Page 1

ASSEMBLY INSTRUCTIONS

TABLE OF CONTENTS:

Introduction

Pg. 2

Safety Precautions

Pg. 3 - Pg. 4

Assembly Instructions

Pg. 5 - Pg. 9

SBU-400 Exploded View Diagram

Pg. 10

SHS-410 Exploded View Diagram

Pg. 11

SLS-420 Exploded View Diagram

Pg. 12

Decal Placement

Pg. 13

Decal Reference

Pg. 14

Warranty

Back Page

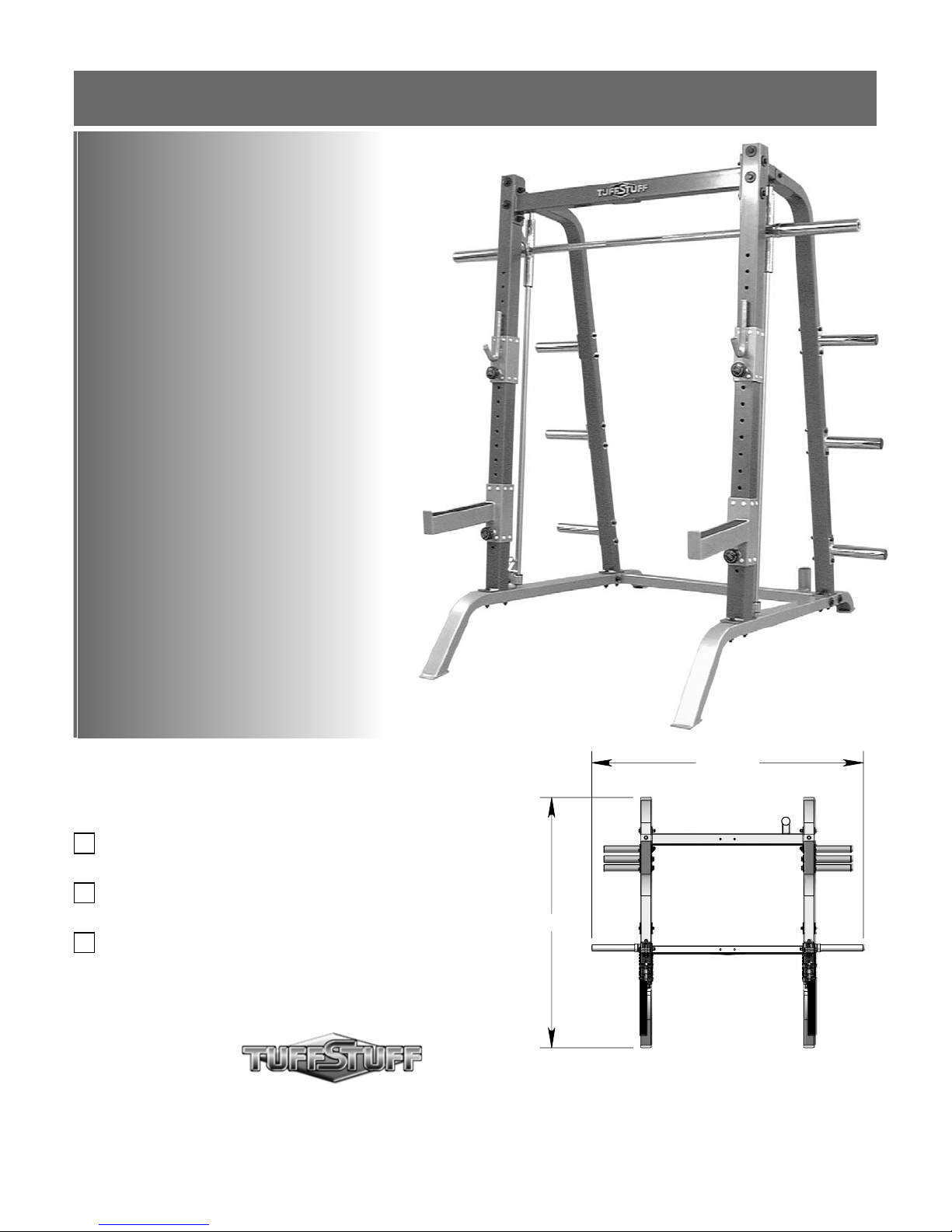

Smith-Half Cage Series

Includes Assembly for:

SBU-400

Base Unit Kit

SHC-410

Half Cage Conversion Kit

SLS-420

Linear Bearing Press System Kit

Revision Date 05-10-06

76 1/2"

70 1/2"

America’s Premier Exercise Equipment

L 70 1/2" W 76 1/2" H 82 1/2"

SBU-400 Rev1

Page 2

About the Smith-Half Cage Series

Congratulations on your new purchase of the Smith-Half Cage

Series. This gym is capable of a variety of different exercises, aswell-as, smooth and user-friendly adjustment features. In addition,

this gym has been designed to meet the needs and performance

requirements for a suitable home exercise machine. We hope you

are completely satisfi ed with this product and wish you many years

of enjoyment.

TuffStuff Equipment

This Tuffstuff product has been built to precise quality standards

and has been carefully packaged to ensure that damage will not

occur during shipment. The Home Lifetime Warranty and signature

indicating fi nal inspection has been conducted by our line foreman,

is an expression of our confi dence in the completeness, the

materials, and workmanship of this product.

