Page 1

A SSEMBLY INSTRUCTION MAN UAL

TABLE OF CONTENTS:

Introduction- Pg. 1

Assembly for TG-150- Fig. 1-71

Cable Mapping Diagram- Pg. 20

Cable Adjustments- Fig. 42, 65, Pg. 19

Exploded View Diagram- Pg. 22

Parts List- Pg. 23

Basic Exercise Chart- Pgs. 24-26

TG-150

Tuff Gym Series

A merica’s Premium Exercise Equipment

Revision Date 11-98

Revision Date 12-98

L 8’-0” W 6’-2” H 6’-5”

Page 2

Introduction

About the TUFF GYM SERIES

Congratulations on your new purchase of the. TG-150,

Tuff Gym Series unit.This gym is capable of a variety of

different exercises, as well as, smooth and user-friendly

adjustment features. In addition, this gym has been designed

to meet the needs and performance requirements for a

suitable home exercise machine. We hope you are

completely satisfied with this product and wish you many

years of enjoyment.

Tuff Stuff Equipment

Every Tuffstuff product has been built to precise quality

standards and has been carefully packaged to ensure that

damage will not occur during shipment. The limited lifetime

warranty and signature indicating final inspection which was

conducted by our line foreman, is an expression of our

confidence in the completeness, the materials, and

workmanship of this product.

Warranty

SEE WARRANTY REGISTRATION CARD

Registration Card

To avoid unnecessary delays in warranty parts and to

insure that a permanent record of your purchase is on file

with our factory, be sure to complete the warranty

registration card and send it to Task Industries today.

Safety Information

1) Familiarize yourself and others with the proper operation

and workout recommendations for each piece of Tuff Stuff

equipment prior to use.

2) Consult with your physician before beginning any

exercise program.

3) Use proper discretion when children are present.

4) Frayed or worn cables can be dangerous and may cause

injury. Periodically check these cables for any indication of

wear.

5) Inspect the TG-150 for any sign of parts or hardware

becoming loose.

6) Keep hands and limbs clear from weight stack and all

other moving parts.

Maintenance Information

1) Lubrication of all moving parts is essential to the longevity

and optimal performance of your TG-150. Initial lubrication

of some parts of your gym have been done at the factory, but

the weight stack guide rods must be lubricated at the time of

assembly. We recommend a clear aerosol, silicone or Teflon

spray.

Note: Do not use oil based lubricants as they will attract

dust,dirt, and grime and will eventually gum up and erode

bushings and sealed bearings.

2) All pulleys and bushings should be checked regularly for

signs of wear.

3) Check and adjust tension on cables periodically as it will

maintain proper anatomical function.

4) Periodically check all moving parts, upholstery and grips

for wear. If replacement is necessary, please contact your

local Tuff Stuff retailer or call our Customer Service

Department.

5) As needed, upholstery may be cleaned with a mild

solution of soap and water. Regular use of a vinyl treatment

will add to the life and appearance of your upholstery.

6) All chrome plated surfaces should be cleaned regularly

to prolong the life and luster of the finish. Wipe machine

down with a damp cloth and dry thoroughly each day. At

least once a week your chrome equipment should be

polished with a commercial grade or automotive type chrome

polish.

Tool Requirements

1) Two 3/4” Open-end wrenches

2) Two 9/16” Open-end wrenches

3) One rubber mallet hammer

4) One can Silicone Spray/ Teflon Spray Lubricant

5) Snap ring pliers

6) Hex Key 5/32” (Supplied)

7) Hex Key 3/16 (Supplied)

8) Windex or household glass cleaner

9) Multi-Purpose Grease

10)

Hardware Measurement Diagram

Specifications

1) Maximum Wt. Capacity

2) Total Machine Weight

3) Footprint (LWH)

Note: Due to continuing product improvements, specifications and designs are subject to change

without notice.

1

- 200 Lbs. Fixed

- 650 Lbs.

- See Front cover

TG-150 Tuff Gym Series

Page 3

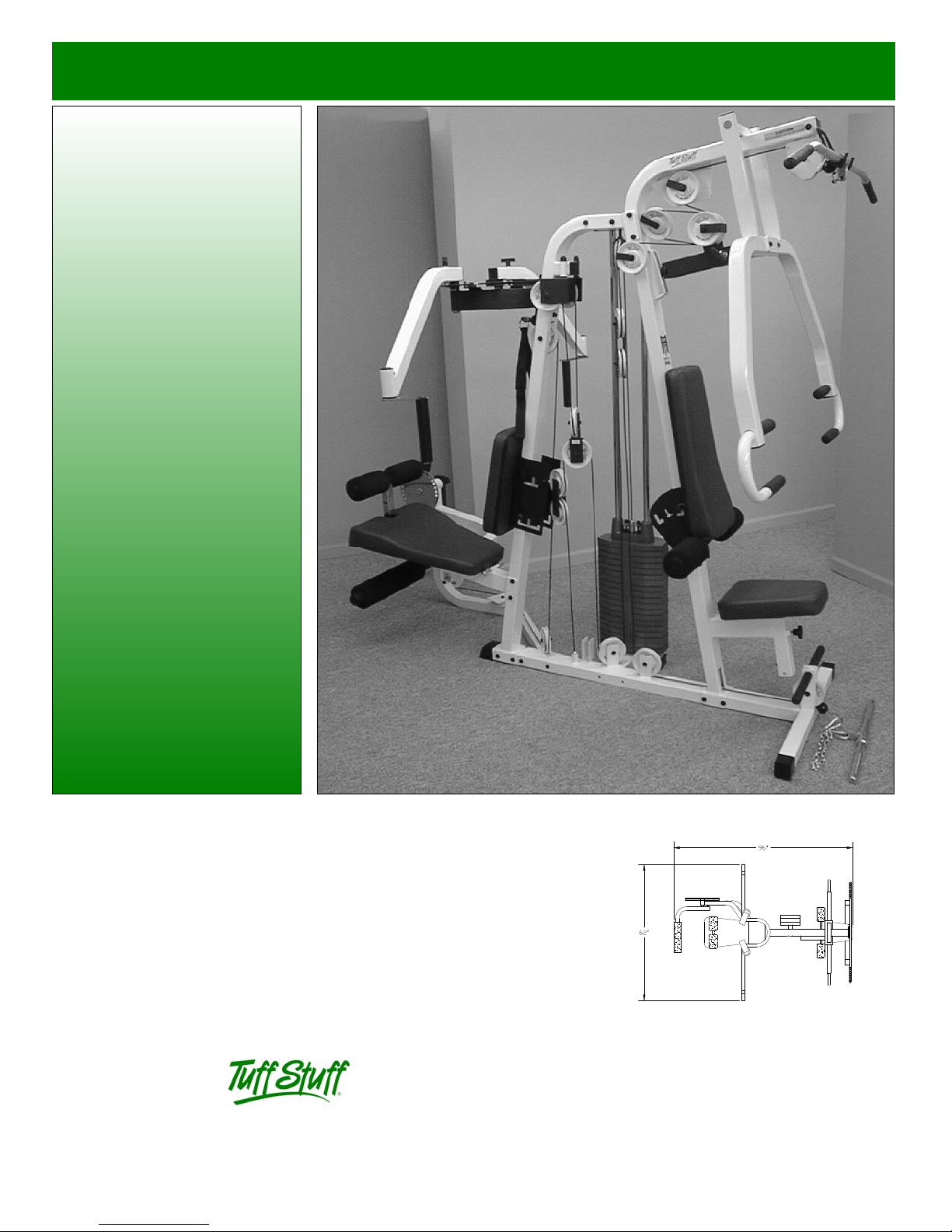

FIG. 1 On a flat surface, lay the Platform (#49) down as shown.

Note: When positioning the Platform (#49), consider the complete

area surface of the TG-150. Use the overhead view on the front page

for designing your layout before assembling. Next, insert two Plastic

End Caps w/groove Sq. 2” (#48) and one Plastic End Cap w/groove 2

X 3 (#50) onto the tube-ends of the Platform (#49), as shown above.

Next, insert two Plastic Insert Caps 2 X 3 (#100) into the Platform

(#49), as shown above. Now, insert two Hard Grips .875 X 8 (#47)

onto the tube-ends of the Platform (#49), as shown above in caption.

Note: Use windex or a household glass cleaner for easy insertion of

these grips, as shown above.

FIG. 2 Next, attach one Nylon Pulley 4 1/2 Rd. (#17-Shown with

arrow) to the Platform (#49) and secure it into place using one Hex

Head Cap Screw 3/8-16 X 2 (#67), two Flat Washer SAE 3/8 (#12) and

one Nylon Insert Jam Lock Nut 3/8-16 (#74). Next, attach three Nylon

Pulleys 4 1/2 Rd. (#17) to the Platform (#49), as shown above, and

them into place using three Hex Head Cap Screws 3/8-16 X 1 3/4

(#69), six Flat Washers SAE 3/8 (#12) and three Nylon Insert Jam

Lock Nuts 3/8-16 (#74). Note: Do not completely fasten the hardware

at this time, as it will be completely secured later in the assembly

process.

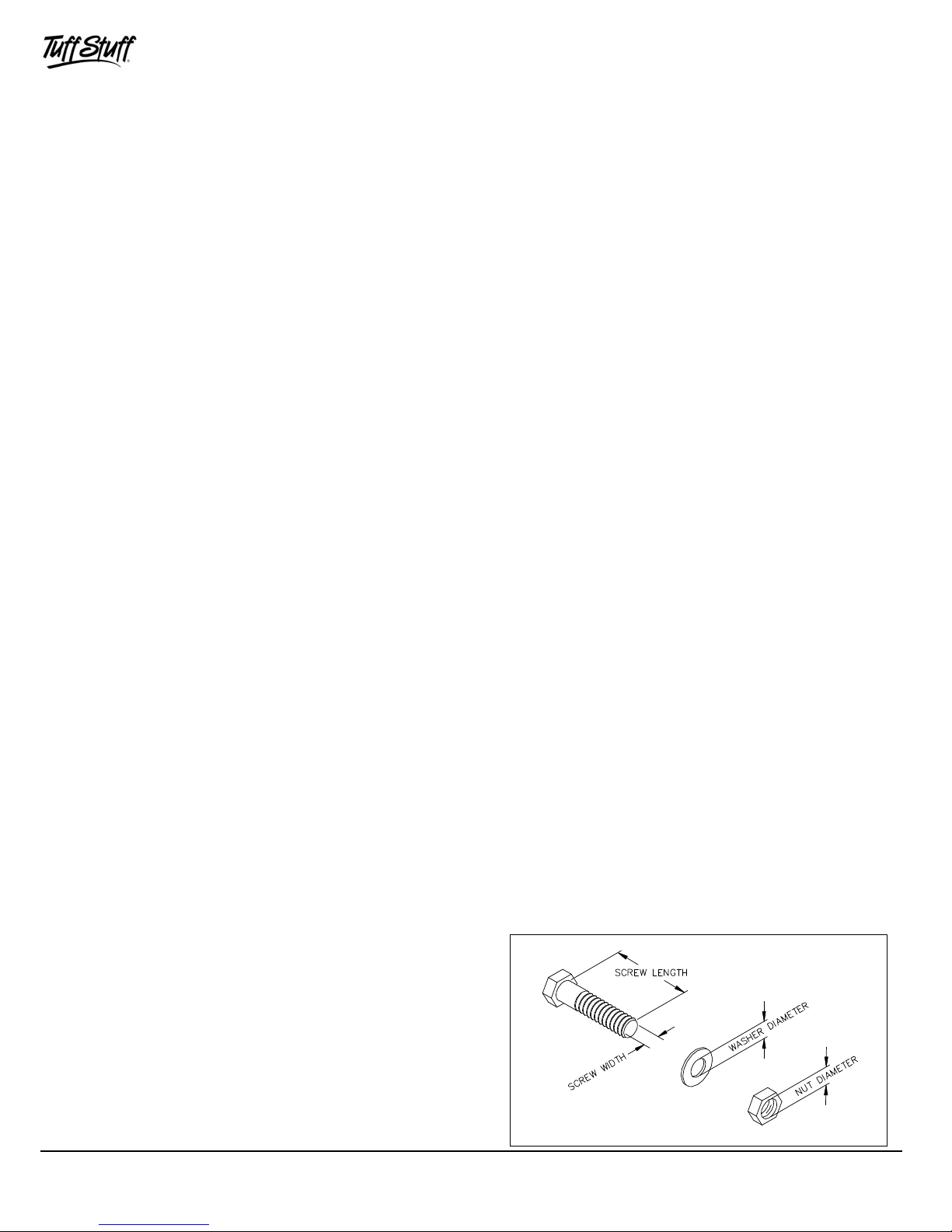

FIG. 3 Next, attach the Front Frame (#57) to the Platform (#49),

as shown above, and secure it into place using two Hex Head Cap

Screws 3/8-16 X 4 (#70), four Flat Washers SAE 3/8 (#12) and two

Nylon Insert Jam Lock Nuts 3/8-16 (#74). Note: The Bench Press

Seat Tube (#62) and the Bench Press Back Pad Bracket have been

pre-assembled by the factory. Also, do not completely fasten the

hardware at this time, as it will be completely secured later in the

assembly process.

