Page 1

A

SERVICE M

CHEST FREEZER

Model : TSD-27CF

NUAL

TSD-27CF

Specification: Subject to change without notice.

SPECIFICATION TSD-27CF

Classification Direct Cool, Manual Defrost, Tropical

Power Source 115VAC, 60 Hz.

Volume 138 Liters (4.9 cu.ft)

Rated Current 2.0 Amp.

Rated Power Input 135 Watts

Power Consumption

High side /Low side

pressure

1.30 kW·h/24h

155psig/-2.22psig

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F 115gm

Overall Dimension 695(W) x595(D) x 910(H) mm

Net Weight/Gross Weight 45 Kg./50 Kg.

ISSUED BY:

REVIEWED BY:

REVISION 2.0

Page 2

PRODUCT SPECIFICATION

CHEST FROZEN SHOWCASE

TSD-27CF

Model TSD-27CF

Classification Sliding glass Door, Direct Cool, Tropical

Color/Door White/ with Door Lock Sliding Glass

Body Finish Baked Acrylic Powder Coat

Temperature Control Thermostat

Defrost System Manual Defrost

Drain Manual Drain

Evaporator Tube Type

Condenser Tube Type

Insulation

Cabinet

Freezer Door

Rigid Polyurethane Foam (Blowing Agent CP)

Rigid Polyurethane Foam

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F

Refrigerant Charge (gm.) 115 gm

Door Lamp None

Fan Motor None

Compressor

KONOR GQY50AD

135 Watts

Compressor Oil 290 ml.POE Polyol Ester (Synthetic)

PTC Starter

Overload Protector

11650X011 signT0296/74/T0296/05,B94-130-74,4TM762PBFZZ-51(6.3):Cut temperature:115125 ℃ ;Close temperature:70-52 ℃ ;

current):3.36A/70℃

8115PTH7M4R7MC1 (3.8Ω~5.6Ω, Max current 18A/180V)

Overload current : 27A;UTC(Min action

Dryer (Desiccant) 15 gm.

Overall Dimension (W x D x H mm.) 695(W) x595(D) x 910(H) mm

Packing Dimension (W x D x H mm.) 765 (W) x 680 (D) x 970(H) mm

Net Weight (kg.) 45kg.

Gross Weight (kg.) 50 kg.

CHARACTERISTIC

Operating Temperature (°C)

