Page 1

Turbo air Speeds Up the Pace of Innovation

Part No. KUCST2901

Refrigeration System

Installation & Operation Manual

Please read this manual completely before attempting to install or operate this equipment !

Package Unit ( TOP MOUNT )

Page 2

CONTENTS

Safety Information …………………………………… 3

Inspection ……………………………………………… 3

Locating SMART 7 Package Unit…………………… 6

Installation Procedure ………………………………… 8

Sequence of Operation ……………………………… 10

Controller Setting …………………………………… 11

System Troubleshooting …………………………… 19

Electrical Wiring Diagram…………………………… 20

2

Page 3

Safety Information

Be sure all power sources are turned off before checking the electric wiring or

appliances to avoid electric shock.

Do not run fan if cover or case is removed. This is to avoid electric shock.

Keep finger away from moving parts.

Avoid touching refrigerant lines. Some parts are very hot and can cause burns.

Avoid contacting sharp edges or coil surface that are a potential injury hazard.

Avoid touching the units or electric box in wet hands to prevent electric shock.

Please call the specialized installation company or trained personnel when you installing,

moving, operating of the unit.

Field wiring must confirm to the requirements of units’ electric specification.

Inspection

A person at the job site to receive material holds responsibility. Each shipment should

be carefully inspected against the bill of lading. The shipping receipt should not be

signed before careful inspection. Check carefully for concealed damage. Any shortage

or damages should be reported to the delivering carrier. If damaged material becomes

the delivering carrier’s responsibility and it should not be returned to Turbo air unless

prior approval is given to do so. Check the serial tag information with invoice. Report

any discrepancies to Turbo air sales representatives.

3

Page 4

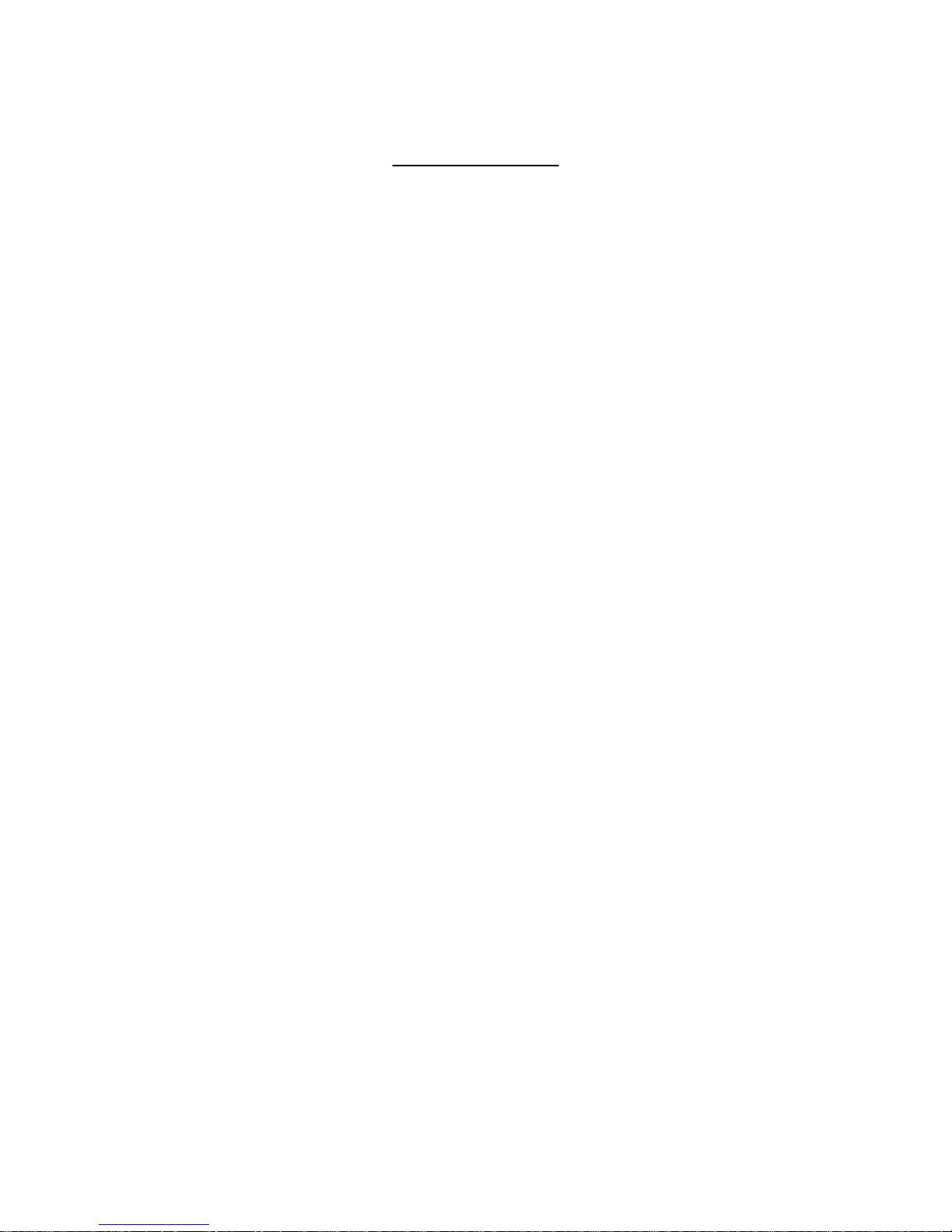

Table 1. INDOOR UNIT - Medium Temperature (Air Defrost System)

Ambient 95℉

Model

STI050MR404A1 5026 5356 115/1/60 11.3 20 R404A 28 YES 5-20R 195 A

STI050MR404A2 5026 5356 208~230/1/60 4.7 15 R404A 28 YES 6-15R 195 A

STI073MR404A2 8059 8675 208~230/1/60 6.0 15 R404A 42 YES 6-15R 226 A

STI100MR404A2 11652 12556 208~230/1/60 14.0 20 R404A 53 YES 6-20R 311 B

STI100MR404A3 11652 12556 208~230/3/60 10.1 15 R404A 53 NO - 318 B

STI126MR404A2 15092 16376 208~230/1/60 14 20 R404A 60 NO - 320 B

STI126MR404A3 15092 16376 208~230/3/60 9.9 15 R404A 60 NO - 317 B

Capacity BTUH

35℉ 38℉

Voltage MCA MOPD

Refrigerant.

Wt

Ref.

oz

Plug

Supplied

Matching

NEMA

Receptacle

NET

Weight

(Lbs)

Fig.