Assembly Notes

1. Read and follow each step of this Assembly Instruction Manual

in sequence. Do not skip ahead, as it will result in an improper

assembly or in having to disassemble parts later.

Prior to the Assembly of the Smith-Half Series

1. We advise you to consult your local TuffStuff retailer if you should

have a question or problem regarding the proper assembly of

this unit.

2. Consider the complete surface area of the Smith-Half Cage

Series. Use the overhead view located on the front page for

designing your layout before assembling. Once the Smith-Half

Cage Series has been fully assembled it will be heavy and

diffi cult to move, therefore you should assemble the unit in the

area where it is to be used upon completion.

Warranty

SEE A COPY OF WARRANTY ON BACK PAGE.

Registration Card

To avoid unnecessary delays in warranty service and to insure that

a permanent record of your purchase is on fi le with our factory,

be sure to complete the warranty registration card and send it to

TuffStuff Fitness Equipment today.

Specifi cations

SBU-400 SHC-410 SLS-420

1. Maximum Wt. Capacity N/A 400 lbs. 300 lbs.

2. Total Machine Weight 220 lbs. 40 lbs. 80 lbs.

3. Footprint (LWH) - See Front Cover

Note: Due to continuing product improvements, specifi cations and designs are subject to change

without notice.

3. It is recommended that another person assist you with the

assembly of this unit.

4. Neatly organize and identify all parts according to the Parts List

and the Exploded View Diagrams.

Tool Requirements

1. One 3/4” combination wrench

2. One 9/16” combination wrench

3. One ratchet

4. One 3/4” socket

5. One 9/16” socket

6. One rubber mallet

7. Measuring tape

8. Utility knife

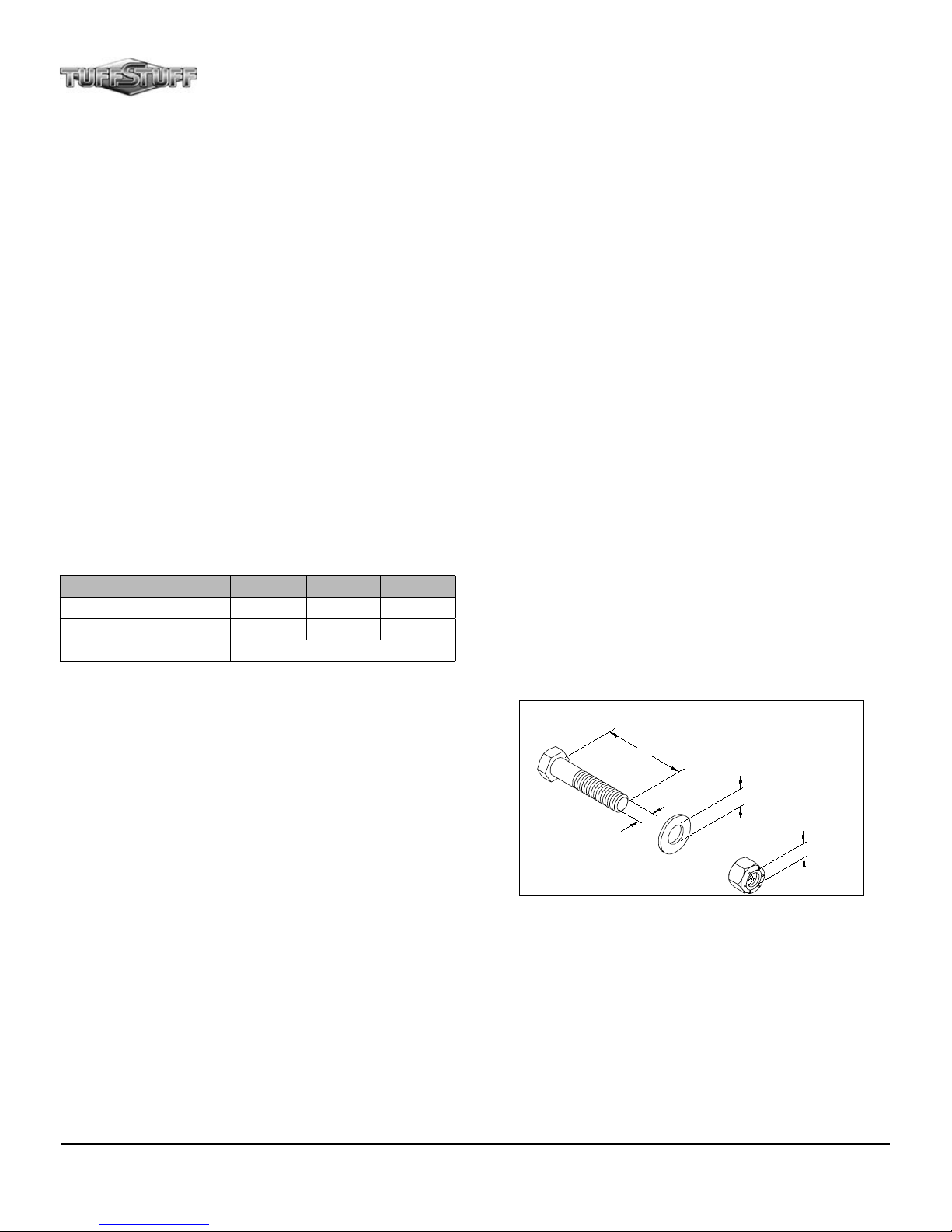

Hardware Measurement Diagram

H

T

G

N

E

L

W

E

R

C

S

R

E

H

S

A

W

H

T

D

I

WW

E

R

C

S

R

E

T

E

M

A

I

D

R

E

T

E

M

A

I

D

T

U

N

2

Smith-Half Cage Series

Page 3

Safety Precautions

Safety First

Regardless of how enthusiastic you may be about getting on your

equipment and exercising, take the time to ensure that your safety is not

jeopardized. A moment’s lack of attention can result in an accident, as

can failure to observe certain simple safety precautions.

