Page 1

ASSEMBLY INSTRUCTIONS

TABLE OF CONTENTS:

Introduction

Pg. 1

Safety Precautions

Pg. 1

Assembly

Pg. 2 - Pg. 9

Cable Adjustment

Pg. 7

Cable Mapping Diagram

Fold-out Pg. 10

Exploded View Diagram

Fold-out Pg. 11

Parts List

Pg. 12

Warranty

Back Page

SP-407

Single Column

A m e r i c a ’ s P r e m i e r E x e r c i s e E q u i p m e n t

Revision Date 06-26-02

42 1/2"

43 1/4"

L 42 1/2" W 43 1/4" H 90 1/2"

© 2003 TuffStuff Fitness Equipment, Inc.

SP-407 Rev0

Page 2

Introduction

SCREW LENGHT

About the Single Column SP-407

Congratulations on your new purchase of the Single Column.

We hope you are completely satisfied with this product and

wish you many years of enjoyment.

Tuff Stuff Equipment

This Tuffstuff product has been built to precise quality

standards and has been carefully packaged to ensure that

damage will not occur during shipment. The limited lifetime

warranty and signature indicating final inspection has been

conducted by our line foreman, is an expression of our

confidence in the completeness, the materials, and

workmanship of this product.

Warranty

SEE A COPY OF WARRANTY ON BACK PAGE

Registration Card

To avoid unnecessary delays in warranty service and to

insure that a permanent record of your purchase is on file

with our factory, be sure to complete the warranty

registration card and send it to Task Industries today.

Specifications

1. Maximum Wt. Capacity - 150 Lbs.

2. Total Machine Weight - 455 Lbs.

3. Footprint (LWH) - See Front Page

Prior to the Assembly of the Single Column

1. We advise you to consult your local Tuff Stuff retailer if

you should have a question or problem regarding the

proper assembly of this unit.

2. Neatly organize and identify all parts according to the

Parts List and the Exploded View Diagram .

Tool Requirements

1. One 3/4” combination wrench

2. One 9/16” combination wrench

3. One 1/2” combination wrench

4. One 7/16” combination wrench

5. One ratchet

6. One 9/16” socket

7. One 3/4” socket

8. One 7/16” socket

9. Rubber mallet

10. Windex or household glass cleaner

11. One can silicone spray / teflon spray lubricant

12. Measuring tape

13. Utility knife

Hardware Measurement Diagram

Note: Due to continuing product improvements, specifications and designs are subject to change

without notice.

S afety First

Regardless of how enthusiastic you may be about getting on

your equipment and exercising, take the time to ensure that

your safety is not jeopardized. A moment’s lack of attention

can result in an accident, as can failure to observe certain

safety precautions.

1. Read, study and understand the Owner’s Manual and all

the warning labels on this product. Furthermore, it is

recommended to familiarize yourself and others with the

proper operation and workout recommendations for this

Tuff Stuff product prior to use. Some of this information

can be obtained in this Owner’s Manual, as-well-as from

your local Tuff Stuff retailer.

2. It is imperative that you retain this Owner’s Manual and be

sure all warning labels are legible and intact.

Replacement of Owner’s Manuals and labels are available

from your local Tuff Stuff retailer.

3. Consult with your physician before beginning any exercise

program.

Safety Precautions

WASHER DIAMETER

SCREW WIDTH

4. Use proper discretion when children are present.

5. Frayed or worn cables can be dangerous and may cause

injury. Periodically check these cables for any indication

of wear.

6. Keep hands, limbs, loose clothing and long hair well out of

the way of moving parts.

7. Do not attempt to lift more weight than you can control

safely.

8. Inspect the Unit for any sign of wear on parts, hardware

becoming loose or cracks on welds. If a problem is found,

do not use or allow the machine to be used until the

defective part is repaired or replaced.

