Page 1

NO: 98856604 F 1/2019

TUME-AGRI OY

User manual

JC 3000 Star XL

JC 4000 Star

Seed Drill

Valid for serial numbers AH 53053 – onward

Read this manual before commissioni ng!

Translation

Page 2

2

EC Declar ation of Con form ity for the M ach ine

(Machine Directive 2006/42/EC, Annex II A)

Manufacturer: Tume-Agri Oy

Add.: Sudenkorventie 1

FI - 14200 TURENKI

Name and address of person authorized to compile a technical file:

Name: Heimo Valli Address: Sudenkorventie 1, FI-14200 Turenki

Hereby declares that

Seed drills JC 3000 Star XL ja JC 4000 Star Serial number ___________________

• are in compliance with the applicable decrees of the Machine Directive

(2006/42/EC)

and in addition declares, that

• the following standardized European directives and standards have been applied:

SFS-EN ISO 12100-1:2003

Place and date: Turenki 3.2.2017

Signature:

Patrik Jungarå

Managing Director

Page 3

3

Table of Contents

1. For the machine user and others responsible for the machine ............. 4

2. General safety regulations ................................................................... 4

3. Intended use of the m achine ................................................................ 6

4. Machine commissioning ...................................................................... 7

5. Drawbar installation ........................................................................... 10

6. Feeding equipment ground wheel ...................................................... 16

7. Filling the container ........................................................................... 17

8. Emptying containers .......................................................................... 19

9. Seed feeding equipment and adjustments ......................................... 20

10. Fertilizer feeding equipment and adjustments ................................. 22

11. Sowing table examples ................................................................... 25

12. Calibration test ................................................................................ 26

13. Field test ......................................................................................... 30

14. Fertilizer application depth adjustment ............................................ 30

15. Adjusting the sowing depth ............................................................. 31

16. Harrow adjustment ......................................................................... 33

17. Fertilizer coulters ............................................................................ 34

18. Seed coulters.................................................................................. 34

19. Area meter ...................................................................................... 35

20. Drill maintenance ............................................................................ 36

21. Most common repairs ..................................................................... 38

22. Decommissioning the machine ....................................................... 43

23. Technical Information ..................................................................... 43

24. Optional equipment and accessories .............................................. 44

Annex 1: Lubrication points.

Page 4

4

1. For the machine user and others responsible for the

machine

We wish you every success with your TUME seed drill. This instruction manual provides best-practice

instructions for the use, adjustment, maintenance and storage of Tume JC -machinery. Following the

instructions in this book will ensure that your machine will pr o vide you with lon g, trouble-free service.

It is very important that you familiarize yourself with the instructions before making full-time use of the

machine. Please retain this manual and keep it in an easily accessible location. The replacement part number

of the manual is printed on t he cover . Pleas e m ake a rec ord of this num ber , as it will enable you to order a

new copy should the need arise.

Both the manufacturer, Tume-Agri Oy, and authorized resellers will be happy to provide assistance in

questions relating to the use or maintenance of this machine.

About the presentation of this manual

As this publication is distributed across our international sales network, the equipment depicted in illustrations

(both the standard equipment and accessories) may vary based on the country in which you are located. For

certain countries, covers may for lega l and otherwise im portant reasons be opened or removed in cert ain

illustrations in order to provide a clearer view of the object in question. The machine must not be used without

protective covers. In order to guar antee safe us e, you m ust ensure that all covers are intact or instal led in

place before starting work.

When a reference is made in this manua l t o "l ef t" a nd " right " si des , t his is when viewed from the rear of the

machine looking forwards in the direction of travel.

Tume-Agri Oy is c ontinually deve loping its products, and therefore reserves the right to make changes and

improvements without prior notice and with no commitment to m ake retro-active changes to any prod ucts

sold prior to the changes.

2. General safety regulations

All persons handling, maintaining or who have any form of access to a TUME-seed drill must be

thoroughly familiar with this instruction manual before using, or performing maintenance or repairs

on the machine. Be sure to comply with the instructions in this manual!

Entrust the performance of difficult repairs to an authorized brand repair shop.

Use only original Tume parts, and do not make structural modifications to the machine without the

agreement of the manufacturer.

Working or being located under a machine without supported hydraulics is strictly prohibited.

Secure the position of the machine by closing the lift cylinder safety vents, see Figs. 38-39. If you

must leave the machine unattended, lower the machine and lock the markers mechanically.

Staying on the machine or on the step level when the ma chine is in motion is strictly prohibited.

The driver must ensure that no persons are close by when the machine is in motion or when

hydraulic functions such as engine or lowering or raising markers are being used.

Before reversing the machine, make sure that no one, e.g. children, is standing to its rear.

Page 5

5

Work machine lubrication, adjustments and cleaning are prohibited while the machine is in motion.

Turn off the tractor engine and apply the hand brake during all maintenance. Ensure that no

outsider can access the control equipment of th e tractor or machinery when you are maintaining or

repairing the machine!

A

ll covers must be mounted in position when the machine is in operation.

Ensure that the traction device, hydraulic lines and electrical wiring are correctly connected to the

tractor and work machine. Lines and cables must be laid out in such a way that they are not at risk

of damage when the machine is in use.

Damaged hydraulic lines and connectors must be replaced without delay Tractor hydraulic vents

and connections must not leak and must be in good condition. These ensure the correct transport

position of the machine.

Hydraulic markers may raise or lower at high speed, especially if the throttle valve is set too wide

or if the hydraulic flow rate produced by the tractor is high. Be particularly careful when attempting

to raise or lower the markers for the first time. Ensure that nobody is under or in the path of th e

hydraulically-raised markers.

The markers must be mechanically locked into their upper position before transporting the

machine by road, or when the machine is parked and the machine driver is not present.

Ensure that a minimum of 20% weight is placed on the tractor’s front axle under all conditions. Use

additional weights as required. Be particularly careful if connecting suspension arms to the tractor.

The maximum permissible driving speed under good conditions is 30 km/h. On uneven terrain,

special care must be taken, and speed must be reduced. Transfers should preferably be performed

with empty containers. Carrying loads on top of the machine is prohibited. Do not drive over rocks

or other obstacles so as to avoid tire damage.

Use caution when moving on top of the machine to carry out cleaning or maintenance, or when

filling the containers.

Make sure that the machine is carefully parked when disconnecting the machine from the trac to r.

The machine must be mechanically prevented as required from rolling downhill. The machine’s

lifting hydraulics should be locked at the stopcocks (see Figs. 38–39), markers should be

mechanically locked into their transport position and the hydraulic lines to the tractor must be

depressurized. The tow bar must be supported with a machine support stand.

When heated, coated surfaces may emit vapors that are harmful to human health. Ensure that work

premises are properly ventilated, for example during welding. Remove the paint if necessary, e.g.

by abrasion.

Use only manufacturer-approved accessories and equipment. Modifications which do not comply

with the manufacturer’s instructions an d th e consequences thereof are the responsibility of the

party performing such modifications.

We in particular recommend the use of optional eye protection and a respiratory mask, especially

when filling the seed dressing device. The use of protective equipment is particularly important

when cleaning the machine with a high-pressure device.

The seed drill does not significantly increase noise levels inside the working area of the tractor

cabin. Ear protectors may need to be used, dependent on tractor noise levels.

We recommend that safety boots be worn when handling heavy or sharp components (such as

parts of the tow-bar and coulter).

You should also keep your machine up-to-date in terms of the required equipment for road use, in

the event that the machine must be transported on public roads. Road use regulations may often

change

Page 6

6

3. Intended use of the machine

The TUME JC seed dril l can be us ed to p lant m os t comm on grain, oil and herbac eous plant se eds, as we ll

as peas and beans. Gr anular fertilizer c an also be planted usin g a fertilizer dr ill. Seed dressing a nd grass

seed drills ma y be acquired as optional equipm ent. Such equipment enables dressing during dr illing and

grass seed planting to protect the seeds. In addition, the mac hine can be used separ ately for fer tilizing or

drilling only.

Seeds and fertilizers needed for work can be transported to nearby fields in machine containers if the roads

used for transport are in g ood condition. T he maximum permissible driving speed in this c ase is 15 km/h.

On uneven roads a nd long dri ves, transport must be car ried out with the machine in em pty condition. The

machine may not be used to transport anything els e but seeds and ferti lizers required for immediate use,

and no additional load, objects, animals or passengers are allowed in the containers or on top of the machine.

General machine capabilities

The fertilizer feeding equip ment is designe d for the feedi ng of granular fer tilizers only. The use of powdertype fertilizers will usually cause difficulties. At worst, powder fertilizers may cause the feeding equipment to

jam, and for this reason, only granular fertilizers must be used.

Fertilizer application depth can be adjusted between 8 cm and the surface.

