Tundra HTS3024 User Manual

Owner Manual

POWER INVERTERS

HTS324 / HTS624 / HTS1224

See page 12 for

HTS1824 / HTS2524 / HTS3024 models

ONLY install using

appropriate Tundra

CM Series installation kit

(http://www.tundrainternational.com/en/pages/cmseries)

2

Table of contents

1 INTRODUCTION .......................................................................................................................................... 3

1.1 Disclaimer ................................................................................................................................................................. 3

1.2 Output waveform ....................................................................................................................................................... 3

2 FRONT & REAR PANELS ........................................................................................................................... 3

3 PERMANENT INSTALLATION ................................................................................................................. 4

3.1 Recommended material HTS 324 HTS 624 HTS 1224 ............................................................................................. 4

3.2 Recommended tools ................................................................................................................................................... 4

3.3 Where to install .......................................................................................................................................................... 4

3.4 Mounting the inverter ................................................................................................................................................ 5

3.5 Ground ....................................................................................................................................................................... 5

3.6 Battery cables............................................................................................................................................................. 5

3.6.1 Preparation of the cable connected to the “positive” end ................................................................................... 6

3.6.2 Preparation of the cable connected to the negative side ..................................................................................... 7

3.7 Connecting the Inverter ............................................................................................................................................. 7

3.8 Connection of the batteries ........................................................................................................................................ 7

3.8.1 Positive Terminal................................................................................................................................................ 7

3.8.2 Negative Terminal .............................................................................................................................................. 7

4 OPERATION .................................................................................................................................................. 8

4.1 Operating limits ......................................................................................................................................................... 8

5 MAINTENANCE ........................................................................................................................................... 8

6 TROUBLESHOOTING ................................................................................................................................. 8

6.1 Television and CB radio interference ........................................................................................................................ 8

6.2 Troubleshooting guide ............................................................................................................................................... 9

7 SPECIFICATIONS ...................................................................................................................................... 10

8 LIMITED ONE-YEAR WARRANTY ....................................................................................................... 11

HTS-324_1224-GD-0114-EN

3

1 Introduction

Congratulations! You have purchased one of the most sophisticated and reliable power inverters on the market today. Incorporating

some of the latest technological developments, it will give years of trouble free operation for your truck, boat, R.V. or other.

In order to get the most out of your inverter, the installation procedure must be followed carefully and it must also be properly used.

Please thoroughly read this manual before installing and using your new inverter. It is important to pay special attention to the

CAUTION and WARNING statements in this manual as well as on the inverter. Should the inverter be exposed to rain, moisture,

or strong impact, have it inspected by a qualified technician before use.

WARNING! The electrical current at the entrance and exit of your inverter may cause severe personal injury; make

certain that you have read and understand all the parts of this manual before installing and using your

inverter.

WARNING! The inverter produces an electrical current similar to that found in most North American homes, with all

the accompanying dangers. Be sure to install the product out of the reach of children.

1.1 Disclaimer

Electrical codes vary depending on location and the type of installation. Electrical installations must meet local and national wiring

codes and should be performed by a qualified electrician.

The inverter’s specifications are subject to change without notice.

1.2 Output waveform

The AC output of your inverter is regulated to 120 volts and its waveform is called a “Pure Sine Wave.” It is a waveform identical to

the sine waves delivered by utility power.

2 Front & rear panels

FRONT PANEL

ON/OFF switch: The ON/OFF switch turns the inverter’s control circuit ON and OFF. It does not disconnect power from

the inverter; you must disconnect the AC (120 volts) and DC (24 volts) power before working on

any circuits connected to the inverter. When the switch is on but no power is being supplied to a load,

the inverter draws less than 500 mA. This is a very low current draw but left in this state the inverter will

eventually drain your batteries.

AC Outlets: The maximum output of your inverter can go through any of the two AC outlets.

CAUTION! Leave in the OFF position during the installation.

REAR PANEL

Chassis ground screw: The chassis ground screw must be properly connected to the chassis of your vehicle before operating the

inverter.