Table 2. INDOOR UNIT – Low Temperature (Electric Defrost System)

Ambient 95℉

Model

STI021LR404A2 2849 2423 1643 208~230/1/60 8.0 15 R404A 28 YES 6-15R 195 A

STI048LR404A2 5957 4603 3514 208~230/1/60 16.4 25 R404A 42 YES 6-15R 226 A

STI053LR404A2 7395 5406 4002 208~230/1/60 19.5 30 R404A 53 YES 6-20R 311 B

STI053LR404A3 7395 5406 4002 208~230/3/60 13.3 20 R404A 53 NO - 318 B

STI069LR404A2 9139 7520 5439 208~230/1/60 19.8 30 R404A 60 NO - 320 B

STI069LR404A3 9139 7520 5439 208~230/3/60 13.9 20 R404A 60 NO - 317 B

Capacity BTUH

0℉ −10℉ −20℉

Voltage MCA MOPD

Refrigerant.

Wt

Ref.

oz

Plug

Supplied

Matching

NEMA

Receptacle

NET

Weight

(Lbs)

Fig.

Table 3. OUTDOOR UNIT - Medium Temperature (Air Defrost System)

Ambient 95℉

Model

STX050MR404A2 5026 5356 208~230/1/60 4.7 15 R404A 24 NO - 205 A

STX073MR404A2 8059 8675 208~230/1/60 6.0 15 R404A 28 NO - 236 A

STX100MR404A2 11652 12556 208~230/1/60 14.0 20 R404A 46 NO - 319 B

STX100MR404A3 11652 12556 208~230/3/60 10.1 15 R404A 46 NO - 327 B

STX126MR404A2 15092 16376 208~230/1/60 14 20 R404A 46 NO - 329 B

STX126MR404A3 15092 16376 208~230/3/60 9.9 15 R404A 46 NO - 325 B

Capacity BTUH

35℉ 38℉

Voltage MCA MOPD

Refrigerant.

Wt

Ref.

oz

Plug

Supplied

Matching

NEMA

Receptacle

NET

Weight

(Lbs)

Fig.

Table 4. OUTDOOR UNIT – Low Temperature (Electric Defrost System)

Ambient 95℉

Model

STX021LR404A2 2849 2423 1643 208~230/1/60 8.0 15 R404A 28 NO - 213 A

STX048LR404A2 5957 4603 3514 208~230/1/60 16.4 25 R404A 42 NO - 248 A

STX053LR404A2 7395 5406 4002 208~230/1/60 19.5 30 R404A 53 NO - 320 B

STX053LR404A3 7395 5406 4002 208~230/3/60 13.3 20 R404A 53 NO - 317 B

STX069LR404A2 9139 7520 5439 208~230/1/60 19.8 30 R404A 60 NO - 328 B

STX069LR404A3 9139 7520 5439 208~230/3/60 13.9 20 R404A 60 NO - 324 B

Capacity BTUH

0℉ −10℉ −20℉

Refrigerant.

Voltage MCA MOPD

4

Ref.

Wt

oz

Plug

Supplied

Matching

NEMA

Receptacle

NET

Weight

(Lbs)

Fig.

Page 5

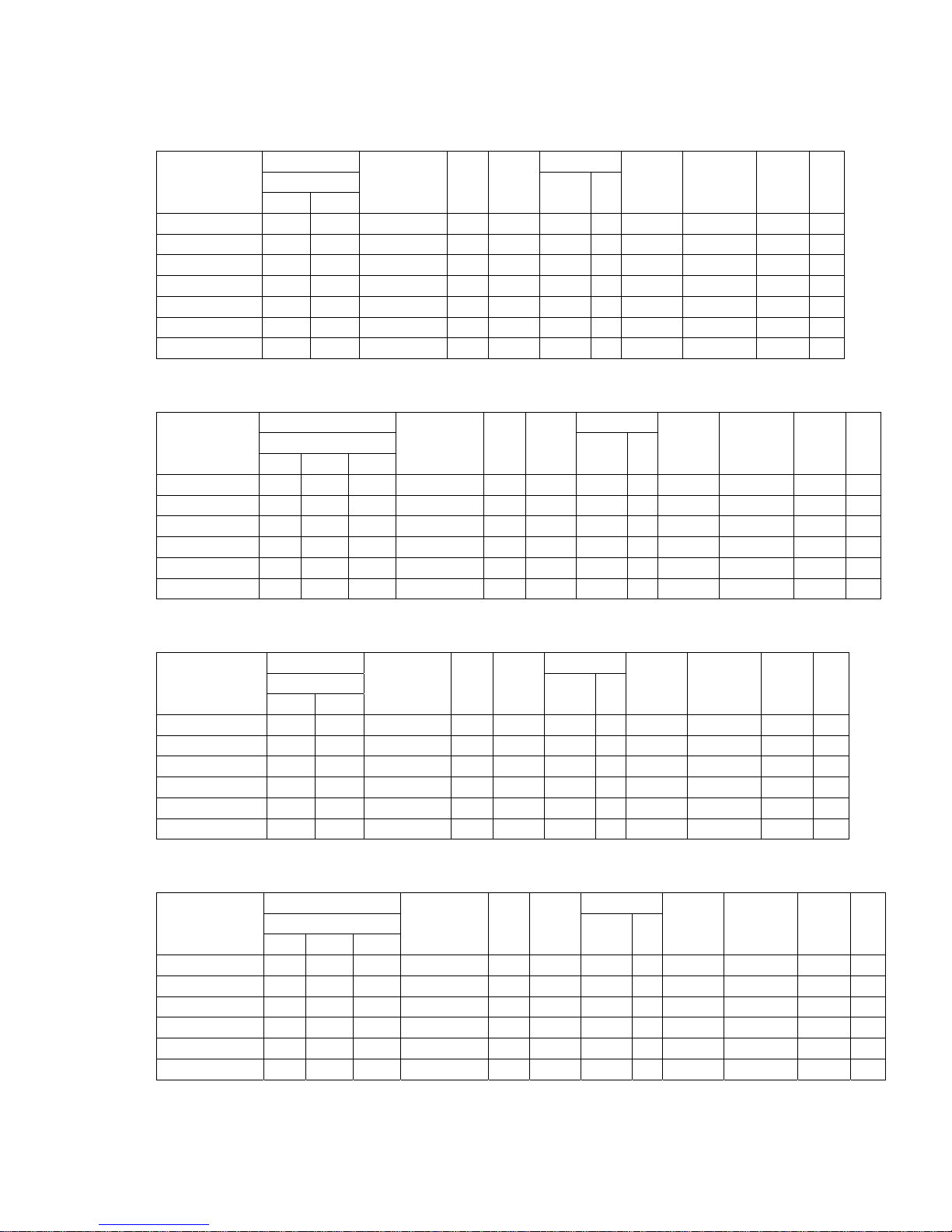

Figure A. INDOOR UNIT – Medium Cabinet (Opening Size : 25 inch x 25 inch)

