Page 1

REPAIR

This kind of airplane is far different from the

traditional wood made airplane covered with

covering, it is all plastic includes the fuselage,

wing and tail feathers. Enclosed in the kit, there is

a repair bag includes a super glue, epoxy and ABS

sheets. Use the furnish materials to repair your

plane if there is any damaged. Cut a proper size of

ABS sheet for the crack area as a patch, sand the

glue area with 300-400 grit sand paper first, this

will enhance the adhesion. Patch the crack area or

anywhere need to be reinforced with super glue.

Use epoxy instead of super glue if contacts any

foam inside the wing. Check Thunder Tiger

authorized distributors for customer service or

tech support if any problem is encountered.

MEMO

Assembly Manual

Specifications:

Wing Span: 67.00 (1700mm)

Wing Area: 682 sq.in. (44 sq. dm )

Length: 49.20 (1250mm)

Weight: 6.60 lbs.(3000g)

Engine: .61 2C Req'd

.91 4C Req'd

Radio: 4CH Req'd

2

Warranty

This kit is guaranteed to be free from defects in material and workmanship at the date of purchase.

It does not cover any damage caused by use or modification. The warranty does not extend

beyond the product itself and is limited only to the original cost of the kit. By the act of building this

user-assembled kit, the user accepts all resulting in liability for damage caused by the final

product. If the buyer is not prepared to accept this liability, it can be returned new and unused to

the place of purchase for a refund.

JE6982

116

Page 2

INTRODUCTION

Introduction

Thanks for purchasing the ABS ( ABS is a “polymericed alloy” of the three materials Acrylonitrile,

Butadiene and Styrene) series airplane from Thunder Tiger, this kind of airplane is far different from the

traditional wood made airplane covered with covering. The plane is all plastic includes the fuselage, wing

and tail feathers which are impact and water resistance that we ensure you will have longer enjoy time with

this product.

ITEMS NEEDED

This is not a toy. Assembly and running this product requires adult supervision.

To gain the most from this

airplane kit, it is important that you read the instructions thoroughly and then follow them exactly. This

instruction manual has been written with a novice modelers in mind, but includes many hints and modeling

tips that even experienced modeler can benefit from. We strongly suggest that you read through the

construction sequence and eliminate many questions you might have if you did not read the manual prior to

starting the actual construction.

The first thing you should do before beginning assembly is to check the contents of your kit against the

parts list on pages 4 and 5. If any parts are missing, contact your dealer or authorised Thunder Tiger

Distributors immediately for replacement.

Browse www.thundertiger.com for more information or

customer service if you encounter any problems.

TABLE OF CONTENTS

INTRODUCTION..............................................................................................................2

OTHER ITEMS REQUIRED.......................................................................................2

ITEMS NEEDED.....................................................................................................3

PARTS DRAWING...............................................................................................................4-5

PRE-ASSEMBLE NOTES....................................................................................6

WING..........................................................................................................6-7

FUSELAGE...........................................................................................................8-10

TAIL..........................................................................................................11-12

ENGINE.............................................................................................................12-13

RADIO......................................................................................................14

BALANCE.............................................................................................................................15

PEPAIR.................................................................................................................................16

Adhesives- You will need two types of adhesives for the

Cessna 177- Epoxy and Instant ( cyanoacrylate )

adhesives. We recommend that you purchase both 5minute and 30-minute epoxy to cut down on assembly

time, but you can get by with only 30-minute epoxy if time

is no important. You will also need a small bottle of both

"Thick" and "Thin" instant adhesive.

Tools-Model assembly can be much easier if the proper

tools are used. Therefore we have included in our

checklist to above, a complete listing of all the tools we

used to assemble our prototype models. As you will

notice, many household tools can be utilized during

construction.

No.9160

Flight Equipment There are several “support” items

that you will need to purchase in order to get your engine

running and your plane in the air. These are listed at the

bottom.

