Page 1

No: C-98786604 11/2018

USER MANUAL

Titan 3000

Titan 4000

Starting from serial number AH-53150

All rights to structural changes reserved

Read the manual before operating the machine!

Translation

Page 2

2

EC Declaration of Conformity for the Machine

(Machine Directive 2006/42/EC, Annex II A)

Manufacturer: Tume-Agri Oy

Add.: Sudenkorventie 1

FI - 14200 TURENKI

Name and address of person authorized to compile a technical file:

Name: Heimo Valli Address: Sudenkorventie 1, FI-14200 Turenki

Hereby declares that

Seed drills TUME Titan 3000 and 4000 Serial number ___________________

• are in compliance with the applicable decrees of the Machine Directive

(2006/42/EC)

and in addition declares, that

• the following standardized European directives and standards have been applied:

SFS

-EN ISO 12100-1:2003

Place and date: Turenki 3.2.2016

Signature:

Patrik Jungarå

Page 3

1

CONTENT

1. FOR THE USER OF THE MACHINE AND FOR THOSE RESPONSIBLE FOR THE MACHINE ............. 3

2. GENERAL SAFETY INSTRUCTIONS ............................................................................................... 3

3. PURPOSE OF USE ........................................................................................................................ 4

Using the machine exceptionally for sowing only ..................................................................... 5

Using the machine for fertilising only ........................................................................................ 5

4. GENERAL SOWING-RELATED INSTRUCTIONS ............................................................................. 5

Selecting the seeding depth ....................................................................................................... 5

Correct sowing time ................................................................................................................... 6

Sowing into the minimally tilled soil .......................................................................................... 6

Sowing into the normally tilled soil ............................................................................................ 6

5. TYRE EQUIPMENT FOR THE MACHINES MOVING ON THE FIELD ............................................... 7

6. TAKING THE MACHINE INTO USE ................................

................................

...............................

7

Operational principle for the set of wheels ............................................................................... 7

Installing the drawbar ................................................................................................................ 8

Attaching the machine to the tractor ........................................................................................ 9

Driving instructions .................................................................................................................. 10

7. GROUND WHEEL FOR THE FEEDING SYSTEM........................................................................... 11

8. FILLING THE HOPPERS .............................................................................................................. 12

Timing the filling ....................................................................................................................... 12

Adjustable hopper volume ....................................................................................................... 12

Filling method ........................................................................................................................... 12

9. EMPTYING THE HOPPERS ......................................................................................................... 13

Emptying the fertiliser hopper ................................................................................................. 13

Emptying the seed hopper ................................

.......................................................................

13

10. SEED FEEDING SYSTEM AND ITS ADJUSTMENTS .................................................................... 13

General description .................................................................................................................. 13

Turning the transmission cassette ........................................................................................... 15

Bottom valves ........................................................................................................................... 15

11. FERTILISER FEEDING SYSTEM AND ITS ADJUSTMENTS .......................................................... 16

General description .................................................................................................................. 16

Adjusting the amount of fertiliser feed .................................................................................... 16

12. EXAMPLES OF HOW TO USE THE SOWING CHART ................................................................. 17

Example of adjustment when sowing grain ............................................................................. 19

Example of adjustment using fine seeds .................................................................................. 19

Page 4

2

Example of adjustment, fertiliser ............................................................................................. 19

13. CALIBRATION .......................................................................................................................... 20

Simultaneous calibration for seeds and fertilizer .................................................................... 22

Using the calibration equipment on the fertiliser side ............................................................ 22

Instructions for improving sowing accuracy ............................................................................ 22

14. FIELD TEST ................................

.............................................................................................. 23

15. ADJUSTING THE SEEDING DEPTH AND FERTILISING DEPTH................................................... 24

Performing the adjustment ................................................................

................................

...... 24

16. ADJUSTING THE REAR HARROW ............................................................................................ 25

17. DRILL MAINTENANCE ............................................................................................................. 26

Lubricating ................................................................................................................................ 27

Noteworthy hints for using the machine ................................................................................. 28

Storage ..................................................................................................................................... 28

18. TECHNICAL DETAILS ................................................................................................................ 29

19. ACCESSORIES .......................................................................................................................... 30

Middle markers ........................................................................................................................ 30

Grass seeder ............................................................................................................................. 31

Grass seeder calibration ........................................................................................................... 33

Page 5

3

1. FOR THE USER OF THE MACHINE AND FOR THOSE RESPONSIBLE FOR THE

MACHINE

We wish you the best success with our TUME seed and fertilizer drill. This instruction manual

gives you the correct methods to use, adjust, maintain and store Tume Titan. When you follow

the instructions in this book your machine will serve you impeccably for a long time. It is very

important to read the instructions well in advance of starting the seasonal use of the machine.

Keep the user manual safe and easily available. There is a storage space for the user manual in a

box at the right side of the machine. The space is marked with a sticker. Both the manufacturer,

Tume-Agri Oy, and an authorised dealer are happy to help you with any machine-related issues.

Please note the following about the presentation of this manual

Because this publication is distributed in international sales networks, the machines in the

pictures (as well as their standard equipment and accessories) may vary according to the

country. In certain countries the statutory and otherwise important guards have in some pictures

been opened or removed so that the item in the picture can be seen more clearly. It is not

permitted to use the machine without guards. Ensure for your own safety that all guards

are

intact or installed in place before you start working.

The "left" and "right" side mentioned in this manual are established from the vantage point of

looking at the machine from the back towards the front.

Tume-Agri Oy continuously develops its products and therefore reserves the right to change and

improve them without committing itself to make changes to previously sold products.

2. GENERAL SAFETY INSTRUCTIONS

All persons who use, maintain or otherwise handle the TUME seed and fertiliser drill must familiarise themselves with this user manual before they start working with the machine.

It is absolutely forbidden to work or remain underneath a machine with unsupported hydraulics.

Ensure that the machi n e st a ys elev at ed by closing the safety valves in the lifting cylinders. Lower

the machine down if you have to leave it unsupervised.

Do not leave the machine on a slope when you remove it from the tr actor.

It is forbidden to be on top of the machine or on the step when the machine is moving. The driver

must make sure that no people are near the machine when it is moving.

It is forbidden to lubricate, ad just or clean the machine when it is moving. Turn off the tractor engine

and switch on the handbrake during mainte nance work.

All guards must be fixed in place.

Ensure that the drawbar, hydraulic hoses and electric cables are connected corr ectly to the tractor

and the machine.

Any broken hydraulic hoses and connectors must be replaced immediately. The tractor's hydraulic

valves and connections must not leak and they must be in good condition. The machine's

transportation position depends on them.

Page 6

4

The hydraulic middle markers available as accessories may move extremely fast, especially if their

hydraulic choke valv es are t oo open and the tractor produces too much hyd raulics. Be esp eciall y

careful when attempting to lift and lower the markers for the first time. Make sure that nobody is

under the marker which is lifted up with hydraulics, or within the reach of the trajectory.

Make sure that the front axis of the tractor holds at least 20 percent

of the tractor's

weight under

all circumstances. Use e xtra weights if necessary. Be especially caref ul if the seed and fertiliser

drill is connected to the front tillage equipment and y ou lift it with the tractor's lifti ng device, during

reversing, for example. The fastest allowed speed in good conditions is 30 km/h. On uneven

surfaces you must take extra care and lower your speed. Transportation should be m ade when the

hoppers are empty. It is forbidden to carry a load on top of the machine. Avoid driving over stones

and other obstacles to save tyres.