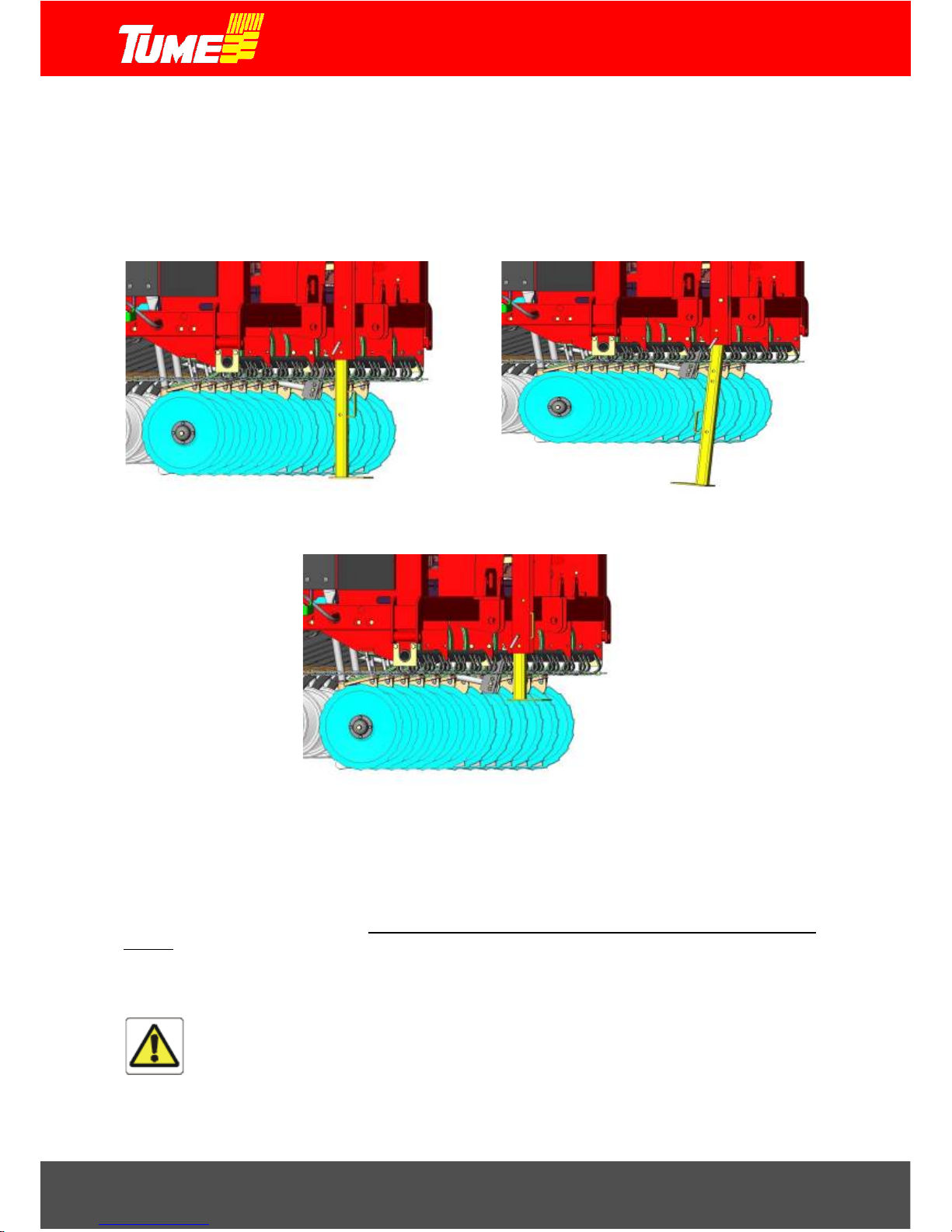

Drills can be fitted with different planting coulters depending on the prevailing conditions, see Fig. 36. Under

difficult, blocking conditions, the machine operates at its best when equipped with disc coulters. Other

alternatives include dra g and wing coulters. Drag coulters are usually used in rigi d ground t ypes, when th e

basic tillage is plowing. Wing coulters are best used for basic tillage, particularly for lighter ground types.

The coulter weightin g adjustm ent range covers the needs for all ground types. The coulter’s suspens ion is

designed in such a way tha t ground un evenness will not significant ly im pact coulter weighting. For shallow

drilling, especia l l y on light gr ounds , the coulter suspension must be adjusted to a low level. For rigid ground

types and deeper planting applications, higher weightings must be used.

Standard fertilizer coulters, see Fig. 34, are narro w and operate in a vert ical position. Thes e can be used

under most conditions. Fertilizer coulters have a high degree of flexibility, and ther ef or e do not block easily.

JC Laser models are supplied with standard plate coulters on the seed side and single-disc fertilizer coulters

on the fertilizer side, see Fig. 35. Laser models are suitable for all kinds of sowing and especially to conditions

where sowing is replaced by light tillage.

For conditions where wear is a particular concern, t he tips of drag coulters can be fitted with replaceable

ceramic pieces, and fertilizer coulter tips can be reinforced with wolfram carbide. This equipment can

increase durability up to ten-fold compared to ordinary means.

The support wheels fitted to the rear of the JC also operate as roller wheels. Two rows of seeds and one row

of fertilizer are applied by each wheel. Their rolling ef fect is ade quate u nder n orm al condit ions. The harrow

fitted to the rear of the wh eels spreads the earthwork lef t between the wheels, breaks up the run in the

middle, and finalizes sowing. No easily smudged tracks are left on the field.

With the optional grass seed drill, the m achine can simultaneous ly sow fertilizer, pr otective plant or grass

seeds, or equival ent. In its so-called H ST vers ion, th e s ame dev ice ca n also b e u sed to ap pl y certain trace

fertilizers and start phosphorus.

When equipped with a f ertilizer remote control device, the m achine is particularly suited for block s with

varying ground types. T he driver can adjust the fertilizer feed from the cabin during the drive, optimally

matching each ground t ype. Fertilizer rem ote control is fitted as s tandard with the TC+ on-board computer

(optional).

Other accessories are described in Section 24.

Page 7

7

4. Machine commissioning

Support stand

The support stand in the machine front wall is used for storing and transporting the machine, see Figs. 1 and

2. The support stand is raised during sowing, see Fig. 3.

Figure 1. Support stand during storage.

Figure 2. Support stand during vehicle

transport.

Figure 3. Support stand during sowing.

Running gear, adjustable joints and lift cylinders

The adjustable joints of the running gear are locked and immobilized with a loc king flat bar when ever the

machine is being loaded or transported. When commissioning the machine, remove the flat bar and re-install

it so that the pins protrude through the elongated slots. The running gear can then be adjusted to

the

unevenness of the terra in, s ee Fig. 4. The machine should not be used with its back level locked into a rigid

position! Check that the lift cylinder locking taps are open, see Figs. 38–39.

If the machine must for any reason be used with the back level lock ed in a rigid position, s pecial c are m ust

be taken when driving over uneven terrain. Severe loads will be applied on the back level and individual tires!

Caution!

The machine must not be used without adjustable joint flat bars. These must always be

installed during use.

Page 8

8

Figure 4. Adjustable joint restriction and

locking bar.

Figure 5. Ground wheel in vehicle

transport position.

Using the ground wheel

The wheel which the machine uses for power transmission, the ground wheel, is positioned as shown i n Fi g.

5 for certai n vehicle transport m ovements. Retract the wheel and remove the transport supp ort from the

container seam. Turn wheel as in figure 15.

Tow bar alternatives and bar installation

Tume JC machines are supplied as standard with a common lowe r si de ba r , with which the machine can be

towed from a tractor tow-hook or agricultura l towing device. Standard de liver y also includes a tow-triangle,

see Fig. 6. A tow-triangle is attached to a 3-point lifting device on the tractor (category 2). A tow-bar is usually

packed to the back of the machine at the original manufacturer. Smaller parts are packed in containers.

Alternatively, an adjustable multi-function shaft m ay be s elected f or the m achine , which c an be used eith er

as an ordinary bottom-mounted side shaft, s uc h as with the Tume CultiPack c ultiv ator . A tow-triangle is not

provided with the multi-function shaft.

Upper support for the seed dr ill tow-bar is provided either by a mechanical push-bar (provided as standard)

or by a hydraulic push-bar (optional). The hydraulic push-bar allows the front part of the machine to be lifted

up, regardless of whether the tow-bar is connected to the pull-hook of a tractor, agricultural towing device or

optional roller.