Flight Equipment Needed Check List

Foam Rubber Padding for the radio

Stick on Lead Strip for balancing the plane

3 or 4 Props (see engine instructions)

10%-15% Glow Fuel

Fuel Pump or Bulb

Electric Starter or “ Chicken Stick”

Glow starter

Extra Glow Plug(s)

Silicon Tubing

ITEMS REQUIRED FOR ASSEMBLY

A checklist is also provided on the next page which

will make shopping for these items easier.

Radio - A 4- channel radio with 4 standard servos is

required. Most lower priced 4-channel radios only

come with three standard servos so you may need to

purchase the fourth servo separately.

ACCESSORIES

No.1263-65

Carry Master-Thunder Tiger offer a complete

organizer of field equipment. All you need is included.

2

No.9801

Engine The Thunder Tiger PRO-61 and F-91S are the

ideal engines for this airplane. These quiet running engines

are easy to start, require no special break in periods, are

very easy to maintain and will last for years.

Comprehensive Items Needed Check List

4-Channel Radio with 4 Standard Servos

5-Minute Epoxy (4 ounces or so)

30-Minute Epoxy (4 ounces or so)

“Thin” Instant Adhesive (1/2 ounce)

“Thick” Instant Adhesive (1/2 ounce)

Hobby Knife and Blades

Epoxy Mixing Sticks and/or Brushes

Sandpaper (150 grit)

Masking Tape

Rubbing Alcohol

Paper Towels

Ruler

90 Degree Triangle

Waxed Paper

Fine-Point, Felt-Tip Pen

Misc. Household Tools

Drill and Bits 2mm,5mm,8mm (5/64", 13/64", 5/16")

