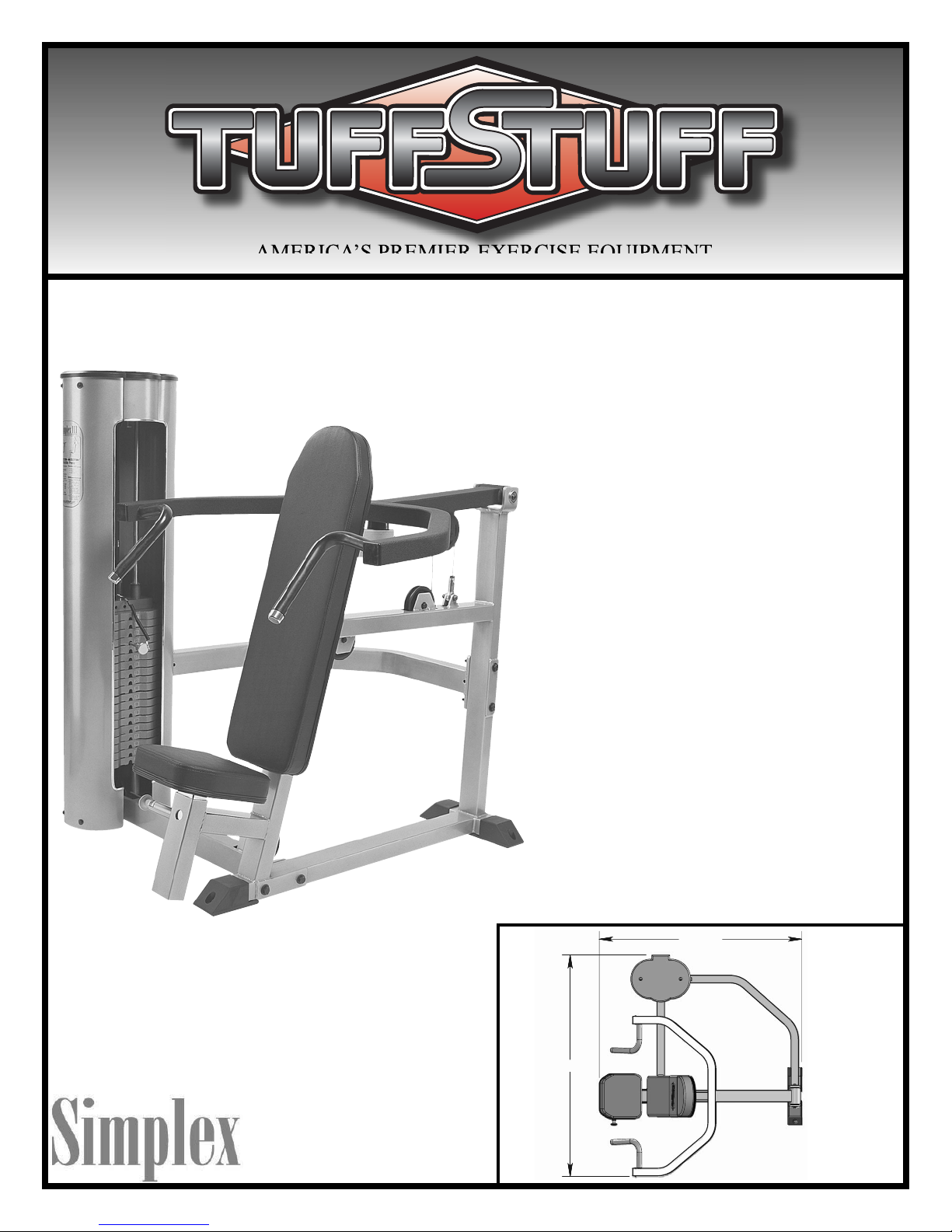

Page 1

AMERICA’S PREMIER EXERCISE EQUIPMENT

SHOULDER PRESS

ASSEMBLY MANUAL

SP-4402

REV. 0

PLATINUM

50 1/2"

55 1/4"

L 50 1/2" W 55 1/4" H 54 3/4"

Page 2

Introduction

About the Shoulder Press SP-4402

Congratulations on your new purchase of the Shoulder Press. We

hope you are completely satis ed with this product and wish you

many years of enjoyment.

Tuff Stuff Equipment

This Tuffstuff product has been built to precise quality standards and

has been carefully packaged to ensure that damage will not occur

during shipment. The TuffStuff Warranty and signature indicating

final inspection has been conducted by our line foreman, is an

expression of our con dence in the completeness, the materials,

and workmanship of this product.

Warranty

SEE A COPY OF WARRANTY ON BACK PAGE.