3

1. Read, study and understand the Assembly Instructions and all the

warning labels on this product. Furthermore, it is recommended to

familiarize yourself and others with the proper operation and workout

recommendations for this TuffStuff product prior to use. Some of

this information can be obtained in this Assembly Instructions, aswell-as from your local TuffStuff Retailer.

2. It is imperative that you retain this Assembly Instructions and be

sure all warning labels are legible and intact. Replacement of the

Assembly Instructions and labels are available from your local

TuffStuff Retailer.

3. Consult with your physician before beginning any exercise

program.

4. Use proper discretion when children are present.

5. Keep hands, limbs, loose clothing and long hair well out of the way

of moving parts.

6. Do not attempt to lift more weight than you can control safely.

7. Inspect the Smith-Half Cage for any sign of wear on parts, hardware

becoming loose or cracks on welds. If a Problem is found do not

use or allow the machine to be used until defective part is repaired

or replaced.

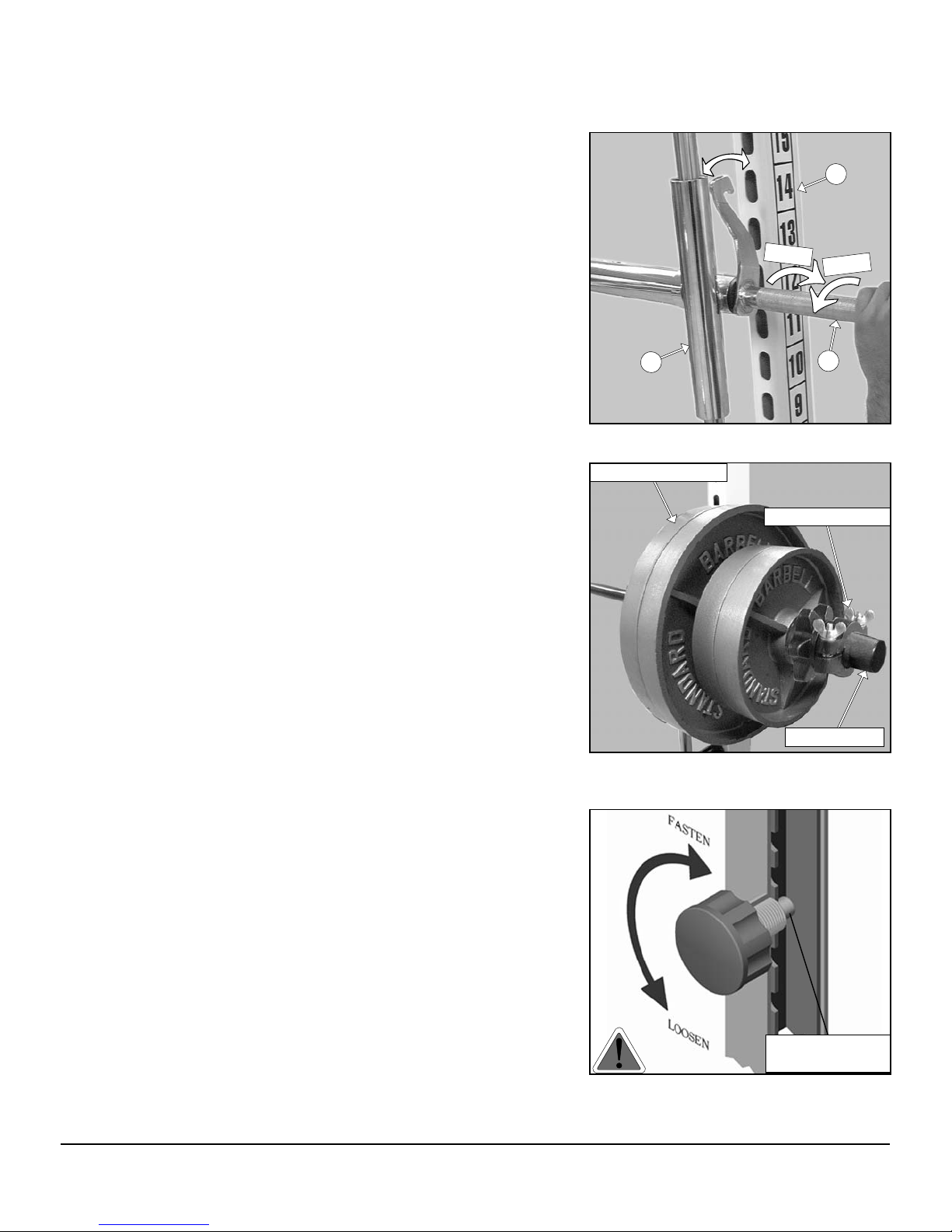

8. The Press Bar (#12) has a swivel locking mechanism that allows

you to safely lock out the Press Bar (#12) at virtually any setting.

