Page 1

Turbo air Speeds UP the Pace of Innovation

Commercial refrigerator Service Manual

Please read this manual completely before attempting

to install or operate this equipment!

SAK – 50R SAK – 50L

SAK – 60R SAK – 60L

SAK – 70R SAK – 70L

Page 2

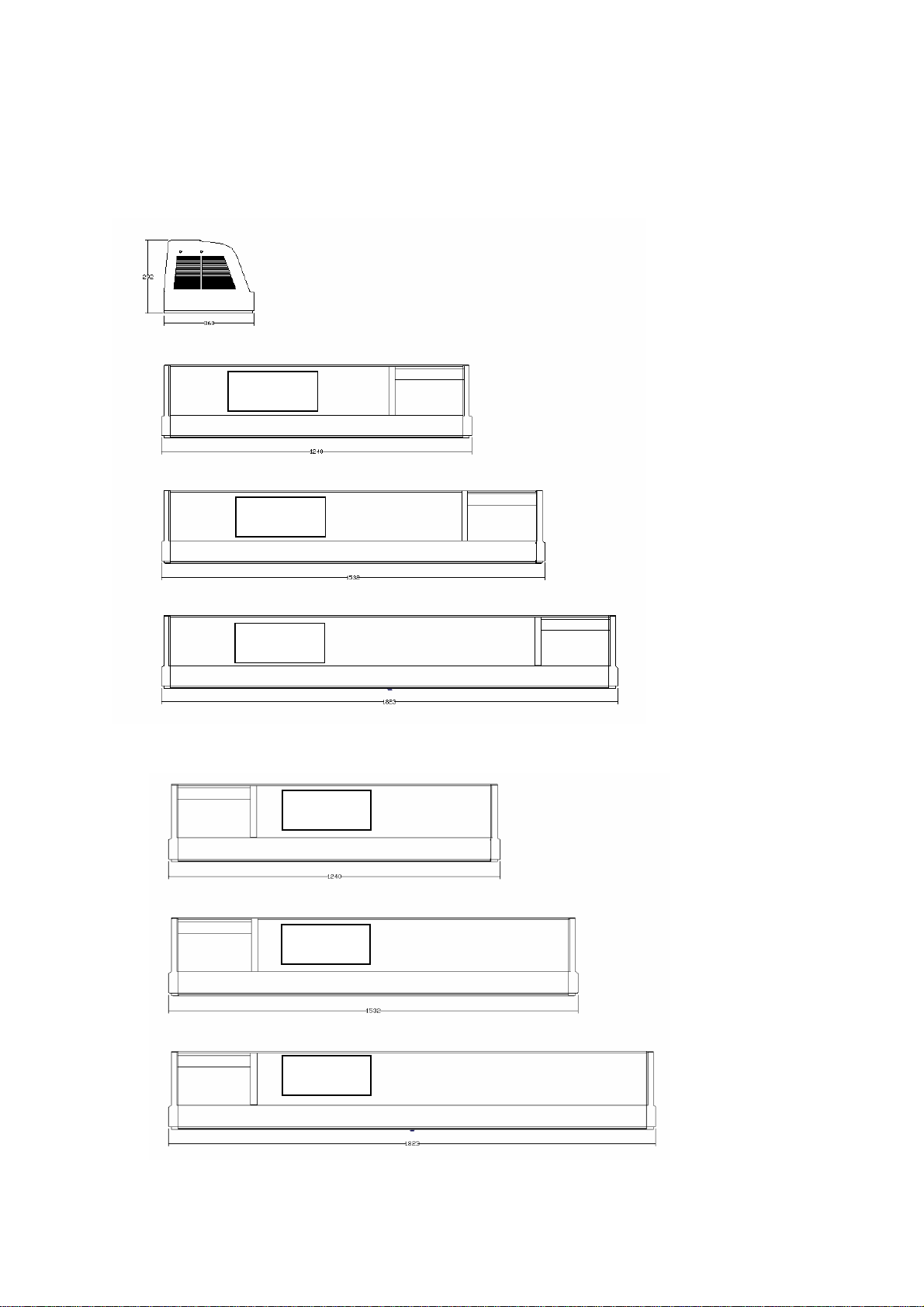

Difference of SAK models

SAK-50R

SAK-60R

SAK-70R

SAK-50L

SAK-60L

SAK-70L

Page 3

TABLE OF CONTENTS

◇ MAIN COMPONENTS

1. Compressor

2. Overload protector

3. Run capacitor

4. Condenser fan motor

◇ WIRING DIAGRAM

◇ POWER INPUT/OUTPUT

◇ CONDENSER COIL

◇ PART NAME

◇ SAK-50*, SAK-60*, SAK-70*, (SVC PART LIST)

