Page 1

INSTALLATION INSTRUCTIONS

QC CHECK

VISUAL INSPECTION

BEARING INSPECTION

SLIDE TEST

DRAWER STOP

RUBBER SEAL

CORRECT KEY (& COMBO

SETTING)

PUSHBUTTON LOCK TEST

COMBO LOCK TEST (IF INCL)

LATCH TEST

SHIPPING PACKAGE

DIVIDERS (IF INCL)

TRIM KIT (IF INCL)

MOUNTING KITS (IF INCL)

VERIFY CROSS BRACES

UNLOCKED WITH KEY INSIDE

QC INSPECTOR INITIALS ____________

Rear Cargo Drawer – Part #167

Please read and fill out the enclosed warranty registration card to activate

your warranty.

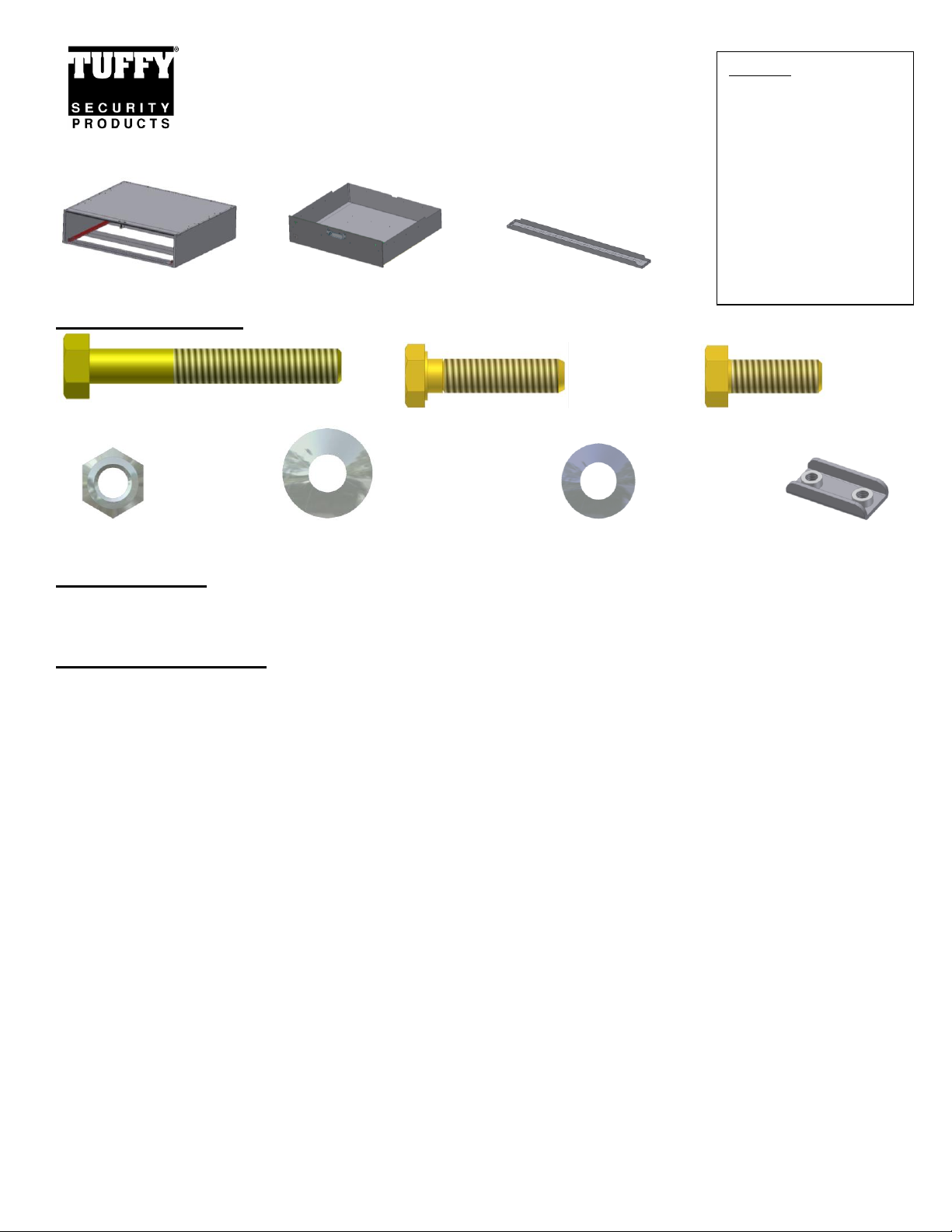

Enclosure Drawer #8 (2) Mounting Brackets

Shipping Package

#5.2.1 (8) 5/16-18x2 1/4” Bolts #5.2.6 (8) 5/16-18x1 ¼” Bolts #5.2.4 (8) 5/16-18x7/8” Bolts