See Fig. A.

Lock

11

Fig. A Illustration above depicts the Press Bar

(#12) locking mechanism.

Barbell Weight Plates

Olympic Bar Collar

Fig. B Caution: Use collars to prevent the weight

plates from falling off the Olympic Adaptors (#10).

Unlock

12

Weight Prong

9. If you are adding or storing weight plates on the Olympic Adapters

(#10), do not over-load them. Allow enough space for weight collars.

See Fig. B

10. Pay special attention to the Turn/ Pull Pins w/Knob (#134) located

on the Bar Holders (#9) and the Bar Safety Spotters (#7, #8). Be

sure they are fully engaged into the selectorized holes of the Front

Uprights (#3). Refer to Fig. C for further illustration.

Smith-Half Cage Series

Turn/Pull Pin w/Knob

Fully Engaged

Fig. C Caution: Check that all Turn/Pull Pins

w/Knob (#134) to be fully engaged into the selected

holes of the Front Uprights (#3).

3

Page 4

Safety Precautions

Press Bar

Correctly Engaged

12

Locking Locking

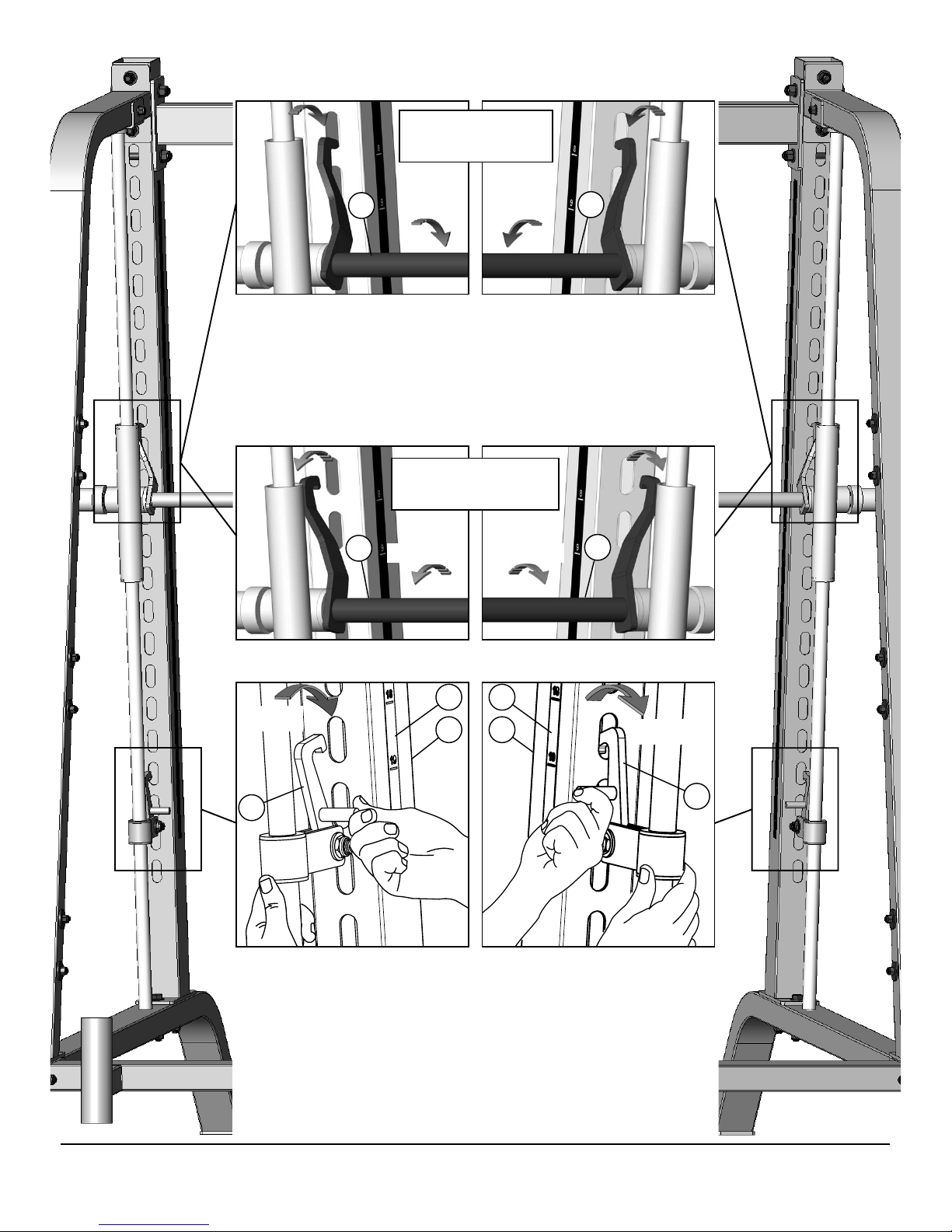

11. DANGER: Once the unit is completely assembled take the time to ensure

that the unit is assembled correctly square and perpendicular. Pay special

attention to the Press Bar (#12) making sure both hooks engage uniformly and

completely into each locking position. If both of the Press Bar Hooks are not

engaging uniformly into the receptacle holes, it will be necessary to loosen

some frame hardware then re-align the frame and re-tighten the hardware.