Page 4

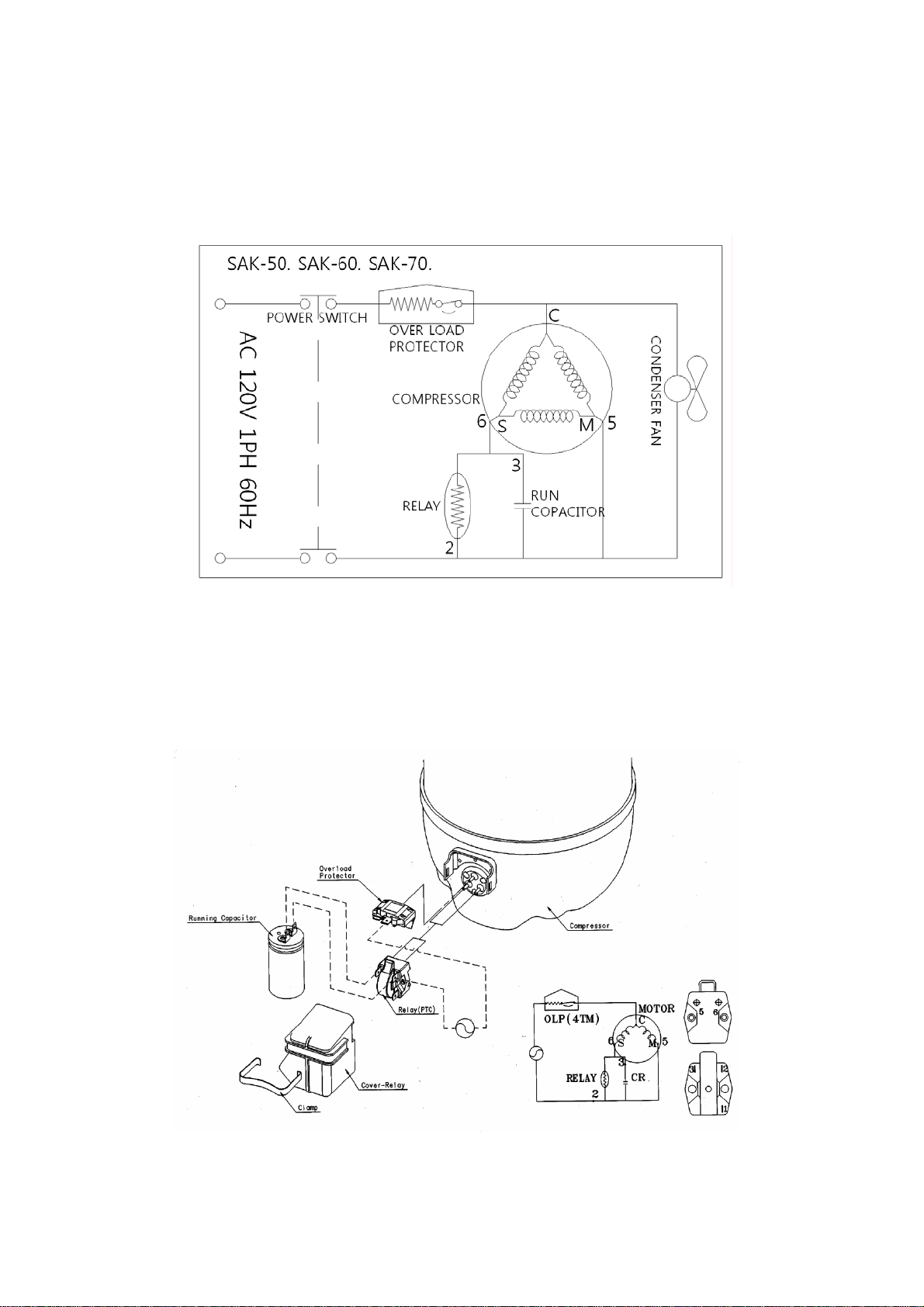

MAIN COMPONENTS

1. Compressor

Manufacturer SAMSUNG KWANGJU ELECTRONICS CO LTD

Designation SD152C-L1U

Electrical Rating

V, Hz, Phase 115 V, 60 Hz, 1 Ph

RLA(+) 1.29/1.92 A

LRA 9.4/9.6 A

2. Overload Protector

Manufacturer Texas Instruments

Model or Designation 4TM412PFBYY

3. Run Capacitor

Rating, uF, V 12 uF, 250 V

Rating, uF, V 000 uF, 250 V

4. Condenser Fan Motor

Manufacturer FULLTECH ELECTORIC CO LTD

Model UF-12A11

Rating V, Hz, Phase, A or W 115 V, 60 Hz, 1 Ph, 12 W

Page 5

WIRING DIAGRAM

Page 6

POWER INPUT/OUTPUT

a. After installing unit and all electrical to the Display, Display is ready to start up.

b. Power input is controlled by pushing the button.

iii Apporx 30min interval is needed to reactivate display case after power off.

SPECIFICATION

Model SAK-50* SAK-60* SAK-70*

Dimension

(W×D×H) in

Electricity 120V/1Ph/60Hz

Power Input 3A 3A 3A

Compressor SD152C-L1U2

Refrigerant R-134a

Weight of Case 76.06lbs 87.08lbs 98.10lbs

LOCATION OF DISPLAY CASE

MERCHANDISER

Display is designed to be in an ambient 75 degrees Fahrenheit (dry bulb) or colder and 55 percent relative humidity. If unit is

installed in a warm ambient Display will not cool effectively. Move the display to the final location before removing shipping skid.

Allow 3 inches from back of Display to wall. Condenser is located in beside of Display. Do not block inlet /outlet.