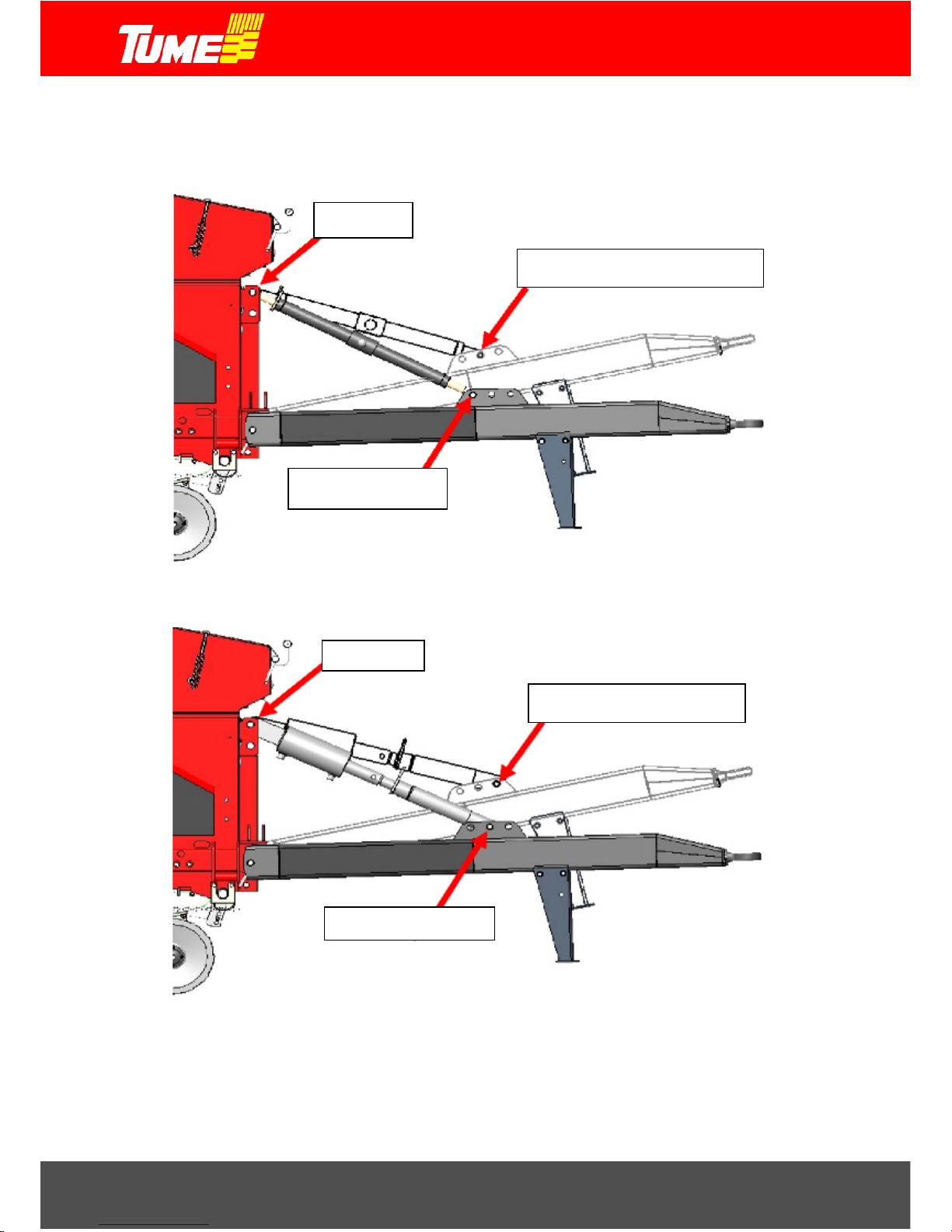

The bottom side tow-bar with tow-triangle is assembled according to Fig. 6. Fig. 7 shows the tow-bar

connection to the machine, when upper support is provided by a mechanical push-bar and the m achine is

connected to a tractor tow-hook or tow-triangle. Fig. 8 shows an as sem bly with a hydraulic push-bar. Here,

the machine is connected t o wheel packer. Note the position of the shaft pin in the upper and lower

shaft positions.

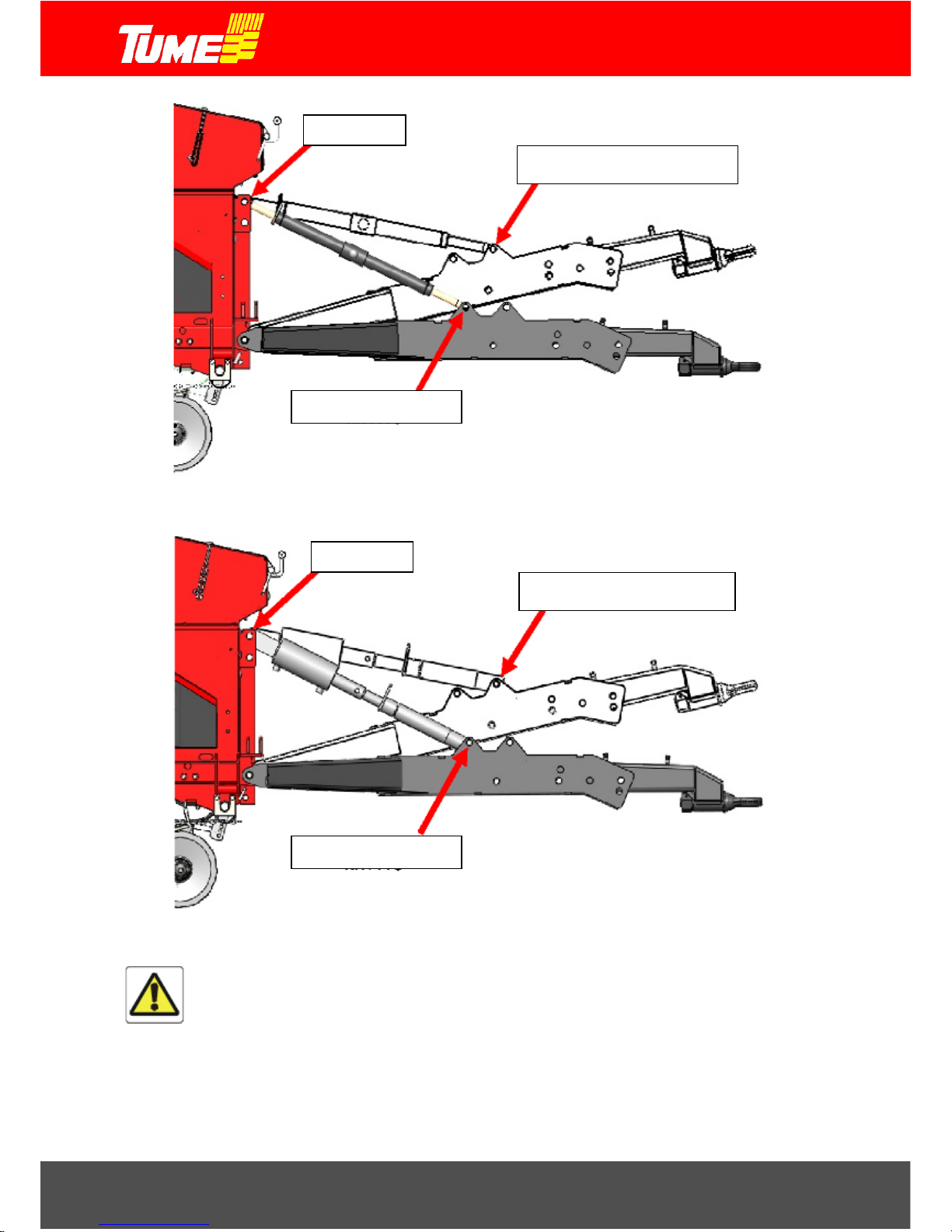

A multi-function tow-bar concept is shown in Fig. 9. Installation with mechanical push-bar is depicted in figure

10. The installation for the hydraulic push-bar is shown in Fig. 11.

Page 9

9

Figure 6. Standard tow-bar assembly.

The towing device is attached to the machine frame side brackets. The push-bar (hy draulic or mechanical)

in the picture is connected to the upper holes of the bracket on the front of the hopper.

Hydraulic lines and electrical wires are pulled through the tow-bar and attached to hanging hooks on the towbar. The hydraulic push-bar (optional) tube is connected to its own, one-way hydraulic valve.

Once the hydraulic line layout is com pleted, these sh ould be fixed in posit ion by bending the line supports

so that the lines remain in place.

Adjust the push-bar working dimension so that the machine is horizontal when calculated in terms of working

depth and attached to the tow-point at working height (tractor tow-hook, tow-bars in working position,

intermediate cultivat or towing point, etc.). Ensure th at the push-bar cylinder is in its retrac ted posi tion whe n

carrying out this adj ustment. Fine t uning of the towing device can be perfor med in the f ield, under sowing

conditions.

tow link

tow triangle

mechanical push-bar

drawbar cylinder

Page 10

10

5. Drawbar install ation

Figure 7. Standard tow-bar and turnbuckle.

Figure 8. Standard tow-bar and tow-bar cylinder.

upper hole

upper hole

for use with wheel packer

for use with wheel packer

for use with tractor

for use with tractor

Page 11

11

Figure 7. Multi-function shaft assembly.

drawbar cylinder

mechanical push-bar

Page 12

12

Figure 10. Multi-function tow-bar and turnbuckle.

Figure 11. Multi-function tow-bar and tow-bar cylinder.

WARNING - DANGER!

Never over-extend the push-bar, as this m ay reach the outer limit of the adjustment

range and the push-bar will bend or break. In a worst-case scenario, the person

performing the adjustment may then become trapped under a tilting machine.

Note that there are no restrictors on the helical bars of the push-bar preventing

adjustment beyond the permissible range. The portion of exposed thread must always

be less that the amount of thread within the inserted thread! Become acquainted with

the adjustment range measurements provided in this instruction manual, Figs. 12 and

13.

upper hole

upper hole

for use with tractor

for use with tractor

for use with wheel packer

for use with wheel packer

Page 13

13

Machine connection to tractor

Tow-bar alternatives and bar connections

Standard tow-bar

The JC seed drill is usually attached to a tractor tow hitch, agricultural towing device or to the towing point of

an optional roller (middle wheel packer).

The bottom standard tow-bar also comes with a tow-triangle, with which the JC can be towed from a tractor

3-point lift device.

WARNING!

When using a tow-triangle connection, special attention must be paid to tractor front

end weighting in order to maintain contr ollability. When the JC is connected to a tractor

tow-bar with a tow-triangle, the machine containers must be empty during transport. In

addition, ensure that the steering fro nt axle bears at lea st 20% of the tractor’s mass

(use additional weights), and that the tractor’s right and left side brakes are

interconnected.

WARNING!

The tow-triangle must be connected in as ve rtical a position as possible. Adjust to the

correct position using the tractor tow-bar. Never r aise or low er the tow-triangle to an

unnecessary height. Ensure that the tow-bar angle is not excessive wh en v iew ed from

side-on. The maximu m permis sible angle to the horizontal is +/- 9

°. Excessivel y sharp

angles can destroy the tow-triangle or tow-link.

Multi-function tow-bar

If a multi-function tow-bar is selected for the JC, the machine can usually be connected as normal to a tractor

tow-hook or agricultural towing device (with the bar installed as a lower tow-bar, see Fig . 10,11) or also to

higher-mounted tow-points. A bar set as an upper tow-bar is depicted in Figures 10 and 11. The upper towbar can for example be connected to the towing point of a Tume CultiPack intermediate cultivator.

WARNING!

The upper tow-bar must never be connected to a tractor push-bar bracket or other such

tow-point that is located above the rear axle of the tractor.

When using the upper tow-bar with a milling cutter or other lifting device fitting cutter,

it must be ensured that the tractor remains controllable even when the cutter is lifted

such that it is supported by the lifting device. In road traffic, the steering front axle must

for safety reasons have an adequate weighting of at least 20% of the tractor’s total

mass. Use additional weights if needed. Move the machine as necessary only with

empty containers!