Never select a line of drive where the furthest wheels of the machine are "on top of nothing". This

is when the machine may tilt too much. Selecting a wrong line of drive may lead to the machine

falling over.

Be very careful when moving on top of the machine during cleaning and maintenance or when

filling the hopper.

The painted surface of the machine may emit gases hazardous to health when it is heated. Ensure

good ventilation of the working area during any welding work, for example.

Use only the accessories and devices approved by the manufacturer. Any changes differing from

the manufacturer's instructions and their consequences are the responsibility of the person

making those changes.

We recommend that a respirator mask is worn, especially when filling the seed dre ssing device,

which is available as an accessory. The seed and fertiliser drill does not cause substantial increase

in the noise level in the tractor's cab. The need to use any hearing protectors depends on the

tractor's noise level. When handling heavy a nd sharp components (such as the parts of the drawbar

and the coulters), we recommend using safety boots.

Keep your machine up to date with regard to the required road traffic regulations if you must

transport your machine on public roads. These regulations may often change.

3. PURPOSE OF USE

General

Tume Titan – seed and fertiliser drill is designed for simultaneous seeding and fertilising,

especially in minimally tilled conditions. However, Titan is also well suited for seeding

traditionally cultivated soil. When required, the machine can be used for seeding only or

fertilising only with the preconditions mentioned later on. Titan's support wheel set is structured

in such a way that it closes the seed furrow and also conveniently makes the soil compact.

Accessories can be used to add to Tume Titan's features, and then the combination of the

machine and the accessory can be used simultaneously with seeding and fertilising, during the

same drive, to till or level the field, sow grass seeds, disinfect the seed to be sown as well as dig

furrows for plant protection spraying.

It is forbidden to use Tume Titan for other purposes than those mentioned. For example, the

machine is not designed for transferring material at speed or for storing materials in the

machine's hoppers. The machine should be filled close to the field to be sown and the

Page 7

5

transportation speed, when loaded, should be reasonably low with a sensible ratio regarding the

load in the hoppers and the uneven surfaces of the ground. It is absolutely forbidden to carry

people on the machine!

Using the machine exceptionally for sowing only

If you are not using the fertiliser you should move the divider wall in the hopper to its furthest

front position in order to maximise the seed hopper volume. With certain reservations it is also

possible to sow grain crops through both hoppers. Thus, the whole hopper capacity can be used

to sow seeds. Take care also that the sieves on the fertiliser side do not puncture the seeds to

be sown. If so, the sieves must be removed. When performing calibration test the total amount

of sowing is obtained by adding together the calibration totals from the fertiliser side and seed

side. We recommend that you sow about 50 % from the sowing amount from the seed side and

the remaining 50 % from the fertiliser side. For example: If the total sowing amount is 300 kg per

hectare, sow 150 per hectare from the seed side and 150 per hectare from the fertiliser side.

With the above-mentioned special cases it should be remembered that the sowing charts

supplied with the machine do not apply.

Using the machine for fertilising only

Tume Titan can also be used for applying fertiliser only, on at least minimally tilled fields. For this

purpose the fertiliser is filled into either the fertiliser hopper or seed hopper or both.

When the whole machine is filled with fertiliser, you must remember that fertiliser is usually

heavier material than seeds. This is why the machine must not be filled to the full and the

maximum total weight allowance given in the specifications must be followed.

4. GENERAL SOWING-RELATED INSTRUCTIONS

Selecting the seeding depth

With Tume Titan the fertiliser and seed is sown into the soil through the same coulters. There is

no need to change the hopper's height from the ground, because there are no separate fertiliser

coulters. The machine's upper and lower positions have been pre-set in the factory so they don't

have to be changed. The upper and lower positions are limited with an electric valve.

NOTE!

If you have to use the machine without connecting the power cables, you must be careful

not to lift the machine too high or lower it too low:

- If the peripheral support for the wheels of the machine is reduced, the machine is too high.

- If the machine rests on the lifting cylinder limiters it is too low down. Lift the machine about

2cm.

The seeding depth is adjusted by pressurising the coulters. The main rule is that the seeding

depth is determined by the tilling: The seed is sown into the bottom of the tilling, when the

Page 8

6

capillary increase of the dampness in the soil is at its best to benefit the seed and sprouting will

be even.

When selecting the seeding depth, the seed's requirements and the soil's dampness conditions

must be taken into account. Find out about the seeding depth for the seed in a good time and

try and arrange the sowing time so that the soil in the suitable depth is damp enough at the time

of sowing. Usually the working depth for small seeds fluctuates between 1 and 3cm, and for

normal grains the suitable seeding depth is 3-5cm.

Correct sowing time

Determining the correct sowing time is based on the dampness and temperature of the soil, as

well as monitoring the current and forecast weather conditions. The type of soil and the crop to

be sown have a fundamental effect on the optimal seeding time so universal guidelines cannot

be given here.

At the time of sowing the soil in the seeding depth should be tillable, but still damp. The soil is

too damp for sowing, if you can make cohesive "long loaves" by hand from the soil material.

The time of sowing for the plants which cannot withstand frost or cold may have to be postponed

regardless of the

soil's dampness, if the forecast or current temperature conditions so require.

Sowing into the minimally tilled soil

Tume Titan is ideal for sowing into the minimally tilled soil. For minimal tilling you should use

equipment which leaves an even, suitably fine and compacted soil and where its seeding depth

can be adjusted with sufficient accuracy.

Minimal tilling performed just before sowing should, at least on clay soil, be made a little deeper

than the seeding depth. Thus it is ensured that the dampness in the seeding depth will remain.

The recommended minimal tilling method for spring sowing is to perform the tilling in the

autumn to the depth of 10-12cm, when the plant debris will mix into the topsoil and do not form

an insulating layer on the surface. This method enables the start of normal time sowing in spring,

which is important, at least in the countries with a short growing period.

With Tume Titan you can sow in spring straight into the soil which was lightly tilled in the autumn,

if the field is sufficiently flat. If required, the light surface tilling can be made during sowing by

connecting the Tume CultiPack cultivator to the front of the seed and fertiliser drill. Please note

that especially in spring the tilling must not be deeper than the seeding depth.

Sowing into the normally tilled soil

The sowing cultivation must be made into the shallow and, especially on clay soils, maximum

seeding depth. This ensures that the dampness is better preserved which ensures better

sprouting.

It is easy to adjust the coulter pressure in Tume Titan, because it is done with hydraulics. This is

done with a single-action hydraulic valve. Monitor the seeding depth of the seed. Ensure that on

clay soil, for example, has enough pressure so that the seed will go to the bottom of the seeding

Page 9

7

depth. On the other hand, the coulter pressure should be less on the light soil, so that the seed

does not go in too deep.