TG-150 Tuff Gym Series

FIG. 4 Next, carefully maneuver the Back Frame (#14) onto the

Platform (#49), as shown above, and secure it into place using two

Hex Head Cap Screws 3/8-16 X 4 (#70), four Flat Washers SAE 3/8

(#12) and two Nylon Insert Jam Lock Nuts 3/8-16 (#74). Note: The

Pec Dec Back Pad Bracket (#15) has been pre-assembled by the

factory.

2

Page 4

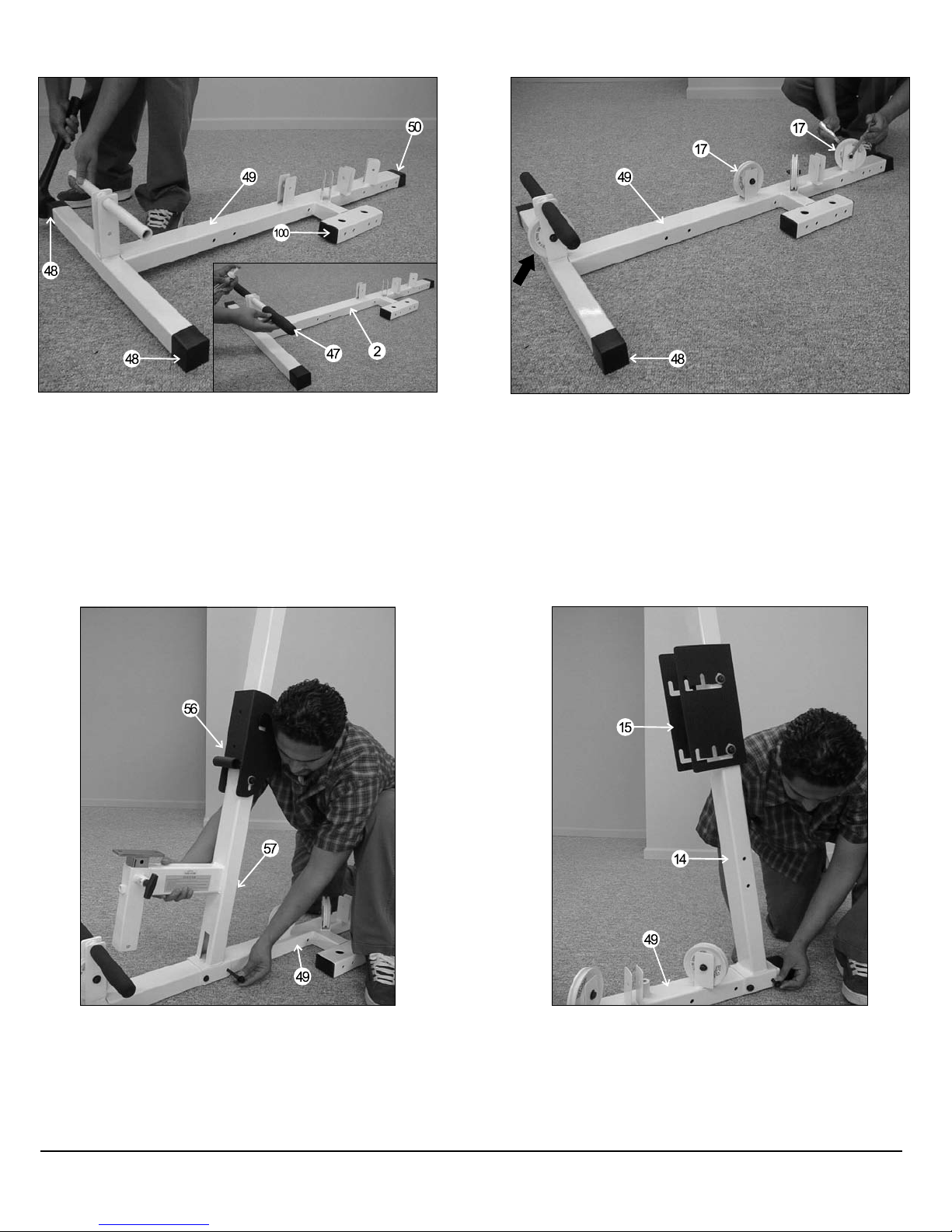

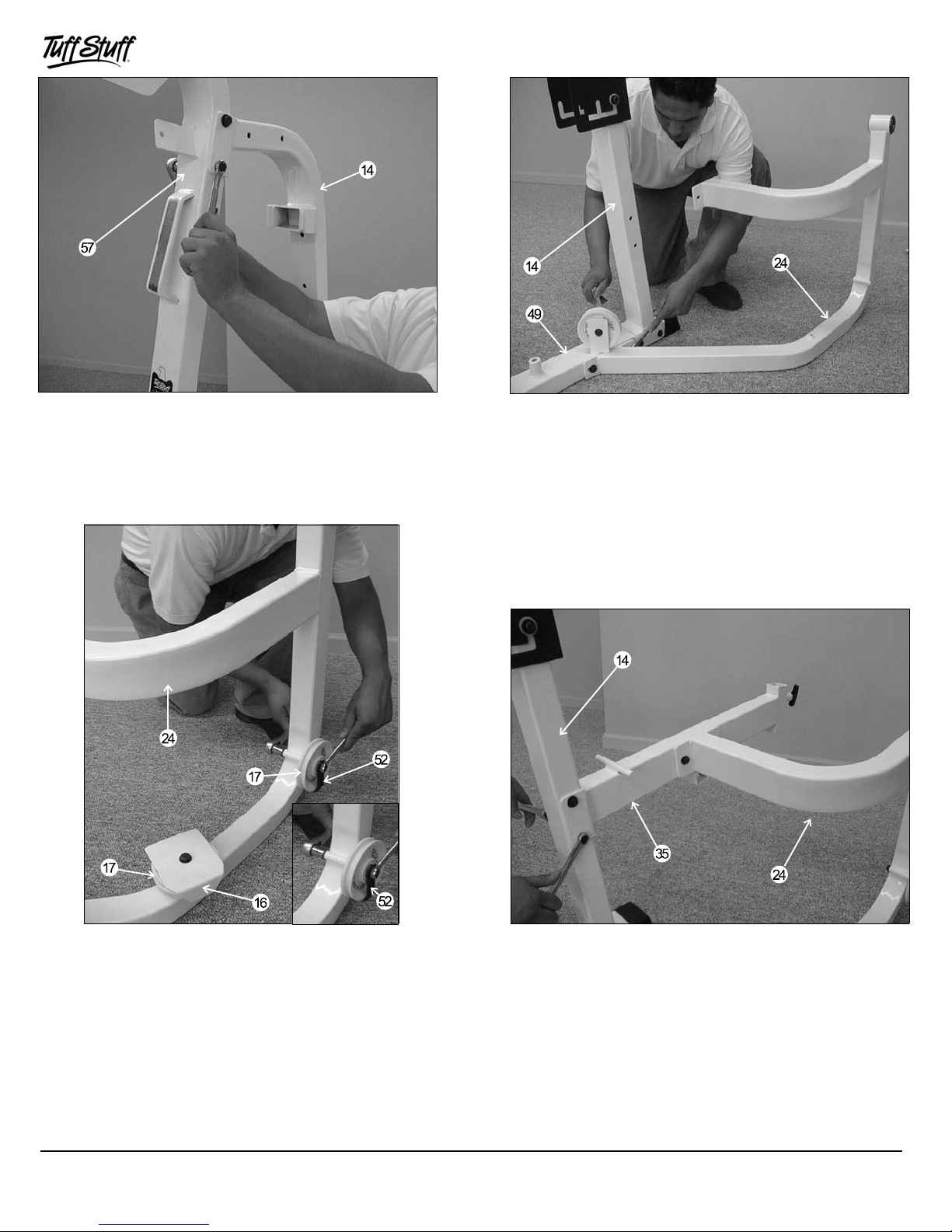

FIG. 5 Continue attaching the Back Frame (#14) to the Front

Frame (#57) and secure it into place using two Hex Head Cap Screws

3/8-16 X 4 (#70), four Flat Washers SAE 3/8 (#12) and two Nylon

Insert Jam Lock Nuts 3/8-16 (#74). Note: Do not completely fasten

the hardware at this time, as it will be completely secured later in the

assembly process.

FIG. 6 Attach the Leg Extension Main Frame (#24), as shown

above, to the Platform (#49) and secure it into place using two Hex

Head Cap Screws 3/8-16 X 3 3/4 (#108), four Flat Washers SAE 3/8

(#12) and two Nylon Insert Jam Lock Nuts 3/8-16 (#74). Note: Do not

completely fasten the hardware at this time, as it will be completely

secured later in the assembly process.

FIG. 7 Next, attach one Nylon Pulley 4 1/2 Rd. (#17), as shown

above in caption, to the Leg Extension Main Frame (#24) and

secure it into place using one Hex Head Cap Screw 3/8-16 X 4 1/4

(#71), one Cable Retainer Bracket (#52), two Flat Washers SAE 3/8

(#12) and one Nylon Insert Jam Lock Nut 3/8-16 (#74). Note: Position

the Cable Retainer Bracket (#52), as shown above in caption. Next,

attach the other Nylon Pulley 4 1/2 Rd. (#17) and the Cable Retainer

Plate (#16) and secure them into place using one Hex Head Cap

Screw 3/8-16 X 1 3/4 (#69) and one Flat Washer SAE 3/8 (#12). Note:

Position the Cable Retainer Plate (#16), as shown above.

3

FIG. 8 Affix the Pec Dec Seat Frame (#35) to the Back Frame

(#14) and secure it into place using two Hex Head Cap Screw 3/8-16

X 4 (#70), four Flat Washer SAE 3/8 (#12) and two Nylon Insert Jam

Lock Nuts 3/8-16 (#74). Next, attach the mid-section of the Pec Dec

Seat Frame (#35) to the Leg Extension Seat Frame (#24) and

secure it into place using two Hex Head Cap Screws 3/8-16 X 2 3/4

(#77), four Flat Washers SAE 3/8” (#12) and two Nylon Insert Jam

Lock Nuts 3/8-16 (#74). Note: Do not completely fasten the hardware

at this time, as it will be completely secured later in the assembly

process.