Model

Dial Position

Temperature Control

WARM 1

NORMAL 4

COLD 7

-10.0°C ± 2 °C

-15.0°C ± 2 °C

-20.0°C ± 2 °C

Page 3

CHEST FROZEN SHOWCASE

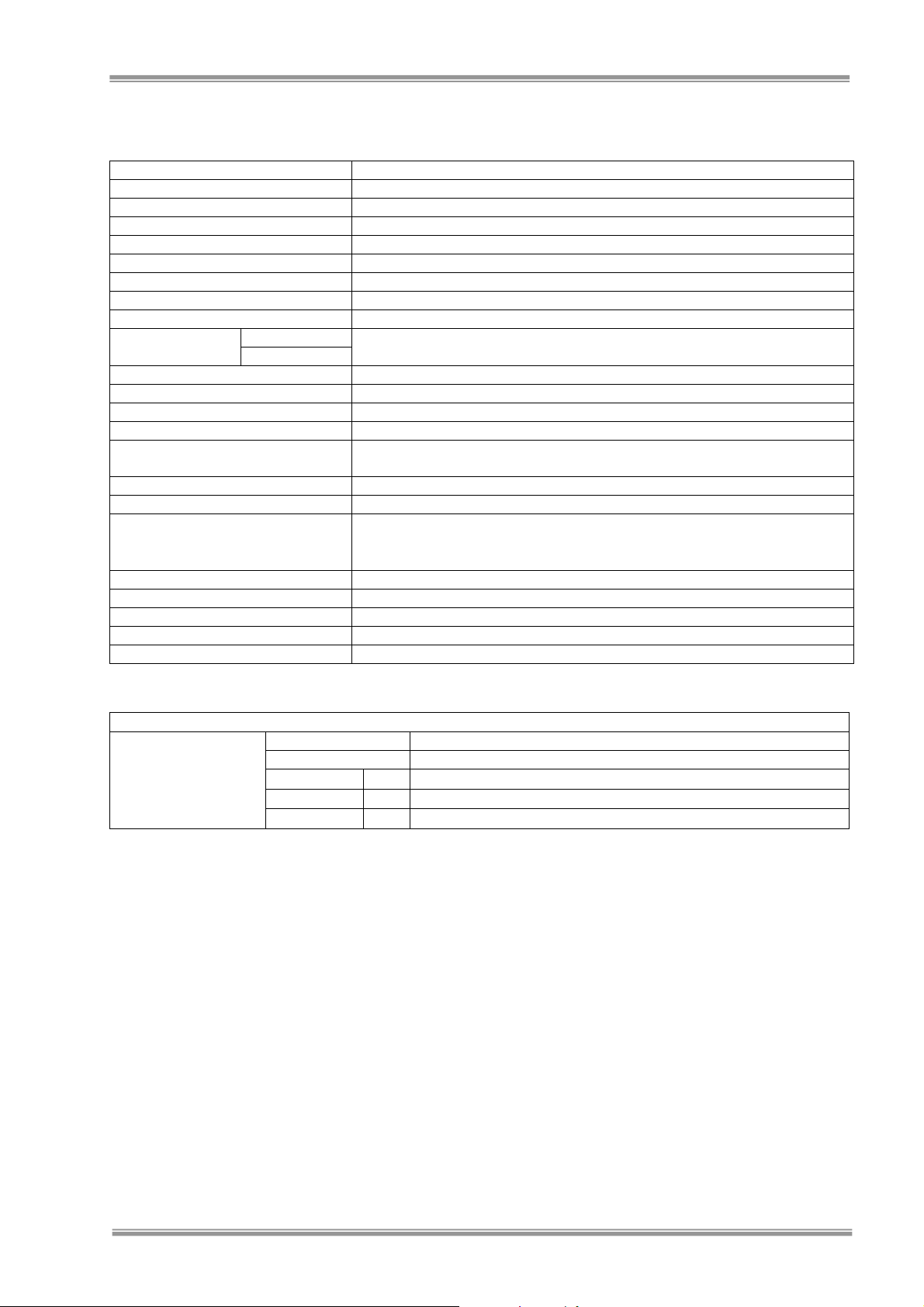

ELEC. CIRCUIT: TSD-27CF

TSD-27CF

COOLING SYSTEM

TSD-27CF

Page 4

CHEST FROZEN SHOWCASE

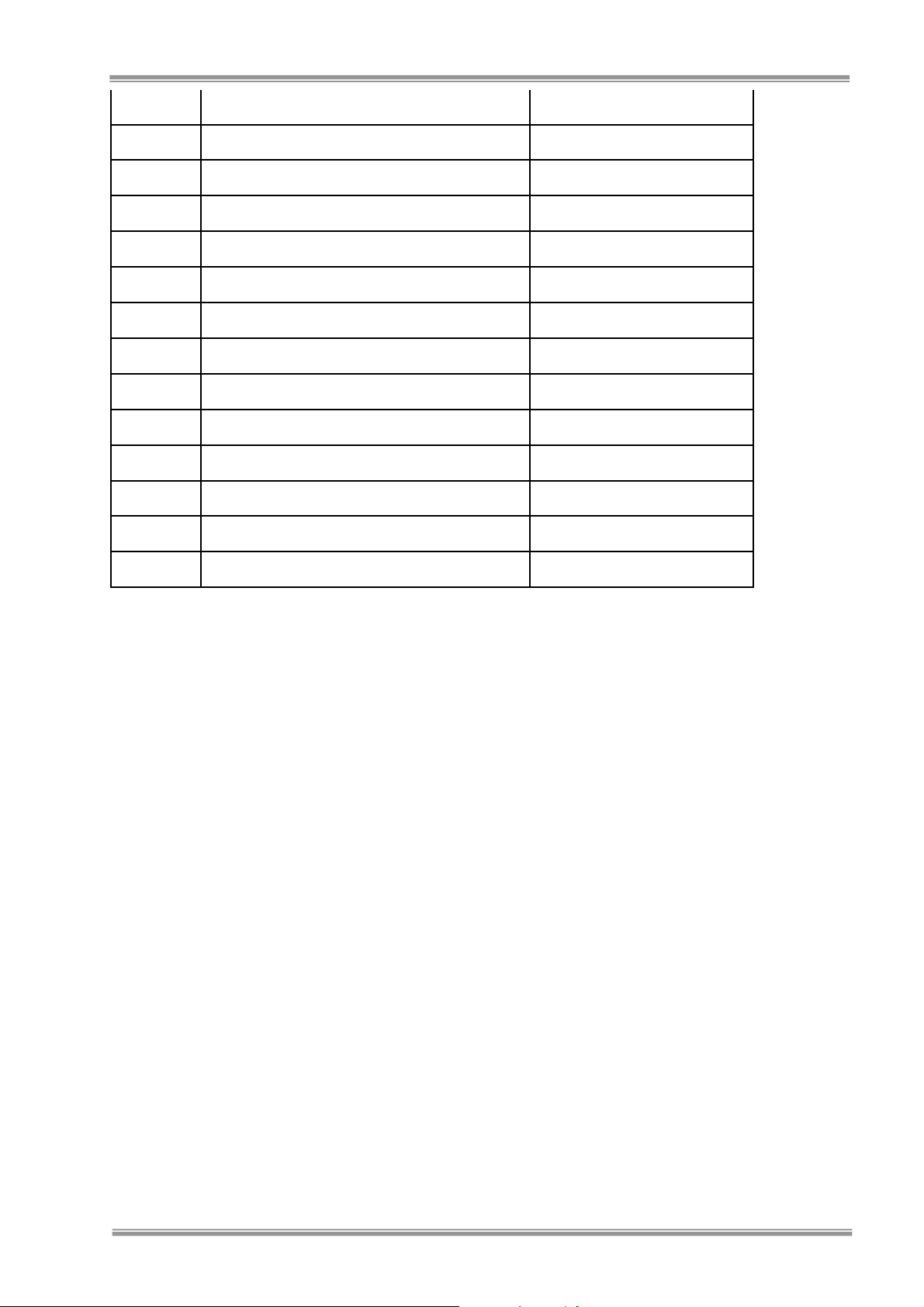

PARTS LIST of TSD-27CF

TSD-27CF

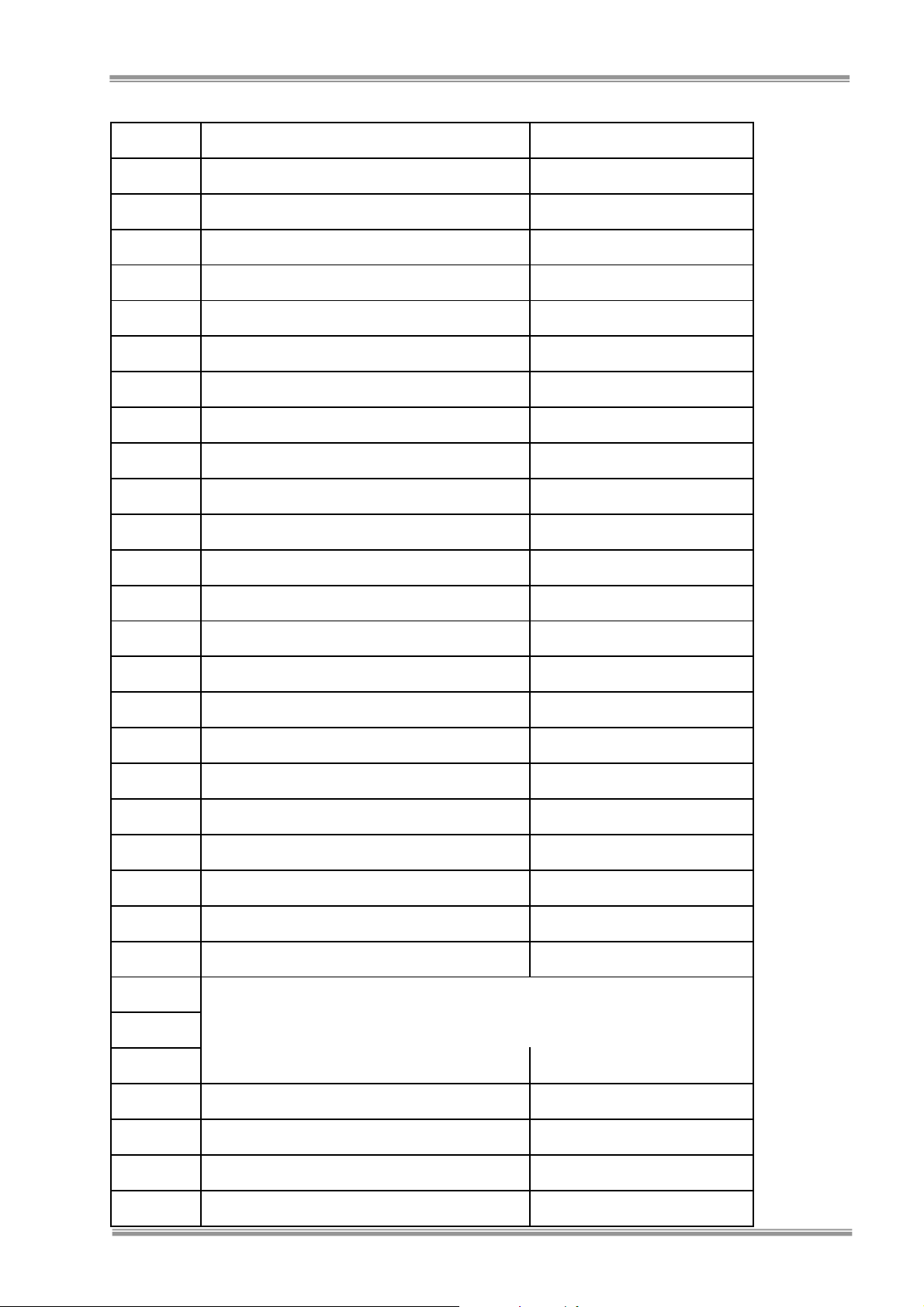

S/N Part name qty

101 Upper glass door 1

102 Lower glass door 1

103 Food basket 2

201 Foaming body 1

202 Side cover holder A 2

203 Screw ST3.5X13-C-H 2

204 Side cover 1

205 Side cover holder B 1

206 Side cover holder C 1

207 thermostat 1

208 Thermostat panel 1

209 Red indicator light 1

210 Green indicator light 1

211 Thermostat knob 1

212 Thermostat panelcover

213 Castor 2” 4

214 Base support 1

215 Screw ST4.2x16-C-H 4

216 Condenser support 4

217 Screw ST4.2x16-C-H 2

218 Condenser 1

219 Dryer filter 1

220 Dryer filter support 1

221

222

Cappilary tube

suction tube

1

1

223 Compressor support 1

301 CompressorGQY50AD 1

302 Compressor clip 2

303 Compressor anti-vibration gasket 4

304 Over load protector 1

Page 5

CHEST FROZEN SHOWCASE

TSD-27CF