Registration Card

To avoid unnecessary delays in warranty service and to insure that

a permanent record of your purchase is on le with our factory,

be sure to complete the warranty registration card and send it to

TuffStuff Fitness Equipment today.

Specifi cations

1. Maximum Wt. Capacity - 200 lbs.

2. Total Machine Weight - 575 lbs.

3. Footprint (LWH) - See Front Cover.

Note: Due to continuing product improvements, speci cations and designs are subject to change

without notice.

Prior to the Assembly of the Shoulder Press

1. We advise you to consult your local Tuff Stuff retailer if you should

have a question or problem regarding the proper assembly of

this unit.

Tool Requirements

1. One 7/8” combination wrench

2. One 3/4” combination wrench

3. One 9/16” combination wrench

4. One 7/16” combination wrench

5. One ratchet

6. One 3/4” socket

7. One 9/16” socket

8. One 7/16” socket

9. One rubber mallet

10. Windex or household glass cleaner

11. Measuring tape

12. Utility knife

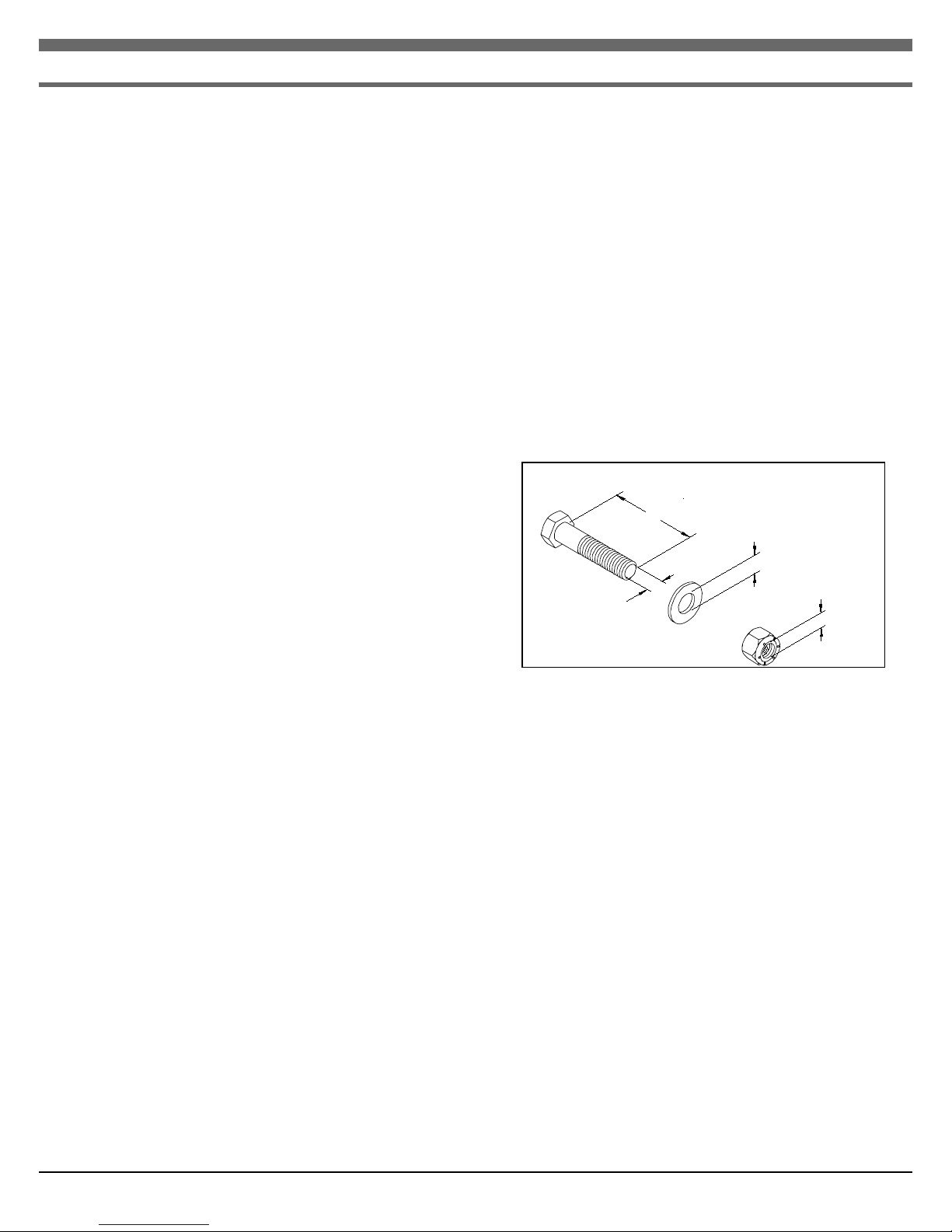

Hardware Measurement Diagram

H

T

G

N

E

L

W

E

R

C

S

R

E

H

S

A

W

H

T

D

I

W W

E

R

C

S

R

E

T

E

M

A

I

D

R

E

T

E

M

A

I

D

T

U

N

Safety Precautions

Safety First

Regardless of how enthusiastic you may be about getting on

your equipment and exercising, take the time to ensure that your

safety is not jeopardized. A moment’s lack of attention can result

in an accident, as can failure to observe certain simple safety

precautions.