Fan(s): In order for the inverter to properly operate, the fan(s) opening must never be obstructed. Allow at least

six inches of clearance around the inverter for airflow. All fans are thermostatic and operate upon the

interior temperature of the inverter.

HTS-324_1224-GD-0114-EN

4

3 Permanent Installation

The use of the Tundra International installation kit is strongly recommended. This complete installation kit is custom designed to

maximize performances. It has been developed to promote safe installation and to help eliminate the difficult task of identifying and

shopping for the requisite materials in stores.

CAUTION! Before installation, make sure that the inverter is turned “OFF.”

3.1 Recommended material HTS 324 HTS 624 HTS 1224

- Tundra CM series installation kit N/A N/A CM1000

OR

- Welding cable Awg 10 Awg 4 Awg 4

- 6 Tin plated terminal lugs

- PVC strain relief for flexible cable ½” ½” ½”

- DC fuse block

- DC fuse 20A 100 A 100 A

- Plastic « loom » tubing

- Red and black heat shrinkable tubing

- Plastic cable ties

- Clamps and bolts

- Heavy duty AC power distribution center

3.2 Recommended tools

- Hand held crimping tool for terminal lugs * Mandatory

- Hollow punch or hole saw for metal

- Drill bit set for metal

- Screw driver set

- Open end wrench set

- Side cutters

- Power drill

3.3 Where to install

Your inverter should be installed in a location that meets the following requirements:

- Dry: Keep the inverter away from any water or moisture.

- Cool: Ambient air temperature should be between 32 and 85 degrees Fahrenheit (0 and 30o Celsius).

- Ventilated: Ensure that the unit is located in a well-ventilated compartment. At least 6 inches of clearance are required

around the inverter for air flow. Verify that all ventilation openings on the unit (front and rear panels) are

not obstructed.

CAUTION! To avoid fire hazards and/or overheating, do not cover or obstruct any ventilation openings. Do not install

the inverter in a zero clearance compartment.

- Safe: Do not install the inverter in the same compartment as batteries, or in any compartment capable of storing

flammable liquids (such as gasoline). Power inverters may produce sparks that can result in fire if exposed

to flammable vapors.

HTS-324_1224-GD-0114-EN

5

WARNING! This equipment contains components that tend to produce arcs or sparks. To reduce the risk of fire or

explosion, do not install in a compartment containing batteries or flammable materials, or in a location

that requires ignition protected equipment.

- Close to batteries: Install the inverter as close as possible to batteries (but not in the same compartment) in order to minimize

the cable length required to connect the inverter to the batteries. It is better and cheaper to run longer AC

wire (between the inverter and your appliances) than DC cables (between the inverter and the batteries).

3.4 Mounting the inverter

When you have decided where to place it, mount the inverter on a flat surface using the mounting flanges. Mounting hardware should

be corrosion resistant, and 1/4” or larger. The inverter may be mounted horizontally on a vertical surface (the fans’ opening must not

point up or down) or on a horizontal surface. Upside down installation is not recommended, as it may put too much stress on the

housing of your power inverter.

