Page 1

CAUTION!

PLEASE KEEP POWER

SWITCH ON BEFORE

OPERATING THIS EQUIPMENT

Turbo Air Speed up the Pace of Innovation

Refrigerator

Freezer

Installation and Operation Manual

Please read this manual completely before attempting to install or operate this equipment!

Full Stainless Steel Interior and Exterior

SOLID DOOR

REFRIGERATOR

PRO-26R PRO-26-2R

PRO-50R PRO-50-4R

PRO-77R PRO-77-6R

SOLID DOOR

FREEZER

PRO-26F PRO-26-2F

PRO-50F PRO-50-4F

PRO-77F PRO-77-6F

www.turboairinc.com

Page 2

CONTENTS

1. SPECIFICATION

PAGE

..........................................................................................

2

2. SERIAL NUMBER

........................................................................................

2

3. INSTALLATION............................................................................................ 3

4. CLEANING

...................................................................................................

4

5. BASIC OPERATION

5-1. REFRIGERATORS........................................................................... 5~8

5-2. FREEZERS..................................................................................... 9~12

6. BEFORE REQUESTING SERVICE

...........................................................

13

7. STAINLESS STEEL EQUIPMENT CARE AND CLEANING .................14~15

8. WARRANTY

.........................................................................................

16~17

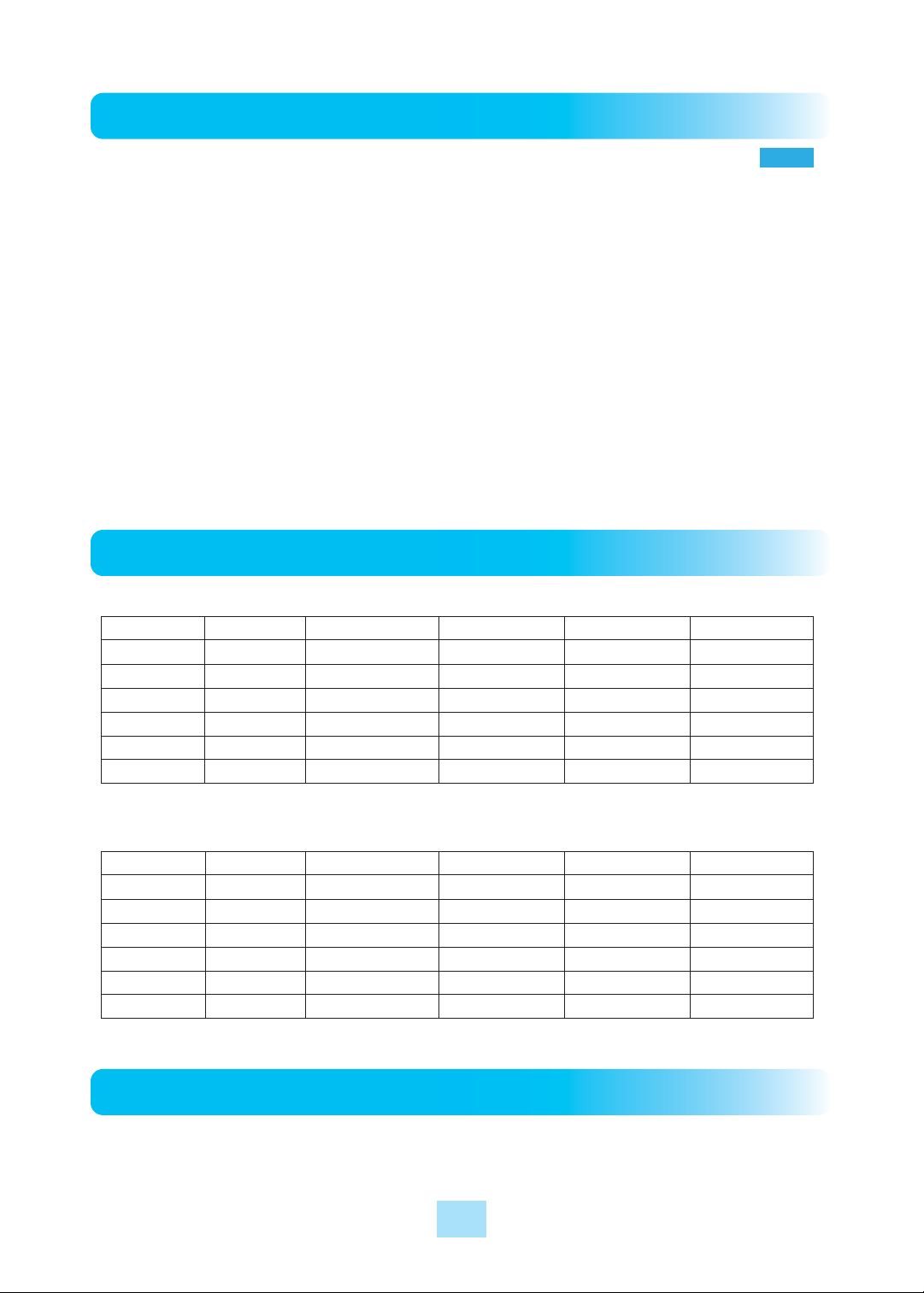

SPECIFICATION

Refrigerators

MODEL COMP H.P. V/Hz REFRIGERANT AMPS WEIGHT

PRO-26R 1/3 115V/60Hz R-134A 5.2A 315lbs

PRO-50R 1/2 115V/60Hz R-134A 9.1A 484lbs

PRO-77R

PRO-26-2R

PRO-50-4R

PRO-77-6R

1 115V/60Hz R-134A 11.3A 698lbs

1/3 115V/60Hz R-134A 5.2A 315lbs

1/2 115V/60Hz R-134A 9.1A 484lbs

1 115V/60Hz R-134A 11.3A 698lbs

Freezers

MODEL COMP H.P. V/Hz REFRIGERANT AMPS WEIGHT

PRO-26F

PRO-50F

PRO-77F

PRO-26-2F

PRO-50-4F

PRO-77-6F

3/4 115V/60Hz R-404A 7.8A 338lbs

11/4 115V/60Hz R-404A 10.5A 490lbs

11/2

3/4 115V/60Hz R-404A 7.8A 338lbs

11/4 115V/60Hz R-404A 10.5A 490lbs

11/2

115V/208~230V/60Hz

115V/208~230V/60Hz

R-404A 13.8A 740lbs

R-404A 13.8A 740lbs

SERIAL NUMBER

The serial number is located on the data label inside.

Please retain the unitʼs serial number for service purpose.

2

Page 3

INSTALLATION

1. GOOD AIR CIRCULATION

- Be sure to avoid any partition and object which may stop the air flow.

- Be sure that air space is allowed to flow the rear of the unit.