3

Page 3

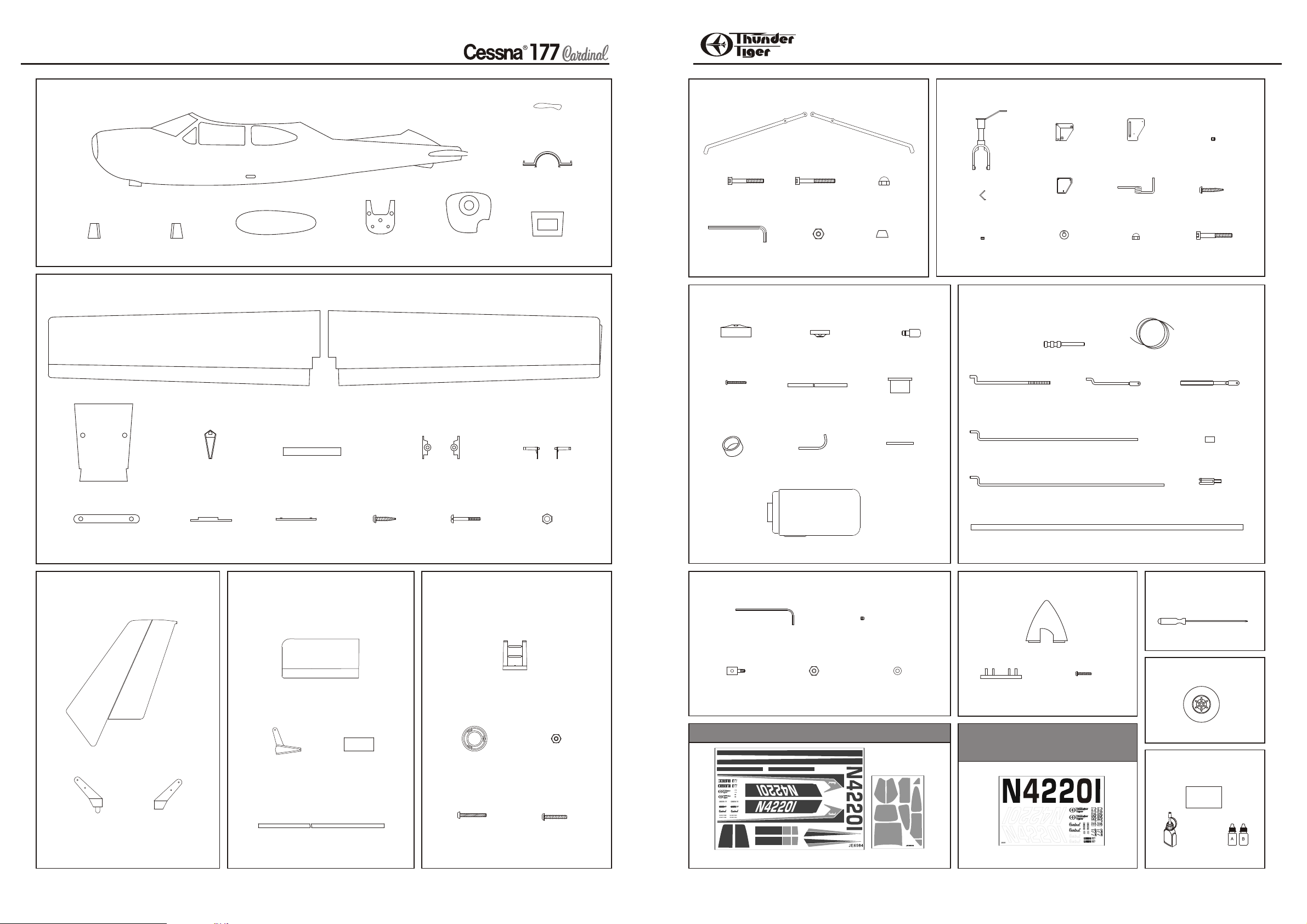

PARTS DRAWINGS

PARTS DRAWINGS

AS6681 Fuselage Set

AS6681-1 (K20)

Nut Support A (1) Nut Support B (1)

AS6682 Main Wing Set

AS6682-1 (K20)

Muffle Fairing (1)

Main Wing (L/1,R/1)

Rubber Band (2)

Fuselage (1)

Centre Bulkhead (1) Servo Tray (1)

Firewall (1)

Fuel Tank Support (1)

AS6686 Main Landing Gear Set

Main Gear

(L/1,R/1)

4X30mm Socket

Screw (3)

Hex Wrench (1)

4X35mm

Screw (2)

M4 Nut (5)

M4

Locknut (2)

M4 Cone (3)

AS6688 400cc Fuel Tank

Cap (1) Back Plate (1)

3x20mm Self

-tapping Screw (1)

Silicon Tube (1)

Rubber Stopper (1)

Clunk (1)

AS6687 Nose Gear Set

Nose Gear

Mount A (1)

Nose Gear (1)

Damper

Linkage(1)

Nose Gear

Spacer(1)

Nose Gear

Back Plate (1)

Wheel

Collar (1)

AS6689 Linkage Set

Threaded Adaptor (2)

Aileron Pushrod (2)

Nose Gear

Mount B (1)

Nose Gear

Wire(1)

M4

Locknut (1)

Z-Bend End

W / Hole (2)

3x3mm

Setscrew (1)

3x25mm

Wood Screw (3)

4X40mm Socket

Screw (1)

Wire 2 (1)M

Threaded End

W / Hole (2)

Aileron End

Cap (2)

Center Sleeve (1)

Wing Joiner (1)

Aileron Servo

Rail U (1)

AS6683 Vertical Tail Set

AS6683-1 (K20)

Rudder (1)

Wood Stick (1)

Aileron Servo

Rail V (1)

3x10mm

Wood Screw (4)

Rod Support (L/1,R/1)

AS6684 Horizontal Tail Set

AS6684-1 (K20)

Horizontal Tail (2)

Elevator

Control Horn (1)

Foam Block (1)

Connecting

Rod (L/1,R/1)

Wing Bolt (2)

M7 Hex Nut (2)

AS6685

Engine Mount Set

Engine Mount (1)

Engine Mount

Back Plate(1)

Hex Nut (3)

Bent Brass Tube (2) Brass Tube (1)Silicon Ring (1)

Fuel Tank (1)

3169 EZ Connector Set AS6675

3282W Spinner

Nose Gear Pushrod (1)

Throttle Pushrod (1)

CFK Pushrod (1)

Brass Tube (4)

Screw Driver

Hex Wrench (1)

3x3mm

Setscrew (2)

Spinner (1)

Screw Driver (1)

3297 Wheel

Pushrod

Retainer (2)