305 Protector clip 1

306 Compressor electric box cover 1

307 Compressor electric box clip 1

308 PTC starter 1

309 Compressor process tube 1

401 Screw M4x22 2

402 Connector box cover 1

403 Connector box support 1

404 Power cord retainer base 1

405 Power cord 1

406 Power cord retainer 1

407 Screw M4x20 2

408 Connector box retainer 1

409 Screw M4x20 2

Page 6

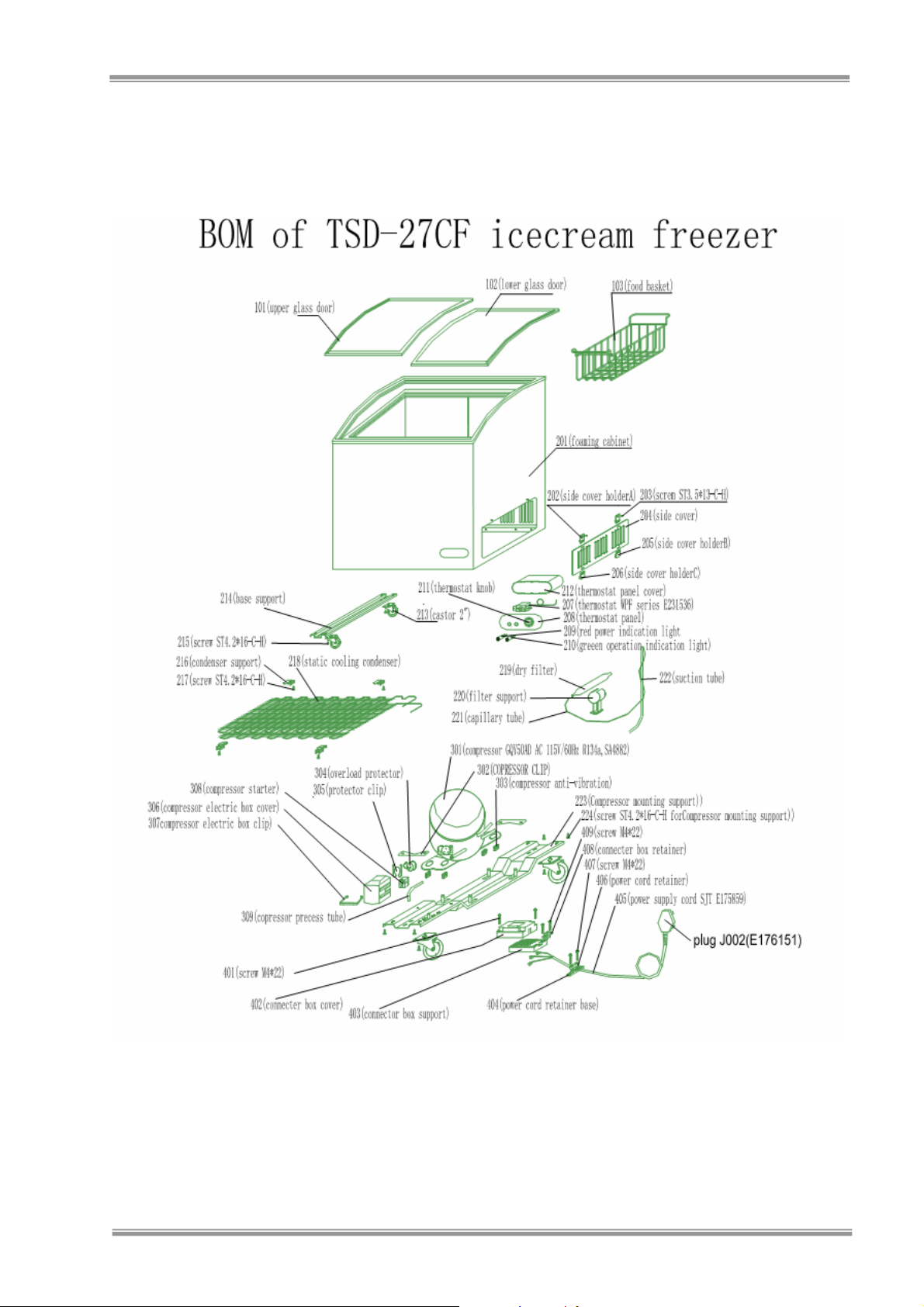

Exploded View of TSD-27CF

CHEST FROZEN SHOWCASE

TSD-27CF

Page 7

CHEST FROZEN SHOWCASE

CHARACTERISTIC

TSD-27CF

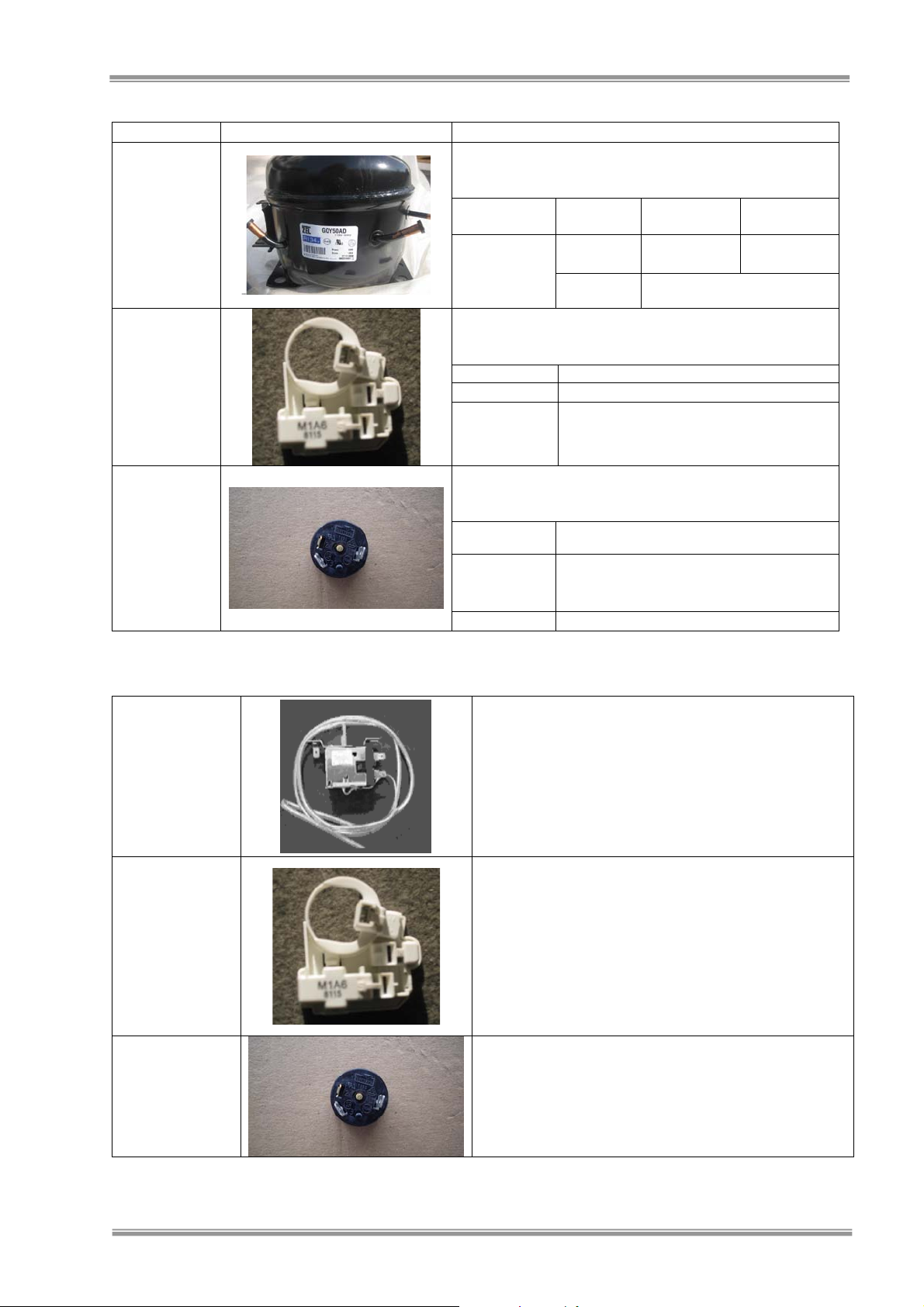

Parts Name Picture Check Method and Criterion

Measure the resistance with a tester.

Compressor

Model :TSD27CF

PTC Starter

Model : TSD27CF

Overload

Protector

Model : TSD27CF

TROUBLE SHOOTING

Thermostat

PTC Starter

Overload Protector

(Ambient temperature : Room temperature 25

Model Main Wiring

KONOR

Normal

GQY50AD

135 WATTS

Abnormal

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

Normal

Abnormal

(3.8Ω~5.6Ω, Max current 18A/180V)

Open(

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

T0296/74/T0296/05,B94-130-74,4TM762PBFZZ-

Less than 1

Normal

125℃ ;Close temperature:70-52℃;