Turbo air recommends that the rear of the unit would be no less than 5 inches from the

wall.

2. PLACE ON STRONG GROUND

- Be sure that the location be chosen has a strong enough floor to support the total

weight of the cabinet and any other contents.

3. DO NOT PLACE NEAR HEAT

- Be sure to avoid hot corners and locations near stoves.

- High ambient temperature will make much lower cooling efficiency.

4. INDOOR USAGE ONLY

- Be sure to install this unit indoor.

- So, It should prohibit getting wet from the rain.

5. STABILIZING

- Make sure the unit is installed in a stable condition with the front wheels locked

while in use.

6. LEVELING

- Be sure that the unit levels from the front to the back and side to side.

7. Unit should be on dedicated outlet.

3

Page 4

CLEANING

1. CLEANING THE INTERIOR AND EXTERIOR

- The interior and exterior of the unit can be cleaned using warm water with soap.

- Do not use an abrasive cleaner because it will scratch the surface.

2. CLEANING THE CONDENSER FINS

- To maintain proper refrigeration performance, the Condenser coil must be free of

dust, dirt, and grease.

This will require periodic cleaning. Condenser fins should be cleaned at least every

three months (90 days) or as needed.

- The pressure switch is installed in the product to protect the compressor. Please

clean the condenser every 90 days or the pressure switch will cut out the unit,

to protect the compressor from high pressure.

3. CLEAN THE GASKET

- The door gasket should be cleaned frequently to maintain proper sealing.

4. CHECK AFTER CLEANING

- Check the unit again for safety.

- Check that the unit is operating properly.

CAUTION

1. POWER CORD

- Be sure that the power cord is connected to the proper voltage.

- A protected circuit of the correct voltage and amperage must be run for

connection of the line cord.

- Turn ʻoffʼ the power switch before disconnecting the power cord, whenever

performing maintenance functions or cleaning the refrigerated cabinet.

- Dual voltage freezer (PRO-77F, PRO-77-6F) requires

receptacle as shown the right sides.

- Compressor warranties are void if compressor

burns out due to low voltage.

2. RE-STARTING

- If disconnected, wait for 5 minutes before re-starting.

4

Page 5

BASIC OPERATION

REFRIGERATORS

1. Plug in and turn on the power switch located on the control box.

The Display panel will be lighted and make a beep sound. The compressor will begin to run.