TG-150 Tuff Gym Series

Page 5

Owners’ Manual: Assembly Instructions

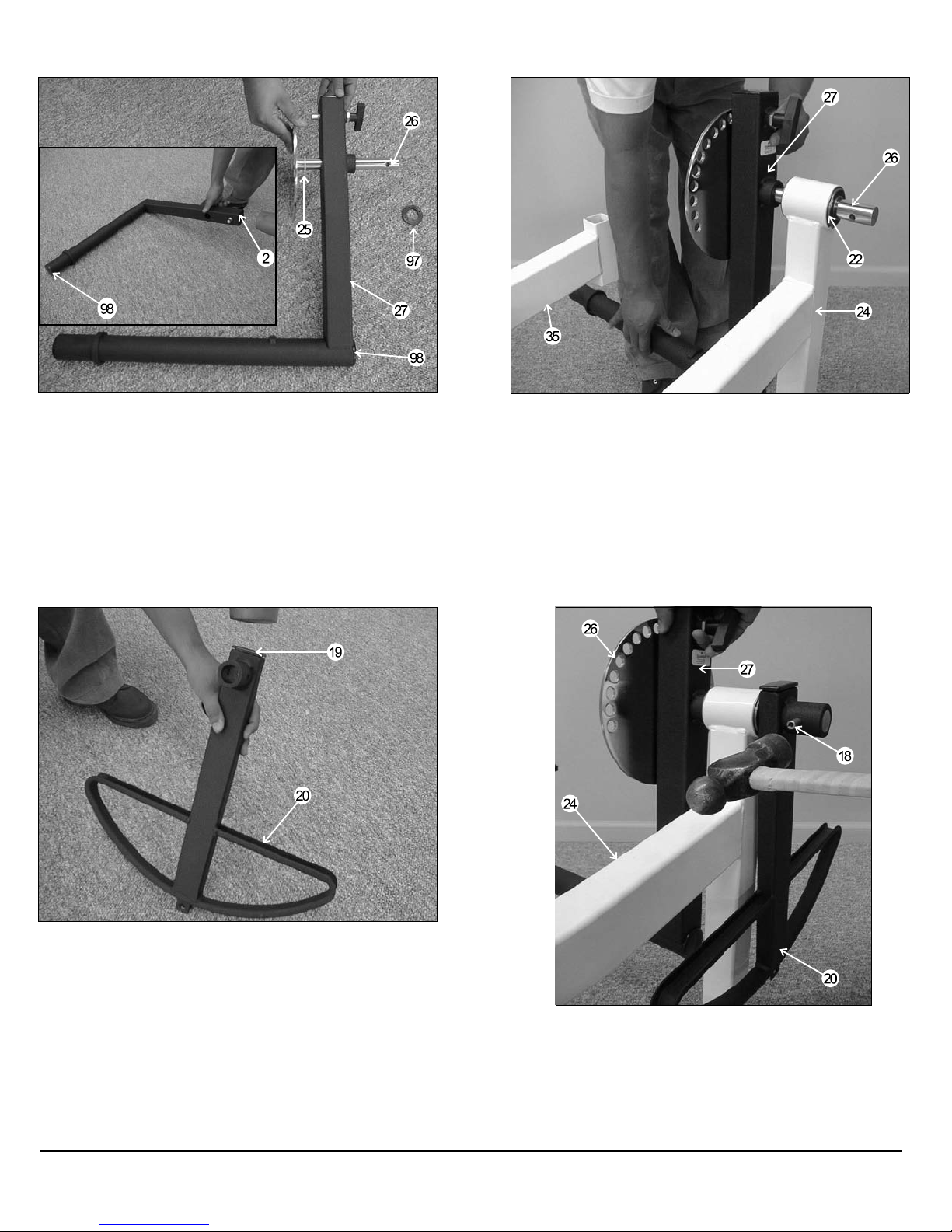

FIG. 9 Locate the L-Arm (#27) and insert two Plastic Insert Cap

Rd. 2” (#98) and one Plastic Insert Cap Sq. 2” (#2) into the tube-ends,

as shown above in caption. Next, affix the Circular Plate w/Axle (#26)

with a Nylon Washer 1 X 1 1/4 (#25) through the receptacle of the L-

Arm (#27), as shown above. Note: The supplied Flat Washer 1” Nylon

(#97) may be used later in the assembly of the Actuator Arm (#20) in

Fig. 12 to relieve any side-to-side movement (if needed) with the

Circular Plate w/Axle (#26) and the Actuator Arm (#20).

FIG. 10 Next, attach the assembled L-Arm (#27) and the Circular

Plate w/Axle (#26) into the receptacle of the Leg Extension Main

Frame (#24). Note: Position the Circular Plate w/Axle (#26),as

shown above in picture. Also, the Ball Bearings #W 516 (#22) have

been pre-assembled by the factory.

FIG. 11 Locate the Actuator Arm (#20) and insert one Plastic

Insert Cap 1 X 2 (#19) into the tube-end, as shown above.

TG-150 Tuff Gym Series

FIG. 12 Next, attach the Actuator Arm (#20) onto the end of

Circular Plate w/Axle (#26), as shown above. Secure it into place

using one Roll Pin 3/8 X 1 1/2 (#18). Note: Be sure Roll Pin 3/8 X 1

1/2 (#18) is completely inserted through the hole and hammed until

one side is flush with the surface.

4

Page 6

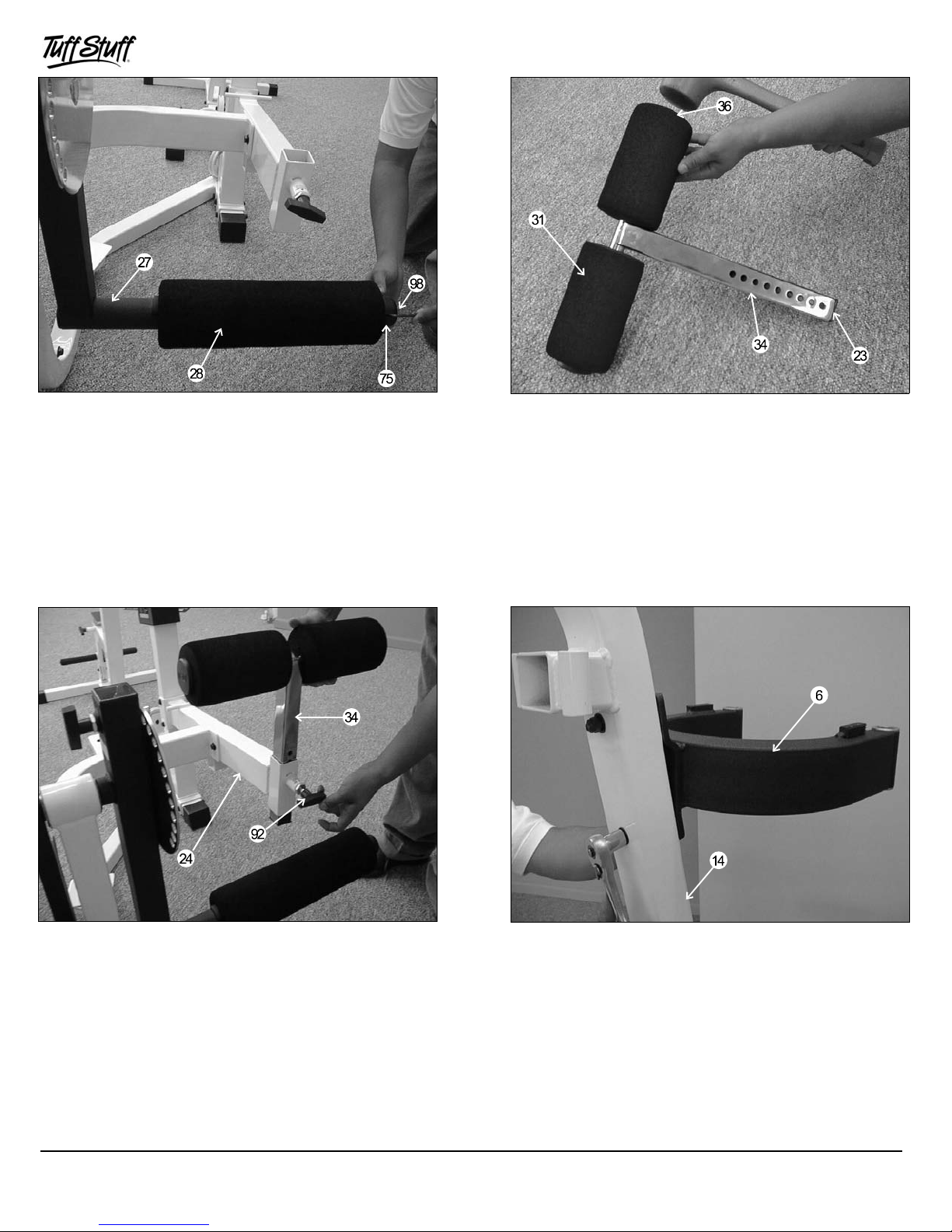

FIG. 13 Next, insert a Foam Foot Roll 1 3/4 X 4 X 16 (#28) over the

L-Arm (#27) and secure it into place using the Foot Roll Collar (#75),

as shown above. Use the supplied Hex Key 5/32” (#95) for fastening

the set screw in the Foot Roll Collar (#75). Next, insert one Plastic

Insert Cap Rd. 2” (#98-Not Shown) into the tube-end of the L-Arm

(#27).

FIG. 14 Locate the Adjustable Hold Down T-Bar (#34) and slide

two Foam Foot Rolls 1 X 4 X 7 (#31) over each end, as shown above.

Next, insert two Foot Roll Plastic End Caps 1” (#36-Not shown) into

the tube-ends of the Adjustable Hold Down T-Bar (#34). Next, insert

one Plastic Insert Cap Sq. 1 1/2 (#23) into the tube-end of the

Adjustable Hold Down T-Bar (#34), as shown above.

FIG. 15 Insert the assembled Adjustable Hold Down T-Bar (#34)

into the receptacle of the Leg Extension Main Frame (#24), as shown

above. Note: Position the Adjustable Hold Down T-Bar (#34) as

pictured above with the selector holes facing the side of the Push-Pull

Pin 3/8 (#92).

5

FIG. 16 Next, locate the Pec Dec Housing Assembly (#6) and

attach it to the Back Frame (#14), as shown above. Secure it into

place using two Hex Head Cap Screws 3/8-16 X 3 (#79), four Flat

Washers SAE 3/8 (#12) and two Nylon Insert Lock Nuts 3/8-16 (#81)

Note: Use the Exploded View Diagram on page 22 for further

illustration of this assembly.

TG-150 Tuff Gym Series

Page 7

Owners’ Manual: Assembly Instructions

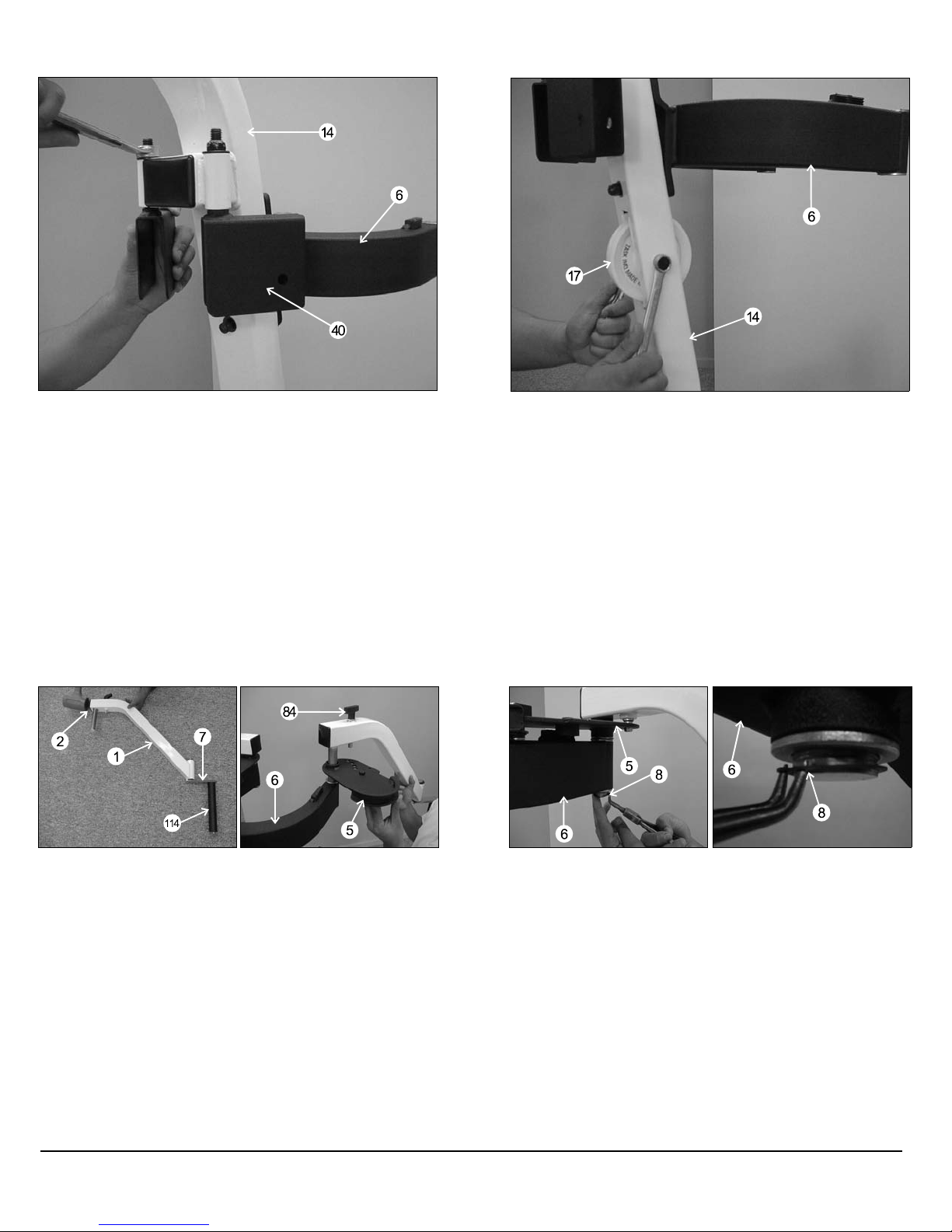

FIG. 17 Next, attach the two Pec Dec Swivel Pulley Brackets

(#40) to the Back Frame (#14), as shown above, and secure them

into place using two Nylon Insert Jam Lock Nuts 1/2-13 (#73) and two

Flat Washers SAE 1/2” (#72). Next, insert one Plastic Insert Cap 2 X 3

(#100) into the tube-end of the Back Frame (#14).