current

:27A;UTC(Min action current):3.36A/70℃

Abnormal

Repair Procedure

1. Set Thermo Knob to OFF position, pull & straightened feeler

bulb

2. Remove Thermostat cover and pull out Thermostat from

Thermo Box

3. Short the thermostat terminal and check, if compressor

runs.

4. Replace thermostat

5. After replacing Thermostat, reverse steps above.

Repair Procedure

1. Release Relay Cover Fixing Clip.

2. Remove Relay Cover.

3. Remove PTC Starter

4. Pull out PTC Starter, check if open and compare value of

resistance with given value, if not

5. Hold receptacle terminal then pull electrical wire from PTC

Starter.

6. Replaces PTC Starter (change overload protector together),

reverse the steps above.

Repair Procedure

1. Check for continuity on overload protector, if open

2. Pull out Overload Protector.

3. Hold receptacle terminal then pull electrical wire from

Overload Protector.

4. Replace overload protector.

°

c)

Auxiliary

Wiring

~8Ω

7

(Approx.)S

Open( ∞ Ω ) or Short Circuited ( 0

Ω

)

°

8115PTH7M4R7MC1

∞ Ω

) or Short Circuited ( 0 Ω )

°

51(6.3)

Ω

(Approx.) Cut temperature:115-

9.9

(Approx.)S

c)

c)

~

Overload

Open(

∞ Ω

)