NUT DIAMETER

1

SP-407 Single Column

Page 3

Owner’s Manual: Assembly Instructions

61

1

21

39

39

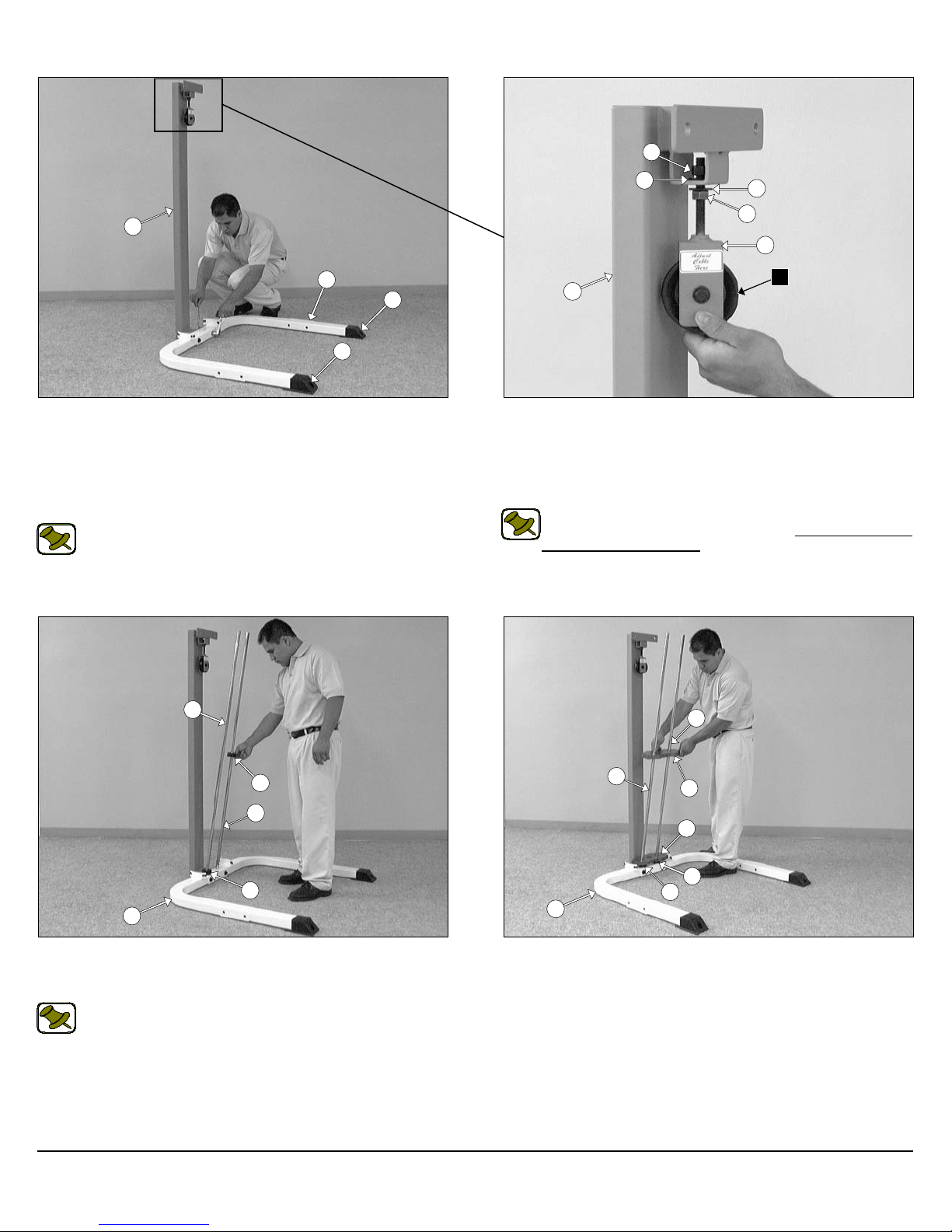

FIG. 1 Using a rubber mallet, insert two Plastic End Caps 2 X 3

(#39) onto the tube-ends of the Base Frame (#21). Next, on a flat

surface attach the Base Frame (#21) to the Weight Stack Frame

(#1) using two Hex Head Cap Screws 1/2-13 X 4 3/4 (#58), four Flat

Washers SAE 1/2” (#60), and two Nylon Insert Lock Nuts 1/2-13

(#59).

Note: Use the overhead view on the cover page for designing

your layout before assembling.

60

60

61

30

G

1

FIG. 2 Attach a Nylon Pulley 3 1/2 Rd. (#15- Labeled G) to the

Adjustable Pulley Bracket (#30) using one Hex Head Cap Screw

3/8-16 X 1 3/4 (#36), two Flat Washers SAE 3/8” (#53), and one Nylon Insert Jam Lock Nut 3/8-16 (#51). Next, affix the Adjustable Pul-

ley Bracket (#30) to the Weight Stack Frame (#1) using two Fin-

ished Hex Nuts 1/2-13 (#61), and two Flat Washers SAE 1/2” (#60).