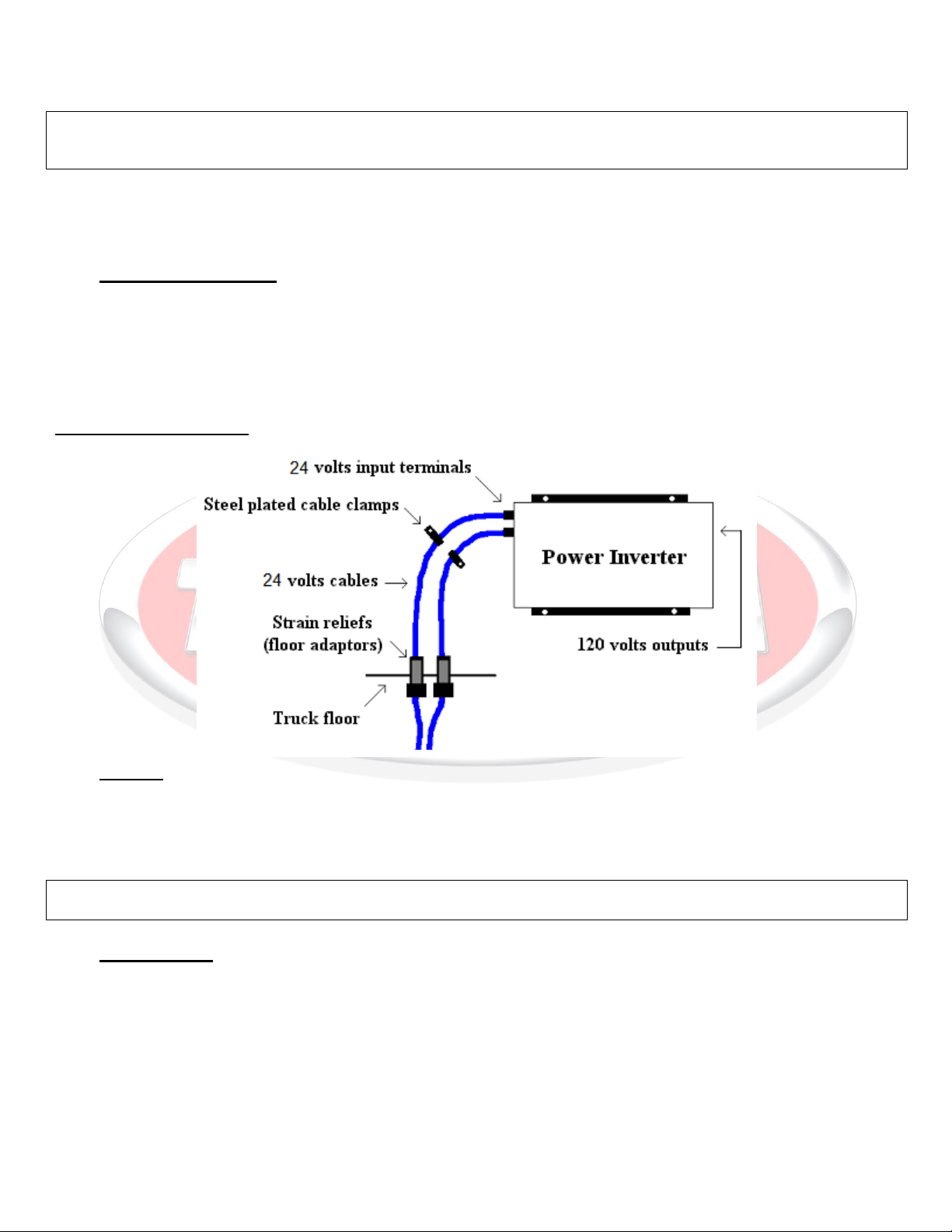

Close to the inverter, drill two holes in the truck’s floor and install the two strain reliefs about 3 inches apart (Figure 3).

Figure 3: Installation schema

3.5 Ground

The inverter has a lug on the rear panel that must be connected, using a #10 AWG copper cable, to the chassis of your vehicle or to a

metallic panel connected to the chassis. This grounding procedure conforms to most electrical codes that require deriving AC sources

to ground in case of malfunctioning. To make sure that you found a good grounding point, run a 12 volt test light from the positive

terminal of your battery to your grounding point. If the light comes on, your installation is more than likely OK.

WARNING! Do not operate the inverter if the ground screw of the inverter is not properly connected to the chassis of

your vehicle, it may result in electrical shock hazard.

3.6 Battery cables

Proper wiring is very important for safe and proper operation of the inverter. Since the inverter has a low voltage (24 volts) and a high

current input, low resistance wiring and connections between the batteries and the inverter is essential in order to deliver the maximum

amount of usable energy to your load. Don’t waste the investment you have made in a highly efficient inverter by using cheap and

undersized wires!