CONDENSER COIL

48.8×14.2×11.5 60.3×14.2×11.5 71.8×14.2×11.5

②

③

1. Disconnect the electrical power to the unit

2. Lift up the Louver to release the Louver from the body.(①)

3. Pull the Louver toward you.(②)

4. Pull on the downward. (③)

5. Brush the dirt, lint, etc from the finned condenser coil.

6. When finished, Louver installed by reverse way of removing

7. Reconnect the electrical power to the unit.

8. Condenser should be cleaned every 1 months or as needed.

①

Page 7

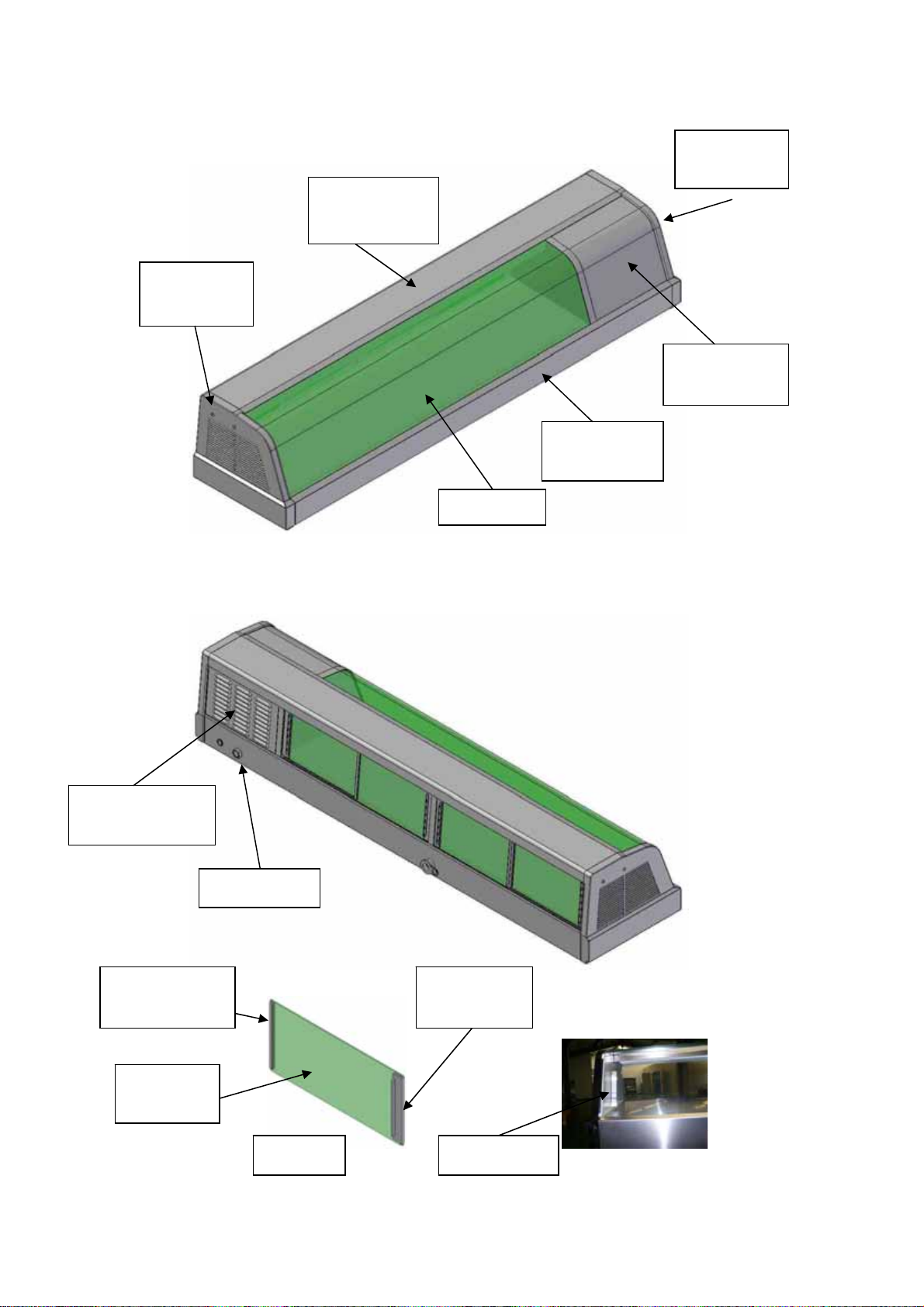

PART NAME

A

A

Side cover L

ABS

Side cover R

Top cover

SUS 304 0.7T

C.D.U. cover

SUS 304 0.7T

Front cover

SUS 304 0.7T

Front glass

Condenser cover

SUS 304 0.7T

Door molding

BS

Power switch

Door handle

BS

Door glass

Door set

Thermometer

Page 8

A

A

A