FIG. 18 Next, insert a Nylon Pulley 4 1/2 Rd. (#17) into the Back

Frame (#14) and secure it into place using one Hex Head Cap Screw

3/8-16 X 3 1/2 (#80), two Flat Washers SAE 3/8 (#12) and one Nylon

Insert Jam Lock Nut 3/8-16 (#74).

FIG. 19 Next, locate the two Pec Dec Arms (#1) and insert one

Plastic Insert Cap Sq. 2” (#2) into each tube-end, as shown above.

Note: The Chrome Swivel Handle (#7) and the PVC Handle (#114)

have been pre-assembled by the factory. Next, attach the Pec Dec

Cam Rt (#5) and the Pec Dec Arm (#1) into the receptacle of the Pec

Dec Housing Assembly (#6), as shown above. Note: Be sure to

position the Pec Dec Cam Rt (#5) as pictured above. Repeat the same

procedure for the Pec Dec Cam Lt (#4). Use the Exploded View

Diagram on page 22 for further illustration of this assembly.

TG-150 Tuff Gym Series

FIG. 20 Secure the Pec Dec Cam Rt (#5) and the Pec Dec Cam

Lt (#4) using two Retaining Snap Rings (#8), as pictured above. If

possible, use special snap ring pliers for this job, as shown above. If

not available, carefully work each Retaining Snap Ring (#8) into the

groove , then push down alternately with a screw driver working the

Retaining Snap Ring (#8) into the groove. Note: Be careful not to

distort the Retaining Snap Ring (#8) or bend it.

6

Page 8

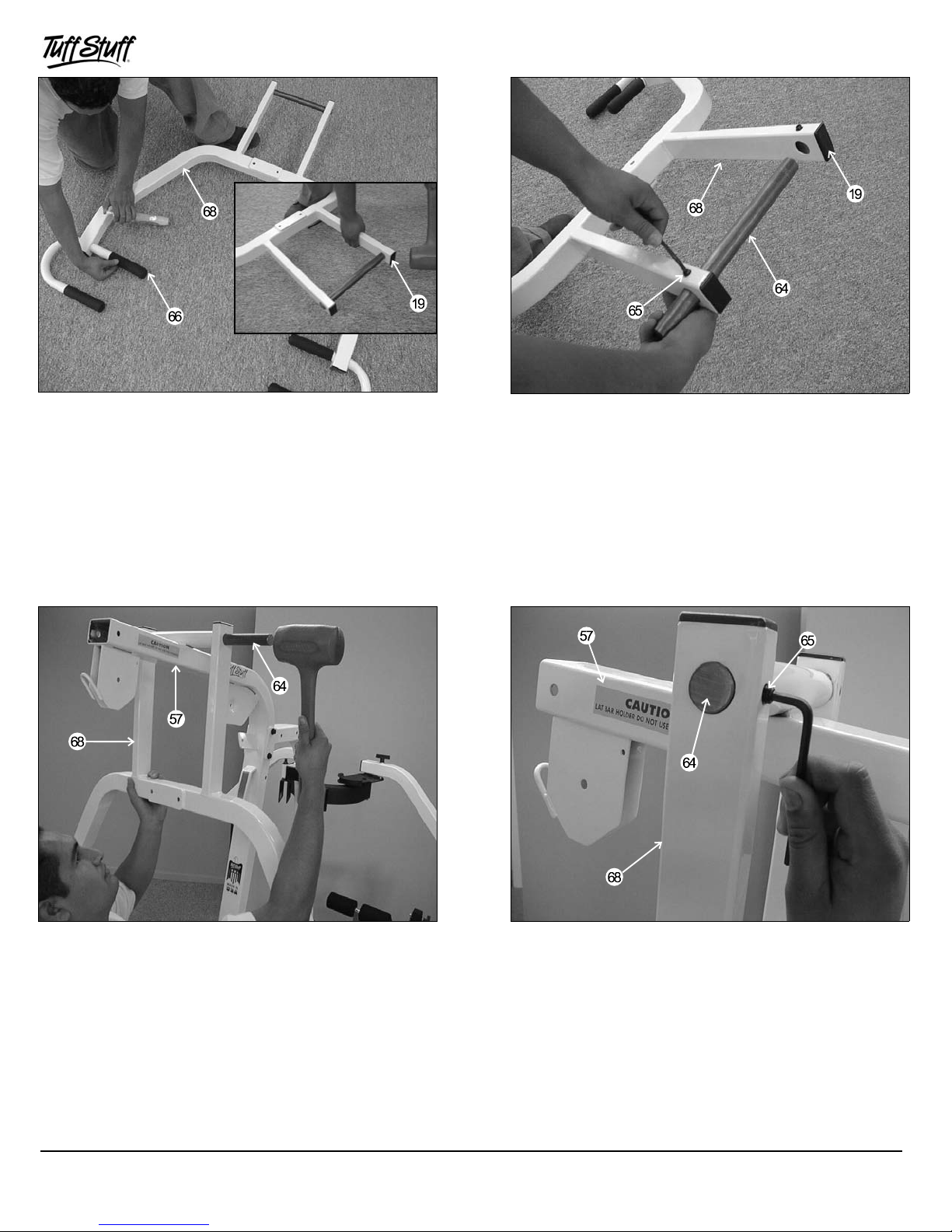

FIG. 21 Locate the Press Bar (#68) and insert four Hard Grips

1.220 X 6” (#66) onto each tube handle, as shown above. Use

Windex or a household glass cleaner for easy insertion of these grips.

Next, insert two Plastic Insert Caps 1 X 2 (#19) into the tube-ends, as

pictured above in caption.

FIG. 22 Next, remove the Pivot Axle 1 X 11 3/4 (#64) from the

Press Bar (#68). Remove the two Socket Set Screws 3/8-16 X 1/2

(#65) in the Press Bar (#68) using the supplied Hex Key 3/16” (#115).

FIG. 23 Attach the Press Bar (#68) to the top of the Front Frame

(#57) receptacle and secure it into place using the Pivot Axle 1 X 11

3/4 (#64). Be sure to position the Press Bar (#68) as pictured

above. Note: Use a rubber mallet hammer until the Pivot Axle 1 X 11

3/4 (#64) is flush with both sides , as shown in Fig. 24. Also, it is

recommended that you grease the Pivot Axle 1 X 11 3/4 (#64) prior to

assembly.

7

FIG. 24 Next, fasten the Pivot Axle 1 X 11 3/4 (#64) on the Press

Bar (#68) using the two Socket Set Screws 3/8-16 X 1/2 (#65) and the

supplied Hex Key 3/16” (#115).

TG-150 Tuff Gym Series

Page 9

Owners’ Manual: Assembly Instructions

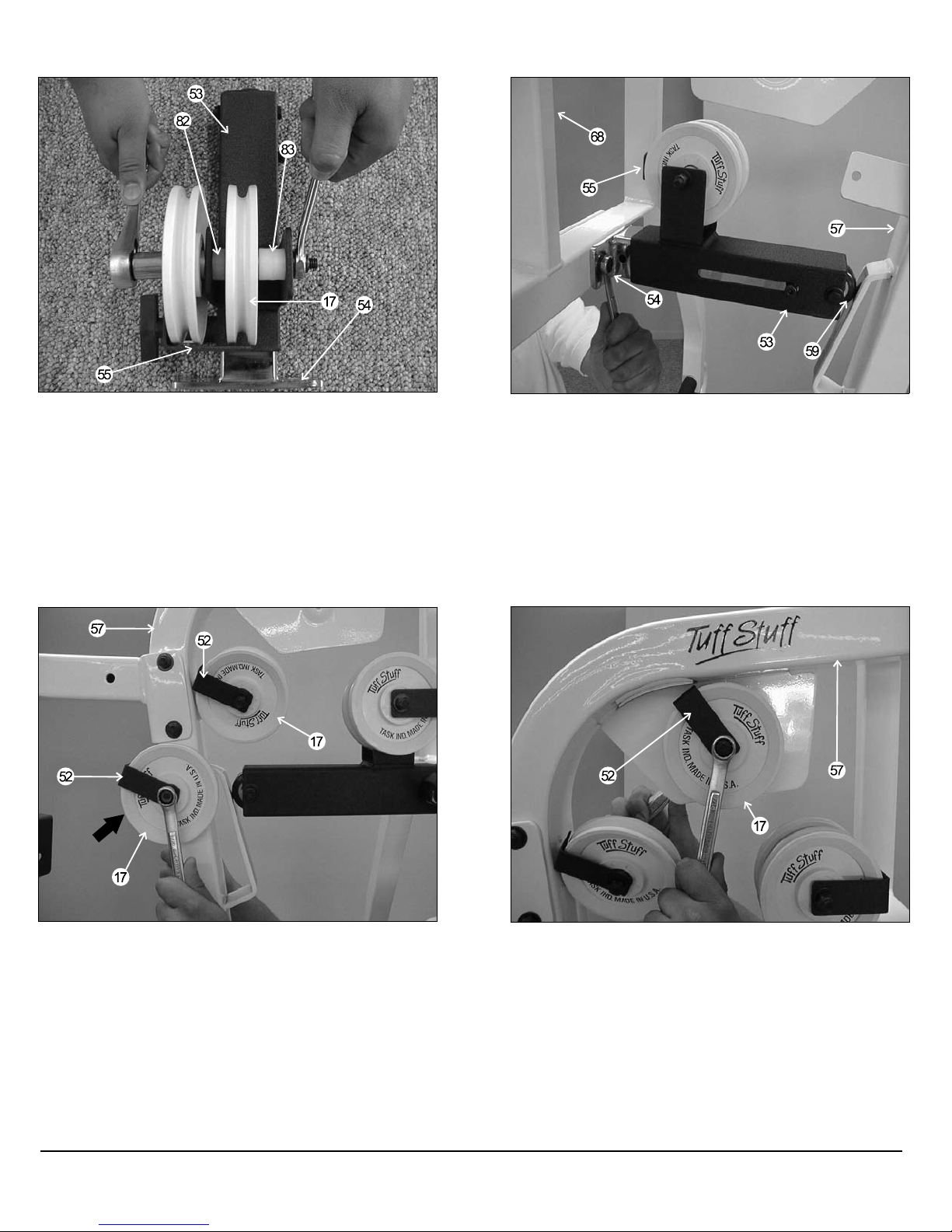

FIG. 25 Locate the Female Adjustment Housing (#53), Cable

Retainer Bracket (LG) (#55) and two Nylon Pulleys 4 1/2 Rd. (#17).