WARNING!

Check all tow-bar parts for wear and other problems regularly! Pay special attention to

the tow-bar l ink and tow-bar c onnection pin and overall wear. Damaged or dangerously

worn parts must be replaced or repaired without delay.

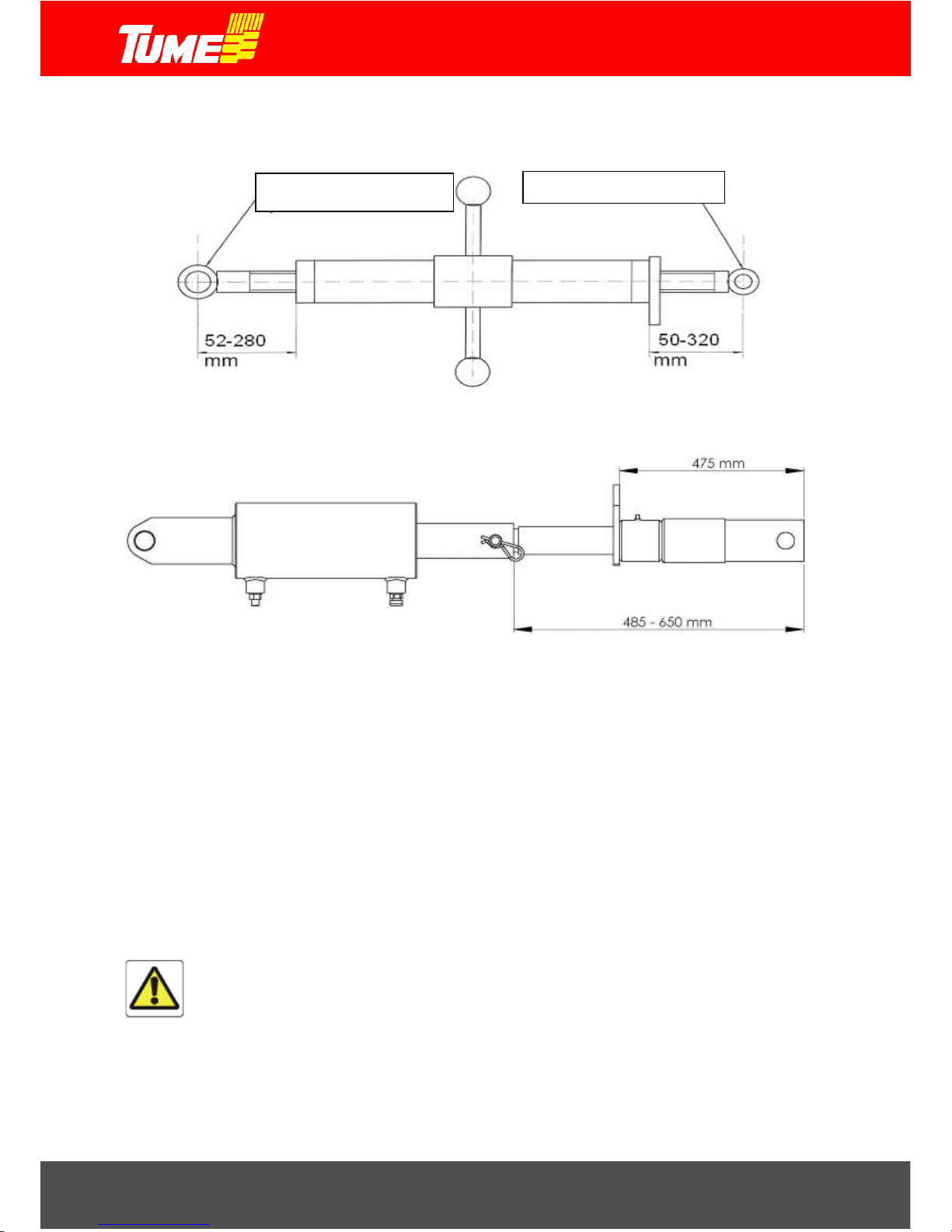

Length adjustment ranges of push-bars supplied with tow-bars

Caution! Follow the instructions provided for length adjustment ranges! Incorrect adjustment can

lead to serious personal injury or equipment damage.

Fig. 12 shows the length adjustment range of a mechanical push-bar provided as standard equipment. Note,

that the area is not symmetrical. Pay separate attention to the measurement adjustment of each end!

Page 14

14

Lock the push-bar with the thread locking pin. Fig. 13 shows the equivalent hydraulic push-bar

measurements.

Figure 8. Length adjustment areas for mechanical push-bar.

Figure 13. Length adjustment areas for hydraulic push-bar with adjustment sleeve.

Connecting hydraulics

Standard JC hydraul ic equipment is connected to a hydraulic outlet intended for external singlefunction cylinders. Bar cylinders supplied as optional equipment require a second single-function

outlet.

If the seed drill is installed with dual-function lift cylinder equipped markers, the two hoses running

from machine are connected to the tractor’s dual-function outlet. Similarly, the hydraulic push-bar of

a multi-function tow-bar (optional) is dual-function, and therefore requires another 2-function outlet.

NOTE! When connecting hydraulic connectors, the tractor’s hydraulic PTO control gear must

be in the lowering or floating position to ease the connection.

WARNING!

When connecting hydraulic lines to the tractor, ensure that the machine, tow-bar or

markers cannot low er uncontrollably and thus harm adjacent people or other objects!

Connect the tow-bar to the tow-point before connecting the hydraulics.

NOTE! Certain tractor models require the use of non-standard hydraulic quick-change

connectors recommended by the tractor manufacturer. Replace the relevant components with

suitable components as required on your tractor in order to ensure proper hydraulic function.

HOPPER END

TOW-BAR END

Page 15

15

Caution! Before starti ng sowing, the relat ive position of coulters and harrow tines to each

other must be ensured with a tow test. This can be carried out in a field or in sof t sand. E ac h

fertilizer coulter m ust always travel at a distanc e half-way betwe en two seed coulters under

direct tow. The gap b etween seed coulters must be approx imately 125 m m, and the harrow

tines must travel bet ween the seed rows. Mo ve the coulters and tines laterally a s required.

This check must be performed at least once per usage period.

Driving instructi ons

Driving instructions for transport

The machine is kept in its upper position by means of the tractor hydraulic valve. For this reason, it must be

ensured during any transport that there ar e no leaks in the trac tor hydraulics, and that the hydraulic lever

controlling the raising or l owering of the m achine is not m oved accidentally. Kee p the lift cylinder safety

taps open during transport as well as during sowing, see Fig. 39.

During transport, the maximum permissible speed is 30 km/h. See general safet y instruc tio ns , Section 2.

Driving instructions for sowing work

If the ground wheel is i n its raised p osition with the tra nsport supp ort (Fig. 5), lower it to its usage pos ition,

see Fig. 14.

Caution! Always move forward when lowering the machine. Otherwise the coulter arms

may become damaged or the coulters may become clogged.

Avoid unnecessar y driving in the sown are a. Select a drivin g technique t hat ensur es that onl y minimal tire

tracks are left in the s own area. It is usually good to start seed ing on the basis of a single block, s o that

sufficiently wide tracks can be generated (usuall y 1-2 ti mes the width of prot ective plant spr aying). Sowing

is then performed back and forth, driving in the direction of the longest side of the block.

Caution! Try wherever possible not to sow the corners of the block in a circular motion,

and raise the machin e at corners. Making steep turns with the machine and coulters

on the ground will cause unnecessary wear to the machine tow-bar and coulters!

All-around sowing is used on irregul ar block s. Lift t he m achine at all corners! Only sow in a gentle circle in

the ground on clearly wide cor ners!

Because of the hydraulic structures, the machine must always be lifted all the way to its upper position. Only

then ca n the machine b e lowered again. Co nversely, when lowering the machine, the l ower position m ust

be reached before the machine can be raised again. When sowing, care must be taken not to lift the machine,

as it cannot be lo wered b ack to its cor rect wor k ing depth u nless i t is fir st raised h igh enough that the depth

control valve (Fig. 31) is reopened.

Fig. 31 shows the valve controlling raising and lowering, moving with the wheel support arm. When the valve

lever r eaches the up and down pos itions of the guiding pins, the valve cl oses and the lif ting or lowerin g

motion is stopped.

Ensure that the harrow is raised sufficiently when lifting the machine. See Section 16, adjusting the harrow.

Caution! Never reverse when the harrow tines are in contact the ground. Similarly, do

not reverse into contact with the earth formation at a field edge or other obstacles.

The machine must be able to work on even terrain in a horizontal position. See Section 14, fertilizer

application depth adj ustment. If the m ac hine is ang le d f or ward as it moves (this can happen if to wed i n any

other way than with the tow-triangle) the towing device push-bar must be extended. If the machine is angled

backwards as it m oved, the push-bar mus t be shorten ed. Note the push-bar adjustment area ! C heck the

Page 16

16

fertilizer and sowing depths after driving f or a certain time. Check the adjus tment of the markers (optional)

by also studying the sowing seam area.

Caution! Only lift and lower the machine when it is moving forward. Never reverse the

machine when the coulters are in the ground and power transmission is connected.

Check periodically for dr ill blockages. Also check the state of all seed an d fertilizer lines and clear any

blockages.

At the start of so wing, check the area that can be sown with a single container. You will then be able to

determine the next estimated filling time based on the area surface.

Keep sufficient amounts of seeds and fertilizer in the container. Particular attention must be paid to this due

to the design of the bottom, especially at the start.

Do not store fertilizer or seeds in containers for several days, especially in moist weather. Damp fertilizer can

lead to feeding problems.