11.3Ω

Page 8

CHEST FROZEN SHOWCASE

TSD-27CF

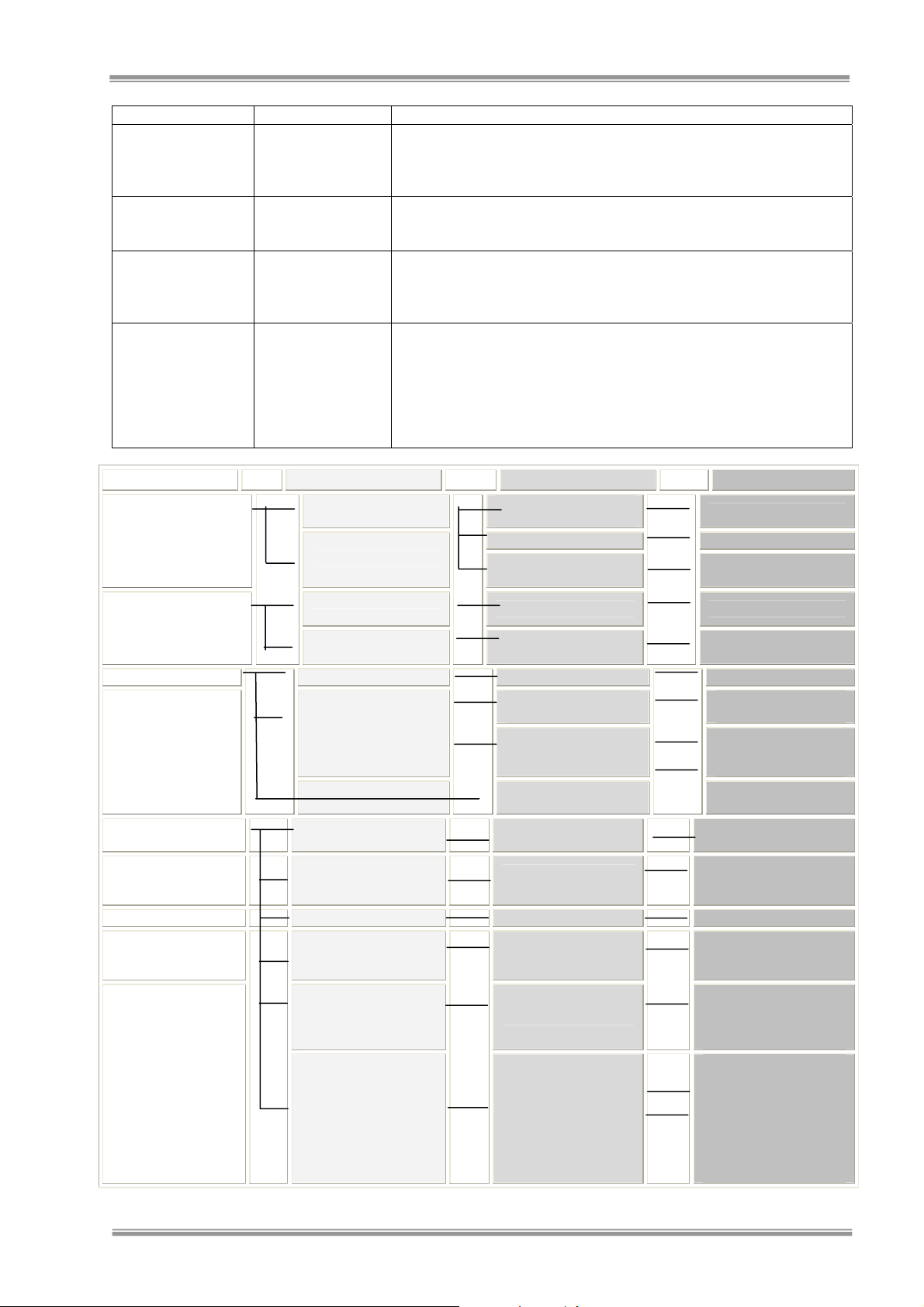

Cause Check Point Correction

Repair Procedure

Compressor

Check coils

resistances

1. Replace compressor if measured resistances differ from given standard

2. Abnormal noise

Repair Procedure

1. Operate unit for 10 minutes with thermostat set at maximum

Not cooling

Check thermostat

setting

Repair Procedure

Insufficient cooling Check gasket gap

1. Check if gap can be resolved by adjustment of door hinges fixing screws.

2. Defrost if accumulation of frost is more than 10mm.

Repair Procedure

Malfunction due to

leaks or clogged

system

Charged (purge) with

nitrogen into the

refrigeration system

& check for leaks on

welds or clogs

1. Check for clog or leak in the cooling system.

2. Repair or replace the clogged or leak section.

3. Evacuate and change filter dryer.

4. Purge with nitrogen to clean and check for leaks

5. Recharge refrigerant, test run and seal system

TROUBLE INSPECTION CAUSES REMEDY

No Power

No Light

Check electric power

supply voltage

Check electrical circuit

Check lamp

Open circuit breaker or

fuse

Open Fuse Replace

Worn out or defective A/C

cord

Open Replace

Fix or replace

Replace

Check lamps socket

Low Cooling Check for thermo setting Setting too low Set thermostat higher

Defective Cooling

System

Check Overload Protector Check for continuity Replace if open.

Check leaks

Check Thermostat

Check PTC starter

resistance against given

value

Check for leaks

Check Compressor

resistance against given

specification

Check Pipe System

Corroded

Deform or warp door

gasket.

Poor weld on joints

Over storage or load or

heavy frost accumulation

Check if compressor runs

by shortening thermostat

Open, no resistance or

differ from given value

Leaks or poor welds on

joints

Defective

Clogged Pipe System or

oil choke

Replace

Adjust door hinges fixing

screws

Repair, purge with

nitrogen re-charge

refrigerant and test run.

Reduce or re-arrange

load or defrost unit

Replace thermostat if

compressor runs.

Replace PTC starter.

Repair, re-weld, purge,

evacuate and recharge

refrigerant

Replace, weld, purge,

check for leaks and recharge refrigerant, test run

and seal system

1. Evacuate then Purge

with nitrogen to remove

clogs

2. Repair or replace

clogged section, evacuate,

purge, check leak and recharge refrigerant. Test

Run and seal system

Page 9

A

SERVICE M

CHEST FREEZER

Model : TSD-35CF

NUAL

TSD-35CF

Specification: Subject to change without notice.

SPECIFICATION TSD-35CF

Classification Direct Cool, Manual Defrost, Tropical

Power Source 115VAC, 60 Hz.

Volume 208 Liters (7.3 cu.ft.)

Rated Current 3.0 Amp.

Rated Power Input 200 Watts

Power Consumption

High side /Low side

pressure

1.80 kW·h/24h

155psig/-2.22psig

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F 160gm

Overall Dimension 895(W) x595(D) x 910(H) mm

Net Weight/Gross Weight 55 Kg./60 Kg.

ISSUED BY:

REVIEWED BY:

REVISION 2.0

Page 10

PRODUCT SPECIFICATION

CHEST FROZEN SHOWCASE

TSD-35CF

Model TSD-35CF

Classification Sliding glass Door, Direct Cool, Tropical

Color/Door White/ with Door Lock Sliding Glass

Body Finish Baked Acrylic Powder Coat

Temperature Control Thermostat

Defrost System Manual Defrost

Drain Manual Drain

Evaporator Tube Type

Condenser Tube Type

Insulation

Cabinet

Freezer Door

Rigid Polyurethane Foam (Blowing Agent CP)

Rigid Polyurethane Foam

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F

Refrigerant Charge (gm.) 160 gm

Door Lamp None

Fan Motor None

Compressor

KONOR GQY70AD

165 Watts

Compressor Oil 290 ml.POE Polyol Ester (Synthetic)

PTC Starter

Overload Protector

11650X011 signT0296/74/T0296/05,B94-130-74,4TM762PBFZZ-51(6.3):Cut temperature:115125 ℃ ;Close temperature:70-52 ℃ ;

current):3.36A/70℃

8115PTH7M4R7MC1 (3.8Ω~5.6Ω, Max current 18A/180V)

Overload current : 27A;UTC(Min action

Dryer (Desiccant) 15 gm.

Overall Dimension (W x D x H mm.) 895(W) x595(D) x 910(H) mm

Packing Dimension (W x D x H mm.) 965 (W) x 680 (D) x 970(H) mm

Net Weight (kg.) 55kg.

Gross Weight (kg.) 60 kg.