Assemble, as shown above, using one Hex Head Cap Screw 3/8-16 X

4 1/4 (#71), one Nylon Spacer 3/8 X 3/4 (#83), one Nylon Spacer 3/8

X 3/8 (#82), two Flat Washers SAE 3/8 (#12) and one Nylon Insert

Lock Nut 3/8-16 (#81). Refer to Fig. 72 on page 21 for further

clarification of this assembly. Note: Be sure to position the Cable

Retainer Bracket (LG) (#55), as pictured above and in Fig. 26. Also,

the Bench Press Selector Tube (#54) has been pre-assembled into

the Female Adjustment Housing (#53) by the factory.

FIG. 26 Next, attach the assembled Bench Press Selector Tube

(#54) and the Female Adjustment Housing (#53) to the Press Bar

(#68). Secure the Bench Press Selector Tube (#54) into place using

two Hex Head Cap Screws 3/8-16 X 3 (#79), four Flat Washers SAE

3/8” (#12) and two Nylon Insert Lock Nuts 3/8-16 (#81). Note: The

Black Caster 2 X 1 (#59), shown above, has been pre-assembled by

the factory.

FIG. 27 Next, attach a Nylon Pulley 4 1/2 Rd. (#17-Shown with

arrow) and a Cable Retainer Brackets (#52) to the Front Frame

(#57), as shown above. Secure it into place using one Hex Head Cap

Screws 3/8-16 X 4 3/4 (#63), two Flat Washers SAE 3/8” (#12) and

one Nylon Insert Jam Lock Nut 3/8-16 (#74). Next, attach the other

Nylon Pulley 4 1/2 Rd. (#17) and a Cable Retainer Brackets (#52)

to the Front Frame (#57) and secure it into place using one Hex Head

Cap Screw 3/8-16 X 1 3/4 (#69), two Flat Washer SAE 3/8” (#12) and

one Nylon Insert Jam Lock Nut 3/8-16 (#74). Note: Be sure to position

both Cable Retainer Brackets (#52), as pictured above.

TG-150 Tuff Gym Series

FIG. 28 Next, attach one Nylon Pulley 4 1/2 Rd. (#17) and a

Cable Retainer Brackets (#52) to the Front Frame (#57) and secure

it into place using one Hex Head Cap Screw 3/8-16 X 1 3/4 (#69), two

Flat Washer SAE 3/8” (#12) and one Nylon Insert Jam Lock Nut 3/8-16

(#74). Note: Be sure to position both Cable Retainer Brackets (#52),

as pictured above.

8

Page 10

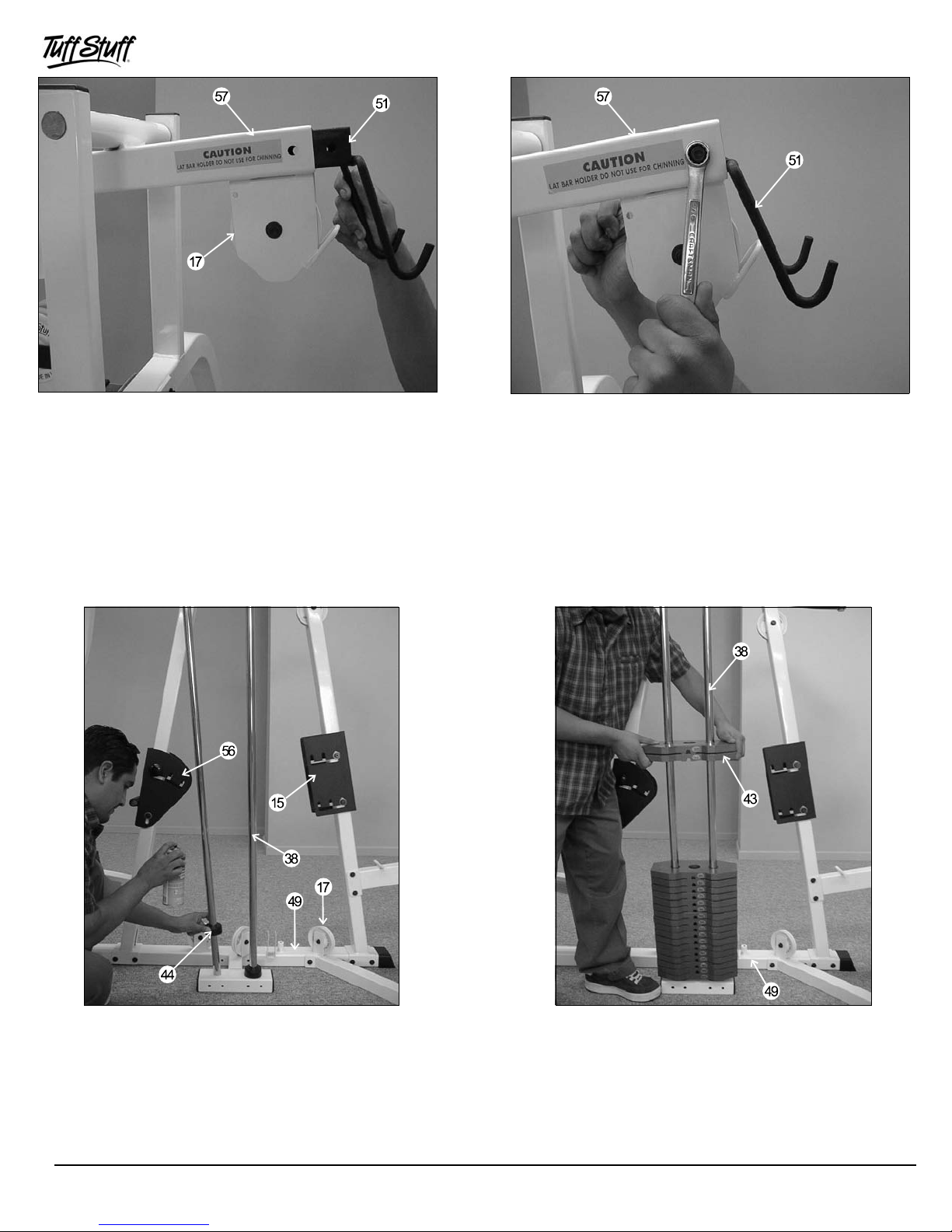

FIG. 29 Attach one Nylon Pulley 4 1/2 Rd. (#17) to the pulley

over

one or two at a time as your skill

are installed

n numerical order, beginning with

bracket on the Front Frame (#57) and secure it into place using one

Hex Head Cap Screw 3/8-16 X 1 3/4 (#69), two Flat Washers SAE

3/8” (#12) and one Nylon Insert Jam Lock Nut 3/8-16 (#74). Next,

insert the Lat Bar Holder (#51) into the tube-end of the Front Frame

(#57), as shown above. Note: Be sure to position the Lat Bar Holder

(#51) as pictured above.

FIG. 30 Secure Lat Bar Holder (#51) it into place using one Hex

Head Cap Screw 3/8-16 X 3 1/2 (#80), two Flat Washers SAE

3/8” (#12) and one Nylon Insert Jam Lock Nut 3/8-16 (#74). Note: Be

sure to position the Lat Bar Holder (#51) as pictured above.

FIG. 31 Insert the two Guide Rods 1 X 72 (#38) into the receptacle

of the Platform (#49), as shown above. Next, insert two Rubber

Donuts 1 X 2 1/2 (#44) onto each Guide Rod 1 X 72 (#38). Note:

Lubricate the Guide Rods 1 X 72 (#38) with silicone or teflon lubricant

at this time.

9

FIG. 32 Carefully begin sliding the 10 Lb Weight Plates (#43)

the Guide Rods 1 X 72 (#38),

permits. Make sure that the 10 Lb Weight Plates (#43)

onto the Guide Rods 1 X 72 (#38) i

the number 200 at the bottom, 190 next, and so on.

TG-150 Tuff Gym Series

Page 11

Owners’ Manual: Assembly Instructions

FIG. 33 Now slide the Top Plate/Selector Bar (#42) over the

Guide Rods 1 X 72 (#38) allowing it to come to rest on the completed

weight stack.

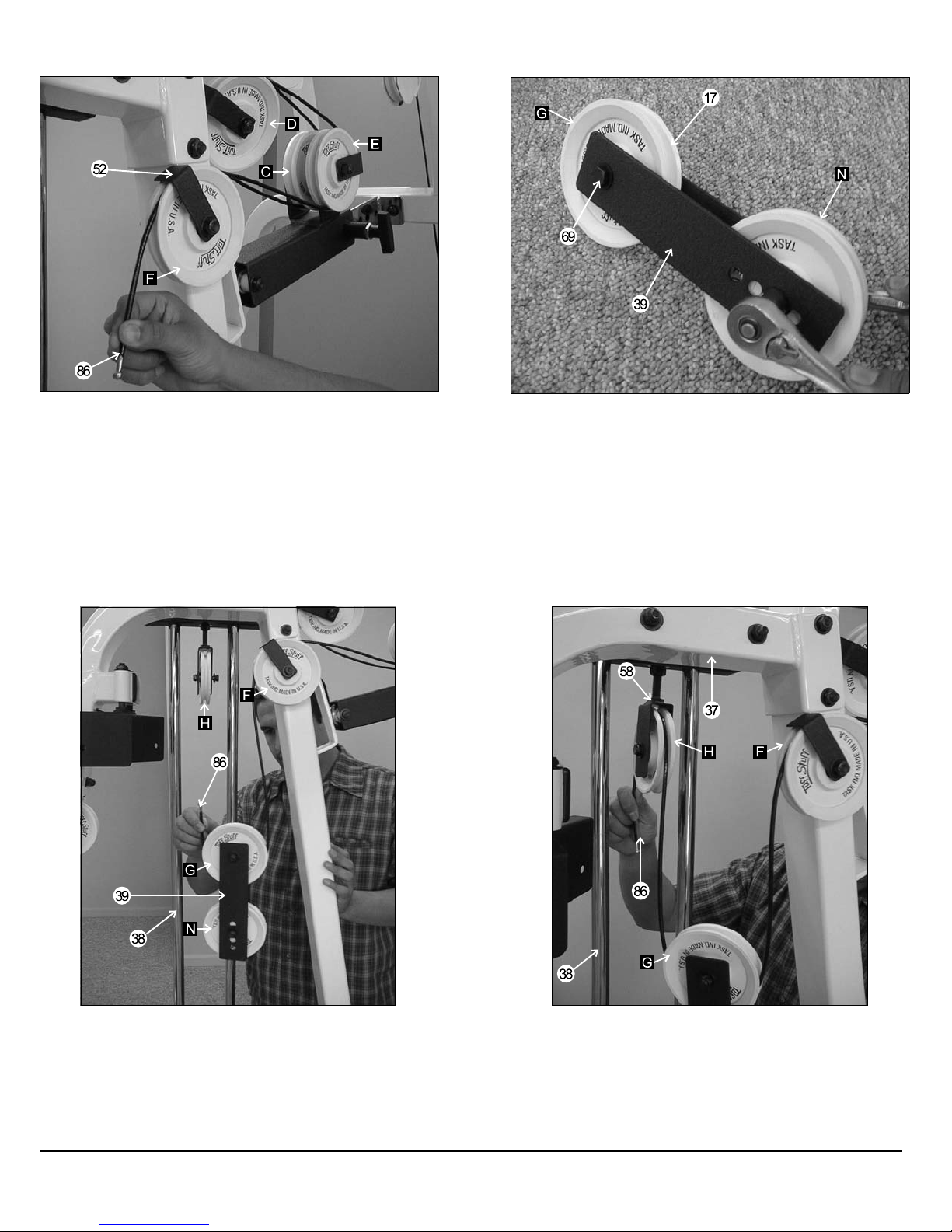

FIG. 35 Maneuver the two Guide Rods 1 X 72 (#38) into the holes

on the bottom side of the Guide Rod Retainer Housing (#37). Next,

mount the Guide Rod Retainer Housing (#37) along with the two

captive Guide Rods 1 X 72 (#38) to the side of the Back Frame (#14).

Secure this assembly using two Hex Head Cap Screws 3/8-16 X 4

(#70), four Flat Washers SAE 3/8” (#12) and two Nylon Insert Jam

Lock Nuts 3/8-16 (#74).