1. Read, study and understand the Assembly Instructions and all the

warning labels on this product. Furthermore, it is recommended

to familiarize yourself and others with the proper operation and

workout recommendations for this Tuff Stuff product prior to

use.

2. It is imperative that you retain this Assembly Instructions and

be sure all warning labels are legible and intact. Replacement

Assembly Instructions and labels are available from your local

Tuff Stuff retailer.

3. Consult with your physician before beginning any exercise

program.

2 SP-4402 Shoulder Press

4. Frayed or worn cables can be dangerous and may cause injury.

Periodically check the cable for any indication of wear.

5. Use proper discretion when children are present.

6. Keep hands, limbs, loose clothing and long hair well out of the

way of moving parts.

7. Do not attempt to lift more weight than you can control safely.

8. Inspect the Unit for any sign of wear on parts, hardware becoming

loose or cracks on welds. If a problem is found do not use or

allow the machine to be used until the defective part is repaired

or replaced.

Page 3

CHART

SP-4402

BOLD FONT = SUB-ASSEMBLY PARTS

REGULAR FONT = HARDWARE

ITEM # DESCRIPTION PART # QTY. ITEM # DESCRIPTION PART # QTY.

3 BACK PAD UP5024 1

4 BOTTOM CROSS BRACE UP5020 1

5 GUIDE ROD 3/4 X 53 3/4 UP0783 2

6 GUIDE ROD RETAINER W/THREAD UP5017 1

7 PIVOT AXLE 1 X 5 1/8 UP5026 1

8 PRESS BAR UP5025 1

9 REAR CROSS BRACE UP5027 1

10 SEAT ELEVATION TUBE UP5022 1

11 SEAT PAD UP5023 1

12 SELECTOR PIN W/COIL 3/8 X 4 GOLD KNOB UP3035 1

13 SHOULDER PRESS CABLE UP5028 1

14 SHOULDER PRESS MAIN FRAME UP5021 1

16 WEIGHT SHROUD 54” UP5029 1

17 WEIGHT SHROUD W/HOLES 54” UP5030 1

18 WEIGHT STACK FRAME 54” UP5016 1

19 WEIGHT STACK SPACER 4” UP0786 2

20 ALUMINUM CAP 1” RD. (CAP-100) BNH0537 2 62 PLASTIC SHROUD LID 5/8 X 14-1/8 X 10 BNH0185 1

21 ALUMINUM INSERT CAP 2 SQ X .105 BNH1502 2 63 PULL PIN 1/2 X 5 5/8 LIGHT SPRING BNH0701 1

22 ALUMINUM INSERT CAP 2 X 3 X .105 BNH1503 2 64 RETAINING SNAP RING EXT. PLAIN 1.886 BNH1832 2

23 BALL BEARING W/GROVE 620SRS BNH1831 2 65 ROD END 1/2-13 BNH1828 1

24 BUTTON HD SOC CAP SCREW B/O 1/4-20 X 3/8 BNH1346 8 66 RUBBER BUMPER 3/8 X 2 1/2 BNH0511 1

25 BUTTON HD SOC CAP SCREW B/O 3/8-16 X 1 BNH0115 2 67 RUBBER DONUT 3/4 X 2 1/2 BNH0068 2

26 CHROME WASHER 3/8 X 1-1/2 BNH1015 2 68 RUBBER FLAT TUBE .94 ID X .115 WALL X 15 1/4 BNH1377 2

28 DECAL-ADJUST CABLE HERE BNH0789 1 69 RUBBER GROMMET 3/4” ID (2867-012) BNH0401 2

29 DECAL-CAUTION 1 3/4 X 5 1/2 BNH0126 1 70 SHOULDER BOLT ALLOY 1/2 X 1 1/4 BNH0098 1

30 DECAL-DANGER TIGHTEN THIS RET..., BNH0142 1 71 SOCKET SET SCREW ALLOY 1/4-20 X 1/4 BNH0790 2

31 DECAL-EXERCISE SP-4402 SHOULDER PRESS BNH1682 1 72 SOCKET SET SCREW ALLOY 10-32 X 1/8 BNH0473 4

32 DECAL-FOR BEST PERFORMANCE 1-1/4 X 1-1/2 BNH0143 1 73 SPLIT BOLT Z/P 1/2-13 X 1 BNH0479 1

33 DECAL-WARNING KEEP HANDS AND FINGERS... BNH0620 1 74 SPLIT HEX TAP BOLT GR-5 B/O 1/2-13 X 3 1/2 BNH1131 1

34 DECAL-WEIGHT NUMBERS REF TP-10 (200 lbs) BNH1542 1 75 SPLIT LOCK WASHER B/O 1/2” BNH0653 4

35 EDGE PROTECTOR CHROME 11 GA BNH1724 4 76 SPLIT LOCK WASHER B/O 3/8” BNH0658 2

37 FINISHED HEX NUT B/O 1/2-13 BNH0201 1 78 STEEL BUMPER WASHER Z/P 3/8” BNH0498 1

38 FLAT HEAD SOCKET CAP SCREW B/O 3/8-16 X 3 BNH0787 2 79 SUPER LUBE TEFLON LUBRICANT 82340 BNH0704 2

39 FLAT WASHER SAE B/O 1/2” BNH0238 16 80 TUFFSTUFF LOGO ALUMINUM LARGE BNH1837 1

40 FLAT WASHER SAE B/O 3/8” BNH0239 21 81 URETHANE BUMPER 1 3/4 BNH0229 3

41 FLAT WASHER USS B/O 1/4” BNH0233 8 82 U-STYLE TAPPED HOLE NUT 1/4-20 BNH0708 8

42 FLAT WASHER USS B/O 3/4 X 2” BNH0878 4 83 U-STYLE TAPPED HOLE NUT 3/8-16 BNH1211 2

43 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 1 BNH0259 2 84 15 LB CAST WEIGHT PLATE GREY (EA) BNH0926 19

44 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 3 3/8 BNH1841 4 85 10 LB TOP PLATE W/ADJ. SLTR BAR 19 WTS BNH1100 1