Optimal seeding results are achie ved at driving speeds of 7-10 km /h. In rocky conditions, the driving

speed must be reduced to suit the circumstances.

The maximum sowing speed with small and regular-sized seeds under good conditions is 15 km/h;

that for sowing peas and beans is 6-7 km/h.

6. Feeding equipment ground wheel

The feeding equipment receives the power to drive it from the ground wheel on the right side of the machine.

The ground wheel is mounted on the container and is therefore lifted when the machine itself is lifted. When

the machine is lifted, the ground-wheel is no longer in contact with the ground and it stops providin g po wer .

A separate power transmission clutch is therefore not required.

Caution! Do not rotate the ground-wheel to reverse direction! Always raise the machine

before reversing the tractor. Both coulters and the ground-wheel must be clearl y off

the ground.

Figure 14. Ground-wheel in work position. Figure 15. Ground-wheel in transport

position.

Page 17

17

7. Filling the container

Using the tarpaulin covers

The drill is equip ped with tarpaulin co vers that can be rolled open with cranks located at its front and rear

edges, see Figs. 16–17. When filling the fertilizer container, you need only open the front part of the tarpaulin

cover, and simila rly, when filling the s eed container, on ly open its back part. T his will prevent m ixing up the

fertilizers and seeds when filling the containers. During transport and sowing, the tarpaulin cover should

preferably b e kept closed and he ld in po sition w ith rubber mounts. This will avoid im purities penetratin g the

containers and securing the cover in position.

Caution! On machines equipped with markers, the front edge crank must compulsorily

be mounted whenever working with rubber holders, see Fig. 16. Otherwise, the crank can

come into contact with a marker arm, leading to the risk of damage.

Figure 16. Tarpaulin cover in work position. Figure 17. Tarpaulin cover in open position.

Use of sieves

Standard sieving equipment is normally fitted to the fertilizer and seed containers of JC seed and fertilizer drills

(this may vary by country and market). These sieves prevent foreign objects from causing feeding

disturbances, or fertilizer crumbs etc. developing in the feeding equipment. The fertilizer sieve must always be

kept in place during container filling and seeding. The seed sieve must also be in place except in the event of

certain exceptions.

Such exceptions include large or elongated seed shapes, which may be too large to fall through the sieve. For

example, many types of oat cause problems, as the grains are long and li ght. If it is rea sonable t o susp ect

that the seeds will not be able to pass through the sieve, the sieves must be temporarily dismantled

and removed fr om the container. When filling or seeding without sieves, special attention must be paid

to ensure that no foreign objects enter the fe eding equipment, i.e. remnants of sack, tools etc.

Timing of the filling

When starting sowing, it is recommended that the machine be moved to the field in empty condition. Fertilizers

and seeds are delivered to the field, i.e. with a tr ai ler, and seed drill filling is car r ied out a t the s ide of the field

block. If the machine must be filled at a distance from the block to be sown, special caution must be exercised

during transport with full containers.

Caution! The maximum transport speed of 30 km/h may only be used on roads in good

condition, and containers must be empty! The maximum permissible driving speed with

full containers is 15 km/h ! On potholed, ro cky or e xtremely na rrow roads, the transport

speed must be adjusted downward according to circumstances.

Monitoring of container levels is possible:

Page 18

18

By looking into the container from time to time, when the machine must be stopped.

By observing the area meter of the machine, when the area size that can be sown with a full container

is clear and the meter reading for the last filling has been recorded.

With optional electronic monitoring equipment. Such devices issue an alert when a certain amount of

fertilizer or seed remains in the container.

WARNING!

Transporting an assisting person or other passengers on the steps of a moving

machine or elsewhere in the machine is strictly prohibited. The seed drill must be at a

standstill when leveling seeds or fertilizers in the containers!

Adjusting the fertilizer and seed container volumes

The position of the f ertilizer and seed container partition can be adj usted s o that the container volume ratios

can be changed. Such adjustments are c arried out by loosening the lock ing screws of the partition sup port

arms (Fig. 18) and moving the partition to the desired position. Remember to re-tighten the support arm locking

screws after making the adjustment. The partition adjustment area can be changed by moving the support arm

ends to other attachments pins (Fig. 18). When using the machine for sowing only, the partition can be moved

fully forward in order to maximize the seed space, see Fig. 19.

Caution! Carry out the adjustment when the containers are empty or nearly empty!

Figure 98. Partition support arm.

Figure 19. Seed container maximum volume

Maximum fill liters

Fertilizer (max)

Seed (min)

Seed (max)

HS/HST device decreases

seed volume

HKL 3000 JC Star XL

2360

1350

3320

330

HKL 4000 JC Star

2580

1580

3640

300

Filling method

The large size of the containers means that their filling level is also relatively high, a consideration if 40-50 kg

sacks must be lifted from ground level. For this reason we recommend working as follows: first place the sacks

on pallets, then raise these with a pallet lifter or front-loader truck forks to a suitable height for machine filling.

Jumbo sacks (500–1000 kg) can be handled with different loaders. Jumbo sacks must never be placed on the

seed drill structures. Do not overload the seed drill. Identify methods for partiall y emptying a jumbo sack.

Page 19

19

WARNING!

When filling the machine, never pass under a load which is suspended from a loader

or otherwise lifted, or under the lifting structure.

When using loose f ertilizer and/or s eeds, we recomm end the use of a high-tipp ing t railer or f ill-screw. When

using a tipping trailer, the tipping point must be selected wit h care in order to prevent the carriage

from overturning. As the JC support wheels and harrow are located at the rear of the machine, certain filling

carriages may not have sufficient reach. The containers can then be filled f rom the side of the machine as

required.

8. Emptying containers

Emptying the fertilizer container

The fertilizer container is emptied through the coulters or by using the test seed troughs.

If the seed container is not fully emptied, care must be exercised to prevent seeds from falling into the

fertilizer. For this r eason, remove the seed feeding cassette (see Figs. 22 and 23) when the see d

feeding does not rotate by means of the ground-wheel or by rotating the fertilizer shaft.

Set the load cover under the machine.

Set the fertilizer feed to the maximum feed amount.

Lift the fertilizer si de feeding equi pment lever for the bottom flaps ov er the scale (Figs. 26 and 28).

The container will then empty almost completely.

Guide the remaining fertilizer, e.g. with a brush, to the feed chambers. Rotate the feeding device with

the ground-wheel a number of tim es, see Fig. 29, until the chambers are empty. Then, swing the

bottom flaps back and forth fast with the adjustment lever until the last fertilizer grains fall out through

the coulters.

Pull the cover out f rom underneath, and ins tall the seed sid e feedin g equipm ent po wer transm ission

cassette back in the original manner.

Emptying the seed container

The feed container can be emptied through the coulters or using the test seeding troughs.

Empty through the coulters, i.e. the load cover is spread underneath the coulters.

Adjust the feeder to the maximum feed amount during the emptying process.

The seed container is emptied by lowering the bottom flap crank fully over the scale (Figs. 20 and 24).

Guide the remaining s eeds into the feed chambers.

Rotate the feed equipment a few times so that the seeds remaining on the feed rollers flow downward.

Note that when rotating the f eeder , some of the fertilizer m a y flow on top of the lo ad c over u nles s the

fertilizer container has been emptied beforehand, or unless the fertilizer feed shaft has been rendered

inoperable with a ring pin (Fig. 27).

Swing the bottom flaps fast with the crank a few times so that no seeds are left on top of the flaps.

The containers can be emptied using the test seeding troughs if only small amounts of seed and

fertilizer remain in the containers. Use of the test seeding troughs is described in Section 12.

The method for emptying is essentially as described above. If large amounts of seed remain in the containers,

the bottom flap crank must be closed when emptying the troughs.

WARNING!

If compressed air is used to clean the containers, remember to use adequate protection

to prevent pollen dust, seed treatment, etc. from penetrating the respirator y system an d

eyes!

Page 20

20

9. Seed feeding equipm ent and adjustment s

Overview

JC seed drills use a groove feed on both the fer tilizer and seed sides. The feeding bodies are called feed

rollers. Under the feed rollers, you can find adjustable bottom flaps with springs, with closing covers on top of

them, see Fig. 20. The f eed chambers are locate d at the bottom of the containers. In practice, this solutio n

provides independence in term s of sowing amounts, despite any til ting of the seed dril l from side to s ide, or

the driving direction. The feeding equipment is manufactured of corrosion-resistant materials. The bottom flap

adjustment lever under the feed rollers is in the cente r of the rear of the m achine, see Figs. 2 0 and 24. For

sowing small seeds, the power transmission ratio can be adjusted by turning the power transmission cassette,

see Figs. 22 and 23.

Figure 20. Structure of seed feeding equipment.

The f eed amount can be changed by adjusti ng the feed rollers mounted on the feeding shaft sideways in

relation to the feed c ham bers, such that this c hanges t he effec tive width of the f eed roller s. Adjustm ents are

made on the left side of the machine with a hand-wheel, see Fig. 21.

Figure 21. Feed adjustment hand-wheel.

Page 21

21

The hand-wheel is lock ed with a plas t ic le ver on which is also marked the main feed scale, 0-10. T he i nterval

between numbers equals a single rotation of the hand-wheel. The outside of the hand-wheel is m arked with

10 locking doors, labeled 0-9. Using these allows 100 dif ferent adjustment positions to be genera ted. W ith

small seed transmission (cassette position II, see Fig. 23) 100 feeding adjustment positions can be generated

in the same way from the sm aller rotation num ber area. T he m ain sc ale value is read f rom the inner edg e of

the hand-wheel.