CHARACTERISTIC

Operating Temperature (°C)

Model

Dial Position

Temperature Control

WARM 1

NORMAL 4

COLD 7

-10.0°C ± 2 °C

-15.0°C ± 2 °C

-25.0°C ± 2 °C

Page 11

CHEST FROZEN SHOWCASE

TSD-35CF

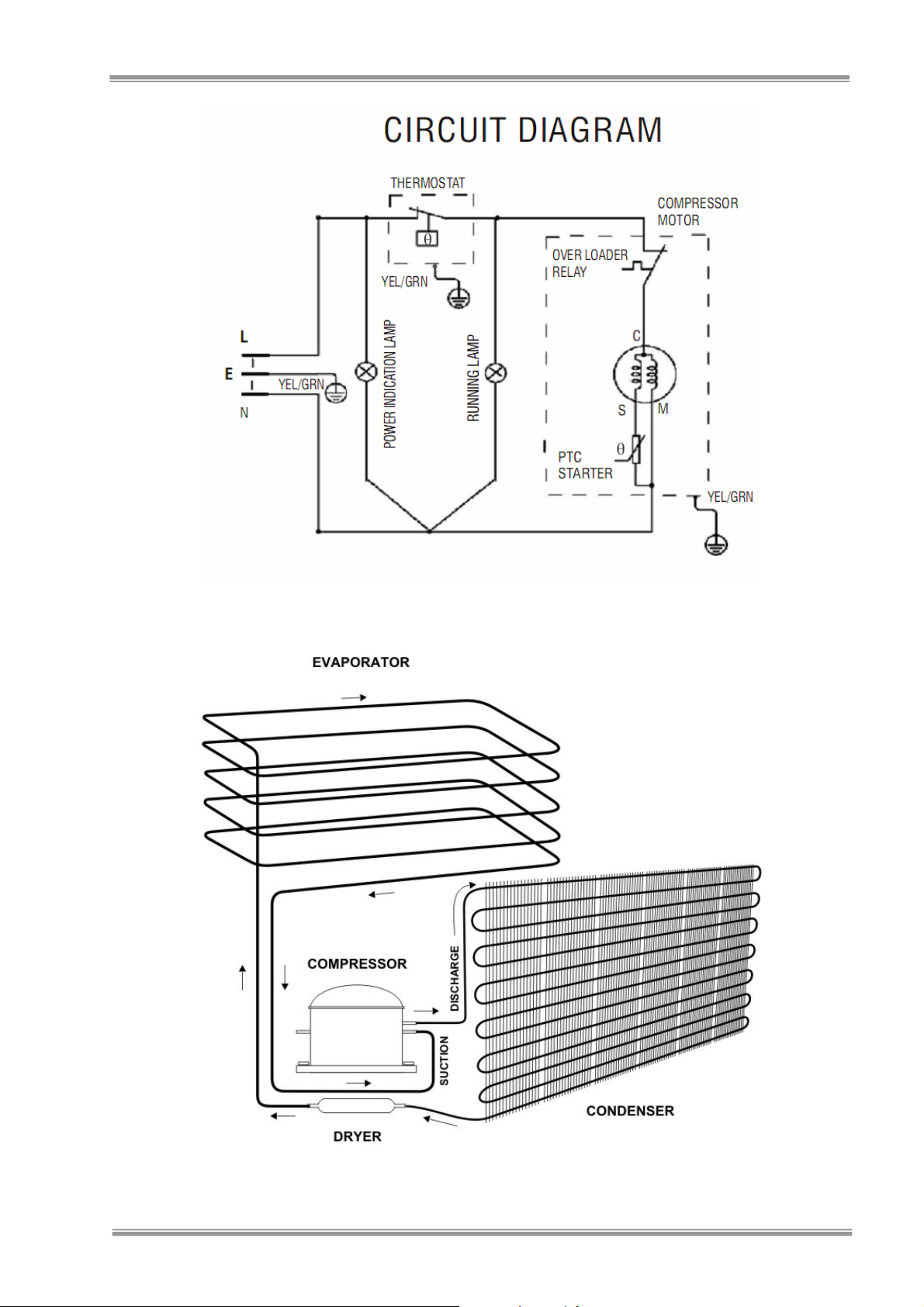

ELEC. CIRCUIT: TSD-35CF

COOLING SYSTEM

TSD-35CF

Page 12

PARTS LIST of TSD-35CF

S/N Part name qty

101 Upper glass door 1

102 Lower glass door 1

103 Food basket 2

201 Foaming body 1

202 Screw ST4.Xx16-C-H 2

203 Exhaust cover 1

204 Side cover holder A 2

205 Screw ST3.5x13-C-H 2

206 Side cover 1

207 Side cover holder B 1

208 Side cover holder C 1

209 thermostat 1

210 Thermostat panel 1

211 Red indicator light 1

212 Green indicator light 1

213 Thermostat knob 1

215 Dryer filter 1

216 Dryer filter support 1

217 Cappilary tube 1

218 suction tube 1

219 Base support 1

220 Screw ST4.2x16-C-H 4

221 Screw 4.2x16-C-H 2

222 Castor 2” 2

223 Screw ST4.2x16-C-H 2

224 Castor 2” 2

225 Screw ST4.2x16-C-H 4

226 Compressor support 1

227

228

301 compressor 1

302 Screw M6x30 4

303 washer 4

304 Over load protector 1

305 Protector clip 1

306 Compressor electric box cover 1

307 Compressor electric box clip 1

308 PTC starter 1

309 Process tube 1

310 Nut M6 4

311 Spring 4

312 Screw M5x10 2

CHEST FROZEN SHOWCASE

TSD-35CF

Fan motor support 1

Screw ST4.2x16-C-H 4

Page 13

CHEST FROZEN SHOWCASE

TSD-35CF

313 anti-vibration gasket cover 4

314 Compressor anti-vibration gasket 4

315 Nut M4 2

316 spring 2

317 Fan motor 1

318 Fan-cool condenser 1

401 Screw M4x22 2

402 Connector box cover 1

403 Connector box support 1

404 Power cord retainer base 1

405 Power cord 1

406 Power cord retainer 1

407 Screw M4x20 2

408 Connector box holder 1

409 Screw M4x20 2

Page 14

Exploded View of TSD-35CF

CHEST FROZEN SHOWCASE

TSD-35CF

Page 15

CHEST FROZEN SHOWCASE

CHARACTERISTIC

TSD-35CF

Parts Name Picture Check Method and Criterion

Measure the resistance with a tester.