Because the machine combination Tume Titan & tractor is rather heavy, we recommend that

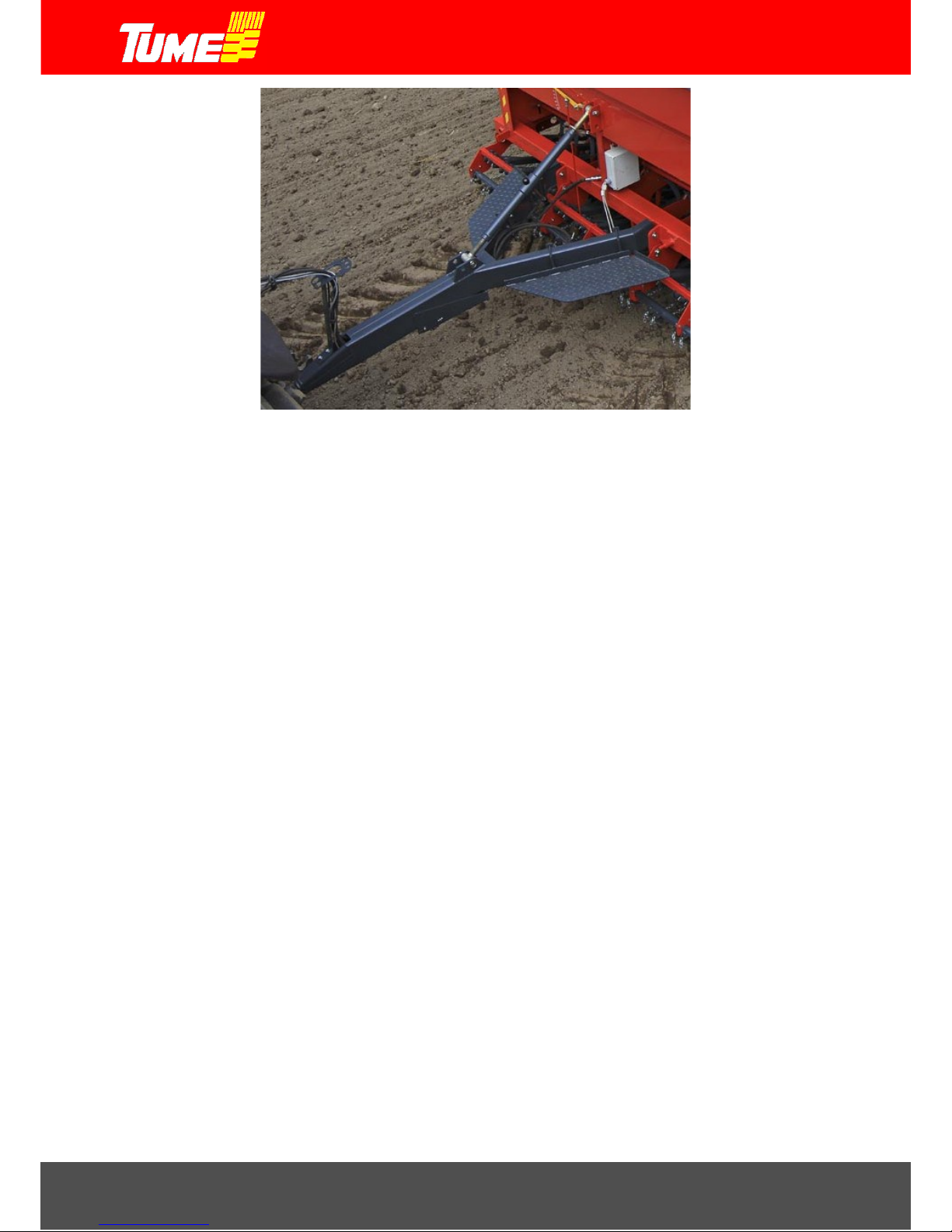

when you sow into tilled soil you use the middle packer (picture 1 below) to level the sprouting.

Picture 1. Middle packer (accessory).

5. TYRE EQUIPMENT FOR THE MACHINES MOVING ON THE FIELD

When moving in fields you should pay attention to preserving and improving the soil structure,

so that the water management is functioning. The soil surface should also be as even as possible.

The machine should move in the field with the tyre equipment which guarantees sufficiently low

surface pressure and the weight of the axes should be as low as possible. You should also avoid

moving around in the field in very wet conditions.

6. TAKING THE MACHINE INTO USE

Operational principle for the set of wheels

The support wheel set works so that the longer cylinders at the machine's ends turn a tubular

frame, which is as wide as the machine, and the furthest pairs of wheels are also attached to this

frame. The middle wheel pairs are attached to the tubular frame with hinges and they work with

their own cylinders. All these cylinders are connected to the same hydraulics circuit so they all

have the same pressure. This is why the pairs of wheels can adjust to the uneven ground surface,

but the rolling power is still constant for the whole working width (picture 2).

The geometry of the support wheel set is designed in such a way that in the working position

(the machine is lowered) the pressure under all wheel pairs is about the same. When the

machine is lifted to upper position the unconnected wheel pairs in the centre carry a little more

load. Thus the probability of damaging the furthest wheel pairs is reduced. These damages often

Page 10

8

happen during transportation.

When Tume Titan is lifted onto a lorry (loading the machine in the factory, for example), a lifting

device specially built for this operation is used. The lifting is performed from the centre wall, in

the driving direction, which is inside the machine's hoppers. It has 2 oblong holes, through which

the lifting devices are threaded (you need 2) and to which the lifting chains are attached. Ensure

that the lifting chains are of even lengths: Titan must be in a straight position for the whole lift.

Open the tarpaulin cover totally for the lift's duration to avoid damaging it!

Titan can also be loaded onto a lorry using a loading ramp, or a transport carriage with a

sufficiently gradual ramp where the driving ramp is as wide as the machine's rear wheel set. The

middle wheel pairs must not fall in between the loading ramps. For the furthest wheel pairs it is

enough that one of the wheels is on the pallet if the machine is transported in the driving

direction.

Note also the scrapers of the rear wheel set when reversing; they are close to the ground. Look

out for obstacles! When reversing over a high threshold or similar, the scrapers lift up higher if

the machine is lowered a bit. Check that you have enough room under the coulters so that they

don't hit obstacles.

Picture 2. Support wheel set.

Installing the drawbar

The drawbar is assembled as shown in picture 3, which also shows how the drawbar ¬is attached

to the machine. Note that the drawbar is always attached to the uppermost holes of ¬the

machine's lower brackets. The lower holes are for attaching a spring front field drag, for example.

The push bar is also attached to its uppermost hole.

Hydraulic hoses and electric cables¬ ¬are¬ attached¬ to¬ the drawbar carefully in such a way

that they cannot be damaged under any driving situations (such as when diving into the tractor's

handle). Thread the hoses through the inside of the box girder.

Page 11

9

Picture 3. Drawbar.

Adjust the length of the push bar so that the machine is horizontal when lowered and attached

to the tractor's towing hook. The ¬fine-tuning of the drawbar is made in the field ¬when sowing.

Attaching the machine to the tractor

Tume Titan is attached to the tractor's towing hook as normal. We do not recommend attaching

the machine to the tractor's tow bars, because it makes the front end of the tractor lighter and

makes controls less effective. Instead the machine can (and is recommended to) be attached to

the middle packer (Picture 1).

When the seed and fertiliser drill is attached to the back of the tractor, lift the support base up.

Place the tractor's tow-bars at such a height that they don't touch the drawbar or the hydraulic

hose controls.

Titan's hydraulics are connected to the hydraulics output meant¬ ¬for the tractor's externals

single-action cylinders.¬ If the machine's accessories include markers, they work with the same

hydraulic valve as lifting and lowering the machine, but in that case the machine must be

connected to the tractor's dual-purpose hydraulics. It must be noted that with many tractor

types you must use the quick couplings recommended by the tractor manufacturer or similar.

Replace these parts if needed with the types suitable for your tractor in order to ensure that the

¬hydraulics function impeccably.

If Titan is attached to the CultiPack cultivator, available as an accessory, it must be equipped with

a different type of a drawbar, which is called multifunctional drawbar. The drawbar can be

shifted into two positions: Bent or straight on the top. The bent position is used for the CultiPack.