#5.2.2 (8) 5/16 Nuts #5.2.5 (8) 5/16 Wide OD Washers #5.2.3 (16) 5/16 Narrow OD Washers #14 (4) Clamps

Tools required

½” Shallow socket with a long extension and a ratchet (Universal joint also helps)

½” Wrench

Mounting Directions

WARNING! This drawer is rated to hold a maximum of 250# evenly distributed. The enclosure is rated to hold

250# on top evenly distributed. This would include any dividers mounted in the drawer. Never stand or sit on the

Tuffy drawer or enclosure. The vehicle should not be operated with the drawer opened and not secured shut.

The drawer should not be operated/opened when not level. Keep hands clear of moving parts and pinch points

when maneuvering the drawer. Do not exceed the rated weight capacity for this product.

FOR SAFETY THE DRAWER REMOVAL REQUIRES AT LEAST (2) PEOPLE. THE DRAWER SHOULD ALWAYS BE

EMPTY BEFORE REMOVING IT. CONSTANT SUPPORT MUST BE APPLIED TO HOLD UP THE FRONT OF THE

DRAWER THROUGHOUT THE ENTIRE REMOVAL PROCESS SO IT DOES NOT CAUSE INJURY AND/OR DAMAGE.

1. Check the floor and wheel well panels of the vehicle for cubby holes containing important gear or require access in an

emergency (Jack, spare tire, spare tire access, fuses, etc.). If floor access is required make sure that it is exposed

and accessible through the opening in the bottom of the drawer enclosure when the drawer is removed. Remove and

relocate any inaccessible items as required.

2. Remove drawer from enclosure. Pull the drawer out until it stops. Lift up the front of the drawer and pull it out a few

inches further until the stop bolts on the drawer slides clear the rollers on the enclosure slide. Pull the drawer again

until it stops being sure to support the front of the drawer. Pivot the front of the drawer down and lift the rear end of

the drawer out so the rollers on the drawer slides pull free through the slots in the enclosure slides. Reverse steps to

install. (See Figure 1)