Rotating the hand-wheel counter-clockwise increases the feed. When the des ired seed sowing amount is

known from the sowing table located inside the machine cover (or from this manual, see Fig. 25), the instructed

feeding adjustment pos ition can then be seen, see Section 11. Note the used power transmiss ion cassette

position, see Figs. 22 and 23.

The hand-wheel should always be adjusted so that the desired adjustment position is always

approached from a greater adjustment position. If the original adjustment position is smaller than

desired, the hand-wheel should be rotated counter-clockwise 1/2-1 times beyond the intended

adjustment, and then rotated backwards to the desired adjustment position.

After this, the adj ustment locking le ver is i nserted i nto a notch on t he hand-wheel, which then lock s both the

wheel and lever. Note that the adjustment position given in the seeding table is for reference only - the actual

feed amount will change betwee n different seed b atches. In order to determine actual feed amounts and

obtain an objectiv e value, you should always perform a calibration or field test, see Sections 12-13

below.

If dirt accumulates on the feeding devic e or seed characteristics change, i.e. be cause of the seed dressing

function, the actual feed a mount may change significantly from its original value. We recommend c leaning a s

needed, but at least on a daily basis. Rollers can be cleane d by adjusting th e feed amount to zero and then

again to the desir ed a djustm ent val ue. In such cases t he pr evious ly stat ed adj ust m ent rule sh ould be k ept i n

mind - i.e. rotate first 1/2-1 times beyond the desired adjustment value. The real feed amount can be checked

by repeating the calibration test.

C

AUTION! THE Hand-wheel must not be forced to a zero-position. Simultaneous rotation of

the feeding axis will ease the adjustment.

C

AUTION! the maximum speed when sowing large seeds such as peas and beans is 6-7

km/h. Ensure that the seed tubes do not become blocked. Blockages can cause damage

to the tramline device.

Seed feeding device speed range selection using the power transmission cassette

The rotation speed of JC seed dri ll seed feeding devi ces in relation to the drivin g speed can be selected b y

rotating the power transmission cassette. Setting I shown in Fig. 22, where the word ”GRAIN” is on the visible

side, provides a higher rotation speed, which is suitable for sowing normal-sized seeds. Rotating the cassette,

see Fig. 23, achieves 80–90% slower speed II, suitable for small seed sowing.

Figure 22. Power transmissi on cass et te

I = GRAIN.

Figure 23. II = SMALL SEED.

Page 22

22

Rotating the power transmission cassette between positions I and II

See Figs. 22 and 23. Remove the ring pins and pull the cassette from its shaft. Rotate the cassette

so that it is in a backward positio n to the same cassette sle eves, with a different side exposed.

Never turn the cassette upside down, i.e. so that the shaft and cassette sleeves switch places. The

selected setting (I or II) is marked on the visible side of the cassette cov er. The position shown in

Fig. 23 allows very small seed amounts, i.e. rapeseed 5 kg/ha, to be sown.

Bottom flaps

Feed accuracy is dependent on the appropriate di stance between the bottom fla p and roll er feeder .

It is important that the bottom flaps are in the correct position, and that they are not adjusted

following a calibration test without repeating the calibration test. Bottom flaps are flexible, in case

any external foreign object protrudes between the bottom flap and feed roller.

Figure 24. Bottom flap adjustment lever, seed.

Adjustment position 4 of the bottom f laps is used only when seeding es pecially lar ge seeds (e. g. certain

canned peas). Note that in position 4 the f eed amount increases when drivin g uph il l.

Caution! The seed can flow out of the container freely when the bottom flap lever is

moved below past the scale.

10. Fertilizer feeding equipment and adjustments

Overview

On the m achine, fertilizer feed chambers make up half the number of the see d feed chambers. Feed

amount adjustments are made by turni ng the feed r ollers mounted on the ferti lizer feed axis s ideways in

relation to the feed c hambers. Adjustment s are made using a hand-wheel on the left side of the machine.

Electrical adjustment is also available as an option.

The feed chambers are located at the bottom of the containers. This solution provides an almost standard

seed amount despite any tilting of the s eed drill from s ide to side, or the dri ving direction. The feed is a

groove-feed type, in which the feed bodies are called feed rollers, see Fig. 28. The feed rollers are equipped

with a helica l thread and are made of plastic. The bottom f laps under the f eed rollers are adj ustable, b y

means of an adjustment lever in the center of the front end of the machine, see Fig. 26. The entire fertilizer

feeding machine is manufactured of corrosion-resistant materials. The fertilizer container enables the

application of all types of granular f ertilizer. The use of powder ed fertilizers should be av oided. A mix ing

shaft is available as an option.

Adjustment instructions for the bottom flap

adjustment lever:

Seed type Adjustment

Small seeds, i.e. rapeseed

Slot 1

Ordinary seeds, grain

Slot 2

Large seeds, i.e. pea

Slot 3

Particularly large seeds

Slot 3 - 4

Granular fertilizer

Slot 2

Page 23

23

Figure 25. Seeding table and usage examples.

Page 24

24

Fertilizer feed amount adjustment

The feed amount is adjus ted using the hand-wheel on the left side of the m achine (Fig. 21). The handwheel is locked with a plastic com ponent on whic h can also be found the main feed scale. The feed value

is read from the part of the scale that is on the inner edge of the hand-wheel. Decimal-step feed adjustment

can be read from the scale on the hand-wheel cover, which is located at the locking lever slots.

The hand-wheel adj ustment range is 10 rotations, with ten loc king slots on the wheel cir cumference for

each rotation. This means that the feed has 100 different adjustment values.

Caution! In order to adjust the feed, the plastic main scale lever must be pr essed

towards the machine side in the direction of the arrow and pressed inw ard so as to

rotate 90 degrees forward when releasing the hand-wheel lock.

After adjustment, the lever should be returned to its locked position in the

handwheel slot.

Rotating the hand-wheel counter-clockwise increases the feed. When the desired fertilizer sowing amount

is known, the sowing tabl e located inside the machine or the so wing table in this m anual, see Fig. 25,

provides a rated feeding adjustment position.

The hand-wheel should al wa ys be adjus t ed s o that t he des ired a dj us tment position is alwa ys appro ac hed

from a greater adjus tment position. If the original adj ustment position is smaller than des ired, the handwheel should be rotate d c o unter -c lock wise 1/2-1 times beyond the inten ded adj ustment, and then rot ate d

backwards to the desired adjustment position.

After this, the adjustm ent locking lever is ins erted into a notc h on the hand-wheel, which then lock s both

the wheel and lever. Note that the adjustment position given in the seeding table is for reference only - the

actual feed amount will change bet ween diff erent seed batch es. A calibration test must be carr ied out in

order to determine the actual feed amount.

Figure 26. Bottom flap adjustment lever,

fertilizer.

Figure 27. Fertilizer feed chain wheel.

The nor mal positio n of the bottom flap is slot 2. Slot 1 can also be use d for ver y small grained fertilizers

(granular size 1-2.5 mm).

Caution! The fertiliz er may flow out of the container if the bottom flap adjustment

lever is moved past slot 2 on the scale.

If moist fertilizer enters the feeding dev ice, the feed rollers can b ecome blocked. Certa in fertilizer types

may also tend to become sticky. This can significantly impact the feed amount.

Page 25

25

Feed rollers can be cleaned by adju sting the feed amount to zero and again back to the desired adjustment

value. In this case, remember the adjustment rule above; first rotate 1/2-1 times past the desired value and

after this back to the corr ect value. Seed tabl e instructions and calibration test perform ance instructions

are given below.

The fertilizer feeding device can be turned off by removing the ring pin from the fertili zer feed shaft

end on the right side of the machine, see Fig. 27.

Figure 28. Fertilizer feeding device.

11. Sowing table examples

General

The sowing table sho wn in Figure 25 gi ves three different use sowing examples.

Note that the sowing amount indicated in the sowing table is for reference only. The actual sowing amount

will depend on the characteristics of the seed used, whi ch will vary significantly based on year and type.

Sowing amounts must be check ed with a calibration tes t, the performance of which is explained later in

Sections 12 and 13.

Seed feed adjustment example for sowing grain

Case 1 To sow oats at 215 kg/ha

The correct bottom flap lev er adj ustment position is noted i n the sowing table. The slot position is

”2”

Select the label "oats"

The machine power transmission cassette is set to "I"

Start from the left margin table along the line 215 kg/ha

Move horizontally to the part where the line crosses the descriptor "oats"

From the intersection, proceed directly down to the lowest scale. The adjustment value is 6.9, and therefore

between 6 and 7 on the main scale. Slot ”9” should then be selected on the circumference scale. Lock this

to 6.9.

Page 26

26

Adjustment example for sowing rapeseed

Case 2 To sow rapeseed at approx. 11 kg/ha

Note that the corr ect p ositi on of the bottom flaps is defined as "1 " in the upper ri ght cor ner of t he

sowing table

Review the small sowing table inserted into the upper left-hand corner of the table

Identify your starting point in the left margin of the small sowing table, at 11 kg/ha

Move horizontally to the right along the 11 kg/ha line to where it intersects with "rapeseed"

Move vertically down to the sub-scale, where it can be seen t hat the c orrec t adj ustm ent value o n

the main scale is "1”, and circumference "4". Then rotate the hand-wheel 1.4 times from zero

Note the l abel "transmis sion II” in the upper left-hand corner of the sm all sowing table. In power

transmission, the small seed setting must therefore be used, meaning that the cas sette m ust

be rotated so that transmission code "II" is visible, and the power transmission cassette is installed

according to Fig. 23, i.e. t he rotation speed is in the slo wer position, with the upper side of the

cassette connected to the shaft further behind.