Note: The black boxed letter pointing to the pulleys are used

throughout this manual as reference to the Cable Mapping Diagram on fold-out page 10. These black boxed letters will be

primarily used for locating certain pulleys during the cable routing process beginning with Fig. 2.

3

13

3

13

21

FIG. 3 Insert the two Guide Rods (#3) into the receptacles of the

Base Frame (#21). Next, slide the Rubber Donuts (#13) onto the

Guide Rods (#3).

Note: Lubricate the Guide Rods (#3) with silicone or teflon lubricant at this time.

3

3

5

5

13

13

21

FIG. 4 Carefully begin sliding the Weight Plates (#5) onto the

Guide Rods (#3), in position as shown above, allowing the first one

to rest on top of the Rubber Donuts (#13).

SP-407 Single Column

2

Page 4

3

4

6

3

84

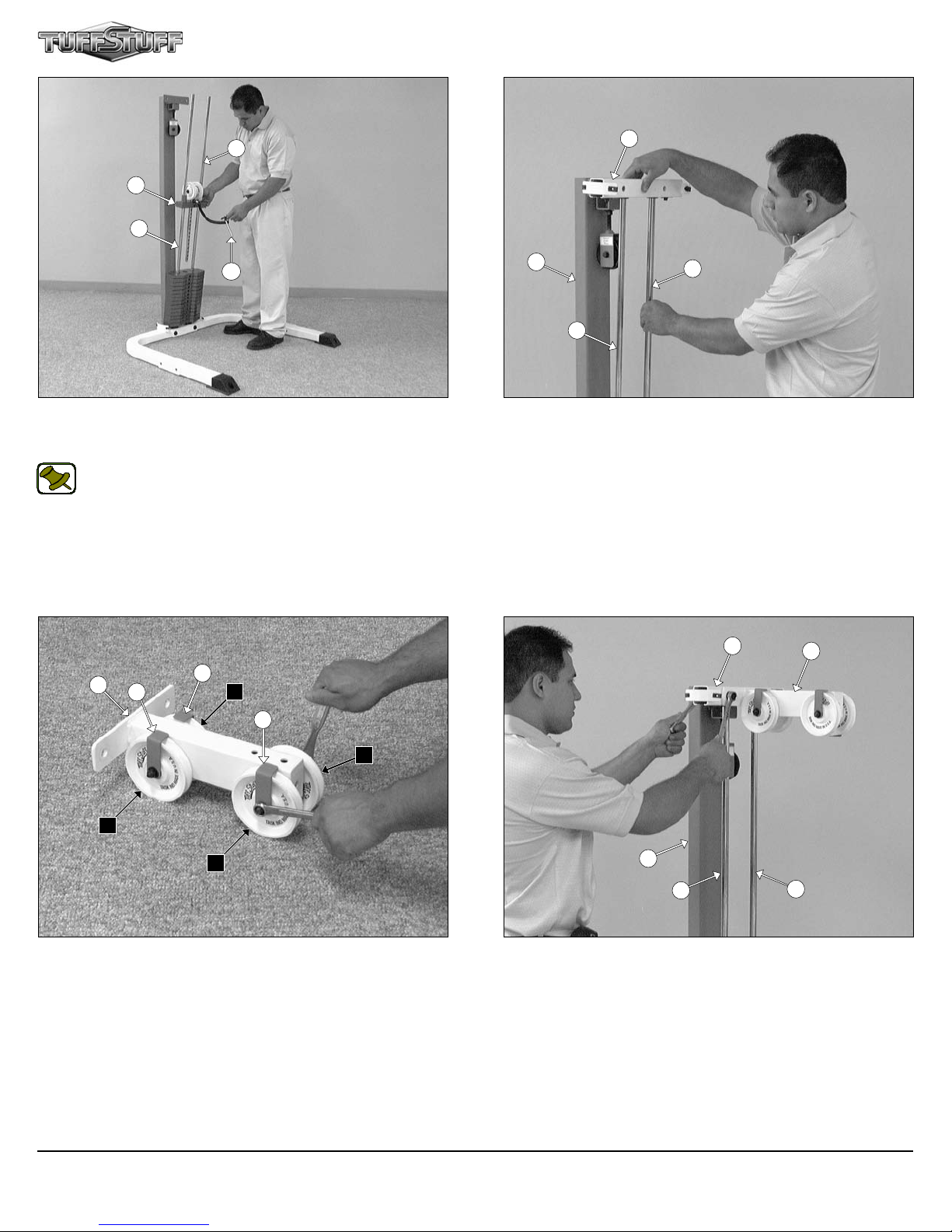

FIG. 5 Slide the assembled Top Plate Selector Bar (#6) onto the

Guide Rods (#3) allowing it to rest on top of the completed Weight

Stack.