The straight lower position is used when towing directly from the tractor's hook or when using

the middle packer. The hoses and electric cables are connected to the multifunctional drawbar

by threading them through the base part and leading the tow link via the steel links on the part

onto the tractor.

Page 12

10

Driving instructions

When you lower the machine down always move it forward at the same time. Otherwise the

coulters may clog up. Keep machine lifting/lowering hydraulic valve from tractor in closed

position while seeding and machine is down.

Avoid driving unnecessarily on the sown area. Choose a driving technique which leaves as few

wheel tracks on the sown area as possible.

In its upper position the machine is supported by the tractor's hydraulic valve. This is why you

must ensure during transportation that the tractor's ¬hydraulic valve cannot accidentally open

or leak. The safety valves of the end lifting cylinders must always be kept open during road

transportation! (Picture 4 below)

On even ground the machine must function in horizontal position. If the machine moves whilst

tilted forward, the push bar of the drawbar¬ must be lengthened. If the machine moves whilst

tilted ¬backwards, the ¬push bar must be shortened. Check and adjust the seeding depths after

driving a short distance, if needed. Check the adjustments for the markings by also inspecting

the sowing seam.

NOTE! Lift and lower the machine only when it is moving forward. Never reverse the machine

when coulters are on the ground and the power transmission is switched on.

Check from time to that the coulters are not blocked. Check also the condition of all seeding

tubes and fertiliser tubes and clean ¬out any blockages. At the start of the sowing check out

the area that can be seeded with one hopper-full. After this the correct filling time can be

determined from the controller's area counter.

Keep enough seeds and fertiliser in the hopper. Because of ¬the design of the bottom you must

pay special attention to this, especially at the start. Don't leave fertiliser or seeds in hoppers for

several days, especially in damp weather. Damp fertiliser can cause ¬feed problems.

Tume Titan is always equipped with double-disc coulters. At high seeding speeds the vertical

fluctuation of seeding is more common with disc coulters than with a machine with Suffolk

coulters. Monitor the seeding depth and change the seeding speed as required. The suitable

speed for tilled soil is usually about 7-10km/h. When sowing peas, the maximum speed is 67km/h. Transportation speed is 30km/h.

Picture 4. Safety valve.

Page 13

11

7. GROUND WHEEL FOR THE FEEDING SYSTEM

The feeding system gets its power from a ground wheel on the left side of the machine. The

ground wheel is attached to the hopper and thus it rises up when the machine is lifted. When

the machine is lifted, the ground wheel leaves the ground and the feeding stops. Thus you don't

need a separate power transmission switch in the machine.

NOTE! Do not rotate the ground wheel into reverse direction! Always lift the machine up before

you reverse the tractor.

The moment of releasing and switching can be controlled by adjusting the ground wheel either

higher or lower in relation to the hopper. This takes place by adjusting the attachment point of

the cable in the centre of the tubular frame of the wheel set.

It is also possible to push the ground wheel in for transportation. Thus the machines maximum

overall transportation width will be the nominal width: 3 or 4 metres. The alternative positions

are shown in pictures 6 and 7. Lock the ground wheel

into the sowing position with your fingers

turning the screw in the base of the supporting rod sleeve and lock it using the locking nut (19mm

key, picture 7).

Picture 6: Ground wheel in working position. Picture 7: Ground wheel in transport position.

Picture 7. Ground wheel locking screw.

Page 14

12

8. FILLING THE HOPPERS

Timing the filling

Before starting sowing we recommend that the machine is transported to the field whilst empty.

The fertiliser and seeds are brought to the field on a ¬trailer, for example, and the seed fertiliser

is filled¬ at the edge of the field. If you have to fill the machine far from the plot to be seeded,

you must be very careful when transporting the machine with full hoppers. The maximum speed

of 30 km/h is only allowed on good roads with empty hoppers! The maximum allowed speed

with full hoppers is 15km/h. Keep the rubber rings of the tarpaulin fastened especially during

transportation!

Emptying the containers may be monitored:

• By looking into the hopper from time to time with the machine stopped.

• By monitoring the machine's area counter once it has been determined how large

the area to be seeded with one hopper-full is, and the meter reading from the

previous time is

memorized.

•

With the electronic controller (

TC), which is included as standard. The device

sounds an alarm when there is only a certain amount of fertiliser or seed left in the

hopper.

Adjustable hopper volume

The divider wall between the fertiliser and seed compartments is adjustable so that the volume

ratios can be adjusted. The adjustment is made by opening the locking screws in the dividing wall

support rods and turning the dividing wall into the required position (Picture 8). Remember to

lock the support rods after adjusting. Note that the height of the dividing wall is also adjustable.

Picture 8. The adjusting rod of the hopper's dividing wall.

Filling method

The machine's filling height is quite high and it has large hopper volume. This is why we

recommend¬ using large sacks for both the seeds and the fertiliser (NOTE: use adequate lifting

equipment or maybe loading screw technology).

Page 15

13

Large sacks can be handled with different loaders. Do not go under a hanging load. The large

sack must not be lowered¬ on top of the seed and fertiliser structures. Do not overload the seed

and fertiliser. Find out about these methods in order to partially empty¬ the large sack.

9. EMPTYING THE HOPPERS

Emptying the fertiliser hopper

The fertiliser hopper is usually emptied through the coulters. Adjust the feed controls to the

maximum position, spread the tarpaulin under the machine and push the lever of the bottom

valves on the fertiliser side all the way down. Then almost all of the hopper will empty. Push the

remaining fertiliser, with a broom for example, into the feed chambers. Turn the feeding¬

¬system round with a crank a few times so that the chambers will empty. Finally¬ swing¬ ¬the

bottom valves quickly with the crank¬ a ¬few times ¬to remove the ¬ fertiliser from the top of

the shutters.

NOTE! Detach the seed-side transmission cassette before turning the ground wheel.

Then seeds will not mix with fertiliser and the varieties don't get mixed up.

Emptying the seed hopper

The seed hopper is emptied in the same way as the fertiliser hopper.

NOTE! If there is fertiliser in the fertiliser hopper when seed hopper is emptied, remove the pin

from the feeder axle (in the left side of the machine).

NOTE! Do not empty both hoppers at the same time so that the fertiliser and the seed don't

mix together.

10. SEED FEEDING SYSTEM AND ITS ADJUSTMENTS

General description

The seeding system consists of threaded rollers, bottom valves with springs and adjustable

closing gates (Picture 10). The feed chambers are located on the bottom of the hopper. This

solution has enabled the amount of seeding to remain almost the same regardless of the seed

and fertiliser ¬drill tilting to the side or to the driving direction. The feeding system is made from

non¬-¬corrosive materials. The ¬bottom valves below the feeding rollers are adjustable and the

adjusting lever is at the rear in the middle of the machine (Picture 10). For sowing fine seed the

gear ratio of the transmission can ¬be changed by rotating ¬the transmission cassette.

Page 16

14

Picture 9. Adjusting the feed with the hand wheel. Picture 10. Principle of the feeding system.

The amount of feed is adjusted by turning the feed roller sideways in relation to the feed

chamber. The adjusting is made with the hand wheel at ¬the left end of the machine. The hand

wheel is locked with a plastic lever which also has the main scale 0-10 for the feed, where the

gap between numbers is the same as one turn of the hand wheel. The adjustment is read from

the inner surface of the hand wheel. The ¬hand wheel has 10 locking positions for each turn and

they are marked 0-9. Thus you can have a total of 100 different adjustment positions. With the

fine ¬seed transmission (cassette position II) you can similarly have 100 -feeding positions from

a smaller area.