Adjustment example, fertilizer side

Case 3 To sow NPK mixed fertilizer at 410 kg/ha

Note that the adjustment of the bottom flaps for granular fertilizer in the upper right-hand corner of

the sowing table is "2"

Start from the left margin of the large sowing table and move to "410 kg/ha"

Proceed horizontally along the 410 kg/ha line to the right to where this intersects with the line with

descriptor "granular fertilizer"

Move vertically down from the intersection to the lowest scale, where it can be seen that the main

scale reading set on t he adjustment wheel locking le ver should be "4". Similarly, the adj ustment

wheel adjustment value must be ”9”.

Caution! Calibration tests should be carried out after any adjust ments in order to

ensure the correct seed and fertilizer amounts. Calibration test rotation amounts

dependent on machine type can be seen in the upper left-hand corner of the sowing

table, in the "Calibration test" section.

12. Calibration test

General

As the adjustment val ues provided in t he sowing table ar e for reference only, a calibration t est must be

performed before starting sowing. Before starting the calibration test, the machine must be adjusted

according to the sowing table.

Caution! Dressed and undressed seeds may require completely different feed

adjustment values in order to achieve the desired feed value. If a seed dressing

device is used on the fertilizer drill, the correct feed adjustment must be ensured and

final adjustments should only be performed as r equired on the machine after the first

filling, once an approx. 2 000 m stretch h as been sown. Note also that different seed

dressing agents will also affect the feed amounts in different ways, and ca n have a

reducing effect of up to 20% compared to undressed se ed!

Ensure that dressing agents are not applied to seeds which are not meant to be

dressed. I.e. sprouti ng rapeseed deterio rates easily. In such cases, we recommen d

fully removing the dressing containers from the seed drill container.

Page 27

27

Before starting the calibration test, check:

The power transmission cassette setting, I or II (Figs. 22 and 23)

The position of the bottom flaps (seed and fertilizer)

The seed feed amount set on the hand-wheel

The fertilizer feed amount set on the hand-wheel

That the cover doors on both fertilizer and seed sides are fully open

That there is seed and fertilizer in the containers

That the tire track device is not active

The machine is slightl y lifted from the ground, meanin g that the feed equipment can be rotated with the

machine ground-wheel, see Fig. 29. Rotation is achie ved with a c rank pin located und er the co ver on the

right side of the machine. Note that the machine must be balanced horizontally.

Tume JC drills are fitted with calibration test troughs as standard on both the seed and fertilizer sides, see

Fig. 30. You can retain bot h troughs in position d uring sowing. Ho wever, always remember to empty the

troughs of dust etc before carrying out any calibration test.

The machine tubes (for both seed and fertilizer) must be set to the calibration test position simultaneously.

This is done using the handle on the right side of the machine, see Fig. 30 position A.

The calibration test can be carried out in 3 different ways:

Simultaneously for both the seed and fertilizer, when the power transmission is in sowing position,

in other words the ring pin on the fertilizer feed shaft is in the inner hole, see Fig. 27.

Separately for seed , then the r ing pi n is rem oved from fertilizer shaf t, see Fig. 27. Remember to

put it back.

Separately for fertilizer, in whic h case th e ring pin is i n the inner hole, see Fig. 2 7, and the power

transmission cassette is removed, see Fig. 30. Remember to replace the cassette following the

calibration test.

Figure 29. Calibration test.

Page 28

28

Figure 30. Using the seed side calibration test system

Simultaneous calibration test for fertilizer and seed.

Place the machine tubes in the calibration test position. Rotate the crank a few times in order to fill the feed

chambers. Then check that each feeding de vice contains seed and f ertilizer. Following this, empty the

calibration test trough carefully.

Rotate the crank the number of times mentioned for the machine type in question in the sowing table. The

sowing table can be foun d on the inner surf ace of the lef t side of the m achine. The rotation speed m ust

correspond approximately to the driving speed used.

Weigh the seed and fertili zer that has entered the test sowing troughs. If the calibration test was carried

out with a number of rounds equivalent to an acre (reference number is given in table), the sowing amount

per hectare can be determined by multiplying the weighing results by 100.

The obtained results may differ from the desired results because of ordinary variations in fertilizer and seed

batches:

If the results obtained differ excessively from the desired f eed res ults , the feed am ount s must be

made more accurate by rotating the hand-wheel

The feed adjustment must be increased or reduced by as many percentage points as the weighed

calibration test amount exceeded or fell below the desired level

The above can be presented as follows:

Desired feed amount

New feed adjustment value = x (present adjustment value)

Observed feed amount

If we then insert sample figures into the formula above:

Desired fertilizer feed amount = 650 kg/ha

Feed amount based on calibration test = 600 kg/ha

Hand-wheel adjustment used in calibration test = 6.5

Corrected value according to formula = (650/600) x 6.5 = 7.0

Caution! The given calculation formula is intended to simplify the determination of

correct adjustment. The end result must however always be checked with a

calibration or field test if an accurate end-result is desired!

Caution! The calculation example given above is for reference only, and is only

intended to demonstrate the use of the calculation formula.

Page 29

29

After performing the calibration test and adjustments, r emember to return the funnel shelves to so wing

position B, see Fig. 30. Also remember to replace the crank pin in position and close the protective covers.

Performing the fertilizer side calibration test:

Remove the power transmission cassette, see Fig. 22.

Check that the fertilizer side bottom flaps are adjusted to the correct position, usually slot 2

Check, that all closing doors are open. Open these if necessary

Select the desired feed amount from the sowing table by adjusting the hand-wheel

Rotate the ground-wheel several times so that the fertilizer chambers fill and the fertilizer feed from

the test sowing chambers stabilises

Set an empty, clean calibration test trough in position

Perform a calibration tes t by rotating the gro und-wheel the number of times stated in the sowing

table

Weigh the fertilizer collected in the trough. Use an accurate scale!

If the result does not match the desired feed amount, correct the adjustment with the hand-wheel.

Familiarize yourself with the method given for calculating probable corrections.

Perform a new calibration test to ensure that the feed amount is correct.

Remove the crank pin and return it to its position in the right side cover

Return the power transmission cassette to its position

If the machine is equipped with an TC+ on-board computer providing fertilizer remote control,

please refer to the additional instructions in the TC manual.

Clean the fertilizer side feed rollers by occasionally rotating the hand-wheel so that the feed is fully

closed. This will enable you to ensure correct feed amounts during calibration tests and during

actual sowing.

When returning the feed ad jus tment bac k t o the value in pr actic e or o ther wise c ha nging the feed

amount, always approach the desired adjustment value from the same direction.

Carrying out a calibration test only on the seed side

It is quite normal to perform the fertilizer side calibration tes t less often than the seed s ide test. For the

duration of the seed-side only calibration test, the power transmission to the fertilizer side should be

switched to idle so that no fertilizer is wasted, see Fig. 27. The fertilizer side is switched to idle by removing

the ring pin shown in the figure.

Caution! If you perform a seed side calibration only and for this reason remove the

pin from the chain-wheel located on the fertilizer shaft, BE SURE TO REMEMBER

TO REPLACE THE PIN IN POSITION BEFORE STARTING SOWING.

FORGETFULNESS WILL HINDER THE FULL FUNCTION OF THE FERTILIZER

FEED!

Instructions for improving sowing accuracy

Calibration test values given in the sowing table are for reference only. Their accuracy depends on ground

quality, cultivation depth, tire pressure, and tire manufacturing tolerances.

The sowing accuracy can be however improved by doing a tow test under sowing conditions. The tow test

is performed by towing the m achine over the distanc e require d to sow one acr e under sowing cond itions

and by simultaneously reducing the ground-wheel rotations. Record the value obtained and use this when

carrying out calibration tests.

If the value measured differs widely from the seeding table value, carry out a new test. In the table below,

the distance W used in the tow test refers to differ ent working widths, eac h matchin g a one-acre s owing

area:

L = 33.3 m when working width = 3.0 m

L = 25.0 m when working width = 4.0 m

Check the area meter accuracy when performing the measurement.

Page 30

30

13. Field test

Field tests are by far the most secure testing method for feed amounts. Performing a field test on a field to

be sown as well as on an already upturned seed bed establishes conditions which matc h sowing very

accurately. Field tests c an be performed for both the seed and fertilizer.

To perform the field test:

Adjust the machine and configure it according to instructions

Measure the driving distance required to sow one acre, dependent on the machine type:

JC 3000

33.3 m

JC 4000

25.0 m

Drive outside of the tes t le n gth f or approx. 10 meters with the machine in working position so th at

each feed chamber is sowing seeds

Empty the contents of the test sowing trough into the container

Drive the distance in accordance with the sowing table above with the machine lowered to sowing

position

Weigh the seeds in the tes t sowing trough. Multiply the weighing results by 100 to obtain the

amount of seed in kg/ha

If tuning adjustments are required, perform the calibration test as described

If the machine is equipped with TC, make sure that the tir e track function is not switched on while

carrying out the test!

14. Fertilizer application depth adj ustment

Overview

The fertilizer application depth can be adjus ted stepless, fr om surf ace application to a depth of approx. 8

cm. Ordinary fertilizer depth for grain plants is 6-7 cm. The depth can be adjusted by changing the closing

moment of the hydraulic valve on the tire support arm, see Fig. 31, and by modifying the length of the towbar push-bar using the adj ustment screw, so that the machine alwa ys travels in a horizontall y balanced

manner in the direction of travel.

Figure 31. Fertilizer depth adjustment.

Page 31

31

Changing the place of pin 1, see Fi g. 31, will produce a ch ange in closing m om ent. The scal e above the

slot, 10-5-0, is equi valent t o t h e a pp licat io n d ept h i n centimeters. Pin 2 lim its the machine lifting heigh t by

closing the valve when the machine is lifted high enough.