Figure B. INDOOR UNIT – Large Cabinet (Opening Size : 25 inch x 38.5 inch)

Figure C. OUTDOOR UNIT – Medium Cabinet (Opening Size : 25 inch x 25 inch)

Figure D. OUTDOOR UNIT – Large Cabinet (Opening Size : 25 inch x 38.5 inch)

5

Page 6

Locating SMART 7 Package Unit

Unit Installation Requirements

1. You must ensure before unit placement on the roof of box that the structural strength of the

box can withstand the weight of SMART7 equipment

2. The unit should be installed away from noise sensitive site and must have proper support for

noise and vibration not to be transmitted into the building.

3. Unit must be located away from steam, hot air or heat generator and placement should be

selected in consideration of ventilation.

4. Indoor units are designed for indoor use only with ambient between 50℉~100℉ and have no

system control following ambient variation.

5. Evaporator section must not be located over doors.

6. Air circulation must cover completely inner space.

7. Installation, service and maintenance must be carried out by licensed contractor in conformity

with the local standard construction code.

Ignoring above requirement will result in system fault, shorten life span and void the warranty,

Unit Transport Requirements.

1. Do not remove shipping skid until ready to move it upon box rooftop.

2. Always watch out not to contact sharp edges and coil surfaces to avoid potential injury. Wear

safety gears always during installation.

3. Use spreader bar to lift the unit upon roof of box not to damage on the cabinet.

4. Do not remove compartment cover of the compressor section, hood for outdoor unit.

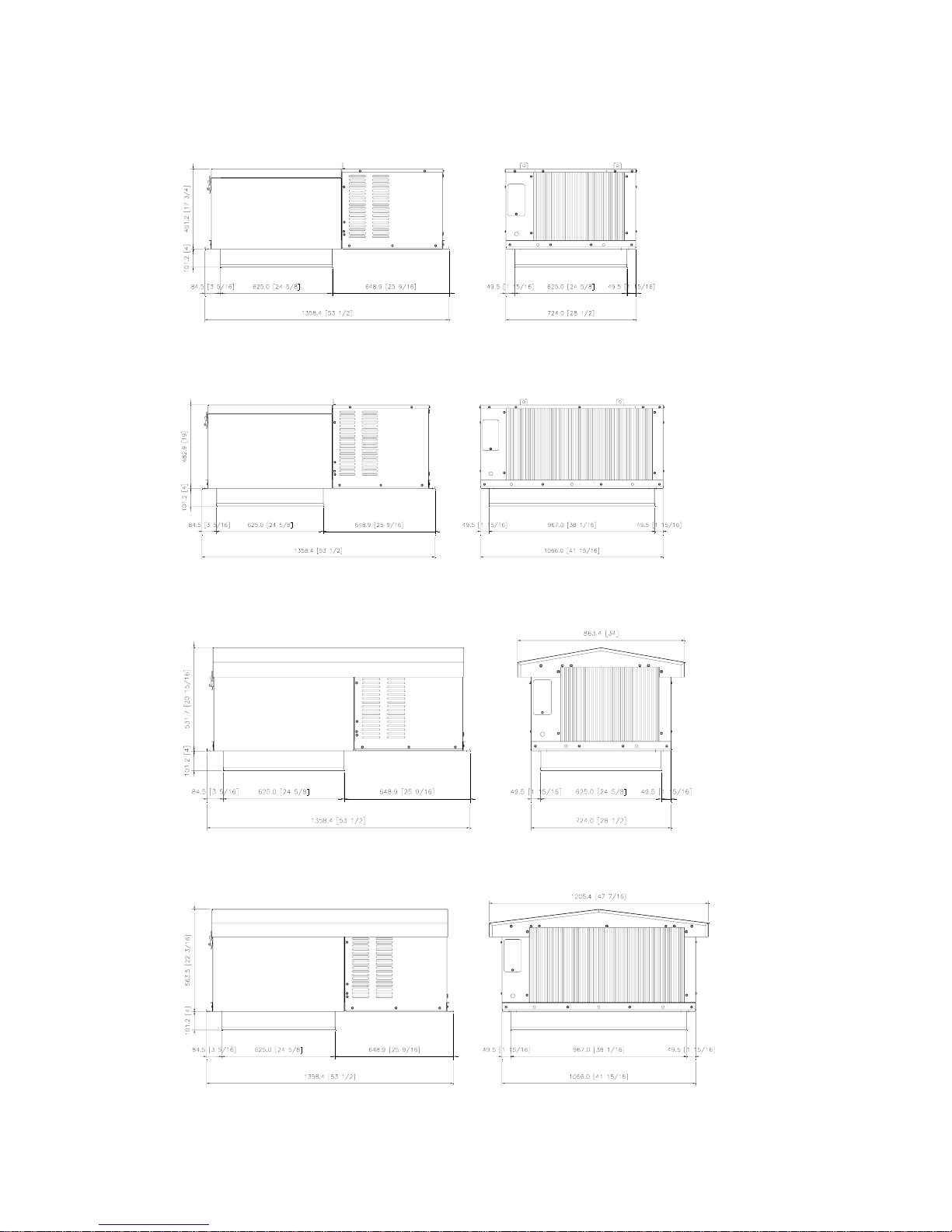

Unit Installation location.

1. Space between wall and air in/outlet must be secured at least 2inch.(refer to Fig. 1)

2. There must be 2 feet space secured at least above unit for service and removal of top

case.(Refer to Fig. 1)

3. Single unit installation must be carried out following Fig. 2.

4. Two or more unit installation must be carried out following Fig. 3.

6

Page 7

Figure 1. Minimum Clearance at Installation of Unit.

W = UNIT WIDTH

Figure 2. One Unit

W = UNIT WIDTH

Figure 3. Two or more Unit

7

Page 8

Installation procedure

Indoor use only ( STI Model )

1. Carefully check package for damages during transportation and unit after opening the

package.

2. Requirements must be followed for installing location on the page of 6~7.

3. Ensure weights of units on the page of 4~5 and that structural strength of the box can

withstand of the weight of the unit.