Use only covered, flexible, copper wires capable of withstanding temperatures in excess of 215° Fahrenheit. We recommend welding

cable as the best size & type for connection between the batteries and your inverter. Keep the cable length as short as possible, no

HTS-324_1224-GD-0114-EN

6

longer than 10 feet. This will ensure that the overall system efficiency is as high as possible, and will keep the voltage drop between

the batteries and the inverter to a minimum. If the voltage drop is too excessive, the inverter may shut down.

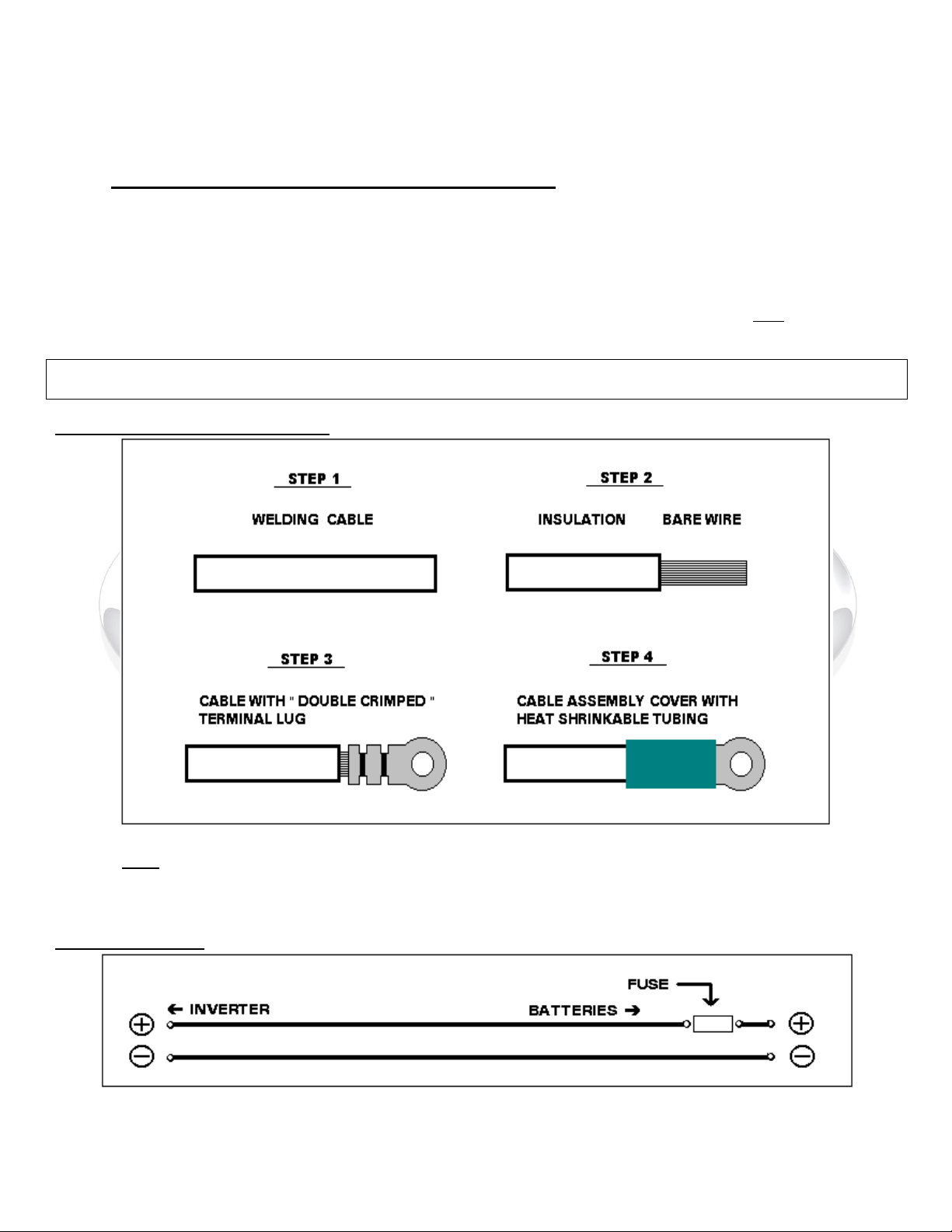

3.6.1 Preparation of the cable connected to the “positive” end

Measure and cut the length of cable necessary to connect the positive (+) end of the battery to that of the inverter, not forgetting the

length needed to allow movement due to the suspension of the cabin. The cable must be cut in two pieces, of which the small part must

be six inches (Figure 5).