Note: Be sure Selector Pin on the Top Plate Selector Bar

(#6) is facing out, as shown above, before sliding the Top

Plate Selector Bar (#6) onto the Guide Rods (#3).

27

31

31

E

1

3

3

FIG. 6 Maneuver the two Guide Rods (#3) into the holes on the

bottom side of the Guide Rod Retainer (#4).

4

27

31

D

I

J

FIG. 7 Assemble four Nylon Pulleys 4 1/2 Rd. (#15-Labeled D, E,

I, J) to the Top Upright Connector (#27) using four Cable Retainer

Brackets (# 31), two Hex Head Cap Screws 3/8-16 X 4 1/2 (#50),

four Flat Washers SAE 3/8” (#53), and two Nylon Insert Jam Lock

Nuts 3/8-16 (#51).

3

1

3

FIG. 8 Attach the Top Upright Connector (#27) to the Guide

Rod Retainer (#4) and the Weight Stack Frame (#1) using two Hex

Head Cap Screws 1/2-13 X 3 1/2 (#56), four Flat Washers SAE

1/2” (#60), and two Nylon Insert Lock Nuts 1/2-13 (#59).

3

SP-407 Single Column

Page 5

83

Owner’s Manual: Assembly Instructions

5

5

21

83

22

Plate

FIG. 9 Adhere the Decal Weight Numbers (#83) to the Weight

Plates (#5) in the corresponding order. Begin with the 20 at the top, 30

next, and so on.

33

24

FIG. 10 Attach the Stabilizer (#22) to the Base Frame (#21) using

four Hex Head Cap Screws 1/2-13 X 4 1/2 (#57), eight Flat Washers

SAE 1/2” (#60), and four Nylon Insert Lock Nuts 1/2-13 (#59).

K

C

FIG. 11 Insert the assembled Carriage (#24) onto the Selector-

ized Upright (#23).

SP-407 Single Column

23

23

31

FIG. 12 Assemble two Nylon Pulleys 4 1/2 Rd. (#15- Labeled C, K)

to the Selectorized Upright (#23) using two Cable Retainer Brack-

ets (#31), two Hex Head Cap Screws 3/8-16 X 3 3/4 (#49), four Flat

Washers SAE 3/8” (#53), and two Nylon Insert Lock Nuts 3/8-16

(#52).

Note: Refer to the Exploded View Diagram on page 11 for further illustration of this assembly.

4

Page 6

27

29

23

26

B

A

FIG. 14 Route the Cable (#29) between the Nylon Pulleys 3 1/2

Rd. (#15-Labeled A, B), then up through the tube of the Double Pul-

ley Bracket (#26).

Note: Refer to the Cable Mapping Diagram on page 10 for further illustration of this routing.

22

FIG. 13 Attach the Selectorized Upright (#23) to the Stabilizer

(#22) using two Hex Head Cap Screws 1/2-13 X 4 1/2 (#57), four Flat

Washers SAE 1/2” (#60), and two Nylon Insert Lock Nuts 1/2-13

(#59). Next, affix the Selectorized Upright (#23) to the Top Upright

Connector (#27) using one Hex Head Cap Screw 3/8-16 X 1 (#48),

and one Flat Washer SAE 3/8” (#53).

31

C

31

D

31

E

29

FIG. 15 Route the Cable (#29) up and over the Nylon Pulley 4 1/2”

Rd. (#14-Labeled C). Next, route down and under the Nylon Pulley 4

1/2” Rd. (#14-Labeled D) then up and over the Nylon Pulley 4 1/2”

Rd. (#14-Labeled E). Make sure the cable passes between the pulleys and the Cable Retainers (#31).

30

G

E

29

F

FIG. 16 Next, route the Cable (#29) down and under the Nylon

Pulley 4 1/2” Rd. (#14-Labeled F) then up and over the Nylon Pulley 3

1/2” Rd. (#15-Labeled G).

Note: Refer to the Cable Mapping Diagram on page 10 for further illustration of this routing.

