Page 1

REFRIGERATOR MANUFACTURER

TBC

95SD/SB

Turbo air

Commercial

Refrigerator

Service Manual

Horizontal Bottle Coolers

Model No. : TBC-24SD/SB

TBC-36SD/SB

TBC-50SD/SB

TBC-65SD/SB

TBC-80SD/SB

-

Page 2

TABLE OF CONTENTS

1. FEATURE CHART

2. WIRING DIAGRAM

3. PART DETAILS

4. MAIN COMPONENTS

5. TEMPERATURE CONTROL INSTRUCTION

6. PARTS LIST

7. REPLACEMENT OF MAIN COMPONENTS

Page 3

1. FEATURE CHART

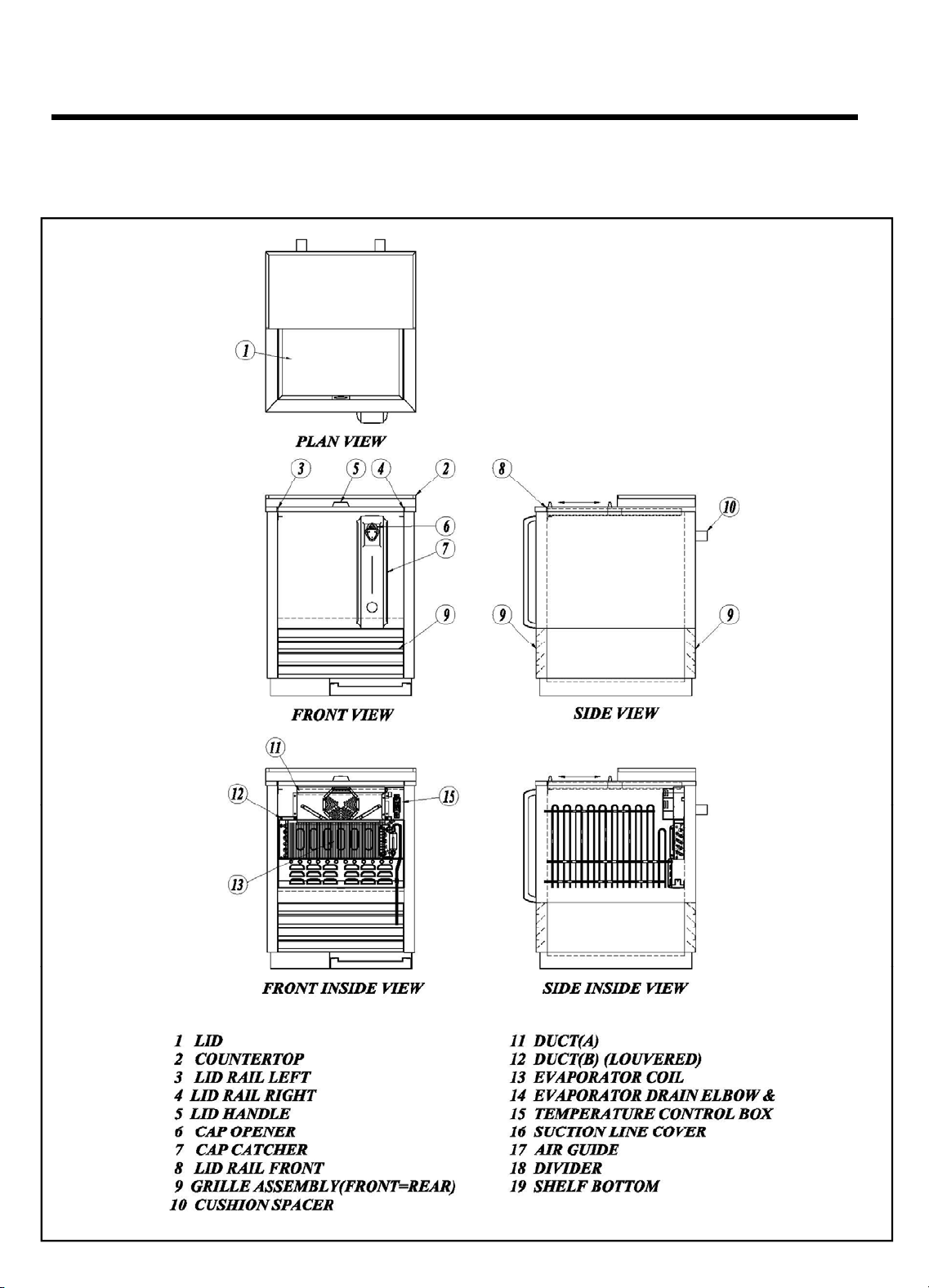

1-1. TBC-24SD/SB