FIG. 34 VIEW OF COMPLETED WEIGHT STACK

FIG. 36 Next, secure the two Guide Rods 1 X 72 (#38) into place

using the four Hex Head Cap Screw 5/16-18 X 1 located on the

Guide Rod Retainer Housing (#37), as shown above. Next, insert

four Plastic Insert Caps 1 X 2 (#19) into the tube-ends of the Guide

Rod Retainer Housing (#37). Next, locate the Top Plate Swivel

Bracket (#58) and secure to the Guide Rod Retainer Housing (#37)

using two Nylon Insert Jam Lock Nuts 1/2-13 (#73) and two Flat

Washers SAE 1/2” (#72). Next, insert one Nylon Pulleys 4 1/2 Rd.

(#17) to the Top Plate Swivel Bracket (#58) and secure it into place

using one Hex Head Cap Screw 3/8-16 X 1 3/4 (#69), two Flat

Washers SAE 3/8” (#12) and one Nylon Insert Jam Lock Nuts 3/8-16

(#74). Note: Refer to Fig. 75 on page 21 for further illustration of this

hardware assembly.

TG-150 Tuff Gym Series

10

10

Page 12

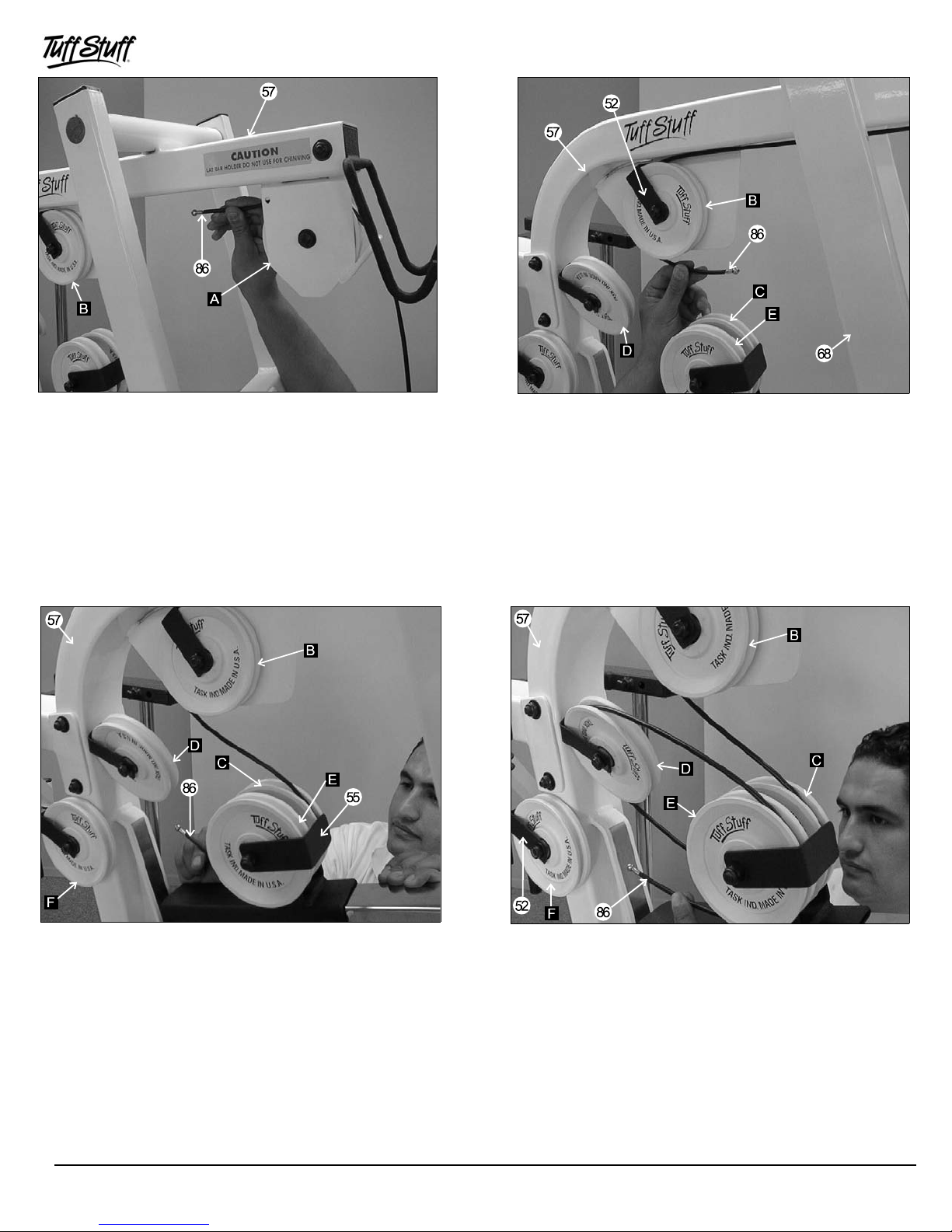

FIG. 37 Locate the Lat Cable (#86-labeled with tape A) and route

the ball-end through the Nylon Pulley 4 1/2 Rd. (#17-Labeled A)

located on the Front Frame (#57), as shown above. Refer to the

Cable Mapping Diagram on page 20 for further detailed illustration of

this routing. Note: The black boxed letters pointing to the pulleys

are used throughout this manual as reference to the cable mapping

diagram on page 20. These black boxed letters will be primarily used

for locating certain pulleys during the cable routing process beginning

with Fig. 37.

FIG. 38 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled B), as shown above. Refer to

the Cable Mapping Diagram on page 20 for further detailed illustration

of this routing.

FIG. 39 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled C), as shown above. Refer to

the Cable Mapping Diagram on page 20 for further detailed illustration

of this routing.

11

FIG. 40 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled D) and the Nylon Pulley 4 1/2

Rd. (#17-Labeled E), as shown above. Refer to the Cable Mapping

Diagram on page 20 for further detailed illustration of this routing.

TG-150 Tuff Gym Series

Page 13

Owners’ Manual: Assembly Instructions

FIG. 41 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled F), as shown above. Refer to

the Cable Mapping Diagram on page 20 for further detailed illustration

of this routing.

FIG. 42

FIG. 42 Assemble the Double Pulley Plates 1/8 X 2 X 9 (#39)

using two Nylon Pulleys 4 1/2 Rd. (#17-Labeled G, N), two Hex Head

Cap Screws 3/8-16 X 1 3/4 (#69), four Flat Washers SAE 3/8” (#12)

and two Nylon Insert Jam Lock Nuts 3/8-16 (#74). Note: The four

holes on the Double Pulley Plates 1/8 X 2 X 9 (#39) are used to

adjust the cable tension once the cable routing has been completed.

FIG. 11

FIG. 43 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled G), as shown above. Refer to

the Cable Mapping Diagram on page 20 for further detailed illustration

of this routing.

TG-150 Tuff Gym Series

FIG. 12

FIG. 44 Next, route the Lat Cable (#86-labeled with tape A) over

the Nylon Pulley 4 1/2 Rd. (#17-Labeled H), as shown above. Refer to

the Cable Mapping Diagram on page 20 for further detailed illustration

of this routing.

12

Page 14

Owners’ Manual: Assembly Instructions

FIG. 45 Next, attach the Lat Cable (#86-labeled with tape A) to

the Top Plate/Selector Bar (#42) and secure it into place using one

Split Bolt 1/2-13 X 1 (#101) and one Split Washer 1/2” (#102), as

shown above. Refer to Fig. 73 on page 21 for further detailed

illustration of this assembly. Note: Be sure this hardware assembly is

securely fastened.

FIG. 46 Next, attach the Lat Bar Chrome 48” (#90) to the Lat

Cable (#86-labeled with tape A) and secure it into place using one

Strap Bracket #20 (#103), one Shoulder Bolt 3/8 X 3/4 (#117) and one

Nylon Insert Lock Nut 5/16-18 (#105). Refer to Cable Mapping

Diagram on page 20 and Fig. 77 on page 21 for further illustration of

this hardware assembly.

FIG. 47 Begin the cable routing for the Pec Dec Cable (#88-

labeled with tape C). Attach the Pec Dec Cable (#88) to the Pec Dec

Cam (#4), as shown above, and secure it into place using one Socket

Cap Screw 1/4-20 X 3/4 (#106) and one Nylon Insert Lock Nut 1/4-20

(#107). Refer to Fig. 76 on page 21 for further detailed illustration of

this hardware assembly.

13

FIG. 48 Next, route the Pec Dec Cable (#88-labeled with tape

C) over the Nylon Pulley 4 1/2 Rd. (#17-Labeled I) located on the Pec

Dec Swivel Pulley Bracket (#40), as shown above. Refer to the Cable

Mapping Diagram on page 20 for further detailed illustration of this

routing.

TG-150 Tuff Gym Series

Page 15

FIG. 49 Next, route the Pec Dec Cable (#88-labeled with tape C)

through the Nylon Pulley 4 1/2 Rd. (#17-Labeled J) located on the

Offset Pulley Bracket (#45), as shown above. Repeat the same

procedure for the termination of the Pec Dec Cable (#88-labeled with

tape C) to the Pec Dec Cam (Rt)(#5). Refer to the Cable Mapping

Diagram on page 20 for further detailed illustration of this routing.

FIG. 50 Next, begin routing the Low Row Cable (#87-labeled

with tape B) under the Nylon Pulley 4 1/2 Rd. (#17-Labeled L), as

shown above. Refer to the Cable Mapping Diagram on page 20 for

further detailed illustration of this routing.

FIG. 51 Next, route the Low Row Cable (#87-labeled with tape B)

under the Nylon Pulley 4 1/2 Rd. (#17-Labeled M), as shown above.

Refer to the Cable Mapping Diagram on page 20 for further detailed

illustration of this routing.

TG-150 Tuff Gym Series

FIG. 52 Next, route the Low Row Cable (#87-labeled with tape B)

under the Nylon Pulley 4 1/2 Rd. (#17-Labeled N), as shown above.

Refer to the Cable Mapping Diagram on page 20 for further detailed

illustration of this routing.

14

Page 16

FIG. 53 Next, route the Low Row Cable (#87-labeled with tape B)

under the Nylon Pulley 4 1/2 Rd. (#17-Labeled O), as shown above.

Refer to the Cable Mapping Diagram on page 20 for further detailed

illustration of this routing.

FIG. 54 Next, route the Low Row Cable (#87-labeled with

tape B) over the Nylon Pulley 4 1/2 Rd. (#17-Labeled P) located on

the Offset Pulley Bracket (#45), as shown above. Refer to the Cable

Mapping Diagram on page 20 for further detailed illustration of this

routing.

FIG. 55 Next, locate the two Double Pulley Plates (#46) and

attach two Nylon Pulleys 4 1/2 Rd. (#17), as shown above. Secure

them into place using two Hex Head Cap Screws 3/8-16 X 1 3/4 (#69),

four Flat Washers SAE 3/8: (#12) and two Nylon Insert Jam Lock Nuts

3/8-16 (#74).

15

FIG. 56 Continue to route the Low Row Cable (#87-labeled with

tape B) under the Nylon Pulley 4 1/2 Rd. (#17-Labeled Q) located on

the Double Pulley Plates (#46), as shown above. Refer to the Cable

Mapping Diagram on page 20 for further detailed illustration of this

routing.

TG-150 Tuff Gym Series

Page 17

FIG. 57 Next, route the Low Row Cable (#87-labeled with tape

B) over the Nylon Pulley 4 1/2 Rd. (#17-Labeled R) located on the

Back Frame (#14), as shown above. Next, attach the Abdominal Strap

(#116), as shown above. Note: Use Fig. 78 for completing this

hardware assembly. Refer to the Cable Mapping Diagram on page 20

for further detailed illustration of this routing.

Owners’ Manual: Assembly Instructions

FIG. 58 Abdominal Strap View

FIG. 59 Begin the cable routing for the Leg Extension Cable (#89-

labeled with tape D). Attach the looped end of the Leg Extension

Cable (#89-labeled with tape D) to the Actuator Arm (#20) and

secure it into place using one Hex Head Cap Screw 3/8-16 X 1 (#13)

and one Nylon Insert Jam Lock Nut 3/8-16 (#74). Refer to the Cable

Mapping Diagram on page 20 for further detailed illustration of this

routing.

TG-150 Tuff Gym Series

FIG. 60 Next, route the Leg Extension Cable (#89-labeled with

tape D) under the Nylon Pulley 4 1/2 Rd. (#17-Labeled L) located on

the Leg Extension Main Frame (#24), as shown above. Refer to the

Cable Mapping Diagram on page 20 for further detailed illustration of

this routing.