45 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 5/8 BNH1843 4

Parts List

46 HEX HEAD CAP SCREW GR-5 B/O 1/4-20 X 3/4 BNH0890 8

47 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1 1/2 BNH0303 2

48 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1-3/4 BNH0274 6

49 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 3 1/4 BNH0312 4

50 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 4 BNH0285 1

51 HEX KEY 3/32” BNH0372 1

52 HEX KEY 7/32” BNH0575 2

53 HEX KEY 1/4” BNH0375 1

54 HEX KEY 5/32” BNH0373 1

55 HEX KEY 1/8” BNH0767 1

56 NYLON INSERT JAM LOCK NUT B/O 3/8-16 BNH0365 7

57 NYLON INSERT LOCK NUT B/O 1/2-13 BNH0212 8

58 NYLON INSERT LOCK NUT B/O 3/8-16 BNH0214 1

59 NYLON PULLEY 3/8 X 1 X 4 1/2 BLACK BNH0506 6

60 PLASTIC END CAP 2 X 3 BNH0606 3

61 PLASTIC SHROUD GAP COVER 3” BNH1829 1

3SP-4402 Shoulder Press

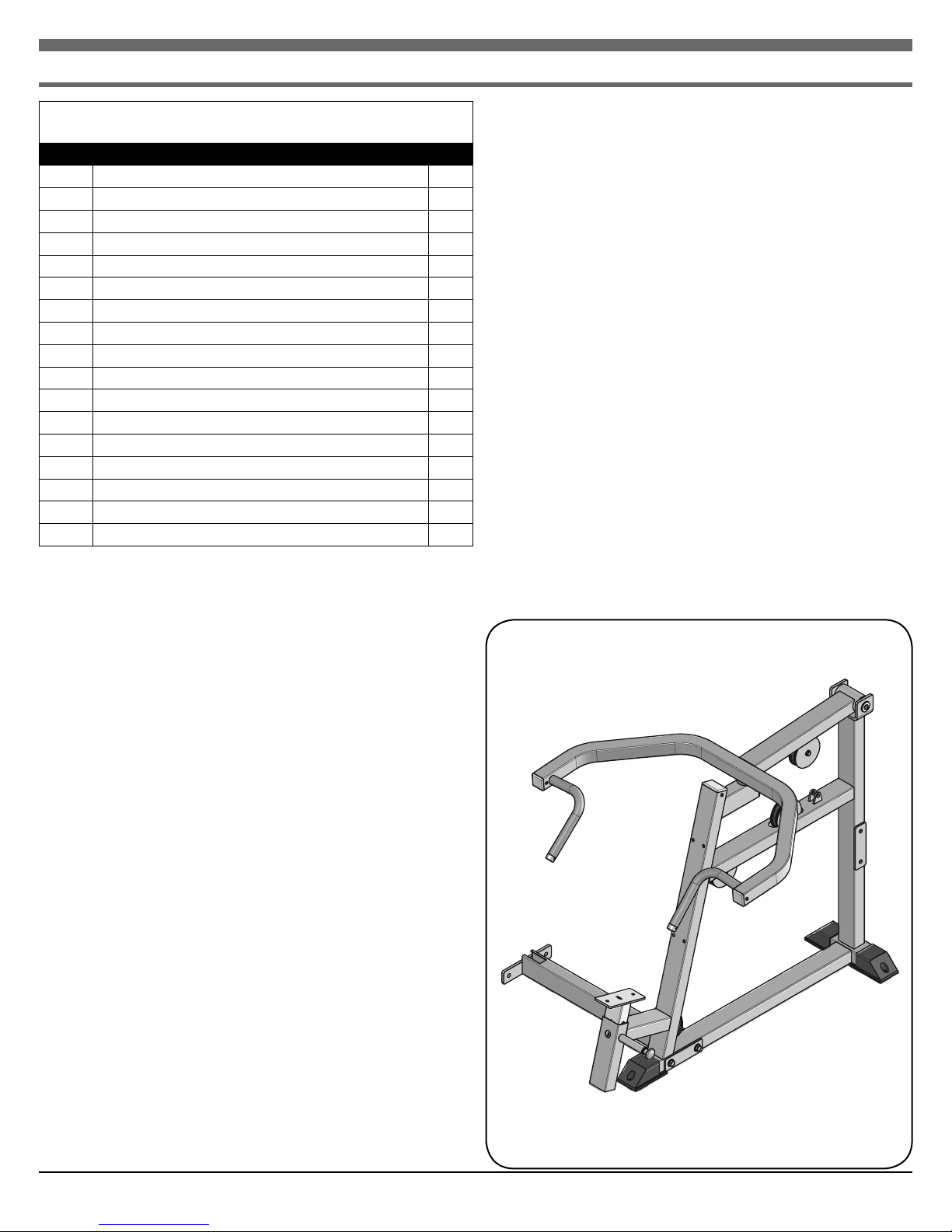

Page 4

Step 1

Assembly List

ITEM # DESCRIPTION QTY.

4 BOTTOM CROSS BRACE 1

7 PIVOT AXLE 1 X 5 1/8 1

8 PRESS BAR 1

10 SEAT ELEVATION TUBE 1

14 SHOULDER PRESS MAIN FRAME 1

25 BUTTON HEAD SCREW B/O 3/8-16 X 1 2

26 CHROME WASHER 3/8 X 1 1/2 2

39 FLAT WASHER SAE B/O 1/2” 4

40 FLAT WASHER SAE B/O 3/8” 8

45 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 5/8 2

48 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1-3/4 4

56 NYLON INSERT JAM LOCK NUT B/O 3/8-16 4

57 NYLON INSERT LOCK NUT B/O 1/2-13 2

59 NYLON PULLEY 3/8 X 1 X 4 1/2 BLACK 4

60 PLASTIC END CAP 2 X 3 3

76 SPLIT LOCK WASHER B/O 3/8” 2

4 SP-4402 Shoulder Press

Page 5

56