Page 4

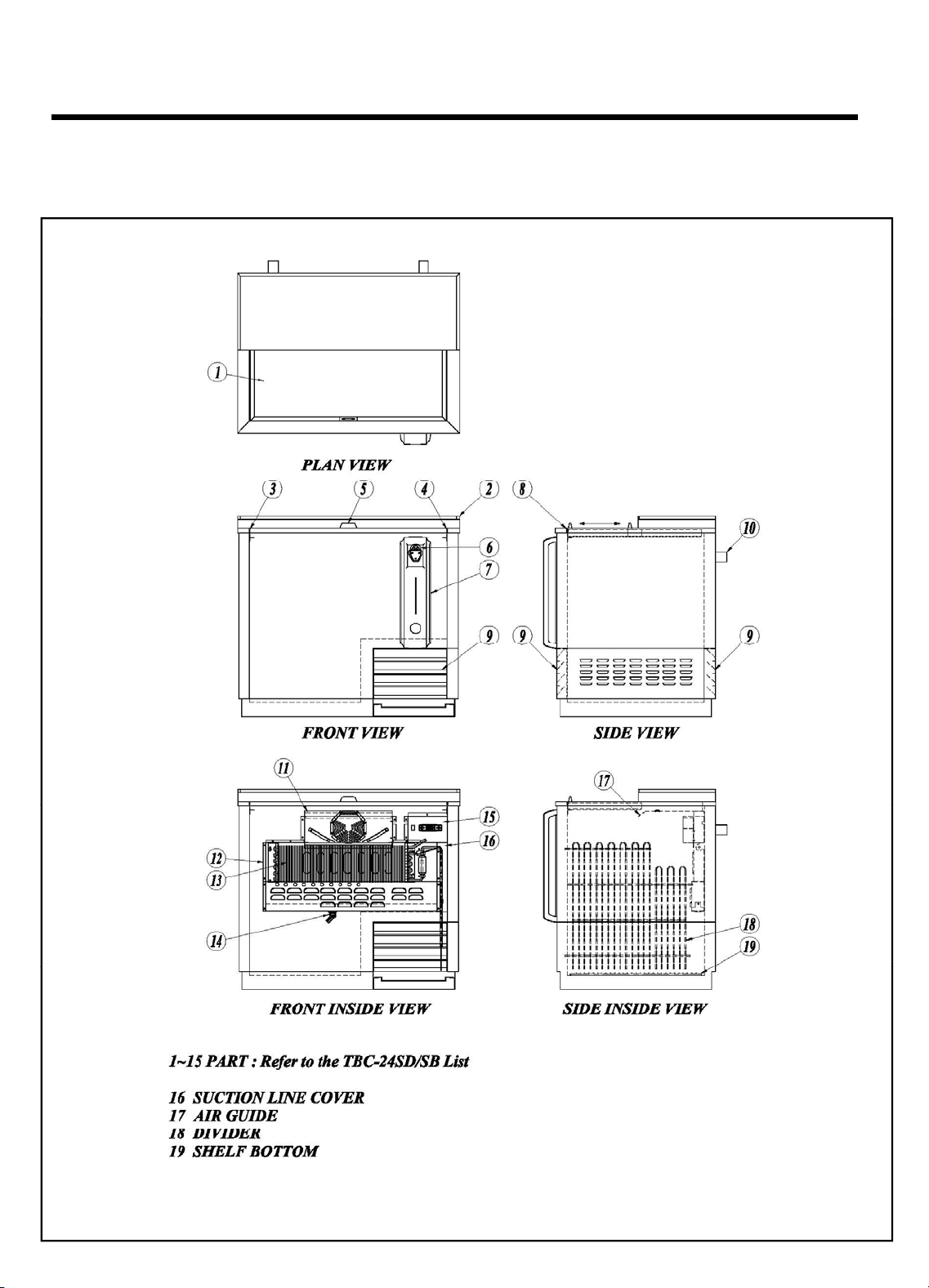

1-2. TBC-36SD/SB

FEATURE CHART

Page 5

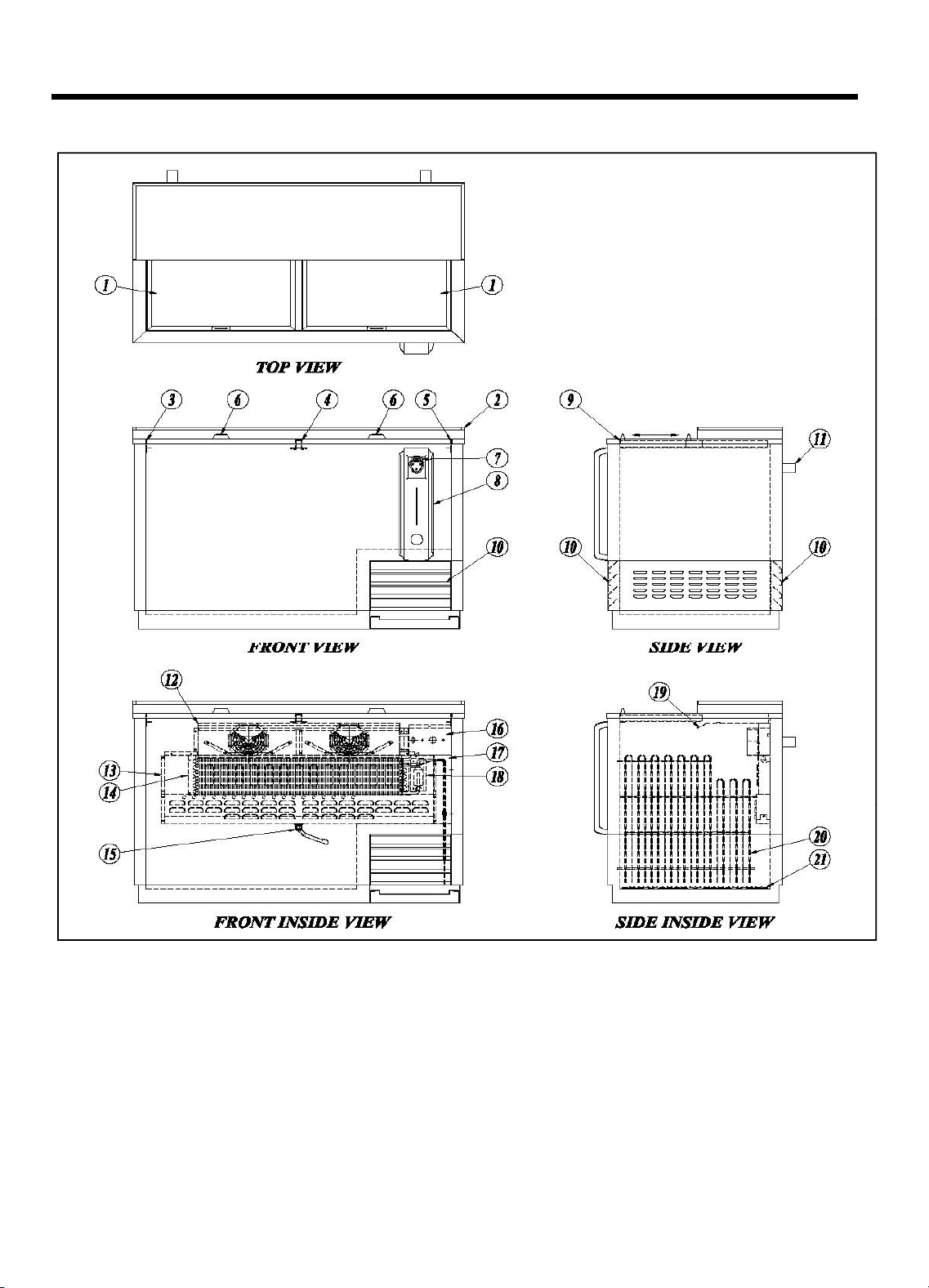

1-3. TBC-50SD/SB, TBC-65SD/SB

1.LID

11.CUSHION SPACER

8.CAP CATCHER

18.LEAK TEST COVER

FEATURE CHART

2. COUNTER TOP

3. LID RAIL LEFT

4. LID RAIL MIDDLE

5. LID RAIL RIGHT

6. LID HANDLE

7. CAP OPENER

9. LID RAIL FRONT

10. GILLE ASSEMBLEY(FRONT = REAR)

12. DUCT(A)

13. DUCT(B) (LOUVERED)

14. EVAPORATOR COIL

15. EVAPORATOR DRAIN ELBOW & HOSE