2. The default temperature setting is No. “5”.

3. The compressor is automatically cycled by the electronic controller (PCB, RD-Sensor).

4. The Defrost cycle is automatically controlled by he PCB.

5. Set level toward “1” for higher temperature and toward “9” for lower temperature.

6. The interior light is activated by the rocker switch at the bottom of the grille when the

door is opened.

7. Evaporator fan motor(s) will run after all doors are completely closed.

PRO-26R PRO-26-2R

PRO-50R PRO-50-4R

PRO-77R PRO-77-6R

5

Page 6

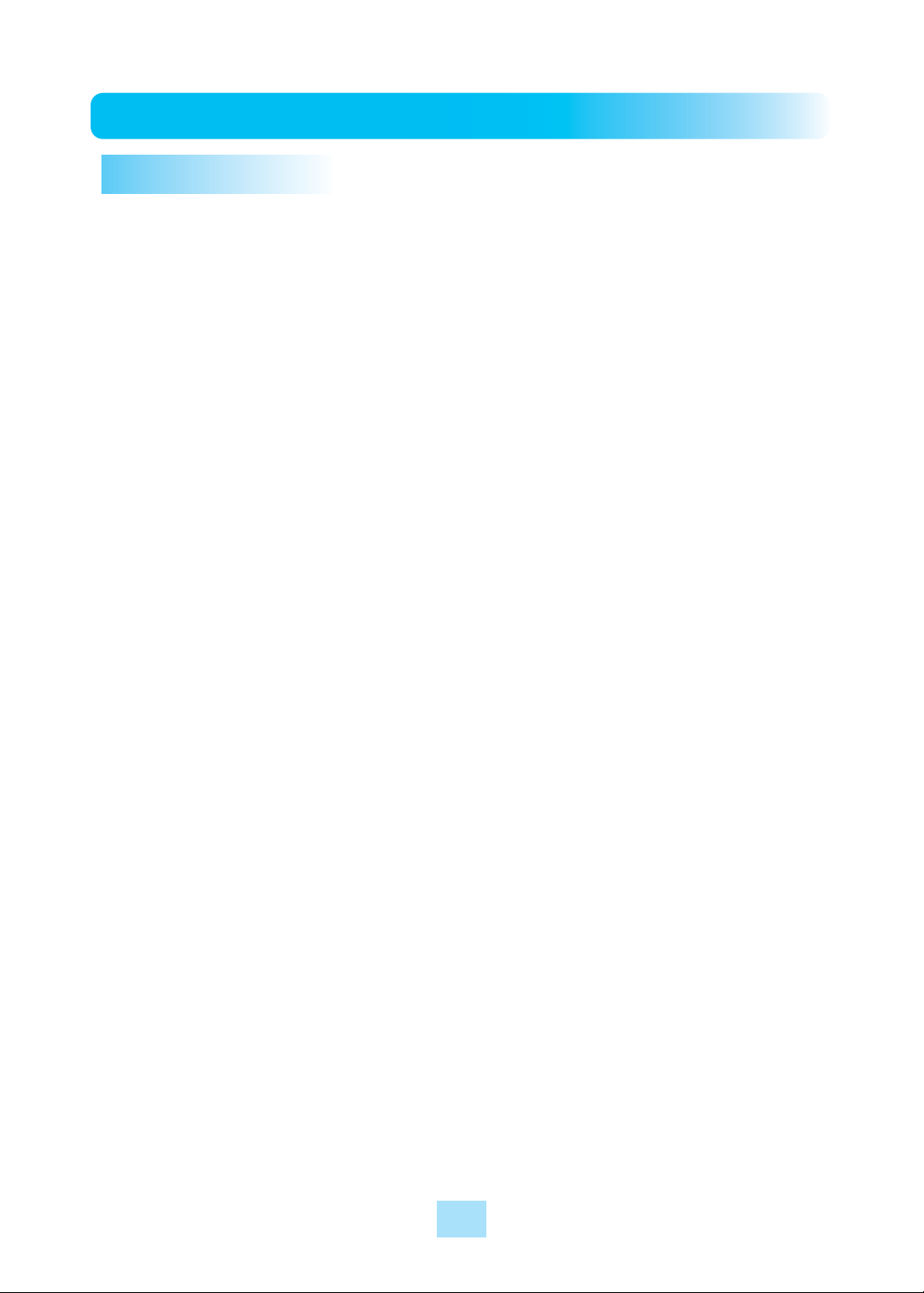

DISPLAY PANEL OF REFRIGERATOR

9

TEMPERATURE T.C.