Page 1 of 4 – 10/13/2010 – Rev6/8/2011

Page 2

FIGURE 1

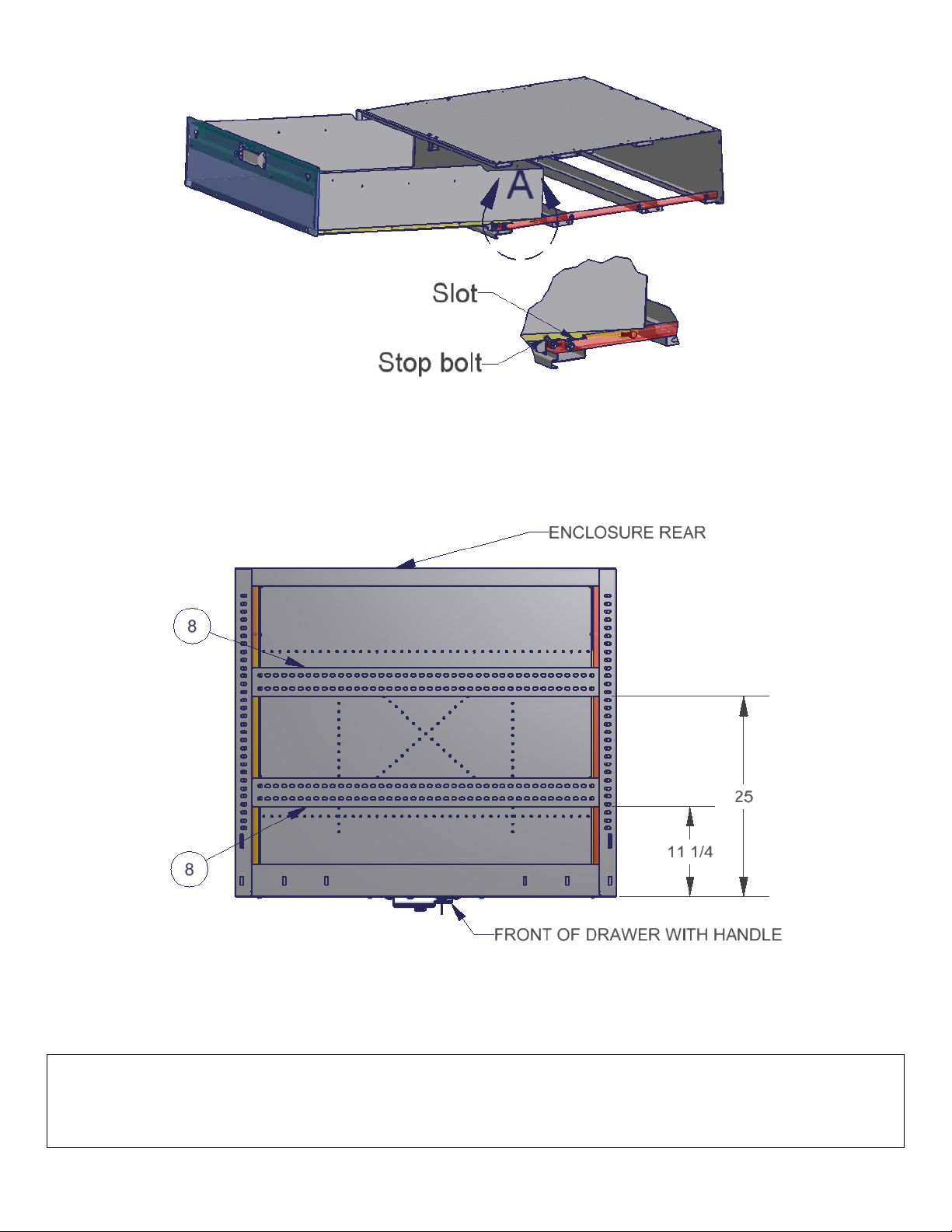

3. The drawer is shipped without the Mounting Brackets #8 installed due to the wide variety of mounting point locations

in different vehicles. Place the drawer enclosure in the vehicle in the desired mounting location and mark where the

#8 mounting brackets should be located. The #8 mounting brackets should be directly above the anchors used for the

seat mounts if available. Make sure the rear door of the vehicle shuts with the drawer installed and the seats function

properly. (See Figure 2 for the Chevy Tahoe standard mounting location)

FIGURE 2 (Chevy Tahoe standard mounting location shown, mounting bracket location varies by vehicle)