4. Clean the roof surface of box for close adhesion of unit gasket to the surface.

5. Consult to box manufacturer for any processes necessary to ensure the integrity of the

exposed form in the panels is not compromised.

6. Check mounting surface as level of surface should be within 1/8inch per a feet.

7. Place carefully unit into the provided opening with the evaporator air flow directly forward the

door and ensure the grill not to damage during installation.

8. Secure that the condenser airflow is not obstructed.

9. Drain is not needed as condensate is vaporized by hot gas lines in the drain panel from the

compressor discharge.

10. Install trim pieces around the open on the ceiling of box.

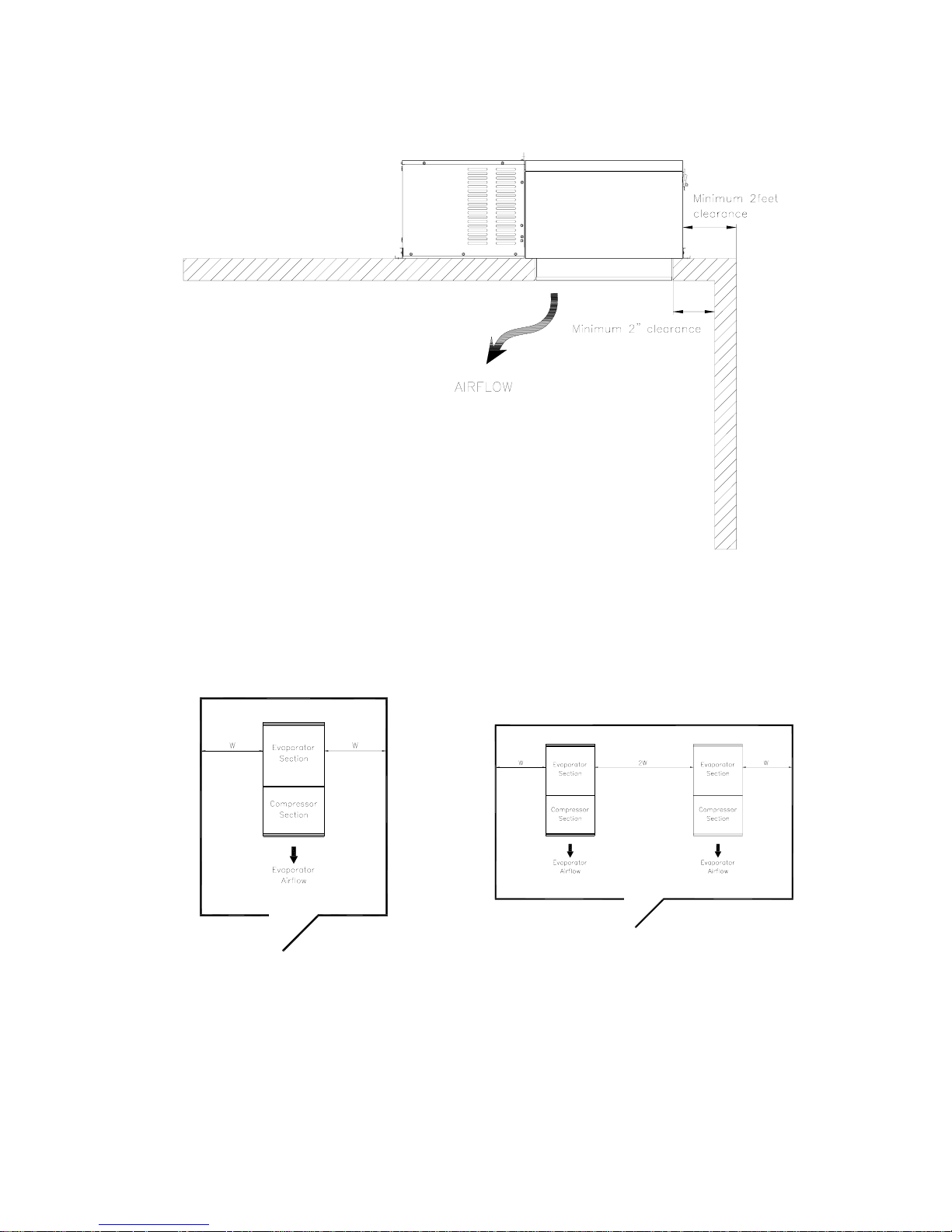

Outdoor use only ( STX Model )

Installation is the same as indoor models except as follows :