AS6690 Decal

M2 Washer (2) M2 Nut (2)

(Only comes with 4595-K10)

Backplate (1)

AS6691 Decal

(Only comes with 4595-K20)

3x12mm Self

-tapping Screw (2)

Wheel (3)

AS6680

Repair Bag

Clevis (6)

Rudder Control

Horn A (1)

Rudder Control

Horn B (1)

Elevator Spar (1)

4

4x25mm

Screw (3)

4x24mm Self

-tapping Screw (4)

Decal (1)

ABS(2)

Decal (1)

CA Glue(1)

Epoxy(1)

5

Page 4

PREASSEMBLY

PRE-ASSEMBLY NOTES

1. If you are not an experienced pilot, plan to have a fully

competent pilot check your completed model and help

you with your first flights. Even though we have tried to

provide you with a very thorough instruction manual,

models are rather complicated and an experienced

modeler can quickly check over your model to make sure

your first flights are successful.

2. Please assemble your model exactly according to these

instructions . Do not attempt to modify or change the

Cessna 177 in any way as doing so may adversely change

its flying characteristics.

3. Before you begin, please check the entire contents of

this kit against the parts drawing make sure that no parts

are missing or damaged. This will also help you to

become familiar with each component of your plane. If

you find that any of the parts are either missing or

damaged, please contact your dealer immediately for

replacement.

Note: Your dealer cannot accept kits for return if

construction has begun.

4. Trial fit each part before gluing it in place. Make sure

you are using the correct part and that it fits well before

assembling. No amount of glue can make up for a poor

fitting part.

2.Trail fit the wing joiner, make sure it is level with

the wing surface. Next apply enough epoxy to

joiner and wing slot cut. Epoxy this wing joiner in

place with the wood stick under two wing halves,

this is for correct “ Dihedral” of the main wing.

5.Sand the wing center area where is going to glue

the Centre Sleeve. This is to enhance the

adhesion.

WING

8.Secure the aileron servo in place. Next thread

the clevis onto the aileron pushrod, insert the Zbend end to the aileron control horn then snap on

the clevis to the servo horn as shown.

Suggest to install two servos and set up the

“FLAPRON”, this will help the landing slower.

WING ASSEMBLY

1.Locate the wing parts as shown, you may refer to

the parts drawing of main wing set in page 4.

3.Locate two Aileron End Caps, then CA them in

place. Drill the wing bolt hole through the wing with

8mm drill bit.

4.Temporally install the Centre Sleeve, mark the

guide lines on both wing surface when it centered.

6.Glue the Centre Sleeve in place with epoxy or

thick CA. Next install the aileron Connecting Rod

and Rod Support. Make sure leave 1mm between

the control horn and support bearing.

U

V

7.Locate the Aileron Servo Rails, note the servo

rail will have to accommodate to your servo size

before you secure on the aileron servo well. Also

make sure the Rails are at right positions.

9.Drill 2mm holes for the rudder pull-pull wire as

photo shown.

10.Drill 5mm inlet hole as photo indicated.

6

7

Page 5

FUSELAGE

FUSELAGE

4mm

3mm

10mm

11. Using a 4mm drill bit to drill through the front

bulkhead for the engine mounting screws. Drill

3mm holes for the nose leg mounting holes on the

firewall. Drill 10mm hole for the steering pushrod

as photo shown.

12.Glue the Engine Mount and Nose Gear Back

Plates in the firewall, make sure the holes are

aligned. Fit the 4mm nuts into the Engine Mount

Back Plate.

14.Drill three 4mm holes in the positions of centre

bulkhead.

15.Place the cones in the position of centre

bulkhead and CA them in place. Insert the M7 nuts

in the nut support.

17.Both sand the glue area on bulkhead and

fuselage. Trail fit the assembled bulkhead into the

position as photo shown. You may use the

furnished screw driver thread through the fuselage

and bulkhead is against the screw driver. Note the

screw driver should move forward to the very end.

CA the bulkhead in place firmly.

A

18. Locate the Main Landing Gear and mounting

screws as shown.