5

SP-407 Single Column

Page 7

G

Owner’s Manual: Assembly Instructions

I J

29

H

26

H F

6

FIG. 17 Next, route the Cable (#29) down and under the Nylon

Pulley 4 1/2” Rd. (#14-Labeled H).

Note: Refer to the Cable Mapping Diagram on page 10 for further illustration of this routing.

25

M

K

FIG. 18 Route the Cable (#29) up and over the Nylon Pulleys 4

1/2” Rd. (#14-Labeled I, J). Next, route down and under the Nylon

Pulley 4 1/2” Rd. (#14-Labeled K). Make sure the cable passes between the pulleys and the Cable Retainers (#31).

Note: Refer to the Cable Mapping Diagram on page 10 for further illustration of this routing.

65

66

63

L

29

FIG. 19 Continue Routing the Cable (#29) up and over the Nylon

Pulley 3 1/2” Rd. (#15-Labeled L). Next, attach a Nylon Ball 1 3/4 X

1/4 (#63), and a Strap Bracket (#65) to the end of the Cable.

Note: Refer to the Cable Mapping Diagram on page 10 for further illustration of this routing.

65

SP-407 Single Column

65

66

29

FIG. 20 Attach the Snap Links (#66) to both ends of the Cable

(#29) using two Shoulder Bolts 3/8 X 3/4 (#64), and two Nylon Insert

Lock Nuts 5/16-18 (#62).

6

Page 8

CABLE ADJUSTMENT

It is imperative that you maintain proper cable adjustment to ensure

a safe and smooth operation.

Caution: The Cable should be inspected and adjusted periodically to avoid any slack in the cable which would, consequently, prevent any damage to the equipment or personal

injury.

61

1

61

Cable Adjustment

1. Loosen the bottom Finished Hex Nut 1/2-13 (#61).

2. Adjust the top Finished Hex Nut 1/2-13 (#61) to give the

cable proper tension.

3. Re-tighten the bottom Finished Hex Nut 1/2-13 (#61) to

complete the adjustment.

30

7

SP-407 Single Column

Page 9

Owner’s Manual: Assembly Instructions

10

7

2

21

FIG. 21 Affix the Weight Shroud (#2), at the bottom, to the Base

Frame (#21), and at the top, to the Guide Rod Retainer (#4) using

four Hex Head Cap Screws 1/4-20 X 3/4 (#18), and four Flat Washers

1/4” (#17).

Loosely Fasten: Do not completely fasten this hardware assembly at this time, as it will be completely fastened later in

the assembly process.

9

10

9

FIG. 22 Connect the two Plastic Shroud Edge Protectors (#9) to

the Plastic Shroud Gap Cover (#7) using the two Plastic Connectors

(#10).

7

7

2

9

FIG. 23 Attach the Plastic Shroud Gap Cover (#7) and the Plastic

Shroud Edge Protector (#9) to the edge of the Weight Shroud (#2).

SP-407 Single Column

2

9

FIG. 24 Align the edge of the Weight Shroud (#2) with the

grooves of the Plastic Shroud Gap Cover (#7) and the Plastic Shroud

Edge Protector (#9).

8

Page 10

4

8

2

21

FIG. 25 Affix the Weight Shroud (#2), at the bottom, to the Base

Frame (#21), and at the top, to the Guide Rod Retainer (#4) using

four Hex Head Cap Screws 1/4-20 X 3/4 (#18), and four Flat Washers

1/4” (#17).

32

2

FIG. 26 Secure the Plastic Shroud Lid (#8) to Guide Rod Retainer

(#4) using two Flat Head Socket Cap Screws 3/8-16 X 3 (#19).

2

27

FIG. 27 Attach the Handles (#32) to the Top Upright Connector

(#27) using two Hex Head Cap Screws 3/8-16 X 3 3/4 (#49), four Flat

Washers SAE 3/8” (#53), and two Nylon Insert Lock Nuts 3/8-16

(#52).

9

SP-407 Single Column

Page 11

Owner’s Manual: Assembly Instructions

PLASTIC SHROUD GAP COVER CONNECTOR

DECAL-EXERCISE SP-407 SINGLE COLUMN 4 1/2 X 26

DECAL-LARGE TUFFSTUFF LOGO DIAMOND SHAPE

DECAL-WARNING KEEP HANDS AND FINGERS...

