Page 1

A SSEMBLY INSTRUCTION MAN UAL

START

FINISH

LEG PRESS

Revision Date 12-98

TG-11L

Leg Press (Option)

L 8’-7” W 6’-6” H 7’ -0”

Foot Print Shown Above with TG-150

L 8’-7” W 6’-6” H 7’ -0”

Foot Print Shown Above with TG-250

A merica’s Premium Exercise Equipment

Page 2

Introduction

About the Leg Press (TG-11L)

Congratulations on your new purchase of the Leg Press (TG-11L) . We

hope you are completely satisfied with this product and wish you many

years of enjoyment.

Tuff Stuff Equipment

Every Tuffstuff product has been built to precise quality standards and

has been carefully packaged to ensure that damage will not occur during

shipment. The limited lifetime warranty and signature indicating final

inspection has been conducted by our line foreman, is an expression of our

confidence in the completeness, the materials, and workmanship of this

product.

Warranty

SEE WARRANTY REGISTRATION CARD

Registration Card

To avoid unnecessary delays in warranty service and to insure that a

permanent record of your purchase is on file with our factory, be sure to

complete the warranty registration card and send it to Task Industries today.

Safety Information

1) Familiarize yourself and others with the proper operation and workout

recommendations for each piece of Tuff Stuff equipment prior to use.

2) Consult with your physician before beginning any exercise program.

3) Use proper discretion when children are present.

4) Inspect machine for any sign of parts or hardware becoming loose.

5) Periodically check the cable for any indication of wear.

6) Keep hands and limbs clear from weight stack and all

other moving parts.

Maintenance Information

1) Lubrication of the axles is essential to the longevity and optimal

performance of your TG-11L Leg Press. We recommend a multi-purpose

grease for this application.

2) All cables and bushings should be checked regularly for signs of wear.

3) Periodically check all moving parts, upholstery and grips for wear. If

replacement is necessary, please contact your local Tuff Stuff retailer or call

our Customer Service Department.

4) As needed, upholstery may be cleaned with a mild solution of soap and

water. Regular use of a vinyl treatment will add to the life and appearance of

your upholstery.

Tool Requirements

1) Two 3/4” Open-end wrenches

2) Two 9/16” Open -end wrenches

3) One rubber mallet hammer

4) Multi- Purpose Grease

5) Hex Key 3/16 (Supplied)