40

40

48

8

59

25

76

26

59

57

39

7

56

40

59

40

48

56

40

4

57

10

39

56

40

48

40

60

59

14

39

45

26

76

25

60

60

39

45

5SP-4402 Shoulder Press

Page 6

Step 2

Assembly List

ITEM # DESCRIPTION QTY.

6 GUIDE ROD RETAINER W/THREAD 1

9 REAR CROSS BRACE 1

12 SELECTOR PIN W/COIL 3/8 X 4 GOLD KNOB 1

17 WEIGHT SHROUD W/HOLES 54” 1

18 WEIGHT STACK FRAME 54” 1

19 WEIGHT STACK SPACER 4” 2

39 FLAT WASHER SAE B/O 1/2” 12

40 FLAT WASHER SAE B/O 3/8” 4

41 FLAT WASHER USS B/O 1/4” 4

42 FLAT WASHER USS B/O 3/4 X 2” 4

43 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 1 2

44 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 3 3/8 4

45 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 5/8 2

46 HEX HEAD CAP SCREW GR-5 B/O 1/4-20 X 3/4 4

48 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1 3/4 2

56 NYLON INSERT JAM LOCK NUT B/O 3/8-16 2

57 NYLON INSERT LOCK NUT B/O 1/2-13 6

59 NYLON PULLEY 3/8 X 1 X 4 1/2 BLACK 2

67 RUBBER DONUT 3/4 X 2 1/2 2

75 SPLIT LOCK WASHER B/O 1/2” 2

84 15 LB CAST WEIGHT PLATE GREY 19

85 10 LB TOP PLATE W/ADJ. SLTR BAR 19 WTS 1

6 SP-4402 Shoulder Press

Page 7

45

41

46

17 75 43 9 57 39

46

39

574375

41

46

39

45

39

44

39

44

46

39

56

40

57 39

44

57

39

39

59

39

39

40 56

59

12

18

5

40

48

40

57

67

48

42

57

19

39

42

6

85

5

84

67

42

19

42

7SP-4402 Shoulder Press

Page 8

Step 3 Cable Mapping Diagram

FIG. A

13

74

37

75

85

12

A

8 SP-4402 Shoulder Press

B

C

Page 9

FIG. B

13

73

75

58

65

F

14

70

E

D

?

