Turbines, Inc. CDS1000 Installation And Operation Manual

Model CDS1000

Installation and Operation

Also covers the CDS1000-B

PO Box 933, 15935 US Hwy 283 N.

Altus, OK 73522-0933

Seneca: 864-882-4544

http://turbinesincorporated.com

Manual part number 900484

Revision E

Copyright 2013-2016 Turbines Inc. All rights reserved.

Information contained herein is subject to change at any time without prior notice.

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

Notice

Proprietary Notice

The information contained in this publication is derived in part from proprietary data and trade

secrets. This information has been prepared for the expressed purpose of assisting operating and

maintenance personnel in the efficient use of the instrument described herein. Publication of this

information does not convey any rights to use or reproduce it or to use for any purpose other than

in connection with the installation, operation, and maintenance of the equipment described

herein.

Copyright 2014

Printed in the USA. All Rights Reserved.

SAFETY INSTRUCTIONS

The following instructions must be observed.

Every effort has been made to design and manufacture this instrument to be safe for its

intended use. A hazardous situation may occur if this instrument is not used for its intended

purpose or is used incorrectly. Please note operating instructions provided in this manual.

The instrument must be installed, operated, and maintained by personnel who have been

properly trained. Personnel must read and understand this manual prior to installation and/or

operation of the instrument.

The manufacturer assumes no liability for damage caused by incorrect use of the instrument

or for modifications or changes made to the instrument.

Technical Improvements

Turbines Incorporated may modify the technical data herein without notice.

CDS1000 Page ii

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

Table of Contents

Warranty ......................................................................................................................................... 4

Description ...................................................................................................................................... 5

Features: .................................................................................................................................. 5

Overview: ................................................................................................................................ 5

Theory of Operation:............................................................................................................... 5

Modes of Operation: ............................................................................................................... 6

Operating Mode ...................................................................................................................... 6

Programming Mode ................................................................................................................ 6

Prove Mode ............................................................................................................................. 6

Installation....................................................................................................................................... 7

Operation......................................................................................................................................... 8

Programming................................................................................................................................... 9

Specifications ................................................................................................................................ 13

Hardware: .............................................................................................................................. 13

Software: ............................................................................................................................... 13

Troubleshooting ............................................................................................................................ 14

Illustrations ................................................................................................................................... 15

Wiring ........................................................................................................................................... 17

Return Policy ................................................................................................................................ 18

All Returns: ........................................................................................................................... 18

Warranty Claim: .................................................................................................................... 18

Non-Warranty Repair: .......................................................................................................... 18

Expedited Orders/Repairs: .................................................................................................... 18

Wrong Product/Excess Quantity Shipped: ............................................................................ 18

Other Returns for Credit: ...................................................................................................... 18

Turbines R&D Return Information: ...................................................................................... 18

Field Calibration ........................................................................................................................... 19

Calibration Methods: ............................................................................................................ 19

Calculating new Kfactors: ..................................................................................................... 19

Programming a new Kfactor: ................................................................................................ 20

Revision History ........................................................................................................................... 21

CDS1000 Page iii

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

Warranty

Turbines Inc. of Altus Oklahoma provides the following statement of warranty and is subject to

the following terms and conditions. No other warranty or guaranty express or implied shall be

operative or binding upon the company at any time, or under any circumstances.

Turbines Inc. shall warranty that the product(s) described hereunder shall be free from material

defect, shall be of the first quality, manufactured in accordance with the standards and practices

of the highest workmanship and materials, for a period not to exceed 12 months (one year)

following the date of purchase by the end user, subject to limitations as described:

Article 1: The warranty shall be limited to equipment for which the company has been fully paid.

In the event of nonpayment, the company reserves the right to void any warranties that may

otherwise apply.

Article 2: This warranty shall specifically exclude any deterioration or effects resulting from the

normal wear and tear of the equipment or components thereof.

Article 3: This warranty shall specifically exclude damage that has resulted from improper

installation of, improper maintenance of, unauthorized change or modification to, improper

operation of, and/or misuse or abuse of the subject equipment.

Article 4: At the manufacturer’s sole option, any equipment covered hereunder shall be either

repaired or replaced at the manufacturer’s expense during the term of the warranty, subject to

said equipment being shipped prepaid to the manufacturer’s place of business: Turbines R&D,

LLC, 112 Lumber Lane Suite A, Seneca, SC, USA, 29672. No equipment shall be accepted

unless first authorized in writing by the manufacturer. Non-warranty damage shall be repaired

solely at the customer’s expense.

Article 5: In no event shall the manufacturer’s liability exceed the original cost of said equipment

at the time of original purchase. The manufacturer shall, under no circumstances and/or at any

time, assume any liability for merchantability, or any damages or contingent liabilities that may

arise from the purchase or use of said equipment by any parties.

Article 6: This warranty is non-transferable and shall apply exclusively to the original end

purchaser or end user of said equipment.

Article 7:

factors, upon proper installation, use, handling, and maintenance.

The expected useful service life of said equipment shall vary dependent, among other

CDS1000 Page 4

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

Description

The CDS1000 Flow Monitor is a microcontroller based rate/totalizer that is capable of

calculating the effects of changes in temperature on computed values.