6) Measuring tape

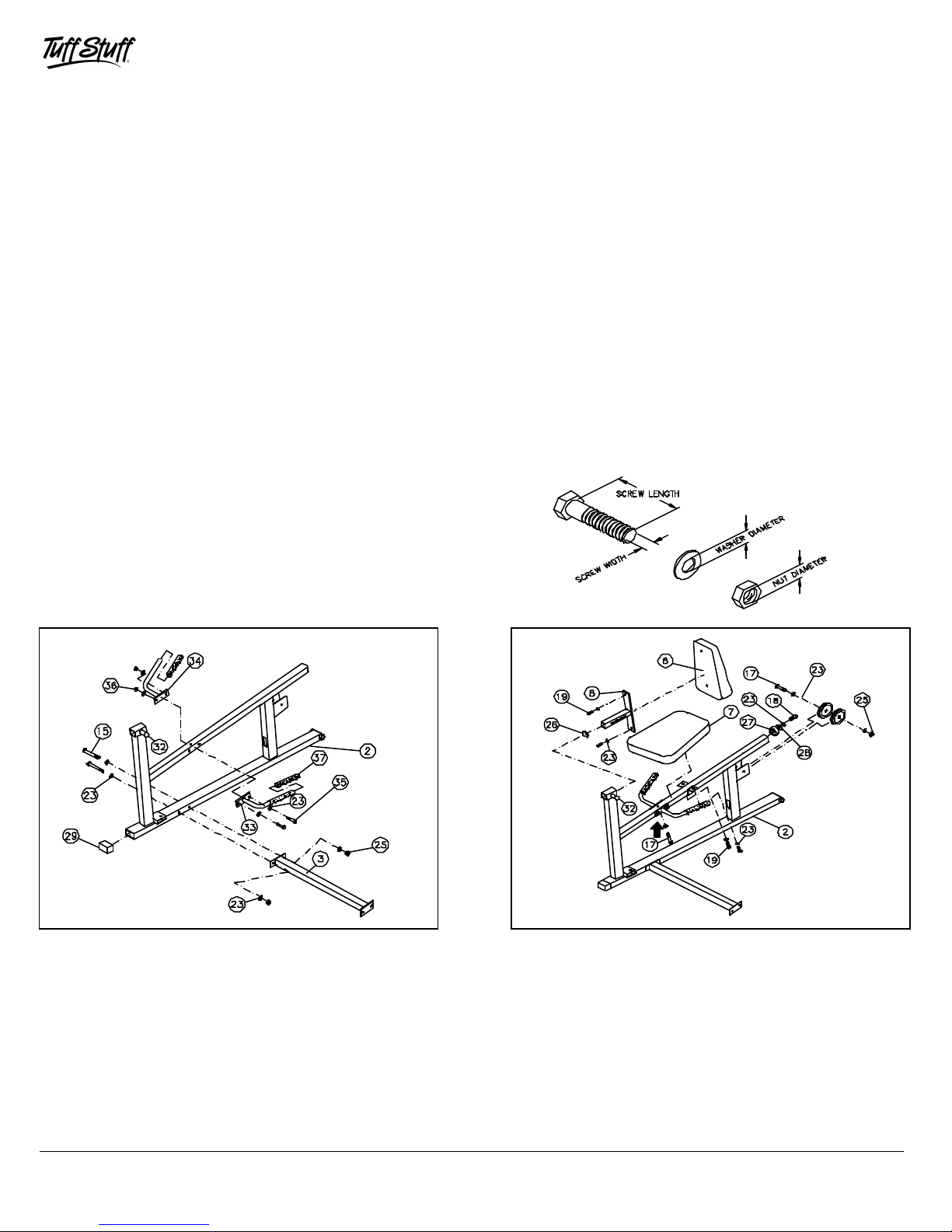

Hardware Measurement Diagram

FIG. 1 Start by mounting the Stabilizer Support (#3) onto the Main

Frame (#2) and secure it into place using two Hex Head Cap Screws 3/8-

16 X 3 3/4 (#15), four Flat Washers SAE 3/8 (#23) and two Nylon Insert

Jam Lock Nuts 3/8-16 (#25). Next, attach the Handle Rt. (#33) and the

Handle Lt. (#34) to the Main Frame (#2) and secure them into place

using two Hex Head Cap Screw 3/8-16 X 3 1/4 (#35), four Flat Washers

SAE 3/8 (# 23) and two Regular Nylon Insert Lock Nut 3/8-16 (#36). Next,

insert two Hard Grips .875 X 8 (#37) over the tube ends of the Handle Rt .

(#33) and the Handle Lt. (#34). Note: It is recommended to use windex

or a household glass cleaner for easy insertion of the Hard

Grips .875 X 8 (#37) . Next, insert one Plastic End Cap w/Groove 2 X 3

(#29) onto the tube end of the Main Frame (#2).

1

1

FIG. 2 Next, mount the Back Pad (#6) onto the Adjustable Back

Pad Tube (#8) and secure it into place using two Hex Head Cap

Screws 3/8-16 X 1 (#19) and two Flat Washers SAE 3/8 (#23). Next,

insert one Plastic Insert Cap 1 3/4 Sq. (#26) into the Adjustable Back

Pad Tube (#8),as shown above. Next, attach the Seat Pad (#7) to the

Main Frame (#2) and secure it into place using two Hex Head Cap

Screws 3/8-16 X 1 (#19), one Hex Head Cap Screw 3/8-16 X 2 3/4

(#17-Labeled with arrow) and three Flat Washers SAE (#23). Next,

attach two Nylon Pulleys 4 1/2” Rd. (#30) into the front pulley bracket

of the Main Frame (#2). Secure them into place using one Hex Head

Cap Screw 3/8-16 X 2 3/4 (#17), two Flat Washers SAE 3/8 (#23) and

one Nylon Insert Jam Lock Nut 3/8-16 (#25). Next, mount the Rubber

Bumper (#27) onto the Main Frame (#2) and secure it into place using

one Hex Head Cap Screw 3/8-16 X 1 3/4 (#18),one Steel Washer 3/8

(#28) and one Flat Washer SAE 3/8 (#23).

TG - 11L Leg Press

TG-11L Leg Press (Option)