?

Note: Some parts have

been cut away for clarity.

9SP-4402 Shoulder Press

Page 10

Step 4

Assembly List

ITEM # DESCRIPTION QTY.

3 BACK PAD 1

11 SEAT PAD 1

16 WEIGHT SHROUD 54” 1

38 FLAT HEAD SOCKET CAP SCREW B/O 3/8-16 X 3 2

40 FLAT WASHER SAE B/O 3/8” 6

41 FLAT WASHER USS B/O 1/4” 4

46 HEX HEAD CAP SCREW GR-5 B/O 1/4-20 X 3/4 4

47 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1 1/2 2

49 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 3 1/4 4

61 PLASTIC SHROUD GAP COVER 3” 1

62 PLASTIC SHROUD LID 5/8 X 14 1/8 X 10 1

71 SOCKET HEAD CAP SCREW B/O 1/4-20 X 1/4 2

10 SP-4402 Shoulder Press

Page 11

38

62

3

71

4146

41

46

16

61

11

4146

40

41

47

46

40

47

40

40

40

49

49

49

11SP-4402 Shoulder Press

Page 12

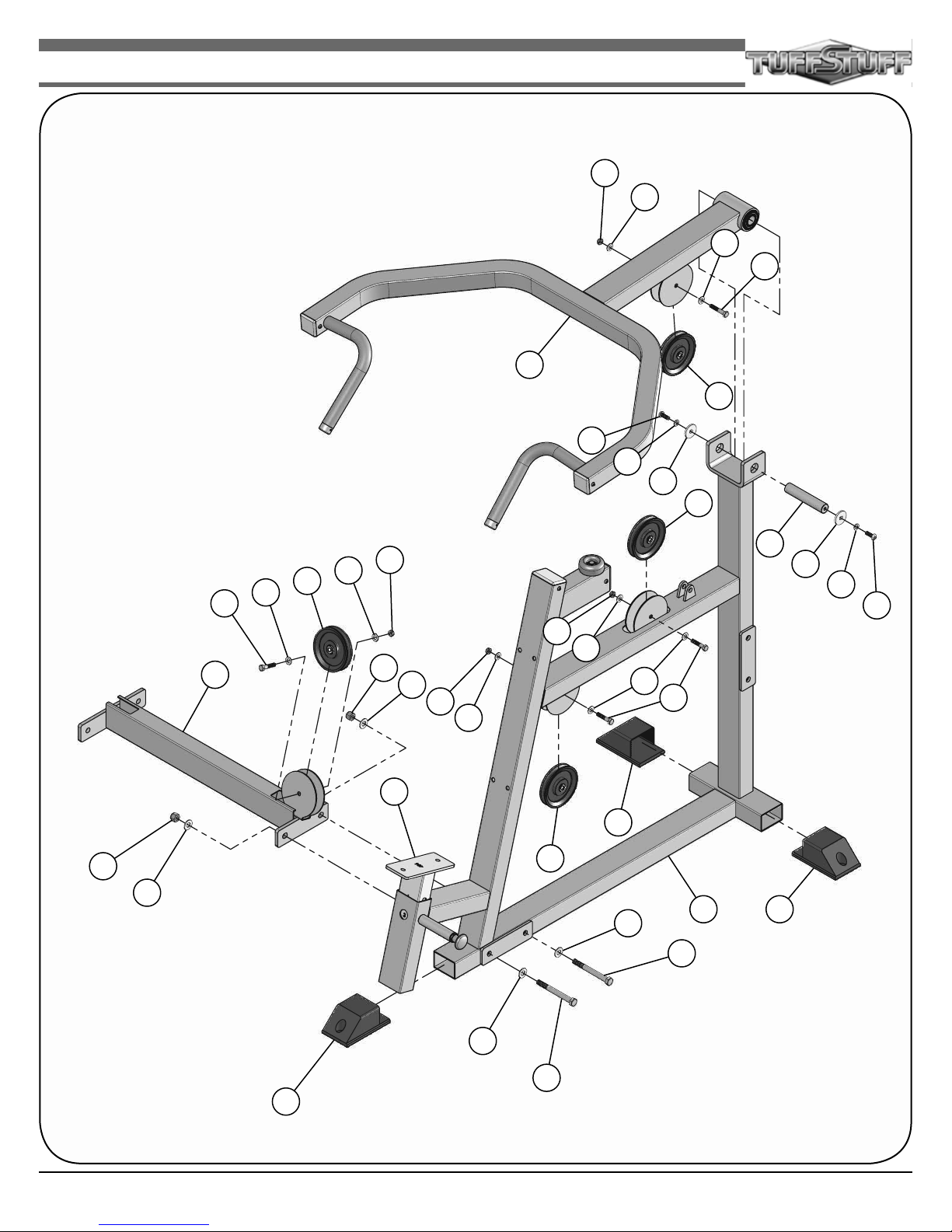

SP-4402 Exploded View Diagram

38

41

46

41

46

16

71

62

82

83

35

83

41 46

39

12

40

57

39

44

4039

59 59

5657

35

35

40

56

57

39

82

4

81

6

69

5

85

61

35

67

42

19

4469

39

485

84

48

67

42 81

19

42

40

18

39

41 46

41 46

41 46

44

57

75

75 43

39

4317

42

41

46

41

46

12 SP-4402 Shoulder Press

75

37

81

74 13

39

73

58

44

75

65

57

70

39

48

40 56

59

40

Page 13

64

23

9

57 39

56

40

24

21

72

24

68

72

20

3

24

3957

15

50

78

66

24

24

8

21

24

56

24

25

76

26

59

22

23

64

40

48

59

7

26

76

25

47

40

10

11

47

40

22

39

45

40

48

56

40

59

49

40

14

39

39

6360

45

39

45

60

13SP-4402 Shoulder Press

Page 14

Maintenance

TuffStuff Basic Strength Equipment Safety and General Maintenance

All TUFFSTUFF strength equipment is designed and manufactured to offer maximum, long-life service

with minimal maintenance. However, safety inspection and routine maintenance in your facility should be

the upmost importance in your daily operation. Information presented in these pages will serve as a basic

guideline to design your own inspection procedures.

Part One: General Inspection and Cleaning

Equipment should be wiped down with a damp cloth and dried on a daily basis. The powder coat nish

should be polished with a good car wax on a monthly basis. A daily wipe down of the upholstery with a lanolin based hand cleaner or Naugahyde Cleaner. Do not use cleaners such as Lysol or Windex as they will

dry out and crack the vinyl. Lanolin hand cleaner dissolves the sweat and lubricates the vinyl, maintaining

its natural exibility. Sweat is corrosive and when left on the frame and components will eventually cause