16

Page 18

FIG. 61 Next, route the Leg Extension Cable (#89-labeled with

tape D) under the Nylon Pulley 4 1/2 Rd. (#17-Labeled T) located on

the Leg Extension Main Frame (#24) and up- and -over the Nylon

Pulley 4 1/2 Rd. (#17-Labeled U) located on the Platform (#49), as

shown above. Refer to the Cable Mapping Diagram on page 20 for

further detailed illustration of this routing.

FIG. 62 Next, route the Leg Extension Cable (#89-labeled with

tape D) over the Nylon Pulley 4 1/2 Rd. (#17-Labeled V) located on

the Double Pulley Plates(#46), as shown above. Refer to the Cable

Mapping Diagram on page 20 for further detailed illustration of this

routing.

FIG. 63 Next, route the Leg Extension Cable (#89-labeled with

tape D) to the threaded socket on the Platform (#49), as shown

above, and secure it into place using one Split Bolt 1/2-13 X 1 (#101)

and one Split Washer 1/2” (#102). Refer to the Fig 74 on page 21 for

further detailed illustration of this hardware assembly.

17

FIG. 64 Note: This cable termination is for the TG-150 only. For

the cable routing instructions for the TG-11L (Leg Press) , please

see TG-11L Instruction Manuel. If you have a TG-11L (Leg Press),

this Leg Extension Cable (#89-labeled with tape D) will be replaced

with the Leg Press Station cable supplied with the TG-11L.

TG-150 Tuff Gym Series

Page 19

Owners’ Manual: Assembly Instructions

FIG. 65 Cable Adjustment for the Leg Extension Cable (#89-

labeled with tape D). The Top Plate Swivel Bracket (#59) has been

designed to allow adjustment for the Leg Extension Cable (#89-

labeled with tape D) or the TG-11L (Leg Press Option) cable. To

adjust this cable, simply loosen the bottom nut (Labeled B), then begin

fastening the top nut (Labeled A) until the proper tension has been

achieved with this cable. Note: Over-tightening this cable will cause

the Top Plate/Selector Bar (#42) to lift and become a alignment

problem with the weight pin for the weight stack. Refer to the Cable

Tension Picture on page 19, as it displays an example of the

recommended tension for all cables.

FIG. 66 Next, locate the Leg Ext /Leg Curl Seat Pad (#29) and

attach the Seat Elevation Bracket (#32). Secure it into place using

two Hex Head Cap Screws 3/8-16 X 1 (#13) and two Flat Washers

SAE 3/8” (#12). Next, attach one Metal Hinge (#33) to the Leg Ext /

Leg Curl Seat Pad (#29), as shown above, and secure it into place

using one Hex Head Cap Screw 3/8-16 X 1 (#13) and one Flat Washer

SAE 3/8” (#12). Note: Be sure to position the Metal Hinge (#33), as

pictured above and in Fig. 67.

FIG. 67 Next, attach the Leg Ext /Leg Curl Seat Pad (#29) with the

other Metal Hinge (#33) to the Pec Dec Seat Frame (#35) and secure

it into place using one Hex Head Cap Screw 3/8-16 X 1 (#13) and one

Flat Washer SAE 3/8” (#12).

TG-250 Tuff Gym Series

FIG. 68 Next, attach the Back Pad (#11) to the Pec Dec Back Pad

Bracket (#15) and secure it into place using two Hex head Cap

Screws 3/8-16 X 1 (#13) and two Flat Washers SAE 3/8” (#12). Note:

The Pec Dec Back Pad Bracket (#15) has been pre-assembled to the

Back Frame (#14) by the factory.

18

Page 20

FIG. 69 Next, attach the Bench Press Seat Pad (#61) to the

Bench Press Seat Tube (#62) and secure it into place using two Hex

Head Cap Screws 3/8-16 X 1 (#13) and two Flat Washers SAE

3/8” (#12). Note: The Bench Press Seat Tube (#62) has been

attached to the Front Frame (#57) by the factory. Next, fasten the

Black Knob 1/2-13 X1 (#96) to the threaded nut of the Front Frame

(#57), as shown above.

FIG. 70 Next, attach the Bench Press Back Pad (#60) to the

Bench Press Back Pad Bracket (#56) and secure it into place using

two Hex Head Cap Screws 3/8-16 X 1 (#13) and two Flat Washers

SAE 3/8” (#12). Refer to the Exploded View Diagram on page 22 for

further illustration of this hardware assembly. Note: The Bench Press

Back Pad Bracket (#56) has been pre-assembled to the Front Frame

(#57) by the factory. Next, attach the Rubber Bumper 3/8 X 1

1/2” (#99) to the Bench Press Back Pad (#60) and secure it into

place using one Hex Head Cap Screw 3/8-16 X 1 (#13) and one Flat

Washer SAE 3/8” (#12).

FIG. 71 Next, attach the Foot Roll Tube 1 X 23 3/4 (#91) and

insert it into the receptacle of the Bench Press Back Pad Bracket

(#56). Next, insert a Foam Foot Roll 1 X 4 X 7 (#31) and one Foot Roll

Plastic End Cap 1” (#36) into each tube-end of the Foot Roll Tube 1 X

23 3/4 (#91), as shown above.

19

Cable Tension Picture: This picture shown above illustrates the

proper tension to be achieved when adjusting the cable tension.

This concludes the assembly of the TG-150. It is recommended that

you check and secure all hardware assemblies and inspect all the

cable routing for proper tension and assembly.

TG-150 Tuff Gym Series

Page 21

FIG. A

COMPLETE CABLE MAPPING DIAGRAM

FIG. B

TG-150 Tuff Gym Series

20

Page 22

FIG. 72

FIG. 73

FIG. 74

FIG. 76

FIG. 77

FIG. 75

FIG. 78

21

TG-150 Tuff Gym Series

Page 23

Owners’ Manual: Assembly Instructions

TG-150 EXPLODED VIEW DIAGRAM

TG-150 Tuff Gym Series

22

Page 24

TG-150 PARTS LIST

Item No.