16. TEMPERATURE CONTROL BOX

17. SUCTION LINE COVER

19. AIR GUIDE

20. DIVIDER

21. SHELF BOTTOM

Page 6

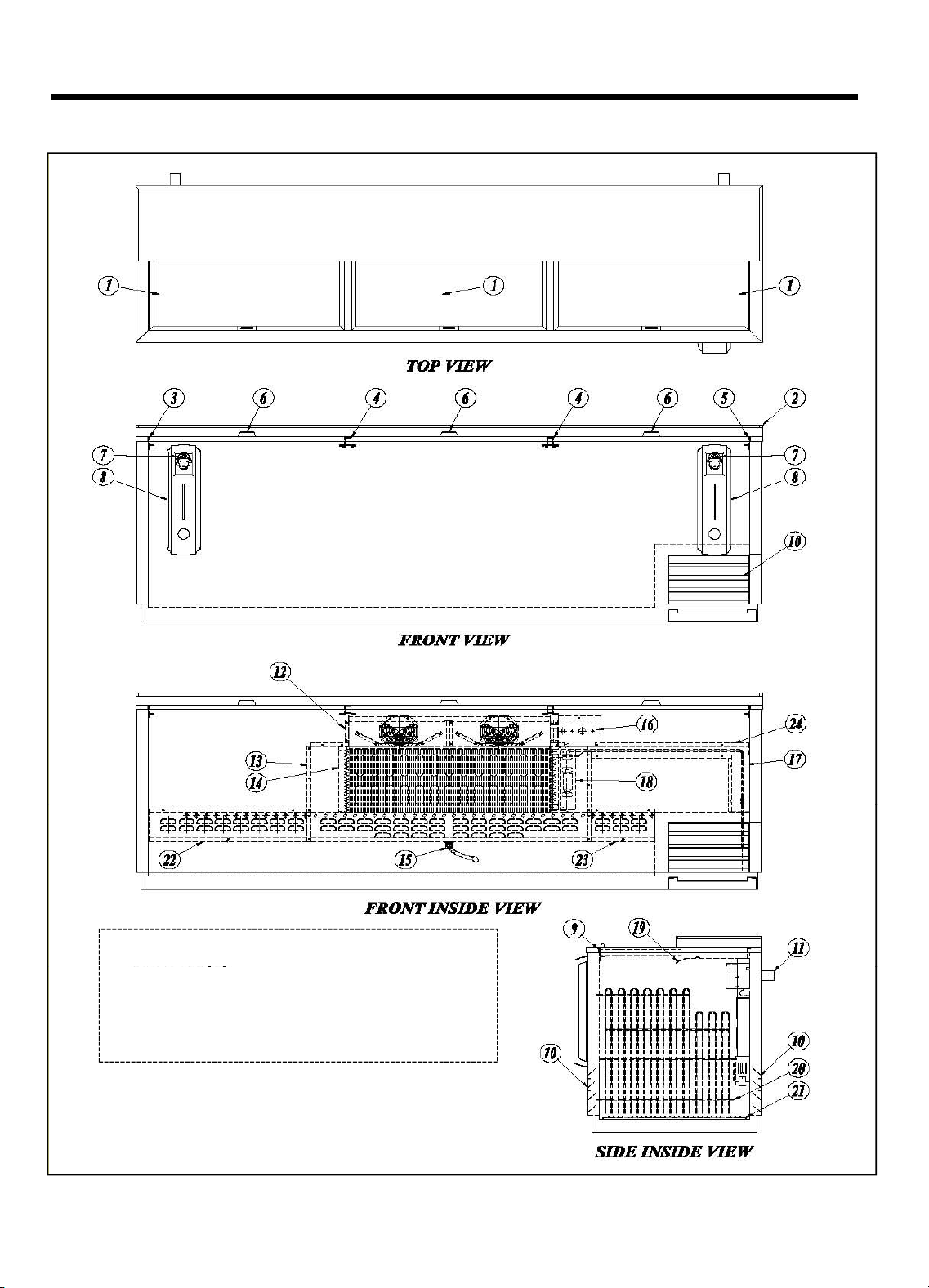

1-4. TBC-80SD/SB, TBC-95SD/SB

FEATURE CHART

1~21 PART : Refer to the TBC-50SD/SB LIST

22. DUCT(C)

23. DUCT(D)

24. SUCTION LINE COVER(HORIZONTAL)

Page 7

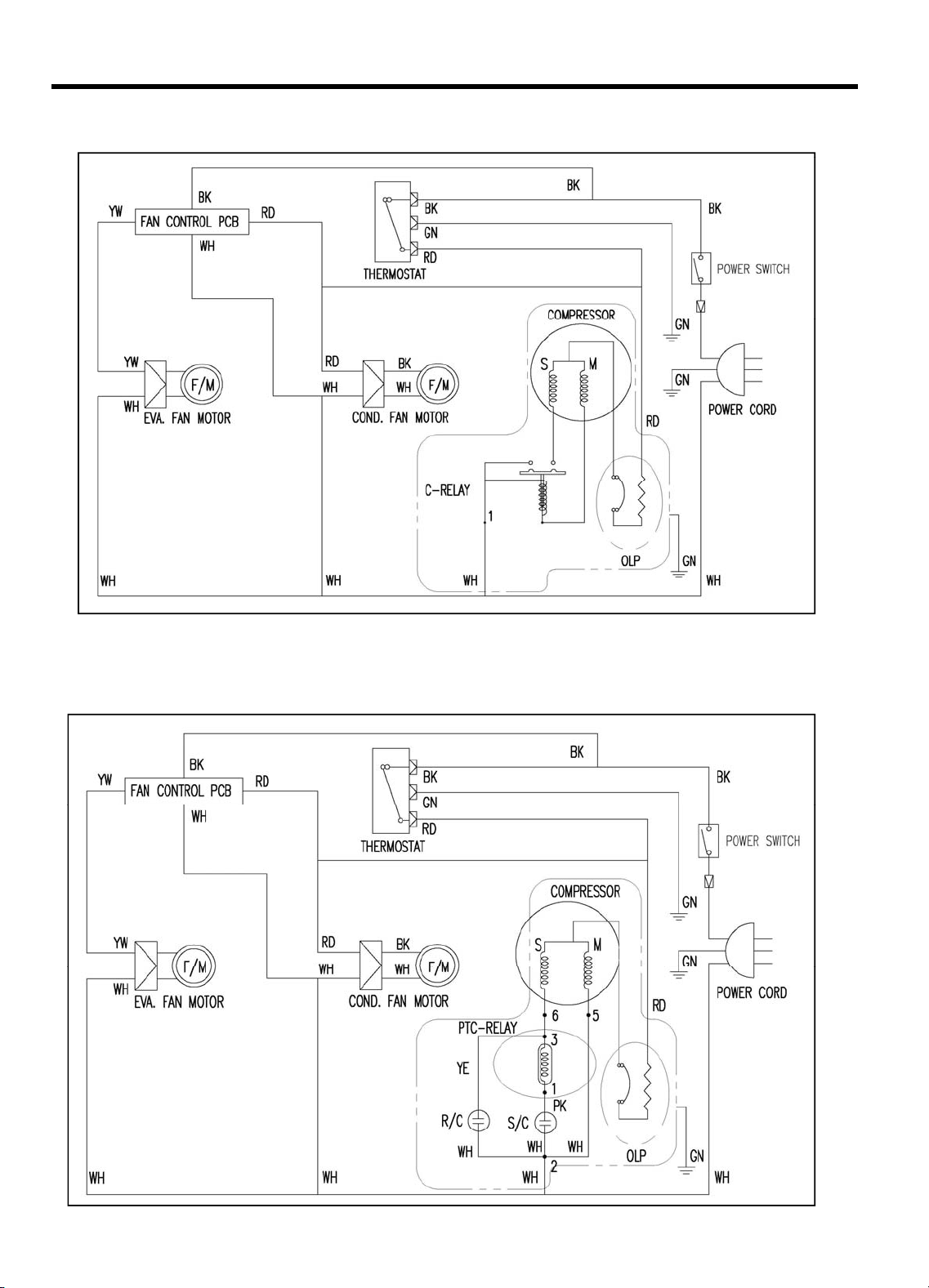

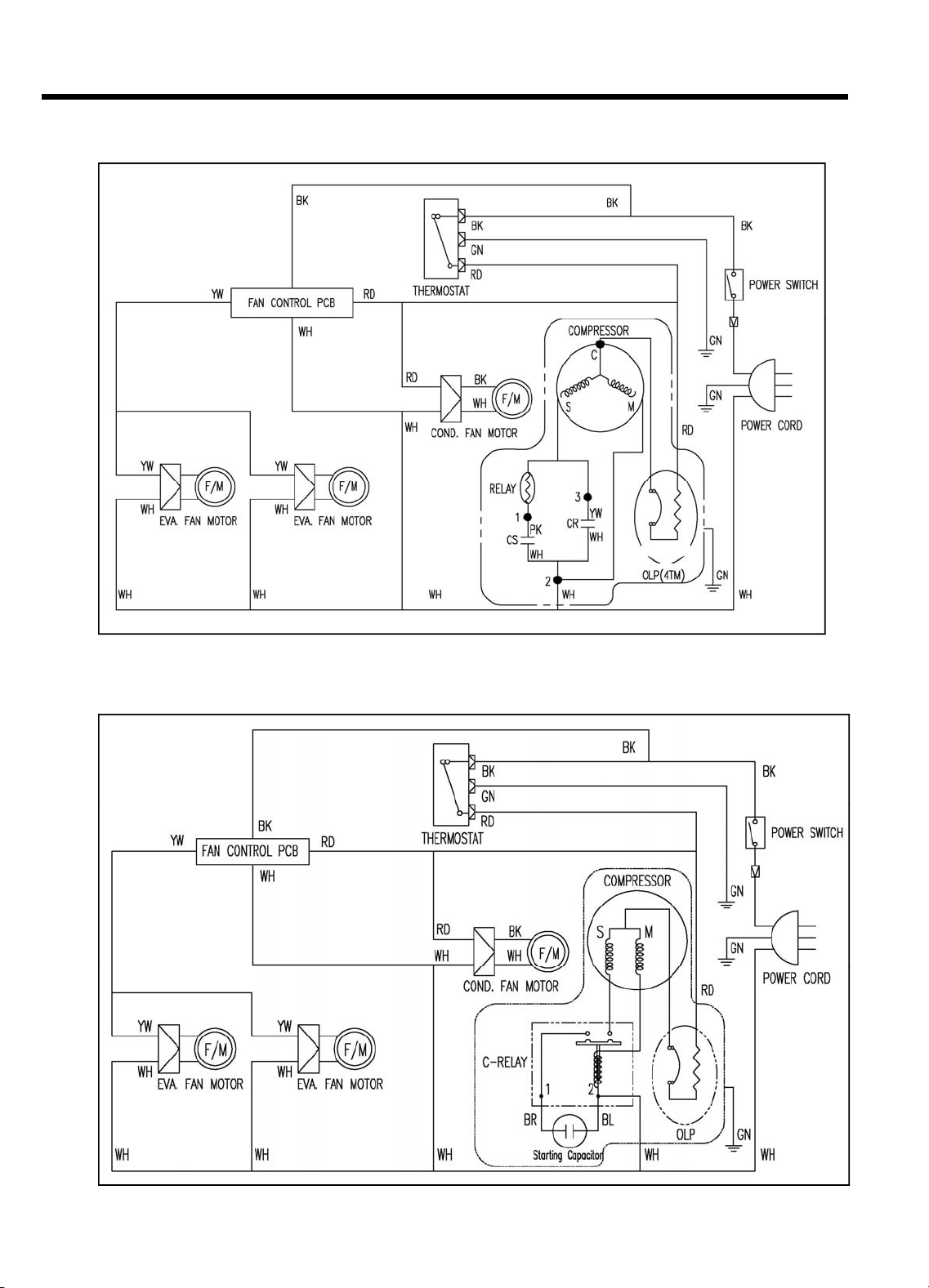

2. WIRING DIAGRAM

2-1. TBC-24SD/SB

2-2. TBC-36SD/SB

Page 8

WIRING DIAGRAM