B

20. Trail fit the servo in the servo tray, trim the

servo tray if it is necessary. Next trail fit the servo

tray into fuselage and slide into the position

locking the front of the tray into the recess of the

central bulkhead. Remove the servo tray and

slightly sand the glue area then CA the servo trail

in place.

21.Locate the engine mount then secure the

engine mount in place with three 4x25mm screws.

13.Insert the firewall through the center opening of

the fuselage and place in right position. You may

need to push the firewall forward to the place until

it fits correctly in the formed recess.

16.Glue the support to the bulkhead and insert the

M4 nuts in the cones.

4x30mm

A

4x35mm

19.Insert the legs through the fuselage and place

on the bulkhead then secure the main gear firmly

with two 4x35mm screws and one 4x30mm socket

screw.

B

22.Locate the nose gear accessories and 3x25mm

wood screws as shown.

98

Page 6

TAI LFUSELAGE

23.Sandwich the Nose Gear Wire with the Nose

Gear Mount, then secure mount firmly in place

with three 3x25mm wood screws.

24.Install the wheel on the main gear with 4x30mm

socket screw one M4 nut and one M4 locknut. Do

the same on the other side.

26.Assemble the scale nose gear, make sure

wheel could rotate freely. CA the Damper Linkage

on the Scale Nose Gear. Next thread the Z-bend

end to the steering arm.

27.Thread the nose gear pushrod into the fuselage

then install the scale nose gear onto the nose gear

wire the secure it in place with collar and 3x3mm

setscrew.

29. Make mark at the center of the tail spar as

shown.

31.When epoxy has cured, repeat the operation

with the other tail half with the addition of more

epoxy on the roots of the tail to glue two halves

together. You may use mask tape to hold two

halves together until it cures. Make sure two

halves are aligned accurately. CA the Elevator

Control Horn in place firmly as shown.

32.You may use file to enlarge the elevator

pushrod exit hole so clevis will not contact the

fuselage. Also trim the fuselage end as shown so

horizontal tail can go in.

25.Locate the scale nose gear accessories as

shown. Thread the clevis onto the pushrod.

28.Locate the horizontal tail halves then use

hobby knife carefully trim away the molded cap at

the root of the tail halves for the elevator spar.

10

30.Pay Attention to the Spar Installation: Apply a

generous coat of epoxy to the narrow edges of the

spare on one side only of the halfway point. Hold

the spare horizontally so the epoxied edges face

to the leading and trailing edges of the tail, then

insert it in the tail up to the marked point( step 1).

When arrive the marked point then carefully rotate

the spar (step 2). Place the tail half leading edge

down on flat surface and support the extended

part of the Foam Block(step 3). Move it back and

forth for about 5mm two or three times to even

distribute the epoxy(step 4).

33.Temporarily install main wing in place with the

two Wing Bolts. Trail fit the tail in place and check

the alignment with the wing and fuselage. The tail

should be parallel to the wing when looking forward

from the rear and top of the model. When satisfied,

make mark on the tail along the fuselage. Remove

the tail and slightly sand the glue area then CA tail

in place.

11

Page 7

ENGINE

34.Locate the Vertical Fin and Rudder Control

Horns, cut away the molding caps on the base of

the fin. This is for pushrod can go through.

37.Locate the spinner , engine prop nut, washer

and prepare a suitable propeller for your engine.

40.Locate the throttle pushrod and engine

mounting screws. Connect the throttle pushrod to

the throttle lever.

ENGINE

43.Secure the engine on the engine mount firmly

with the furnished mounting screws.

35.Fit the two rudder control horns to the rudder,

pushing them firmly together. CA each control horn

around the base in place. Pour a few drops of

epoxy into indicated hole.

1mm

38.Temporarily fit the engine to the engine mount

and install the propeller and spinner being used.

Slide the engine on the mount until there is about

1mm (1/16”) gap between the back plate and the

front of fuselage. Make mark of the engine

mounting holes. It may need to trim the engine

opening to fit your engine.

44.Use the muffler hole as the guide to drill a hole

on the cowl. Enlarge the hole up to 6mm in

diameter so you can thread the muffler bolt in.