corrosion or rust. When performing these cleaning sessions, it is the perfect time to inspect the equipment

and note any problems for the maintenance personnel to correct.

1. Check equipment if it is operating properly.

2. Check the cable for loose ttings or frayed cable and is seating properly on the pulleys and

cams.

3. Make sure that the proper weight stack selector pin is with each machine and that the pin functions properly.

4. If something appears loose be sure to have it tightened immediately.

5. If a piece of equipment appears damaged or not operation properly, place the piece out-of-service immediately.

Part Two: Maintenance

In this paragraph, we will discuss the inspection of the cables, pulleys and their associated components. If

there exists the potential for injury to occur on a machine, it will most likely lie in the cable system. It is important to inspect the cables frequently and let it be known to all users that it is their responsibility to report

any worn-out cable to prevent a sudden failure that can result in an injury. Cables are moving parts, meaning cable-wear will occur regardless of the type or size used. In the advent of the 3/16” mill-spec cable this

wear takes longer to become apparent and this is why frequent inspections are so important.

1. Check the cable termination at the weight stack. To perform any cable tension adjustment,

loosen the hex jam nut and thread the hex tap bolt in or out to give cable the proper tension.

Re-tightened the hex jam nut when adjustment is complete and make sure the hex tap bolt is

threaded 1/2” into the socket of the selector bar top plate.

2. Check the cable as it terminates at the cam. Check the end tting for any signs of fraying in this

area. Inspect the bolt and nut and/or screw holding the tting and be sure that it is tight.

3. Check the cables as it passes over all pulley wheels. Visually inspect the cables and pulleys. A

cable that is wearing will exhibit a ballooned surface that passes over the pulley. This is and early

warning sign to replace the cable.

14 SP-4402 Shoulder Press

Page 15

Maintenance

Part Three: Lubrication

Bearing and linear bearings systems have advanced over the years but they must be maintained on a regular basis if you expect them to last and perform ef ciently. TuffStuff uses only the highest quality bearings

and linear motion components that are virtually trouble-free but requires the regular preventive maintenance

to insure long-lasting performance.