2-3. TBC-50SD/SB, TBC-65SD/SB

2-4. TBC-80SD/SB, TBC-95SD/SB

Page 9

3. PART DETAILS

3-1. EVAPORATOR FAN MOTOR

Motor B

t

TBC

50SD/SB

3-2. CONDENSER FAN MOTOR

Evaporator Fan Blade

Motor Bracket

Evaporator Fan Motor

Condenser Fan Blade

Motor Bracket

Condenser Fan Motor

TBC-24SD/SB

TBC-36SD/SB

racke

Condenser Fan Motor

Condenser Fan Blade

TBC-65SD/SB

TBC-80SD/SB

TBC-95SD/SB

Page 10

PART DETAILS

3-3. DUCT(A) : EVAPORATOR FAN MOTOR DUCT

3-4. DUCT(B),(C),(D)

DUCT(C)

DUCT(B) DUCT(D)

Page 11

PART DETAILS

3-5. EVAPORATOR COIL

[ TBC-50SD/SB, TBC-65SD/SB ]

[ TBC-80SD/SB, TBC-95SD/SB ]

SENSOR INLET

ACCUMULATOR

Page 12

PART DETAILS

3

6. CONDENSER COIL

-

[ TBC-50SD/SB, TBC-65SD/SB ] [ TBC-80SD/SB, TBC-95SD/SB ]

Page 13

PART DETAILS

3-7. DIVIDER

[ TBC-24SD/SB]

[ TBC-36SD/SB, TBC-50SD/SB, TBC-65SD/SB ]

3-8. DIVIDER SPRING

[ TBC-80SD/SB, TBC-95SD/SB ]

Page 14

PART DETAILS

AC input

3-9. COUNTER TOP