8

7

6

5

4

3

2

1

FAN DOOR

TURBO COOLING

TEMPERATURE

˚F

TEMP. SETTING

TURBO COOLING

FAN RUNNING

DOOR OPENING

TURBO COOLING

BUTTON

TEMP. CONTROL BUTTON

(SEE TO PAGE 7)

INNER TEMP.

(SEE TO PAGE 8)

(SEE TO PAGE 7)

6

Page 7

TURBO COOLING

1. If you push the T.C. button again during Turbo Cooling mode, the compressor will

return to the normal operation.

2. During the Turbo Cooling mode works, the temperature Up/Down button will not

affect the compressorʼs operation.

UP/DOWN BUTTON (Temperature control button)

1. By pushing the up/down button, you can set the inside temperature level from ʻ1ʼ to

ʻ9ʼ.

2. If you want lower temperature, push the Down button to be lighted higher level

numbers.

7

Page 8

INNER TEMPERATURE DISPLAY

1. It displays the inside temperature.

2. Display range is 14˚F to 69˚F (-10˚C ~ +20˚C).

3. When the inside temperature is lower than 14˚F, the panel will display ʻ ʼ.

and, higher than 69˚F, the panel will display ʻ ʼ.

FAN RUNNING INDICATOR

1. If the fan motor is running, fan running indicator will be turned on.

2. Evaporator fan motor is activated when the door (both doors for PRO-50R,

PRO-50-4R all three doors for PRO-77R, PRO-77-6R) is closed.

DOOR OPENING INDICATOR

1. If any door is opened, door opening indicator will be turned on.

2. In case that any door was opened around 30 seconds, warning beep sound will ring

three (3) times.

3. In case of passing around 1 minute, warning beep sound will ring again five (5) times.

4. In case of passing around 5 minutes, the beep sound will ring continuously.

5. On all the conditions good, the beep sound will stop immediately if door is closed

properly.

8

Page 9

BASIC OPERATION

FREEZER

1. Plug in and turn on the power switch located on the bottom of the top grille right side.

The Display panel will be lighted and make a beep sound. The compressor will begin

to run.

2. The default temperature setting is No. “5”.

3. The compressor is automatically cycled by the electronic controller (PCB, F-Sensor).

4. The Defrost cycle is automatically controlled by the D-sensor, and the PCB.

5. Set level toward “1” for higher temperatures and toward “9” for lower temperatures.

PRO-26F PRO-26-2F

PRO-50F PRO-50-4F

PRO-77F PRO-77-6F

6. The interior light is activated by the rocker switch at the bottom of the grille when the

door is opened.

7. Evaporator fan motor(s) will run after all doors are completely closed.

8. Good Air Flow in freezer unit is critical.

Be careful to load product so that it neither presses against the back wall, nor reaches

within four inches from the evaporator compartment.