The tow-bar (meaning the tractor tow-bar he ight) is adjusted so that the machine travels in its sowing

position horizontally. The length of the towing device push-bar can also be adjusted. If the m achine is

equipped with a tow-bar with a h ydraulic push-bar (recommended, for ex ample with rollers), t his can be

used to adjust the fertilizer depth. The cylinder in question is actuated by a separate hydraulic valve on the

tractor. This function is in completely independent of the machine’s raising/lower i ng cir cuit. Increasing the

push-bar length raises the fertilizer coulters correspondingly. Adjustments of this kind can be n ecessary,

for example on soft ground. It is recommended not to raise the roller, but rather to adjust it using the pushbar.

Adjusting the fertilizer application depth

Adjustments must be per formed in the fie ld or on sof t ground in order to enable the fertilizer coulters t o

press into the ground. A dj u s t pin 1, see Fig. 31, and center this on the desir e d p l acement level (along the

10-5-0 cm scale).

Lower the machine while driving forward. Stop the tractor once the machine has lowered. Do not allow the

tractor to move backwards, so as not to block the coulters. Check the correct position of the machine. The

machine must be horizontal. Adjust as required using the tow-bar push-bar adjustment screw or by raising

or lowering the tractor tow-bars.

If the machine work ing position is in th e field direction and the towing device push-bar does not r equire

adjustment, the fertilizer application depth can be measured. Application depth is measured from the

sowing track by digging up vis ibl e fertilizer grains. D uri ng the m eas ur ement, you can also define the seed

sowing depth, see Section 15.

If the fertilizer ap plication depth is incorrect, cha nge the adj ustment and perform a new test. Application

depth changes depend somewhat on t he fill of the m achine, ground type etc. T he effect of these factors

can be reduced by measuring application depths under differ ent c on dit ions an d b y a dj us tin g t he machine

application depth according to an average value. Variations of a few centimetres in the fertilizer application

depth are permissible without having a major impact on the crop.

15. Adjusting the sowing depth

General

Correct sowing depth is one of the most important factors influencing sprouting. In a JC-type

machine, sowing is carried out at the moist bottom of the tillage layer. The best guarantee of

successful sowing is co rrectly performed tillage. T illage must be performed in a properly timed

manner such that the crumb size in the till age layer is adequatel y refined. Excessive tillage can

cause a risk of smudging or crusting.

Tillage should be performed to the intended sowing depth. Sowing depths should be selecte d based on

the sowed plant a nd ground humidity condit ions. With small seeds, the correct sowing depth is 1-3 cm

based on the sowed plan t and ground humidity condit ions. The sowing depth bet ween grains may vary

between 2.5-5 cm. As wit h all plants, it is esse ntial that sowing is performed on humid, level ground in

order to ensure sprouting. Become acquainted with the conditions appropriate for different plants and their

sowing depths with the help of guides and study materials.

The tractor must be equipped with wheels suita ble to ens ure that the surface pressure remains low enough

to avoid compress ion or tire grooves. The use of addi tional devices to conde nse the area of the roller or

between the tractor wheels is recommended. This will ensure even sprouting across the entire working

width.

Page 32

32

Driving speeds must be adapted to conditions. At excessively high driving speeds, the coulters may bounce

and rise from the set sowing depth. Sufficient coulter spring loading will secure the coulters to the ground.

On light and moist ter rains, the coulter working depth can be limited by using disc coulters, which are

equipped with a limiting cup on the disc. In light t illage conditions, where m anaging tillage depth may

already cause pro blems, disc coulters may also be a suitable choice to prevent excessively deep sowing.

Adequate moisture sh ould be ens ured so that the see ds are not planted in a ground la yer which is either

too dry or too loose.

Setting the sowing depth

As noted above, the so wing dept h is to a m ajor degr ee determ ined b y tillage d epth. Changi ng the coulter

spring loading can significantly im pact the sowing dep th. On light grounds an d when sowing at shallow

depths, the spring loading should be kept low, and increased on more solid terrain. Correct coulter

weighting must always be ens ured under pract ical conditio ns and the seed plac ement in the tillage la yer

must be observed.

The coulter spring load can be adjusted either coulter-specifically or by using so-called central adjustment.

Coulter loads against the ground can be adjusted between 2 and 20 kg. The respective operating depth is

dependent on the coulter type, tillage a nd ground t ype. Sowing de pths should alwa ys be check ed under

actual conditions, and it should be ensured that the seeds are sown into a moist ground layer.

Sowing depth adjustm ent can be performed mos t convenientl y by means of the main adjustment s crew,

located in the center of the rear of the machine, see Fig. 32. Rotating the crank clockwise will increase the

coulter weighting. The storage location for the adjustment crank is inside the frame tube, see Fig. 5 (arrow).

The sowing depth can also be adjusted coulter-specifically. To do this, move the weighting spring extension

chain on the retaining hook on the front of the machine.

Adjusting the chain, e. g. 1-2 loops tighter, is usually required to com pensate for tractor tire track s. The

coulter springs of TUME drills are designed in such a way that the coulter height has no significant impact

on coulter weig hti ng. T her e f or e, an y ch ange in placement depth will not signif icant l y impact the weighting

of the coulters.

Figure 32. Main adjustment screw.

Page 33

33

16. Harrow adjustment

Figure 33. Harrow.

Basic adjustments to the harrow tines in terms of vertical direction and working width are performed at the

original manufactur er. It is however useful to secure these adjustments during commissioning and, f or

example, annually the start of seasonal us e. T he a ngl e of the tines mus t al wa ys b e adj uste d ac c or ding to

working conditions. The support chain adjustments must then be checked periodically, and it must in

particular be ensur ed that the harrow is raised suf ficiently high when the machine is rais ed to a vertical

position. Adjustments are described below.

The operating depth of the tines can be adjusted by adjusting the tines vertically.

Vertical adjustm ents are mainly perform ed by changing the lower a ngle of the harrow, by adjusting th e

limiting screws (see “A”, Fig. 33). The operating height can also be changed by adjusting the tine mounting

bar installation he ight in relation to their mounting arms (see “B”, Fig. 33). The adjustment is made by

changing the position of the U-holders on the square tube of the arm.

The harrow tines can be adjust ed by changing the adjus tment of the limiting sc rews (see “ C”, Fig. 33).

Especially where large amounts of plant waste can b e found on the ground, the tines s hould be a djusted

to a gentle “surrendering" angle. On rigid terr ains where basic til lage is carried out by plowin g, steeper

angles can be used in order to obtain better ground penetration.

Support chain adjustment must be sufficiently t ight so that the harrow tines cannot touch the ground

when the machine is raised. Rough adjustments to the support chain can be made by attaching the spring

to a suitable link in the support c hain. Fine tuning c an then be done b y selecting the most suitable of the

two holes at each end of the support chain.

Because the support chain is fitted with a spring, adequate adjustments can be made to lighten the harrow

in its working position.

Caution! Reversing the machine when the harrow tines are in contact with the ground is

prohibited. Reversing with the harrow in an excessively low position may damage the

harrow and machine tires. Ensure that the harrow support chains are suffic iently a djusted!

Page 34

34

17. Fertilizer coulters

Figure 34. Fertilizer coulter.

Figure 35. Laser fertilizer coulter.

The fertilizer coulters supplied as stand ard are very narrow and operate at an a lmost perpendicular

angle to the ground surface. For these reaso ns, the coulters do not noticeably bring moist clods of

earth to the surface. The blade of the fertilizer coulter can be dropped down in order to compensate

for wear, see Fig. 34. The blade has severa l mounting holes. As required, rem ove the hexagonal

screw and adjust the worn blade one hole downwards. Lock again with the hexagonal screw.

If the wing part “A” has wor n th in, it must be changed. A weldable c ons umable part is avai lable - as

for more information from your distributor or from the original manufacturer.

JC Laser coulters have single-disc fertili zer coulters, which ha ve the advantage of not becoming

blocked, such as in light tillage conditions. One requirement for the trouble-free function of the laserfertilizer coulter is th at the gap between the scraper and t he disc is so sm all as possible. T he disc

can touch lightly to the scraper while rotating.

18. Seed coulters

Seed coulters consist of a coulter tube and tip part. The major seed coulter types include drag coulters and

disc coulters. In addition to the above, the JC coulter range also includes a wing coulter. All of these coulter

types incorporate the same tub e component. Chan ging the tip is a relatively fast task, which means that

the machine can be adjusted to a variety of different conditions as required by acquiring the required coulter

set.

Drag coulters can be used under mos t conditions . T he m ost suitable a pplicat ions are f ound in cl ay areas

where plowing is the f orm of basic tillage. Because of its flexibility, the coulter is not likely to becom e

blocked. Drag coulters are also availa bl e fitted with an aluminum ox ide or c er am ic tip, which inc re as es tip

durability approximately ten-fold compared to a cast tip.

Disc plates are recommended for conditions where plant waste occurs in significant amounts. Disc

coulters are also suitable for general use (i.e. minimal tillage and cultivation without plow).

Wing coulters sow the seeds across an approx. 70 mm wide swath. Wing coulters usually provide a larger

crop than row sowing, espec ially on m oist an d irrigate d grounds with f avorable c onditions . Wing coulters

are not suited to crusted ground types or conditions where there is plenty of plant waste in the tillage layer.

Compensation for

blade wear

Wing A

Page 35

35

Figure 36. Drag, disc and wing coulters.

19. Area meter

Electric area meters are fitted to TUME drills as standard, and come with large-sized numbering and

convenient location, so that the tractor driver can easily read the meter during operations.

When the area which can be so wn with a single full container is known, the meter can eas ily provide a

indication for refill timings, by adding the las t f i ll ar ea measurement to the measurement of the area to be

sown with a full container.

The numbers on the left side of the c e nter line of the area meter display the full

hectares, while those on the right display tenths and hundreds.

Figure 37. Area meter.

Area meter instructions