NOTE! In order to adjust the feed the plastic lever must be pressed to the end of the machine to

the direction of the arrow and turned 90 degrees at the same time to release the locking.

When the hand wheel is turned anti-clockwise the feed increases. When the¬ required amount

of seed is known, the sowing chart inside the machine's¬ cover provides advisory adjusting

position for the feeding¬¬.

Note the position of the cassette in use. It is advisable to make the adjustment so that the

required adjustment position is always approached¬ from a bigger adjustment position. If the

original adjustment position is smaller than the required one, the hand wheel must be turned

anti-clockwise 1/2-1 turns past the intended adjustment, after which the wheel is turned back

to the required position.

After the adjustment the locking lever is turned into the hole in the hand wheel to lock both the

wheel and the lever. Please note that the adjustment¬ position provided by the sowing chart is

advisory and the actual amount¬ of feed varies between different seed batches. We recommend

that the amount of feed¬ is checked with calibration.

If dirt accumulates in the feeding system, the feed rollers may clog up. This can have a crucial

effect on the amount ¬of feed. We recommend a good clean from time to time. The rollers can

be cleaned by setting the amount of feed to zero and then back to the required adjustment

value. Then you must remember the previous instruction to turn the wheel first 1/2-1 turns past

the required adjustment value.

Bottom valve adjustment lever

Bottom valve

Feeding roller

Closing gate

Page 17

15

If the machine has a seed dressing device, the calibration must be run again after about one

hectare's seeding. A mordant can reduce the amount of feed as much as 20%!

NOTE! The hand wheel must not be turned to zero position by force. Simultaneous turning of

the feeding axle makes adjusting easier. The use of the sowing chart and calibration test

instructions are dealt with later.

NOTE! The maximum speed when sowing peas and beans is 6-7km/h.

Turning the transmission cassette

Picture 11. Transmission cassette. Grain / Fine seed.

When the bigger chain wheel of the cassette is forward, it is set for grain. When the smaller chain

wheel is forward it is set for fine seeds. The setting is marked in the cover of the cassette on its

visible side. Picture 11 shows the setting for grain. Make the turn as follows: Remove the

linchpins and pull the cassette off its axis. Turn the cassette upside down. The sticker on the

cassette shows the setting.

Bottom valves

The feeding accuracy depends on the distance between the bottom valve and the feed roller, so

it is important that the bottom valves are in the correct position, and they are not adjusted after

calibration without repeating the calibration. The bottom valves give way, if a hard-foreign

object gets between the drum valve and the feed roller.

Here are the advisory adjustments to the most common seeds. If you sow other varieties than

those mentioned, compare the seeds for their sizes and properties with those mentioned and

run calibration according to these adjustments.

Page 18

16

Picture 12. Adjusting the bottom valves.

Bottom valve positions:

Grains notch 2

Pea notch 3

Fine seeds

notch 1

Bean notch 4

11. FERTILISER FEEDING SYSTEM AND ITS ADJUSTMENTS

General description

The machine has as many fertiliser feeding chambers as those that feed seed. The amount of

feed is adjusted by ¬turning the feed roller sideways in relation to the feed chamber. The

adjusting is made with the hand wheel at the left side of the machine.

The feed chambers are located on the bottom of the hopper. This solution has enabled the

amount of seeding to remain almost the same regardless of¬ the seed and fertiliser drill tilting

to the side or to the driving direction. The feed rollers are plastic rollers equipped with threaded

cogging. The bottom¬ valves below the feed rollers are adjustable.¬ The adjusting lever is at the

front of the machine in the middle. The whole fertiliser feeding system is made from noncorrosive materials.

You can sow all grainy fertilisers through the fertiliser hopper.¬ The feeding system is not suitable

for feeding powdery fertilisers.

Adjusting the amount of fertiliser feed

The amount of feed is adjusted from the hand wheel at the right end of¬ the machine. The hand

wheel is locked with a plastic part which¬ also has the main scale for the feed.

NOTE! In order to adjust the feed the plastic lever must be pressed to the end of the machine to

the direction of the arrow and turned 90 degrees at the same time to release the hand

wheel locking.

When ¬the hand wheel is turned anticlockwise the feed increases. When the¬ required amount

of seed is known, the sowing chart inside the machine's¬ ¬cover¬ provides advisory adjusting

position for the¬ feeding¬.

It is advisable to make the adjustment so that the required adjustment¬ position is always

approached from a bigger adjustment¬ position. If the original adjustment ¬position is smaller

than the required one, the hand wheel must ¬be turned anti-clockwise 1/2-1 turns past the

intended adjustment, after which the wheel is turned back to the required position.

Page 19

17

After the adjustment the locking lever is turned into the hole in the hand wheel to lock both the

wheel and the lever. Please note that the adjustment¬ position provided by the sowing chart is

advisory and the actual amount¬ of feed varies between different fertiliser batches. We

recommend that the amount of feed¬ is checked with calibration.

The machine can also be equipped with an accessory TC-Plus, an electric fertiliser controller. In

this case the fertiliser side does not have hand wheel and the adjustment is made with the lever

mechanism which is operated by a spindle motor. The instructions on how to adjust the fertiliser

is found in the TC -controller user manual.

The normal position of bottom valves with grainy fertiliser is notch 2. If wet fertiliser enters the

feeding system, feed rollers might clog up. This might have a crucial effect on the feed rate.

The rollers can be cleaned by setting the amount of feed to zero and then back to the required

adjustment value. Then you must remember the previous instruction to turn the wheel first 1/21 turns past the required adjustment value and then back to the correct value (from bigger to

smaller). The instructions on how to use the sowing chart and how to perform calibration are

explained later.

The fertiliser feeder can be switched off by removing the linchpin from the end of fertiliser feeder

axle from the left side of the machine.

NOTE! When attempting to get to an exceptionally large fertilizer level, the double-chain wheel

in the left end of the machine must be turned so that Z 22 is in use. Then in the sowing table the

red line will be followed!

12. EXAMPLES OF HOW TO USE THE SOWING CHART

Please note that the amount of seeding shown in the sowing chart (picture 13) is only advisory.

The actual sowing ¬amount depends on the properties of the seed used. These vary considerably

yearly and by their varieties. The sowing amount must be checked by calibration and its

operation is explained later.

Page 20

18

Picture 13. Sowing chart.

Page 21

19

Example of adjustment when sowing grain

Case 1: We want to sow oats, 200kg/ha.

• Note the correct position of the bottom valves from the top right of the chart,

marked "cereal". The correct adjustment is "2".

• Select description "oats"

• Check the machine's transmission which should be "1"

• Let's start from the edge of the chart, from 200 kg/ha

• Proceed to the horizontal line where this line goes across the description "oats"

• From the crossing point we go straight down to the scale where we see that the

adjustment must be "6.8"

This means that the hand wheel must be opened for 6 turns plus another 0.8 turns on top. So

the hand wheel is locked to the notch with the reading 8.

Example of adjustment using fine seeds

Case 2: We want to sow rape, 8 kg/ha.