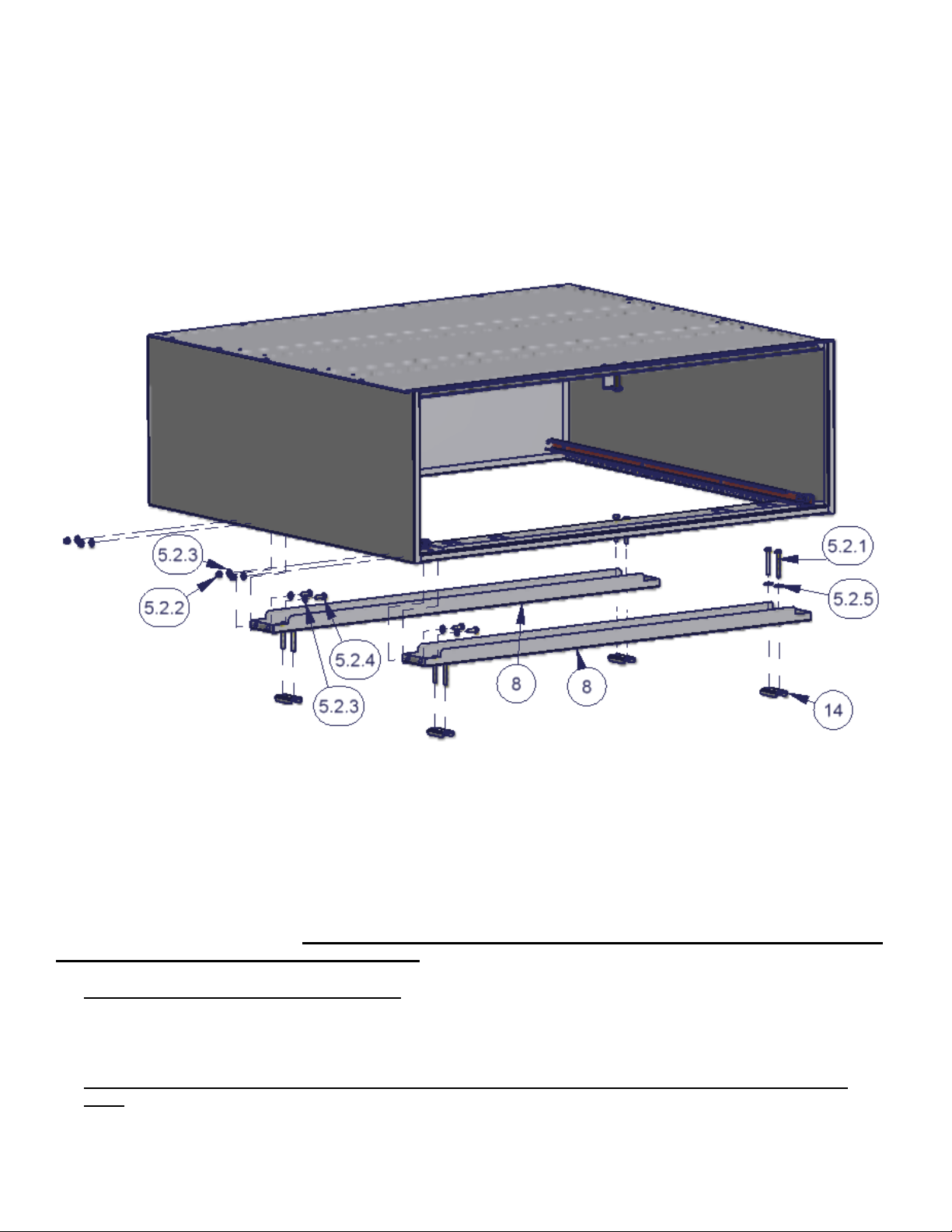

4. Remove the Enclosure from the vehicle and fasten the #8 Mounting Brackets to the enclosure with the #5.2.4 bolts,

#5.2.2 nuts and #5.2.3 washers. These bolts are difficult to reach; Use a ½” shallow socket with a long extension and

a ratchet (Universal joint also helps) and a ½” wrench on the other end. Unbolting the slide using a 7/16” wrench will

make things easier as well. (See Figure 3)

If the vehicle is not equipped with seat anchor points or the drawer requires additional mounting points you can drill 3/8”

holes in the floor aligned with holes in the #8 mounting brackets and fasten the drawer to the floor using the hardware

provided with the #14 clamps on the underside of the vehicle floor. Warning! Be sure there is nothing on the

underside of the vehicle floor which will be damaged when drilling. Most vehicles have a gas tank and gas lines

in that area.

Page 2 of 4 – 10/13/2010 – Rev6/8/2011

Page 3

5. With the enclosure placed in the desired mounting location insert the (4) #14 clamps on the underside of the seat

anchors in the vehicle floor and using a ½” socket, extension, and ratchet fasten them to the #8 mounting brackets

with the #5.2.1 Bolts and #5.2.5 Washers (#5.2.6 Bolts are a shorter length and may alternately be required for

mounting in some vehicles). Be sure the anchor point is completely enclosed between the Bolts and is “sandwiched”

between the #14 clamp and #8 mounting bracket and cannot slip out from behind it. Do not over tighten these bolts

or damage to the #8 mounting brackets will occur due to the necessary gap. (See Figure 3)

6. Insert the drawer and test the operation. Make sure there is clearance between the drawer handle and the rear

tailgate. Test to make sure that access to any important compartments in the floor or side panels are maintained.

FIGURE 3

ATTENTION:

FREQUENT LUBRICATION IS NECESSARY ON THE LOCKING SYSTEM

The pushbutton lock contains an “O” ring seal to protect the interior from dust and water. If this mechanism is not

lubricated regularly it will become difficult to operate and it may not return to its home position preventing the key from

operating the lock. If this happens simply pull up on the pushbutton to manually bring it back to its home position.

Lubricate the pushbutton with a light lubricant such as silicone spray. The pushbutton may have to be periodically

disassembled and cleaned.

Required Periodic maintenance: Failure to perform periodic maintenance can result in the loss of access inside

the security enclosure and failure of components.

Lubrication is required for all moving parts. The schedule will vary depending on the level of usage and

environmental conditions. Once a month is a good starting point. Be sure to lubricate all friction points

completely. Use high temperature lithium grease. Key lubrication points are shown on the illustration below

for the latch system with the optional pushbutton combination lock. Some lube points in the illustration will

not be present on other latch systems. (See figure 4)

If the latch handle is removed or has been bumped out of alignment it will need to be adjusted correctly

again. The gap shown between the knob and the stop is critical and can vary slightly. If the gap is too small

the knob cannot be turned enough to unlock the latch. If the gap is too large then the knob can be turned

past its stop point which trips the internal clutch and will not unlock the latch. Adjust the handle so the gap

Page 3 of 4 – 10/13/2010 – Rev6/8/2011

Page 4

is the largest possible initially then if the clutch is tripped move it in small increments until it unlatches

correctly. (See figure 5)

All fasteners should be checked to ensure they are not loose. The schedule will vary depending on the level

of usage, environmental conditions and typical vibration encountered. Once a month is a good starting

point. Loctite may need to be reapplied after extended periods of time.

Figure 4

Figure 5

Call (970) 564-1762 for Technical Support

Page 4 of 4 – 10/13/2010 – Rev6/8/2011

Loading...

Loading...