Strip a half-inch off each of the four cable ends, insert the longer section of the cable in a PVC strain relief, and install good quality tin

plated terminal lugs on the bare wires. Crimp the terminals with a hand held crimping tool (the use of locked pliers (Vice-Grip) is not

recommended), until the entire cable is crimped, and then cover each section of bared wire with good quality RED shrinkable tubing

(Figure 4).

CAUTION! Do not solder the terminal lugs to cables. Solid and low resistance connections to the DC power source are

essential in order to properly operate the inverter. The soldering cannot provide such connections.

Figure 4: Terminals’ crimping procedure

3.6.1.1 Fuse

A main fuse must be installed in the battery casing on the positive cable (+) between the batteries and the inverter, as close as possible

to the batteries. In this way (and in the event of cable rupture), the DC current would be cut at the batteries and would not cause a fire.

Figure 5: Fuse schema

HTS-324_1224-GD-0114-EN

7

We recommend a fuse of type “CNL”, mounted on a fuse holder, type “CNL.” Plug one terminal of the small and the long cable’s

sections on the fuse holder, as illustrated in figure 5, and install the fuse. Without tightening them too much, the terminals must be

solidly fixed onto the fuse holder, and must not be able to move around.

CAUTION! Not installing a fuse can result in fire that may cause severe injuries and/or damages.

3.6.2 Preparation of the cable connected to the negative side

Determine and cut the length of cable which you need to connect the negative side (-) of the battery to that of the inverter, without

forgetting the necessary length to allow movements due to the suspension of the cabin. Strip approximately a half-inch of insulation

from the two ends of the cable, insert the cable through the second PVC strain relief, and install good quality tin plated terminal lugs on

the stripped sections. Crimp the terminals with a hand held crimping tool (the use of a locked plier (Vice-Grip) is not recommended)

until the whole cable is crimped and then cover each section of stripped cable with good quality BLACK shrinkable tubing (refer to

Figure 4).

3.7 Connecting the Inverter

The next step is to make sure that the inverter is turned OFF. Insert the rubber insulators (included with the inverter) on the terminal

lugs and connect the cables (terminal lugs) to the inverter’s DC input terminals: the terminal covered with the RED shrink tube to the

positive (+) pole and the terminal covered with the BLACK shrink tube to the negative (-) pole. Make a secure connection using the

nuts included with the inverter. The terminal must not move around on the DC terminal, but it must not be too tight either. The rubber

insulators will protect the DC connections and will prevent the terminal from being touched by other metallic pieces.

CAUTION! Never put a washer or a nut between the terminal lugs and the 24 volts DC input terminals; this results in

poor conductivity and may cause the inverter to overheat and cause a fire.

Tighten the PVC strain relief nut on the cables until the rubber seal is properly compressed and the cables cannot move. Run the cables

under your cab and cover them with plastic loom to prevent damage from road debris. Fasten both cables together every 4 inches with

plastic cable ties; try to run both DC (24 volts) cables as close as possible together to reduce the risk of interference with your

television or CB radio. While keeping in mind to allow cables to move with your cabin air suspension, secure the cables to the chassis

from the cabin’s floor to the batteries with several metallic clamps covered with rubber. These clamps will prevent the cables from

being cut or damaged by the vehicle’s vibrations.

3.8 Connection of the batteries

If you are working with a multiple battery bank, choose a battery with no accessory connected, as it will extend your battery’s life.