• Note that on the top right corner of the chart the correct position for bottom valves

is "1"

• Examine the small sowing chart

• We find the starting point from the left side of the small sowing chart at 8kg/ha

• Proceed along the horizontal line 8kg/ha to the right where this line goes across

the description "rape"

• From the crossing point we go straight down to the scale where we see that the

correct adjustment is "2.2"

• We note that on the top left corner of the small sowing chart is a mark

"transmission II". So we must use the fine seed setting in transmission, so the

cassette must be turned so that the cassette is on the level shown at position "II"

Example of adjustment, fertiliser

Case 3: We want to sow NPK mixed fertiliser, 500 kg/ha.

• We note from the top right corner of the sowing chart that the correct adjustment

for the bottom valves is "2".

• We start from the edge of the big sowing chart, at "500 kg/ha"

• We proceed horizontally along the 500kg/ha line to the right to the point where

this line and the description "granular fertiliser" cross

• From the crossing point we go straight down to the scale where we see that the

reading in the main scale in the hand wheel lever should be "5.0". After the

adjustments you should perform calibration in order to ensure correct sowing

amount.

Page 22

20

13. CALIBRATION

General

Because the adjustment values provided in the sowing chart are¬ ¬only advisory, you must

perform calibration before seeding. Before starting¬ calibration, adjust the machine according

to the sowing chart.

Check:

• Transmission cassette settings I / II

• Position of bottom valves (seed and fertiliser)

• The amount of seed feed from the hand wheel

• That the tram lining device is not in use

• The amount of fertiliser feed from the hand wheel

• That the closing gates are fully open

• That there is fertiliser and seed in the hoppers

The machine is lifted a little from the ground so that the ground wheel leaves the ground and it

can be turned. Turning is easy when the rotating tool is in its place as shown in picture 14. This

rotating tool is located under the cover which is at the left side of the machine.

It is easy to put the machine's tubing system (for seeds and fertiliser) to the calibration position

all at the same time. This is done from the handle at the right side of the machine (Picture 15).

• Lift the clamping device upwards

• Pull the handle out with a firm grip, using both hands, up to its limiter

Calibration can be made in three ways:

•

At the same time for the seed and the fertiliser, when ¬all pins of the transmission are in

place.

• Separately for the seed, when the linchpin is removed from the end of the fertiliser axle.

Remember to put the linchpin back after the ¬calibration!

• Separately for the fertiliser, when the pin of the seed-side cassette is removed.

Remember to put the linchpin back after the calibration!

Page 23

21

Picture 14. Ground wheel in a calibration position

.

Picture 15. Hose shelves in a calibration position.

Calibration troughs for both seed-side and fertiliser-side are supplied as standard with Tume

Titan. You can also keep these troughs in place during sowing. However, always remember to

empty the troughs from dust etc. before performing the calibration.

After the calibration pull the calibration throughs out and weigh the seeds and fertiliser in them.

NOTE! After you finish the calibration, remember to push the handle of the calibration

equipment back inside (from the right side of the machine) and lock it with its spring. After this

Page 24

22

the seeds and fertiliser go back into the coulters instead of the calibration troughs. Finally close

the protective cover at the right side.

Picture 16. Emptying the calibration trough.

Simultaneous calibration for seeds and fertilizer

Turn the crank a few times so that the feeding chambers fill up properly. After this carefully

empty the calibration troughs.

Turn the ground wheel for the number of turns mentioned in the sowing chart for this machine

type. The rotating speed must match¬ the driving speed used.

Weigh the seed and fertiliser in the sowing troughs. If the calibration was made with the number

of turns per are, the sowing amount per hectare is obtained by multiplying the weighing results

by one hundred.

After you finish the calibration remember to push the hose shelves back to the sowing position

and lock the handle.

Put the ground wheel rotating tool back to place and close the protective covers.

Using the calibration equipment on the fertiliser side

The test is performed as above, but the pin of the seed-side transmission cassette is removed

for the duration of calibration.

Instructions for improving sowing accuracy

The calibration value in the sowing chart is advisory. The type of soil and tilling depth, for

example, has an effect on its accuracy.

Page 25

23

This is why the sowing chart gives an advisory range for calibration values:

Titan 3000: 11 – 12 r/a

Titan 4000: 8.25 –

9 r/a

The accuracy of the sowing amount can be increased by performing a field test in sowing

conditions. The field test is performed by towing the machine for a distance needed to sow one

are and by counting at the same time the rotations of the ground wheel. Write down the

resulting calibration value and use it when you perform calibrations.

If the value you measured is vastly different from the value in the sowing chart, perform another

test. The table below shows the distances "L" used in the field test for different working widths.

L = 33.3m, when the working width is 3.0m

L = 25m, when the working width is 4.0m

Check the accuracy of the area counter at the same time.

14. FIELD TEST

Field test is absolutely the most reliable testing method for the sowing amount. If you perform

the field test in the field¬ to be sown and on the soil ¬already tilled, you will achieve sowing

conditions which match the sowing event very closely. Field test can be performed for both seeds

and fertilisers.

Performing the field test:

• Adjust the machine in accordance with the calibration instructions

• Measure the distance matching one acre of sowing, which ¬for the machine models:

Titan 3000 - 33.3 m

Titan 4000

- 25.0 m

•

Drive outside the test distance for about 10 metres with the machine in working position

so that each seed chamber feeds seed.

• Empty the contents of the calibration troughs.

• Drive a distance as shown in the above table at normal sowing speed with the machine

lowered to the sowing position.

•

Weigh the seeds and/or fertilisers in the calibration

troughs and multiply the results by

100 so that you will receive the amount of seeds and/or fertiliser kg/ha.

• If checking is needed, do as described in the calibration instructions

Page 26

24

15. ADJUSTING THE SEEDING DEPTH AND FERTILISING DEPTH

NOTE! First of all remember to check that the machine is horizontal in the sowing position. The

adjustment is made using the push rod on the machine's drawbar. Check the straightness

from the seam between the hopper and the additional hopper: It must be in the same

direction as the field surface.

Lower the machine down whilst driving it forward at the same time.

Stop the tractor whilst the

machine is lowered. Don't allow the tractor to jerk backwards so that the coulters don't get

clogged up. Check that the machine is in correct position. The ¬machine must be in horizontal

position. If required, adjust the machine so that¬ it is horizontal from the push rod's adjusting

screw.

Correct seeding depth and getting the seed into the bottom of the tilled soil is one of the most

important factors affecting sprouting. Tume Titan has large diameter double-disc coulters which

penetrate well and which have notched outside perimeter. The coulters are designed to be used

in both minimally tilled and traditionally tilled conditions. The Titan coulters can be pressurised

with the power of as much as 60 kg. The pressurisation takes place with the hydraulic cylinder

using the tractor's single-action hydraulic valve. The coulter pressurisation is sufficient when the

seed is placed correctly to the bottom of the furrow and maybe slightly below (= the coulter disc

makes a small groove to the bottom). NOTE! Take care that pressurisation is not too strong,

because for example with rape the seeding depth which is too deep can harm sprouting.

We could say that the main rule with the sowing tilling depth is that the tilling must always be

made into the intended sowing depth. The seeding depth must be selected in accordance with

the crop and the dampness of the soil. The correct seeding depth for fine seed is 1 – 3cm and

with grains 3 – 5cm. It is essential for all crops that the seeding is made into damp soil in order

to ensure the germination. The seed must not be left in the dry loose soil.

The driving speed must also be taken into account. If the driving speed is too high, it will increase

the vertical spread of the seed in the soil. In certain circumstances you cannot use too high

pressure on the coulters and especially then the coulters might bounce more if the speed is too

high. Rule of thumb could be that every time you drive at higher speed than 12 km/h, risks are

increased.