If Problem persists, Do Not Use the Machine and contact your TuffStuff

Retailer.

12

Disengaged Press Bar

During Exercise

12

Unlocking Unlocking

12. The illustrations above depict the Press Bar disengaged setting which is used

during exercise.

12

58 58

Locking

14

13. DANGER: The Safety Spotter Hooks (#14, #15) prevent the Press Bar from

being lowered below required point and avoid getting crushed under the Press

Bar (#12) if the weight is too heavy to control. Use the Decal-numbers (#58)

on the Front Uprights (#3) to ensure that the Safety Spotter Hooks (#14,#15)

are set to an equal adjustment setting (same height).

Before you add weight plates to the Press Bar (#12), you must fi rst set-up the

Safety Spotter Hooks (#14,#15) for the required exercise. It is recommended

that you test the desired setting without weight plates on the Press Bar (#12)

to make sure the Safety Spotter Hooks (#14,#15) are set to the appropriate

exercise setting.

3 3

Unlocking

15

4

Smith-Half Cage Series

Page 5

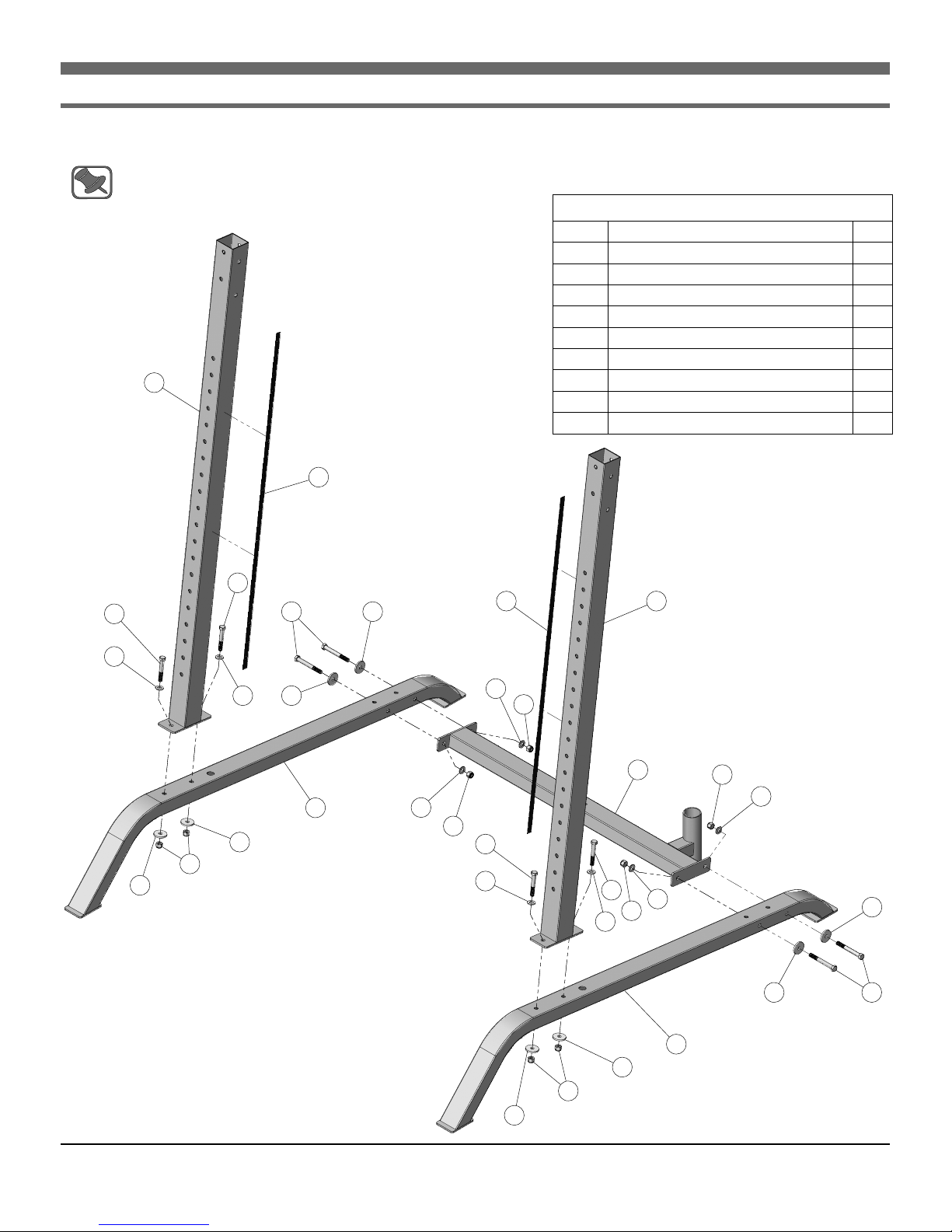

Step 1 Assembling Base Unit

A. Locate the two Bottom Side Frames (#2) and attach them to the Bottom Cross Brace (#1) using hardware shown.

B. Attach the two Front Uprights (#3) to the two Bottom Side Frames (#2) using hardware shown.

Note: Make sure to assemble the Front Uprights (#3) with the oval hole pattern towards the back of the Unit, and the

Decal-Numbers (#58) towards the inside of the Unit.