Side cover L

BS

Top cover

SUS 394

Top cover base

Side cover R

BS

Front cover

Condenser cover

Door post

BS

Side cover bracket R

GI 0.8T

Condenser filter

SUS 304 0.7T

Drain cap

PE

Drain pipe

PVC

Page 9

A

Evaporator

Evaporator cover

SUS 304 0.7T

Bottom shelf

SUS 304 0.8T

Drain cap

PE

Condenser

Capillary tube

D: 2mm

L : 2400mm

Condenser fan motor

Compressor

Urethane form case

Drain hole

BS

Urethane form base

GI 1T

Page 10

Thermometer

Drier

Page 11

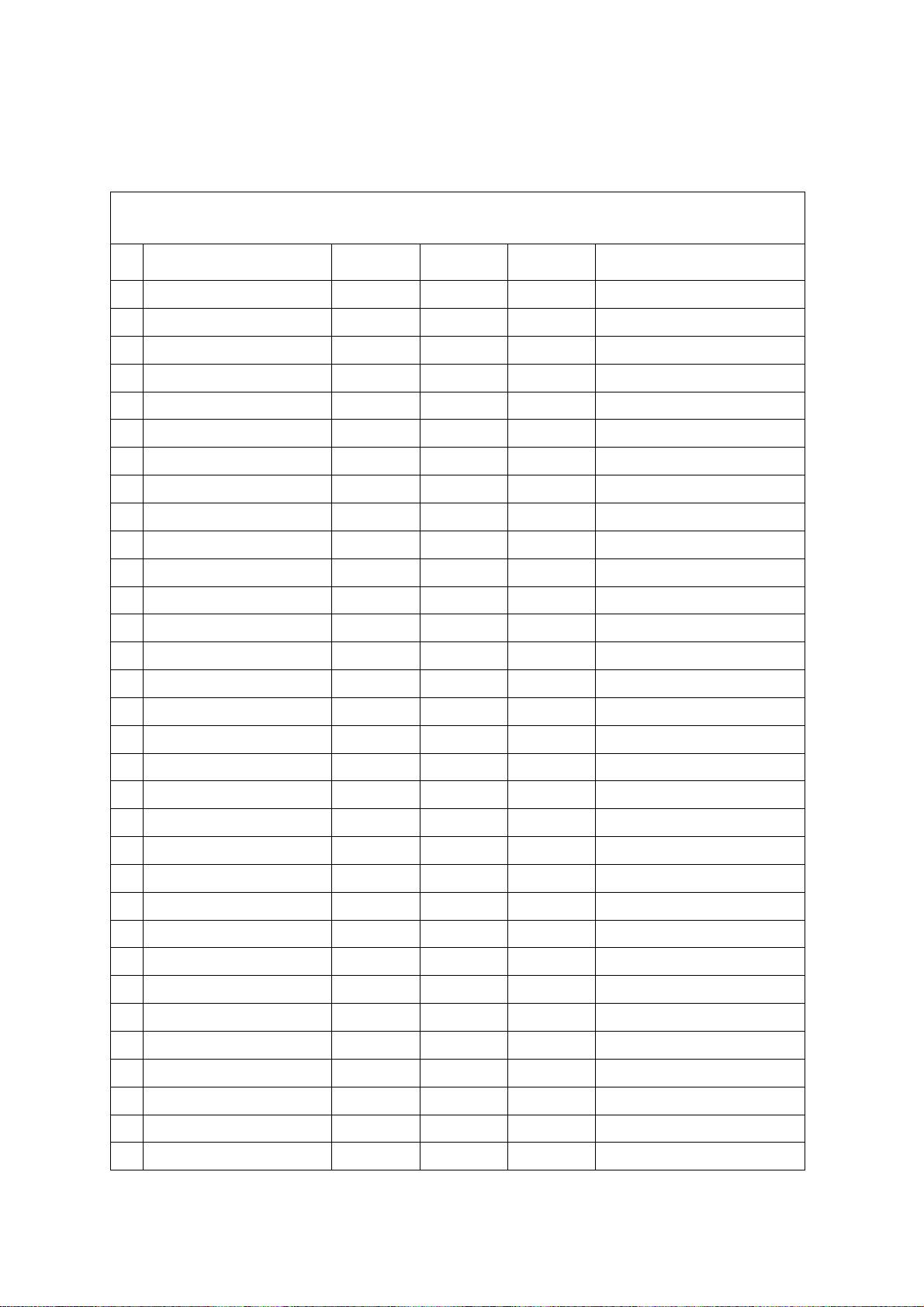

PART LIST

SAK-50. SAK-60. SAK-70. PART LIST

Part name

1 Bottom shelf 3 5 5 SUS-304 0.8T

2 C.D.U. cover 1 1 1 SUS-304 0.7T

3 Capillary tube 1 1 1 CU

4 Compressor 1 1 1 SAMSUNG SD-152C-L1U

5 Condenser 1 1 1 CU + AL

6 Condenser cover 1 1 1 SUS-304 0.7T

7 Condenser fan motor 1 1 1 UF-12A11