9

Page 10

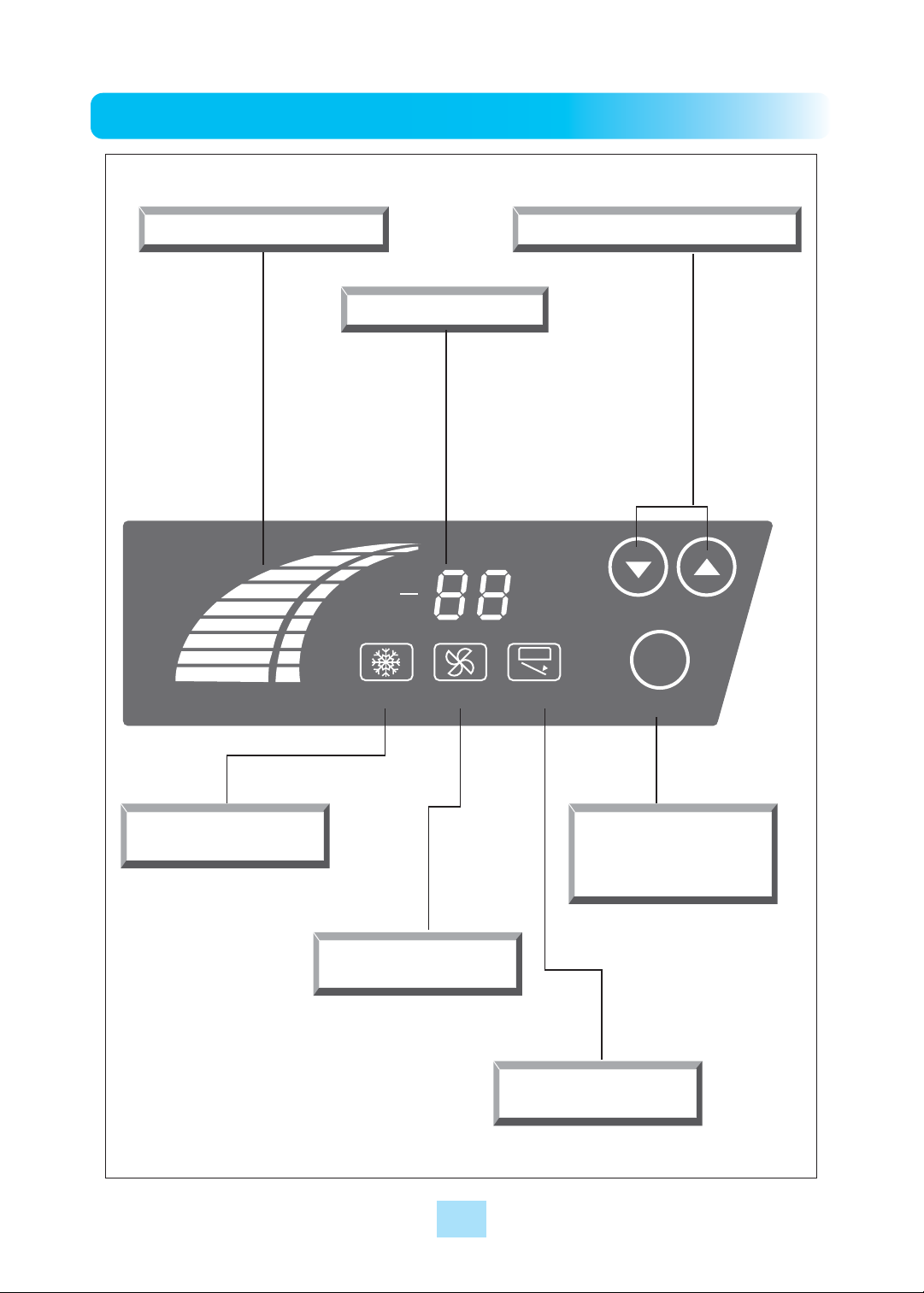

DISPLAY PANEL OF FREEZER

9

TEMPERATURE D.F.

8

7

6

5

4

3

2

1

FAN DOOR

MANUAL DEFROST

TEMPERATURE

˚F

TEMP. SETTING

MANUAL DEFROST

FAN RUNNING

DOOR OPENING

MANUAL DEFROST

BUTTON

TEMP. CONTROL BUTTON

(SEE TO PAGE 11)

INNER TEMP.

(SEE TO PAGE 12)

(SEE TO PAGE 11)

10

Page 11

MANUAL DEFROST

1. If you push MANUAL DEFROST button for 5 seconds, the Defrost will start.

2. During the Manual Defrost mode, the Up/Down button for the temperature control

can not make the compressor cycle ON or OFF.

3. If you want to change the Manual Defrost mode to the normal mode, push MANUAL

DEFROST button for 5 seconds.

UP/DOWN BUTTON (Temperature control button)

1. By pushing the up/down button, you can set the inside temperature level from ʻ1ʼ to

ʻ9ʼ.

2. If you want lower temperatures, push the Down button to be lighted higher level

numbers.

DEFROST

1. The electronic defrost controller is set at the factory to provide a defrost cycle.

2. If it is necessary to change the intervals of defrost due to unusual operating

conditions, it can be accomplished by adjusting the switch which is located on the

inside of the top grille.

3. Once all frost is eliminated, the temperature continues to rise until it reaches 60˚F

(15˚C). When this temperature is sensed by the defrost limit control, the defrost

control changes to refrigeration mode.

4. The panel displays “ ” during the defrost cycle.

11

Page 12

INNER TEMPERATURE DISPLAY

1. It displays inside temperature.

2. Display range is -50˚F to 50˚F (-45˚C ~ +10˚C).

3. When inside temperature is lower than -50˚F, the panel will display ʻ ʼ.

and, higher than +50˚F, the panel will show ʻ ʼ.

FAN RUNNING INDICATOR

1. If the fan motor is running, fan running indicator will be turned on.

2. Evaporator fan motor is activated when the door (both doors for PRO-50F, PRO-50-4F

all three doors for PRO-77F, PRO-77-6F) is closed.

DOOR OPENING INDICATOR

1. If any door is opened, door opening indicator will be turned on.

2. In case that any door was opened around 30 seconds, warning beep sound will ring

three (3) times.