3-10. Fan Control PCB

Fan output

Compressor

on/off signal

Page 15

4. MAIN COMPONENTS

1. COMPRESSOR

896 BTU/h

LBP

C-95SD/S

C

95S /S

TBC-95SD/SB

TBC-80SD/SB

MODEL PART NAME PART NO.

TBC-24SD/SB HFL11Y-1 30289A0400 1/10 HP

TBC-36SD/SB HBL27YE-1 3952127G10 1/4 HP

TBC-50SD/SB

TBC-65SD/SB

TBC-80SD/SB

TB

B

SK1A1C-L2W 30200Q1200 1/3 HP

CAE4456Y 30200B4500 1/2 HP

HORSE

POWER MOTOR (RLA)

CAPACITY

373 BTU/h LBP

(94 Kcal/h) RSIR

(226 Kcal/h) CSR

1,202 BTU/h LBP

(303 Kcal/h) CSR

5,592BTU/h HBP

(1,410 Kcal/h)

TYPE OF Current

1.9A DAEWOO

3.7A DAEWOO

4.0A SAMSUNG

CSIR

9.0A TECUMSEH

2. COMPRESSOR RELAY, OVERLOAD

MODEL RELAY OVERLOAD PROTECTOR MAKER

TBC-24SD/SB S068 (PTC-RSIR) 4TM-293THBYY-52 DAEWOO

TBC-36SD/SB S068 (PTC-CSR) 4TM 783SHBZZ-52 DAEWOO

MAKER

TBC-50SD/SB

J531Q34E22OM3503 4TM 795TFBZZ-53 SAMSUNG

TBC-65SD/SB

TBC-80SD/SB

KPF498***** T0889 TECUMSEH

3. COMPRESSOR CAPACITOR

MODEL STARTING PART NO. RUNNING PART NO.