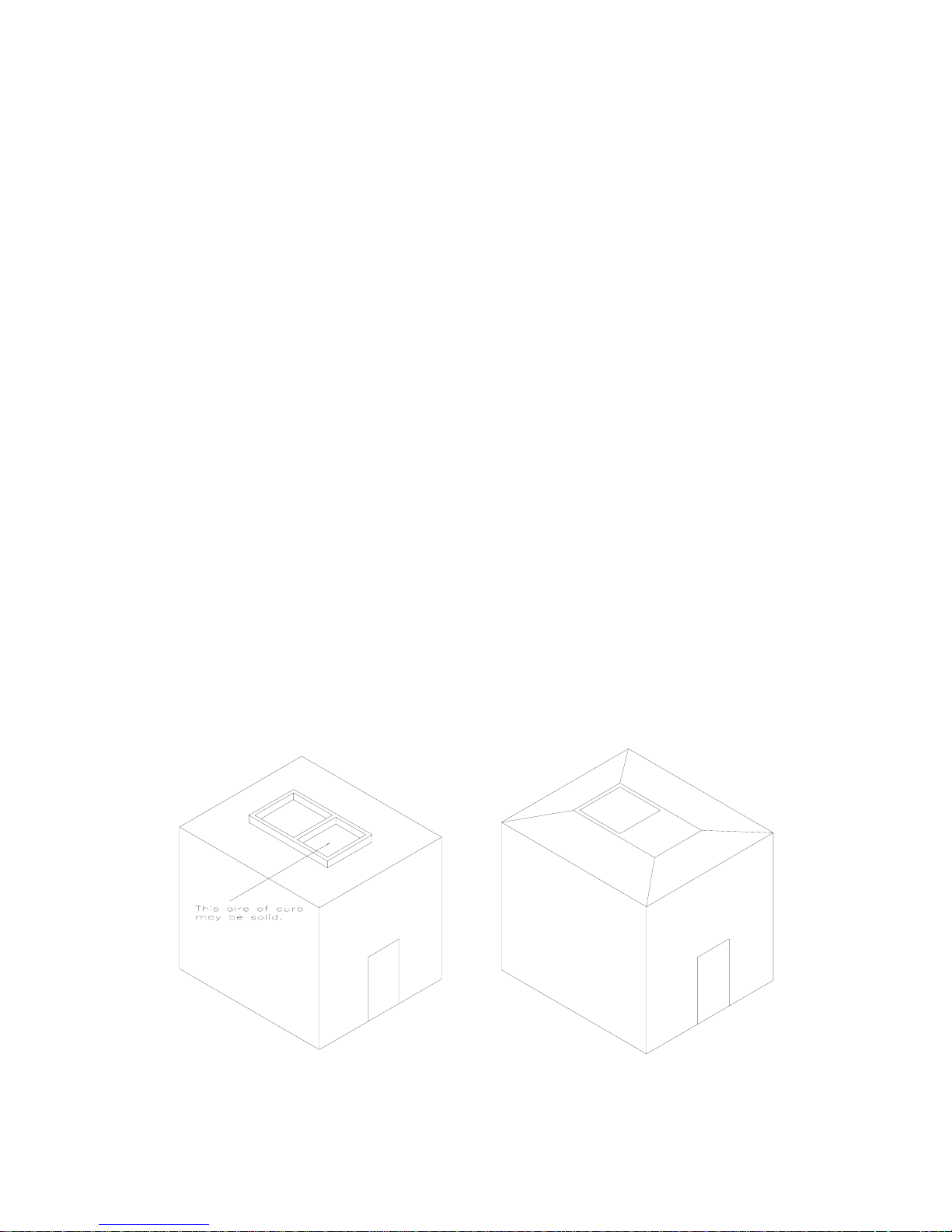

1. Units must be curb mounted ( Figure 4 ~ 5 ). Cabinet size refers to dimension size on page 5.

2. The condensate drain outlet pipe is located on the side of the unit. Field piping may be

connected to the outlet provided it is adequately sloped and heated for freezing weather

conditions.

3. After connecting electrical power, reinstall compressor compartment cover and weather hood.

Figure 4. Curb placed on roof of box.

Figure 5. Roof membrane placed over curb.

8

Page 9

Check before Unit Start-up.

1. Check all electrical and refrigerant connections.

2. Observe all applicable building and electrical codes when wiring.

3. Make sure power supply has correct voltage and phase for unit and is fused properly.

4. If unit is connected with a power cord, use the cord with plug to connect to power supply.

If unit is not connected with a power cord, use hard wire to connect to power supply.

IMPORTANT

Do not use extension cords to connect unit to power.

Plug-in to grounded three prong outlet.

Do not remove grounding prong.

Do not use a power adapter.

5. All medium temperature models are preset to factory default settings as :

a) 3 hours of compressor runtime between defrosts.

b) Defrost termination temperature = 38 F / 3.5 C

6. All low Temperature Models are preset to factory default settings at table 4.

Standard Maintenanc e Guideline.

After first year of operation and under normal usage, maintenance should cover the following

items at least once every six months.

1. Check all electrical and refrigerant connections.

2. Check all wiring and insulators.

3. Check contactors for proper operation and for state of contact points.

4. Check all fan motor. Tighten motor mount bolts, nuts and fan set screws.

5. Clean the heatexchanger (evaporator and condenser) coil surface.

6. Check the operation of the control system. Make sure all safety controls are operating

properly.

7. Check the defrost control system. Make sure all defrost controls are operating properly.

8. Check the drain pan and drain line. If necessary, clean the drain pan and drain line.

9. Check the all heaters. Make sure the crankcase and drain line heaters are operating properly.

After installation of unit, it must be checked at least once for proper defrosting. The amount and

pattern of frosting can vary considerably. It is dependent on the temperature of the room, the

type of product being stored, how often new product is brought into the room and how often

door is opened. Therefore, it may be necessary to periodically change the number of defrost

cycles or adjust the duration of defrost.

9

Page 10

Sequence of Operation.

Operation of Refrigeration.

1. When switch is turned on, power is provided to the temperature control, compressor,

condenser and evaporator fan motor. And they will run until the box temperature setting is

reached.

2. When the box temperature reaches a setting, the compressor and condenser fan motors shut

off while evaporator fan motor is working.

3. When the box temperature rises above the set point and minimum off-time has elapsed, the

compressor contactor will be re-energized and re-operated.

Operation of Defrost.

1. Under normal electric defrost operation, the temperature/defrost control will de-energize the

compressor contactor, evaporator fans and energize the defrost heaters. But under normal air

defrost operation, the control will de-energize the compressor contactor and keep an evaporator

fan motor working.

2. When the coil has defrosted completely and reached the preset coil sensor temperature,

defrost heater cuts off and fan delay / drip sequences begin.

3. The control energizes the compressor and condenser fan motor and they restart.

4. When the coil temperature reaches 35℉ or fan delay time has elapsed, the evaporator fans

will be energized and started.

10

Page 11

Controller Setting.

Danfoss EKC 102D Electronic Controller ( Low Temperature).

The EKC 102D is used for temperature control refrigeration appliances and cold room.

It contains a temperature control where the signal con be received from one temperature sensor.

The sensor is placed in the cold air flow after the evaporator or in the warm air flow just before

the evaporator. The controller controls the defrost with either air defrost or electric defrost.

Renewed cutin after defrost can be accomplished based on time or temperature.

11

Page 12

The buttons;

Display

The values will be shown with three digits, and with a setting you can determine whether the

temperature are to be shown in ℃ or ℉.

Set menu

1. Push the upper button until a parameter is shown

2. Push the upper or the lower button and find that parameter you want to change

3. Push the middle button until the parameter value is shown

4. Push the upper or the lower button and select the new value

5. Push the middle button again to enter the value.

Set temperature

1. Push the middle button until the temperature value is shown

2. Push the upper or the lower button and select the new value

3. Push the middle button to select the setting.

Reading the temperature at sensor S5

12

Page 13

Push briefly the lower button

Manuel start or stop of a defrost

Push the lower button for four seconds.

Light emitting diode

= refrigeration

= defrost

= fan running

Cutout alarm relay / receipt alarm / see alarm code.

Push briefly the upper button.

If there are several alarm codes they are found in a rolling stack. Push the uppermost or

lowermost button to scan the rolling stack.

Electric Defrost Control Factory Default Settings.

Temperature

Set Point

-10℉

Defrost Start

Times

Defrost

Duration

Drip Time Fan Delay

4/day 40 min 2 min 2 min

Defrost

Termination

Set Point

65℉

Listing of Controller Parameters and Settings (Electric Defrost Control).