Before going further, it is important to correctly identify the cable connected to the positive terminal of the inverter, and the one

connected to the negative terminal. The cables must go from the positive terminal of the inverter to the positive terminal of the

battery, and of the negative terminal of the inverter to the negative terminal of the battery. Incorrectly connecting the battery

and inverter will damage your inverter permanently and is not covered by the warranty. Always connect the positive terminals

before the negative.

CAUTION! Reversing the polarity when connecting the DC cables will permanently damage your inverter. THIS IS

NOT COVERED BY THE WARRANTY.

3.8.1 Positive Terminal

Always connect the positive terminals before the negative. Plug the small section of the cable connected to the positive terminal of the

inverter to the positive terminal of the battery, by solidly fixing the terminal with the nut. Without tightening them too much, the

terminals must not be able to move around.

3.8.2 Negative Terminal

The last step is to connect the cable between the negative terminal of the inverter to the negative terminal of the battery, by solidly

fixing the terminal with the nut. Without tightening them too much, the terminals must not be able to move around.

HTS-324_1224-GD-0114-EN

8

WARNING! You may observe a spark when making the cable connections since current may flow and charge

capacitors in the inverter. This is normal. Do not make cable connections in the presence of flammable

fumes; it may result in explosion and/or fire.

4 Operation

To operate the power inverter, turn it on by using the ON/OFF switch on the front panel. The inverter is now ready to deliver AC 120

volts power to your load. If you are operating several loads from the inverter, turn them on separately after the inverter itself has been

turned on. This will ensure that the inverter does not have to deliver the starting power for all the loads at once.

4.1 Operating limits

Power output: Your inverter is designed to deliver its full output power continuously, and has a double power surge

capacity for 1 second.

Input voltage: The inverter will operate with input voltages between 21 and 30 volts. Optimum performance is achieved,

however, with input voltages between 24.0 and 28.0 volts. If the voltage drops lower than 22.0 volts, the low

battery warning alarm will sound.

The inverter will shut down if the voltage drops below 21 volts. This protects your batteries from being

over-discharged. The inverter will not restart unless the input voltage exceeds 26 volts.

The inverter will shut down if the voltage exceeds 30 volts. This protects the inverter from excessive input

voltage. While the inverter incorporates protection against over voltage, it may still be damaged if the input

voltage exceeds 32 volts.

5 Maintenance

Very little maintenance is required to keep the inverter operating properly. You should clean the exterior with a dry cloth to prevent

dust accumulation. A regular maintenance check is recommended, DC input bolts or screws should be tightened periodically, cables

should also be inspected for solidity and exterior condition. You must also keep your batteries as clean as possible to prevent current

loss that may affect inverter operation.

CAUTION! If you work on the DC input terminals of your power inverter, disconnect both wires at the battery side to

avoid any short circuit.

6 Troubleshooting

6.1 Television and CB radio interference

Operating your inverter can interfere with television and CB radio reception. If this occurs, the following steps may help to alleviate

the problem:

Make sure that your inverter is properly grounded to the chassis of your vehicle.

Reduce power consumption while watching television

Move the television as far as possible from your inverter

Run both DC cables as close as possible together with cable ties.