Assembly List

Item # Description Qty.

1 BOTTOM CROSS BRACE 1

2 BOTTOM SIDE FRAME 2

3 FRONT UPRIGHT 2

58 DECAL-NUMBERS 1-20 TEFLON 2

65 FLAT WASHER 1/2 X 1 3/4 8

67 FLAT WASHER SAE 1/2” 8

3

58

72 HEX HEAD CAP SCREW 1/2-13 X 3 1/4 4

74 HEX HEAD CAP SCREW 1/2-13 X 4 1/4 4

101 NYLON INSERT LOCK NUT 1/2-13 8

72

72

67

67

65

101

65

74

65

2

65

67

101

58 3

67

101

72

67

72

67

101

1

67

101

67

65

65

74

Smith-Half Cage Series

2

65

101

65

5

Page 6

Step 2 Assembling the Half Cage Conversion Kit (SHC-410)

A. Slide the two Bar Safety Spotters (#7, #8) onto the Front Uprights (#3).

B. Slide the two Bar Holders (#9) onto the Front Uprights (#4).

Item # Description Qty.

7 LEFT SIDE BAR SAFETY SPOTTER 1

8 RIGHT SIDE BAR SAFETY SPOTTER 1

9 BAR HOLDER 2

63 FLAT PHILLIPS SCREW 8-32 X 1/4 4

134 TURN/PULL PIN W/KNOB AND LOCK 4

9

63

134

3

Assembly List

3

134

8

63

9

7

6

Smith-Half Cage Series

Page 7

Step 3 Assembling the Press Bar (SLS-420)

A. Insert the Linear Shafts 1 X 69 11/16 (#13) into the receptacles of the Bottom Side Frames (#2).

B. Insert the Safety Spotter Assemblies (#14, #15) onto the Linear Shafts (#13).

Caution: It is strongly recommended to use another person in assisting with the following assembly.

C. Align the Chrome Press Bar Housings (#11) with the Linear Shafts (#13) and carefully begin sliding the Chrome Press

Bar Assembly (#12) onto the Linear Shafts (#13).

Assembly List

Item # Description Qty.

12 CHROME PRESS BAR ASSEMBLY 1

13 LINEAR SHAFT 1 X 69 11/16 2

13

11

12

14 LEFT SAFETY SPOTTER ASSEMBLY 1

15 RIGHT SAFETY SPOTTER ASSEMBLY 1

13

15

14

2

2

11

Smith-Half Cage Series

7

Page 8

Step 4 Assembling the Rear Side Supports

A. Attach the two Shaft Retainer Brackets (#17) to the Linear Shafts (#13).

B. Affi x the two Rear Side Supports (#5) to the two Bottom Side Frames (#2) using hardware shown.

C. Affi x the two Rear Side Supports (#5) to the two Front Uprights (#3) using hardware shown.

D. Secure the two Shaft Retainers Brackets (#17) along with the two confi ned Linear Shafts (#13) to the Rear Side

Supports (#5) using hardware shown.

Assembly List

Item # Description Qty.

5 REAR SIDE SUPPORT 2

17* SHAFT RETAINER BRACKET 2

101

67

84

68

65

17

74

13

65

3

101

67

68

102

102

5

68

74

65

101

67

65 FLAT WASHER 1/2 X 1 3/4 8

67 FLAT WASHER SAE 1/2” 8

68* FLAT WASHER SAE 3/8” 4

72 HEX HEAD CAP SCREW 1/2-13 X 3 1/4 4

74 HEX HEAD CAP SCREW 1/2-13 X 4 1/4 4

84* HEX HEAD CAP SCREW 3/8-16 X 4 2

101 NYLON INSERT LOCK NUT 1/2-13 8

102* NYLON INSERT LOCK NUT 3/8-16 2

* Items Required Only for SLS-420

101

67

17

72

67

65

101

65

68

84

13

72

67

101

65

5

72

67

65

8

Smith-Half Cage Series

Page 9

Step 5 Assembling the Top Cross Brace and the Olympic Adapters

A. Attach the Top Cross Brace (#6) to the Front Uprights (#3) using hardware shown.

B. Insert Plastic Insert Caps 1 7/8” Rd. (#110) into the tube-ends of the Olympic Adapters w/Plate (#4).

C. Attach the six Olympic Adapters w/Plate (#4) to the two Rear Side Supports (#5) using hardware shown.

Assembly List

Item # Description Qty.