DECAL-WEIGHT NUMBERS 20-150 LB/KGS (14 PC SET)

NYLON STEM BUTTON 12.5 mm X 26 mm x 9.5 mm

SP-407 Single Column

Parts List

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

Item No. Description Part No. Qty. Item No. Description Part No. Qty.

1 WEIGHT STACK FRAME 62" LONG UP0991 1 43 RUBBER GRIP 1/2 X 4 BNH0530 1

2 WEIGHT SHROUD 60" LONG UP0776 2 44 RUBBER GRIP 1 ID X .125 X 8 BNH0966 2

3 GUIDE ROD 3/4 X 61 5/8 UP0990 2 45 URETHANE BUMPER 962 BNH0244 2

4 GUIDE ROD RETAINER UP0784 1 46 BUTTON HEAD SOCKET CAP SCREW B/O 3/8-16 X 1 BNH0115 1

5 10 LB CAST WEIGHT PLATE GREY BNH0904 14 47 CHROME WASHER 3/8 X 1 1/2 BNH1015 1

6 10 LB TOP PLATE SELECTOR BAR 14 WTS 16.5 LONG BNH1174 1 48 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1 BNH0275 1

7 PLASTIC SHROUD GAP COVER 30" LONG BNH1082 1 49 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 3 3/4 BNH0281 5

8 PLASTIC SHROUD LID 5/8 X 14 1/8 X 10 BNH0185 1 50 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 4 1/2 BNH0284 2