TBC-24SD/SB - - - TBC-36SD/SB 220V/100

TBC-50SD/SB

125V / 125

TBC-65SD/SB

160V / 315

TBC-95SD/SB

㎌

㎌

㎌

3017906900 230V/10

- 250V / 12

---

㎌

㎌

381791600

-

Page 16

MAIN COMPONENTS

4. EVAPORATOR FAN MOTOR

▶

THERMOSTAT ON/OFF SPEC

MODEL PART NAME PART NO. POLE BLADE SIZE MAKER

ALL DAI-6202DEUA 3963339930 2P ZITEL 110mm DAE-YOUNG

5. CONDENSER FAN MOTOR

MODEL PART NAME PART NO. POLE BLADE SIZE MAKER

TBD-1SD

IS-3225DWSQ-2 3963326710 2P ZITEL 150mm SUNG-SHIN

TBB-1SB

TBC-50SD/SB

TBC-65SD/SB

TBC-80SD/SB

TBC-95SD/SB

6. THEMOSTAT

MODEL PART NAME PART NO. MAKER

ALL GNA-242L 30283F1000 SHIN-HAN

MODEL

GNA-242L 8.0 -5.0 5.0 -9.0 2.8 -12.5

IS-4420DWSG-1 3963320410 4P Aluminum 200mm SUNG-SHIN

.

WARM NORMAL COLD

On Off On Off On Off

7. FAN-CONTROL PCB

MODEL PART NAME PART NO. MAKER

ALL FAN CONTROL PCB P0143A0100 NEUROSYS

Page 17

5. TEMPERATUR CONTROL INSTRUCTION

▶

Compressor is automatically turned on and off by thermostat.

5-1. HOW TO USE THE TEMPERATURE CONTROL

▶ Temperature can be controlled by the user.

▶ Settings can be changed by “Dial Knob”.

TEMPERATURE CONTROL

5-2. FAN CONTROL PCB

▶ Cooling Fan Motors are controlled by “Fan Control PCB”

▶ Cooling Fan Motors are continuously operating while compressor is operating

▶ It is repeated during compressor is not operaing that Cooling Fan Motors are

not operating 3 minutes and operating 1 minutes.

Page 18

6. PARTS LIST

Page 19

PARTS LIST

Page 20

7. REPLACEMENT OF MAIN COMPONENTS

▶

CAUTION : Unpl

ug the unit before replacing any part.

7-1. REPLACING DOOR THE EVAPORATOR COIL

A. Remove all lids. Remove the dividers.

(Now, you can replace the evaporator fan motor or the temperature control(thermostat) if you

unscrew the duct(A) or the temperature control box.)

B. Cut the silicone line around the countertop frame with a knife.

Remove all screws in back of the countertop frame.

C. Remove all the screws around the lid rail.

Lift the countertop from the rear first. Push countertop forward and top will come off.

Page 21

REPLACEMENT OF MAIN COMPONENTS

D. Carefully move the countertop to a safe place.

See the join bracket and understand join system.

E. This is the duct(A) and the temperature control box.

Unscrew the temperature control box if necessary.

E. Unplug the temperature control harness assembl y.

Page 22

REPLACEMENT OF MAIN COMPONENTS

G. Pull the sensing tube of the temperature control.

Replace the temperature control if necessary.

H. Remove the screws on duct(A) and Remove.

I. Unplug the evaporator fan motor harness assembly if necessary.

Page 23

REPLACEMENT OF MAIN COMPONENTS

J. Remove screws to the evaporator fan motor if necessary and replace it with new one.

K. Remove the screws on duct(B) and Remove.

L. Remove the screws on the suction line cover(horizontal) if necessary.

Page 24

REPLACEMENT OF MAIN COMPONENTS

() () y

M. Remove screws to the duct(C) and the duct(D) if necessary.

N. Now evaporator coil is visible.

To replace it, cut out at the welding point between the accumulator and the suction line,

and also of the end of the capillary tube.

Page 25

REPLACEMENT OF MAIN COMPONENTS

() () y

In pushing the compressor compartment to the original position, please be careful so the

O. Remove screws to the duct(C) and the duct(D) if necessary.

7-2. ACCESSING CONDENSER COMPARTMENT

A. After removing the front grille assembly, unscrew the compressor base.

Pull the compressor compartment slowly.

Compressor, Condenser coil, Condenser fan motor, etc. can be replaced.

•

capillary tube does not bend.

Loading...

Loading...