Performing the adjustment

The seeding depth is adjusted by changing the spring loading of the coulter extension spring. The

basic adjustment to the pressurization springs is made coulter-specifically with the chains on the

extension spring. During the sowing the adjustment is made centrally with hydraulic cylinders.

Titan has a mechanism in the coulter pressurization which prevents the unnecessary loading of

the coulters when the machine is in the upper position (picture 17, point D). When the machine

is lifted the adjusting cylinder of the coulter pressurization is able to move backwards with lever

mechanism and the coulter pressurization eases every time the machine is lifted.

NOTE! The adjustment of the coulter-specific pressurization from the extension spring chains

(picture 17, point C) must be made when the machine is in the upper position with the springs

Page 27

25

released. Check in the sowing position that you get the sufficient coulter pressurization with the

cylinder. Avoid too much pressurization strength!

The pressurization of coulters against the ground can be adjusted within the range 10-60 kp. The

corresponding working depth depends on tilling and the type of soil. Monitor the working depth

from time to time when the work is proceeding.

The springs of the Tume Titan coulters are designed so that the coulter's height does not really

affect the coulter's pressurization. D

C

Picture 17. Central adjustment of coulters.

16. ADJUSTING THE REAR HARROW

Picture 18. Rear harrow.

Page 28

26

The lateral distribution of the spikes in the rear harrow has been made in the factory. However,

you should check the adjustment when the machine is sowing in the field and moves the spikes

sideways. The lateral movement is adjusted so that the spikes move in the centre of the

embankment between support wheels and the wheel track. The working angle can also be

adjusted. The working angle is adjusted with taps which limit the square pipe (to which the spikes

are attached) turning backwards.

Vertical adjustment is made with edge chains. This adjustment affects not only the working

depth, but also the moment of lifting: at which stage of lifting does the rear harrow leave the

ground? The lower ends of the chains are equipped with protective tubes which also prevent the

rear harrow being installed too high. If the rear harrow is adjusted too high, the rear step will be

damaged when the machine is lifted up.

Check the working depth every time when you change the rear harrow angle adjustment

NOTE! After adjustments ensure that when the machine is lifted all the way up the rear harrow

also raises enough for reversing and transportation. Remember that if the low lift is switched on,

the rear harrow is on the ground and you must not reverse!

The purpo

se of low lift is that when the machine is lifted up in the headland, the rear harrow

stays on the ground and covers the tracks of the seed drill. See how to use low lift in the TC user

manual.

17. DRILL MAINTENANCE

We advise that you contact the dealer when you require more demanding repairs. The following

presents actions which most of the time can be taken on a farm. Read the maintenance

instructions carefully. If you¬ follow the instructions, TUME- seed and fertiliser drill works

impeccably from one year to the next. If you neglect the maintenance according to these

instructions, the warranty will become void.

Always switch off the tractor engine before starting maintenance work and switch the handbrake

on.

DANGER! ALWAYS CLOSE THE SAFETY VALVES IN BOTH LIFTING CYLINDERS, IF THE MACHINE

HAS TO BE UP DURING MAINTENANCE. DO NOT GO UNDER THE MACHINE IF IT RELIES ONLY

ON HYDRAULICS!

Page 29

27

Picture 19. Lifting cylinder safety valve open.

NOTE! Transportation is not allowed when safety valves (picture 19) are closed.

The machine's hydraulic circuit is pressurized even when it has been removed from the tractor.

DANGER! THE MACHINE'S PAINTED SURFACE MAY EMIT GASES HARMFUL TO HEALTH WHEN

IT GETS HOT. TAKE CARE THAT THE WORKING SPACE IS SUFFICIENTLY VENTILATED, DURING

WELDING FOR EXAMPLE.

Lubricating

The transmission block chains must be lubricated at 50 hours intervals or when required. For

lubrication, use only SAE 10 or SAE 20 lubricant.

The adjusting screw of the drawbar's hydraulic push rod must be lubricated¬ ¬with¬ ¬lubricant

and Vaseline annually.

The ball bearings of the coulter discs are permanently lubricated so they don't require

maintenance.

The nipples which must be lubricated with a lubrication squeezer at 100-hour intervals are in the

following locations:

Wheel set: -the sliding surfaces of the strut in relation to the hopper

-cylinder nipples

Ground wheel: -hopper sleeve

Transmission: -the user wheel of the fertiliser axle

Central adjustment: -the tap of the rocker arm which moves the cylinder

The central markers, available as accessories, also have lubrication nipples

Check the tightness of the screwed joints regularly every 100 hours. The above-mentioned

checks must be made to a new machine twice after 25 hours and after this every 100 hours.

Page 30

28

Noteworthy hints for using the machine

Some large and light seeds

(such as some types of oats) might have difficulties when the seeds

flow through the sieves. In this case remove the sieves from the hopper. Take special care when

filling the hopper so that no large particles can mix with the seed and damage the feeding

system.

Always lift the rear steps up when you drive the machine: Both in sowing work and

transportation.

Note that when we talk about the machine's protrusion, we mean two things: The protrusion

which determines the accuracy of the sowing amounts means the protrusion of the ground

wheel which rotates the machine's feeding system: How many times the ground wheel turns per

acre (see 13, Instructions for improving sowing accuracy). The protrusion which affects the

accuracy of the area measuring is determined with the support wheels protrusion. Find out,

using a towing test, how far forward the machine moves in your sowing conditions, after the

support wheel rotates once.

The machine's calibrations are made into troughs under the feed chambers both on the see

d-

side and fertiliser

-side. Be very careful when pushing the troughs

into place. Keep them in as

straight a line as possible in relation to the machine. If the tub is pushed with force so that its

end points upwards, the tub might hit some of the feed chambers and damage them.

Your seed and fertiliser drill is equipped with an electronic control device which has surface

sensors for the seed and the fertiliser so be careful when lifting the sieves from the hoppers. If a

sieve hits a sensor it may damage it.

You must also be careful when installing and removing the containers for the seed dressing

device.

If the protective cover on the right side of the machine does not close, you might have left the

calibration settings on. If the calibration handler is pulled out, the cover cannot be closed. This

is a good rule of thumb.

Storage

When the machine is not in use, it must be stored cleaned and serviced in a covered space. Lower

the machine. Do not leave the machine on hydraulics. The hoppers are emptied from fertiliser

and seeds.

The machine is washed outside and inside with water. Use a pressure washer with care (Max.

water temperature should be 60 degrees and pressure 100 bar), do not direct the spray into the

ball bearings or the components of the electronic accessories, such as sensors and solenoids. Do

not remove or damage warning, name or instruction stickers by washing them too hard.

Lubricate the machine as instructed. The spots where the paint has worn off can be protected

with anti-corrosive oil.

Any damages found during cleaning are recorded. It is advisable to order spare parts in good

time before the start of the season, so that the repairs are completed on time.