67

101

65

74

84

68

65

3

110

110

84

68

4

84

68

84

68

4

6

101

67

51

102

101

67

51

102

65

74

51

102

102

6TOP CROSS BRACE 1

4OLYMPIC ADAPTER W/PLATE 6

51 CHROME WASHER 3/8 X 1 1/2 12

65 FLAT WASHER 1/2 X 1 3/4 4

67 FLAT WASHER SAE 1/2” 4

68 FLAT WASHER SAE 3/8” 12

74 HEX HEAD CAP SCREW 1/2-13 X 4 1/4 4

84 HEX HEAD CAP SCREW 3/8-16 X 4 12

101 NYLON INSERT LOCK NUT 1/2-13 4

102 NYLON INSERT LOCK NUT 3/8-16 12

110 PLASTIC INSERT CAP 1 7/8” RD. 6

65

74

102

5

68

102

51

4

68

51

51

102

84

84

110

Smith-Half Cage Series

68

84

4

68

84

110

9

Page 10

65

74

74

72

67

65

65

SBU-400 Exploded View Diagram

101

58

65

84

74

2

110

68

67

84

65

65

67

72

67

68

101

101

67

101

6

101

67

101

74

67

65

65

58

67

67

72

3

72

67

67

101

5

64

133

101

4

72

67

51

102

51

67

101

65

67

101

1

101

67

65

65

67

102

51

72

67

67

74

54

101

5

101

51

65

72

67

68

4

68

84

110

84

65

3

72

67

65

101

65

74

CHART

65

SBU-400

101

65

65

101

65

2

BOLD FONT = SUB-ASSEMBLY PARTS

REGULAR FONT = HARDWARE

ITEM # DESCRIPTION PART # QTY. ITEM # DESCRIPTION PART # QTY.

1 BOTTOM CROSS BRACE UP3482 1

2 BOTTOM SIDE FRAME UP3481 2

3 FRONT UPRIGHT UP3483 2

4OLYMPIC ADAPTER W/PLATE UP2202 6

5 REAR SIDE SUPPORT UP3484 2

6TOP CROSS BRACE UP3485 1

51 CHROME WASHER 3/8 X 1 1/2 BNH1015 12 102 NYLON INSERT LOCK NUT 3/8-16 BNH0214 12

54 DECAL-CAUTION 1 3/4 X 5 1/2 BNH0126 1 110 PLASTIC INSERT CAP 1 7/8” RD. BNH0003 6

58 DECAL-NUMBERS 1-20 TEFLON BNH1547 2 133 TUFFSTUFF LOGO ALUMINUM (LG) BNH1324 1

64 FLAT PHILLIPS SCREW ZINC # 5 X 1/2 BNH1481 2 139 DECAL-REFERENCE LEFT SIDE ( L ) BNH1850 1

65 FLAT WASHER 1/2 X 1 3/4 BNH0241 20 140 DECAL-REFERENCE RIGHT SIDE ( R ) BNH1851 1

Parts List

67 FLAT WASHER SAE 1/2” BNH0238 20

68 FLAT WASHER SAE 3/8” BNH0239 12

72 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 3 1/4 BNH0576 8

74 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 1/4 BNH0291 12

84 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 4 BNH0285 12

101 NYLON INSERT LOCK NUT 1/2-13 BNH0212 20

10

Smith-Half Cage Series

Page 11

SHC-410 Exploded View Diagram

107

9

118

134

134

63

63

107

8

9

7

CHART

BOLD FONT = SUB-ASSEMBLY PARTS

REGULAR FONT = HARDWARE

ITEM # DESCRIPTION PART # QTY. ITEM # DESCRIPTION PART # QTY.

7 LEFT SIDE BAR SAFETY SPOTTER UP3487 1

8 RIGHT SIDE BAR SAFETY SPOTTER UP3486 1

9 BAR HOLDER UP3488 2

63 FLAT PHILLIPS MACHINE SCREW 8-32 X 1/4 BNH0408 4

Smith-Half Cage Series

SHC-410

Parts List

107 NYLON STEM BUTTON 12.5 mm X 26 mm X 9.5 mm BNH0547 64

118 RUBBER CORR MAT 1/8 X 1 7/8 X 15 1/2 BNH1247 2

134 TURN/PULL PIN W/KNOB AND LOCK BNH0989 4

11

Page 12

84

68

17

92

11

13

90

68

102

SLS-420 Exploded View Diagram

102

68

17

68

84

13

90

92

71

15

CHART

67

98

67

99

98

16

92

90

12

108

14

89

99

16

98

11

95

92

67

SLS-420

90

98

67

95

89

48

10

122

88

71

BOLD FONT = SUB-ASSEMBLY PARTS

REGULAR FONT = HARDWARE

ITEM # DESCRIPTION PART # QTY. ITEM # DESCRIPTION PART # QTY.

10 CHROME OLYMPIC ADAPTER UP0679 2

11 CHROME PRESS BAR HOUSING UP0680 2

12 CHROME PRESS BAR W/HOOKS UP0678 1

13 LINEAR SHAFT 1 X 69 11/16 UP3489 2

14 SAFETY HOOK LT UP0525 1

15 SAFETY HOOK RT UP0524 1

16 SAFETY SPOTTER BRACKET UP0523 2

17 SHAFT RETAINER BRACKET UP3490 2

48 BRONZE BUSHING 1 1/8 X 1 11/32 X 3/4 BNH0735 2 122 SHOULDER BOLT 14 mm X 14 mm THREAD 1/2-13 BNH0426 2

67 FLAT WASHER SAE 1/2” BNH0238 4 136 DECAL-FOR BEST PERFORMANCE 1 1/4 X 1 1/2 BNH0143 2

68 FLAT WASHER SAE 3/8” BNH0239 4 137 DECAL-DANGER ENGAGE SAFETY SPOTTER 1.5 X 1 BNH1848 4

71 HEX HEAD CAP SCREW 1/2-13 X 1 1/2 BNH0727 2 138 DECAL-DANGER ENGAGE SAFETY SPOTTER 1.75 X 4 BNH1849 4

84 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 4 BNH0285 2 139 DECAL-REFERENCE LEFT SIDE ( L ) BNH1850 1