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

Item No. Description Part No. Qty

1 PEC DEC ARM TG150-01-00 2

2 PLASTIC INSERT CAP SQ. 2" BNH0012 5

3 BRONZE BUSHING 1 X 1 1/4 BNH0527 8

4 PEC DEC CAM (LT) TG150-04-00 1 62 BENCH PRESS SEAT TUBE TG150-62-00 1

5 PEC DEC CAM (RT) TG150-05-00 1

6 PEC DEC HOUSING ASSEMBLY TG150-06-00 1 64 PIVOT AXLE 1 X 11 3/4 UP067 1

7 CHROME SWIVAL HANDLE UP144 2

8 EXT. RETAINING SNAP RING .925 X 1" BNH00419

9 PLASTIC KNOB 5/16 -18 X 1 BNH0177 2 67 HEX HEAD CAP SCREW 3/8 -16 X 2 BNH0279 1

10 NYLON WASHER USS 3/8" BNH0248 16

11 BACK PAD UP129 1

12 FLAT WASHER SAE 3/8" BNH0239 105 70 HEX HEAD CAP SCREW 3/8 -16 X 4 BNH0285 8

13 HEX HEAD CAP SCREW 3/8 -16 X 1 BNH0275 12 71 HEX HEAD CAP SCREW 3/8 -16 X 4 1/4 BNH0317 2

14 BACK FRAME TG150-14-00 1

15 PEC DEC BACK PAD BRACKET TG150-15-00 1

16 CABLE RETAINER PLATE TG150-16-00 1

17 WHITE NYLON PULLEY 4 1/2 BNH0556 22

18 ROLL PIN 3/8 X 1 1/2 BNH0483 1 76 SHOULDER BOLT 3/8 X 3/8 BNH0422 8

19 PLASTIC INSERT CAP REQ. 1 X 2 BNH0005 5 77 HEX HEAD CAP SCREW 3/8 -16 X 2 3/4 BNH0278 4

20 ACTUATOR ARM UP159 1 78 HEX HEAD CAP SCREW 5/16 -18 X 1 BNH0290 2

21 AB CRUNCH INSERT BRACKET UP119 1

22 BALL BEARING # W 516 BNH0628 2 80 HEX HEAD CAP SCREW 3/8 -16 X 3 1/2 BNH0280 2

23 PLASTIC INSERT CAP SQ. 1 1/2" BNH0009 1 81 NYLON INSERT LOCK NUT 3/8 - 16 BNH0214 3

24 LEG EXTENSION MAIN FRAME TG150-24-00 1

25 NYLON WASHER 1 X 1 1/4 BNH0393 2 83 NYLON SPACER 3/8 X 3/4 BNH0392 1

26 CIRCULAR PLATE W / AXLE UP106 1

27 L- ARM TG150-27-00 1

28 FOAM FOOT ROLL 1 3/4 X 4 X 16 BNH0041 1

29 LEG EXT / CURL SEAT PAD UP105 1

30 L - LOCKING PIN BNH0045 1

31 FOAM FOOT ROLL 1 X 4 X 7 BNH0043 4

32 SEAT ELEVATION BRACKET 2 1/4 ID UP104 1

33 METAL HINGE BNH0046 2

34 ADJUSTABLE HOLD DOWN T- BAR UP108 1

35 PEC DEC SEAT FRAME TG150-35-00 1 93 LOW ROW BAR 16" UP094 1

36 FOOT ROLL PLASTIC END CAPS 1" BNH0397 4 94 NYLON BALL 1 3/4 X 5/16 BNH0592 3

37 GUIDE ROD RETAINER HOUSING TG150-37-00 1

38 GUIDE ROD 1 X 72 UP124 2

39 ADJUSTABLE PULLEY PLATE 1/8 X2X9 UP092 2

40 PEC DEC SWIVAL PULLEY BRACKET LG UP126 2

41 SELECTOR PIN 3/8 X 4 BNH0064 1 99 RUBBER BUMPER 3/8 X 1 1/2 BNH0514 1

42 TOP PLATE / SELECTOR BAR UP003 1

43 10 LB WEIGHT PLATE BNH0561 19

44 RUBBER DONUT 1 X 2 1/2" BNH0062 2 102 SPLIT WASHER 1/2" BNH0572 2

45 OFFSET PULLEY BRACKET UP121 1

46 DOUBLE PULLEY PLATE UP134 2

47 HARD GRIP .875 X 8 BNH0523 6 105 NYLON INSERT LOCK NUT 5/16 -18 BNH0215 2

48 PLASTIC END CAP W/GROOVE SQ. 2" BNH0051 2 106 SOCKET CAP SCREW 1/4 -20 X 3/4 BNH0718 2

49 PLATFORM TG150-49-00 1

50 PLASTIC END CAP W/GROOVE REQ. 2 X3 BNH0049 1 108 HEX HEAD CAP SCREW 3/8 -16 X 3 3/4 BNH0281 4

51 LAT BAR HOLDER TG150-51-00 1

52 CABLE RETAINER BRACKET L-SHAPED UP014 4

53 FEMALE ADJUSTMENT HOUSING TG150-53-00 1

54 BENCH PRESS SELECTOR TUBE TG150-54-00 1

55 CABLE RETAINER BRACKET (LG) UP160 1

56 BENCH PRESS BACK PAD BRACKET TG150-56-00 1

57 FRONT FRAME TG150-57-00 1

58 TOP PLATE SWIVAL BRACKET SMALL UP127 1

59 BLACK CASTER 2 X 1 BNH0633 1

60 BENCH PRESS BACK PAD UP128 1

61 BENCH PRESS SEAT PAD TG150-61-00 1

63 HEX HEAD CAP SCREW 3/8 -16 X 4 3/4 BNH0318 1

SOCKET SET SCREW 3/8-16 X 1/2 BNH0474

65

6

66 HARD GRIP 1.220 X 6" BNH0525 4

68 PRESS BAR TG150-68-00 1

69 HEX HEAD CAP SCREW 3/8 -16 X 1 3/4 BNH0274 17

72 FLAT WASHER SAE 1/2 " BNH0238 6

73 NYLON INSERT JAM LOCK NUT 1/2 - 13 BNH0366 4

74 NYLON INSERT JAM LOCK NUT 3/8 - 16 BNH0365 41

75 FOOT ROLL COLLAR UP083 1

79 HEX HEAD CAP SCREW 3/8 -16 X 3 BNH0282 4

82 NYLON SPACER 3/8 X 3/8 BNH0729 3

84 PUSH PULL PIN 1/2" SPECIAL BNH0516 3

85 PUSH PULL PIN 1/2" BNH0515 2

86 LAT CABLE ( A ) TG150-86-00 1

87 LOW ROW CABLE ( B ) TG150-87-00 1

88 PEC DEC CABLE ( C ) TG150-88-00 1

89 LEG EXTENSION CABLE ( D ) TG150-89-00 1

90 LAT BAR CHROME 48" UP093 1

91 FOOT ROLL TUBE 1 X 23 3/4 UP180 1

92 PUSH PULL PIN 3/8" BNH0517 1

95 HEX KEY 5/32" BNH0373 1

96 BLACK KNOB 1/2 -13 X 1 BNH0055 1

97 FLAT NYLON WASHER SAE 1" BNH0240 1

98 PLASTIC INSERT CAP RD. 2" BNH0004 2

100 PLASTIC INSERT CAP REQ. 2 X 3 BNH0052 3

101 SPLIT BOLT 1/2 -13 X 1 BNH0479 2

103 STRAP BRACKET # 20 BNH0562 2

104 2" ABS PIPE X 15 1/2" BNH0716 1

107 NYLON INSERT LOCK NUT 1/4 -20 BNH0213 2

109 COIL CHAIN 3/16 X 21" BNH0017 1

110 NYLON BUSHING 1 X 1 1/2 BNH0531 4

111 SNAP LINK 8 MM X 80 MM BNH0065 3

113 SOCKET SET SCREW 5/16 -18 X 3/8 BNH0478 1

114 PVC HANDLE BNH0415 2

115 HEX KEY 3/16" BNH0371 1

116 ABDOMINAL STRAP BNH0821 1

117 SHOULDER BOLT 3/8 X 3/4 BNH0718 2

Description Part No. Qty

2

23

TG-150 Tuff Gym Series

Page 25

2. Hold the abdominal strap and assume the starting

Owners’ Manual: Assembly Instructions

START

FINISH

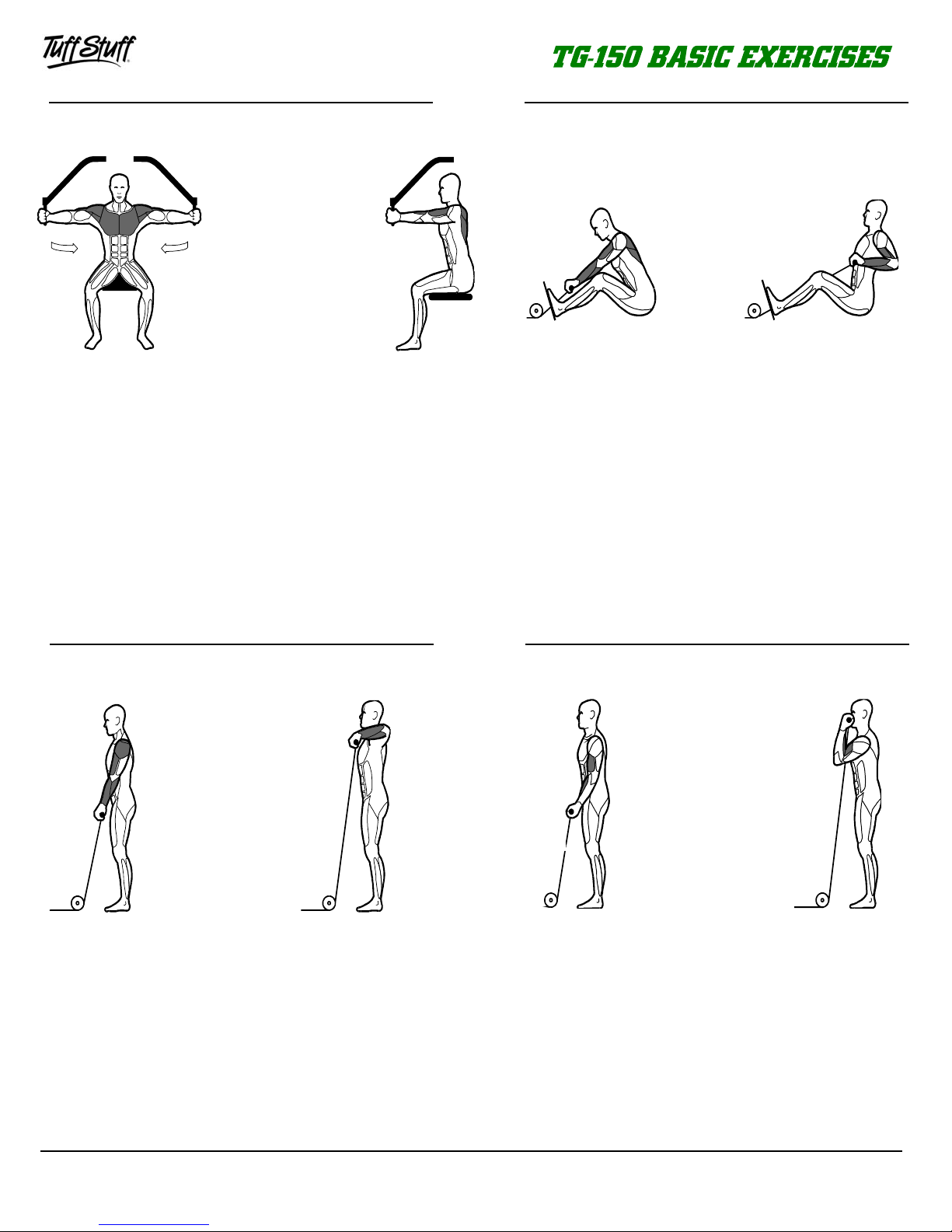

VERTICAL CHEST PRESS

1. Select the desired weight.

2. Sit with the press arm as shown.

3. Push the press arm outward.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

START

FINISH

VERTICAL INCLINE PRESS

1. Select the desired weight.

2. Sit with the press arm and the seat back

positioned as shown.

3. Push the press arm forward.

4. Slowly return arms to the starting position.

Repeat for desired number of repetitions.

START

FINISH

VERTICAL SHOULDER PRESS

1. Select the desired weight.

2. Sit with the press arm and the seat back

positioned as shown.

3. Push the press arm upward.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

START

FINISH

ABDOMINAL CRUNCH

1. Select the desired weight.

position as shown.

3. Pull the cable forward using your stomach.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

TG-150 Tuff Gym Series

24

Page 26

START

FINISH

START

FINISH

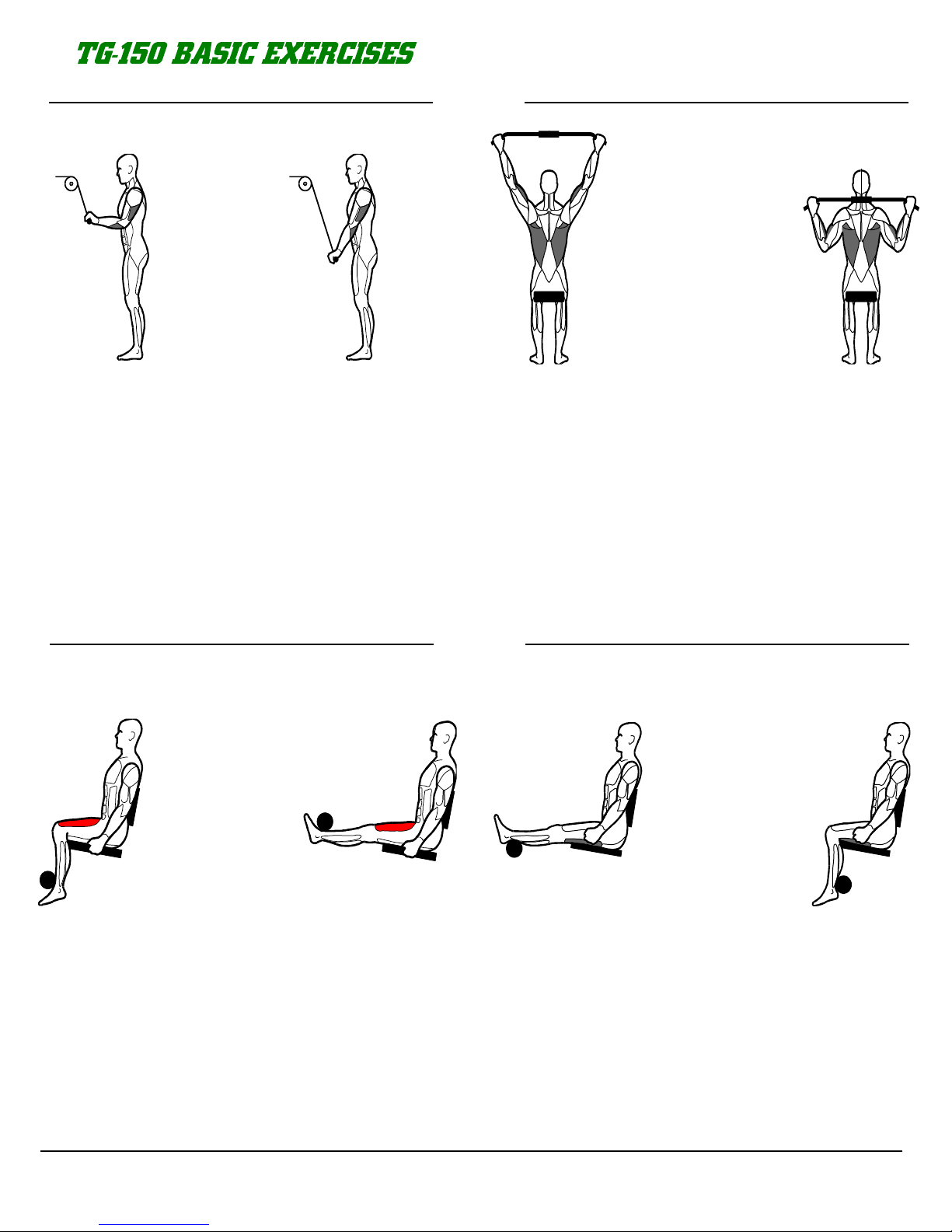

PECTORAL CONTRACTOR

1. Select the desired weight.

2. Assume the starting position as shown.

3. Push forward and rotate the arms in front of your

body simultaneously.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

START

FINISH

LOW ROW

1. Select the desired weight.

2. Assume the starting position as shown.

3. Pull the cable using your arm and upper body.

4. Slowly return arms to the starting position.

Repeat for desired number of repetitions.

START

FINISH

UPRIGHT ROW

1. Select the desired weight.

2. Assume the starting position as shown.

3. Pull the cable using your arm and shoulders.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

25

STANDING ARM CURL

1. Select the desired weight.

2. Stand and pick up bar.

3. Lift bar in front of your body as shown.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

TG-150 Tuff Gym Series

Page 27

Owners’ Manual: Assembly Instructions

START

FINISH

TRICEP PUSHDOWN

1. Select the desired weight.

2. Using the lat cable, follow diagrams for start and

end positions.

3. Slowly return to the starting position.

Repeat for desired number of repetitions.

START

FINISH

CABLE LAT PULLDOWN

1. Select the desired weight.

2. Assume the sitting position with knees under the

foam rolls.

3. Pull down the lat bar as shown.

4. Slowly return arms to the starting position.

Repeat for desired number of repetitions.

START

FINISH

LEG EXTENSION

1. Select the desired weight.

2. Position adjustable back pad for correct starting

position.

3. Position feet behind the foam pads, and extend

leg upward.

4. Slowly return to the starting position.

Repeat for desired number of repetitions.

START

FINISH

STANDING LEG CURL

1. Select the desired weight.

2. Raise the seat pad until it locks into position.

3. Assume a starting position for either leg as

shown.

4. Curl the leg upward as shown.

5. Slowly return to the starting position.

Repeat for desired number of repetitions.

TG-150 Tuff Gym Series

26

Page 28

DO NOT DISCARD THIS MANUAL

1325 E. Franklin Ave., Pomona, CA 91766

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: taskind@aol.com Net: www.tuffstuff.com

Loading...

Loading...