1. Bronze and nylon bushings, we recommend on a monthly basis to spray a te on-base lubricant

(silicone-free) directly onto the shaft as it passes through these bushings. Spray a small amount

onto the shaft and rotate it through its complete movement and wipe off any excess.

2. Weight stack guide rods and bushings, again use te on spray lubricant and this time spray onto

a rag and wipe the guide rods down with this rag on a weekly basis. Do not use WD-40 or other

lubricants as they attract dirt and will crate a mess between the weight plates and bushings.

3. Sealed bearings pivot points, as the name implies are protected from the outside environment

and require no lubrication. During the machine wipe down, wipe the external bearing surfaces

with the damp rag and dried to prevent the build up of dust and sweat.

4. Linear bearing systems are precision, high load components that require regular maintenance.

Dirt and corrosion are the major culprits in linear bearing failure. The hardened shafts must be

wiped down weekly and lubricated with a light layer of te on grease. We recommend a te onbase (silicone-free) gel/grease for this purpose. Lack of care and maintenance will result in corrosion of the linear shaft causing the bearings to clogged and jammed

If you religiously perform the maintenance procedures, you will increase the life of the machine and ultimately lower your maintenance costs with fewer replaced components and downtime.

Any doubts, equipment with mechanical problems should be placed “Out-of-Service” until all problems are

corrected. If replacement parts are required or maintenance questions, please contact:

.

TuffStuff Fitness Equipment, Inc.

Service Department

1325 E. Franklin Avenue

Pomona, CA 91766

1-800-961-9377

e-mail: service@tuffstuff.net

15SP-4402 Shoulder Press

Page 16

DO NOT DISCARD THIS MANUAL

TUFFSTUFF WARRANTY

TuffStuff warrants to the original purchaser that TuffStuff equipment will be free from defects in material and

workmanship. All warranty periods begin to run from the date of delivery to the original purchaser. The warranty

and remedies set forth herein are conditioned upon proper storage, installation, use and maintenance and conformance with any recommendations of TuffStuff. This warranty does not cover products not manufactured by

TuffStuff or products which are altered without the express written consent of TuffStuff. This warranty as specified:

FULL COMMERCIAL WARRANTY (more than 5 hours of use per day): a) Frames, welds, cams and

weight plates -- Lifetime, b) Pivot bearings, pulleys, bushings, gas shocks and guide rods -- Five (5) years, c)

Belts, linear bearings and pull-pin components -- One (1) year, and d) Upholstery, cables, finish and rubber grips

-- Six (6) months.

LIGHT COMMERCIAL WARRANTY (less than 5 hours of use per day): a) Frames, welds, cams and weight

plates -- Lifetime, b) Pivot bearings, pulleys, bushings, gas shocks and guide rods -- Five (5) years, c) Linear

bearings, finish and pull-pin components -- One (1) year, and d) Upholstery, cables and rubber grips -- Three

(3) months, and all other parts not mentioned elsewhere in this warranty will expire one (1) year from the date of

delivery to the original purchaser. The obligation of TuffStuff under this warranty is limited to repairing or replacing warranted defective parts, as TuffStuff may elect, at TuffStuff’s facility in Pomona, California, without

charge to purchaser for either parts or labor. Purchaser is responsible for installation of repaired or replaced parts,

and all transportation and insurance costs on returned or replaced equipment to and from TuffStuff’s facility in

Pomona.

THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE

SOLE LIABILITY OF TUFFSTUFF WITH REGARD TO WARRANTY. NO IMPLIED STATUTORY

WARRANTY OR IMPLIED STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE SHALL APPLY. IN NO EVENT, WHETHER AS A RESULT OF

BREACH OF CONTRACT, WARRANTY, NEGLIGENCE OR OTHERWISE, SHALL TUFFSTUFF BE

LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITED TO, LOSS OF PROFITS OR REVENUE, LOSS OF USE OF EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTION EQUIPMENT, DOWNTIME COST, OR CLAIMS OF CUSTOMERS

OR PURCHASER FROM SUCH DAMAGE.

This written warranty is the final, complete and exclusive agreement of the parties with respect to the quality or

performance of the equipment and no action for breach of this written warranty or any implied warranty shall be

commenced more than one (1) year after the accrual of the cause of action. No modification o f this warranty or

waiver of its terms shall be binding on either party unless approved in writing by an authorized representative of

the party. Contact TuffStuff Fitness Equipment, Inc. at 1325 E. Franklin Avenue, Pomona, California 91766,

before returning any defective equipment.

TuffStuff Fitness Equipment, Inc.

1325 E. Franklin Avenue

Pomona, CA 91766, USA

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: service@tuffstuff.net Net: www.tuffstuff.net

Loading...

Loading...