Page 31

29

18. TECHNICAL DETAILS

Type

Titan 3000

Titan 4000

Working width (m)

3.0 4.0

Hopper capacity (l)

- Total (= available in organic)

- Seed, min

- Seed, max

- Fertiliser, max

4070

1720

2900

2350

5640

2380

4010

3260

Basic machine weight (kg)

- Empty

- With full hoppers

Wheat and fertiliser

3050

6900

3850

9100

Basic machine dimensions (cm)

- Height to the edge of the hopper

- Width

- Length without the drawbar

208

300

307

208

400

307

Support wheels

- Size

- Quantity

- Pressure (bar)

7.50

– 16

12

1.5

– 2.0

7.50 – 16

16

1.5 – 2.0

Coulter pressurising

- Coulter pressure / coulter (N)

- Runtime weight adjustment

100 – 590

Hydr. Standard

100 – 590

Hydr. Standard

Quantity of coulters (each) seed

24

32

Hydraulics

- Pressure (bar)

- Connection with standard equipment

Equipped with middle markers

150

2 each single-action

1 each single-action

1 each dual-action

170

2 each single-action

1 each single-action

1 each dual-action

Page 32

30

19. ACCESSORIES

TUME continually develops its machines and accessories. If you ¬wish to order new equipment for older

machines, it is advisable to ensure the compatibility of the devices by contacting the manufacturer's

representatives.

Only the following TUME accessories can be used with TUME seed and fertiliser drills. Factory instructions must

absolutely be followed when installing the accessories. Faulty installation or use of other than original -TUME

accessories may endanger the user's safety or damage¬ the machine. The ¬manufacturer is not responsible for any

damages caused by changes ¬ not made in accordance with the factory instructions.

• Markers

• TC-Plus (including the remote control of fertiliser)

• Agitators

• Grass seeder

• Start-up fertiliser device

• Middle packer

• Safety rail to the rear step

• Seed sieves

• Combination drawbar with CultiPack cultivator, for

example)

• CultiPack cultivator

• Steps in the front

Middle markers

If the machine is equipped with middle markers the seed and fertiliser drill must be connected

to the tractor's dual-action hydraulic valve. The markers are connected parallel to the machine's

lifting and lowering circuits. The seed and fertiliser drill works with single-action hydraulics, but

the marker requires dual-action. The arm will not start going down if it is not pushed downwards

with hydraulics.

The markers are controlled electronically and their functions are controlled by the TC -controller

in the tractor's cab. It is easy to control the markers, for example close electric poles, because

the machine can be driven to pole-lifting mode. When hydraulic oil is given to the machine from

the tractor in the pole-lifting mode, only the marker rises but the machine stays on the ground.

After the pole is passed, the same marker lowers down.

Because Titan is equipped with TC -controller, the controller can also be used for the low-lift

feature of the machine. This means that when the low-lift is switched on, the machine rises only

a little from the ground, but the rear harrow stays on the ground. Field end turns faster and

harrow molds the wheel tracks of the headland.

The trajectory speed of the markers can be adjusted with the control valve in the machine's valve

compartment (picture 20). Adjust the valve to a small flow to start with. Do this so that the

marker arm movement is calm and does not cause damages or risky situations. Adjust the valve

to the suitable speed during the actual sowing, when the tractor’s oil, for example, has reached

the normal temperature.

Page 33

31

Picture 20. Titan

valve block.

NOTE: The markers can be locked into their upper positions with rotating valves in the hydraulic

circuit. We recommend locking the markers during road transportation and m maintenance

work.

Grass seeder

The grass seeder is intended for sowing different types of grass seeds and their mixtures. The

seeds are directed into the soil via hoses. The hoses are installed in such a way that the coulter

slightly covers the seeds with soil. The sowing speed, for example, has an effect on how well the

grass seeds are covered.

The grass seeder is integrated into the rear wall of the seed and fertiliser drill. Thus the tarpaulin

of the basic machine also covers the grass seeder. Because the grass seeder is partly integrated

into the basic machine, it reduces the capacity of the seed hopper about 200 litres depending on

the working width.

Threaded rollers form the feeding system of the grass seeder. The amount of feed is adjusted by

moving the threaded rollers side-to-side. The adjustment is made with the adjusting wheel at

the left end of the seed drill, which is locked in the required position with a plastic locking device.

When the locking device is opened, it must be pressed in the direction of the arrow towards the

end of the machine, in which case the locking device can be turned to the side from the adjusting

wheel.

DO NOT TURN THE LOCKING DEVICE BY FORCE!

The main scale on the locking device is dived into intervals of 0 – 10, where one interval is one

turn of the adjusting wheel. The adjusting wheel has 10 locking positions for each turn and they

Down limit /

pole lift

Up limit / pole

lift

Marker valve

Marker valve

Marker stop valve

Marker speed

adjustment

Page 34

32

are marked 0 - 9. Thus you can have a total of 100 different adjustment positions. The total turns

are read from the locking device scale from the inner surface of the adjusting wheel.

The feeding system has adjustable bottom valves. The adjusting lever is in the middle of the

machine. The adjusting notch 1 is normally used for fine seeds

The closing gates between the bottom and the feeding chamber must be adjusted to the halfclosed position, if the device is used for sowing fine and easily flown materials (such as clover).

Instead, when sowing light and easy-to pour grass seeds (such as meadow fescue) closing gates

must be fully open.

Advisory feeding adjustment is made with the sowing chart. Select the required amount of feed

(kg/ha) from the vertical line on the chart and follow the horizontal line to the right until the line

crosses the diagram for the material to be sown. You can read the required adjustment value

from the point corresponding to the crossing point from the horizontal line of the charts. The

numbers on the line correspond with main scale on the locking device (hand wheel rotations).

The sowing chart values are only advisory, so always check the correct amount of feed with

calibration!

The grass seeds are sown on the surface of the field, after the coulters but before the rear wheel

set. The Titan grass seed hoses have carbide runners which guarantee the even positions of the

hoses. NOTE: The two hoses on both edges are placed across each other so that they don't get

damaged during the machine's lifting or lowering movement.

Picture 21. Installing the chains in the grass seeder.

Page 35

33

Grass seeder calibration

Remove the seed and fertiliser feeds from the basic machine (take pins off the feed axle).

Adjust the hand wheel to the setting you require as shown in the sowing chart. Check the correct

position of the bottom valves (notch).

Pour the seeds into the hopper.

Remove the calibration shelving pins from the rear corners of the hopper.

Install the calibration troughs into their supports.

Turn the hand wheel for a few rotations. Thus you ensure that the feeding chambers are full.

Turn the ground wheel for the amount matching with 10 acres (Titan 3000: 110 – 120 turns, Titan

4000: 82 – 90 turns).

Weigh the amount of seed and multiply by 10. The resulting sum shows the required amount for

a hectare. For example: if the calibration troughs have the total amount of seed of 1.5kg, a

hectare requires 10 x 1.5 kg = 15.0 kg. NOTE! The machine vibrations during the run may increase

the sowing amount compared to the calibration when using small quantities of seed. Monitor

the seed flow as the sowing progresses.

The grass seeder can be switched off by removing the linchpin on the chain wheel at the end of

the feed axle and transferring it into the empty hole at the end of the axle. Thus the chain wheel

rotates freely on the feed axle. The mixer axle of the grass seeder (accessory) can be switched

off separately if required by removing the pin in the user end of the mixer axle inside the hopper.

Ensure that when the hopper is filled, no hard objects, clumps of fertiliser or other such things

which can damage the feeding system can enter the hopper.

Extremely fine grains of the sowing material may fit between the seeding chamber and the

adjuster sleeve on top of the feeding roller. This may cause tightness when adjusting the sowing

amount from the hand wheel. The device must be rotated a few times every time when the

adjustment starts to feel stiff.

Page 36

34

TUME-

AGRI OY

PL 77

14201 TURENKI

FINLAND

PUH. 0207 433 060 TEL. (int.) +358 207 433 060

www.tumeagri.fi

Loading...

Loading...