Compressor

Model :TSD35CF

PTC Starter

Model : TSD35CF

Overload

Protector

Model : TSD35CF

TROUBLE SHOOTING

Thermostat

PTC Starter

Overload Protector

(Ambient temperature : Room temperature 25

Model Main Wiring

KONOR

Normal

GQY70AD

164 WATTS

Abnormal

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

Normal

Abnormal

Open(

8115PTH7M4R7MC1

(3.8Ω~5.6Ω, Max current 18A/180V)

∞ Ω

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

Normal

T0296/74/T0296/05,B94-130-74,4TM762PBFZZ-

Less than 1

125℃ ;Close temperature:70-52℃;Overload

current

Ω

:27A;UTC(Min action current):3.36A/70℃

Abnormal

Repair Procedure

1. Set Thermo Knob to OFF position, pull & straightened feeler

bulb

2. Remove Thermostat cover and pull out Thermostat from

Thermo Box

3. Short the thermostat terminal and check, if compressor

runs.

4. Replace thermostat

5. After replacing Thermostat, reverse steps above.

Repair Procedure

1. Release Relay Cover Fixing Clip.

2. Remove Relay Cover.

3. Remove PTC Starter

4. Pull out PTC Starter, check if open and compare value of

resistance with given value, if not

5. Hold receptacle terminal then pull electrical wire from PTC

Starter.

6. Replaces PTC Starter (change overload protector together),

reverse the steps above.

Repair Procedure

1. Check for continuity on overload protector, if open

2. Pull out Overload Protector.

3. Hold receptacle terminal then pull electrical wire from

Overload Protector.

4. Replace overload protector.

°

c)

Auxiliary

Wiring

~

2.9

2.5

Ω

(Approx.)S

Open( ∞ Ω ) or Short Circuited ( 0

Ω

)

°

4.1

(Approx.)S

c)

~

4.7Ω

) or Short Circuited ( 0 Ω )

°

c)

51(6.3)

(Approx.) Cut temperature:115-

Open(

∞ Ω

)

Page 16

CHEST FROZEN SHOWCASE

TSD-35CF

Cause Check Point Correction

Repair Procedure

Compressor

Check coils

resistances

1. Replace compressor if measured resistances differ from given standard

2. Abnormal noise

Repair Procedure

1. Operate unit for 10 minutes with thermostat set at maximum

Not cooling

Check thermostat

setting

Repair Procedure

Insufficient cooling Check gasket gap

1. Check if gap can be resolved by adjustment of door hinges fixing screws.

2. Defrost if accumulation of frost is more than 10mm.

Repair Procedure

Malfunction due to

leaks or clogged

system

Charged (purge) with

nitrogen into the

refrigeration system

& check for leaks on

welds or clogs

1. Check for clog or leak in the cooling system.

2. Repair or replace the clogged or leak section.

3. Evacuate and change filter dryer.

4. Purge with nitrogen to clean and check for leaks

5. Recharge refrigerant, test run and seal system

TROUBLE INSPECTION CAUSES REMEDY

No Power

No Light

Check electric power

supply voltage

Check electrical circuit

Check lamp

Open circuit breaker or

fuse

Open Fuse Replace

Worn out or defective A/C

cord

Open Replace

Fix or replace

Replace

Check lamps socket

Low Cooling Check for thermo setting Setting too low Set thermostat higher

Defective Cooling

System

Check Overload Protector Check for continuity Replace if open.

Check leaks

Check Thermostat

Check PTC starter

resistance against given

value

Check for leaks

Check Compressor

resistance against given

specification

Check Pipe System

Corroded

Deform or warp door

gasket.

Poor weld on joints

Over storage or load or

heavy frost accumulation

Check if compressor runs

by shortening thermostat

Open, no resistance or

differ from given value

Leaks or poor welds on

joints

Defective

Clogged Pipe System or

oil choke

Replace

Adjust door hinges fixing

screws

Repair, purge with

nitrogen re-charge

refrigerant and test run.

Reduce or re-arrange

load or defrost unit

Replace thermostat if

compressor runs.

Replace PTC starter.

Repair, re-weld, purge,

evacuate and recharge

refrigerant

Replace, weld, purge,

check for leaks and recharge refrigerant, test run

and seal system

1. Evacuate then Purge

with nitrogen to remove

clogs

2. Repair or replace

clogged section, evacuate,

purge, check leak and recharge refrigerant. Test

Run and seal system

Page 17

A

SERVICE M

CHEST FREEZER

Model : TSD-47CF/TSD-60CF

NUAL

TSD-47CF/TSD-60CF

Specification: Subject to change without notice.

SPECIFICATION TSD-47CF TSD-60CF

Classification Direct Cool, Manual Defrost, Tropical

Power Source 115VAC, 60 Hz.

Volume 298 Liters (10.5 cu.ft.) 318 Liters (11.2 cu.ft.)

Rated Current 2.5 Amp.

Rated Power Input 270 Watts

Power Consumption

High side /Low side

pressure

3.2 kW·h/24h 3.5 kW·h/24h

155psig/-2.22psig

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F 215gm

Overall Dimension 1215(W) x600(D) x 910(H) mm 1295(W) x600(D) x 910(H) mm

Net Weight/Gross Weight 62 Kg./73 Kg. 64 Kg./75 Kg.

ISSUED BY:

REVIEWED BY:

REVISION 2.0

Page 18

PRODUCT SPECIFICATION

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

Model TSD-47CF TSD-60CF

Classification Sliding glass Door, Direct Cool, Tropical

Color/Door White/ with Door Lock Sliding Glass

Body Finish Baked Acrylic Powder Coat

Temperature Control Thermostat

Defrost System Manual Defrost

Drain Manual Drain

Evaporator Tube Type

Condenser Tube Type+Fan-cooling Condenser

Insulation

Cabinet

Freezer Door

Rigid Polyurethane Foam (Blowing Agent CP)

Rigid Polyurethane Foam

Refrigerant HFC-134a (Tetrafluoroethane) CF3CH2F

Refrigerant Charge (gm.) 215 gm

Door Lamp None

Fan Motor ZCF-200(100V-125V/60Hz)

Compressor

DONPER EU1121BZ

160 Watts

Compressor Oil 290 ml.POE Polyol Ester (Synthetic)

PTC Starter

QP2-4.7C

Overload Protector B85-105(220VAC 1.5A-15A 80℃-140℃)

compressor capacity CBB60(15µF ±5%C,250V.AC 50/60Hz)

Dryer (Desiccant) 20 gm.

Overall Dimension (W x D x H mm.) 1215(W) x600(D) x 910(H) mm 1295(W) x600(D) x 910(H) mm

Packing Dimension (W x D x H mm.) 1270(W) x680(D) x 980(H) mm 1355(W) x680(D) x 980(H) mm

Net Weight (kg.) 62kg. 64kg.

Gross Weight (kg.) 73 kg. 75 kg.