3. In case of passing around 1 minute, warning beep sound will ring again five (5) times.

4. In case of passing around 5 minutes, the beep sound will ring continuously.

5. The beep sound will stop immediately if door is closed properly.

12

Page 13

BEFORE REQUESTING SERVICE

SYMPTOMS CAUSES SOLUTIONS

Freezer is melting

food.

The unit does not

refrigerate at all.

The unit does not

refrigerate well.

There is a loud noise.

There are dew-drops

on the unit exterior.

• The controller is set too high to

contain food fresh.

• There is a power connection

failure problem.

• The unit is in sunlight or near a

heating device.

• The unit contains hot food or too

much food.

• The unit door is opened too

frequently or left open long.

• The temp. dial is not on the

correct position.

• The condenser is clogged.

• The floor is too weak or the

leveling feet is set incorrectly.

• The back-side of the unit is too

close to the wall.

• The tray is not in the correct

position.

• High-moisture air can produce

dewdrops during rainy season.

• Turn the temperature dial to a

warmer position.

•

Check the power cord and plug in

it correctly

• Check the installation place.

• Check the condition of stored

food.

• Check the position of the temp

control dial.

• Check the installation and

adjust the tray position.

• Wipe with a dry cloth.

.

There are dew-drops

on the unit interior.

The door does not

close tightly.

• The door is opened too

frequently or left open long.

• Damp food is stored.

• The door is bent.

• The unit is a levelling failure.

• The door gasket has come out.

• Keep the door closed to

remove dewdrops.

• Level the unit again.

• Reposition the gasket.

The following points are not malfunctions:

• A water-flowing sound can be heard when the compressor stops.

This is the sound of REFRIGERANT flowing.

• The compressor does not run against defrosting function.

13

Page 14

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

CAUTION : Do not use any steel wool, abrasive or chlorine based products to

clean stainless steel surfaces.

Stainless Steel Opponents

There are three basic things which can break down your stainless steel’s passivity layer and allow

corrosion to rear its ugly head.

1) Scratches from wire brushes, scrapers, and steel pads are just a few examples of items that

can be abrasive to stainless steel’s surface.

2) Deposits left on your stainless steel can leave spots. You may have hard or soft water depend-

ing on what part of the country you live in. Hard water can leave spots. Hard water that is

heated can leave deposits if left to sit too long. These deposits can cause the passive layer to

break down and rust your stainless steel. All deposits left from food prep or service should be

removed as soon as possible.

3) Chlorides are present in table salt, food, and water. Household and industrial cleaners are the

worst type of chlorides to use.

8 step that can help prevent rust on stainless steel:

1. Using the correct cleaning tools

Use non-abrasive tools when cleaning your stainless steel products. The stainless steel’s

passive layer will not be harmed by soft cloths and plastic scouring pads. Step 2 tells you how

to find the polishing marks.

2. Cleaning along the polish lines

Polishing lines or “grain” are visible on some stainless steels. Always scrub parallel to visible

lines on some stainless steels. Use a plastic scouring pad or soft cloth when you cannot see

the grain.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners

While many traditional cleaners are loaded with chlorides, the industry is providing an ever

increasing choice of non-chloride cleaners. If you are not sure of your cleaners chloride content

contact your cleaner supplier. If they tell you that your present cleaner contains chlorides, ask if

they have an alternative. Avoid cleaners containing quaternary salts as they can attack

stainless steel, causing pitting and rusting.

14

Page 15

4. Water Treatment

To reduce deposits, soften the hard water when possible. Installation of certain filters can

remove corrosive and distasteful elements. Salts in a properly maintained water softener can

be to your advantage. Contact a treatment specialist if you are not sure of the proper water

treatment.

5. Maintaining the cleanliness of your food equipment

Use cleaners at recommended strength (alkaline, alkaline chlorinated or non-chloride). Avoid

build-up of hard stains by cleaning frequently. When boiling water with your stainless steel

equipment, the single most likely cause of damage is chlorides in the water. Heating nay

cleaners containing chlorides will have the same damaging effects.

6. Rinse

When using chlorinated cleaners you must rinse and wipe dry immediately. It is better to wipe

standing cleaning agents and water as soon as possible. Allow the stainless steel equipment to

air dry. Oxygen helps maintain the passivity film on stainless steel.

7. Hydrochloric acid (muriatic acid) should never be used on stainless steel.

8. Regularly restore/passivate stainless steel.

Recommended cleaners for certain situation/environments of stainless steel.

A) Soap, ammonia and detergent medallion applied with a cloth or sponge can be used for

routine cleaning.

B) Arcal 20, Lac-O-Nu Ecoshine applied provides barrier film for fingerprints and smears.