Parameters

Function Description Codes

Normal operation

Temperature (set point) --- -58°F 122°F -10°F

Thermostat

Differential When the temperature is higher than the reference +

the set differential, the compressor relay will be cut

in. It will cut out again when the temperature comes

down to the set reference.

Max. limitation of setpoint

setting

Min. limitation of setpoint

setting

Adjustment of

temperature indication

Temperature unit (°C/°F) Set here if the controller is to show temperature

Correction of the signal

from Sair

Manual service(-1), stop With this setting refrigeration can be started, stopped r12 -1 1 1

The controller’s setting range for the setpoint may be

narrowed down, so that much too high or much too

low values are not set accidentally-with resulting

damages.

If the temperature at the products and the

temperature received by the controller are not

identical, an offset adjustment of the shown display

temperature can be carried out.

values in °C or in °F.

Compensation possibility through long sensor cable. r09 -18 K 18 K 0 K

r01 0,1 K 36 K 3 K

r02 -56°F 122°F 37°F

r03 -58°F 120°F -23°F

r04 -36 K 36 K 0.0 K

r05 °C °F °F

Min.-

value

Max.value

Factory

setting

13

Page 14

regulation(0), start

regulation (1)

Displacement of reference

during night operation

Activation of reference

displacement r40

Value of reference

displacement (can be

activated by r39 or DI)

Alarm

Delay for temperature

alarm

Delay for door alarm The time delay is set in minutes.

Function Description Codes

Delay for temperature

alarm after defrost

High alarm limit Here you set when the alarm for high temperature is

Low alarm limit Here you set when the alarm for low temperature is

Alarm delay DI1 A cut-out/cut-in input will result in alarm when the

High alarm limit for

condenser temperature

(o70)

or a manual override of the outputs can be allowed.

1 = regulation

0 = regulation is stopped

-1 = regulation is stopped - override allowed.

Stopped regulation will give a "Standby alarm".

The thermostat’s reference will be the setpoint plus

this value when the controller changes over to night

operation.

(Select a negative value if the function is used for

”quick cooling”.)

When the function is changed to ON the thermostat

differential will be increased by the value in r40.

Activation can also take place via input DI (defined in

o02).

The thermostat reference and the alarm values are

shifted the following number of degrees when the

displacement is activated.

Activation can take place via r39 or input DI

If one of the two limit values is exceeded, a timer

function will commence. The alarm will not become

active until the set time delay has been passed. The

time delay is set in minutes.

The function is defined in o02.

Parameters

This time delay is used during start-up (recovery

time), during defrost, in the cooling phase after a

defrost. There will be change-over to the normal time

delay (A03) when the temperature has dropped

below the set upper alarm limit.

The time delay is set in minutes.

to start. The limit value is set in °C (absolute value).

The limit value will be raised during night operation.

The value is the same as the one set for night

setback, but will only be raised if the value is positive.

The limit value will also be raised in connection with

reference displacement r39.

to start. The limit value is set in °C (absolute value).

The limit value will also be raised in connection with

reference displacement r39.

time delay is passed. The function is defined in o02.

If the Saux (S5) sensor is used for monitoring the

condenser’s temperature you must set the value at

which the alarm is to become activated. The value is

set in °C. There is no alarm delay. The alarm

disappears again when the temperature has dropped

r13 -18 K 18 K 0 K

r39 OFF on OFF

r40 -90 K 90 K 0 K

A03 0 min 240

A04 0 min 240

Min.-

value

A12 0 min 240

A13 -58°F 122°F 38°F

A14 -58°F 122°F -25°F

A27 0 min 240

A37 32°F 210°F 122°F

min

min

Max.value

min

min

50 min

60 min

Factory

setting

180

min

30 min

14

Page 15

10 degrees. Definition of Saux (S5) takes place in

o69/o70.

Compressor

Min. ON-time Min. ON-time (in minutes) c01 0 min 30 min 0 min

Min. OFF-time Min. OFF-time (in minutes) c02 0 min 30 min 4 min

Compressor relay must

cutin and out inversely

(NC-function)

Defrost

Defrost method "non" = No, "el" = EL, "Gas" =GAS d01 no gas EL

Defrost stop temperature The defrost is stopped at a given temperature which

Interval between defrost

starts

Max. defrost duration This setting is a safety time so that the defrost will be

Function Description Codes

Displacement of time on

cutin of defrost at start-up

Drip off time Here you set the time that is to elapse from a defrost

Delay for fan start after

defrost

Fan start temperature The fan may also be started a little earlier than

Fan cutin during defrost you can set whether fan is to operate during defrost. d09 no yes no

Defrost sensor

(0=time, 1=S5, 2=Sair)

Defrost at start-up Here you can set if the controller is to start with a

Max. aggregate

refrigeration time between

two defrosts

0: Normal function where the relay cuts in when

refrigeration is demanded

1: Reversed function where the relay cuts out when

refrigeration is demanded (this wiring produces the

result that there will be refrigeration if the supply

voltage to the controller fails). (When two

compressors are cut in and out the two relays will

operate in opposite directions).

is measured with a sensor (the sensor is defined in

d10). The temperature value is set.

Determines the time interval between the beginning

of two defrost cycles.

The interval time is not active when set to 0.

stopped if there has not already been a stop based

on temperature. (The setting will be the defrost time if

d10 is selected to be 0)

Parameters

The function delays the interval time d03 by the set

number of minutes, but it only does it once, and this

at the very first defrost taking place when voltage is

connected to the controller.

The function will be active after each and every

power failure.

and until the compressor is to start again. (The time

when water drips off the evaporator).

Here you set the time that is to elapse from

compressor start after a defrost and until the fan may

start again.

(The time when water is “tied” to the evaporator).

mentioned under “Delay of fan start after defrost”, if

the defrost sensor S5 registers another allowable

value than the one set here.

Here you define the defrost sensor.

0: None, defrost is based on time 1=S5. 2=Sair

defrost if the power has been cut.