8 Condenser filter 1 1 1

9 Door glass 2 4 4 Glass 3.2T

10 Door handle 2 4 4 ABS

11 Door molding 2 4 4 ABS

12 Door post 3 4 4 ABS

SAK-50 SAK-60 SAK-70 비 고

13 Drain cap 2 2 2 PE

14 Drier 1 1 1 Cu ,1/4

15 Evaporator 1 1 1 CU + AL

16 Evaporator cover 1 1 1 SUS-304 0.7T

17 Front cover 1 1 1 SUS-304 0.7T

18 Front glass 1 1 1 Glass 5T

19 Over load protector 1 1 1 4TM412PFBYY

20 Power switch 1 1 1 KPB25AT

21 Run capacitor 1 1 1 12uF 250V

22 Side cover bracket L,R 1 1 1 GI 0.8T

23 Side cover L 1 1 1 ABS

24 Side cover R 1 1 1 ABS

25 Start Relay 1 1 1 JAHWA 6R8M

26 Thermometer 1 1 1 MILJOCO CORP B9-122

27 Top cover 1 1 1 SUS-304 0.7T

28 Top cover base 1 1 1 ABS

29 Urethane form base 1 1 1 GI 1T

30 Urethane form case 1 1 1 ABS + Urethane form

Page 12

Loading...

Loading...