88 HEX KEY M14 BNH1303 1 140 DECAL-REFERENCE RIGHT SIDE ( R ) BNH1851 1

12

Parts List

89 INTERNAL RETAINING RING 1 7/16” BNH1308 4

90 INTERNAL RETAINING RING 1 9/16” BNH0095 4

92 LINEAR BEARING BNH0770 4

95 NEEDLE-ROLLER BEARING (HMK-2830) BNH1307 4

98 NYLON BUSHING 1 X 1 1/2 BNH0531 4

99 NYLON INSERT JAM LOCK NUT 1/2-13 BNH0366 2

102 NYLON INSERT LOCK NUT 3/8-16 BNH0214 2

108 NYLON WASHER 1 1/8 X 2 X 1/4 BNH0388 2

Smith-Half Cage Series

Page 13

Decal Placements

54

BNH0126

CENTERED, 52" FROM BOTTOM

EDGE OF THE TUBE.

5

52"

VERTICALLY AND HORIZONTALLY

CENTERED ALONG THE TUBE.

BNH1324

8 1/2"

64

133

BNH1547

CENTERED, 8 1/2" DOWN

FROM TOP OF THE TUBE.

58

6

8 1/2"

BNH1849

CENTERED TO THE SIDE OF THE TUBE,

1/2" DOWN FROM TOP OF THE TUBE.

(BOTH SIDES)

BNH0143

CENTERED ON FRONT

OF THE TUBE

R

140

137

15

1/2"

136

11

137

138

16

14

138

BNH1848

CENTERED ON PLATE.

(BOTH SIDES)

137

3

16

BNH1848

CENTERED ON PLATE.

(BOTH SIDES)

CENTERED ON FRONT

139

BNH0143

OF THE TUBE.

R

1/2"

136

138

58

3

140

R

139

L

11

L

138

BNH1849

CENTERED TO THE SIDE OF THE TUBE,

1/2" DOWN FROM TOP OF THE TUBE.

(BOTH SIDES)

Smith-Half Cage Series

13

Page 14

Decal Reference

54

BNH0126

DANGER

!

Engage this Safety

Spotter Hook PRIOR to

performing the exercise

137

BNH1848

!

DANGER

Engage the Safety

Spotter Hook to the

required stop position

for each exercise.

Failure to comply

would allow this press

bar to drop beyond

your own capability

and could result in

serious injury to you.

138

BNH1849

139

BNH1850

133

BNH1324

140

BNH1851

SCALE 1 : 2

14

136

BNH0143

58

BNH1547

Smith-Half Cage Series

Page 15

DO NOT DISCARD THIS MANUAL

HOME LIFETIME WARRANTY

TuffStuff products are warranted to the retail purchaser to be free from defects in materials and workmanship.

TuffStuff exclusive Home Lifetime Warranty coverage extends for the life of the product while owned by the

original retail purchaser, and used only in a home or residential setting unless otherwise noted in the owner’s

manual.

This warranty does not cover:

1. TuffStuff products sold for and used in a commercial or institutional setting.

2. Any damage, failure or loss caused by accident, misuse, neglect, abuse, improper assembly, improper

maintenance, or failure to follow instructions or warnings in the owner’s manual and warning labels

posted on the machine.

3. Use of products in a manner for which they were not designed.

4. Original product that is altered, or the use of replacement parts and components of another manufacturer other than TuffStuff.

Limitations:

The foregoing shall constitute the sole remedy of the purchaser and the sole liability of TuffStuff with regard to

warranty, whether express or implied by operation of law or otherwise, including but not limited to any implied

warranties of merchantability or fitness. TuffStuff shall in no event be liable for incidental or consequential

losses, damages or expenses in connection with exercise products. TuffStuff’s liability hereunder is expressly

limited to the repairs or replacements of warranted defective parts.

Procedures:

Warranty service will be performed at TuffStuff’s facility in Pomona, California. TuffStuff will have the option of

either repair or replacement at no charge for any defective product. Purchaser is responsible for installation of

repaired or replaced parts and all transportation and insurance costs on returned or replaced equipment to and

from TuffStuff’s facility in Pomona.

This warranty gives you specific legal rights and you may also have other rights, which may vary from state to

state. Effective July 1, 2004.

This warranty is the final, complete and exclusive agreement of the parties with respect to the quality or performance of the equipment

and no action for breach of this written warranty or any implied warranty shall be commenced more than one (1) year after the accrual

of the cause of action. No modification of this warranty or waiver of its terms shall be binding on either party unless approved in

writing by an authorized representative of the party. Contact TuffStuff at 1325 E. Franklin Avenue, Pomona, California 91766, before

returning any defective equipment.

Note: Retain your sales receipt and be sure to mail in the warranty registration card to insure that a

permanent record of your purchase is on file with the factory and to avoid unnecessary delays in

warranty service.

TuffStuff Fitness Equipment, Inc.

1325 E. Franklin Avenue

Pomona, CA 91766, USA

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: service@tuffstuff.net Net: www.tuffstuff.net

Loading...

Loading...