C) Cameo, Talc, Zud First Impression is applied by rubbing in the direction of the polished lines

for stubborn stains and discoloring.

D) Easy-off and De-Grease it oven aid are excellent for removals on all finishes for grease-fatty

acids, blood and burnt-on foods.

E) Any good commercial detergent can be applied with a sponge or cloth to remove grease and

oil.

F) Benefit, Super Sheen, Sheila Shine are good for restoration/passivation.

15

Page 16

MANUFACTURING COMPANY

THREE YEAR WARRANTY

Turbo air warrants to the original purchaser of every new Turbo air refrigerated unit, the cabinet and all parts thereof, to be free

from defects in material or workmanship, under normal use and service, for a period of three (3) year from the date of original

installation or 39 months after shipment date from Turbo air , whichever occurs first.

Any parts covered by this warranty that are examined and determined by Turbo air to have been defective within three (3) year of

original installation or thirty nine (39) months after shipment date from manufacturer, whichever occurs first, shall be repaired or

replaced as stated below. Turbo air shall be deemed to have fully complied with its obligation under the foregoing warranties by

electing either one of the following procedures, at the sole discretion of Turbo air.

1. Furnishing a replacement part, freight collect, in even exchange for the returned part, freight collect.

2. Receiving the defective part, freight collect; repairing it; and returning it, freight collect.

ADDITIONAL TWO YEAR COMPRESSOR WARRANTY

In addition to the three (3) year warranty stated above, Turbo air warrants its hermetically and semi-hermetically sealed

compressor to be free from defects in both material and workmanship under normal use and service for a period of two (2)

additional years from the date of original installation but not to exceed five (5) years and three (3) months after shipment from

manufacturer.

Compressors determined by Turbo air have been defective within this extended time period will, at Turbo airʼs option, be either

repaired or replaced with a compressor or compressor parts of similar design and capacity.

The two (2) year extended compressor warranty applies only to hermetically and semi-hermetically sealed parts of the

compressor and does not apply to any other parts or components, including, but not limited to, cabinet, paint finish, temperature

control, refrigerant, metering device, driers, motor starting equipment, fan assembly any other electrical component, etcetera.

134A(404A) COMPRESSOR WARRANTY

The five year compressor warranty detailed above will be voided if the following procedure is not carefully adhered to:

1. This system contains R134A refrigerant and polyol ester lubricant. The Polyol ester lubricant has rapid moisture absorbing

qualities. If long exposure to the ambient conditions occur, the lubricant must be removed and replaced with new. Listed below

are the approved lubricants for the Tecumseh compressors.

1 ICI-Emkarate RL 184

2 Emery-2927-A

3 Mobile Artic 22A

Failure to comply with recommended lubricant specification will void the compressor warranty.

2. Dryer replacement is very important and must be changed when a system is opened for servicing. dryer must be used with XH-

9 desiccant.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must obtained.

Page 17

What is NOT covered by this warranty

Turbo airʼs sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional

limitations below. This warranty neither assumes nor authorizes any person to assume obligations other than expressly covered by

this warranty.

1. WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original

purchaser/user to whom delivered. ANY SUCH ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANTIES HEREIN

MADE AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

2. NO CONSEQUENTIAL DAMAGES. TURBO AIR IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS OR

SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES OR DAMAGES

ARISING FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT ON ACCOUNT OF REFRIGERATION

FAILURE.

3. ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE,

FLOOD, ACTS OF GOD. TURBO AIR is not responsible for the repair or replacement of any parts that Turbo Air determines

have been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or

installation, fire, flood, or an Act of God.

4. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO

OTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, EXCEPT THE THREE(3) YEAR WARRANTY AND THE

ADDITIONAL TWO(2) YEAR COMPRESSOR WARRANTY AS DESCRIBED ABOVE. THESE WARRANTIES ARE

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY AND MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF.

5. TRANSPORTATION COSTS. Turbo Air will accept parts covered under this warranty freight collect, provided that shipment

has received prior approval. Turbo Air is not responsible for any other transporation costs, but will ship freight collect parts

either repaired or replaced under these warranties.

6. WARRANTY CLAIMS. All claims should include: model number of the cooler, the serial number of the cabinet, proof of

purchase, date of installation, and all pertinent information supporting the existence of the alleged defect. Any action or breach

of these warranty provisions must be commenced within three (3) year after that cause of action has accrued.

4184 E. Conant St.

Long Beach, CA 90808

TEL : 310-900-1000

FAX : 310-900-1077

TOLL FREE : 1-800-627-0032

(U.S.A. & Canada)

Website : www.turboairinc.com

Page 18

Warranty Claims...