Features:

- Real time graphics and display of operating parameters

- Programmable 2-10 point flow meter linearization

- Delivery total can be toggled between metered and base conditions

- Battery backup for intermittent power outages

- All features/configuration settings are field programmable with plain text menus

- Pump control based on temperature to protect pump seals

- Optional pump control based on pump discharge pressure to further protect pump seals

- Large graphical display for showing various flow parameters

- Backlight for low light display viewing

- Built-in self test system of diagnostics

- Comprehensive internal warning and error reporting system

- Pump and turbine maintenance timers

- Non-resettable “Grand” totalizer

- RS-232 and Bluetooth communications available

- Level 3 Audit trail for all sealable meteorological parameters

Overview:

When introduced to flow the turbine flowmeter generates an AC sinewave signal within the

pickup coil located directly above the turbine’s rotor. The signal of the pickup coil is

amplified, divided, corrected, and displayed by the CDS1000. The displayed total is

corrected for temperature by sensing the resistance of the RTD temperature probe. Delivery

information, consisting of 17 selectable parameters, is transmitted via Bluetooth or RS232

communications depending on which data collection device or printer is selected. This

unique integrated system provides the end user a configurable, compact total delivery system.

Theory of Operation:

The TI turbine flowmeter is a velocity measurement device that measures fluid velocity and

volume with one moving component, the rotor. The momentum of the flowing fluid engages

the low mass rotor resulting in the rotor rotating at an angular velocity that is proportional to

the fluid velocity. The rotor’s rotation generates an AC sinewave signal in the pickup coil. TI

turbine flow meters are linear devices therefore the signal output frequency is proportional to

the flowrate within the designed flow range. Another benefit of a linear turbine meter is its

Kfactor, the number of pulses generated per unit volume (gallons, pounds etc.) is consistent

over the entire flow range. The total number of pulses generated is directly related to the total

volume. The displayed total in the desired engineering unit is acquired by dividing the total

pulses by the Kfactor. Because product density is influenced by fluid temperature; volumetric

flow meters require temperature to be measured and calculated into the final summation for

the displayed total to be exact. A temperature compensation algorithm accomplishes this by

CDS1000 Page 5

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

computing the fluid density for the measured temperature and adjusts the volumetric or mass

delivery total.

Simply stated, temperature compensation adds pulses to the pulse total when the detected

temperature is colder than the products reference temperature and subtracts pulses when the

product temperature is warmer than the reference temperature. The rate at which the pulses

are added or subtracted is determined by the measured temperature departure from the

products reference temperature.

Modes of Operation:

The CDS1000 program offers 3 modes, Operating, Programming, and Prove. Any mode that

can affect the calibration of the CDS1000 is password protected. The CDS1000 has a 2 tiered

password level of security, Privileged and User/Weights and Measures. The Privileged

password is maintained exclusively for Factory use and allows access to ALL menu options.

The Weights and Measures password allows access to all displayed menu options except two,

Initialization Options 5,8 Hardware test/calibrate and Loaner respectively.

Operating Mode

The Operating mode is the power up mode for the CDS1000; all others must be accessed

with a password. The Operating screen containing all delivery information is the normal

display for this mode. The Detail screen is also accessible in this mode without a password.

Programming Mode

The Programming mode and associated menu’s permit the CDS1000 to be configured to the

operating conditions of the application. When accessed, the first Display is CDS1000

Initialization Options menu containing 9 options. Options 2,3,5 and 8 are password protected.

Options 5,8 require a Privileged password and are intended for Factory use only

Prove Mode

..

The Prove mode permits convenient calibration of the trailer’s delivery system. This mode

temporarily aborts certain safeguard features and therefore is password protected. To access

this mode, depress the SETUP key while in Operating mode. The system will prompt for a

password, either User/Weights and Measures or Privileged, to be entered. If an incorrect

password is entered or the ESC key is depressed, the CDS1000 will revert to the Operating

mode. The Prove mode allows entering, changing or viewing the Kfactor. The Prove mode is

retained until the CDS1000 is either turned “Off” or no flow activity is detected for 5

minutes. The Prove mode has the following operational characteristics:

The *CDS1000* message is replaced with the PROVER message on the operating screen

A password is not required to change the Kfactor

The pump cooldown timer is disabled (pump enabled)

The Totalizer can be reset regardless of the presence of flow

“

Not a legal delivery” is displayed above the delivery totalizer and on a printed ticket

CDS1000 Page 6

Turbines Incorporated Cryogenic Flow Delivery System CDS1000 Manual (Rev E)

Installation

For best equipment performance, please follow these simple installation/operation/programming

instructions:

1. Ensure that you have removed all the equipment from the shipping box:

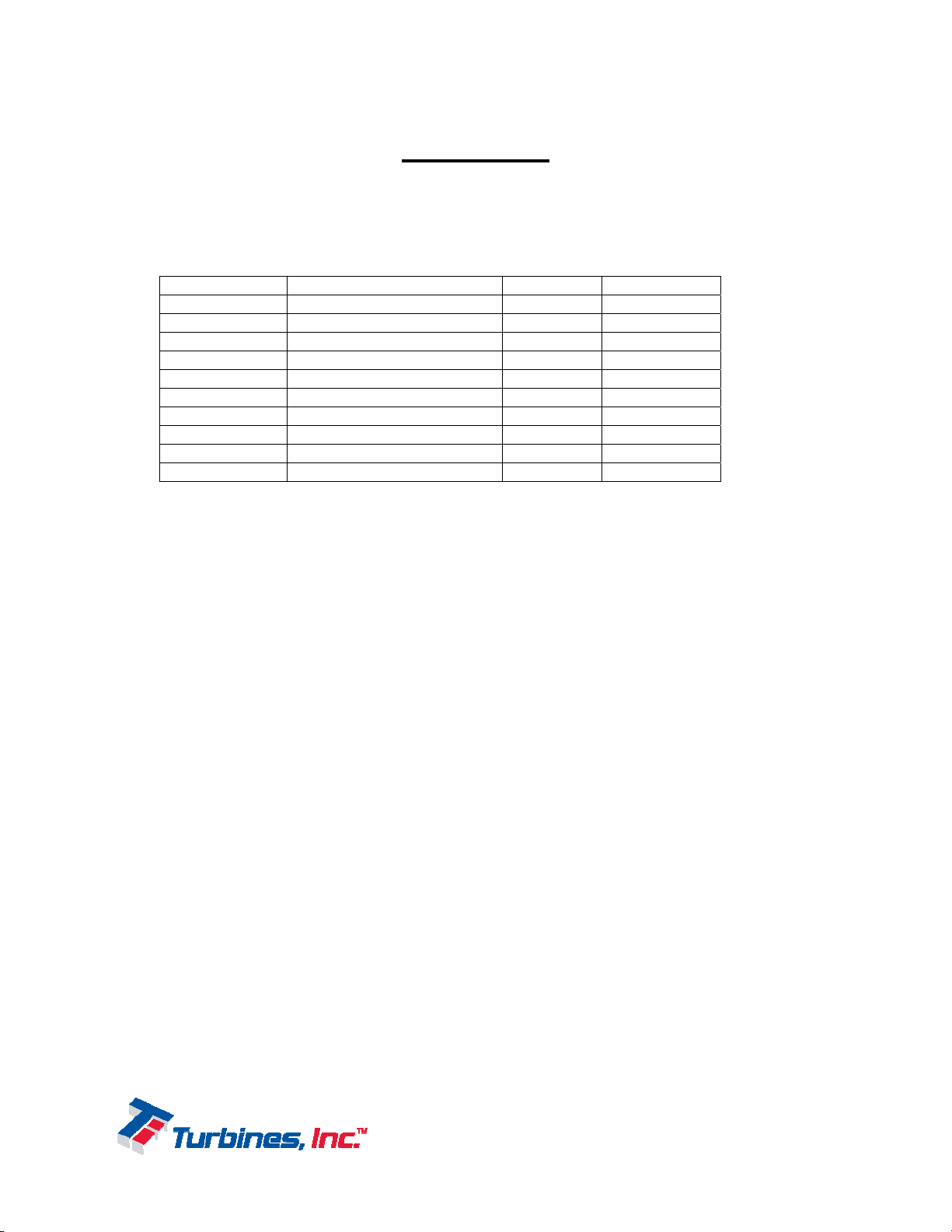

Model # Description CDS1000 CDS1000-B

CDS1000 Main Unit √ √

900037 Power Cable √

900038 Signal Cable √

900039 Temperature Cable √

900040 Mounting Bracket* √

900206 Temperature Sensor √

900058 Knobs (2)* √ √

900062 PCO Cable **

900558 Pressure Sensor **

900506 Pressure Sensor Cable **

* Part of the CDS1000

** Optional equipment

2. Install any piping that was ordered. Temperature probe coupling should be down-stream

of the turbine.

3. Mount the CDS1000 at a height and angle ensuring ease of accessibility and visibility.

a. Avoid installing under piping that defrosts often or near pumps that may spray

liquid.

b. Use at least 4¼-20 bolts with lock washers and/or lock nuts.

4. Install cables and connect to the rear panel. Do not over tighten! Connectors should be

hand tight.

a. Route cables and tie wrap excess so that no rubbing of the cables will occur.

b. Allow slack in the cables to allow the CDS1000 to rotate for easy access to the

rear panel.

5. Connect the power cable to the vehicle battery or other constant power source. It is not

recommended to connect the power to the lighting system of the truck/trailer.

a. Power connections are polarity insensitive (+ and – may be reversed).

6. Install the temperature probe:

a. If using the PCO control: downstream of the pump

b. If not using the PCO: Downstream of the turbine

c. Connect the temperature probe wire to the top of the temperature probe. Tighten

cable lock nut hand tight.

7. Install turbine meter and connect to signal cable or connect signal cable to existing meter.

Tighten cable lock nut hand tight.

8.

Press the CDS1000 power button and observe LED lights are on or flashing. The main

LCD screen will indicate run mode.

CDS1000 Page 7

Loading...

Loading...