Set here is the refrigeration time allowed without

defrosts. If the time is passed, a defrost will be

started. With setting = 0 the function is cut out.

c30 0 /

OFF

d02 32°F 77°F 65°F

d03 0

hours

d04 0 min 180

Min.-

value

d05 0 min 240

d06 0 min 60 min 2 min

d07 0 min 60 min 2 min

d08 5°F 32°F 23°F

d10 0 2 0

d13 no yes no

d18 0

hours

1 / on 0 / OFF

48

6 hours

hours

40 min

min

Max.value

hours

min

48

Factory

setting

0 min

0 hours

15

Page 16

Defrost on demand - S5

temperature’s permitted

variation during frost

build-up. On central plant

choose 20 K (=off)

Fans

Fan stop at cutout

compressor

Delay of fan stop If you have chosen to stop the fan when the

Fan stop temperature

(S5)

Function Description Codes

Miscellaneous

Delay of output signals

after start-up

Input signal on DI1.

Function:

Access code 1 (all

settings)

Used sensor type (Pt

/PTC/NTC)

The controller will follow the effectivity of the evap-

orator, and via internal calculations and measure-

ements of the S5 temperature it will be able to start a

defrost when the variation of the S5 temperature

becomes larger than required. Here you set how

large a slide of the S5 temperature can be allowed.

When the value is passed, a defrost will start.

The function can only be used in 1:1 systems when

the evaporating temperature will become lower to

ensure that the air temperature will be maintained. In

central systems the function must be cut out.

With setting = 20 the function is cut out

Here you can select whether the fan is to be stopped

when the compressor is cut out

compressor is cut out, you can delay the fan stop

when the compressor has stopped.

Here you can set the time delay.

The function stops the fans in an error situation, so

that they will not provide power to the appliance. If

the defrost sensor registers a higher temperature

than the one set here, the fans will be stopped. There

will be re-start at 2 K below the setting.

The function is not active during a defrost or start-up

after a defrost.

With setting +50°C the function is interrupted.

Parameters

After start-up or a power failure the controller’s

functions can be delayed so that overloading of the

electricity supply network is avoided.

Here you can set the time delay.

0=not used. 1=status on DI1. 2=door function with

alarm when open. 3=door alarm when open.

4=defrost start (pulse-pressure). 5=ext.main switch.

6=night operation 7=change reference (activate r40).

8=alarm function when closed. 9=alarm function

when open. 10=case cleaning (pulse pressure).

11=Inject off when open.

If the settings in the controller are to be protected

with an access code you can set a numerical value

between 0 and 100. If not, you can cancel the

function with setting 0. (99 will always give you

access).

Normally a Pt 1000 sensor with great signal accuracy

is used. But you can also use a sensor with another

signal accuracy. That may either be a PTC sensor

(1000 ohm at 25°C) or an NTC sensor (5000 Ohm at

25°C).

d19 0 K 36 K 36 K

F01 no yes no

F02 0 min 30 min 0 min

F04 -58°F 122°F 35°F

Min.-

value

o01 0 s 600 s 5 s

o02 0 11 0

o05 0 100 0

o06 Pt ntc Ptc

Max.value

Factory

setting

16

Page 17

All the mounted sensors must be of the same type.

Display step = 0.5 (normal

0.1 at Pt sensor)

Case cleaning. 0=no case

cleaning. 1=Fans only.

2=All output Off.

Access code 2 (partly

access)

Replace the controllers

factory settings with the

present settings

Select application for S5

sensor (0=defrost sensor,

1= product sensor,

2=condenser sensor with

alarm)

Yes: Gives steps of 0.5°

No: Gives steps of 0.1°

The status of the function can be followed here or the

function can be started manually.

0 = Normal operation (no cleaning)

1 = Cleaning with fans operating. All other outputs

are Off.

2 = Cleaning with stopped fans. All outputs are Off.

If the function is controlled by a signal at the DI input,

the relevant status can be seen here in the menu.

There is access to adjustments of values, but not to

configuration settings. If the settings in the controller

are to be protected with an access code you can set

a numerical value between 0 and 100. If not, you can

cancel the function with setting 0. If the function is

used, access code 1 (o05) must also be used.

With this setting you save the controller’s actual

settings as a new basic setting (the earlier factory

settings are overwritten).

EKC 102A, B, C

Here you define the application for the S5 sensor.

0: Defrost sensor

1: Product sensor

o15 no yes no

o46 0 2 0

o64 0 100 0

o67 OFF On OFF

o70 0 2 0

Operating Status

The controller goes through some regulating situations where it is just waiting for the next point

of the regulation. To make these “why is nothing happening” situations visible, you can see an

operating status on the display. Push briefly (1s) the upper button. If there is a status code, it

will be shown on the display. The individual status codes have the following meanings:

Code

S0 Regulating

S2 When the compressor is operating it must run for at least x minutes.

S3 When the compressor is stopped, it must remain stopped for at least x minutes.

S10 Refrigeration stopped by main switch. Either with r12 or a DI-input

S11 Refrigeration stopped by thermostat

S14 Defrost sequence. Defrost in progress

S15 Defrost sequence. Fan delay

S16 Refrigeration stopped because of open DI input

S17 Door is open. DI input is open

S20 Emergency cooling

S25 Manual control of outputs

S29 Case cleaning

S32 Delay on outputs during start-up

Other display

Non non: The defrost temperature cannot be displayed. There is no sensor

-d- -d-: Defrost in progress. /First cooling after defrost

PS PS: Password required. Set password

17

Page 18

Fault Message

In an error situation the LED’s on the front will flash and the alarm relay will be activated. If you

push the top button in this situation you can see the alarm report in the display. If there are

several, you can continue pushing to see them.

There are two kinds of error reports - it can either be an alarm occurring during the daily

operation, or there may be a defect in the installation.

A-alarms will not become visible until the set time delay has expired.

E-alarms, on the other hand, will become visible the moment the error occurs.

(An A alarm will not be visible as long as there is an active E alarm).

Here are the messages that may appear:

Code

A1 High temperature alarm

A2 Low temperature alarm

A4 Door alarm

A15 Alarm. Signal from DI input

A45 Standby position (stopped refrigeration via r12 or DI input)

A59 Case cleaning. Signal from DI input

A61 Condenser temperature alarm

E1 Faults in the controller

E27 Sensor error on S5

E29 Sensor error on Sair

E30 Sensor error on Saux

When copying settings to or from a copying key with functions o65 or o66, the following information may

appear:

0: Copying concluded and OK

4: Copying key not correctly mounted

5: Copying was not correct. Repeat copying

6: Copying to EKC incorrect. Repeat copying

7: Copying to copying key incorrect. Repeat copying

8: Copying not possible. Order number or SW version do not match

9: Communication error and timeout

10: Copying still going on

(The information can be found in o65 or o66 a couple of seconds after copying has been started).

Danfoss ETC 1H1 Controller (Medium Temperature).