CHARACTERISTIC

Operating Temperature (°C)

Model

Dial Position

Temperature Control

WARM 1

NORMAL 4

COLD 7

-10.0°C ± 2 °C

-15.0°C ± 2 °C

-25.0°C ± 2 °C

Page 19

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

ELEC. CIRCUIT: TSD-47CF/TSD-60CF

COOLING SYSTEM

TSD-47CF/TSD-60CF

Page 20

CHEST FROZEN SHOWCASE

PARTS LIST of TSD-47CF/TSD-60CF

TSD-47CF/TSD-60CF

S/N Part name qty

101 Upper glass door 1

102 Lower glass door 1

103 Food basket 4

201 Foaming body 1

202 Screw ST4.Xx16-C-H 2

203 Exhaust cover 1

204 Side cover holder A 2

205 Screw ST3.5x13-C-H 2

206 Side cover 1

207 Side cover holder B 1

208 Side cover holder C 1

209 thermostat 1

210 Thermostat panel 1

211 Red indicator light 1

212 Green indicator light 1

213 Thermostat knob 1

215 Dryer filter 1

216 Dryer filter support 1

217

218

Cappilary tube

suction tube

1

1

219 Base support 1

220 Screw ST4.2x16-C-H 4

221 Screw 4.2x16-C-H 2

222 Castor 2” 2

223 Screw ST4.2x16-C-H 2

224 Castor 2” 2

225 Screw ST4.2x16-C-H 4

226 Compressor support 1

227

228

Fan motor support 1

Screw ST4.2x16-C-H 4

301 Compressor EU1121BZ 1

302 Screw M6x30 4

Page 21

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

303 washer 4

304 Over load protector 1

305 Protector clip 1

306 Compressor electric box cover 1

307 Compressor electric box clip 1

308 PTC starter 1

309 Process tube 1

310 Nut M6 4

311 Spring 4

312 Screw M5x10 2

313 anti-vibration gasket cover 4

314 Compressor anti-vibration gasket 4

315 Nut M4 2

316 spring 2

317 Fan motor ZCF-200 1

318 Fan-cool condenser 1

401 Screw M4x22 2

402 Connector box cover 1

403 Connector box support 1

404 Power cord retainer base 1

405 Power cord 1

406 Power cord retainer 1

407 Screw M4x20 2

408 Connector box holder 1

409 Screw M4x20 2

Page 22

Exploded View of TSD-47CF

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

Page 23

Exploded View of TSD-60CF

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

Page 24

CHEST FROZEN SHOWCASE

CHARACTERISTIC

TSD-47CF/TSD-60CF

Parts Name Picture Check Method and Criterion

Compressor

Model :TSD47CF/TSD60CF

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model Main Wiring

~

2.9

DONPER

EU1121BZ

160 WATTS

Normal

Abnormal

2.5

(Approx.)S

Open( ∞ Ω ) or Short Circuited ( 0

Ω

)

Measure the resistance with a tester.

°

c)

Auxiliary

Wiring

Ω

4.1

~

4.7Ω

(Approx.)S

PTC Starter

Model : TSD47CF/TSD60CF

Overload

Protector

Model : TSD47CF/TSD60CF

compressor

capacity

TROUBLE SHOOTING

Thermostat

PTC Starter

(Ambient temperature : Room temperature 25

Model

Normal

Abnormal

(3.8Ω~5.6Ω, Max current 18A/180V)

Open(

∞ Ω

) or Short Circuited ( 0 Ω )

°

QP2-4.7C

c)

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

Less than 1

Normal

current

Abnormal

Ω

(Approx.) Cut temperature:115-125

℃ ;Close temperature:70-52℃;

:27A;UTC(Min action current):3.36A/70℃

Open(

B85-105

∞ Ω

°

c)

Overload

)

Measure the resistance with a tester.

(Ambient temperature : Room temperature 25

Model

CBB60(15µF ±5%C,250V.AC 50/60Hz)

°

c)

Normal

Abnormal

Open(

∞ Ω

)

Repair Procedure

1. Set Thermo Knob to OFF position, pull & straightened feeler

bulb

2. Remove Thermostat cover and pull out Thermostat from

Thermo Box

3. Short the thermostat terminal and check, if compressor runs.

4. Replace thermostat

5. After replacing Thermostat, reverse steps above.

Repair Procedure

1. Release Relay Cover Fixing Clip.

2. Remove Relay Cover.

3. Remove PTC Starter

4. Pull out PTC Starter, check if open and compare value of

resistance with given value, if not

5. Hold receptacle terminal then pull electrical wire from PTC

Starter.

6. Replaces PTC Starter (change overload protector together),

reverse the steps above.

Page 25

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

Repair Procedure

1. Check for continuity on overload protector, if open

Overload Protector

2. Pull out Overload Protector.

3. Hold receptacle terminal then pull electrical wire from Overload

Protector.

4. Replace overload protector.

Cause Check Point Correction

Repair Procedure

Compressor

Check coils

resistances

1. Replace compressor if measured resistances differ from given standard

2. Abnormal noise

Repair Procedure

1. Operate unit for 10 minutes with thermostat set at maximum

Not cooling

Check thermostat

setting

Repair Procedure

Insufficient cooling Check gasket gap

1. Check if gap can be resolved by adjustment of door hinges fixing screws.

2. Defrost if accumulation of frost is more than 10mm.

Repair Procedure

Malfunction due to

leaks or clogged

system

Charged (purge) with

nitrogen into the

refrigeration system

& check for leaks on

welds or clogs

1. Check for clog or leak in the cooling system.

2. Repair or replace the clogged or leak section.

3. Evacuate and change filter dryer.

4. Purge with nitrogen to clean and check for leaks

5. Recharge refrigerant, test run and seal system

TROUBLE INSPECTION CAUSES REMEDY

No Power

No Light

Check electric power

supply voltage

Check electrical circuit

Check lamp

Open circuit breaker or

fuse

Open Fuse Replace

Worn out or defective A/C

cord

Open Replace

Fix or replace

Replace

Check lamps socket

Low Cooling Check for thermo setting Setting too low Set thermostat higher

Defective Cooling

System

Check Overload Protector Check for continuity Replace if open.

Check leaks

Check Thermostat

Check PTC starter

resistance against given

value

Check for leaks

Check Compressor

resistance against given

specification

Check Pipe System

Corroded

Deform or warp door

gasket.

Poor weld on joints

Over storage or load or

heavy frost accumulation

Check if compressor runs

by shortening thermostat

Open, no resistance or

differ from given value

Leaks or poor welds on

joints

Defective

Clogged Pipe System or 1. Evacuate then Purge

Replace

Adjust door hinges fixing

screws

Repair, purge with

nitrogen re-charge

refrigerant and test run.

Reduce or re-arrange

load or defrost unit

Replace thermostat if

compressor runs.

Replace PTC starter.

Repair, re-weld, purge,

evacuate and recharge

refrigerant

Replace, weld, purge,

check for leaks and recharge refrigerant, test run

and seal system

Page 26

CHEST FROZEN SHOWCASE

TSD-47CF/TSD-60CF

oil choke with nitrogen to remove

clogs

2. Repair or replace

clogged section, evacuate,

purge, check leak and recharge refrigerant. Test

Run and seal system

Loading...

Loading...