All claims for parts or labor must be made directly thorough Turbo Air.

All claims should include: model number of the unit, the serial number of the cabinet, proof of purchase, date of installation, and all

pertinent information supporting the alleged defect.

In case of compressor replacement under warranty, either compressor or compressor tag must be returned to Turbo Air along with

above listed information.

Failure to comply with warranty policies will result in voiding claims.

Three Year Parts & Labor Warranty...

Turbo Air warrants all new refrigerated components, the cabinet and all parts, to be free from defects in materials or workmanship,

under normal and proper use and maintenance service as specified by Turbo Air and upon proper installation and start-up in

accordance with the instruction packet supplied with each Turbo air unit. Turbo Airʼs obligation under this warranty is limited to a period

of three (3) year from the date of original installation or 39 months after shipment date from Turbo Air, whichever occurs first.

Any part, covered under this warranty, that are by Turbo Air to have been defective within three (3) year of original installation or thirty-nine

(39) months after shipment date from manufacturer, whichever occurs first, is limited to the repair or replacement, including labor

charges, of defective parts or assemblies. The labor warranty shall include standard straight time labor charges only and reasonable

travel time, as determined by Turbo Air.

Additional Two Year Compressor Warranty...

In addition to the three (3) year warranty stated adove, Turbo Air warrants its hermetically sealed compressor to be free from defects in

both material and workmanship under normal and proper use and maintenance service for a period of two (2) additional years from

the date of original installation, but not to exceed five (5) years and three(3) months after shipment from the manufacturer.

Compressor determined by Turbo Air to have been defective within this extended period will, at Turbo Airʼs discretion, be either

repaired or replaced with a compressor or compressor parts of similar design and capacity.

The two (2) year extended compressor warranty applies only to hermetically sealed parts of the compressor and does not apply to any

other parts or components, including, but not limited to, cabinet, paint finish, temperature control, refrigerant, metering device, driers,

motor starting equipment, fan assembly or and other electrical components, etcetera.

404A / 134a Compressor Warranty...

The five-year compressor warranty detailed above will be void if the following procedure is not carefully adhered to:

1. This system contains R404A or R134a refrigerant and polyol ester lubricant. The polyol ester lubricant has rapid moisture absorbing

qualities.

2. Drier replacement is very important and must be changed when a system is opened for servicing. A620 copper drier or better is

highly recommended.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must be obtained.

4. When compressor is grounded, suction drier and 620 drier or better must be replaced.

5. Compressor must be obtained through Turbo Air, unless otherwise specified in writing, through Turbo Airʼs warranty department.

404A / 134a Compressor Warranty...

Turbo Airʼs sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional limitations

below. This warranty neither assumes nor authorizes any person to assume obligations other than those expressly covered by this

warranty.

NO CONSEQUENTIAL DAMAGES. TURBO AIR IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS; OR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES, OR DAMAGES ARISING FROM

FOOD OR PRODUCT SPOILAGE REGARDLESS OF WHETHER OR NOT THEY RESULT FROM REFRIGERATION FAILURE.

WARRANTY IS NOT TRANSFERABLE, This warranty is not assignable and applies only in favor of the original purchaser/user to

whom delivered. ANY SUCH ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANNTIES HEREIN AND SHALL VOID ALL

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR LABOR COVERAGE FOR

COMPONENT FAILURE OR OTHER THE WARRANTY PACKET PROVIDED WITH THE UNIT.

ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE, FOOD, ACTS

OF GOD. Turbo Air is not responsible for the repair or replacement of any parts that Turbo Air determines have been subjected after

the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or installation, fire, flood, or act of GOD.

IMPROPER ELECTRICAL CONNECTIONS. TURBO AIR IS NOT RESPONSIBLE FOR THE REPAIR OR REPLACEMENT OF

FAILED OR DAMAGED COMPONENTS RESULTING FROM ELECTRICAL POWER FAILURE, THE USE OF EXTENSION CORDS,

LOW VOLTAGE, OR VOLTAGE DROPS TO THE UNIT. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE; THERE ARE NO OTHER WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY, EXCEPT THE THREE

(3) YEAR PARTS & LABOR WARRANTY AND THE ADDITIONAL TWO (2) YEAR COMPRESSOR WARRANTY AS DESCRIBED

ABOVE. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY

AND MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES, WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF.

Outside U.S.and Canada; This warranty does not apply to, and Turbo Air is not responsible for, any warranty claims made on products

sold or used outside the continent of the United States and Canada.

New Extended Warranty policy applies to all units sold by Turbo Air starting Dec.1, 2012

Loading...

Loading...