat with a set point of 140°F on and 110°F o. e

aquastat may be disabled in the eld if not required.

• For 24V wiring with transformer see Figure 4.

• For 120V wiring see Figure 5.

Loading...

Loading...