Page 3

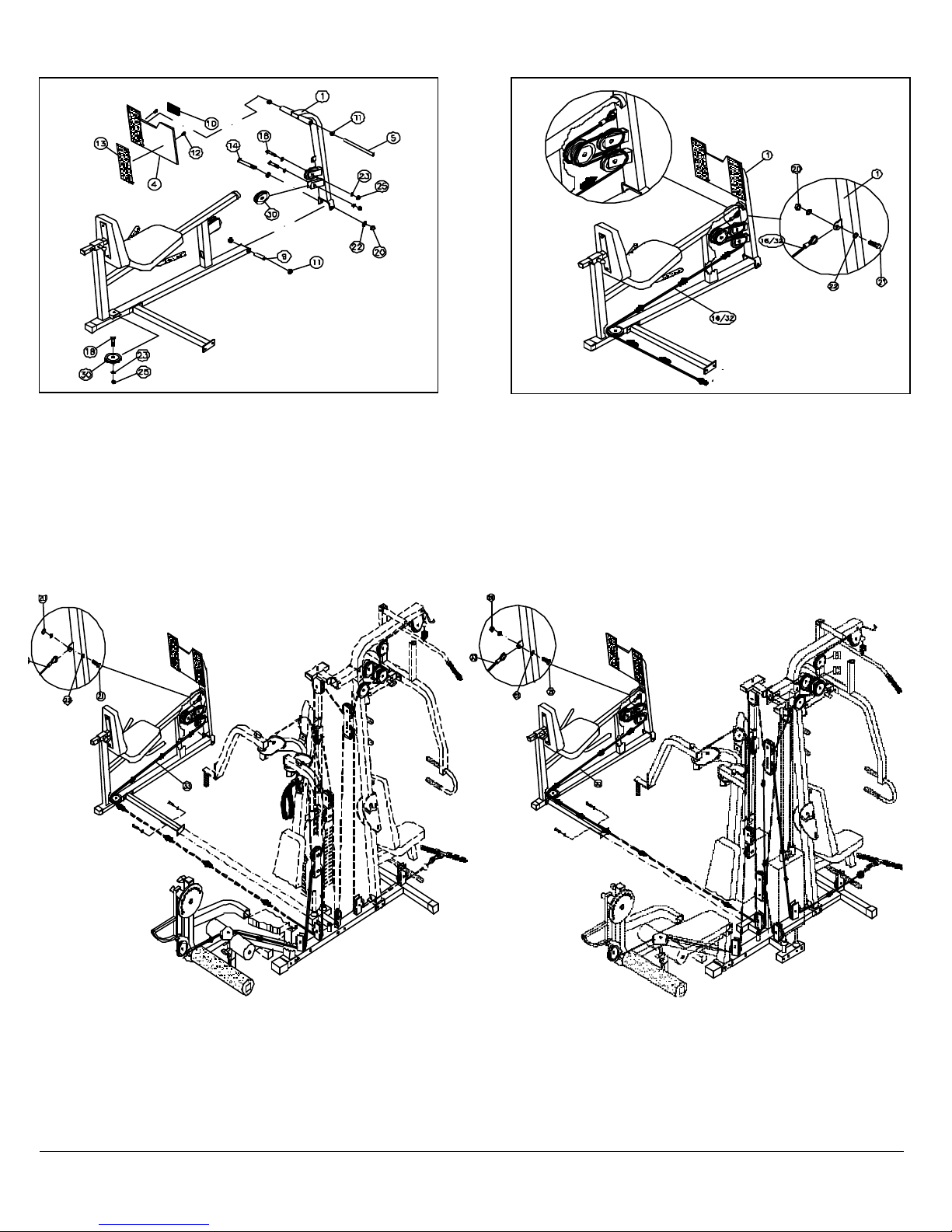

FIG. 2 Attach three Nylon Pulleys 4 1/2 Rd. (#30) ,as shown above.

250, as shown above, and

16 X 3 3/4 (#15),

Main

Labeled

will replace the existing cable you are using for the

Labeled with

will now be used for the Low Row and the Leg Press

Attach two of the Nylon Pulleys 4 1/2 Rd. (#30) to the brackets located

on the Fulcrum (#1) and then one on the Main Frame (#2). Secure all

Nylon Pulleys 4 1/2 Rd. (#30) into place using three Hex Head Cap

Screws 3/8-16 X 1 3/4 (#18), six Flat Washers SAE 3/8 (#23) and three

Nylon Insert Jam Lock Nuts 3/8-16 (#25). Next, insert the Small Axle

(#9) into the Main Frame (#2) . Then mount the Fulcrum (#1) onto the

front of the Main Frame (#2) and secure it into place using one Hex

Head Cap Screw 1/2-13 X 5 1/2 (#14), two Flat Washers SAE 1/2 (#22)

and one Nylon Insert Jam Lock Nut 1/2-13 (#20) . Next, insert the Foot

Plate (#4) onto the Fulcrum (#1), as shown above, with the Large Axle

(#5) and secure it into place using two Set Screws 3/8-16 X 1/2 (#12).

Note: It is recommended to lubricate the axles using a multi-purpose

Owners’ Manual: Assembly Instructions

Note: Some Parts Not

Shown or cut away for

clarity

Fig. 3 Note: Before routing the cable, locate the Main Cable (#16-

Labeled with tape TG-150) or the Main Cable (#31-Labeled with

tape TG-250). The label on the cable will determine which cable is

needed for either the TG-150 or the TG -250. Route the Main Cable

(#31 or #16), as illustrated above, beginning at the TG-150 or TG-250

and finishing at the Fulcrum (#1) mounting bracket. Secure the Main

Cable (#31 or #16) to the Fulcrum (#1) mounting bracket using one

Hex Head Cap Screw 1/2-13 X 1 (#21), two Flat Washers SAE 1/2

(#22) and one Nylon Insert Jam Lock Nut 1/2-13 (#20). Note: Use Fig.