41.Thread the pushrod through the firewall.

36.Insert the fin into the fuselage before the epoxy

cures, make sure the fin sits vertically to the

horizontal tail. CA the fin to the fuselage firmly.

39.Remove the engine and mount from the

fuselage. Drill 3.6mm hole( 9/64”) on the marks

for 4x20mm self tapping screws.

12

42.Next place engine on the engine mount. Trail

to move the pushrod back and forth to make sure

the throttle lever moves smoothly. Bend the

pushrod if necessary.

45.Secure the muffler tightly with the muffler bolts

that come with your engine.

13

Page 8

RADIO

GLASS FILLED NYLON CLAMP PLATE

RUBBER BUNG

GLASS FILLED NYLON CAP

BRASS SCREW

BRASS NUT

BRASS BENT FILLER TUBE

SILICON TUBE

BRASS FEED TUBE

BALANCE

CLUNK

46.If a 4 stroke engine is used , then glue the

Fairing to the muffler well. The pushrod hole on

the firewall may need to drill to accommodate to

your 4 stroke engine throttle lever.

47.Install the servo in place, you will need to install

EZ connectors on the servo horns for rudder servo

and throttle servo( both suggested on the second

hole).

49.Locate the Threaded End w/hole, thread it into

the Clevis at least 6mm, then loop the other end of

cable as you did on Z-Bend End. Snap on the

clevis to the rudder control horn then adjust the

tension. Make sure both cables are equal then

clamp the brass tube. You can adjust the tension

slightly by threading in the clevis.

50. Firstly trim the CFK Pushrod in length of

690mm( 27-5/32”),next locate the Threaded

Adaptor, slightly sand the glue area of adaptor to

make sure there is no oil on it. Apply enough epoxy

to glue the adaptors in the CFK Pushrod at two

ends as shown. Thread the clevises on the

adaptor after epoxy has cured. Apply a silicon ring

to the clevis.

5 TO 10 MM

52.Assemble the tank as figure; install the silicon

rubber ring on the tank and insert the tank in the

opening of the firewall. Insert the Tank Support

and attach it under the fuel tank. You may use

rubber band to hold the tank on support. Next glue

the support inside the fuselage with CA.

53.Finally install the propeller and spinner, note

the propeller must be secured against the pin on

the spinner back plate. Always adjust the

propeller at a good starting angle.

55.Connect the fuel tube properly to the muffler

and carburetor.

BALANCE

3”(75~80mm)

CONTROL THROWS

Make sure the direction of servo moves correctly. If not

switch the reversing switch on the transmitter. If the

control surface does not move far enough, either move

the pushrod out farther on the servo horn or move the

clevis in farther on the control horn. If the control

surface moves too much, either move the pushrod in on

the servo horn or move the clevis out farther on the

control horn. Adjust the control throws as the initial

setting as follows:

48.Cut the cable into two pieces. Next drill a small

hole in the fairing at the rear top of fuselage.

Thread the cable from the hole through the

fuselage to the servo tray. Use a piece of tape to

fix the cable at the fairing from loosening. Now

loop the Z-Bend End first.( first thread the brass

tube, next thread the Z-bend end, go back to the

brass tube again. Adjust the distance between the

Z-bend end and the tube then thread the cable

through the brass tube again and make a circle as

small as possible. Clamp the brass tube with pliers

to lock the cable from loosening. Insert the Z-Bend

Ends to the rudder servo horn at the outmost holes.

Note: make sure two cables are cross each other.

51.Thread the CFK pushrod through the fuselage

and snap on the control horn. Adjust the silicon

ring to keep clevis from loosening. Snap on the

other end to servo horn when elevator and servo

are both in neutral position. Adjust clevis if

necessary.

Thread the Throttle pushrod and Steering pushrod

through the EZ Connectors. Adjust the pushrod

when they are in neutral position.

14

54.Secure the spinner with 3x12mm self-tapping

screws.

15

Aileron

Elevator

Rudder

1/2",12mm

1/2",12mm

5/8”,15mm

5/8”,15mm

1",25mm

1",25mm

Loading...

Loading...