HTS-324_1224-GD-0114-EN

9

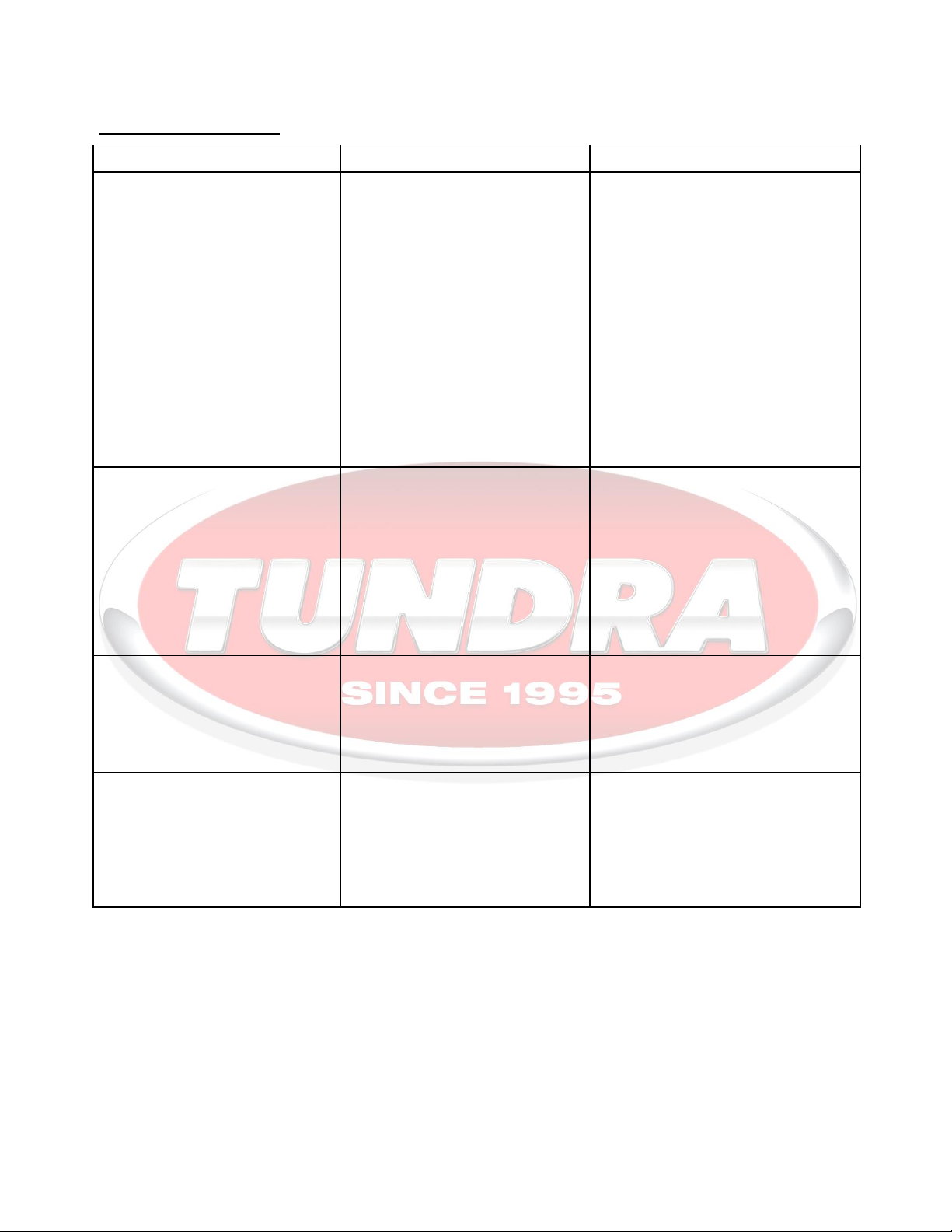

Problem

Possible cause

Solution

Fault indicator ON

Low input voltage

High input voltage

Short circuit or AC wiring error

Inverter overload

Not enough battery capacity

Recharge batteries

Improper Installation. Check each

inverter’s installation steps

Check vehicle’s alternator condition

Check the AC wiring (120 volts) and test

your appliances on an other power supply

to validate their functionality

Remove or reduce load, switch the

inverter OFF at least 5 second and restart

the inverter

No output voltage

Inverter off

No DC power to the inverter

Reverse DC polarity

Turn the inverter on

Check the wiring

Check battery fuse et check the

installation before changing it

Replace internal fuses of the inverter.

Damage caused by reversed polarity is not

covered by the warranty.

Alarm on all the time

Poor battery condition

Poor DC wiring

Poor DC terminal lugs connections

Charge or change battery

Use proper cables and make solid

connections

Use proper crimping tool

Overheat

Thermal shutdown

Improper installation

Reduce load

Allow inverter to cool off

Improve ventilation

Install properly

6.2 Troubleshooting guide

HTS-324_1224-GD-0114-EN

Loading...

Loading...