A and Fig. B and your TG-150 Or TG-250 Instruction Manual for

further clarification of the this cable routing.

Fig. A

TG-11L to TG-150

Cable Routing Diagram

FIG. A Attach the TG-11L to the TG-150, as shown above, and

secure it into using two Hex Head Cap Screws 3/8-16 X 3 3/4 (#15), four

Flat Washers SAE 3/8 (#23) and two Nylon Insert Jam Lock Nuts 3/8-16

(#25). When installing the TG-11L you will receive a new cable, the Main

Cable (#16-Labeled with tape TG-150). This Main Cable (#16-Labeled

with tape TG-150) will replace the existing cable you are using for the

Leg Extension station on the TG-150. This new Main Cable (#16-Labeled

with tape TG-150) will now be used for the Leg Extension and the Leg

Fig. B

TG-11L to TG-250

Cable Routing Diagram

FIG. B Attach the TG-11L to the TG-

secure it into place using two Hex Head Cap Screws 3/8four Flat Washers SAE 3/8 (#23) and two Nylon Insert Jam Lock Nuts 3/8

16 (#25). When installing the TG-11L you will receive a new cable,

Cable (#31-Labeled with tape TG-250). This Main Cable (#31with tape TG-250)

Low Row station on the TG-250. This new Main Cable (#31-

tape TG-250)

TG-11L Leg Press (Option)

2

Page 4

DO NOT DISCARD THIS MANUAL

TG-11L PARTS LIST

1

FULCRUM

UP156

120NYLON INSERT JAM LOCK NUT 1/2-13

BNH0366

2

2

MAIN FRAME

UP170

1

21

HEX HEAD CAP SCREW 1/2-13 X 1

BNH0259

13STABILIZER SUPPORT

UP157

122FLAT WASHER SAE 1/2"

BNH0238

4

4

FOOT PLATE

UP155

1

23

FLAT WASHER SAE 3/8"

BNH0239

28

6

BACK PAD

UP145

1

25

NYLON INSERT JAM LOCK NUT 3/8-16

BNH0365

10

26

PLASTIC INSERT CAP 1 3/4 SQ

BNH0053

1

8

ADJUSTABLE BACK PAD TUBE

UP136

1

27

RUBBER BUMPER 3/8 X 2 1/2

BNH0511

1

28

STEEL WASHER 3/8"

BNH0498

1

31

MAIN CABLE ( 250 )

TG11L-31-00

1

33

HANDLE (RT)

UP270

1

16

MAIN CABLE (150 )

TG11L-16-00

135HEX HEAD CAP SCREW 3/8-16 X 3 1/4

BNH0312

2

TG-11L EXPLODED VIEW DIAGRAM

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

Item No. Description Part No. Qty Item No. Description Part No. Qty

5 LARGE AXLE 1 X 10 3/8 UP154 1 24 HEX KEY 3/16" BNH0371 1

7 SEAT PAD UP146 1

9 SMALL AXLE 1 X 4 1/4 UP153 1

10 RUBBER MAT 2 1/2 X 3 1/2 BNH0688 1 29 PLASTIC END CAP W/GROOVE 2X 3 BNH0049 1

11 BRONZE BUSHING 1 X 1 1/4 BNH0527 4 30 WHITE NYLON PULLEY 4 1/2 RD BNH0506 6

12 SET SCREW 3/8-16 X 1/2 BNH0474 2

13 SAFETY TAPE 4 X 12 BNH0492 2 32 PUSH-PULL PIN 1/2 BNH0515 1

14 HEX HEAD CAP SCREW 1/2-13 X 5 1/2 BNH0267 1

15 HEX HEAD CAP SCREW 3/8-16 X 3 3/4 BNH0281 4

17 HEX HEAD CAP SCREW 3/8-16 X 2 3/4 BNH0278 2 36 NYLON INSERT LOCK NUT 3/8-16 BNH0214 2

18 HEX HEAD CAP SCREW 3/8-16 X 1 3/4 BNH0274 4 37 HARD GRIP .875 X 8 BNH0523 2

19 HEX HEAD CAP SCREW 3/8-16 X 1 BNH0275 4

34 HANDLE (LT) UP271 1

1325 E. Franklin Ave., Pomona, CA 91766

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: taskind@aol.com Net: www.tuffstuff.com

Loading...

Loading...