9 PLASTIC SHROUD EDGE PROTECTOR 1/8 X 25 BNH1213 2 51 NYLON INSERT JAM LOCK NUT B/O 3/8-16 BNH0365 8

10

11 EDGE PROTECTOR GRAY 60" LONG BNH1176 2 53 FLAT WASHER SAE B/O 3/8" BNH0239 27

12 URETHANE BUMPER 1 3/4 BNH0229 5 54 SPLIT LOCK WASHER B/O 3/8" BNH0658 1

13 RUBBER DONUT 3/4 X 2 1/2 BNH0068 2 55 SPLIT WASHER Z/P 1/2" BNH0572 1

14 NYLON PULLEY 4 1/2 RD. WHITE BNH0556 8 56 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 3-1/2 BNH0263 2

15 NYLON PULLEY 3 1/2 RD. BNH0553 5 57 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 1/2 BNH0265 6

16 U-STYLE TAPPED HOLE NUT 1/4-20 BNH0708 8 58 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 3/4 BNH0895 2

17 FLAT WASHER USS B/O 1/4" BNH0233 8 59 NYLON INSERT LOCK NUT B/O 1/2-13 BNH0212 10

18 HEX HEAD CAP SCREW GR-5 B/O 1/4-20 X 3/4 BNH0890 8 60 FLAT WASHER SAE B/O 1/2" BNH0238 22

19 FLAT HEAD SOCKET CAP SCREW B/O 3/8-16 X 3 BNH0787 2 61 FINISHED HEX NUT B/O 1/2-13 BNH0201 3

20 RUBBER GROMMET 3/4" ID (2867-012) BNH0401 2 62 NYLON INSERT LOCK NUT B/O 5/16-18 BNH0215 2

21 BASE FRAME UP0992 1 63 NYLON BALL 1 3/4 X 1/4 BNH0047 2

22 STABILIZER UP0993 1 64 SHOULDER BOLT ALLOY 3/8 X 3/4 BNH0718 2

23 HIGH/LOW SELECTORIZED UPRIGHT UP0994 1 65 STRAP BRACKET 20 #SF20 STAINLESS STEEL BNH0562 2

24 HIGH/LOW CARRIAGE UP0999 1 66 SNAP LINK Z/P 8MM X 80MM BNH0065 3

25 HIGH/LOW DOUBLE PULLEY BKT (SOLID SHANK) UP1022 1 67 HEX KEY 3/32" BNH0372 1

26 HIGH/LOW DOUBLE PULLEY BKT (HOLLOW SHANK) UP1023 1 68 HEX KEY 7/32" BNH0575 1

27 TOP UPRIGHT CONNECTOR UP0995 1 69 U-STYLE TAPPED HOLE NUT 3/8-16 BNH1211 2

28 TOP PLATE DOUBLE PULLEY BRACKET UP0996 1 70 NYLON D HANDLE BNH1215 2

29 SINGLE COLUMN CABLE UP0997 1 71 LEATHER ANKLE STRAP 20000-ALAS 1

30 ADJUSTABLE PULLEY BRACKET UP0127 1 72 COIL CHAIN Z/P 3/16 X 8 BNH1214 1

31 CABLE RETAINER BRACKET(L-SHAPED) UP0014 6 73 DECAL-SIMPLEX II (1 7/8 X 5 3/16) BNH1199 1

32 HANDLES UP1024 1 74 DECAL-TUFFSTUFF (2 3/4 X 19 1/16) BNH1200 1

33 PUSH PULL PIN 1/2 X 2 7/8 LIGHT SPRING BNH0542 1 75

34 BRONZE BUSHING 1 X 1 1/4 X 3/4 X 1 1/2 X 1/8 BNH0527 4 76

35 RETAINING SNAP RING EXT. PLAIN .925 X 1 X .042 BNH0419 1 77 DECAL-ADJUST CABLE HERE BNH0789 1

36 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 1 3/4 BNH0274 5 78 DECAL-FOR BEST PERFORMANCE 1-1/4 X 1-1/2 BNH0143 1

37 PLASTIC INSERT CAP 2" SQ. BNH0012 2 79 DECAL-DANGER TIGHTEN THIS RET..., 3/4 X 1-1/2 BNH0142 1

38 PLASTIC TUBE END 1 X 1 1/4 X 3/8 BNH1089 1 80 DECAL-CAUTION 1 3/4 X 5-1/2 HORIZONTAL BNH0126 1

39 PLASTIC END CAP 2 X 3 (SIMPLEX LINE) BNH0606 2 81

40 ALUMINUM CAP 1" RD. (CAP-100) BNH0537 2 82 SUPER LUBE TEFLON LUBRICANT 82340 BNH0704 2

41 SOCKET SET SCREW ALLOY 10-32 X 1/8 BNH0473 4 83

42

BNH1183 2 52 NYLON INSERT LOCK NUT B/O 3/8-16 BNH0214 4

BNH1198 1

BNH0360 1

BNH0620 1

BNH1203 1

BNH0547 8 84 SELECTOR PIN W/COIL DOUBLE LOCK UP0466 1

SP-407 Single Column

12

Page 12

DO NOT DISCARD THIS MANUAL

LIMITED WARRANTY

TuffStuff warrants to the original purchaser only that TuffStuff equipment will be free from defects in

material and workmanship. The warranty and remedies set forth herein are conditioned upon proper

storage, installation, use, maintenance and conformance with any recommendations of TuffStuff. This

warranty does not cover products not manufactured by TuffStuff or products which are altered without

the express written consent of TuffStuff. This warranty as specified: a) Frame structure and welds —

Lifetime, b) Moving parts (e.g. pulleys, bearings, bushings) — 5 years; c) Cables upholstery, handgrips, finish and any miscellaneous parts not listed — 1 year; from the day of delivery to the original

purchaser. The obligation of TuffStuff under this warranty is limited to repairing or replacing warranted

defective parts, as TuffStuff may elect, at TuffStuff’s facility in Pomona, California, without charge to

purchaser for either parts or labor. Purchaser is responsible for installation of repaired or replaced

parts, and all transportation and insurance costs on returned or replaced equipment to and from

TuffStuff’s facility in Pomona.

THE FORGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE

SOLE LIABILITY OF TUFFSTUFF WITH REGARD TO WARRANTY. NO IMPLIED STATUTORY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY, NEGLIGENCE OR OTHERWISE, SHALL TUFFSTUFF BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFITS OR

REVENUE, LOSS OF USE OF EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTION

EQUIPMENT, DOWNTIME COST, OR CLAIMS OF CUSTOMERS OR PURCHASER FROM SUCH

DAMAGE.

This warranty is the final, complete and exclusive agreement of the parties with respect to the quality

or performance of the equipment and no action for breach of this written warranty or any implied warranty shall be commenced more than one (1) year after the accrual of the cause of action. No modification of this warranty or waiver of its terms shall be binding on either party unless approved in writing

by an authorized representative of the party. Contact TuffStuff at 1325 E. Franklin Avenue, Pomona,

California 91766, before returning any defective equipment.

Note: Retain your sales receipt and be sure to mail in the warranty registration card to insure that a

permanent record of your purchase is on file with the factory and to avoid unnecessary delays in

warranty service.

TuffStuff Fitness Equipment, Inc.

1325 E. Franklin Avenue

Pomona, CA 91766, USA

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: service@tuffstuff.net Net: www.tuffstuff.net

Loading...

Loading...