Cooler units utilize an electronic temperature control. The temperature may be adjusted by

setting the dial. This control is preset to provide 3 hours of compressor run time between

defrost cycles. Defrosts are temperature terminated and can not be reprogrammed. The

temperature control is programmed for minimum on cycle of one minute and minimum off cycle

of four minutes.

Air Defrost Sequence of Operation.

Air defrost units are preprogrammed for 3 hours of compressor run time between defrosts.

These periods are not reprogrammable. After 3 hours, the temperature control will turn the

18

Page 19

compressor off. When the coil temperature reaches 38°F the control will terminate the defrost

cycle.

Room Thermostat Settings :

Settings Warm position Cold position Minimum time(Sec) Maximum time (Min)

Cut in [°F] 55 34 60 Not used

Cut out [°F] 52 43 240 Not used

Defrost Temperature[°F] 38 38

Alarm on high temp [°F] Not used Not used

Alarm on low temp [°F] Not used Not used

0 = Unit off (not an electrical disconnect)

1 = 52°F (11°C)

2 = 49°F (9°C)

3 = 45°F (7°C)

4 = 41°F (5°C)

5 = 38°F (3°C)

6 = 34°F (1°C)

Note: If power is interrupted to the unit during the refrigeration off-cycle (system at temperature

setpoint, compressor off), the thermostat will initiate an extra defrost period approximately one

hour after power is restored.

System troubleshooting.

Symptoms Possible causes Solution

Main switch open Close switch

Check electrical circuits and motor winding for shorts or gro unds.

Replace fuse after fault is corrected.

Overloads are automatically reset. Check unit when unit come back on

line.

Compressor not running

Noisy Compressor

High discharge pressure.

Low discharge pressure.

High suction pressure

Low suction pressure.

Blown fuse

Loose wiring Check all wire junctions. Tighten all terminal screws.

System cable shut down Replace shutdown cable.

Thermal overload tripped

Defective contactor or contactor coil Replace or repair

System shut down by safety devices. Check cause of shut down

No cooling required. Wait until calls for cooling

Motor electrical trouble. Check motor for open windings, short circuit or burn out.

Flooding of liquid refrigerant into crankcase Check expansion valve setting

Worn compressor. Replace compressor

Non-condensable in system. Remove non-condensable.

Too much refrigerant Remove excess refrigerant

Fan not running Check electrical circuit and fuse.

Dirty condenser coil Clean condenser coil

Liquid line solenoid not open Repair or replace coil

Insufficient refrigerant Check leaks. Add charge.

Low suction pressure See corrective steps for low suction pressure.

Excessive loads Reduce load.

Expansion valve overfeeding. Check bulb location and clamping. Adjust superheat..

Expansion valve malfunctioning. Check and reset for proper superheat.

Lack of refrigerant. Check for leaks. Add charge.

19

Page 20

Evaporator dirty or iced. Clean. Check defrost parameters and modify as required.

Evaporator dirty or iced Clean and defrost.

Compressor thermal

protector switch open.

Fan(s) will not operate

Room temperature too

high.

Ice accumulating on

ceiling around grill.

Coil not clearing of frost

during defrost cycle.

Ice accumulating in drain

pan.

Condenser coil dirty. Clean. coil

Too much refrigerant Remove excess refrigerant

Clogged liquid line filter drier. Replace filter drier.

Operating beyond design conditions Add facilities so that conditions are within allowable limits.

Main swich open. Close switch.

Blown fuses. Replace fuses. Check for short circuits or overload conditions.

Defective motor Replace motor.

Coil does not get cold enough to reset thermostat. Adjust f an delay setting of control.

Controller or sensor defective. Replace defective component.

Unit in defrost cycle. Wait for completion of cycle.

Controller temperature set too high. Adjust control

Superheat too high. Check and reset for proper super heat

Insufficient refrigerant Check leaks. Add charge

Evaporator coil iced Manually defrost coil. Check defrost controls for malfunction.

Defrost duration is too long. Adjust defrost termination temperature.

Fan delay not delaying fans after defrost peri od. Adjust fan del ay setting or replace sensor.

Defective defrost control or sensor. Replace defective component.

Too many defrost. Adjust number of defrosts.

Coil temperature not getting above freezing point

during defrost.

Not enough defrost cycles per day. Adjust control for more defrost cycles.

Defrost cycle too short. Adjust defrost control, defrost duration setting.

Defective defrost control or sensor. Replace defective component.

Defective heaters. Replace heater.

Unit not installed properly (out of level) Check and adjust if necessary.

Drain line plugged. Clean drain line.

Defective control. Replace defective component.

Check heater operation.

Electrical Wiring Diagram.

Diagram 1. Wiring diagram for SMART 7, Air Defrost 115V / 1Ph / 60Hz.

Model : STI050MR404A1

Diagram 2. Wiring diagram for SMART 7, Air Defrost 208~230V / 1Ph / 60Hz.

20

Page 21

Model : STI050MR404A2, STX050MR404A2

Diagram 3. Wiring diagram for SMART 7, Air Defrost 208~230V / 1Ph / 60Hz.

Model : STI075MR404A2, STI100MR404A2, STI130MR404A2

21

Page 22

Diagram4. Wiring diagram for SMART 7, Air Defrost 208~230V / 1Ph / 60Hz.

Model : STX075MR404A2 , STX100MR404A2 , STX130MR404A2

Diagram5. Wiring diagram for SMART 7, Air Defrost 208~230V / 3Ph / 60Hz.

Model : STI100MR404A3, STI130MR404A3, STX100MR404A3, STX130MR404A3

22

Page 23

Diagram6. Wiring diagram for SMART 7, Electric Defrost 208~230V / 1Ph / 60Hz.

Model : STI022LR404A2, STI045LR404A2, STI055LR404A2, STI070LR404A2

Diagram7. Wiring diagram for SMART 7, Electric Defrost 208~230V / 1Ph / 60Hz.

Model : STX022LR404A2, STX045LR404A2, STX055LR404A2, STX070LR404A2

23

Page 24

Diagram8. Wiring diagram for SMART 7, Electric Defrost 208~230V / 3Ph / 60Hz.

Model : STI055LR404A3 , STI070LR404A3 , STX055LR404A3 , STX070LR404A3

24

Page 25

1250 Victoria street

CARSON, CA 90746

TEL : 310-900-1000

FAX : 310-900-1077

Toll Free : 1-800-381-7770

1-800-627-0032

(U.S.A & Canada)

http://www.turboairinc.com

25

Loading...

Loading...